Page 1

Contents

■

Cascade Controller Option

Safety

Safety regulations ................................................................................................... 4

Warning against unintended start ........................................................................... 4

Operation m odes

Cascade Control Operation ................................................................................... 6

Standa

Master/Slave Cascade Control Mode .................................................................... 8

Instal

Installing the cascade controller option card .......................................................... 9

Standard cascad e control wiring diagram .............................................................. 17

Option

Master drive in master/slave control wiring diagram .............................................. 19

Slave drive in master/slave control wiring diagram ................................................. 20

Changed Drive functions

Introduction ............................................................................................................ 21

Changed

Serial communications(parameter 500) .................................................................. 22

and precautions

............................................................................................ 6

rd Cascade Control Mode .......................................................................... 7

lation and Wiring Instructions

al Hand/Off/Auto Switch .............................................................................. 18

systemstop functions .............................................................................. 22

................................................................................ 3

..................................................... 9

............................................................................ 21

User Int

How to use the LCP for programming ................................................................... 23

Control keys for parameter setup .......................................................................... 23

Indicat

Drive Control .......................................................................................................... 23

Display modes ....................................................................................................... 24

Changin

Parameter setting procedure .................................................................................. 26

Example of how to change parameter data ........................................................... 26

Manual in

VLT D rive and Cascade Controller Setup

Introduc

Quick Menu Summary ........................................................................................... 29

Language ............................................................................................................... 29

Motor nam

Relay outputs ......................................................................................................... 32

Alternate programming ........................................................................................... 36

Standard Cascade Controller Setup

Introduction ............................................................................................................ 38

Initial S

Alternate programming ........................................................................................... 45

erface

or lamps ...................................................................................................... 23

g data ....................................................................................................... 25

itialization ................................................................................................ 26

tion ............................................................................................................ 28

eplate data ............................................................................................ 30

etup ............................................................................................................ 39

................................................................................................... 23

........................................... 28

..................................................... 38

Master/S

Introduction ............................................................................................................ 46

Initial Setup ............................................................................................................ 46

MG.60.I3.02 - VLT is a registered Danfoss trademark

lave Cascade Control Setup

................................................... 46

1

Page 2

Cascade Controller Option

Step 1: Master drive programming ........................................................................ 46

Step 2: Slave drive programming .......................................................................... 49

ate programming: .......................................................................................... 50

Altern

System Optimisation

System

Best efficiency frequency ....................................................................................... 52

Optimization of the process regulator .................................................................... 53

start up and final adjustments ................................................................... 52

Feedback Transmitter Wiring

Connecting feedback transmitters ......................................................................... 54

Single 0

Two 0 - 10 V feedback transmitter connections: ................................................... 54

Two 4 - 20 mA feedback transmitters connection: ................................................ 55

Two feed

Programming example ........................................................................................... 55

Paramet

Parameter group 700 d efinitions ............................................................................ 57

Service

Display information ................................................................................................. 58

Relay status ........................................................................................................... 59

- 10 V feedback transmitter connection: .................................................. 54

back signals and two setpoints: .............................................................. 55

er group 700, all parameters

parameters

.................................................................................... 52

................................................................... 54

................................................... 57

........................................................................................ 58

2

MG.60.I3.02 - VLT is a registered Danfoss trademark

Page 3

Safety and precautions

■

Cascade Controller Option

Cascade Controller Option

175ZA677.11

for

VLT 6000 HVAC

and

Safety and precautions

VLT 8000 AQUA

Operating Instructions

When reading through this Operating Instructions,

you will come across various symbols that

require special attention.

The symbols used are the following:

Indicates a general warning.

NB!:

Indicates something to be noted by the reader.

Indicates a high-voltage warning.

MG.60.I3.02 - VLT is a registered Danfoss trademark

3

Page 4

Cascade Controller Option

The voltage of the frequency converter

is dangerous whenever the equipment is

connec

of the motor or the frequency converter may cause

damage to the equipment, serious personal injury

th. Consequently, the instructions in this

or dea

manual, as well as national and local rules and

safety regulations, must be complied with.

NB!:

UsingtheVLTDialogSoftwareorthe

FC protocol for serial communication can

cause unintended behaviour of motors

and plant and must be avoided.

Safety regulations

■

1. The VLT frequency converter must be

on-nected from mains if repair work is to be

disc

carried out.Check that the mains supply has been

disconnected and that the necessary time has

sed before removing motor and mains plugs.

pas

2. The [OFF/STOP] key on the control panel of the

VLT frequency converter does n

equipment from mains and is thus n

the

to be used as a safety switch.

ted to mains. Incorrect instal-lation

ot disconnect

ot

necessary time has passed before removing

motor and mains plugs.

7. Reliab

8. Please note that the VLT frequency converter

Warning against unintended start

■

1. The motor can be brought to a stop by

2. While parameters are being changed, the

le galvanic isolation (PELV) is not complied

with if the RFI switch is placed in OFF position.

This means that all control in- and outputs

ly be considered low-voltage terminals

can on

with basic galvanic isolation.

has mo

the DC-bus terminals are used. Check that

all voltage inputs have been disconnected and

that t

repair w o rk is commenced.

means of digital commands, bus commands,

references or a local stop, while the frequency

converter is connected to mains.

If personal safety considerations make it necessary

to ensure that no unintended start occurs, t

stop functions are not sufficient.

motor may start. Consequently,

[OFF/ STOP] must always be activated, after

which data can be modified.

re voltage inputs than L1, L2, L3 when

he necessary time has passed before

the stop key

hese

NB!:

The IMMEDIATE STOP function will release all

slave relays a

switch. The SEQUENCED STOP will stage off

the slave relays a

3. Correct protective earthing of the equipment

st be established, the user must be protected

mu

against supply voltage, and the motor must be

protected against overload in accordance with

plicable national and local regulations.

ap

4. The earth leakage currents are higher than 3.5 mA.

5. Protection against motor overload is included

the factory setting. Parameter 117, Motor

in

thermal protection, default value is ETR trip

1. For the North American market: The ETR

unctions ensure overload protection of the motor,

f

Class 20, in accordance with NEC.

NB!:

Motor Thermal Protection is initialised at 1.0 x

rated motor current and rated motor frequency

(see parameter 117, Motor thermal protection).

nd can not be used as a safety

nd can not be used as a safety switch

6. Do n

4

ot remove the plugs for the motor and

mains supply while the VLT frequency converter

is connected to mains. Check that the mains

supply has been disconnected and that the

MG.60.I3.02 - VLT is a registered Danfoss trademark

Page 5

Cascade Controller Option

Warning:

Touching the electrical parts may be fatal - even after the equipment has

been disconnected from mains.

200-240 and 380-480 V: wait at least 15 minutes

550-600 V: VL T 6002/8002 - 6027/8027: wait at least 15 minutes

550-600 V: VL T 6032/8032 - 6300/8300: wait at least 30 minutes

175ZA678.11

Safety and precautions

MG.60.I3.02 - VLT is a registered Danfoss trademark

5

Page 6

Operation modes

■

Cascade Control Operation

■

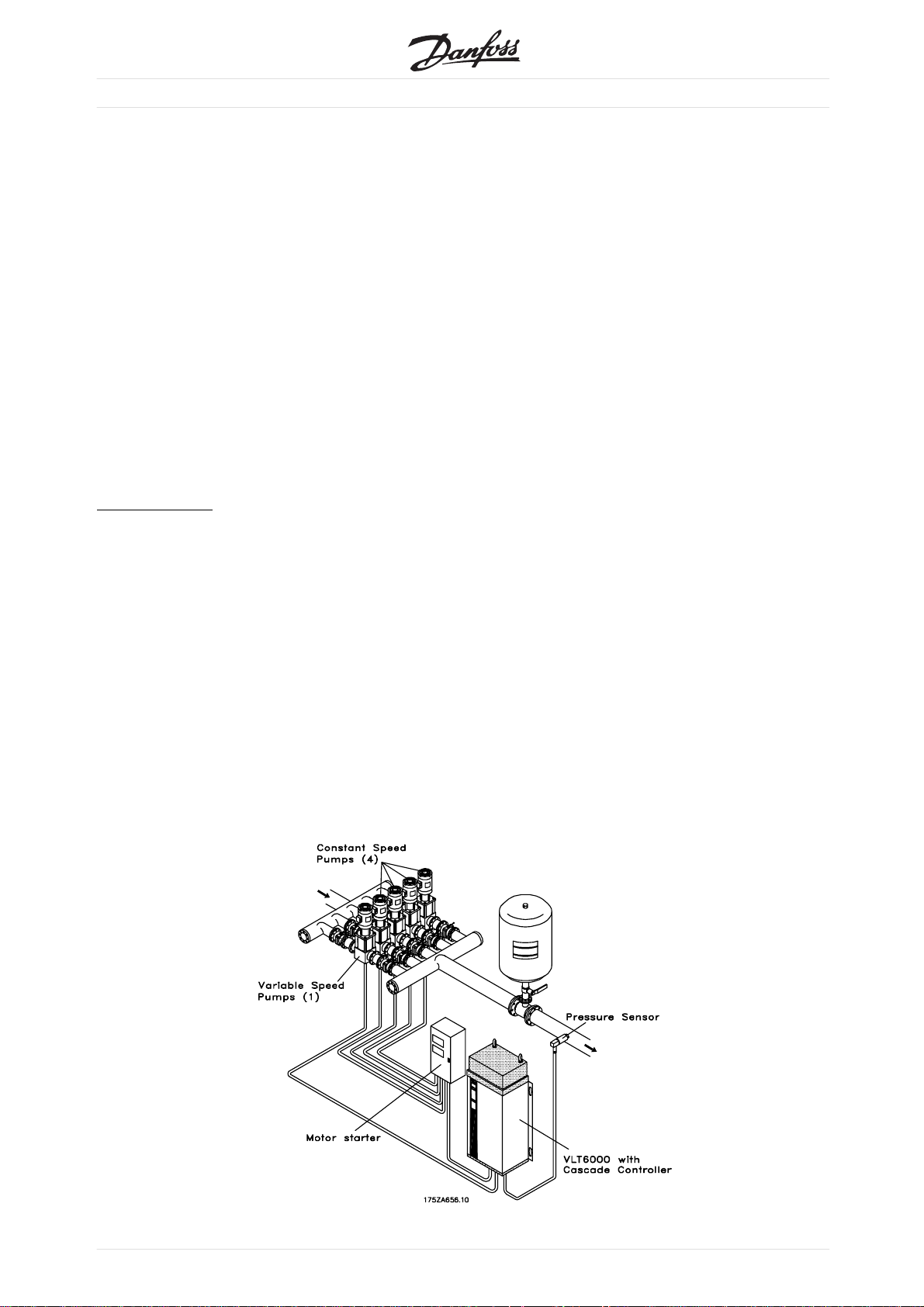

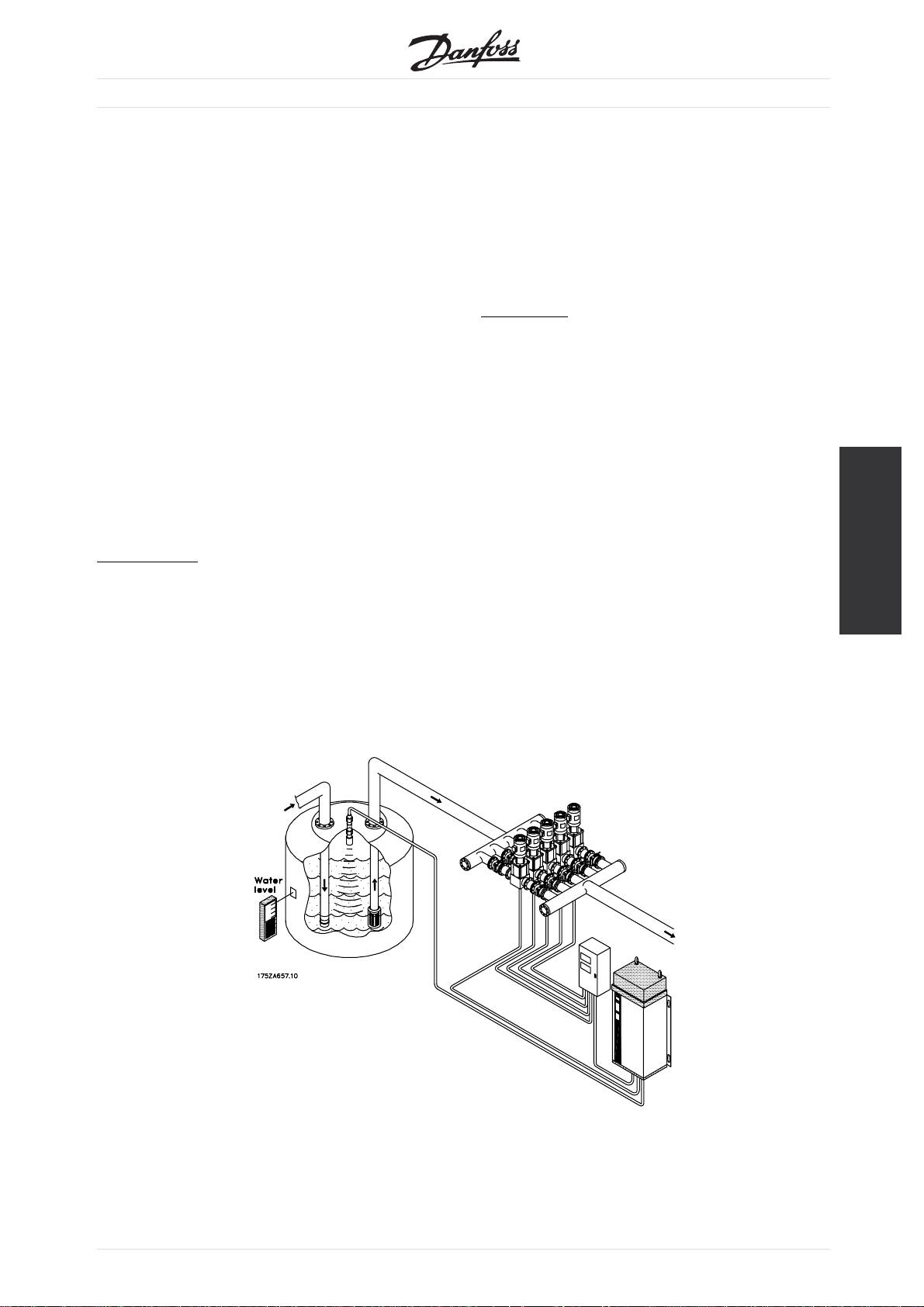

With the cascade controller option card, the frequency

converter can automatically control up to five

motors. Staging motors on or off is done cyclically,

in accordance with operating hours. This function

assures equal use over time and eliminates concern

about starting a seldom used motor. The cascade

controller includes four Form C relays having contacts

rated 250 V, 2 A (non-inductive) that are used to

control the motor con tactors. The controller option

card installs in the frequency converter control card

cassette and can be ordered factory installed. The

cascade controller is effective in applications where

multiple motors are used to control a common flow,

level or pressure involving pumps, fans, and blowers.

eedback Signals

F

An important advantage to the cascade controller

option is that it is based upon the VLTs advanced

PID controller. This means that programming is

done in selected units of measurement appropriate

to the application and that the feedback and

setpoints can be displayed. Unlike drives that base

staging upon frequency, feedback allows precise

control in response to actual system demand. The

VLTs PID controller accommodates two feedback

signals and two setpoints which allows regulating

a system with different setpoint zones.

Cascade Controller Option

In pumping applications, when a pressure feedback

signal is not practical, the feedback signal may be

taken near the pump by measuring flow. When the

flow rate is low, the pressure needed is low. At

increased flow, the pumps need to provide greater

pressure to compensate for the increased pressure

drop in the piping. The setpoint should be adjusted

to match the flow in these cases. While difficult

to accomplish with standard PID controllers, the

cascade controller provides an easy solution. By

programming one setpoint for minimum flow and

the other for maximum flow, the VLT calculates

intermediate setpoints based on the flow required.

Cascade control operation depends on the general

system design. Two operational modes are available:

1. Standard Cascade Control, with one speed

controlled pump/fan and up to four fixed

speed pumps/fans. Programming for this

mode is described in Chapter 6, Standard

Cascade Control Mode Setup.

2. Master / Slave Cascade Control has all

pumps/fans speed controlled through the Master

drive. Programming is described in Chapter 7,

Master/Slave Cascade Control Mode Setup.

Standard Cascade Control Mode

6

MG.60.I3.02 - VLT is a registered Danfoss trademark

Page 7

Standard Cascade Control Mode

■

In standard cascade control, a frequency converter

e Cascade Controller option card installed

with th

controls a variable speed motor and is used to

stage additional constant speed motors on and

y varying the speed of the initial motor,

off. B

variable speed control is provided for the system.

This maintains constant pressure while eliminating

ure surges, resulting in reduced system

press

stress and quieter operation.

The motors can be of equal or differing sizes. The

controller offers a selection of eight pre-defined pump

combinations. Selections allow mixing pumps of

100%, 200% and 300% capacity. This provides a

dynamic capacity range of 9 to 1. The VLT drives

internal PID controller directs the cascade option

card based upon the feedback signal. The cascade

controller will continue operation of the constant speed

motors to meet demand should the drive trip.

Cascade Controller Option

When the master drive is the only one running, the

drives sleep mode can discontinue system operation

when not needed while staying ready to start on

demand. Variable speed control with fixed speed

motors optimizes energy consumption and avoids

damaging a pump running at near no flow condition

L

evel Control

With level control, multiple pumps can be used to

keep a constant level in applications such as a buffer

tank. Typically, a water level sensor provides a

feedback signal for the VLT’s built-in PID controller.

Precise level control is maintained in response to

the system setpoint. With a cascade controller,

additional fixed speed pumps will be staged on or

off, as required, to maintain level control.

stage Timer

D

eA de-stage timer takes effect in standard control

when the drive runs continuously at minimum speed

h one or more constant speed motors running.

wit

Since a variable speed pump at minimum speed

adds no or very limited flow to the system, it is

visable to stop a constant speed motor and

ad

allow the drive to provide the required flow. The

de-stage timer is programmable to avoid frequent

taging of the constant speed motors.

s

Operation modes

Level Control in Standard Cascade Control Mode

MG.60.I3.02 - VLT is a registered Danfoss trademark

7

Page 8

Master/Slave Cascade Control Mode

■

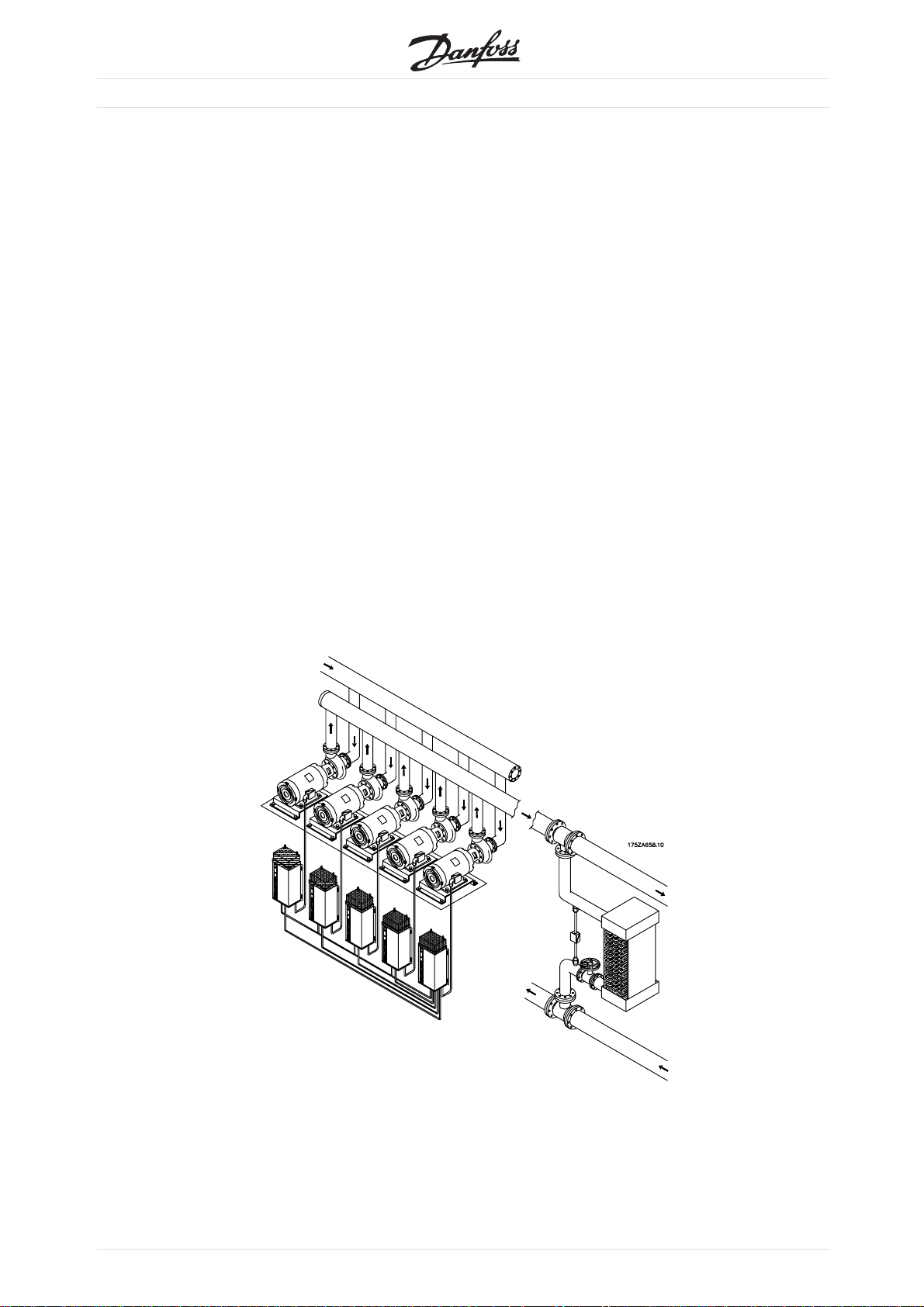

Master/slave systems control multiple pumps in

el at the same output frequency. Pumps are

parall

staged on and off as required to meet the systems

demand. The master/slave control mode of operation

des maximum system efficiency.

provi

In master/salve control, each motor has its own

adjustable frequency drive which responds to control

from a master drive which contains the cascade

option card. The master drive sends a pulse speed

reference signal to the drives under control to ensure

that all operate at the same speed. The motors

must be of equal size. In some applications, it may

be advisable for a second drive with a cascade

card to act as an auxiliary controller.

Sequential staging of drives on or off is provided by

master drive in response to system feedback,

the

maintaining precise setpoint control. Pressure surge

and water hammer are eliminated. Because all

he operating pumps run at the same speed,

of t

the possibility of running a pump continuously into

a closed check valve is all but eliminated. This

duces pump maintenance by minimizing the

re

wear on pump seals and bearings.

Cascade Controller Option

Danfoss has available the Multiple Unit Staging

Efficiency Calculator (MUSEC), a free software program

available on the Danfoss website. By entering pump

and system data, MUSEC provides the programmer

with master drive on and off staging frequencies

at optimal efficiency for each pump: for example,

three motors providing flow at reduced speed rather

than two at full speed. This often results in 10% to

15% additional savings over similar control systems.

For a free download, go to www.danfoss.com

and enter MUSEC in the search box.

Best efficiency is attained when a pressure transmitter

is placed at the farthest significant load in the system.

If this is not practical and the pressure transmitter

is placed close to the discharge of the pumps, or

when pump data and system characteristics are

not accessible, alternative ways of programming

the cascade controller are provided.

Master/Slave Cascade Control Mode

8

MG.60.I3.02 - VLT is a registered Danfoss trademark

Page 9

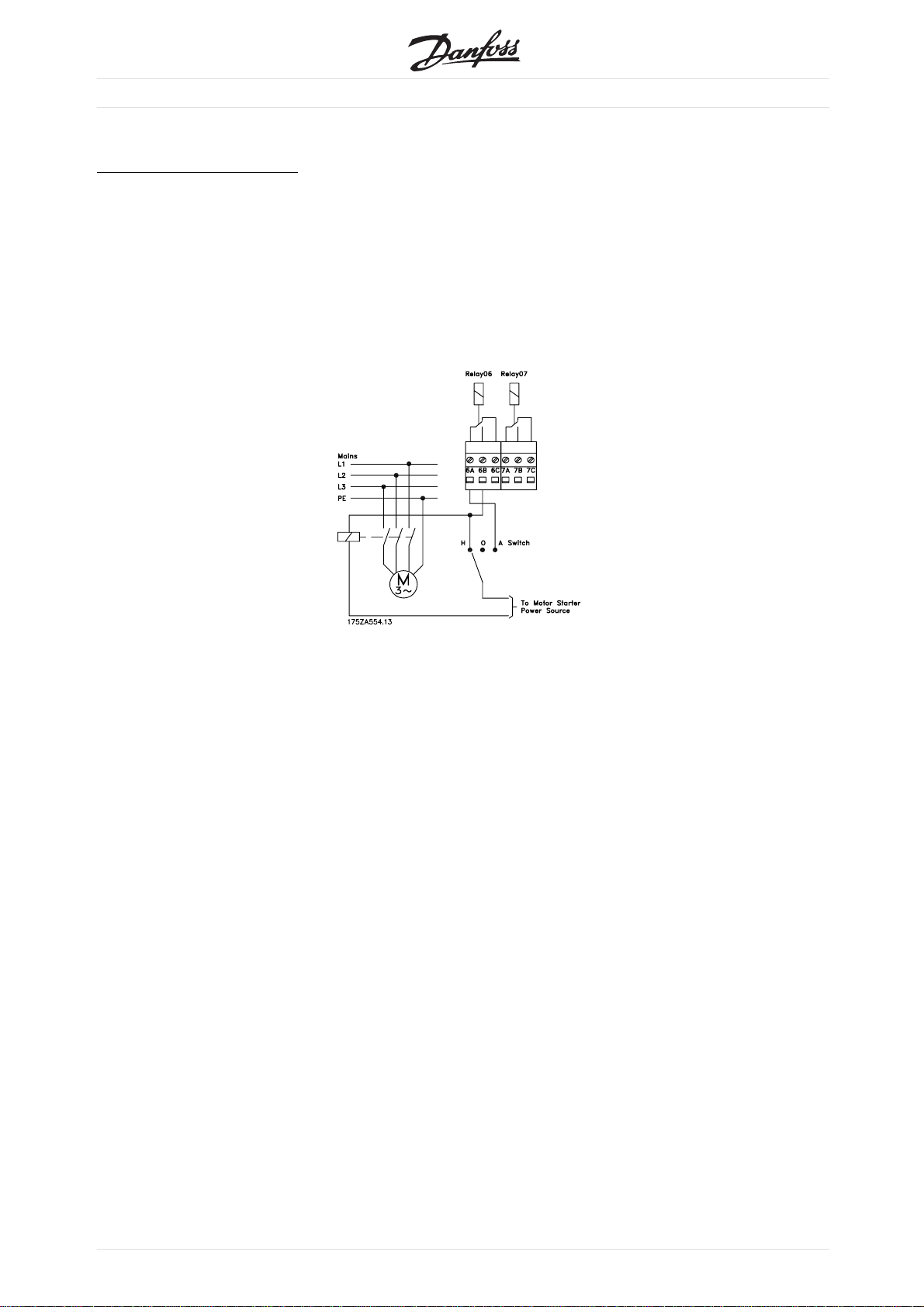

Installation and Wiring Instructions

■

Installing the cascade controller option card

■

This chapter provides instructions for installing the

cascade controller option card into a VLT adjustable

frequency drive. In Standard cascade control mode,

the option card installs into the VLT controlling up to

four additional motors. In Master/Slave mode, the

option card installs in the Master drive controlling

up to four additional slave drives.

Cascade Controller Option

DANGER

VLT adjustable frequency drive

contains dangerous voltages when

connected to line voltage. After

disconnecting from line, wait at least 14 minutes

before touching any electrical components.

Relay o utput connections vary according to the mode

of operation and configuration of the system. Typical

wiring diagrams are also provided in this chapter.

Adhere to all safety guidelines provided in

the VLT Operating Instructions. See the

VLT Operating Instructions for details and for

instructions on drive operation.

orque tightening requirements

T

Tighten all fittings described in this chapter to 7.1

in-lbs (0.8 Nm), unless specified otherwise.

O

ptional transmitter connections

VLT drive terminals12 and 13 provide a 24 VDC,

200 mA power supply. This supply can be used

to power remote transmitters without need for an

external power supply. See wiring instructions in

Chapter 10, Feedback Transmitter Wiring.

WARNING

Only a competent electrician should

carry out electrical installation.

Improper installation of motor or VLT

can cause equipment failure, serious injury

or death. Follow this manual and National

Electrical Code and local safety codes.

CAUTION

Electronic components of VLT

adjustable frequency drive are

sensitive to electrostatic discharge

(ESD). ESD can reduce performance or destroy

sensitive electronic components. Follow

proper ESD procedures during installation

or servicing to prevent damage.

Installation and

Wiring Instructions

MG.60.I3.02 - VLT is a registered Danfoss trademark

9

Page 10

Cascade Controller Option

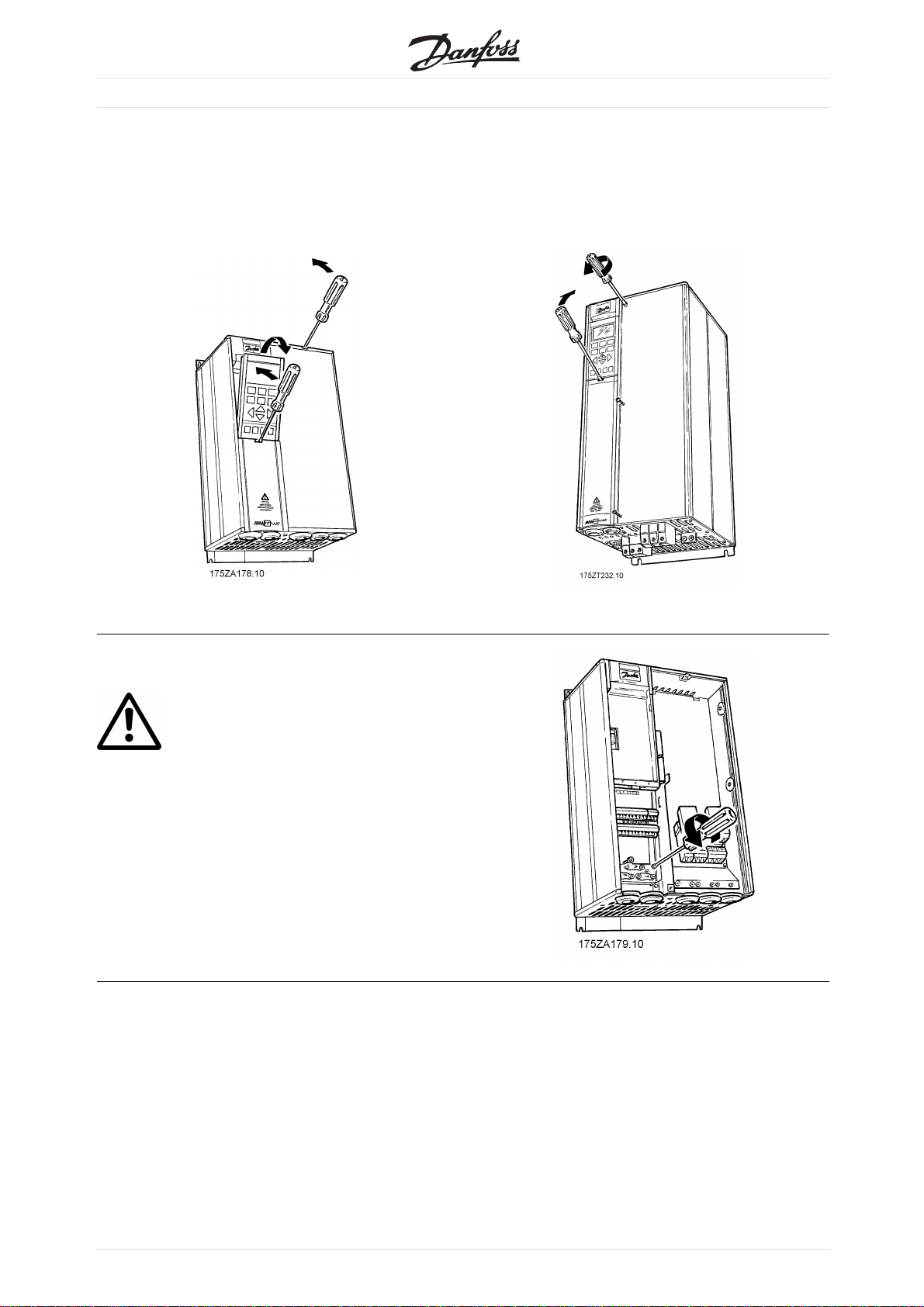

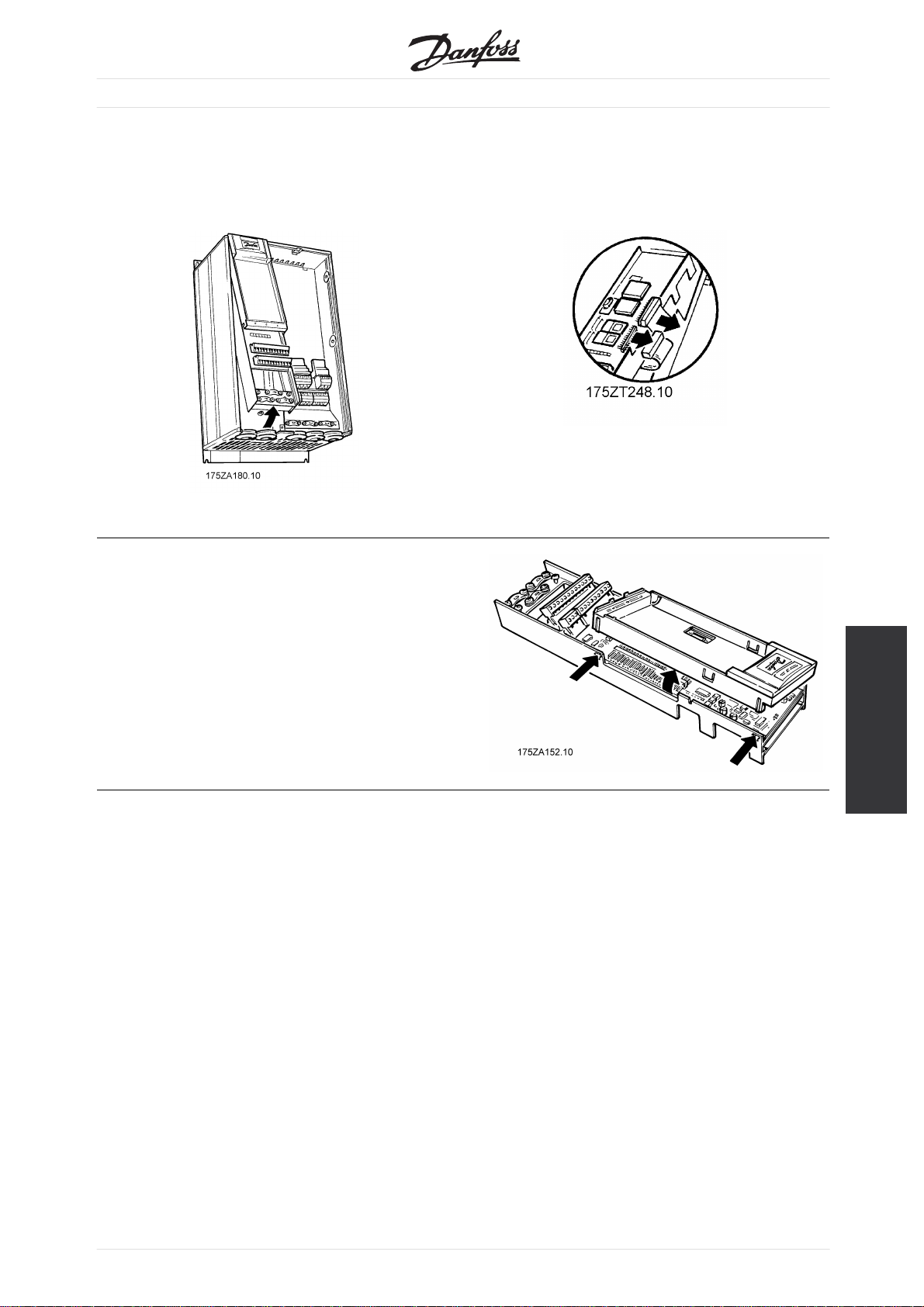

1. Access to Control Card Cassette

■

•

Remove Local Control Panel (LCP) keypad by

g out from top by hand. LCP connector

pullin

on panel back will disconnect.

•

Remove terminal protective cover by gently

prying with screw driver at top notch and lift

cover o

•

Open access cover to internal VLT components.

(Drive configurations vary.)

ut of guide pin fittings.

2. Disconnect VLT Drive Control Wiring

■

Touching electrical parts may be fatal

– even after equipment has been

disconnected from AC line. To be sure

that capacitors have fully discharged, wait 14

minutes after power has been removed before

touching any internal component.

•

Remove control wiring by unplugging

connector terminals.

•

Remove wiring clamp by removing two

screws. Save for reassembly.

•

Loosen two captive screws securing control

board cassette to VLT chassis.

10

MG.60.I3.02 - VLT is a registered Danfoss trademark

Page 11

Cascade Controller Option

3. Remove VLT Cassette and Ribbon Cables

■

•

Lift control board cassette from bottom.

•

4. Remove LCP Keypad Cradle

■

•

•

nect two ribbon cables from VLT

Discon

control board.

Push tabs at side of LCP cradle to release clips.

Pull out to disengage and lift cradle free.

•

Unhinge cassette at top to remove.

Installation and

Wiring Instructions

MG.60.I3.02 - VLT is a registered Danfoss trademark

11

Page 12

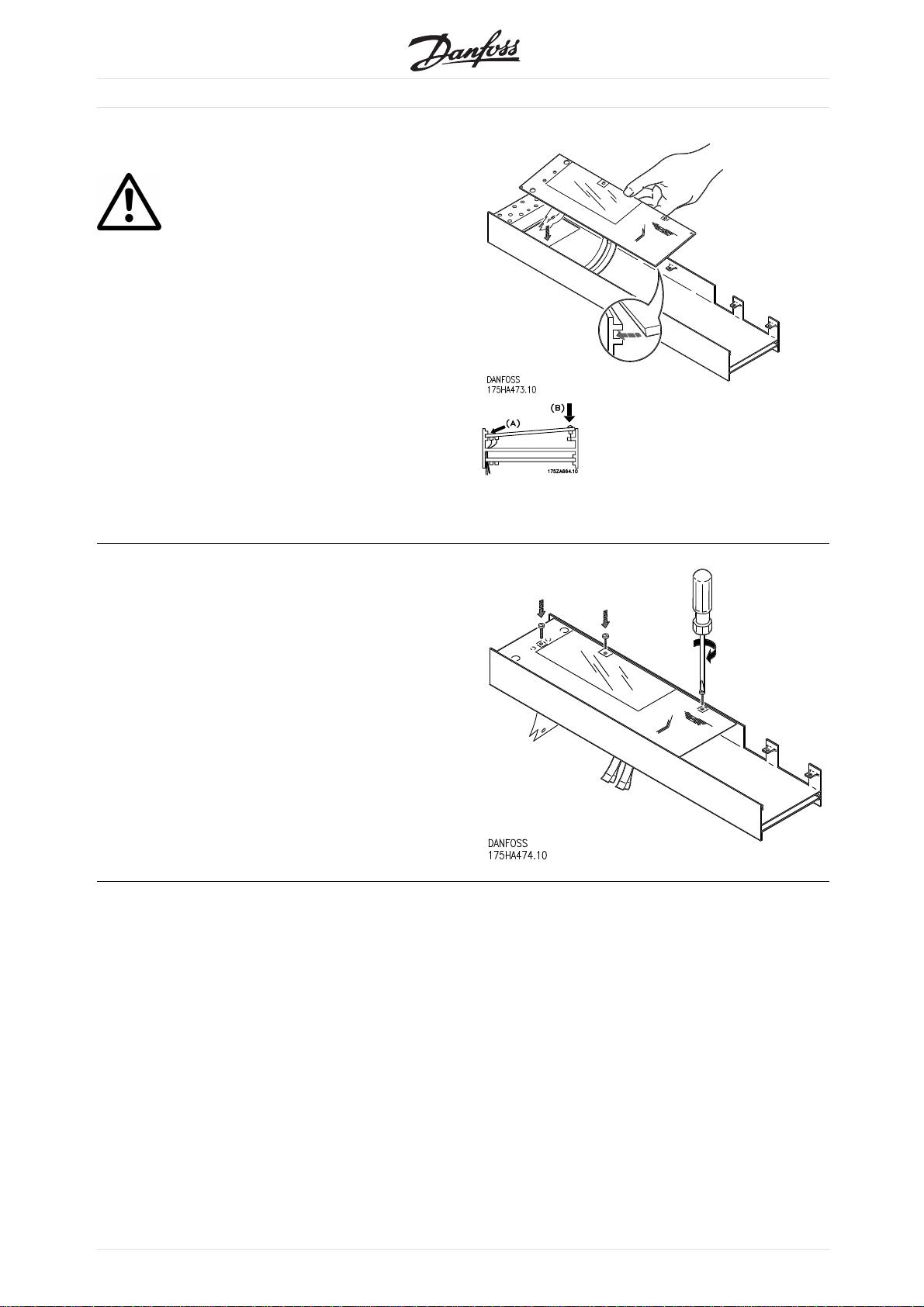

5. Cascade OptionCard Ribbon Cable Routing

■

Electronic components of VLT and

cascade controller option card are

sensitive to electrostatic discharge

(ESD). Follow proper ESD procedures to

prevent component damage. ESD procedures

to prevent component damage.

Cascade Controller Option

•

•

•

•

6. Secure Option Card

■

•

ribbon cables from cascade controller

Route

option card through slot at side of VLT

control board cassette. Option card mounts

component side down.

with

Feed plastic option card insulation pad through

terminal opening in control board cassette.

rt edge of option card into slot (A)

Inse

in side of cassette.

Align opposite side of card with mounting

s (B) provided.

hole

Secure option card to control board cassette

with 3 self-tapping screws and washers provided.

Use a Torx T-10 screw driver.

12

MG.60.I3.02 - VLT is a registered Danfoss trademark

Page 13

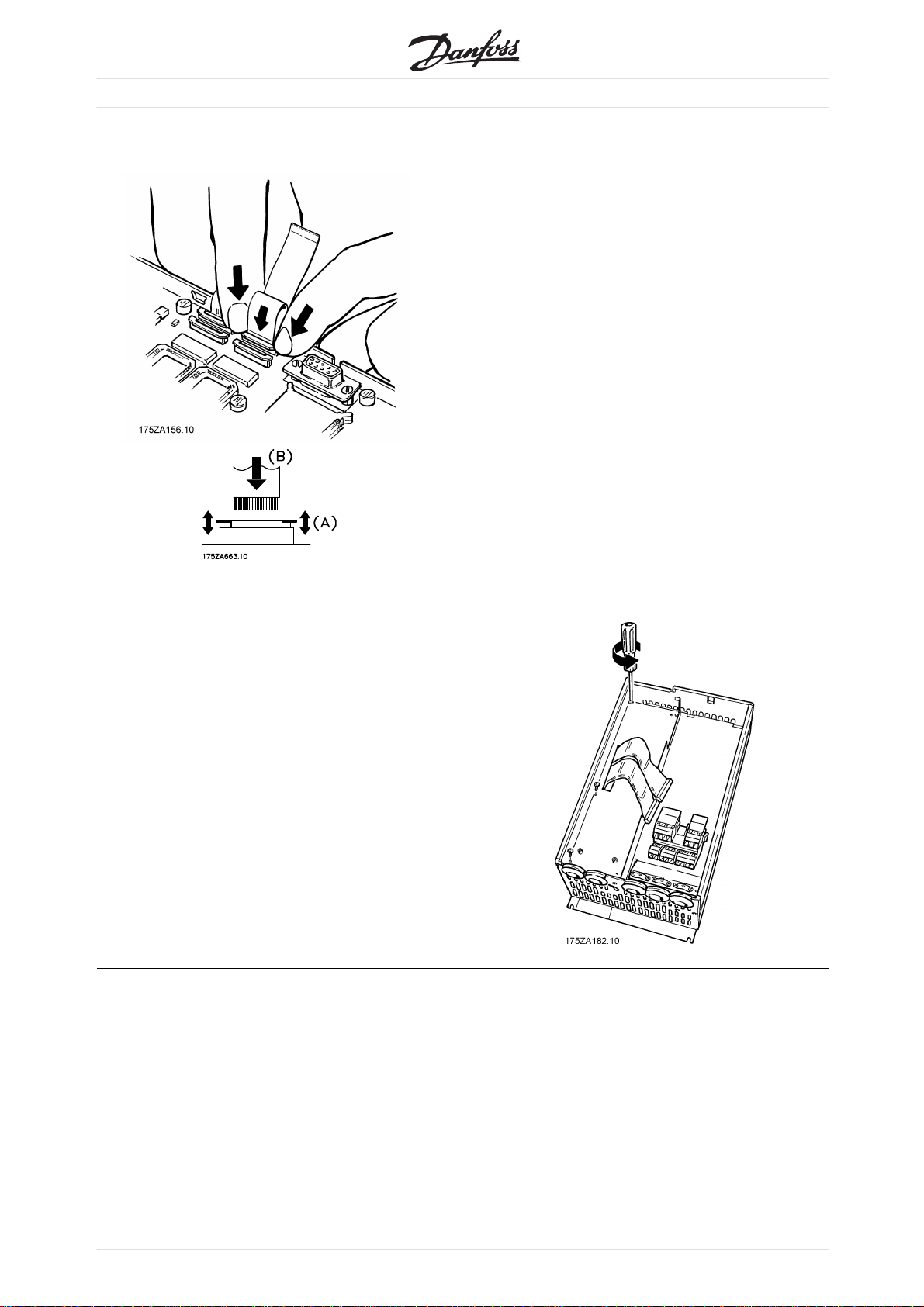

7. Connect Option Card Ribbon Cable to

■

VLT Control Board

•

Pull up

cable socket.

•

DO NOT remove blue insulation on end of

option

into corresponding socket (B) on VLT control

board and push collar closed. Be sure not

to cri

•

Repeat procedure for all ribbon cables.

collar (A) of control board ribbon

card ribbon cable. Insert ribbon cable

mp ribbon cables.

Cascade Controller Option

Installation and

Wiring Instructions

MG.60.I3.02 - VLT is a registered Danfoss trademark

13

Page 14

Cascade Controller Option

8. Chassis Ground Connection

■

•

Location of holes to mount grounding strips in VLT

chassis can vary with drive configuration.

•

When applicable, remove mounting screws

located in chassis using Torx T-20 screw driver

and save for reassembly. Otherwise, grounding

strips attach with screws provided.

14

MG.60.I3.02 - VLT is a registered Danfoss trademark

Page 15

9. Install Chassis Ground Connections

■

•

Align ground strips over corresponding screw

(Strip with fewest contact points mounts

holes.

on right side of chassis.)

•

Replace screws removed and add additional

screws

Torx T-20 screw driver.

10. Replace VLT Control Board Cassette

■

•

Attach LCP keypad craddle to VLT control

board cassette removed in step 4. Ensure not

to crimp option card ribbon cables.

•

Connect two ribbon cables to control board in

corresonding connectors as removed in step 3.

•

Hinge VLT cassette at top of VLT chassis and

reposition into place. Use Torx T-20 screwdriver

to fasten two captive screws. Ensure not to

crimp control board ribbon cables.

provided, as necessary. Use a

Cascade Controller Option

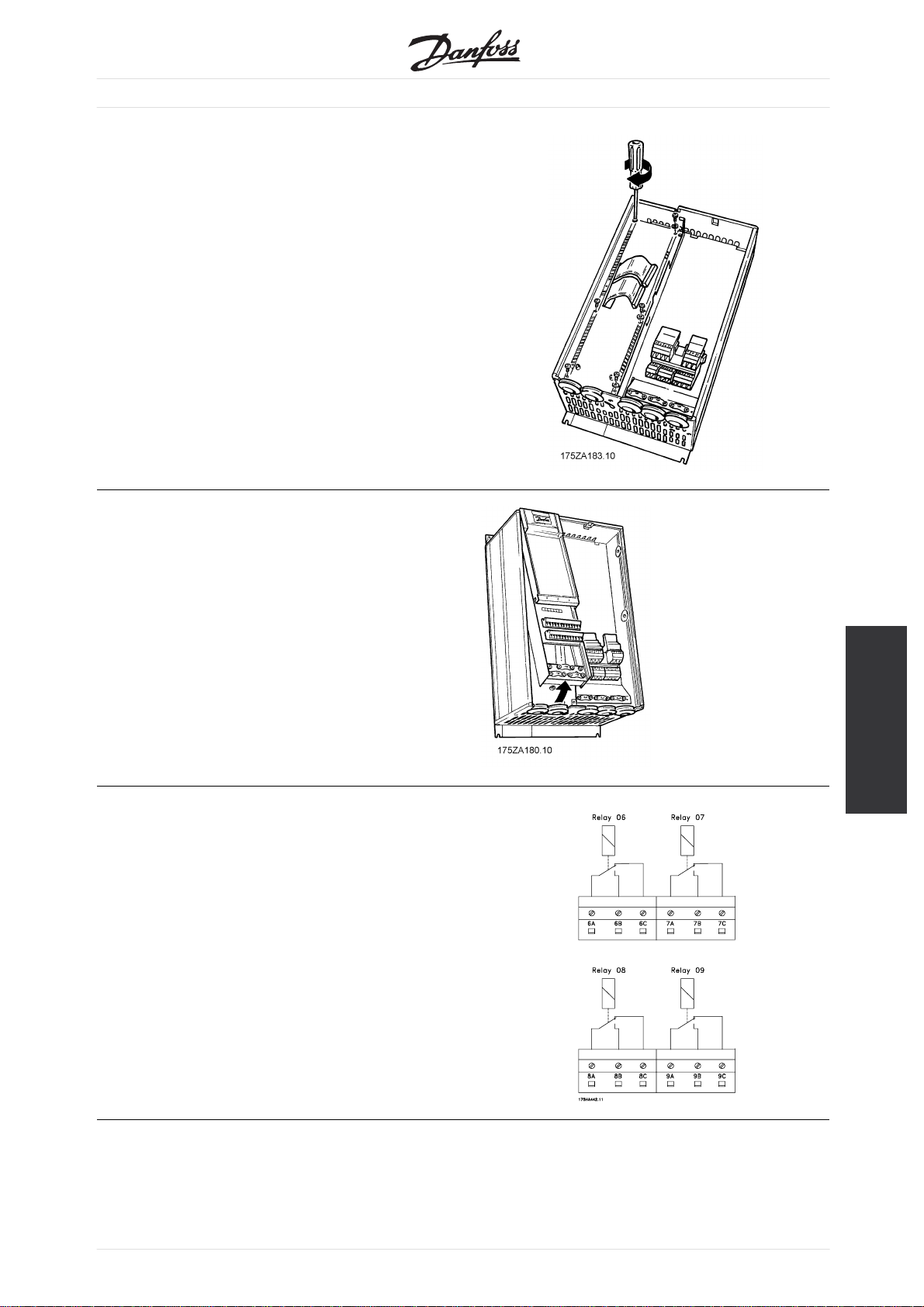

11. Relay Output Connection

■

•

Connect relay output cables to terminal blocks

provided as required by application. (See

wiring diagrams in this chapter.)

•

Insert relay terminal blocks firmly into corresponding

terminal sockets on control board.

•

Secure relay wiring with bottom right wiring

clamp and fasten.

Relay 6-9: A-B make, A-C break

Max. 240 VAC, 2 A

Max. cross-section: 1.5 mm

Torque: 0.22 - 0.25 Nm

2

(28-16 AWG)

Installation and

Wiring Instructions

MG.60.I3.02 - VLT is a registered Danfoss trademark

15

Page 16

12. Remove Wiring Clamp Mounting Fixture

■

•

Option card insulation pad is designed to use top

most ca

•

Use screw driver to remove top most wiring clamp.

13. Reconnect VLT Control Terminals and

■

Secure Option Card InsulationPad

•

Reconnect VLT control terminals removed in step

2bypressingfirmlyintocorresponding

terminal socket.

•

Crease option card insulation pad flap and insert

into slot in side of control card cassette.

•

Attach insulation pad to top most clamp position

with one screw from removed wiring clamp.

•

Route VLT control terminal wiring through

bottom left wiring clamp and fasten.

ble wiring clamp screw hole for attaching.

Cascade Controller Option

14. Final Reassembly

■

•

Secure access cover to internal VLT components.

•

Replace LCP keypad by positioning guide slots

at bottom of cradle and snaping into place.

•

Attach terminal protective cover by positioning

guide pins at bottom of cover into control card

cassette and snaping into place.

Transmitter wiring

■

Please refer to chapter 10, Feedback

Transmitter Wiring.

16

MG.60.I3.02 - VLT is a registered Danfoss trademark

Page 17

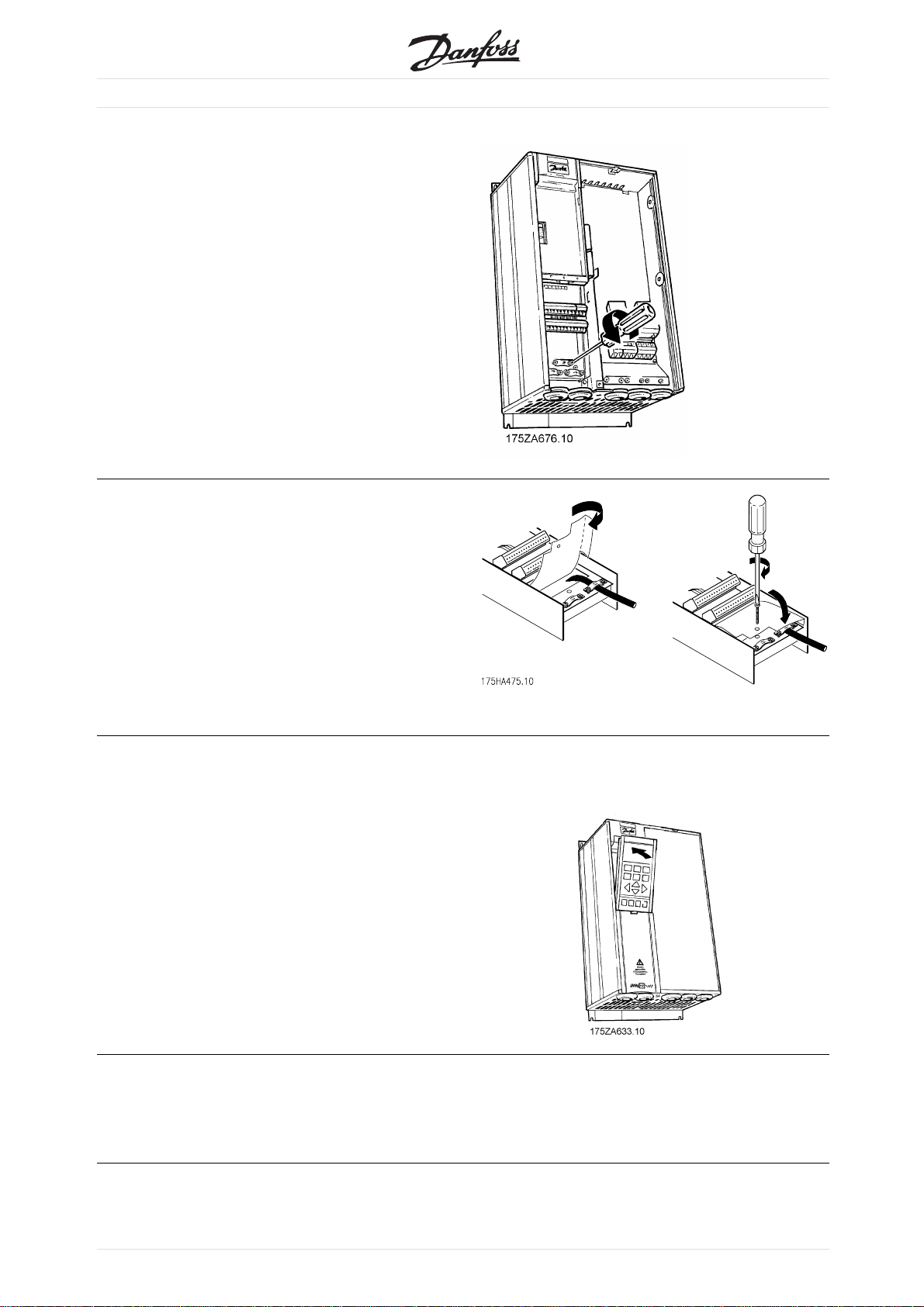

Standard cascade control wiring diagram

■

The wiring diagram shows an example for a

rd cascade control system with 4 fixed

standa

speed motors, a 4-20 mA pressure transmitter,

and external safety interlock.

Cascade Controller Option

Power terminal connections Control board terminal

connections

Option card terminal connections

Installation and

Wiring Instructions

MG.60.I3.02 - VLT is a registered Danfoss trademark

17

Page 18

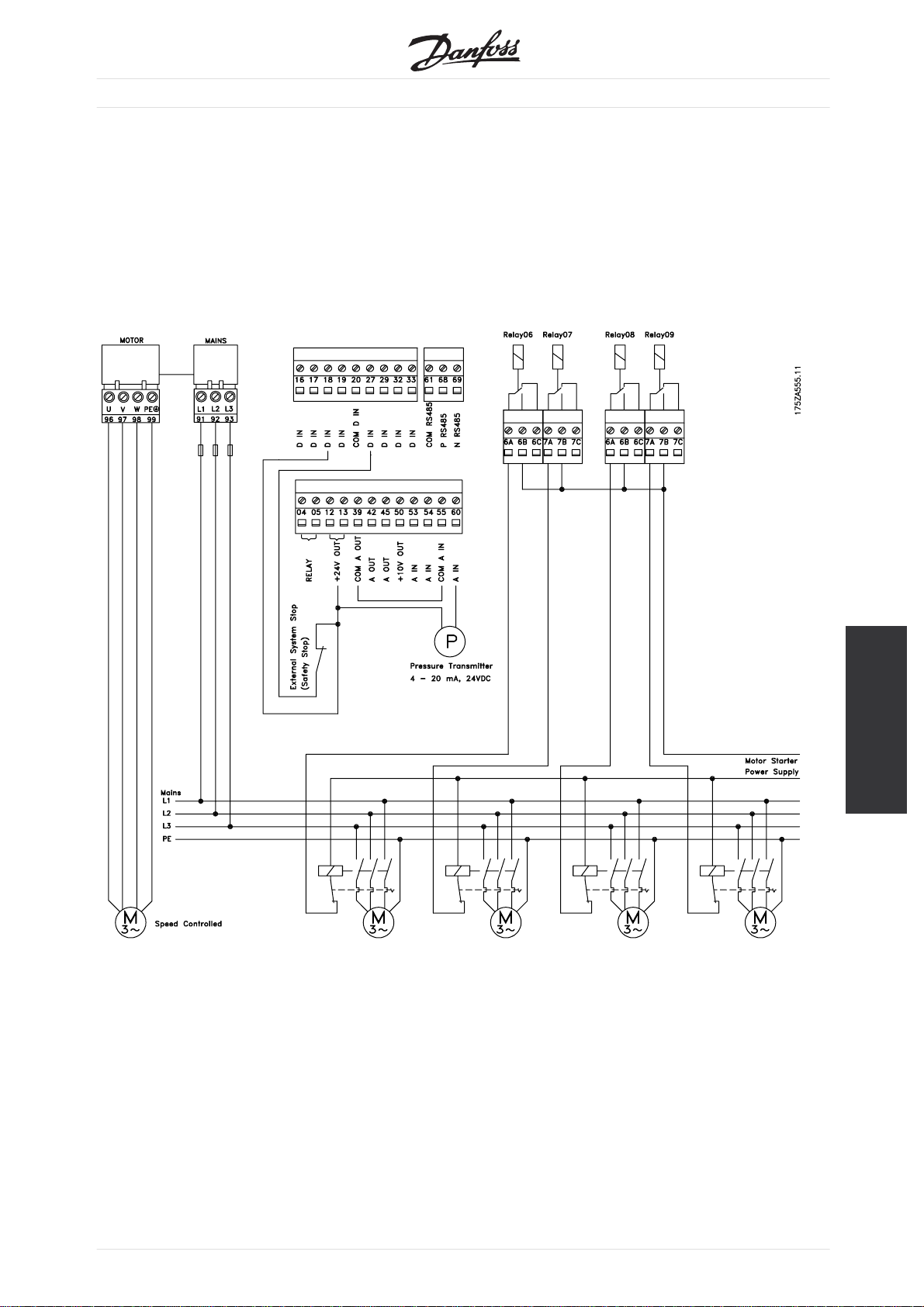

Optional Hand/Off/Auto Switch

■

ptional Hand/Off/Auto Switch

O

dard cascade control mode, an optional

In stan

Hand/Off/Auto switch on the constant speed motor

starter is common. During normal operation, the

switch

automatic start and stop commands to the motor.

The HAND position allows manual operation of the

motor

switch to OFF. For a motor in the OFF position, the

is set to AUTO and the drive will signal

. The motor can be disabled by setting the

Cascade Controller Option

cascade controller will try to start it by triggering

its relay. Since no contribution will occur, the next

pump will be switched on. The relay timer will,

however, assume operation for a disabled motor.

See Chapter 12, Service Parameters.

The diagram below provides wiring instructions

for an optional Hand/Off/Auto switch.

18

MG.60.I3.02 - VLT is a registered Danfoss trademark

Page 19

Cascade Controller Option

Master drive inmaster/slave control wiring diagram

■

The wiring diagram below shows an example of a

Master

system demonstrates a 4-20 mA pressure transmitter,

drive in Master/Slave cascade control. The

Power terminal connections Control board terminal

connections

an external safety interlock and four slave drives. The

slave drive speed reference is provided from terminal

17 as a p

used for the Start/Stop command to the slave drives.

ulse signal. The relays on the option card are

Option card terminal connections

Master Drive

Installation and

Wiring Instructions

MG.60.I3.02 - VLT is a registered Danfoss trademark

19

Page 20

Cascade Controller Option

Slave drive in master/slave control wiring diagram

■

Each slave drive is wired in the same way, receiving

the Sta

from the master drive. The speed reference and its

common are typically looped from Slave-to-Slave.

Power terminal connections Control board terminal connections

rt/Stop command and a pulse speed reference

20

Slave Drive

MG.60.I3.02 - VLT is a registered Danfoss trademark

Page 21

Cascade Controller Option

Changed Drive functions

■

Introduction

■

Installation of the Cascade Controller Option card

into the VLT adjustable frequency drive overrides

some existing drive functions. Changes to the default

parameter setting are shown in the tables below.

Data entered into the drive parameters are used

to program the drive and cascade controller for

system operation. The modified parameter default

settings make programming the cascade controller

easier. See Chapter 5, User Interface, for instructions

on programming drive parameters.

Changed Default Settings with the Cascade Controller Option Card

Parameter Description Previous default New default

100 Configuration Open loop Closed loop

201 Minimum output freq. 0.0 Hz 40% of nominal frequency

205 Maximum reference 60 Hz 100%

206 Ramp-up time Varies with unit See table below

207 Ramp-down time Varies with unit See table below

304 Terminal 27 (digital input) Safety interlock Coasting stop, inverse

308 Terminal 53 (analog in V) Reference No operation

314 Terminal 60 (analog in A) Reference Feedback (4 20 mA)

318 Function after time out No function Stop (sequence stop)

417 Feedback Function Maximum Virtual Control Curve

427 PID lowpass filter time 0.01 sec. 0.20 sec.

In addition, parameters that need to be programmed

for cascade control operation are assembled

sequentially in a new and expanded 39 item Quick

Menu. Programming is simplified by following the

Quick Menu items in sequence for either Standard

cascade control or Master/Slave cascade control.

The new Quick Menu is described in Chapter 6, VLT

Drive and Cascade Controller Card Setup.

New options are also available to stop pumps or fans

controlled in cascade operation. A summary of VLT

changed functionality is presented in this chapter.

(24 Hz)

VLT Type Ramp Up (parameter

206)

Ramp Down(parameter

207)

8005/6002 8011/6011 1 sec. 1sec.

8016/6016 8062/6062 3 sec. 2sec.

8072/6072 8300/6275 5 sec. 3sec.

8350/6350 8600/6550 8 sec. 5sec.

Changed Drive functions

MG.60.I3.02 - VLT is a registered Danfoss trademark

21

Page 22

Changed systemstop functions

■

Two stop functions are provided by the cascade

ller option. One function quickly stops a

contro

system. The other stages off pumps in a sequence,

allowing for a controlled pressure stop.

Do not use these functions as emergency

stops. Some functions do not turn

off all pumps.

Standard cascade control mode

Stop functions in Standard cascade control are

described in the table below. In a sequenced

stop, there is a one ramp-down time delay

between each staging off of motors.

Standard Cascade Control

Function Description

OFF/STOP key Provides a sequenced stop

for all constant speed motors

in opposite order as staged

on. Controller decelerates its

motortoastop.

STOP via

Terminals 16 and

17 (parameters

300 and 301)

Controller decelerates its

motortoastop.Withmotor

stopped, controller provides

sequenced stop for constant

speed motors.

STOP via

Terminal 18

(parameter 302)

Constant speed motors

continue to operate normally

with feedback signal from

drive. Controller decelerates

its motor to a stop.

STOP via

Terminal 27

Coast Inverse

Constant speed motors stop

immediately. Controller coasts

its motor to a stop.

(parameter 304)

STOP via

Terminal 27

Safety Interlock

Constant speed motors stop

immediately. Controller coasts

its motor to a stop.

(parameter 304)

Cascade Controller Option

Master/Slave cascade control mode

Stop fu

are described in the table below.

OFF/STOP key Provides a sequenced

STOP vi

and 17 (parameters 300

and 301)

STOP via Terminal 18

(parameter 302)

STOP v

27 Coast Inverse

(parameter 304)

STOP via Terminal

27 Safety Interlock

(parameter 304)

Serial communications(parameter 500)

■

The Danfoss FC protocol may be used only with

VLT Dialog software for programming and setting

up drive and cascade controller parameters.

nctions in Master/Slave cascade control

Master/Slave Cascade Control

Function Description

stop for all slave motors

in opposite order as

staged on.

Master decelerates its

motortoastop.

aTerminal16

Slave m

otors all stop

together. Master

decelerates its motor to

.

astop

Slave motors all stop

together. Master

decelerates its motor to

astop.

ia Terminal

motors all stop

Slave

together. Master coasts

its motor to a stop.

Slave motors all stop

together. Master coasts

its motor to a stop.

22

MG.60.I3.02 - VLT is a registered Danfoss trademark

Page 23

User Interface

■

How to use the LCP for programming

■

The combined display and keypad on the front of the

VLT is called the Local Control Panel (LCP).

The LCP is the user interface to the VLT

adjustable frequency drive.

The LCP has several user functions: programming

the VLT; displaying operational data, along with

warnings and cautions; to reset the drive after

a fault; and, in local control, to start/stop and

control the speed of the drive.

Control keys for parameter setup

■

Each parameter determines an operational function

the drive. Many parameters are used in combinations

with others. The keys shown below are used for

programming the drive by selecting from parameter

options or entering data in the parameter, as

applicable. The LCP keys are also used for selecting

the data displayed during normal operation of the drive.

Cascade Controller Option

[+/-] are used to scroll through parameters and for

changing a selected parameter. These keys can also

be used to change the drive speed as a function of

the local reference. In addition, the keys are used in

Display mode to switch between readouts.

[<>] are used when selecting a parameter group

and for moving the cursor to the desired digit

when changing numerical values.

Indicator lamps

■

At the bottom of the control panel are three indicator

lamps: a red alarm lamp, a yellow warning lamp,

and a green voltage (power on) lamp.

If pre-determined threshold values are exceeded,

the alarm and/or warning lamp is activated,

and a status or alarm text is displayed. The

power-on light is activated when the VLT adjustable

frequency drive receives voltage.

[DISPLAY/MODE] is used to change display modes

or to return to the Display mode from either the

Quick Menu or the Extend Menu mode.

[QUICK MENU] gives access to the programming

parameters in the Quick Menu. These are the

most commonly used parameters in setting

up the drive functions.

[EXTEND MENU] gives access to all drive parameters,

including Quick Menu items.

[CHANGE DATA] is used for changing a parameter

setting selected in either the Extend Menu

or the Quick Menu mode.

[CANCEL] is used if a change to a selected

parameter is not to be carried out.

[OK] is used for confirming a change to a

selected parameter.

Drive Control

■

Keys for control of the drive are described below.3

[HAND START] is used if the VLT drive is to be started

and controlled from the LCP. The VLT drive will start

the motor when [HAND START] is pressed.

NB!:

The motor will start when [HAND START]

is activated if parameter 201, Output

frequency low limit, is set to an output

frequency greater than 0 Hz.

The following control signals are active on the control

terminals when [HAND START] is activated:

•

Hand Start - Off Stop - Auto Start - Reset

•

Safety interlock

•

Coasting stop inverse

•

Reversing

User Interface

MG.60.I3.02 - VLT is a registered Danfoss trademark

23

Page 24

Cascade Controller Option

•

Setup select lsb - Setup select msb

•

Jog

•

Run per

•

Lock for data change

•

Stop command from serial communication

missive

[OFF/STOP] is used for stopping the connected

motor in Hand or Auto mode. This key can be

diabled in parameter 013. If the stop function is

activated, the main display will flash.

[AUTO START] is used if the VLT is to be controlled

through the control terminals. When a start

signal is act ive on the control terminals and/or

serial bus, the VLT drive will start.

NB!:

Drive can start at anytime with a start signal

through digital inputs. Digital inputs have

higher priority than control keys [HAND

START] and [AUTO START].

[RESET] is used for manually resetting the drive after

a fault trip (alarm). In this case, the top line of the

display will show TRIP (RESET). If the top line of the

display shows TRIP (AUTO START), the drive will

automatically restart. If the top line of the display

shows TRIPLOCK (DISC. MAINS), input power to the

drive must be removed before the trip can be reset.

Display modes

■

In Auto operational mode, information is displayed in

any of three programmable displays. Pressing the

[DISPLAY MODE] key enters display mode and toggle

between modes I and II. In Display mode, the [+] and

[-] keys scroll through all data display options. When

in Mode II, holding down the [DISPLAY MODE] key

identifies the units the display is showing on the top

line. Mode IV is available only in local Hand operation.

In normal operation, three data readouts can be

shown on the first (top) line of the display. One readout

is available for line 2 (the large display). Parameters

008, 009 and 010 select the data displayed on the

top line. Parameter 007, Large Display Readout,

selects the data displayed on line 2.

The list on the next page defines the operating

data that can be selected for the display readouts.

Line 4 (bottom line) automatically displays the

operating status of the drive.

The active setup number and an arrow indicating

the direction of motor rotation is shown on the right

side of the large display. Clockwise indicates forward

and counterclockwise indicates reverse. The arrow

body is removed if a stop command is given or if

the output frequency falls below 0.01 Hz.

Warnings and alarms (fault trips) will also be displayed.

During an alarm, ALARM and the alarm number

is shown on the large display. An explanation is

given in line 3 or in lines 3 and 4. For a warning,

WARN. and the warning number is shown with an

explanation in line 3 and/or 4. Both alarms and

warnings cause the display to flash.

VAR 1.1 VAR 1.2 VAR 1.3

VAR 2

SETUP

1

STATUS

The list below gives the operating data options for

the first and second line of the LCP display.

Data Item: Unit:

Resulting reference, % [%]

Resulting reference, unit [unit]

Frequency [Hz]

%ofmaximumoutput

frequency

Motor current [A]

Power [kW]

Power Power [HP]

Output energy [kWh]

Hours run [hours]

User-defined readout [unit]

Setpoint 1 [unit]

Setpoint 2 [unit]

Feedback 1 [unit]

Feedback 2 [unit]

Feedback [unit]

Motor voltage [V]

DC-link voltage [V]

Thermal load on motor [%]

Thermal load on VLT [%]

Input status, digital input [binary code]

Input status, analog

terminal 53

Input status, analog

terminal 54

Input status, analog

terminal 60

Output status, relay status [binary code]

Pulse reference [Hz]

External reference [%]

Heat sink temperature [

User-defined text [-]

[%]

[V]

[V]

[mA]

C]

24

MG.60.I3.02 - VLT is a registered Danfoss trademark

Page 25

Cascade Controller Option

Three operating data values can be shown in the

first display line and one in the large display line,

mmed via parameters 007, 008, 009, and 010.

progra

D

isplay mode I

InDisplaymodeI,thedriveisinAutomodewith

reference and control determined via t he control

terminals. Below is an example in which the drive

is running in setup 1, in Auto mode, with a remote

reference, and at an output frequency of 40 Hz.

The text in line 1, FREQUENCY, describes the

r shown in the large display. Line 2 (large

mete

display) shows the current output frequency (40.0

Hz), direction of rotation (reverse arrow), and active

p (1). Line 3 is blank. Line 4 is the status line

setu

and the information is automatically generated for

display by the drive in response to its operation. It

ws that the drive is in auto mode, with a remote

sho

reference, and that the motor is running.

´

FREQUENCY

40.0Hz40.0Hz

40.0Hz

40.0Hz40.0Hz

AUTO REMOTE RUNNING

SETUP

1

175ZA683.10

The last part of line 4 indicates the drive’soperational

status, for example: RUNNING, STOP, or ALARM.

D

isplay mode II

This display mode shows three operating data values

in the top line programmed v ia parameters 007,

008, and 009. Pressing the [DISPLAY MODE] key

toggles between Display modes I and II.

100% 7.8A 5.9kW

SETUP

50.0Hz

AUTO REMOTE RUNNING

Display mode III

Press and hold the [DISPLAY MODE] key while in Mode

II. Mode III is visible as long as the key is depressed.

The top line changes to identify the data names and

units displayed. Lines 2 and 4 are unchanged. When

the key is released, the display returns to Mode II.

REF% CURR.A.POW.,KW

60.0Hz

1

SETUP

1

175ZA685.10

175ZA686.10

Status line (Line 4): Additional automatic displays

forthedrivestatuslineareshownbelow.

80.0% 5.08A 2.15kW

SETUP

40.0Hz

AUTO REMOTE RUNNING

HAND LOCAL STOP

OFF RAMPING

JOGGING

.

.

.

.

STAND BY

The left indicator on the status line displays the

active control mode of the VLT drive. AUTO is

displayed when control is via the control terminals.

HAND indicates that control is local via the keys

ontheLCP.OFFindicatesthatthedriveignores

all control commands and will not run.

The center part of the status line indicates the

reference element that is active. REMOTE means that

reference from the control terminals is active, while

LOCAL indicates that the reference is determined

via the [+] and [-] keys on the control panel.

1

175ZA684.10

AUTO REMOTE RUNNING

Display mode IV

This display mode is used for local operation, where

the local speed reference is given from the keypad. In

this display mode, the reference is determined via the

[+] and [-] keys. Control is carried out through the

bottom keys on the keypad. The first line indicates

the requ ired reference. The third line gives the relative

value of the output frequency in the form of a bar

graph in relation to the maximum frequency.

USE +/- 40Hz

40.0Hz

HAND LOCAL RUNNING

Changing data

■

Regardless of whether a parameter has been selected

under the Quick Menu or the Extend Menu, the

procedure for changing data is the same. Pressing

the [CHANGE DATA] key gives access to changing

the selected parameter. Line 3 displays the parameter

175ZA688.10

User Interface

MG.60.I3.02 - VLT is a registered Danfoss trademark

25

Page 26

Cascade Controller Option

number and title. The underlined function or number

flashing in line 4 on the display is subject to change.

The procedure for changing data depends on

whether the selected parameter represents a

numerical data value or a function.

hanging numeric values

C

If the chosen parameter represents a number

, the flashing digit can be changed by means

value

of the [+] and [-] keys. Position the cursor by

using the [<] and [>] keys, then change the data

e using the [+] and [-] keys.

valu

The selected digit is indicated by a flashing cursor.

Thebottomdisplaylinegivesthedatavaluethat

will be entered (saved) by pressing the [OK] button.

Use [CANCEL] to ignore the change.

FREQUENCY

24.2 Hz

205 MAX. REFERENCE

000060.000 Hz

6

SETUP

1

175ZA687.10

2. Use [+] and [-] keys to find parameter

you choose to edit.

3. Press [

4. Use [+] and [-] keys to select correct parameter

5. Press [Cancel] key to disregard change, or press

Example of how to change parameter data

■

Assume Quick Menu item 9 (parameter 206, Ramp

Up Time) is set at 60 seconds. Change the ramp

up time to 100 seconds as follows:

1. Press [Quick Menu] key.

2. Press [+] key until you reach Quick Menu item

3. Press < key twice hundreds digit will flash.

4. Press [+] key once to change hundreds digit to 1.

5. Press

6. Press [-] key until 6 counts down to 0 and setting

7. Press [

Change Data] key.

setting. To move to a different digit within a

c parameter, use < and > arrows. Flashing

numeri

cursor indicates digit selected to change.

ey to accept change and enter new setting.

[OK] k

9of35

for Ramp Up Time reads 100 s.

(parameter 206), Ramp Up Time.

> key once to move to tens digit.

OK] key to enter new value.

Changing functional values

If the selected parameter is a functional value,

the selected text value can be changed by

meansofthe[+]and[-]keys.

MOTOR CURRENT

SETUP

3.90 A

210 REFERENCE TYPE

SUM

The functional value flashes until signing off by pressing

the [OK] button. The functional value has then been

selected. Use [CANCEL] to ignore the change.

C

hanging listed numeric values

A few parameters offer numeric lists of values that

can be selected from or changed. This means

that if the numeric value is not listed, a value

may be entered using the procedure for changing

numeric values. This applies to parameter 102,

Motor power, parameter 103, Motor voltage,and

parameter 104, Motor frequency.

1

175ZA689.10

Manual initialization

■

The drive can be initialized to return to

factory default settings.

NB!:

Initializing the drive will remove all values and

settings entered into drive. Some factory default

ngs may be for European applications.

setti

1. Remove AC power to drive.

2. Press and hold [DISPLAY MODE] + [CHANGE

DATA]+[OK]keysdownwhileatsametime

applying AC power to drive.

3. Release keys. VLT reverts to factory setting.

It is also possible to carry out initialization via

parameter 620, Operating mode, by selecting Initialize.

Parameter setting procedure

■

Enter or change parameter data or settings as follows:

1. Press [Quick Menu] or [Extended Menu] key.

26

MG.60.I3.02 - VLT is a registered Danfoss trademark

Page 27

Cascade Controller Option

The following parameters are not reset when

using manual initialization:

500, Protocol

600, Operating hours

601, Hours run

602, kWh counter

603, Number of power-ups

604, Number of overtemperatures

605, Number of overvoltages

724 - 737, Operating hours/counters

User Interface

MG.60.I3.02 - VLT is a registered Danfoss trademark

27

Page 28

VLT Drive and Cascade Controller Setup

■

Introduction

■

A new quick menu list is activated when a cascade

controller option card is installed in the VLT adjustable

frequency drive. The original 12 items are expanded

to 39 quick menu items that allow programming

additional drive and cascade controller functions.

See Chapter 4, Changed Drive Functions.

The first 20 items on the new quick menu must

be programmed in sequ ence for initial drive and

cascade controller setup. (See block diagram.) These

20 items are common to both Standard cascade

control mode and Master/Slave control mode. After

initial setup is complete, additional quick menu

items program the drive for the selected mode of

operation. Those instructions are available in Chapter

7, Standard Cascade Control Mode Setup and

Chapter 8, Master/ Slave Control Mode Setup.

Chapter 9, System Optimization, provides instructions

for final adjustments to reach maximum drive and

controller efficiency after system start up.

Cascade Controller Option

selects the mode of operation for further setup.

The Quick Menu Summary table on the next

page describes the menu items.

The VLT adjustable frequency drive has four

independent setups that can be programmed.

The initial programming in this chapter is stored

as Setup 1. See Alternative Programming at

the end of this chapter for instructions on using

the drives multi-setup capability.

VLT drives delivered with the cascade controller

option card already installed, or prepared for field

installation, have been programmed with factory

settings typical for operation. These settings may be

satisfactory for initial start up of the system.

See Chapter 5, Use Interface, for instructions

on programming the VLT drive.

Items 2 6 are motor characteristics. In Standard

cascade control mode, only the motor data from the

variable speed motor run by the cascade controller

are entered. In Master/Slave control, only data from

the motor controlled by the Master drive are entered

at this time. Items 7 19 are basic cascade controller

settings used in either mode of operation. Item 20

28

MG.60.I3.02 - VLT is a registered Danfoss trademark

Page 29

Quick Menu Summary

■

Cascade Controller Option

Quick Menu

numbe

Basic Drive Set Up parameters

001 001 Language 10 languages See VLT 6000 H VAC or VLT

002 102 Motor Power KW/HP 1.1-450/1.5-600

003 103 Motor Volta ge Volts 200 - 480

004 104 Motor Frequency Hz 50 / 60

005 105 Motor Current Amps 0-IVLT max

006 106 Rated Motor Speed RPM 0- fm,n x 60

007 201 Min. Fr equency Hz 0.0 -fmax 2/5 of fnom (NEW)

008 202 Max. Frequency Hz Fmin-120/1000 Fnom x 1.1 (NEW)

009 206 Ramp up time Seconds 1-3600 See table above in 2.4.8

010 207 Ramp down time Seconds 1-3600

011 323 Relay 1 Output Depending on cho ice See VLT 6000 HVAC Manual.

012 326 Relay 2 Output

Basic Set Up for Standard Cascade and Master/Slave.

013 415 Closed loop units Selected acc or ding to your p ro cess.

014 413 Minimum Feedba ck

015 414 Maximum Feedback

016 227 Warning low Feedback Units -999,999.999- FB High -999,999.999

017 228 Warning high Feedback Units FB low- 999,999.999 999,999.999

018 204 Ref.min. Units Min. feedback - Ref.max 0

019 205 Ref.max. Units Ref.min - Max. feedback 0

020 723 Operational Mode select - Standard / M/S Stan dar d Ca scade

021 712 Pump combination 1-8 1

022 713 Staging BandW. % 1. 0 - 100.0 10.0

023 714 Destaging Delay Sec. 0.0 - 3000 15

024 715 Staging Delay Sec. 0.0 - 3000 15

025 716 Override BW %ofsetpoint 2.0 - 10 0.0 20.0

026 717 Override Timer Sec. 0.0 - 300 5

027 718 Transition frequency %offnom fmin - 120.0 60

028 418 Setpoint 1 (H0) Bar (or equiv.) Refmin - Refmax 6bar

029 419 Setpoint 2 (H1) Bar (or equiv.) Refmin - Refmax 6bar

030 721 Destage Timer Timer Sec. 0.0 - 600 30

031 722 Pump cycling Enabled/Disabled Enabled

032 319 Analog/digital outputs - [1] - [43] F out 020mA

033 739 M/S Stage on frequencies Hz Fmin-Fmax Fmin

034 740 M/S stage off frequencies Hz Fmin-Fmax Fmax

PID Controller tun ing

035 420 Normal/Inverse control Normal/Inverse Normal mode

036 422 PID Start up frequency Hz Fmin-fmax 0Hz

037 427 PID Lowpass filter time Sec. 0.01 10.00 1. 00

038 423 PID Proportional Gain Factor 0.00 10.0 0. 01

039 424 PID Integrator time Sec. 0.01 9999.0 OFF

Parame-

r

ter nu

ber

Name Units Range Factory setting

m-

8000 AQUA manuals.

Controller Setup

VLT Drive and Cascade

Language

■

Quick Menu 001 Par. 001 Language

(LANGU

AGE)

Value:

✭English(ENGLISH)

German(DEUTSCH)

MG.60.I3.02 - VLT is a registered Danfoss trademark

French (FRANCAIS)

Danish (DANSK)

Spanish (ESPAÑOL)

Italian(ITALIANO)

Swedish (SVENSKA)

Dutch (NEDERLANDS)

29

Page 30

Cascade Controller Option

Portuguese(PORTUGUESA)

Finnish (SUOMI)

Function:

This choice defines the language to be

used on the display.

Description of choice:

Select the display language.

NB!:

It is important that the values set in parameters

102-106, Motor nameplate data, correspond

to the nameplate data of the motor.

Motor nameplate data

■

Quick Menu 002 Par. 102 Motor power

(MOTOR POWER)

Value:

0.1/3 HP (0.25 KW)

0.5 HP (0.37 KW)

0.75 HP (0.55 KW)

1.0 HP (0.75 KW)

1.5 HP (1.10 KW)

2 HP (1.50 KW)

3 HP (2.20 KW)

4 HP (3.00 KW)

5 HP (4.00 KW)

7.5 HP (5.50 KW)

10 HP (7.50 KW)

15 HP (11.00 KW)

20 HP (15.00 KW)

25 HP (18.50 KW)

30 HP (22.00 KW)

40 HP (30.00 KW)

50 HP (37.00 KW)

60 HP (45.00 KW)

75 HP (55.00 KW)

100 HP (75.00 KW)

125 HP (90.00 KW)

150 HP (110.00 KW)

200 HP (132.00 KW)

250 HP (160.00 KW)

300 HP (200.00 KW)

350 HP (250.00 KW)

400 HP (300.00 KW)

450 HP (315.00 KW)

500 HP (355.00 KW)

600 HP (400.00 KW)

✭Depends on the unit

[000.25]

[000.37]

[000.55]

[000.75]

[001.10]

[001.50]

[002.20]

[003.00]

[004.00]

[005.50]

[007.50]

[011.00]

[015.00]

[018.50]

[022.00]

[030.00]

[037.00]

[045.00]

[055.00]

[075.00]

[090.00]

[110.00]

[132.00]

[160.00]

[200.00]

[250.00]

[300.00]

[315.00]

[355.00]

[400.00]

is the full rating of the drive. The drive can operate

motors undersized by up to four ratings below the

ting of the drive or oversized by one rating.

full ra

Description of choice:

Select a value that equals the nameplate

data on the motor. tage

Quick Menu 003 Par. 103 Motor voltage

(MOTOR VOLTAGE)

Value:

200 V

208 V

220 V

230 V

240 V

380 V

400 V

415 V

440 V

460 V

480 V

500 V

✭Depends on motor

Function:

This is wher

Description of choice:

Select a value that equals the nameplate data on

the motor, regardless of the AC input voltage of

the VLT adjustable frequency drive.

Quick Menu 004 Par. 104 Motor frequency

Value:

50 Hz

60 Hz

Function:

This is where the rated motor frequency is selected.

Description of choice:

Select a value that equals the nameplate

data on the motor.

e the rated motor voltage is selected.

(MOTOR FREQUENCY)

[200]

[208]

[220]

[230]

[240]

[380]

[400]

[400]

[440]

[460]

[480]

[500]

✭ 60

Function:

This sets the power value that corresponds to the

nameplate power of the motor. The default setting

30

MG.60.I3.02 - VLT is a registered Danfoss trademark

Page 31

Cascade Controller Option

Quick Menu 005 Par. 105 Motor current

(MOTOR CURRENT)

Value:

0.01 - Drive rating

✭ Depends on motor

Function:

The rated motor current in amps forms part of the

VLT frequency converter calculations for torque

and motor thermal protection.

Description of choice:

Set a value that equals the nameplate data

on the motor.

NB!:

It is important to enter the correct value, since

this forms part of the VVC

+

control feature.

Quick Menu 006 Par. 106 Rated motor speed

(MOTOR

NOM. SPEED)

Value:

100 - 60000 rpm

✭ Depends on parameter 102, Motor power

Function:

This is where the value is set that corresponds to the

rated motor speed found on the nameplate data.

Description of choice:

Set a value that corresponds to the motor

nameplate data.

NB!:

It is important to set the correct value, since

+

this forms part of the VVC

control feature.

Description of choice:

Set a value from 0.0 Hz to the Output frequency high

limit set in Quick Menu item 008 (parameter 202).

Quick Menu 008 Par. 202 Output frequency

high limit

(MAX. FREQUENCY)

Value:

Para 201 setting - Para 200 limit

✭ 60 Hz

Function:

In this parameter, a maximum output frequency can

be selected that corresponds with the maximum motor

speed. The drive will not be able to run continuously

at an output frequency above this value in any mode.

NB!:

e output frequency high limit to 60 Hz

Set th

for US applications. The output frequency

of the VLT frequency converter can never

e a value higher than 1/10 of the switching

assum

frequency (parameter 407, Switching frequency).

Description of choice:

Enter a value between the low frequency limit, set

in Quick Menu item 07 (parameter 201), and the

frequency range limit, set in parameter 200.

Quick Menu 009 Par. 206 Ramp-up time

(RAMPUPTIME)

Value:

1 - 3600 sec.

✭ Depends on unit

Controller Setup

VLT Drive and Cascade

The maximum value equals frequency x 60. Frequency

is set in parameter 104, Motor frequency.

Quick Menu 007 Par. 201 Output frequency

low limit

(MIN. FREQUENCY)

Value:

0.0 - Parameter 202 setting

✭ 0.0 HZ

Function:

This is where to select the minimum output frequency.

The drive will be unable to run continuously

below t

MG.60.I3.02 - VLT is a registered Danfoss trademark

his value in any mode.

Function:

The ramp-up time is the acceleration time from 0 Hz

to the rated motor frequency (parameter 104, Motor

frequency). It is assumed that the output current

does not reach the current limit (set in parameter

215, Current limit). This determines the maximum

acceleration rate for all modes of operation.

31

Page 32

Description of choice:

Set the desired ramp-up time. Too long of a ramp

up can cause sluggish drive operation. Too short of

a ramp up can cause the drive to go into current

limit during acceleration or cause unaccepta ble

torque pulses in the controlled system.

Quick Menu 010 Par. 207 Ramp-down time

(RAMP DOWN TIME)

Value:

1 - 3600 sec..

Function:

The ramp-down time is the deceleration time from

the rated motor frequency (parameter 104, Motor

frequency) to 0 Hz. This ramp-down time may be

automatically extended to prevent an overvoltage trip if

the load regenerates to the drive. This determines the

maximum deceleration rate for all modes of operation.

Description of choice:

Set the desired ramp-down time. Too long of a

ramp down can cause sluggish operation. Too

short of a ramp down can cause the drive to trip off

due to high DC bus voltage or cause unacceptable

torque pulses in the controlled system.

✭ Depends on unit

Cascade Controller Option

Relay 1

1 - 3 break, 1 - 2 make Max. 240 VAC, 2 Amp. The

relay is with the main and motor terminals.

Relay 2

4 - 5 make Max. 50 VAC, 1 A, 60 VA. Max. 75 VDC,

1A,30W.Therelayisonthecontrolcard.

Quick Menu 011 Par. 323 Output relay 1

(RELAY 1 FUNCTION)

Value:

29 optional settings

Function:

This output activates relay switch 01. This 240 volt,

Form C relay can be used for status and warnings.

There are 29 optional settings. It is generally

programmed to provide a remote alarm indication.

No Alarm is the default setting. This indicates the

drive is operating properly and the contact is closed.

The contact opens to indicate an alarm when there

is a fault condition or when the drive looses power.

Terminal wires 1 and 3 are wired together.

Alarm is selected when a loss of power

should not cause an alarm indication. Wire

terminals 1 and 2 together.

See the VLT Operating Instructionsfora

detailed list of relay options.

✭ NO ALARM

Relay outputs

■

Relay outputs 1 and 2 can be used to give the

present drive status or a warning.

If the output is used as a voltage output (0-10 V),

a pull-down resistor of 500

terminal 39 (common for analogue/digital outputs.

See chapter 10 for additional detail).

Iftheoutputisusedasacurrentoutput,the

resulting impedence of the connected equipment

should not exceed 500 W.

32

should be fitted to

Description of choice:

Select relay 1 function.

MG.60.I3.02 - VLT is a registered Danfoss trademark

Page 33

Cascade Controller Option

Quick Menu 012 Par. 326 Output relay 2

(RELAY 2 FUNCTION)

Value:

29 optional settings

✭ RUNNING

Function:

This output activates relay switch 02. This low voltage

relay is generally programmed to provide a remote

run indication. There are 29 optional settings.

Running makes this relay close when the drive

is running. This is the default setting.

Description of choice:

Select relay 2 function.

Quick Menu 013 Par. 415 Units relating

to closed loop

(REF. /

FDBK. UNIT)

Value:

No unit

✭%

rpm

ppm

pulse/s

l/s

l/min

l/h

kg/s

kg/min

kg/h

3

m

/s

3

m

/min

3

m

/h

m/s

mbar

bar

Pa

kPa

mVS

kW

C

GPM

gal/s

gal/min

gal/h

lb/s

lb/min

lb/h

CFM

3

ft

/s

3

ft

/min

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

[18]

[19]

[20]

[21]

[22]

[23]

[24]

[25]

[26]

[27]

[28]

[29]

[30]

[31]

[0]

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

3

ft

/h

ft/s

in wg

ft wg

PSI

lb/in

HP

F

2

[32]

[33]

[34]

[35]

[36]

[37]

[38]

[39]

Function:

This unit will be used for the reading in the Display

modeandasaunitforMinimum / Maximum

Feedback, Minimum / Maximum Reference, Warning

Feedback High/Low and for the H1, H0 and the

calculated Hmx parameter settings/readings.

Description of choice:

Select the unit for the reference/feedback signal.

Quick Menu 014 Par. 413 Minimum feedback

(MIN. FEEDBACK)

Value:

-999,999.999 - FB

MAX

✭ 0.000

Function:

Parameters 413, Minimum feedback and 414,

Maximum feedback are used to scale the feedback

signal ensuring that it shows the feedback signal

proportionally to the signal at the input.

Description of choice:

Setthevaluetobeshownonthedisplaywhenthe

feedback signal is at its minimum value.

Quick Menu 015 Par. 414 Maximum feedback

(MAX. FEEDBACK)

Value:

FB

- 999,999.999

MIN

✭ 100.000

Function:

Parameters 413, Minimum feedback and 414,

Maximum feedback are used to scale the feedback

signal ensuring that it shows the feedback signal

proportionally to the signal at the input.

Description of choice:

Setthevaluetobeshownonthedisplaywhenthe

feedback signal is at its maximum value.

Controller Setup

VLT Drive and Cascade

MG.60.I3.02 - VLT is a registered Danfoss trademark

33

Page 34

Cascade Controller Option

Quick Menu 016 Par. 227 Warning:

Low feedback

(WARN LOW FDBK)

Value:

-999,999.999 - FB

(parameter 228)

HIGH

✭ -999.999,999

Function:

If the feedback signal is below the limit programmed

in this parameter, the display will show a

flashing FEEDBACK LOW.

The warning functions in parameters 221-228

are not active during ramp up after a start

command, ramp down after a stop command

or while stopped. The warning functions are

activated when the output frequency has reached

the resulting reference. The signal output can

be programmed to generate a warning signal via

terminal 42 or 45 or via the relay output.

In Closed loop, the unit for the feedback is programmed

in parameter 415, Units related to closed loop.

Description of choice:

Set the desired value within the feedback range

between parameter 413, Minimum Feedback,and

parameter 414, Maximum Feedback.

Quick Menu 018 Par. 204 Minimum reference

(MIN. REFERENCE)

Value:

Parameter 100 Configuration = Closed loop [1].

-Par.413 Minimum feedback

-par.205Ref

MAX

✭ -999.999,999

Function:

The Minimum Reference sets the minimum value

of the sum of all references. If Closed loop has

been selected in parameter 100, Configuration,

the minimum reference is limited by parameter

413, Minimum Feedback. Minimum reference is

ignored when the local reference is active. In

this case, minimum reference is determined by

parameter 201, Minimum Frequency.

Description of choice:

Set the desired value within the feedback range

between parameter 413, Minimum Feedback and

parameter 414, Maximum Feedback.

QuickMenu 017 Par. 228 Warning High feedback

(WARN. HIGH FDBK)

Value:

FB

(parameter 227) - 999,999.999

LOW

✭ -999.999,999

Function:

If the feedback signal is above the limit programmed

in this parameter, the display will show a

flashing FEEDBACK HIGH.

The warning functions in parameters 221-228 are

not active during ramp-up after a start command,

ramp-down after a stop command or while

stop-ped. The warning functions are activated when

the output frequency has reached the resulting

reference. The signal outputs can be prog rammed

to generate a warning signal via terminal 42 or

45 and via the relay outputs.

Description of choice:

Set the Minimum Reference, which is the lowest

reference value that can be set for the drive. The

unit for this reference is set in parameter 415.

Quick Menu 019 Par. 205 Maximum reference

(MAX. REFERENCE)

Value:

Par. 204 Ref

- par. 414 Maximum feedback

MIN

✭ 50.000 Hz

Function:

The Maximum reference gives the maximum value

that can be assumed by the sum of all references.

The Maximum Reference is limited to be with the

settings of Parameter 414 Maximum Feedback.

The Maximum reference is ignored when the local

reference is active (parameter 203 Reference site).

Description of choice:

Set the Maximum reference, which is the highest

reference value that can be set for the drive.

In Closed loop, the unit for the feedback is programmed

in parameter 415 Units related to closed loop.

34

Quick Menu 020 Par. 723 Mode Select

(MODE SELECT)

Value:

Standard Control

✭ Master/Slave

Master/Slave Control

MG.60.I3.02 - VLT is a registered Danfoss trademark

Page 35

Function:

Standard cascade control mode operation is a system

consisting of one adjustable speed pump and up to

four constant speed pumps. Master/Slave cascade

control mode operation is for a system using variable

speed pumps controlled by a Master drive.

NB!:

Set the correct control option. Improper setting

may result in system damage, operational

errors, or wasted energy.

Description of choice:

Select Standard Control for operating the cascade

controller option card in Standard control mode.

Select Master/Slave Control for operating the cascade

controller option card in Master/Slave control mode.

Cascade Controller Option

Controller Setup

VLT Drive and Cascade

MG.60.I3.02 - VLT is a registered Danfoss trademark

35

Page 36

Cascade Controller Option

Alternate programming

■

etup configuration and copying parameters

S

The fre

setups that can be programmed. Each setup

acts independently in controlling the drive. An

exampl

setups for day/night or summer/winter operation.

Any of the four setups can be used.

The setup is selected in Extended Menu parameter

002, Active Setup, for programming and operation.

Setups are changed manually by switching between

active setups in parameter 002. It is also possible

to change setups through digital inputs or serial

communication by selecting Multi-Setup in parameter

002 and providing an external signal.

The number of the active setup selected is

show

the second line of the display.

The Extended Menu is accessed by pressing the

[EXTEND. MENU] key on the LCP keypad.

A short cut to programming more than one setup is

pos

Setup Copy. This enables copying one setup to

another. After an active setup has been programmed

an

other setups need be changed.

All setups can be transferred from one frequency

converter to another (in the same VLT series) by

using the frequency converter’s removeable keypad.

Extended Menu parameter 004, LCP Copy,allows

this function. First, upload all parameter values to

the keypad. The keypad can then be removed and

plugged into another frequency converter where

all parameter values can be downloaded. If motor

or drive sizes differ, Download Power-independent

Parameters can be selected in parameter 004 to omit

downloading motor and current dependent data.

✭Setup 1 (SETUP 1)

This parameter defines the setup number that controls

the drive. All parameters can be programmed in four

quency converter has four parameter

e application would be programming different

n on the keypad display under Setup in

sible by using Extended Menu parameter 003,

d copied, just those parameters unique to the

Extended Menu Par. 002 Active Setup

(ACTIVE SETUP)

Value:

Factory Setup (FACTORY SETUP)

Setup 2 (SETUP 2)

Setup 3 (SETUP 3)

Setup 4 (SETUP 4)

Multi-Setup(MULTI SETUP)

Function:

[0]

[1]

[2]

[3]

[4]

[5]

individual parameter setups: Setup 1, Setup 2, Setup

3 and Setup 4. There is also a pre-programmed

nly setup, called the Factory Setup.

read-o

Description of choice:

Factory Setup contains the parameter values preset at

the factory. This setup can be used as a data source if

the other setups are to be returned to a known state.

Setups 1 through 4 are four individual setups that

can be programmed and selected as required.

Multi-Setup is used if remote switching between

different setups is required. Terminals 16, 17, 29,

32, 33 and the serial communication port can be

used for switching between setups.

Extended MenuExtended Par. 003 Setup Copy

(SETUP COPY)

Value:

✭No copying (NO COPY)

Copy active Setup to Setup 1

(COPY TO SETUP 1)

Copy active Setup to Setup 2

(COPY TO SETUP 2)

Copy active Setup to Setup 3

(COPY TO SETUP 3)

Copy active Setup to Setup 4

(COPY TO SETUP 4)

Copy active Setup to All

(COPY TO ALL)

Function:

A copy is made from the active setup selected

in parameter 002, Active Setup, to the setup

or setups selected here.