Page 1

Installation guide

Electric regulating valves

Type CCMT 3 – 10 Light

Refrigerant:

R74 4

For other refrigerants, contact Danfoss.

027R7256

Max working pressure:

Steel Connections : 140 bar / 2030 psig

Bi-metal Connections : 130 bar / 1885 psig

Note! Bi metal Connections :

120 bar / 1740 psig for UL approval.

Warning! Do not connect directly to AC / DC power source. Connect valve to appropriate

controller/driver only. Do not operate valve while assembling or disassembling.

For more language options

and more information on

the valve refer to the website.

ccmt.danfoss.com

Ambient temperature:

Min. -40 °C / -40 °F

Max. 50 °C / 122 °F

Fluid temperature:

Min. -20 °C / -4 °F on valve inlet

Min. -40 °C / -40 °F on valve outlet

Max. 55 °C / 131 °F on valve inlet / outlet

Note!

Stepper motor type: Bipolar

Total full steps: 210

Step rate: 100 s tp/s

Phase current: 350 mA RMS

Coil resistance: 15 ohm

• CCMT valves are delivered in open position, ready for brazing.

• Filter with a maximum mesh of 100 μm recommended to install on

the inlet line that can resists particles size above 100 μm.

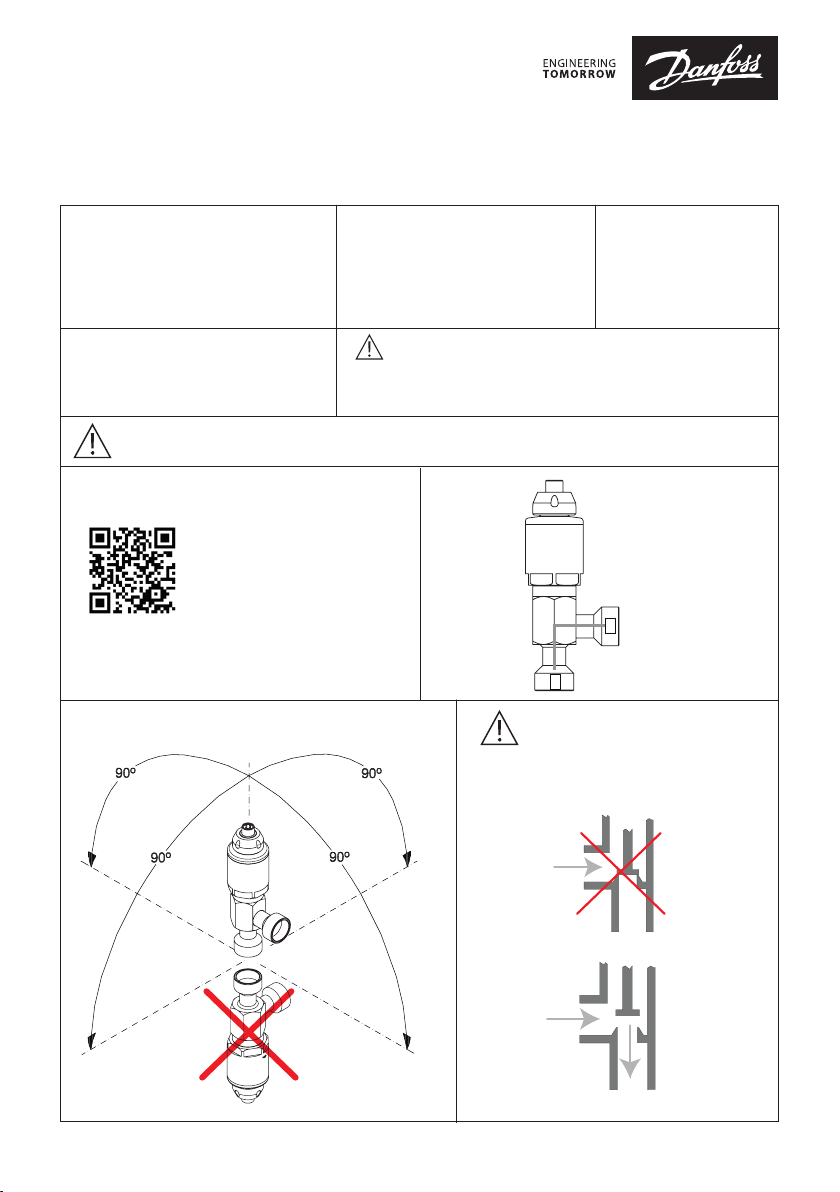

Flow direction

Flow direction: A to B

A

B

027R7256

Mounting direction

1 | © Danfoss | DCS (rm) | 2021.01

Warning!

• Do not disassemble the valve

before brazing or welding.

• Valve must be open during

brazing and welding.

Fully closed

Open

AN328924 650798en- 000201

Page 2

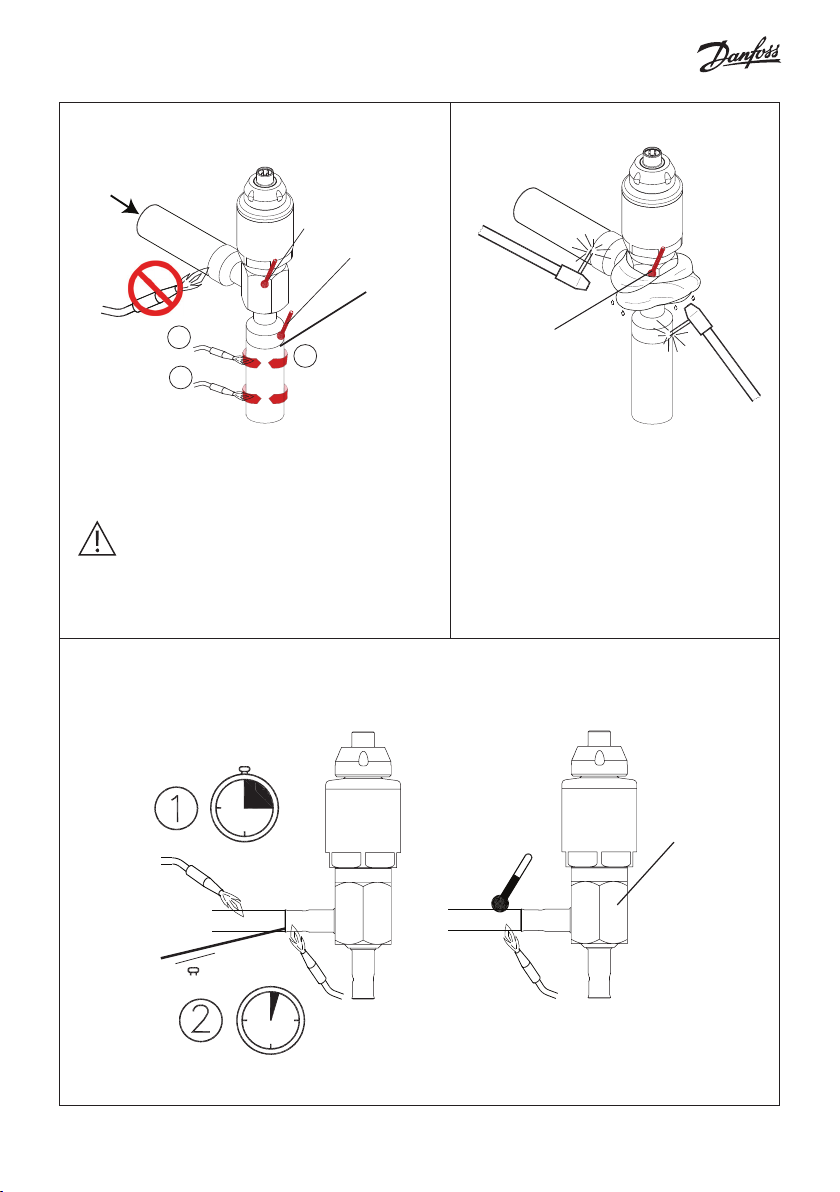

Brazing

Valve connection:

Valve body:

N

2

max. 100 °C / 212 °F

max. 700 °C / 1300 °F

Materials

for brazing

Welding

2

3

Recommendation

Solder n ozzle 4 - 6 mm

N (5/32 in - 15/64 in)

Materials used for brazing:

• Flus: Metalli tenacity No. 5 Powder or Braze Tec special h paste.

• Filler: Silver-Flo 55 (BS:AG 14/ DIN L-Ag55 Sn) or Silver-Flo 56

(AWS B Ag-7).

Filler metals containing Phosphor i.e. BS: CP 1/ DIN L-Ag 15P or

BS: CP 3/ DIN L-Ag P7 must not be used.

Note: N2 gas from opposite side of soldering point.

Bi-Metal Brazing

Copper tube 10 - 15 sec

1

Warning

max. 100 °C / 212 °F

Recommendation for TIG welding

• Power approximately 60A.

• Use Shield gas charge - Argon.

• Material for welding - approximately 2 mm thick

stainless steel alloy.

Valve body:

Max. 100˚C / 212˚F

Min. 5% Ag

No Flux

© Danfoss | DCS (rm) | 2021.01

Valve connection:

Max. 700˚C / 1300˚F

AN328924 650798en- 000201 | 2

Page 3

Electrical connections

A1

Danfoss

34G166.10

Sufficiently tighten M12 by hand

B1

B2

A

B

A1 / A2 = coil I

B1 / B2 = coil II

Insulation

When used with duty cycle in a range from 20% to 50%

or with Danfoss AK-XM 208C stepper driver:

• Insulation is not to be used on valve motor

• Insulation is acceptable on the valve body only

Note: operation with duty cycle above 50% is not

possible irrespective of insulation method.

A2

M12 connection

on CCMT valve

Insulation

Warning

© Danfoss | DCS (rm) | 2021.01

AN328924 650798en- 000201 | 3

Page 4

Service only

Danfoss

27H312.10

1

2

3

Compressed air

to remove dirt

Replace O-ring

Max. torque:

20 Nm / 14.8 ft-lbf

© Danfoss | DCS (rm) | 2021.01

AN328924 650798en- 000201 | 4

Loading...

Loading...