Page 1

Application guide

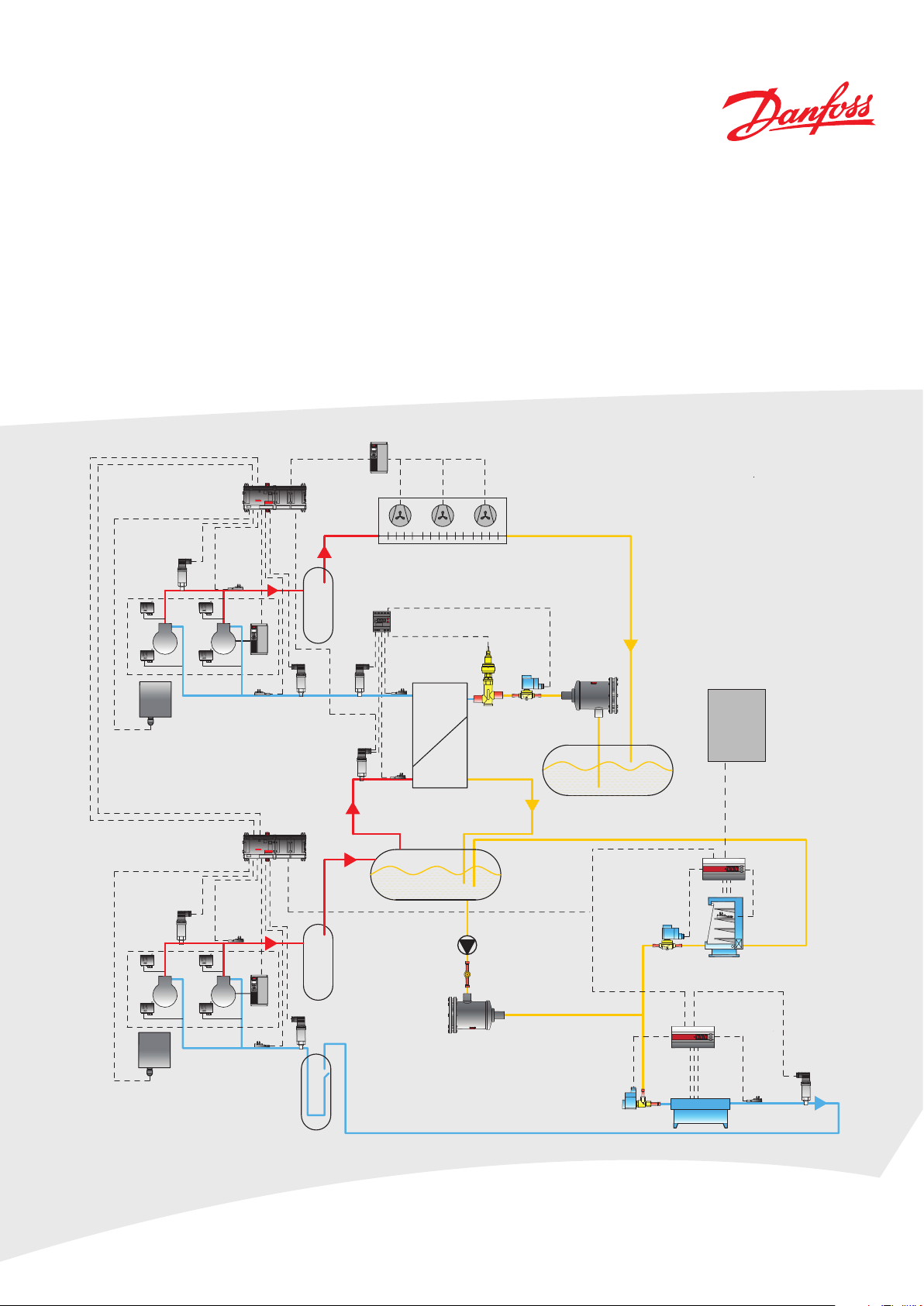

AKS 32 R

AKS 32R

GD/DGS

AKS 11

AKS 2050

AKS 11

AK-PC 740/780

GD/DGS

AKS 11

AKS 32R

AKD 102

AKS 11

DCR

Pump

SGN

AKS 2050

AKS 11

EKC 313

EVR

ETS

DCR

AKD 102

AKD 102

AK-CC 450

AKS 11

AKVH

AK-CC 550 A

AKS 11

AK-PC 740/780

Danfoss

R64-2050.11

AKS 32R

AK-SC 255/

AK-SM 350/

AK-SM 720/

AKA 245

AKS 32R

AKS 11

EVRH

Cascade HC/HFC - CO2 system

How to control the system

www.danfoss.com/co2

Page 2

2 Application guide RA8AB102 © Danfoss 10/2010 Cascade HC/HFC - CO2 system

General description

EKC 313

AK-CC 550

AK-CC 450

Cascade systems are typical not used in FR applications with traditional refrigerants. There are a

few reasons for this such as the need to maintain

two different refrigerants in one system; system

control strategy (especially that of a cascade heat

exchanger) is more complex. At the same time

using CO2 in cascade systems gives a number of

advantages:

• Eciency of the system is high even in the hot

climates

• Only a small amount of refrigerant is needed for

high temperature stage

• Temperature dierence for cascade heat exchanger is relatively low

• On the high side various refrigerants can be

used ex HC/HFC or NH3.

Ammonia/CO2 cascade systems have the highest

efficiency of all. If HFC is to be used at a high tem-

perature stage, R134a is a preferable option due

to its thermo dynamical properties and lower

(compared to R404A) GWP potential.

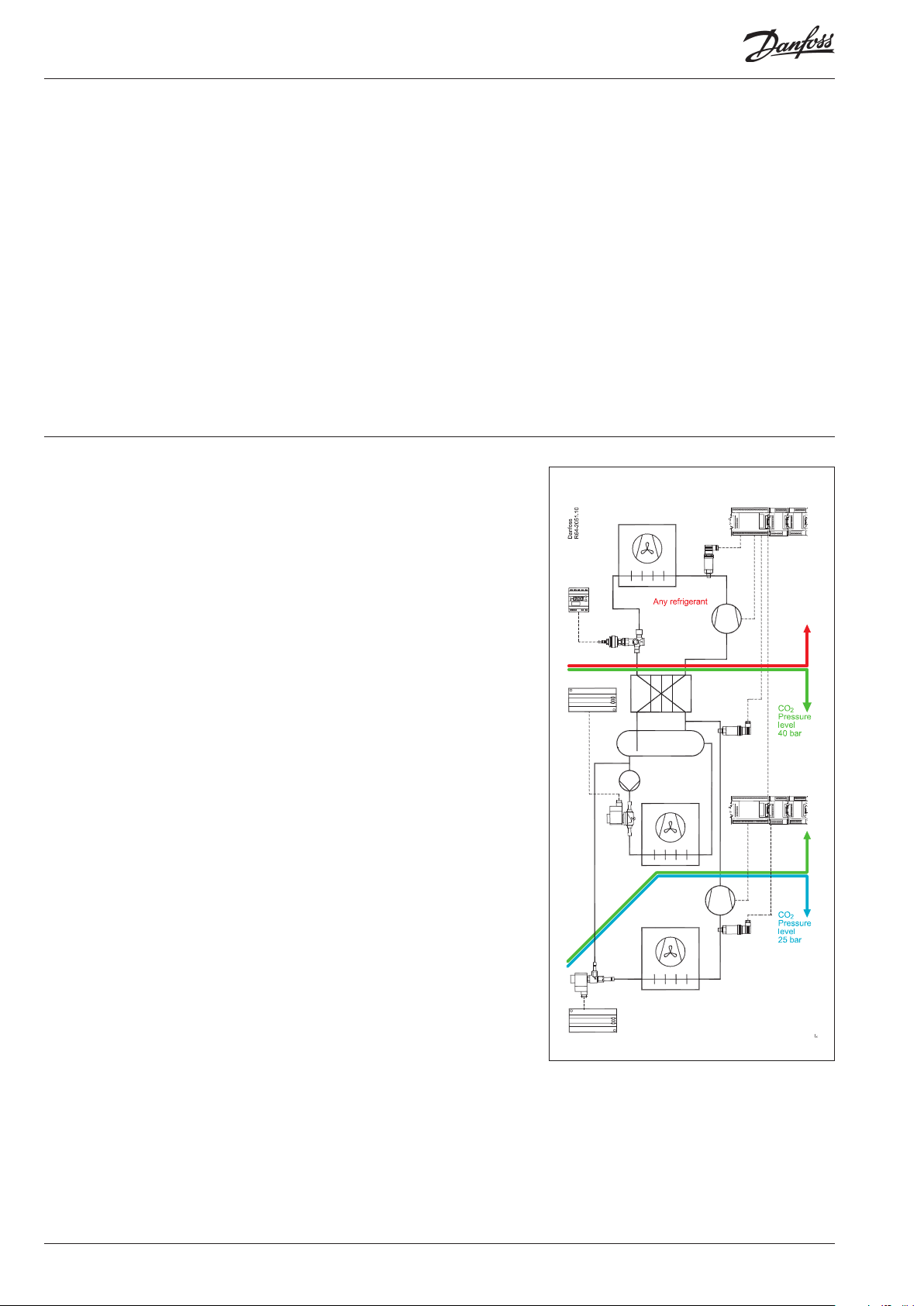

Temperatures and pressures

in cascade systems

Intermediate temperature in a cascade system is

selected based on the required temperature for

high temperature cases in a store which means

they can be cooled by CO2 directly. Intermediate

temperature can also be optimised for the highest energy efficiency if the system is used for low

temperature only.

Since a cascade system actually consists of two

different refrigeration systems which are interfaced but isolated at the cascade heat exchanger,

the design working pressure for each can be

different. CO2 design pressure is normally based

on the availability of components and is equal to

40-45 bar (corresponding to +5 - +10°C).

In order to prevent pressure from increasing

above the previously mentioned measurements,

standstill systems are recommended. Safety

valves should have the highest setting. Stand still

pressure can be achieved by raising the desing

pressure to 80-90 bar.

For example:

CO2 side

• System design working pressure (saturated suction temperature): 40 bar (+5°C)

• Safety valve settings: 36 bar (-10% MWP)

• System emergency relief setting: 34 bar (-1°C)

• CO2 discharge pressure setting: 30 bar (-5°C)

The higher the efficiency of the cascade heat

exchanger, the lower the difference between

the condensation temperature of CO2 and the

evaporating temperature of the refrigerant on

the high temperature side. As the temperature

difference on the cascade condenser increases,

the overall efficiency of the refrigeration system

decreases!

AK-PC 740/780

AK-PC 740/780

Page 3

Cascade HC/HFC - CO2 system Application guide RA8AB102 © Danfoss 10/2010 3

Temperatures and pressures

in cascade systems (continued)

On systems with low temperatures of the discharge CO2 gas (low superheat), the superheat

of the expansion valve can be the dimensioning

factor for the heat exchanger.

If a CO2 system has high superheat, then desuper-heaters need to be used in order to reduce

the load on the high temperature side.

Optimal intermediate pressure in CO2 cascade

systems depends on a number of parameters

(high temperature refrigerant, load pattern etc.).

Generally 2 cases need to be considered:

1) Systems with load at the medium temperature.

In this case intermediate pressure should be as

high as possible in order to reduce the load at

the high temperature stage. The limitations are

therefore required temperature on the intermediate level and pressure rating of the system.

2) Systems without load at medium temperature.

In this case the intermediate temperature should

be in the range of -10 - 0°C (due to the high pressure of the CO2 LT) where lower limit is defined

by efficiency and higher by system pressure

rating

Operating sequence of cascade systems

Injection into cascade heat

exchanger

In Cascade Systems, it is essential that at least

one compressor in the high temperature side is

running before the first compressor in the low

temperature side can start. Otherwise, the compressor in the low temperature side may be cut

out due to high pressure.

The same sequence is also valid for filling up the

system. First of all, the high temperature circuit

needs to be filled with refrigerant and started up.

When this is done, the CO2 can be filled into the

low temperature system.

Injecting liquid into a plate heat exchanger is

not a trivial matter. The heat exchanger is often

compact and therefore the time constant is very

low. AKV valves are not recommended for this

application.

It is recommended to use motor valves or other

valves that give constant flow. Desuper-heating

of CO2 gas entering the cascade heat exchanger

can also be recommended for three reasons.

The high temperature expansion valve (ETS) to

the cascade heat exchanger should begin simultaneously with the high temperature compressors. After this, the valve controls the superheat

of the high temperature gas. LT compressors are

then started up by the CO2 pressure increase on

the suction line.

Danfoss pack controllers such as AK-PC 740 and

AK-PC 780 are specially designed with built in

control functions to coordinate these operations.

Distribution on the CO2 side is also a critical

issue. This is why the heat exchanger has to be

designed for direct expansion to make sure the

mixture of gas and liquid is evenly distributed to

the heat exchanger.

When the heat exchanger is designed for reasonable pressure drop at part load, the oil transport

and distribution should work under most conditions.

One reason is that the gas is often 60°C and

therefore the heat can be rejected to the ambient

or used for heat recovery without problems. The

second reason is to reduce thermal stress in the

heat exchanger. The third reason is that the CO2

gas gives very high heat fluxes which therefore

create unstable conditions on the evaporation

side. Therefore it is recommended to reduce the

superheat on the CO2 side.

Page 4

4 Application guide RA8AB102 © Danfoss 10/2010 Cascade HC/HFC - CO2 system

AKS 32 R

AKS 32R

GD/DGS

AKS 11

AKS 2050

AKS 11

AK-PC 740/780

GD/DGS

AKS 11

AKS 32R

AKD 102

AKS 11

DCR

Pump

SGN

AKS 2050

AKS 11

EKC 313

EVR

ETS

DCR

AKD 102

AKD 102

AK-CC 450

AKS 11

AKVH

AK-CC 550 A

AKS 11

AK-PC 740/780

Danfoss

R64-2050.11

AKS 32R

AK-SC 255/

AK-SM 350/

AK-SM 720/

AKA 245

AKS 32R

AKS 11

EVRH

Cascade HFC - CO2 system

Page 5

Cascade HC/HFC - CO2 system Application guide RA8AB102 © Danfoss 10/2010 5

Controls of Cascade system

Control of cascade systems can be divided into:

• Condenser capacity control

• Compressor capacity control

• Cascade injection control

• MT evaporator CO2 ow control

• LT evaporator injection control

Condenser capacity control

Compressor capacity

controls

Capacity control of the condenser can be accomplished via step regulation or speed control

of the fans.

As regulating sensor for the capacity distributor the condenser pressure should be selected.

The reference for the regulation can be defined

in two ways. Either as a xed reference or as a

reference that varies according to the outdoor

temperature. The reference for the condensing

pressure is set in °C (°F).

Pack controller AK-PC 740 (up to 4 compressors)

or AK-PC 780 (up to 8 compressors) controls the

LT suction pressure and is a standard controller

for controlling one suction group in any refrigeration system. The controller is capable of regulating variable speed of two compressors combined

with one-step compressors of the same or different sizes, depending on the choice of coupling

pattern.

Cap. reqquest

Cap.release

A unique feature in the AK-PC 740/780 make it

possible to use the Pc pressure in the LT CO2 side

as control sensor for the HT suction pressure. This

to ensure fast and stable control of the condensing pressure of LT CO2 side.

Low-pressure /

high-pressure coordination

Oil Management /

Oil equalisation

The AK-PC 740/780 is also able to coordinate the

LT and HT start to ensure a smooth operation.

Here the high-pressure compressors can start

either as a result of:

- Load on the high-pressure circuit

- Requirements from the low-pressure circuit

The high-pressure circuit will still ensure that the

low-pressure circuit is only permitted to start

when at least one high-pressure compressor has

started. It will also ensure that security timers and

compressor timers are complied with.

The build in oil management system covers most

systems found on the market to day. Can be used

with CO2 as well as all other conventional refrigerants and support input signals from :

• Level switch on compressor

• Level switch on oil separator

• Level switch on oil receiver

• Pressure transmitter on oil receiver

HT comp. release

output

LT comp. release.

input

Here both a relay output and an On/off input are used on both controllers.

HT comp. request

input

LT comp. request

output

Oil supply to the compressors is managed by

activating solenoid valves with user defined ON/

Off pulse sequences.

Page 6

6 Application guide RA8AB102 © Danfoss 10/2010 Cascade HC/HFC - CO2 system

Cascade injection control

In systems with cascade regulating and CO2

as refrigerant on the low temperature circuit

EKC 313 can regulate liquid injection (by means

of an ETS stepper expansion valve) into the cas-

cade heat exchanger in one of two ways:

• Optimize superheat

• Regulate the condensation pressure at the low

temperature circuit while ensuring that the

superheat does not become too low.

If there are no evaporators on the high temperature circuit the cascade controller should be set

in control mode 1 to optimise superheat. In this

application the condensation pressure on the low

temperature circuit should be controlled by the

compressor capacity controller in the high tem-

perature circuit. Here the LT PC signal is received

at the HT P0 input.

MT evaporator CO2 flow

control

LT evaporator injection

control

The air temperature in the medium temperature

display cases or rooms is controlled by opening/

closing a solenoid valve/motor valve in the CO2

supply to the evaporator. The actual temperature

control can take place in two ways: as ordinary

ON/OFF regulation with a differential, or as

modulating control (PWM) where the temperature variation will not be nearly as big as in ON/

OFF control.

In a system with several evaporators supplied by

the same CO2 liquid pump, modulating temperature control should be chosen as this also

provides a more constant flow of CO2 to the CO2

pump.

Injection control for the low temperature case

and cold room evaporators is an AK-CC 550A

utilizing pulse-width-modulating injection valves

AKVH and patented adaptive software algorithms

to optimise system performance and operation.

Period time, n63

Pressure control

The Danfoss CO2 controllers have more pressure

safety functions which prevents safety valves to

open and hereby loss of charge.

AK PC 740 pack controller

A max compressor discharge pressure safety

function will reduce compressor capacity

Page 7

Cascade HC/HFC - CO2 system Application guide RA8AB102 © Danfoss 10/2010 7

AK-PC 740

Flexible controller for capacity control of

compressors and condenser fans. Number of

I/O can be extended with AK-XM extension

modules.

• 4 compressors with up to 3 un-loaders

• 6 fans

• Max. 60 inputs/outputs

• Variable speed control on lead compressor and

condenser fans

• Build in oil Management functions

• Release-request function for coordination between

high-pressure and low-pressure compressors.

AK-PC 780

As AK-PC 740 plus:

AK-CC 450

Complete refrigeration appliance control with

great flexibility to adapt to all types of refrigeration appliances and cold storage rooms.

AK-CC 550A

As AK-CC 450 +

AK-CC 750

Flexible refrigeration appliance controller for

control of up to 4 evaporators.

• 8 compressors with up to 3 un-loaders

• 8 fans.

• Max. 100 inputs/outputs.

• For cooling with brine or pumped CO

• For use with a thermostatic expansion valve.

• Energy optimisation of the whole refrigeration

appliance

• One controller for several dierent refrigeration

appliances

• Natural, electric or hot gas defrost

• For cooling with Electronic expansion valve

• Adaptive control of superheat

• Adaptive defrosting based on evaporator perform-

ance

2

EKC 313

Controller for liquid injection in cascade heat

exchangers with CO2 as refrigerant on the low

temperature circuit.

ETS

ETS is a series of electrically operated (stepper

motor) expansion valve

• Stepper motor driver for ETS or CCM expansion

valve.

• 0 - 10 V output for ICMTS valves

• Electrically operated expansion valves for precise

liquid injection in evaporators

• Fully balanced, providing bi-ow feature as well as

solenoid tight shut-off function in both flow directions.

Page 8

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alternations can be made without subsequential changes being necessary in specifications already agreed.

All trademarks in this material are property of the respecitve companies. Danfoss and Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

8 Application guide RA8AB102 © Danfoss 10/2010 Cascade HC/HFC - CO2 system

FC-SPMC

Loading...

Loading...