Page 1

Data sheet

Disinfection Process Control & Temperature Registration

CCR2+ Control

Features

Fig. 1 CCR2+ Disinfection Process Control &

Temperature Registration

The CCR2+ is a controller used for optimising

the thermal disinfection process in hot water

systems with functions such as temperature

registration and/or monitoring circulation hot

water systems.

The CCR2+ can be applied independently, only

for temperature registration in circulation hot

water systems.

Thermal disinfection is one of the most effective

physical methods for bacteria pasteurisation

(Legionella pnemophila).

By optimising the thermal disinfection process,

the energy consumption and the disinfection

time are reduced.

By thermal disinfection the risk of bacteria

contamination in hot water systems can be

reduced significantly.

By temperature registration, the correct

temperature level in the hot water circulation

system can be controlled continuously and data

can be stored for later reference.

Disinfection temperature and time can be

adjusted:

• Disinfection temperatures from

50 °C to 78 °C;

• Disinfection time for the individual riser

within in the range: minimum to maximum.

Minimum required time is recommended

based on Brundrett resources and related to

temperature and is automatically limited by

producer. It cannot be adjusted below and

above the recommended values.

The CCR2+ incorporates LED status indicator,

build in Web-Server App, Wi-Fi connection and

LAN port, which allow the user to manually set

and monitor measured parameters from the

system on smart device or PC.

In addition, the CCR2+ also incorporates build in

memory to store temperature data.

The system monitoring function is based on

temperature registration and storage of data in

the memory.

The storage rate (frequency of temperature

sampling) can be adjusted by the user via the

CCR2+ settings menu.

Data can be copied and processed in excel files

(table, charts, graphs, etc.). All storage data are

recorded based on special algorithms, which

allow indication of genuine of stored data!

The sampling rate can be defined from the menu

within the range: minimum 1min. The sampling

rate has significant influence on period of data

storage.

From a technical point of view, the CCR2+

can control any number of risers due to the

possibility of parallel and sequence connections.

One unit of the CCR2+ can control 20 risers

equipped with thermo actuators type TWA-A

and PT1000 sensors (S1 … S20), plus one PT 1000

sensor (S0) in the supply pipe. The S0 sensor is

used for initiating the disinfection process (fig. 3)

or for registrating the supply temperature (Fig. 2)

(Fig. 4 wiring scheme: S0 input). The S0 sensor is

included in the package.

Additional functions:

• LED status indicators

• Build in web server for acess via mobile

devices or PC

• Alarm output;

• Pump protection function (cavitations in case

of closing all valves);

• Indication of state of disinfection process

realisation.

• System expansion via CCR+ Slave Unit

(+16 risers)

The CCR2+ power supply ~24 V (DC), 50 Hz and

output control of actuators 24 V.

Installation: on standard DIN relay.

Note: transformer is not included.

Recommended transformer: 150 VA, 24 V DC.

It is possible to connect CCR2+ to BMS system

via RS 485 in standard Fbus or ModBus RTU or IP

Modbus.

See the instructions for details.

© Danfoss | 2018.10 VD.D3.K1.02 | 1

Page 2

Data sheet Disinfection Process Control & Temperature Registration

1278910 19 20

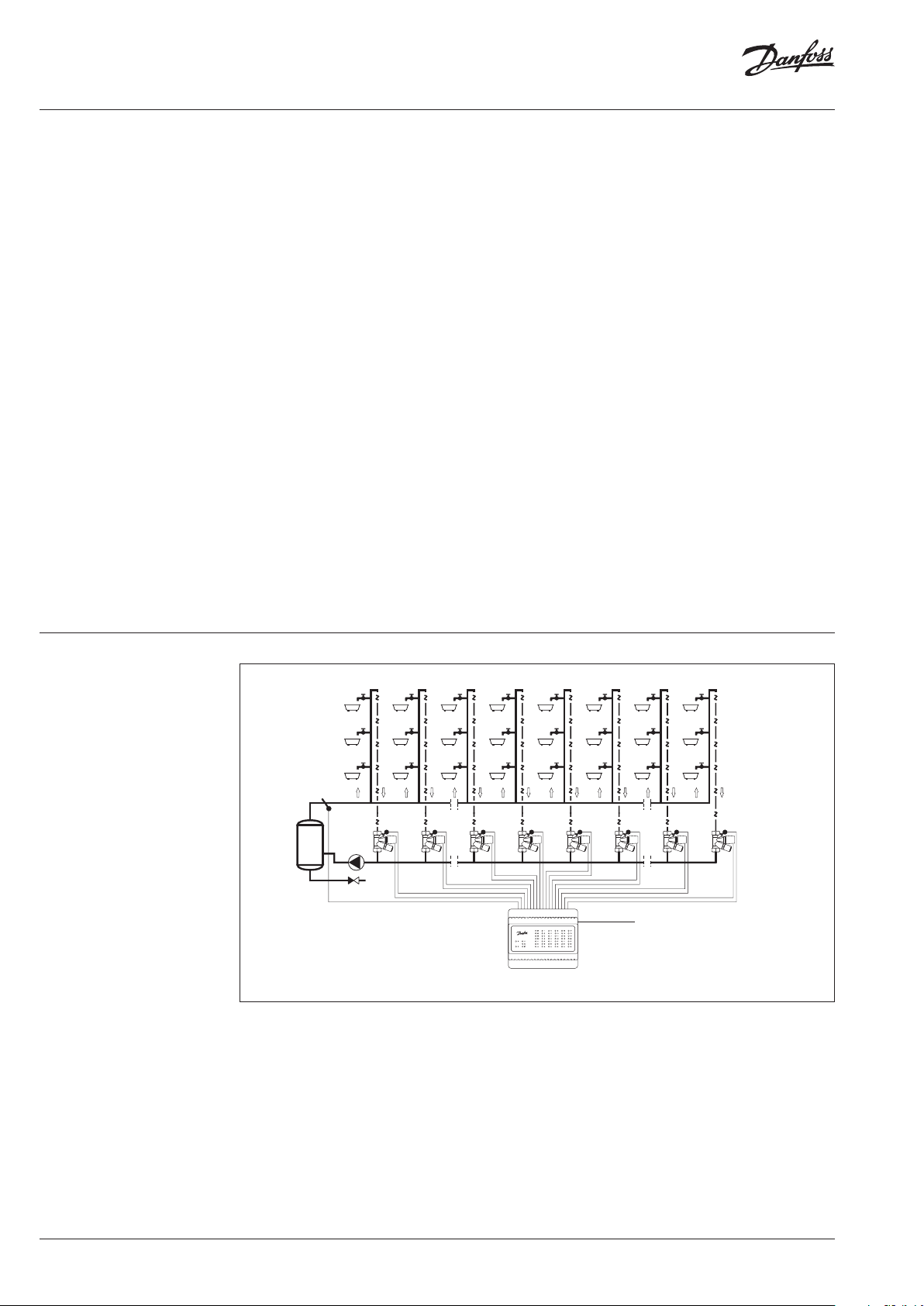

CCR2+ System expansion

The system can also be expanded. For systems

up to 36 risers/loops CCR2+ system can be

expanded. With CCR+ Slave Unit, connected

to CCR2+ Controller (master), system can be

expanded with additional 16 risers/loops: 20

(CCR2+) + 16 (CCR+ Slave).

Very big systems (with more that 37) risers/loops

can be expanded with several CCR2+ Controlers

(with connected CCR+ Slave Unit on each

master), which are connected (see instructions):

• by parallel connection CCR2+ (with Slave Unit)

to another CCR2+ (with Slave Unit):

- with one S0 sensor or

- with individual S0 sensor for each CCR2+

(with Slave Unit);

• by sequence connection CCR2+ (with Slave

Unit) to another CCR2+ (with Slave Unit):

- with one S0 sensor or

- with individual S0 sensor for each CCR2+

(with Slave Unit).

This function offers control and registration of

temperatures in extensive installations with a

big number of risers, e.g.: installation with 108

risers/loops require 3 CCR2+ Controlers, with

connected CCR+ Slave Unit on each (3 x 20 + 3 x

16 = 108).

The type of combination after connection

(see instruction of CCR2+) should be selected

from the device menu settings. The correct

combination of connection allows optimatisation

of the total time required for the disinfection

process. For thermal disinfection CCR2+ can work

in two applications:

• As Independed control,

(S0 remote sensor connected)

No connection with heat source (boiler, substation, hot water tank, etc.)

Not fully automatic process. The total

disinfection time for the total installation

should be specified by maintenance service,

and after the disinfection process, the supply

temperature should be reduced manually to

comfort temperature.

• As Dependent control,

(S0 remote sensor connected and additional

connection with weather compensator (e.g.

ECL Comfort), boiler control or hot water

tank - in this case, thermal disinfection can be

performed in a fully automatic way. Moreover,

a second application is not required to specify

the total disinfection time for total installation

as the CCR2+ after finishing the thermal

disinfection in the last riser automatically

returns to comfort temperature by sending

signal (from output O3) to weather or boiler

control (free contact relay required).

Applications

S0

Fig. 2 Scheme of installation for temperature registration independent system (only sensor S0 needed).

MTCV

S1

S2 S7 S8 S9 S10 S19 S20

V1

TWA

V2

TWA

MTCV MTCV MTCV MTCV MTCV MTCV MTCV

V7

TWA

V8

TWA

V9

TWA

24 VDC

V10

TWA

V19

TWA

V20

TWA

2 | VD.D3.K1.02 © Danfoss | 2018.10

Page 3

Data sheet Disinfection Process Control & Temperature Registration

1278910 19 20

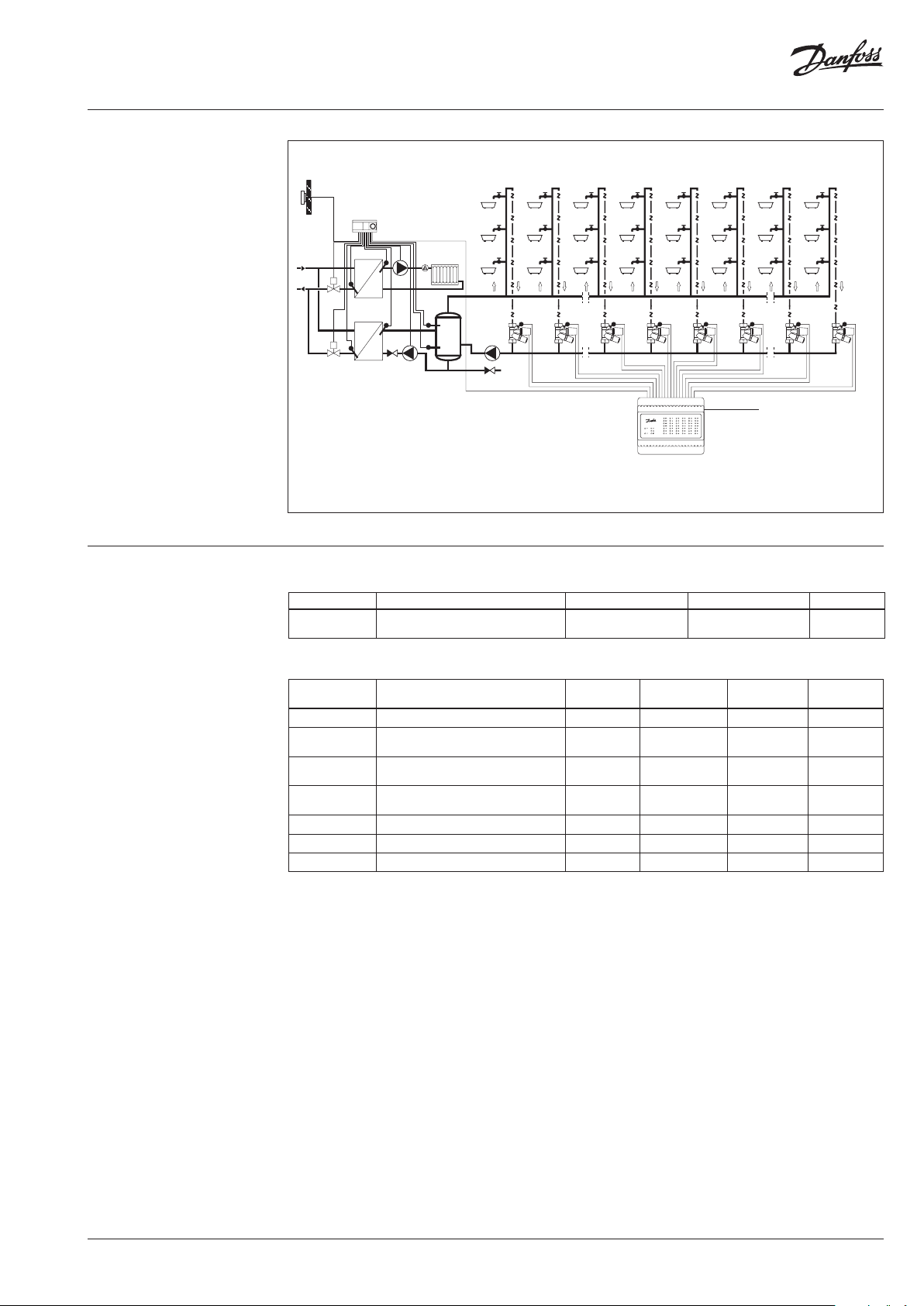

Applications (continuous)

ECL...

* ESMC s ensor S0 is includedwith CCR2+

Controller

Ordering

M

M

S

S

S1

S2

S7

S8

S9

S10

S19

S

S

S

S

V1

V2

V7

TWA

TWA

MTCV

MTCV MTCV MTCV MTCV MTCV MTCV

TWA

V8

TWA

V9

24 VDC

V10

TWA

TWA

S20

V19

TWA

MTCV

Fig. 3 Scheme of installation for disinfection and registration temperature

- dependent system (sensor S0 and connection to weather or another control needed)

Inclusive in the box CCR2+ Controller, 1 pcs ESMC sensor

Typ e Designation Supply voltage Actuator type/nos. Code No.

CCR2+ Controller

Disinfection Process Control

Temperature registration

24 V DC NC / 20 003 Z3851

Accessory

Typ e Designation

Voltage

(currentless)

Comments

TWA-A Thermal actuators 24 V NC VD.SA.P4.02 088H3110

TWA-A / ESMB

Adapter

Socket

Thermal actuators with

temperature sensors ESMB

Adapter for T WA-A actuators

for MTCV

Socket for temperature sensor to

MTCV

24 V NC VD.SA.P4.02 003 Z1043

-

for valve

DN15 / DN20

- for type ESMB VD.57.Y5.02 003Z102 4

ESMB Universal temperature sensor , PT1000 - with 2.5 m cable VD.74.I7.02 0 87B 1184

ESMC Surface Sensor, PT1000 - with 2 m cable VD.74.I7.02 08 7N 0011

CCR+ Slave Unit system expansion (add 16 risers) 24 V DC - - 003Z3852

Data she et

number

Code No.

VD.57.Y5.02 003 Z1022

V20

TWA

VD.D3.K1.02 | 3© Danfoss | 2018.10

Page 4

Data sheet Disinfection Process Control & Temperature Registration

Technical data

1)

To select proper p ower transformer

please follo w formula: 24 V 10VA

(controller) + 7 VA*/per each actuator

Temperature sensor (S0, S1-S20 / S21-36) Pt1000, S0- t ype ESMC / ESM11, S1 … S36 – type ESMB

Temperature range (registration) –20 °C … +120 °C

Measuring accuracy ± 0,1 K

Inputs: B1, B2 and B3 Free contact (5 V 1 mA)

Number of control valves (risers) 20 basic, additional 16 with system ex tension via CCR+ Slave Unit

Output signal to actuators 24 VDC max. 1 A

Alarm signal output 24 VDC max. 1 A

Relay output 0 … 24 DC max. 1 A

Type of memor y Build-In

Capacit y of memory 8 GB

Timer: Real time clock Built-in batter y - service life 10 years

- Wi-Fi (communication port only)

Communication interfaces

Default IP settings

Ambient temperature 0 … 50 °C

Transport temperature –10 … +60 °C

IP rating IP 20,

Power supply 24 VDC

Power consumption (Master controller only)

Power consumption (Slave Unit only)

Weight 0.3 kg

Installation DIN rail 35 mm

1)

- TPC/IP port (LAN cable connection)

- Modbus RS 485 RTU

- IP Modbus (L AN cable connection)

- Default L AN IP adress (static): 192.168.1.100

- Default WiFi acess IP adress (static): 192.168.1.10

- IP address mask: 255.255.255.0

- Gateway adress: 192.168.1.1

- DNS ad dress: 192 .168.1.1

- CCR name: ccrplus

- default password: admin1234

1)

10 VA

2 VA

Function After installation all settings should be carried

out on the CCR2+ according to the instructions in

the device settings menu. User need to connect

to CCR2+ with smarth device or PC.

Temperature registration

The CCR2+ can be used to record temperatures

in a hot water circulation system. Temperatures

are measured by PT 1000 temperature sensors

installed in MTCV valves. If the CCR2+ is used

solely for recording temperatures, it is not

necessary to install any actuators on the MTCV

valves.

Sampling time (data collection) intervals can

be adjusted using the control’s keypad from 1

minute.

Data are stored on internal memory. The data

collecting period depends strongly on and the

sampling interval.

Data are saved in *.csv format and can be

downloaded any time in Data menu.

The data can be visualised in spreadsheet and

graphs.

4 | VD.D3.K1.02 © Danfoss | 2018.10

Page 5

Data sheet Disinfection Process Control & Temperature Registration

The disinfecting procedure

• Start of disinfection

The start of the disinfection process

depends on the temperature signal from

the temperature sensor S0 installed on the

supply pipe of hot water systems or short cut

input B1 (Fig. 4, wiring).

The increased S0 temperature initiates

the thermal disinfection process when the

average long-term supply temperature

(from the last 5 minutes) exceeds the

set disinfection temperature. After the

disinfection process, the CCR2+ activates

all thermo actuators (TWA-A) that opens all

MTCV valves.

Start and progress of the disinfection process

are indicated on device setting menu.

It is possible to use outputs (Fig. 4) to indicate

any external operation of the disinfection

process, e.g.:

heat force,

alarm output.

• The thermal disinfection process

When the temperature of the circulation

water has achieved the set value (S1 … S20,

the disinfection temperature has to be

defined in device settings before the process

starts), the CCR2+ starts to countdown the

required disinfection time for each sensor

S1 … S20.

During the disinfection, the temperature in

the risers is controlled by MTCV + TWA-A

through control opening of MTCV by-pass,

temperature is kept on a constant level, above

(+1K) the minimum required disinfection

temperature.

Pulse Wide Modulation (PWM) functions

are used as TWA-A is thermo actuator. This

solution can provide a very stable regulation

with very low temperature oscillation.

Because the TWA-A is a thermal actuator,

its aperture is controlled by temporarily

switching the actuator on and off with

appropriate fill percentage (PWM-pulse wide

modulation).

If the temperature in the riser is too low, the

pulses switching the actuator on become

longer and the intervals become shorter. If

extending the switch-on pulses does not

result in increasing the temperature, they will

be extended even more, and the intervals

will be shortened, right up to the point where

constant voltage is fed to the actuator with no

intervals in the switched-on state.

If the temperature in the riser is too high, the

pulses switching the actuator on become

shorter and the gaps become longer. If

shortening the switch-on pulses does not

result in an reduction of the temperature,

the pulses will be shortened even more, and

the intervals will be lengthened, right up to

the point where the actuator is completely

switched off and the valve closed.

This procedure ensures that the riser is

protected from excessive and insufficient

temperatures, even though a two-state motor

is used. In order for the described process

to work correctly (without oscillation), its

dynamic parameters should be set in the

CCR2+ (integration time and disinfection

temperature control gain- PID control) or used

factory settings (adapted to thermal actuators

type TWA-A).

After the set time has elapsed, the CCR2+

shuts the disinfecting by-pass in the MTCV

valve for the given riser by switching the

TWA-A actuator off. Water flow in the riser

is now controlled solely by the thermostat

element in the MTCV valve.

The adopted procedure protects the riser

from overheating and reduces the risk of

corrosion or accidental burning and reduces

the overheating costs. Moreover, after

disconnecting the disinfected riser, the

water flow rate in the other risers increases,

accelerating the disinfection process for the

remaining installation.

The disinfection process progress is signalled

by outputs contacts O1,...,O4.. This solution

is applied where it is necessary to inform

the user that the disinfection process is in

progress, e.g. in buildings where it is executed

automatically (hotels, hospitals etc.).

• Problems during the disinfection process

A progress analysis is performed for the

entire system and for every single riser during

the disinfection process at set intervals (the

interval period is among other determined

among other by CCR2+ settings).

A list of risers is prepared based on the

temperature increase rate measurements for

each riser, sorted by the disinfection progress

amount. The average disinfection progress in

all risers is also calculated at this time.

If the average disinfection progress in all risers

is positive (better than that defined in the

settings), the process continues unchanged.

All risers are disinfected, and a subsequent

progress analysis is performed after the set

period.

If the measured progress of the temperature

increase is not positive (slower than defined

in the settings), it is highly probable that the

disinfection will fail. To ensure realisation,

the CCR2+ will (due to special algorithm)

divide the installation into smaller parts

and perform the process for selected risers.

Possible reasons for a non-positive process

can include excessive cooling of the branches,

an underrated pump and/or scaled pipes.

• Algorithm

If progress is insufficient after the interval

period, the CCR2+ divides the risers into two

groups. The first group includes half of the

risers with the best progress. (If there are an

VD.D3.K1.02 | 5© Danfoss | 2018.10

Page 6

Data sheet Disinfection Process Control & Temperature Registration

The disinfecting procedure

(continuous)

odd number of risers, the first group numbers

half of the risers plus one-half.)

The second group comprises the remaining

risers where progress is slow. These risera are

excluded from the disinfection process (the

riser valves are shut).

As a result of disconnecting the slow progress

risers, the pump’s delivery is directed to

a lower number of better risers, and the

possibility of a succesful completion of their

disinfection becomes higher.

After the next interval period, another

analysis of the disinfection progress is

performed, and the process is repeated.

If the progress in the operating risers is

positive, disinfection continues. As each of the

operating risers completes the disinfection,

its valve is shut, while the valve of the next

warmest riser yet to be disinfected is opened.

The number of risers disinfected concurrently

is constant.

If progress is still insufficient, the risers are

again divided into a good half and a bad half,

where the latter is disconnected.

In the worst case scenario, following the last

split, disinfection will be performed in one

riser only and upon its completion the next

riser will be served. If even then the progress

is not satisfactory, it could mean any of the

following. The supply temperature is too low,

hydraulic losses are too high, the pump’s

delivery rate or head is too small.

By applying suitable algorithms, the CCR2+

makes it possible to execute a disinfection

process using the existing circulation pump

even in the most adverse thermal conditions.

• End of the thermal disinfection process

When the disinfection process is finished, the

by-pass at the MTCV is closed.

The LED status indicator and Reading Menu in

App indicates “process successful”.

It is possible to use outputs (Fig. 4) to indicate

any external operation of the disinfection

process, e.g.: Disinfection finished.

If the progress of the process is not positive

(it is not possible to achieve required

disinfection temperature even in a single

riser, above-mentioned problems), the

CCR2+ will stop the process. When the

CCR2+ operates in applications as dependent

control – a signal to the weather compensator

or another boiler control is sent, and the

installation automatically returns to the

comfort temperature. When CCR2+ operates

as independent control, the maintenance

service should reduce the supply temperature

after the signal about turn-off the process.

Upon completing disinfection in the last riser,

the CCR2+ opens O1 output (Heat Force);

and closes O3 output (Dissinfection finished),

signalling that the process is finished. The

main control (in boiler station or sub-station)

automatically reduces the supply temperature

to return to comfort temperature level.

These signals from the CCR2+ are applied to

return to the comfort temperature, when:

• Disinfection process is successful;

• When no progress during the process.

If the supply temperature does not fall (due to

some errors), the CCR2+ initially opens the bypass on the MTCV to achieve a certain flow in

the installation (pump protection function).

• Pump protection against cavitations

When the disinfection process is finished,

the CCR2+ keeps all disinfections, the

by-pass is closed. In case of not reduced

flow temperature after the disinfection

process, the CCR+ runs the pump protection

function. The first valve remains open until

the temperature on the sensor S0 returns

to the normal circulation temperature or

ECL (or other electronic control) opens O1

output (Heat Force) and closes O3 output

(Dissinfection finished).

• Troubleshooting

Disinfection will not be completed if:

- Too low supply temperature in the

circulation system;

- Temperature during the disinfection

process was maintained shorter then preset (e.g., the electronic control reduced

the temperature before the process was

finished);

- The flow in the riser was not sufficient. (e.g.

scale in the pipe …);

- Any errors in the disinfection process are

indicated in the CCR2+ Menu Readings;

- Analyses of the process have to be made.

Disinfection will be aborted by the CCR2+

control if:

- Disinfecting temperature is not attained in

any one of the risers during disinfection, e.g.

the hot water temperature is lowered before

the process is completed;

- The hot water supply temperature measured

by sensor S0 drops below the disinfecting

temperature before disinfection in the risers

is completed;

- Disinfection remains incomplete after 260

minutes;

- In each case of aborting the disinfection

process the control indicates which risers

were not disinfected successfully on CCR2+

Menu Readings.

Disinfection may fail for the entire

installation of only for selected risers.

Failed disinfection is reported by the CCR2+:

- On its App (Menu Readings);

- LED status indicators

- O4 ouput closes (Alarm)

- BMS statuses

6 | VD.D3.K1.02 © Danfoss | 2018.10

Page 7

Data sheet Disinfection Process Control & Temperature Registration

The disinfecting procedure

(continuous)

• Recommendation

Before starting the thermal disinfection

process, please contact your local legislation

institution about local regulation and

requirements.

Perform water tests for Legionella

pneumophila bacteria detection to achieve

information about bacteria concentration and

genus of bacteria as some colonies require

higher pasteurisation temperatures.

A successful thermal disinfection process

depends on many elements (good pipe

insulation, possibility to reach high supply

temperature, good pipe condition- no scale

inside), it is therefore recommended to:

- Start the process from lower required

disinfection temperatures – if the process is

successful try to increase the temperature as

the pasteurisation process is much faster at

higher temperatures;

- Increase the temperature of the process

step by step (e.g. every two degrees)

remember that a higher demand for thermal

disinfection requires a higher supply

temperature (what in many cases can be

limited due to technical problems with heat

sources).

Remember that high temperatures in the

system can scald users and increase the risk of

precipitation lime deposit.

After two – three processes of thermal

disinfections make a water test for bacteria. If

correctly performed, the thermal disinfection

process results will be visible immediately.

• Comments

The Danfoss solution based on electronic

controls (MTCV-C + CCR2+ + TVM-W) of

the thermal disinfection process allows for

maintenance of an appropriate circulation

temperature in the systems simultaneously

with recognising thermal disinfections

in minimum time (for all installations automatically) and reducing scalding (TVM-W)

and precipitation of deposit problems.

The system is designed to provide maximum

guarantee of thermal disinfection, while at the

same time considering the cost aspect!

CCR2+ settings

Temperature set in the circulation risers and disinfection time:

Temperature

of disinfection

(°C)

50 6 h 20 minute 7 h 30minute

51 6 h 10 minute 7 h 20 minute

52 4 h 00 minute 5 h 50 minute

53 2 h 00 minute 4 h 00 minute

54 1 h 00 minute 2 h 00 minute

55 0 h 50 minute 2 h 00 minute

56 0 h 40 minute 1 h 20 minute

57 0 h 20 minute 1 h 00 minute

58 0 h 15 minute 0 h 50 minute

59 0 h 15 minute 0 h 45 minute

60 0 h 14 minute 0 h 40 minute

61 0 h 13 minute 0 h 35 minute

62 0 h 12 minute 0 h 30 minute

63 0 h 12 minute 0 h 28 minute

64 0 h 11 minute 0 h 27 minute

65 0 h 11 minute 0 h 26 minute

Time setting for thermal disinfection

in: hour … Minute …

Minimum required

Maximum

recommended

Temperature

of disinfection

Time setting for thermal disinfection

in: hour … Minute …

(°C)

66 0 h 10 minute 0 h 25 minute

67 0 h 9 minute 0 h 25 minute

68 0 h 8 minute 0 h 22 minute

69 0 h 7 minute 0 h 21 minute

70 0 h 6 minute 0 h 20 minute

71 0 h 6 minute 0 h 18 minute

72 0 h 6 minute 0 h 14 minute

73 0 h 5 minute 0 h 12 minute

74 0 h 4 minute 0 h 10 minute

75 0 h 3 minute 0 h 10 minute

76 0 h 3 minute 0 h 10 minute

77 0 h 2 minute 0 h 9 minute

78 0 h 2 minute 0 h 8 minute

79 0 h 2 minute 0 h 6 minute

80 0 h 2 minute 0 h 6 minute

Minimum required

Maximum

recommended

VD.D3.K1.02 | 7© Danfoss | 2018.10

Page 8

Data sheet Disinfection Process Control & Temperature Registration

Wiring, Dimensions and

Installation

G

G

Lbus

24VDC

G

B

A

POWER

Master

LBus

0V

RS485

24VDC

CCR2+ Controller

TCP/IP

LAN

C

CCCCC

O4

V4

V8

V12

0

O3

V3

O2

O1

Module

V7

V2 V6 V10 V14 V18

V1

V5

Module 1

Module 2

V16

4

V11

V15

V9

V13

Module 3

Module

105 mm

C

O1-4

B1-B3 S0

G

V5-8CV9-12

V1- 4

S5-8 S9-12

S1-4

GGGGG

C

C

V13-16

S13-16

C

V20

5

V19

V17

Module

C

V17-20

S17-20

90 mm

122 mm

45 mm

Disinfection

60 mm

MADE IN POLAND

CCR2+

Process Controller

50 mm

20171213V2.40

003Z3851

Supply 24VDC

Danfoss A/S

6430 Nordborg, Denmark

36 mm

RoHS

Fig. 4 Wiring sheme - CCR+

Master Controller

Connector/port Description

0V

24VDC

Lbus

RS485

C

O1,.. ,O4

C

V1-4

C

V5-8

C

V9 -12

0V – ground (-) power supply

24 V DC(+) power supply

G – ground Lbus port (for system expansion)

Lbus – Lbus por t (for system expansion)

G – ground (Modbus RS 485)

B – port B (Modbus RS 485)

A - port A (Modbus RS 485)

C – common port dedicated to ouputs O1-O4

O1,.. O4 – defined outputs

C – common port dedicated to actuators V1-4

O1 - output: Heat Force

O2 - output: Start next CCR/Slave Unit

O3 - output: Dissinfection finished

O4 - output: Alarm

C – common port dedicated to actuators V5- 8

V5. .V8 – outputs to ac tuators

C – common port dedicated to actuators V9 -12

V9. .V12 – outputs to actuators

TCP/IP

RJ45

4

B1

TCP/IP

Master

POWER

RJ45

S2

B2

S3

B3

Module 1

Module 0

S4

S0

G

G

S10

S6

S11

S7

Module 2

Module

S12

S8

G

G

3

S9

S5

S1

S13

S14

S15

Module

S16

G

S17

S18

S19

Module 5

S20

G

Connector/port Description

C

V13 -16

C

V17-2 0

C – common port dedicated to actuators V13-16

V13..V16 – outputs to actuators

C – common port dedicated to actuators V17-20

V17.. V2 0 – outputs to ac tuators

TC P/IP, L AN TCP/IP port or IP Modbus port

B1-3, S0

G

S1-4

G

S5-8

G

S9 -12

G

S13 -16

G

S17-2 0

G

B1,B2, B3 defined inputs

S0 – temp. sensor

G – common ground dedicated to inputs/sensor

S1.. S4 – inputs from sensors

G – common ground dedicated to sensor S1-4

S5..S8 – inputs from sensors

G – common ground dedicated to sensors S5-8

S9. .S12 – inputs from sensors

G – common ground dedicated to sensors S9-12

S13.. S16 – inputs from sensors

G – common ground dedicated to sensors S13-16

S17. .S 20 – inputs from sensors

G – common ground dedicated to sensors S17-20

8 | VD.D3.K1.02 © Danfoss | 2018.10

Page 9

Data sheet Disinfection Process Control & Temperature Registration

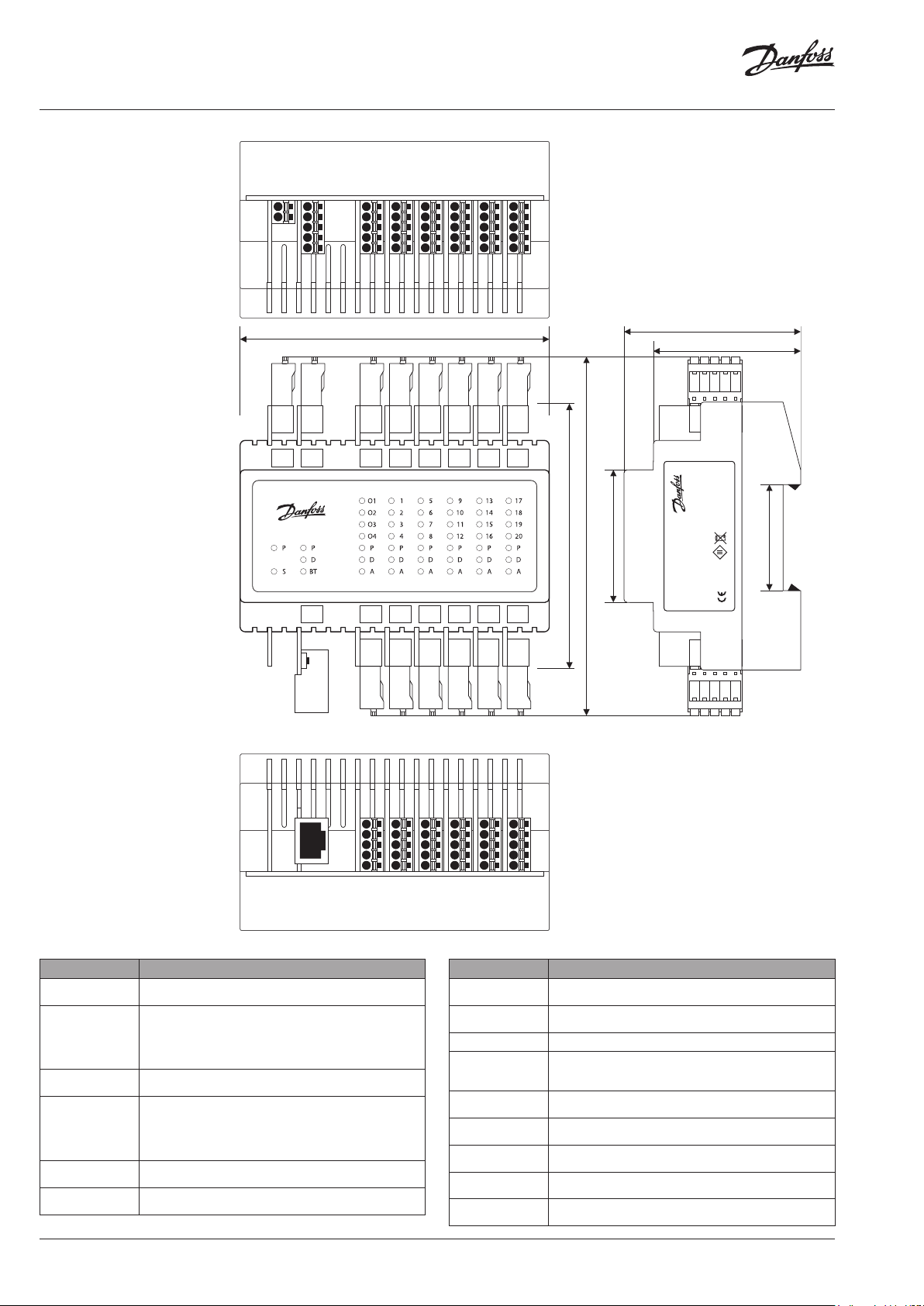

Thermal actuator

TWA-A

Descriptions The thermal actuator TWA-A is for use with the

MTCV and small Danfoss seated valves.

The actuator starts to move:

- when the signal is applied.

Ordering

Technical data

Electrical connection and

mounting

Typ e

TWA-A

TWA-A

Supply voltage 24 V AC/DC +30% to –15% 230 V AC. +10% to –15%

Frequency 50 - 60 Hz

Average power consumption 2 W

Spindle travel time (Danfoss valves) 3 minutes

Ambient temperature 0 - 60 °C

Enclosure IP 41

Cable length 120 0 mm

Max. spindle travel 3 mm

Voltage

(currentless)

230 V~ NC 088H3112

24 V NC 088H3110

Valve

function

Code No.

Blue/Brown

Blue/Brown Green/Green

VD.D3.K1.02 | 9© Danfoss | 2018.10

Page 10

Data sheet Disinfection Process Control & Temperature Registration

Dimensions

Internal

thread

DN 15

DN 20

A

IS O 7/1aIS O 7/1H(mm)H1(mm)L(mm)L1(mm)

Rp ¾ Rp ½ 79 129 75 220 0,55

Rp 1 Rp ¾ 92 129 80 240 0,60

Weight

(kg)

Code No.

00 3Z4515

003Z4520

10 | VD.D3.K1.02 © Danfoss | 2018.10

Page 11

Data sheet Disinfection Process Control & Temperature Registration

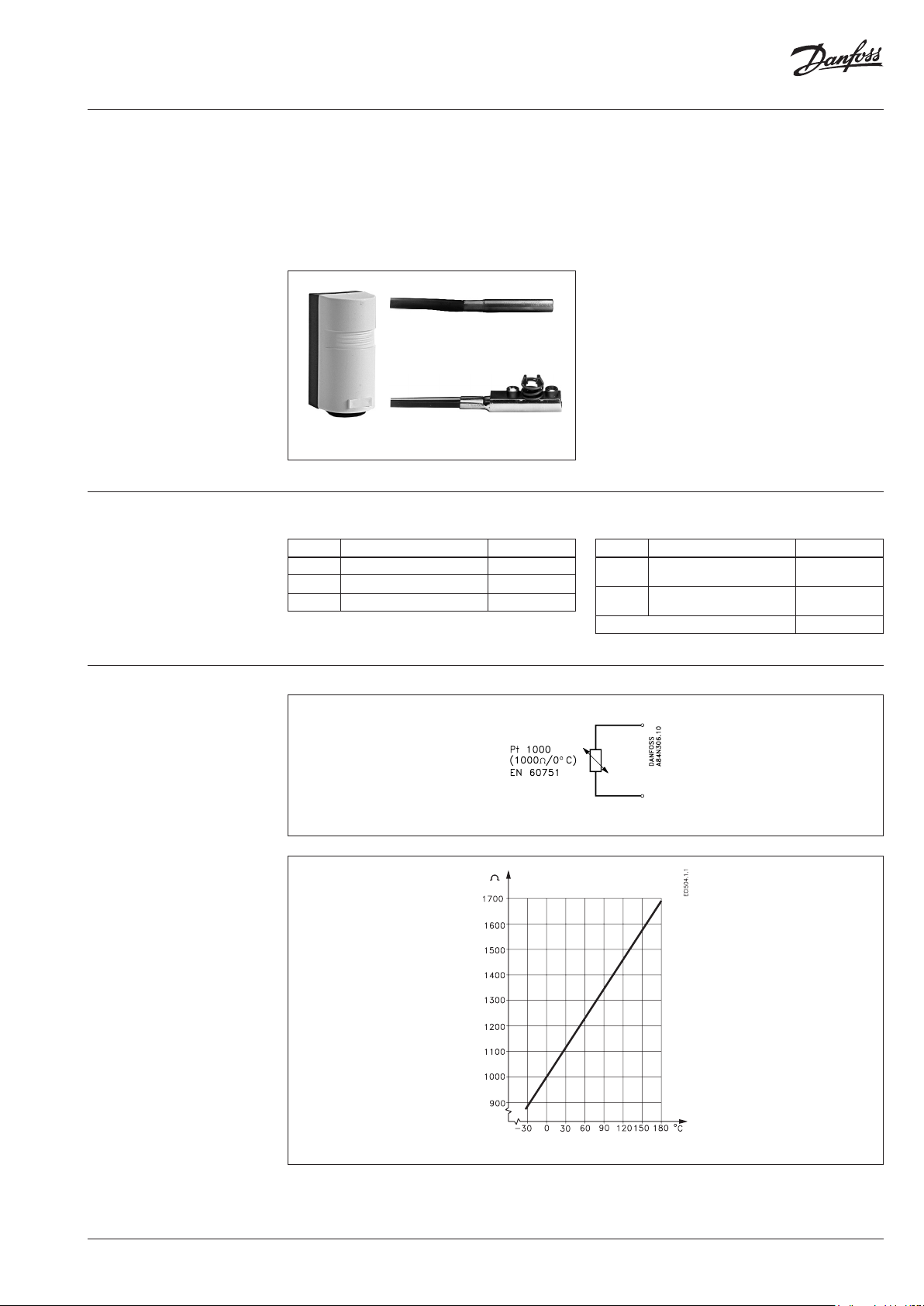

Temperature sensors (Pt 1000)

ESM-11, ESMB, ESMC

Application

Ordering

Wiring

ESMB

ESM -11

ESMC

Temperature sensors

Typ e Designation Code No.

ESM -11 Surface sensor 0 87B 1165

ESMB Universal sensor 0 87B118 4

ESMC Surface sensor 08 7N 0011

- Platinum-based sensors, 1000 W at 0 °C

All the temperature sensors are two-wire devices,

and all connections are inter-changeable.

The surface sensor type ESM-11 has a spring

contact surface to ensure a good heat transfer in

pipes of all sizes.

The basic sensor contains a platinum element

with a characteristic that complies with EN 60751.

Accessories and spare parts

Typ e Designation Code No.

Pocket

Pocket

Heat conduc ting paste, 3.5 cm

Immersion, stainless steel 100

mm, for ESMB (0 87B118 4)

Immersion, stainless steel 250

mm, for ESMB (0 87B118 4)

3

084N1082

084N1083

04 1E0110

Connection cable: 2 × 0.4 - 1.5 mm

Resistance characteristics

2

VD.D3.K1.02 | 11© Danfoss | 2018.10

Page 12

Danfos

produc

Al

Danfoss A/S

Heating Segment

Data sheet Disinfection Process Control & Temperature Registration

Technical data

All temperature sensors contain a Pt 1000 element. Instructions are supplied with the products.

Typ e

ESM -11

ESMB

ESMC

Pocket

Materials

Electrical

connection

Mounting

× = PE (polyethylene) bag

×× = Cardboard

Sensor characteristics Referri ng to EN 60751, Class 2 B Max. deviation 2 K

Time constants

Temperature range Enclosure Time constant PN

0 … 100 °C IP 32 3 s -

0 … 100 °C IP 54 20 s -

0 … 100 °C IP 54 10 s -

0 … 200 °C - See “Data specific” 25

Packing

ESM -11

ESMB

ESMC

Cover: ABS ××

Base: PC (polycarbonate)

Encapsulation: 18/8 stainless steel ×

Cable: 2.5 m, PVC, 2 × 0.2 mm

2

Encapsulation: Top part: nyrol, bottom part: nickel coated Cu ×

Cable: 2 m, PVC, 2 × 0.2 mm

2

Pocket Tube and body: AISI 316

ESM -11 Terminal block for 2 wires in base part

ESMB 2-wire cable (2 × 0.2 mm2)

ESMC 2-wire cable (2 × 0.2 mm2)

ESM-11/ESMC Clamp for tube DN 15-65 supplied

ESMB For pipe or flat surface or in pocket

Pocket G ⁄ A

ESMU (Cu) in pocket

ESMB in pocket

32 s (in water)

160 s (in air)

20 s (in water)

140 s (in air)

Dimensions

s can accept no responsibility for possible errors in catalogues, brochures and o ther printed material. Danfoss reserves the right to alter its pro ducts without notice. This also applies to

ts already on order provided that such alterations can be m ade without subsequential changes being necessary in specications already agreed.

l trademarks in this material are property of the r espective companies. Danfoss and all Danfoss l ogotypes are trademarks of Danfoss A/S. All rights reserve d.

ESM -11

pocket for ESMB

• heating.danfoss.com • +45 7488 2222 • E-Mail: heating@danfoss.com

ESMC

ESMB

© Danfoss | DHS-SRMT/SI | 2018.1012 | VD.D3.K1.02

Loading...

Loading...