Page 1

Data Sheet

Micro Plate Heat Exchanger

Type C39L-EZ

A new compact and high-ecient evaporator

The C39L-EZ is an evaporator designed for use

in high-eciency mini chillers with capacities

up to 40kW, optimized for R410A and R32

respectively.

The Z-pattern channel plate technology pushes

the performance of heat exchangers to the

limits by fully mixing the liquid and gas

refrigerant through a “zigzag” ow, which

increases the heat transfer coecient. At the

same time, inheriting from the dimple plate

pattern of the previous generation of MPHE,

C39L-EZ reduces the water side pressure drop

and the amount of material used. C39L-EZ also

has outstanding performance working as

condenser.

To meet demands for higher seasonal

eciency, the C39L-EZ is designed to work

eciently and increase comfort in modern life

without increasing the carbon footprint.

Helping chillers perform more eciently, it

reduces both energy costs and environmental

impact. The low hold-up volume reduces the

system refrigerant charge and oers valuable

savings.

AI379832793536en-000101

Page 2

Item

Material

Specication

Cover plates

Stainless steel

AISI 304L

Plates

Stainless steel

AISI 316L

Connections

Stainless steel

AISI 304L

Brazing

ller

Pure copper

T2

Micro Plate Heat Exchanger, type C39L-EZ

Features

• Improved heat transfer - equals higher eciency chillers

• Reduced water side pressure drop – equals higher eciency chillers

• Minimal hold-up volume - equals less refrigerant charge and reduced CO2 footprint

• Smaller footprint - enables more compact chillers for easy installation

• Less material utilization – less weight and environment friendly

Portfolio overview

C39L-EZ: Evaporator optimized for R410A, R452B and R454B

C39L-EZ-J: Evaporator optimized for R410A, R452B and R454B

C39L-EZ-F: Evaporator optimized for R32 and R454

Product specication

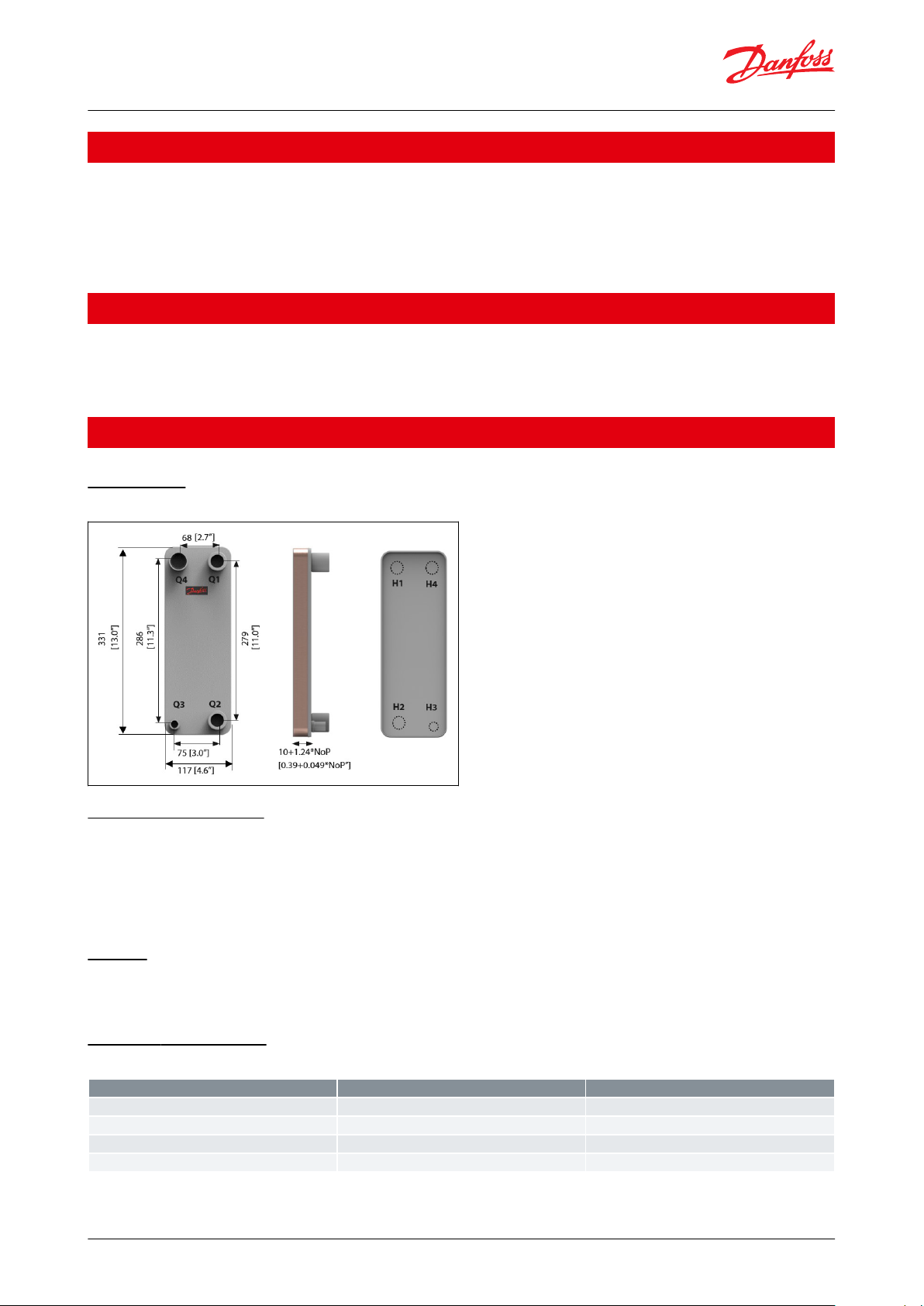

Dimensions

Figure 1: Dimensions

Operating conditions

Max number of plates: 110

Pressure and temperature data:

Min. working temperature: -196 °C (-320 °F)

Max. working temperature: 200 °C (390 °F)

Max. working pressure: 49 bar (710psi) for primary side and 25 bar (363psi) for secondary side

Weight

1.377 + 0.089 x N [kg] / 3.04 + 0.20 x N [lb]

N: Number of Plate

Material specication

Table 1: Standard specication

© Danfoss | Climate Solutions | 2021.06 AI379832793536en-000101 | 2

Page 3

Q4

Q1

H1 H4

H3

H2

Q2

Q3

Micro Plate Heat Exchanger, type C39L-EZ

Other material combinations are available on request. Please contact your Danfoss sales representative for more

information.

Conguration ow

Figure 2: Conguration ow

Parallel ow:

Q1 - Q2 [H1 - H2]: brine/secondary side

Q3 - Q4 [H3 - H4]: primary side

Hold up volume

Q1 - Q2 (l): 0.038 x N/2

Q3 - Q4 (l): 0.030 x (N-2)/2

N: Number of Plate

© Danfoss | Climate Solutions | 2021.06 AI379832793536en-000101 | 3

Page 4

Circuits

Connection type options

Connection size option (in.)

Q1 - Q2 (water-brine side)

BSPP G male

3

⁄8, 1⁄2, 5⁄8, 3⁄4, 7⁄8, 1, 11⁄4

BSPP G female

1

⁄4, 3⁄8, 1⁄2, 5⁄8. 7⁄8, 1

BSPT R male

3

⁄8, 1⁄2, 5⁄8, 3⁄4, 7⁄8, 1, 11⁄4

BSPP R female

1

⁄4, 3⁄8, 1⁄2, 5⁄8. 7⁄8, 1

NPT

3

⁄8, 1⁄2, 5⁄8, 3⁄4, 7⁄8, 1, 11⁄4

Victaulic

3

⁄4, 1, 11⁄4

Q3 (Refrigerant inlet)

Soldering

1

⁄4, 3⁄8, 1⁄2

Q4 (Refrigerant inlet)

Soldering

3

⁄8, 1⁄2, 5⁄8, 3⁄4, 7⁄8, ⁄, 11⁄8

M6 x 20

220 mm

(8.7”)

Danfoss

118U163

Stud bolt position

Bolt sizes

220 mm, middle

M6x20

Micro Plate Heat Exchanger, type C39L-EZ

Ordering

Global or local standard code numbers can be accessed via Store.Danfoss.com on local subsites, with full set of

technical data as well as relevant assets such as documentation and drawings.

Conguring and calculating products

C39L-EZ can be easily customized based on the application needs; model size can be evaluated using Hexact

software. For details, product conguration and code creation please contact your Danfoss Sales representative.

Mechanical connections

Table 2: Mechanical connections

Accessories and spare parts

Figure 3: Stud bolts

MPHE products are not serviceable, i.e. cannot be taken apart and repaired, and there are no spare parts program.As

for accessories, stud bolts, feet and hooks on front and/or back cover plates for mounting support and handling are

available upon request.

Table 3: Stud bolts:

Contact your Danfoss sales representative for further information.

© Danfoss | Climate Solutions | 2021.06 AI379832793536en-000101 | 4

Page 5

Micro Plate Heat Exchanger, type C39L-EZ

Certicates, declarations, and approvals

The list contains all certicates, declarations, and approvals for this product type. Individual code number may have

some or all of these approvals, and certain local approvals may not appear on the list.

Some approvals may change over time. You can check the most current status at danfoss.com or contact your local

Danfoss representative if you have any questions.

Third party approvals

All MPHE and BPHE are certied to European Pressure Equipment Directive (PED) and are approved by Underwriters

Laboratories (UL).

Other certications are available upon request: Kraia, EAC, UA, AS; for others and more details please contact your

local Danfoss representative.

© Danfoss | Climate Solutions | 2021.06 AI379832793536en-000101 | 5

Page 6

Online support

Danfoss oers a wide range of support along with our products, including digital product information, software,

mobile apps, and expert guidance. See the possibilities below.

The Danfoss Product Store

The Danfoss Product Store is your one-stop shop for everything product related—no matter where

you are in the world or what area of the cooling industry you work in. Get quick access to essential

information like product specs, code numbers, technical documentation, certications, accessories,

and more.

Start browsing at store.danfoss.com.

Find technical documentation

Find the technical documentation you need to get your project up and running. Get direct access to

our ocial collection of data sheets, certicates and declarations, manuals and guides, 3D models

and drawings, case stories, brochures, and much more.

Start searching now at www.danfoss.com/en/service-and-support/documentation.

Danfoss Learning

Danfoss Learning is a free online learning platform. It features courses and materials specically

designed to help engineers, installers, service technicians, and wholesalers better understand the

products, applications, industry topics, and trends that will help you do your job better.

Create your Danfoss Learning account for free at www.danfoss.com/en/service-and-support/learning.

Get local information and support

Local Danfoss websites are the main sources for help and information about our company and

products. Find product availability, get the latest regional news, or connect with a nearby expert—all

in your own language.

Find your local Danfoss website here: www.danfoss.com/en/choose-region.

Coolselector®2 - nd the best components for you HVAC/R system

Coolselector®2 makes it easy for engineers, consultants, and designers to nd and order the best

components for refrigeration and air conditioning systems. Run calculations based on your operating

conditions and then choose the best setup for your system design.

Download Coolselector®2 for free at coolselector.danfoss.com.

Hexact for heat exchangers

Hexact for heat exchangers helps you identify the best heat exchanger for your chiller, heat pump, or

other application based on operating conditions. Works for innovative MPHE and traditional BPHE

brazed heat exchangers.

Download Hexact for free at hexact.danfoss.com

Any information, including, but not limited to information on selection of product, its application or use, product design, weight, dimensions, capacity or any other

technical data in product manuals, catalogues descriptions, advertisements, etc. and whether made available in writing, orally, electronically, online or via download,

shall be considered informative, and is only binding if and to the extent, explicit reference is made in a quotation or order conrmation. Danfoss cannot accept any

responsibility for possible errors in catalogues, brochures, videos and other material. Danfoss reserves the right to alter its products without notice. This also applies to

products ordered but not delivered provided that such alterations can be made without changes to form, t or function of the product. All trademarks in this material

are property of Danfoss A/S or Danfoss group companies. Danfoss and the Danfoss logo are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | Climate Solutions | 2021.06 AI379832793536en-000101 | 6

Loading...

Loading...