Page 1

Data sheet

Pressure switch and Thermostat

CAS

The CAS Series consists of a series of pressure

controlled switches and temperature controlled

switches. In this series, special attention has been

given to meeting demands for a high level of

enclosure, robust and compact construction and

resistance to shock and vibration.

The series is suitable for use in alarm and

regulation systems in factories, diesel plants,

compressors, power stations and on board ships.

Features

Approvals

Ship approvals

• A high level of enclosure

• Fixed differential

• Robust and compact construction

CE-marked in accordance with LVD 2006/95/EC EN 60947-1, EN-60947-4-1, EN 60947-5-1

American Bureau of Shipping,

ABS (excl. CAS 139)

Lloyds Register of Shipping, LR (excl. CAS 1080)

Germanischer Lloyd, GL

Bureau Veritas, BV

• Resistance to shock and vibration

• Available with all major marine approvals

Det Norske Veritas, DNV

Registro Italiano Navale, RINA

Maritime Register of Shipping, RMRS

Nippon Kaiji Kyokai, NKK

AI226486438268en-001001 | 1© Danfoss | DCS (jmn) | 2020.06

Page 2

Data sheet | Pressure switch and Thermostat, type CAS

Overview

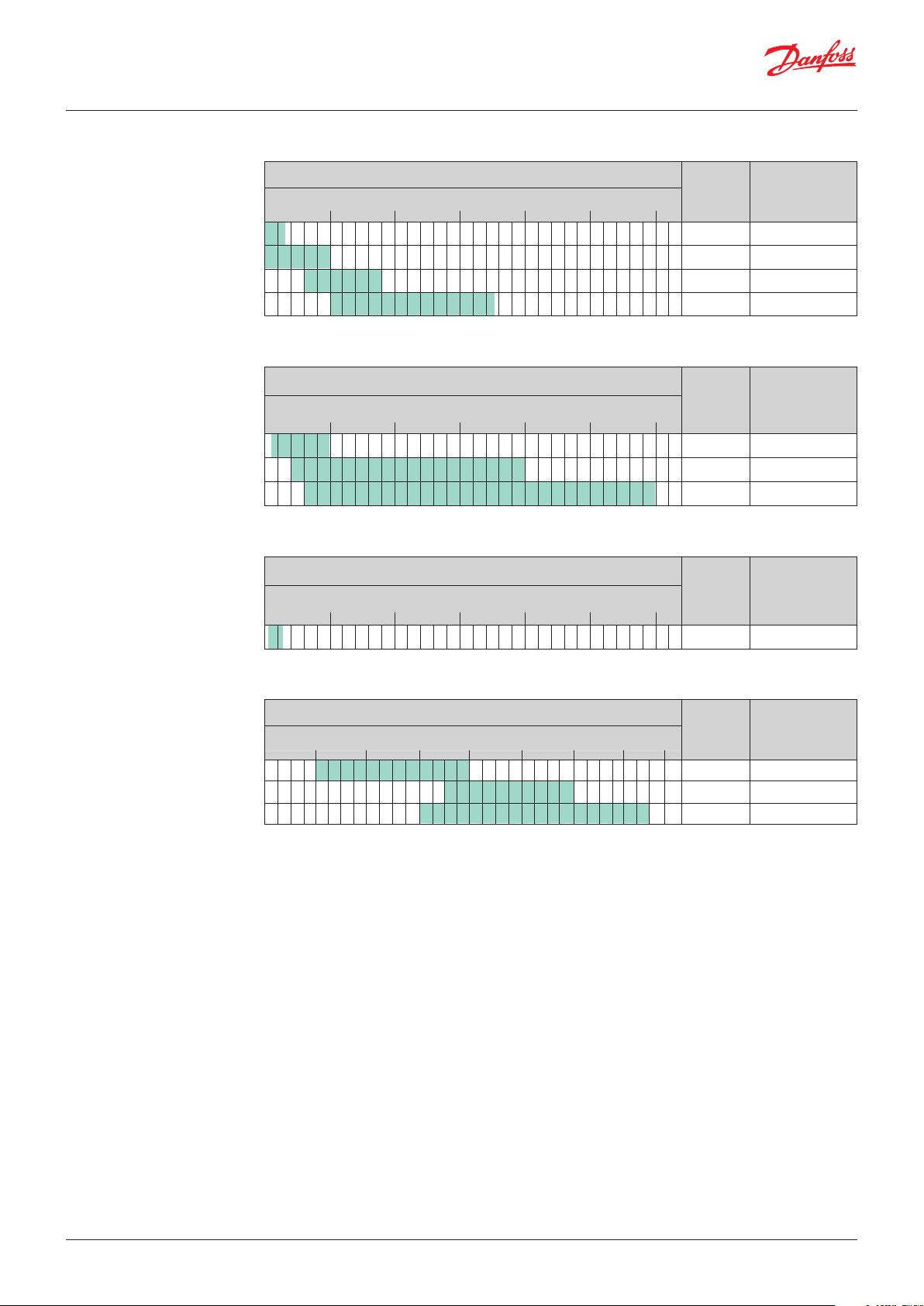

Standard pressure switches

[bar]

0 10 20 30 40 50 60

Pressure switches for high pressure and strongly pulsating media

[bar]

0 10 20 30 40 50 60

Differential pressure switches

[bar]

0 10 20 30 40 50 60

Range P

e

[bar]

Typ e

0 – 3.5 CA S 133

0 – 10 CAS 136

6 – 18 C AS 137

10 – 35 CA S 139

Range P

e

[bar]

Typ e

1 – 10 CAS 143

4 – 40 C AS 145

6 – 60 CA S 147

Range P

e

[bar]

Typ e

Thermostats

[°C]

0 20 40 60 80 100 120 140 160

0.2 – 2.5 CA S 155

Range

[°C]

Typ e

20 – 80 CAS 178

70 – 120 CAS 180

60 – 150 CAS 181

© Danfoss | DCS (jmn) | 2020.062 | AI226486438268en-001001

Page 3

Data sheet | Pressure switch and Thermostat, type CAS

PRESSURE SWITCH

Technical data

Switch Microswitch with single pole changeover (SPDT)

Contact load

Ambient temperature

Temperature

of medium1)

Vibration resistance Vibration-stable in the range 2 – 30 Hz amplitude 1.1 mm and 30 – 100 Hz, 4 g.

Cable entry Pg 13.5 for cable diametrers from 5 – 14 mm.

1)

For water and seawater, max. 80 °C

Materials in contact with the medium

Typ e Materials

Alternating current AC-14 / AC-15: 0.1 A, 220 V

Direct current DC-13: 12 W, 125 V

CAS 133 – 139 -40 – 70 °C

CAS 143 – 155 -25 – 70 °C

CAS 133 – 139 -40 – 100 °C

CAS 143 – 155 -25 – 100 °C

CAS 133, CAS 136,

CAS 137, CAS 139

CAS 143, CAS 145,

CAS 147, CAS 155

Bellows: Stainless steel, material no. 1.4306 (DIN 17440)

Pressure connection: Brass material no. 2.0401 (DIN 17660)

Diaphragm connection: Nickel plated brass CuZn 40 Ob3 ISO R 426 (DIN 17569)

Diaphragm: Nitrile-butadien rubber

Enclosure

IP67 acc. to EN 60529.

The pressure control housing is enamelled

pressure die cast aluminium (GD-AISi 12).

The cover is fastened by four screws which

are anchored to prevent loss.

The enclosure can be sealed with fuse wire.

Identification

The type designation and code no. of the unit

is stamped in the side of the housing.

© Danfoss | DCS (jmn) | 2020.06

AI226486438268en-001001| 3

Page 4

Data sheet | Pressure switch and Thermostat, type CAS

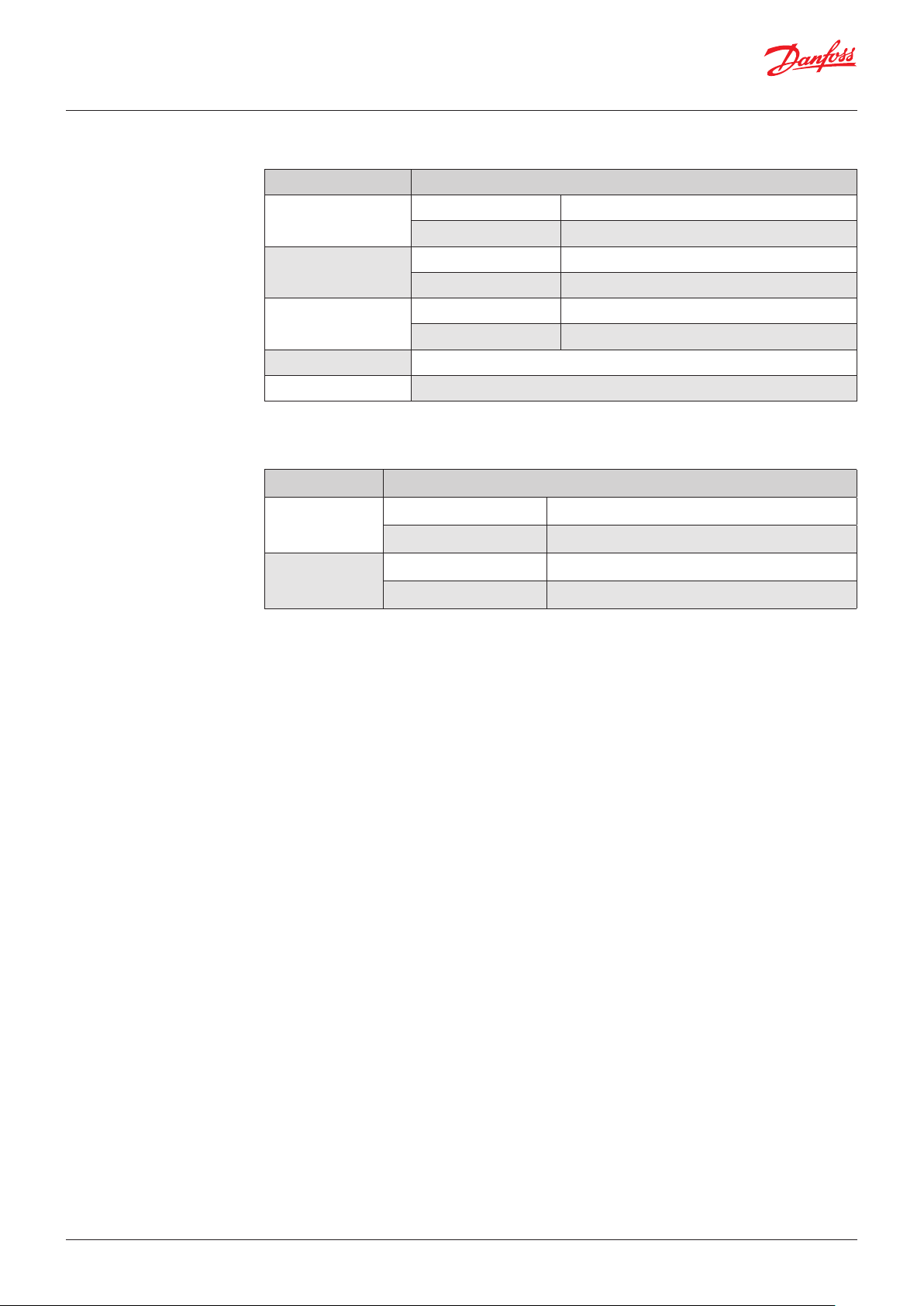

Ordering

Standard pressure switches

Typ e Setting

range p

[bar]

CA S 133 0 – 3.5 0.1 10 10 40 G ¼

CA S 136 0 – 10 0.2 22 22 40 G ¼ 060-315166

CA S 137 6 – 18 0.3 27 27 72 G ¼ 060 -31526 6

CA S 139 10 – 35 0.6 53 53 100 G ¼ 060-315366

Mechanical

differential

e

[bar]

Permissible

operating

pressure

[bar]

Max test

pressure

[bar]

Min. burst

pressure

[bar]

Pressure

connection

Code no.

060-315066

Pressure switches for high pressure and strongly pulsating media

Typ e Setting

range p

[bar]

CA S 143 1 – 10 0.2 – 0.6 12 0 180 240 G ¼ 0 60-316 066

CA S 145 4 – 40 0.8 – 2.4 12 0 180 240 G ¼ 06 0-316166

CA S 147 6 – 60 1 – 3 120 180 240 G ¼ 060-316266

Mechanical

differential

e

[bar]

Permissible

operating

pressure

[bar]

Max test

pressure

[bar]

Min. burst

pressure

[bar]

Pressure

connection

Code no.

Differential pressure switch

Typ e Setting

range p

[bar]

Mechanical

differential

e

[bar]

Permissible

operating

pressure for

low pressure

Max test

pressure

[bar]

Min. burst

pressure

[bar]

Pressure

connection

Code no.

Terminology

[bar]

CA S 155 0.2 – 2.5 0.1 0 – 8 22 42 2 × G ¼ 060-313066

Preferred version

Range setting

The pressure range within which the unit will

give a signal (contact changeover).

Max. test pressure

The highest pressure the unit may be subjected

to when, for example, testing the system for

leakage. Therefore, this presure must not occur

Differential

as a recurring system pressure.

The difference between make pressure and

break pressure (see also page 6).

Min. burst pressure

The pressure which the pressure-sensitive

Permissible burst pressure

element will withstand without leaking.

The highest permanent or recurring pressure the

unit can be loaded with.

© Danfoss | DCS (jmn) | 2020.064 | AI226486438268en-001001

Page 5

Data sheet | Pressure switch and Thermostat, type CAS

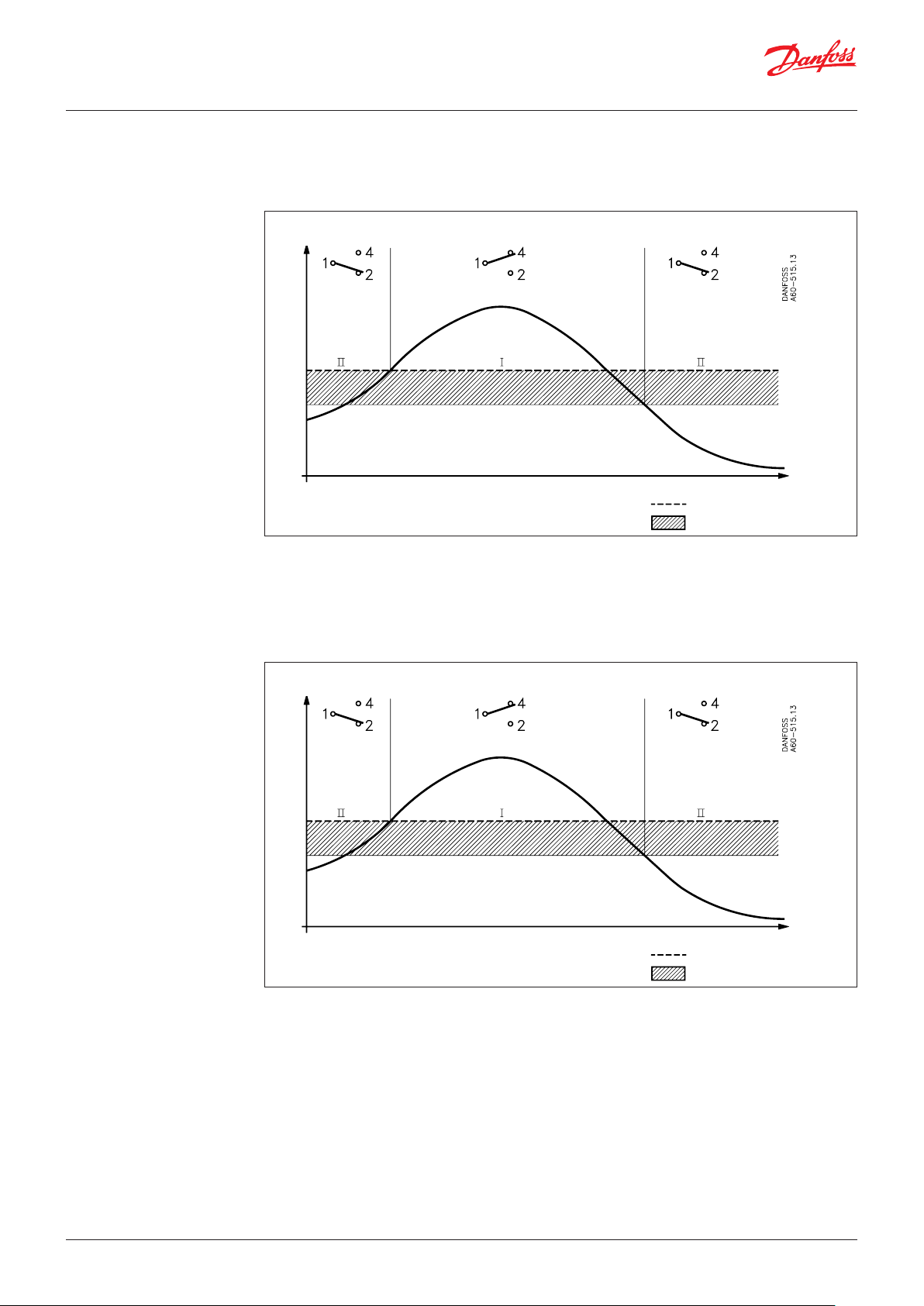

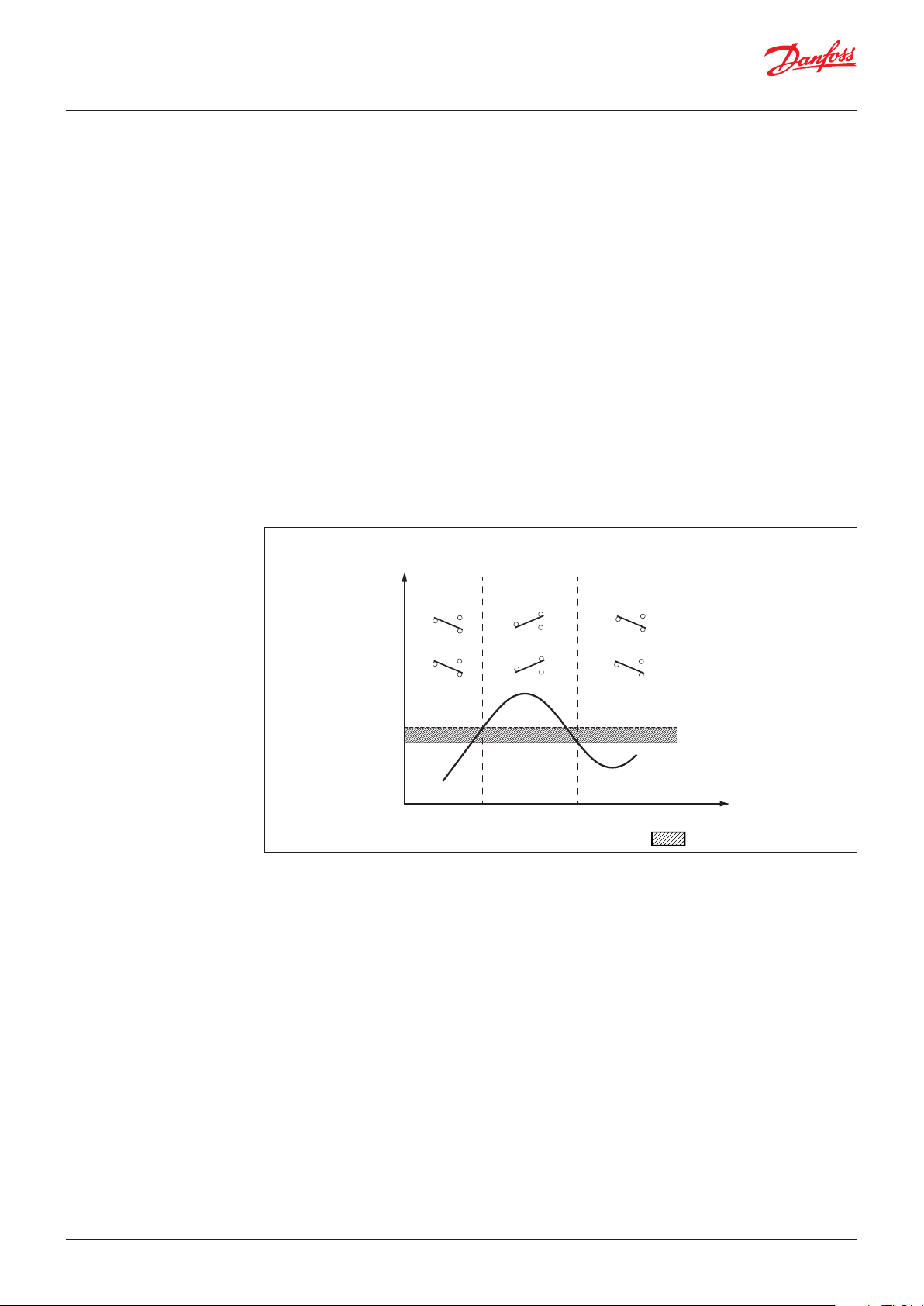

Function

I. Alarm for rising pressure

given at the set range value

II. Alarm for falling pressure

given at the set range value

minus the differential

a. CAS 155

Contacts 1-4 make and contacts 1-2 break when

the differential pressure rises above the set range

value. The contacts changeover to their initial

[bar]

position when the differential pressure again falls

to the range value minus the differential

(see fig. 1).

[s]

Scale setting

Mechanical differentialFig. 6

I. Alarm for rising pressure

given at the set range value

II. Alarm for falling pressure

given at the set range value

minus the differential

b. All other CAS pressure switches

Contacts 1-2 make and contacts 1-4 break when

the pressure falls under the set range value. The

contacts changeover to their initial position

[bar]

Fig. 6

Example 1:

An alarm must be given when the lubrication oil

pressure in a motor falls below 0.8 bar. Select

CAS 133 (range 0 – 3.5 bar).

The minimum permissible lubricating oils

pressure of 0.8 bar must be set using the range

spindle. The differential is fixed at 0.1 bar, i.e. the

alarm will not cut out before the pressure rises to

0.9 bar.

The switch break function is normally used for

alarm purposes, i.e. the alarm must be connected

to terminals 1 and 4.

when the pressure again rises to the set range

value plus the differential (see fig. 2).

[s]

Scale setting

Mechanical differential

Example 2:

When the differential pressure exceeds 1.3 bar

a filter must be cleaned.

The maximum static pressure (LP) for the CAS

155 of 8 bar must not be exceeded.

The pressure control range spindle must be set

at 1.3 bar.

The alarm must be connected to terminals

1 and 2 (alarm for broken circuit).

© Danfoss | DCS (jmn) | 2020.06

AI226486438268en-001001| 5

Page 6

Danfoss

17.9051

Danfoss

60.9030

Data sheet | Pressure switch and Thermostat, type CAS

Accessories

Part Description Qty. Code no.

3

/

connector,

8

5 017-43 686 6

Connector with

nipple

Pipe thread ISO 228-1, G

nipple and AL washer (10 mm ext. 8 mm int. diam)

for solering onto steel or copper tubing,

steel span of jaws 22

3

G

/

connector, nipple and washer

Connector with

nipple

Reducer

Adaptor

Adaptor

Adaptor

Adaptor

8

(10 mm ext./ 6.5 mm int. diam.) for welding,

steel span of jaws 22

3

Pipe thread ISO 228-1, G

/

8

×

7

/

- 20 UNF

16

reducer, washer, brass span of jaws 22

3

Pipe thread ISO 228-1, G

/

×

8

1

/

- 27 NPT

8

with copper washer brass span of jaws 22

Pipe thread ISO 228-1, G

3

/

A × ¼ - 18 NPT

8

with copper washer brass span of jaws 22

Pipe thread ISO 228-1, G

3

/

A × ¼ - 18 NPT

8

with copper washer brass span of jaws 22

7

/

- 20UNF × R

16

3

/

(ISO 7-1) brass, span of jaws 19 1 060-324066

8

1 017- 42296 6

5 017- 42056 6

1 060-333466

1 060-333566

1 060 -333666

Nipple

Damping coil

Armoured

damping coil

G ¼ A × G

3

/

A 060-333266

8

G ¼ A × ext. M10 x 1 with washer 060-333866

Pipe thread ISO 228-1, damping coil with G

connector and 1.5 m copper capillary tube.

3

/

8

1 060-104766

Standard washers are supplied.

Pipe thread ISO 228-1, damping coil with G

connector and 1 m copper capillary tube.

3

/

8

1 060-333366

Standard washers are supplied.

© Danfoss | DCS (jmn) | 2020.066 | AI226486438268en-001001

Page 7

Data sheet | Pressure switch and Thermostat, type CAS

Installation

Fig. 4

1. Range spindle

2. Range scale

3. Locking screw

Fig. 3

Installation

CAS pressure switches are fitted with a 3 mm

steel mounting plate. The units should not be

allowed to hang from the pressure connection.

Pressure connection

When fitting or removing pressure lines, the

spanner flats on the pressure connection should

be used to apply counter-torque.

Steam plant

To protect the pressure element from excessive

heat, the insertion of a water-filled loop is

recommended. The loop can, for example, be

made of 10 mm copper tube as shown in fig. 3.

Water systems

Water in the pressure element is not harmful,

but in case of frost a water-filled pressure

element may burst. To prevent this happening,

the pressure control can be allowed to operate

on an air cushion.

Media resistance

See table of materials in contact with the

medium, page 3. If seawater is involved, types

CAS 143, CAS 145, CAS 147, CAS 155 are

recommended.

Danfoss

60L641.13

Fig. 5

Pulsations

If the pressure medium is superimposed

with severe pulsations, which occur in automatic

sprinkler systems (fire protection), fuel systems

for diesel motors (priming lines), and hydraulic

systems (e.g. propeller systems), etc, types

case CAS 143, CAS 145, CAS 147 are

recommended.

The maximum permissible pulsation level

for these types is 120 bar.

Setting

When the pressure switche cover is removed,

and the locking screw (3) is lossened, the range

can be set with the spindle (1) while at the same

time the scale (2) is being read (fig. 4).

Electrical connection

CAS pressure switches are fitted with a PG 13.5

screwed cable entry that is suitable for cable

diameters from 5 – 13 mm.

Contact function is shown in fig. 5.

© Danfoss | DCS (jmn) | 2020.06

AI226486438268en-001001| 7

Page 8

CAS 133, CAS 136, CAS 143, CAS 145

60-648.10

30

50

Data sheet | Pressure switch and Thermostat, type CAS

Dimensions [mm]

and weights [kg]

Fig. 6 Fig. 7

CAS 137, CAS 139 CAS 147

Fig. 8

Fig. 9

19

CAS 155

G 1/4

40

22

Danfoss

Net weight:

CAS 133-139 approx. 1.0 kg

CAS 143-147 approx. 1.3 kg

CAS 155 approx. 1.5 kg

© Danfoss | DCS (jmn) | 2020.068 | AI226486438268en-001001

Page 9

Data sheet | Pressure switch and Thermostat, type CAS

THERMOSTAT

Technical data

Typ e CAS 178, CAS 180, CAS 181 CAS 1080

Ordering

Switch

Contact load

Ambient temperature -25 – 70 °C

Vibration resistance

Cable entry

Alternating current AC-14 / AC-15: 0.1 A, 220 V

Direct current DC-13: 12 W, 125 V

Microswitch with single pole

changeover (SPDT)

Vibration-stable in the range 2 – 30 Hz, amplitude 1.1 mm

and 30 – 100 Hz, 4 g.

Pg 13.5 for cable diameters

from 5 – 14 mm

Microswitch with single pole

changeover (2 x SPDT)

2 x g 13.5 for cable diameters

from 5 – 14 mm

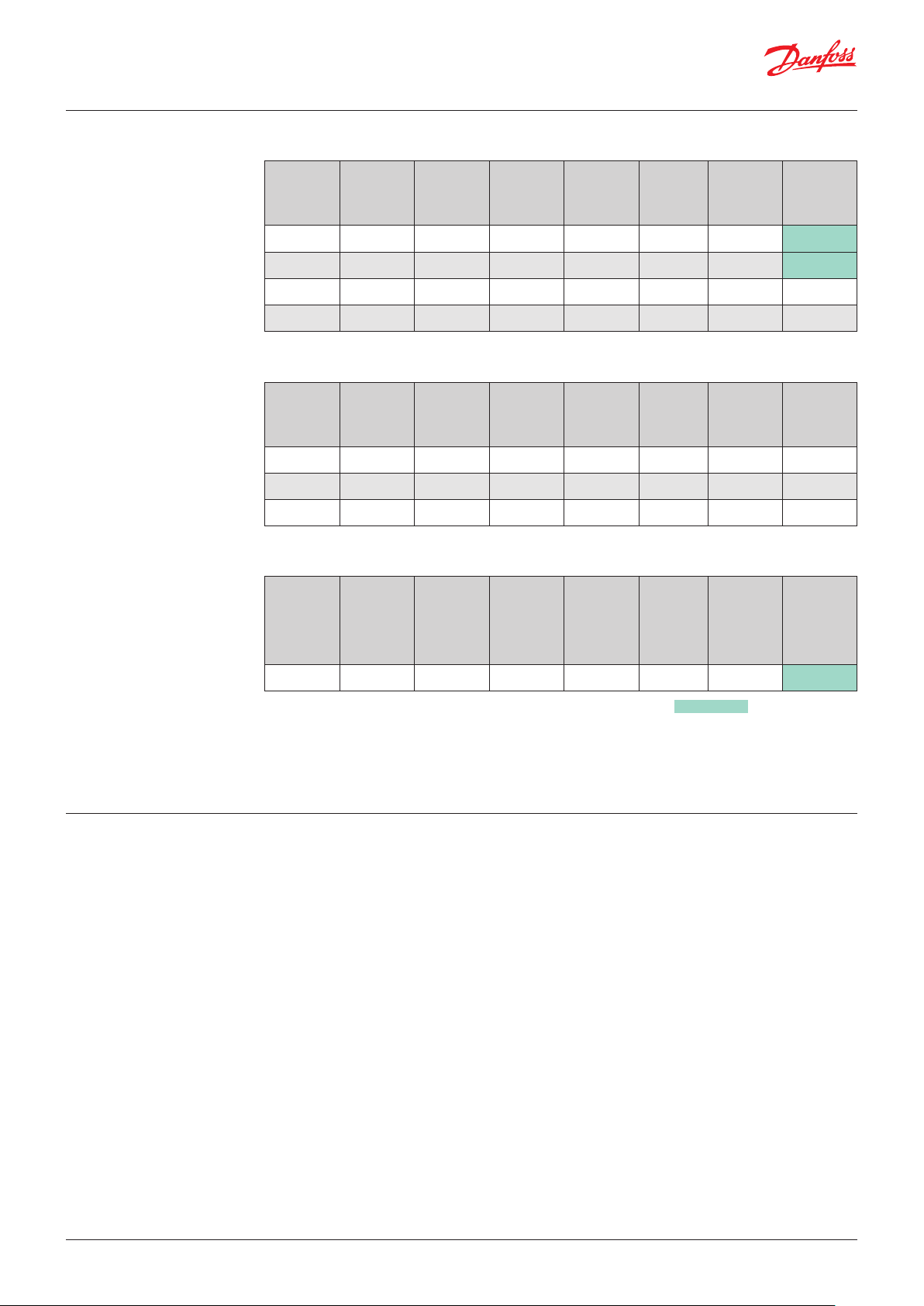

Thermostat, type CAS 178 – CAS 181

Typ e Setting

range

[°C]

CA S 178 20 – 80 2.0 130 65 75 110 160 2 06 0L315166

CAS 180 70 – 120 2.0 220 65 75 110 160 2 060L315366

CAS 181 60 – 150 2.0 250 65 75 110 160 2 060L315566

Mechanical

differential

adjustable / fixed

[°C]

Max. sensor

temperature

[°C]

Suitable

sensor length

(see also

“Accessories”)

[mm]

Capillary

tube

length

[m]

Code no.

2-step thermostat, type CAS 1080

Typ e

Factory setting

Step 1 [°C] Step 2 [°C]

CAS 1080 80 80 2.0 220 200 060L502066

Mechanical

differential

[°C]

Max.

temperature

[°C]

Insert sensor

length

[mm]

Code no.

Enclosure

IP67 acc. to EN 60529.

The thermostat housing is enamelled pressure

die cast aluminium (GD-AISI 12). The cover

is fastened by four screws which are anchored

to prevent loss.

The enclosure can be sealed with fuse wire.

Preferred version

Identification

The type designation and code no. of the unit is

stamped in the side of the housing.

© Danfoss | DCS (jmn) | 2020.06

AI226486438268en-001001| 9

Page 10

Data sheet | Pressure switch and Thermostat, type CAS

Accessories

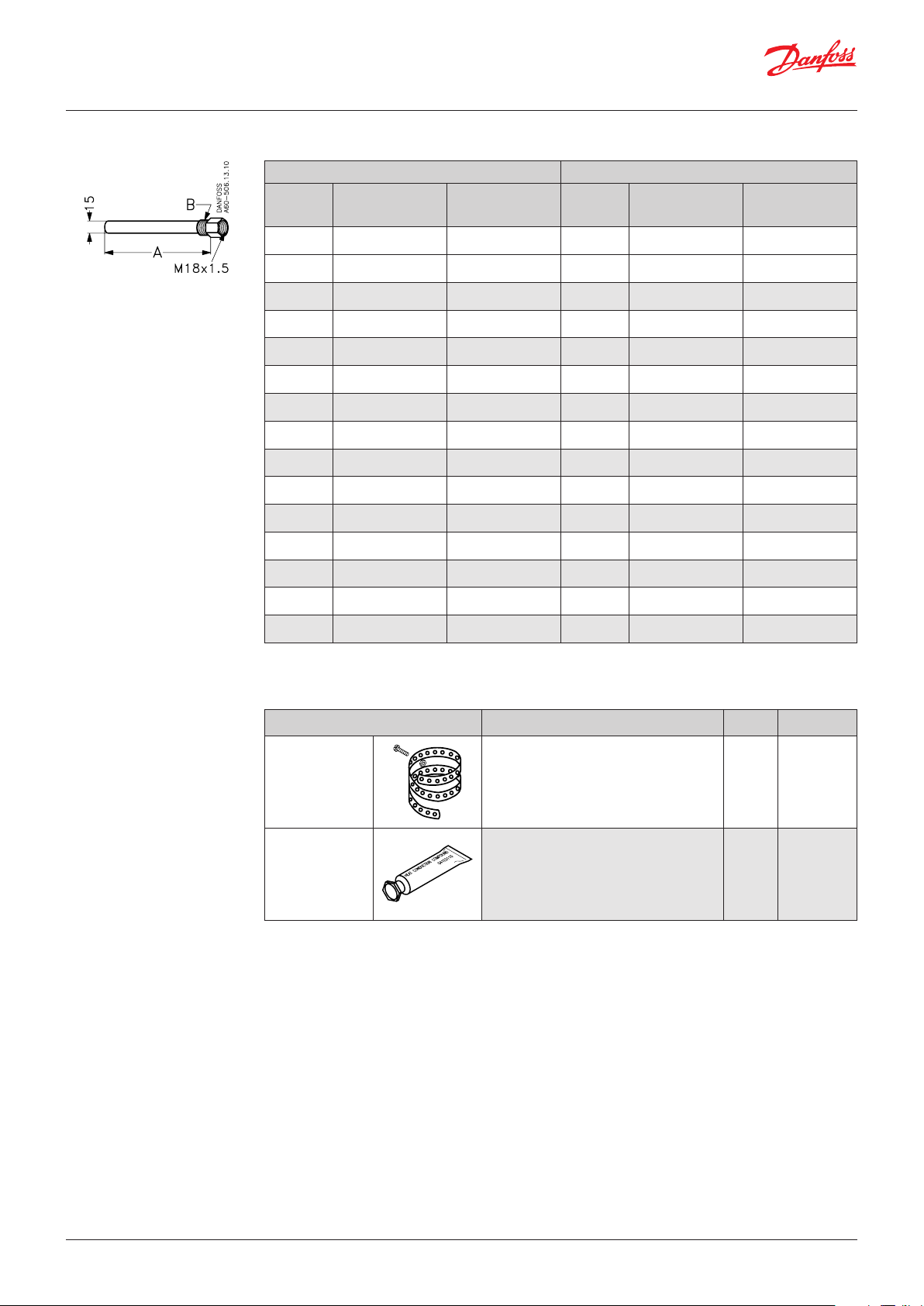

Sensor pockets for thermostats

Brass sensor pocket Steel 18/8 sensor pocket

A

[mm]

65 ½ NPT 060L326566 — — —

75 ½ NPT 060L326466 75 G ½ A 060L326766

75 G ½ A 060L326266 — — —

75 G ¾ A 060L326666 — — —

75 G ½ A (ISO 228/1) 060L328166 — — —

110 ½ NPT 060L328066 110 G ½ A 060L326866

110 G ½ A 060L327166 110 ½ NPT 060L327066

110 G ½ A (ISO 228/1) 060L340666 — — —

110 G ¾ A (ISO 228/1) 060L340366 — — —

160 G ½ A 060L326366 160 G ½ A 060L326966

200 G ½ A 060L320666 — — —

200 G ½ A (ISO 228/1) 060L340866 — — —

200 G ¾ A (ISO 228/1) 060L340266 — — —

Thread

B

Code no.

A

[mm]

Thread

B

Code no.

250 G ½ A 060L325466 — — —

330 G ½ A 060L325566 — — —

Note:

All sensor pockets are supplied without gland nut, gaskets and washes.

Other Accessories Description Qty./unit Code no.

Clamping band

Heat conductive

compound

(Tube with 4.5 cm3)

For CAS temperature controls with remote

sensor (L = 392 mm).

For CAS with sensor fitted in a sensor pocket.

For filling sensor pocket to improve heat

transfer between pocket and sensor.

Application range for compound:

-20 – 150 °C, momentarily up to 220 °C.

10 017- 420 466

1 0 41E0114

© Danfoss | DCS (jmn) | 2020.0610 | AI226486438268en-001001

Page 11

Data sheet | Pressure switch and Thermostat, type CAS

Installation Location of unit: CAS thermostats are designed

to withstand the shocks that occur, for example,

in ships on compressors and in large machine

installations. CAS thermostats are fitted with a

base of 3 mm steel plate for fixing to bulkheads,

etc.

Resistance to media

Material specifications for sensor pockets.

Sensor pocket brass

The tube is made of Ms 72 to DIN 17660, the

threaded portion of So Ms 58 Pb to DIN 17661.

Sensor pocket, stainless steel 18/8

Material designation 1.4305 to DIN 17440.

Permissible media pressure on the sensor pocket as a function of temperature

[bar]

Brass

Sensor position

As far as possible the sensor should be

positioned so that its longitudinal axis is at right

angles to the direction flow. The active part of

the sensor is ø13 mm × 47.5 mm.

The medium

The fastest reaction is obtained from a medium

having high specific heat and high thermal

conductivity. It is therefore advantageous to use

a medium that fulfils these conditions (provided

there is a choice). The flow velocity of the

medium is also of significance. (The optimum

flow velocity for liquids is about 0.3 m/s).

For permissible media pressure see fig. 10.

Stainless steel

1. Range spindle

2. Range scale

3. Locking screw

[°C]

Fig. 10

Setting

When the thermostat cover is removed, and the

locking screw (3) fig. 2 is loosened, the range can

be set with the spindle (1) while at the same time

the scale (2) is being read (fig.11).

Fig. 11

© Danfoss | DCS (jmn) | 2020.06

AI226486438268en-001001| 11

Page 12

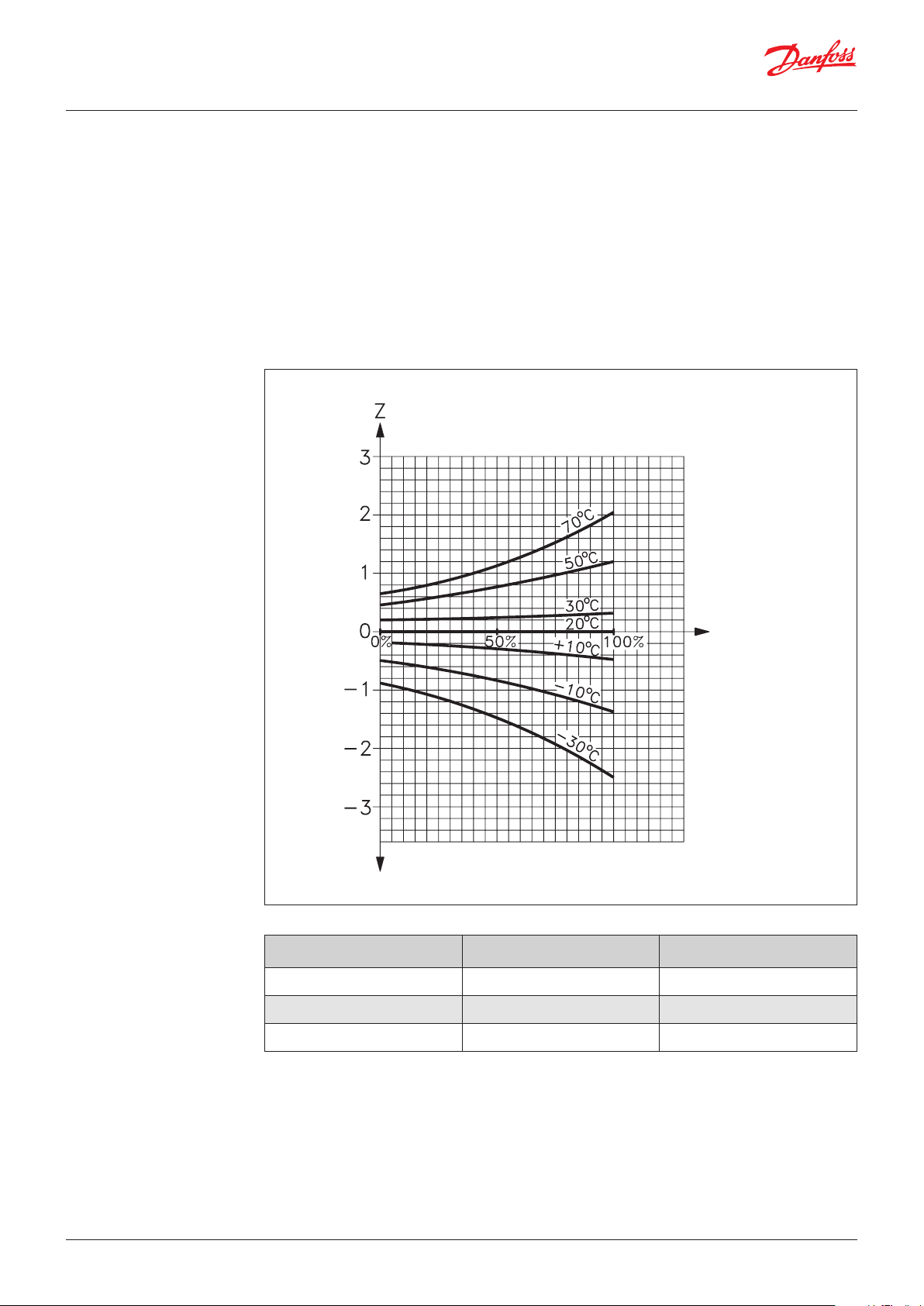

Factor for setting point

Data sheet | Pressure switch and Thermostat, type CAS

Installation

(continued)

Scale correction

The sensor on CAS thermostats contains an

adsorption charge. Therefore function is not

affected whether the sensor is placed warmer or

colder than the remaining part of the

thermostatic element (bellows and capillary

tube).

However, such a charge is to some extent

sensitive to changes in the temperature of

bellows and capillary tube. Under normal

conditions this is of no importance, but if the

thermostat is to be used in extreme ambient

temperatures there will be a scale deviation.

deviation

The deviation can be compensated for as

follows:

Scale correction = Z × a

Z can be found from fig. 12, while “a” is the

correction factor from the table below.

(See example, page 14).

Danfoss

60-413.12

Relative

scale

setting

in [%]

Fi g. 13

Typ e Regulation range

[°C]

CA S 178 20 – 80 2.5

CAS 180 70 – 120 2.4

CAS 181 60 – 150 3.7

Correction factor a

for thermostats

© Danfoss | DCS (jmn) | 2020.0612 | AI226486438268en-001001

Page 13

Danfoss

60L1049.11

Data sheet | Pressure switch and Thermostat, type CAS

Installation

(continued)

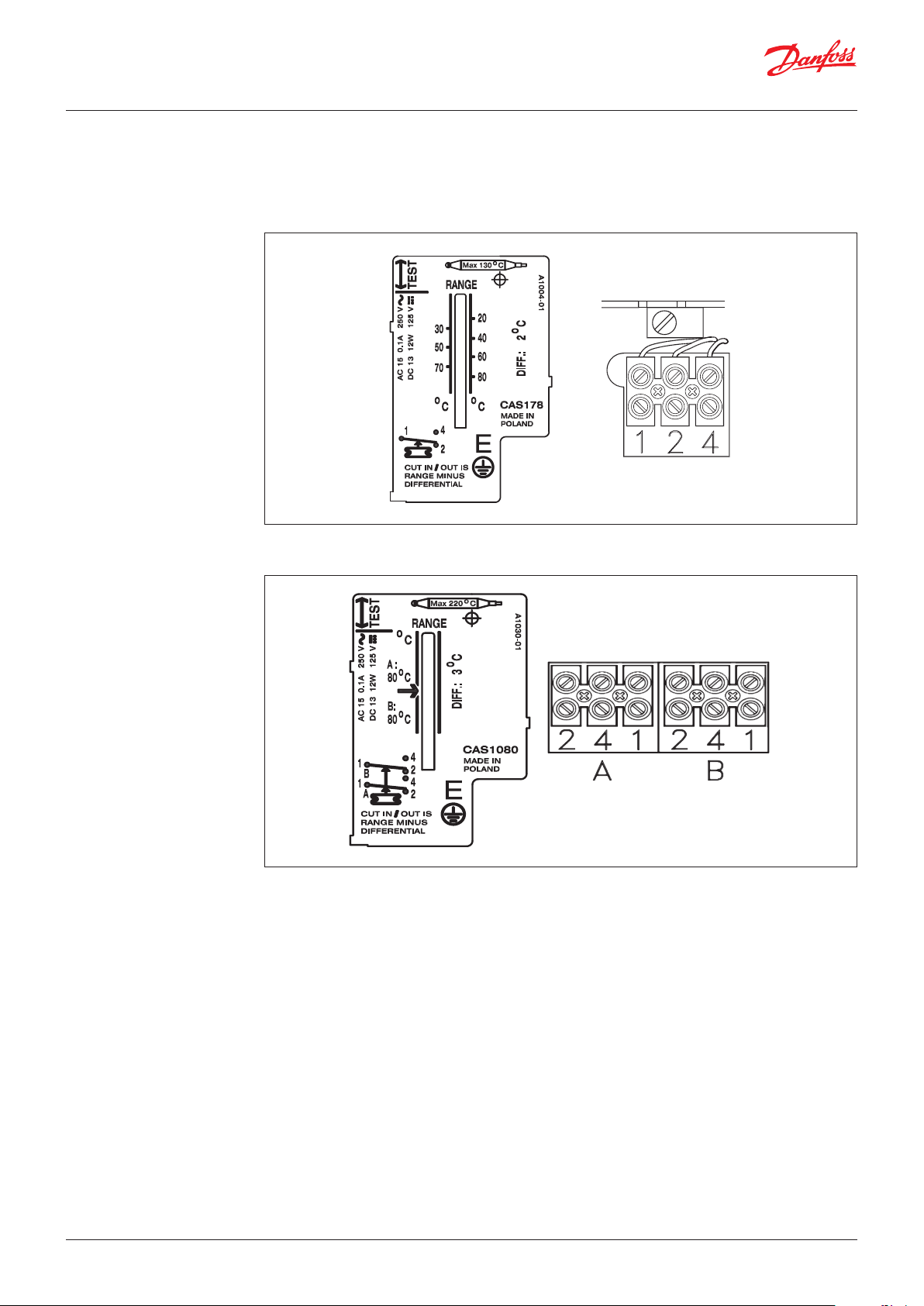

Electrical connection

CAS thermostats are fitted with a Pg 13.5

screwed cable entry suitable for cables

from 5 – 14 mm.

Fig. 14

2-step CAS thermostat, type CAS 1080

© Danfoss | DCS (jmn) | 2020.06

Fig. 15

AI226486438268en-001001| 13

Page 14

Data sheet | Pressure switch and Thermostat, type CAS

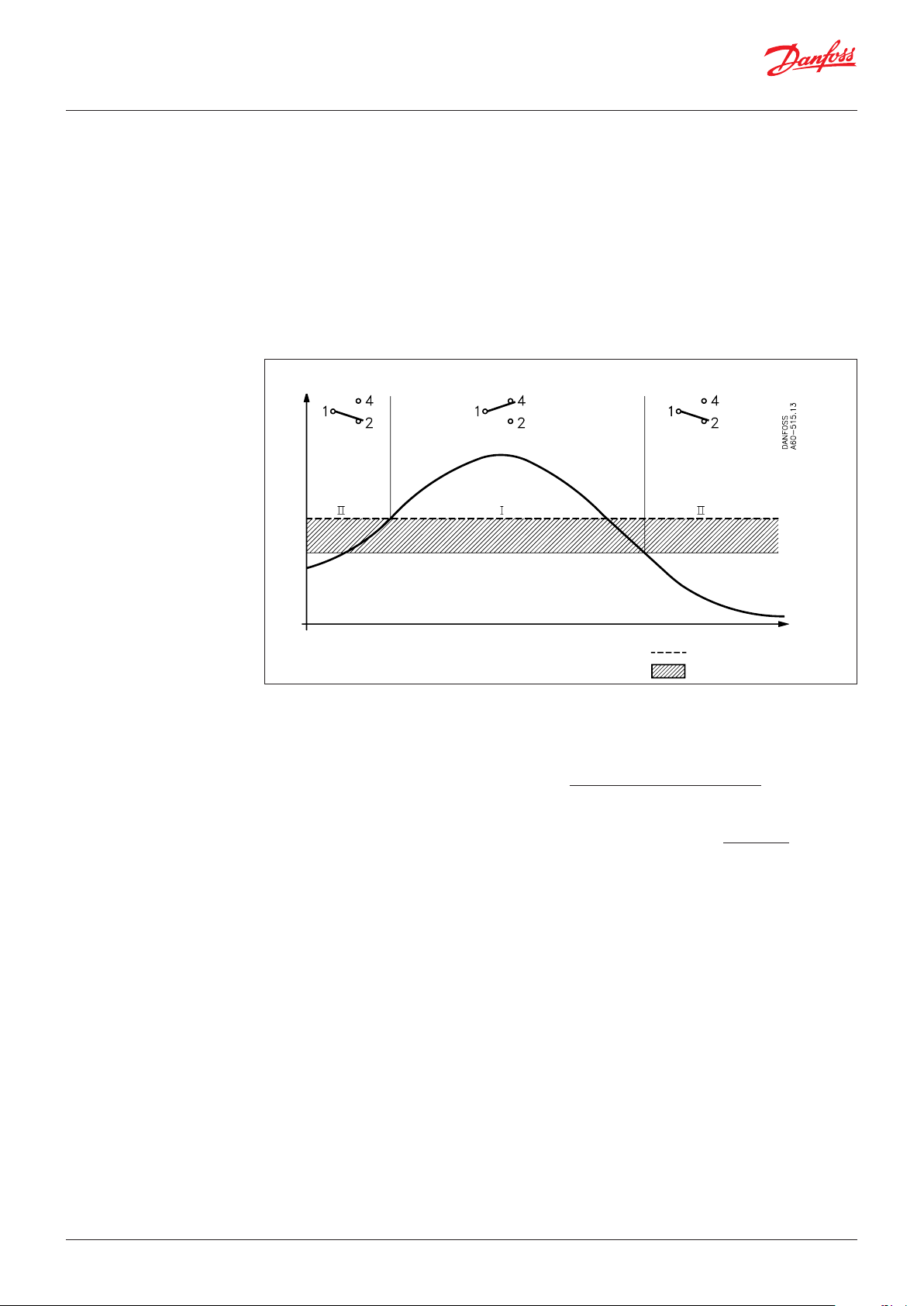

Function

Differentials

The mechanical differential is the differential

determined by the design of the thermostat. The

thermal differential (operating differential) is the

differential the system operates on.

The thermal differential is always greater than

the mechanical differential and depends on

three factors:

1) Medium flow velocity

2) Temperature change rate of the medium

3) Heat transmission to the sensor

[bar]

Thermostat function

Contacts 1-4 make while contacts 1-2 break

when the temperature rises above the scale

setting.

The contacts changeover to their initial position

when the temperature falls to the scale setting

minus the differential. See fig. 16.

I. Alarm for rising temperature given

at range setting value.

II. Alarm for falling temperature given

at range setting value minus the differential.

Fig. 16

Example 1

Diesel engine with cooling water temperature of

85 °C (normal). An alarm must be triggered if the

cooling water temperature exceeds 95 °C.

Choose a CAS thermostat 180 (range 70 – 120 °C).

Main spindle setting: 95 °C.

The required alarm function is obtained by

connecting to thermostat terminals 1-4.

Example 2

Find the necessary scale correction for a CAS 180.

Set 95 °C at 50 °C ambient temperature.

[s]

Scale setting

Mechanical differential

The relative scale setting Z can be calculated

from the following formula:

Setting value - min. scale value

max. scale value - min. scale value

Relative scale setting: 95-70 × 100

120 -70

× 100 = [%]

= 50%

Factor for scale deviation Z fig. 12, Z ≈ 0.7

Correction factor “a=2.4”, see table page 12.

Scale correction = Z × a = 0.7 × 2.4 = 1.7 °C

CAS must be set at 95 + 1.7 = 96.7 °C

© Danfoss | DCS (jmn) | 2020.0614 | AI226486438268en-001001

Page 15

Data sheet | Pressure switch and Thermostat, type CAS

Time [s]

80 °C

Diff. 3 °C

A1

A4

A2

A1

A4

A2

B1

B4

B2

B1

B4

B2

A1

A4

A2

B1

B4

B2

Danfoss

60-1415.11

II III

Function

(continued)

CAS 1080 thermostats have fixed factory

settings.

The thermostats with factory setting

at 80 °C of step 1 and step 2 is used for special

application, where double warning – like cranck

case fire – is requested.

The contacts automatically reset when the

temperature decreases in accordance with the

differential.

Differentials

The mechanical differential is the differential

determined by the design of the thermostat.

The thermal differential (operating differential) is

the differential the contact system operates on.

The thermal differential is always greater than

the mechanical differential and depends on

three factors:

1) Medium flow velocity

2) Temperature change rate of the medium and

3) Heat transmission to the sensor

[°C]

Thermostat function

Contacts 1–4 make while contacts 1–2 break

when the temperature rises above the scale

setting.

The contacts changeover to their initial position

when the temperature falls to the scale setting

minus the differential. See fig. 17.

The contacts marked A correspond to step 1.

The contacts marked B correspond to step 2.

I. Alarm for rising temperature given

at range setting value.

II. Alarm for falling temperature given

at range setting value minus the differential

© Danfoss | DCS (jmn) | 2020.06

[s]

Fi g. 17

Mechanical differential

AI226486438268en-001001| 15

Page 16

Dimensions [mm]

and weights [kg]

CAS with remote sensor and 2 m armoured capillary tube

Fig. 18

2-step thermostat, type CAS 1080

Fig. 19

Net weight: approx. 1.4 kg

A: 200 or 80 mm

B: G ¾ A

Net weight: approx. 1.4 kg

© Danfoss | DCS (jmn) | 2020.06 AI226486438268en-001001 | 16

Loading...

Loading...