Page 1

Installation guide

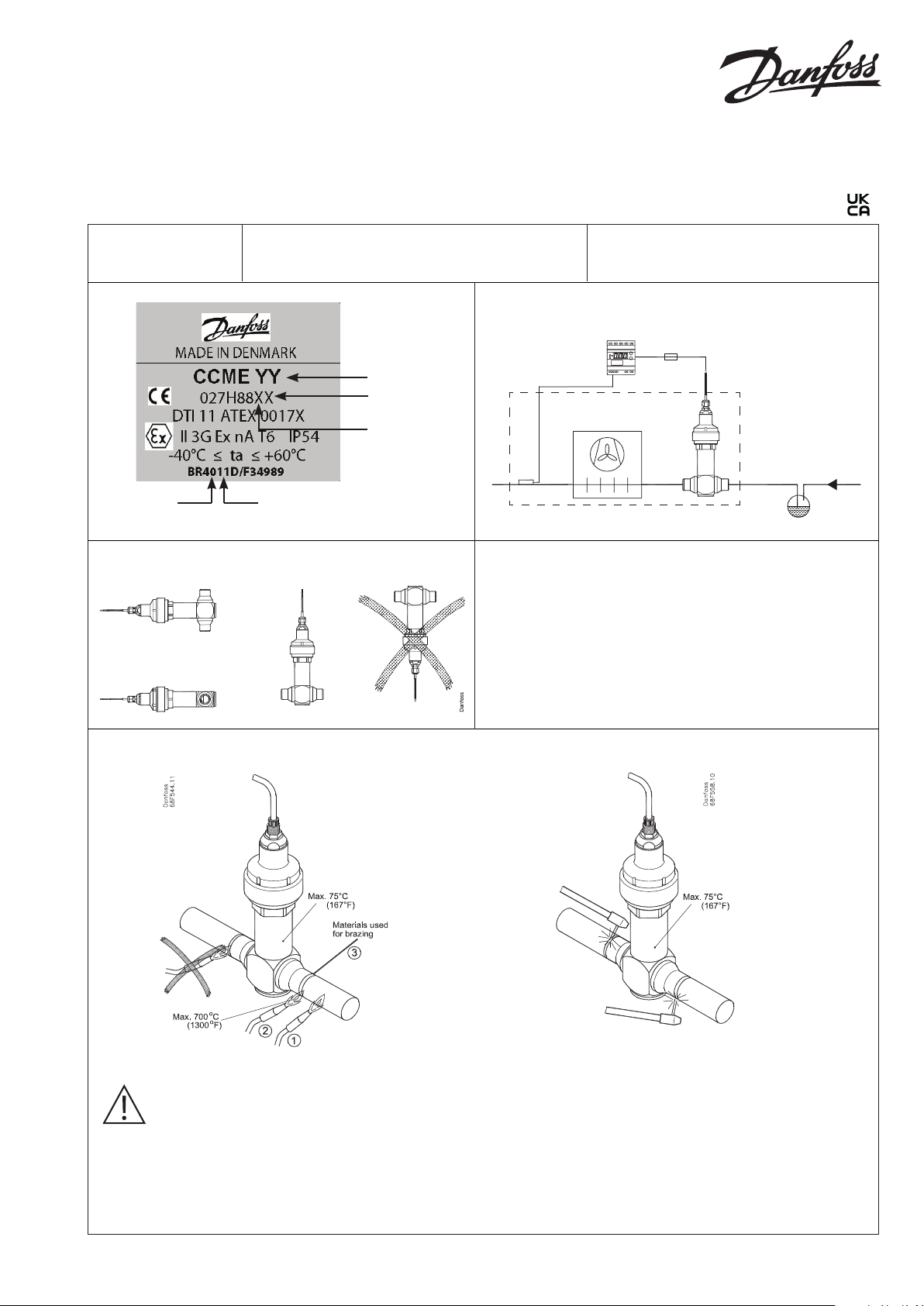

Fuse

Electronic operated valve

Type CCME

Refrigerant: R290

027R9843

Danfoss

34G146.10

Production

week

Mounting

Max. working pressure (PS/MWP): 90 bar (1305 psi)

Max. test pressure (PT): 130 bar (1885 psi)

Application

Danfoss

Valve type

Cable length:

1-9 meter

Valve type:

1=CCME10

2=CCME20

3=CCME30

4=CCME40

Production

year

34G144.10

The valve has to be 100% open when mounting - as delivered.

The valve must be supported with tube supporters either on

the valve itself or on the tubes connected to the valve. The valve

must not be exposed to any external influence like shock or

punches.

A filter with a maximum mesh of 100 μm is required on the inlet

line if the refrigerant contains particles above 100 μm.

Max. ambient temperature: 60 °C (140 °F)

Min. ambient temperature: -40 °C (-40 °F)

2 x 400 mA

NON-ZONE

ATEX ZONE 2

027R9843

Welding

Only allowed when there is no explosion danger.

Always ensure that there is no R290 present in the

pipes and in the surroundings.

To braze the parts they must be cleaned mechanically or

chemically, and after assembly add flux. Heat the parts by placing

the heat most to the part with the best heat transfer. In this case

the tube. When the parts are on brazing temperature add brazing

material.

© Danfoss A/S (AC-MCI/sw), 2021-01 AN027786414846en-000201

Materials used for brazing:

Flus: Metalli tenacity No. 5 Powder or Braze Tec special h paste.

Filler: Silver-Flo 55 (BS:AG 14/ DIN L-Ag55 Sn) or Silver-Flo 56

(AWS B Ag-7).

Filler metals containing Phosphor i.e. BS: CP 1/ DIN L-Ag 15P or

BS: CP 3/ DIN L-Ag P7 must not be used.

Info for UK customers only:Danfoss Ltd. Oxford Road, UB9 4LH Denham, UK

Page 2

Connection

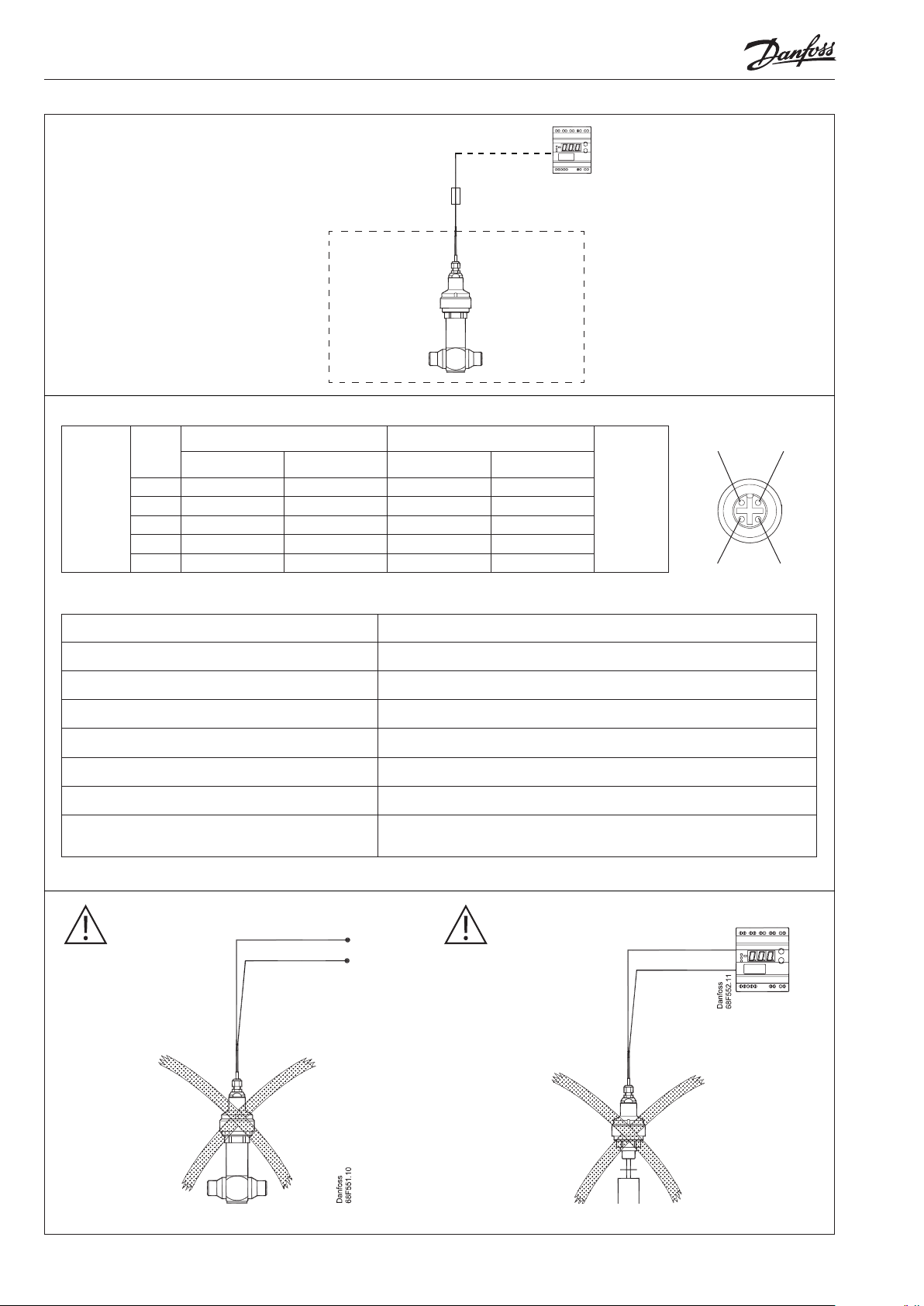

Stepper motor switch sequence

Fuse

2 x 400 mA

ZONE 2

NON-ZONE

Danfoss

34G145.10

STEP

Connection A Connection B Connection C Connection D

1 + - + -

Coil I Coil II

Closing

2 + - - +

OPENING

3 - + - +

4 - + + 1 + - + -

Electrical specifications

Parameter CCME

Stepper motor type / Step mode Bi-polar - permanent magnet / 2 phase full step

Phase resistance 52 Ω ±10 %

Nominal voltage (Constant voltage drive) 12 V dc -4% – 15%, 150 steps/sec.

Phase current (Using chopper drive) 100 mA RMS -4% – 15%,

Max. total power Voltage / current drive: 5.5 / 1.3 W (UL: NEC class 2)

Electrical connection 4 wire 0.5 mm2 (0.02 in2), 0.3 m (1 ft) long cable

Fuses required on wires from connection A and C

(Refer to the drawing above)

For further technical data please refer to the Data sheet

400 mA (each fuse) / IEC 60127

A B

Danfoss

34G147.10

DC

Warning! Warning!

Do not apply power

directly to valve.

Do not apply power to

unassembled valve.

2 | AN027786414846en-000201 © Danfoss A/S (AC-MCI/sw), 2021-01

Page 3

ENGLISH

Commission

Safety

Installation

General remarks

For safety reasons, the installation must

take place under the supervision of an

authorised person taking account of local

safety instructions, for flammable fluids,

and advisories, e.g. EN 60079-14.

The handling of valves and their controls

must be done only by staff trained in all

technical aspects of their operation.

Before installation the pipes must be

depressurised and purged (empty of its

fluid) in order to avoid any danger to the

operator.

In ATEX zone, check that the pipes are

connected to the earth (grounded).. Do

not use insulating pipes (PVC…)

- Check that the valves are suitable for

the actual refrigerant.

- Check that the valves are suitable for|

the actual zone.

Before putting valve into operation, check

that:

- The working conditions are compatible

with the details given on the

identification label.

- All electrical connections have been

properly made.

- Installation is tight after the assembly.

Maintenance

- Maintenance and repair work must be

carried out by qualified personnel (ref.

EN 60079-19)

- The pipe must be depressurized and

purged (emptied of its fluid) in order

to avoid any danger to the operator. If

the installation has carried fluids which

are dangerous in themselves if in

contact with the outside atmosphere

(inflammable, corrosive, toxic,

explosive..)

- All operations must be performed

using suitable protective (clothing,

gloves, mask…).

- Where a control uses an external energy

source, it is essential to isolate this

source before any operation.

As well as the indications given in the

preceding paragraphs of this notice, it is

imperative that the following instructions

be followed:

- This notice must be available on site

where valves are installed.

- Personnel carrying out any intervention

on the valve must be qualified for the

task. In ATEX zone, the personnel must

be educated in the risks of explosion,

and should have received specific ATEX

training (ref. EN 60079-14).

- In case the forwarded media would

be an explosive atmosphere (deliberate

internal explosive) or should it cause an

explosive atmosphere in case of external

leakage, the user must check the

tightness of the installation after

assembling, after a faulty operation or

on a periodic basis undernormal

conditions

- It is the responsibility of the user to

check after the installation of the

valve that there is no leakage. Especially

in case of deliberate internal explosive

atmospheres.

- Internal rules and legislation current

in the country concerned with respect to

health and safety at work must be

applied and respected.

- The valve and its control must not

undergo any modification without prior

approval from our advisory service.

Danfoss is not responsible for any damage

which may be caused by the use of parts,

accessories or controls which are not

original Danfoss parts

- Hot or cold parts of the valve which

present a danger to the operator must

be protected.

- In ATEX zone, the valve and its control

must be cleaned regularly to avoid the

accumulation of dust.

- In ATEX zone do not mount valves at

open ends of lines.

© Danfoss A/S (AC-MCI/sw), 2021-01 AN027786414846en-000201 | 3

Loading...

Loading...