Page 1

Technical Information

BDU Series

Hydrostatic Transmissions

www.danfoss.com

Page 2

Technical Information

BDU Series Hydrostatic Transmissions

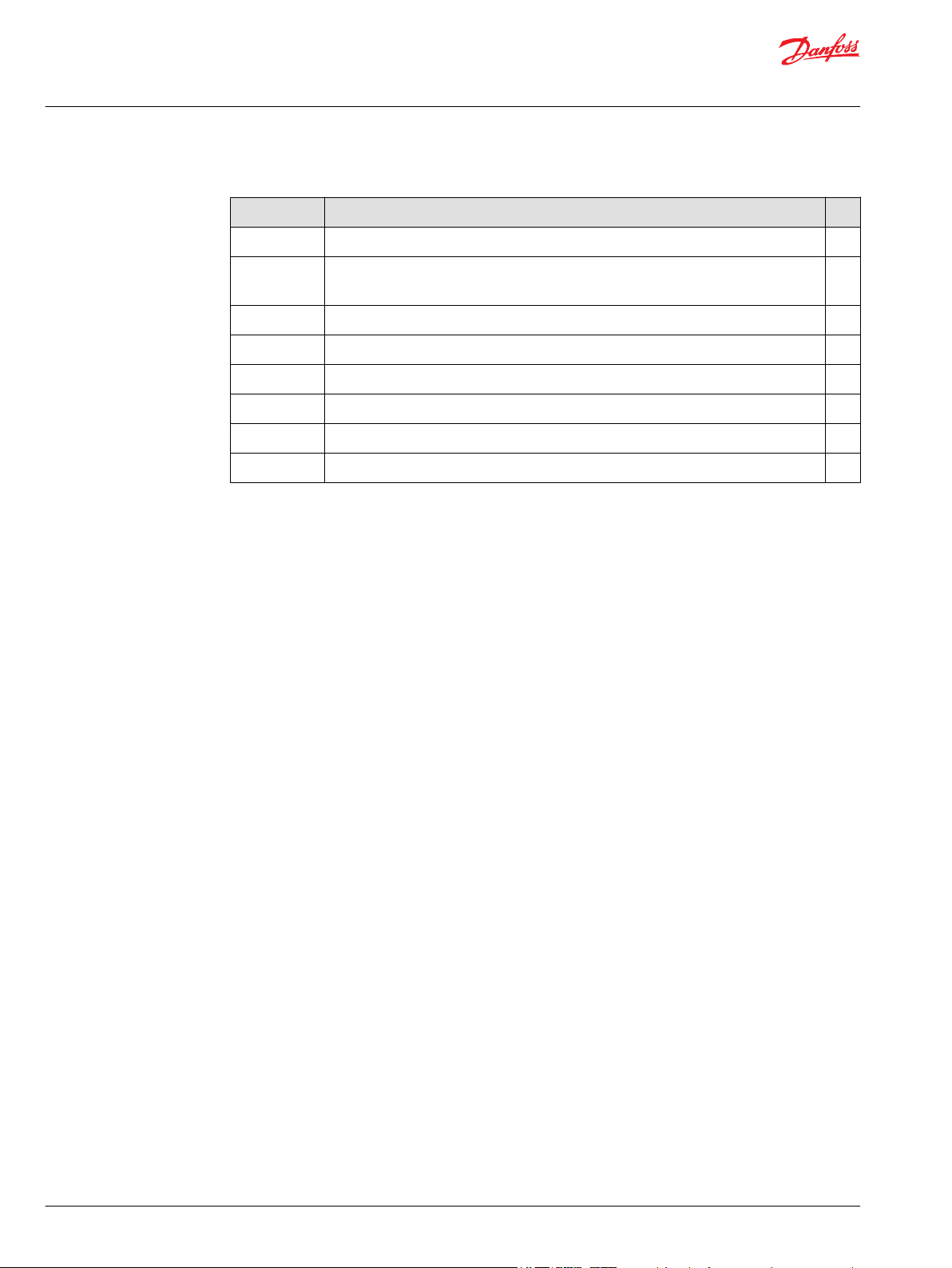

Revision history Table of revisions

Date Changed Rev

November 2021 Removed contents of BDP, and aligned revision number along with DAM Hub. 0207

November 2020 Minor update in Hydraulic Fluid, and changed document number from 'BC00000025' and

'520L0935' to 'BC152886484098'

December 2018 Fixed Model Code "H" 0103

May 2017 Fixed typo 0102

June 2016 Convertd to DITA-CMS 0101

Mar 2010 Correction - Drawing AC

Jan 2009 Correction - Text AB

Jan 2006 First edition AA

0104

2 | © Danfoss | November 2021 BC152886484098en-000207

Page 3

Technical Information

BDU Series Hydrostatic Transmissions

Contents

General Description

BDU Series Family.............................................................................................................................................................................5

Features and Benefits......................................................................................................................................................................5

Design...................................................................................................................................................................................................6

BDU-06/10S........................................................................................................................................................................................ 8

Pictorial Diagram.........................................................................................................................................................................8

System Schematic.......................................................................................................................................................................8

BDU-10L/21L/21H.............................................................................................................................................................................9

Pictorial Diagram.........................................................................................................................................................................9

System Schematic: BDU-21L................................................................................................................................................... 9

System Schematic: BDU-21H................................................................................................................................................10

Technical Specifications

Features and Options................................................................................................................................................................... 11

Operating Parameters..................................................................................................................................................................12

Fluid Specifications....................................................................................................................................................................... 12

Efficiency........................................................................................................................................................................................... 13

BDU-06S....................................................................................................................................................................................... 13

BDU-10S....................................................................................................................................................................................... 13

BDU-10L....................................................................................................................................................................................... 13

BDU-21L/21H..............................................................................................................................................................................14

Operating Parameters

Overview........................................................................................................................................................................................... 15

Input Speed......................................................................................................................................................................................15

System Pressure..............................................................................................................................................................................15

Charge Pressure..............................................................................................................................................................................15

Charge Inlet Pressure....................................................................................................................................................................15

Case Pressure...................................................................................................................................................................................16

Hydraulic Fluids.............................................................................................................................................................................. 16

Temperature and Viscosity.........................................................................................................................................................16

System Design Parameters

Fluid and Filtration........................................................................................................................................................................ 17

Reservoir............................................................................................................................................................................................17

Control Shaft Force........................................................................................................................................................................17

Independent Braking System....................................................................................................................................................17

Features and Options

Shaft Load.........................................................................................................................................................................................18

Shaft Options...................................................................................................................................................................................18

Shaft Options : BDU-06S/10S/10L............................................................................................................................................ 19

Shaft Options : BDU-21L/21H.................................................................................................................................................... 20

Bypass Valve.....................................................................................................................................................................................21

High Pressure Relief Valve (hprv) and Charge Check (Overpressure Protection)...................................................21

Charge Check Valve with Orifice.............................................................................................................................................. 23

Charge Check with Orifice.......................................................................................................................................................... 24

Optional Integrated Reservoir...................................................................................................................................................25

Filter....................................................................................................................................................................................................25

Fan.......................................................................................................................................................................................................26

Component Selection

Maximum System Pressure........................................................................................................................................................ 27

Input Power......................................................................................................................................................................................28

Unit Life..............................................................................................................................................................................................29

Model Code

BDU : Model Code (A - B - C - D - E)..........................................................................................................................................31

BDU : Model Code (F - G).............................................................................................................................................................32

BDU : Model Code (H - J - K)........................................................................................................................................................33

Recommended Installation and Maintenance

©

Danfoss | November 2021 BC152886484098en-000207 | 3

Page 4

Technical Information

BDU Series Hydrostatic Transmissions

Contents

Housing Installation......................................................................................................................................................................34

Shaft Installation.............................................................................................................................................................................34

Start Up Procedure........................................................................................................................................................................ 34

Operation..........................................................................................................................................................................................34

Maintenance....................................................................................................................................................................................34

Installation Drawings

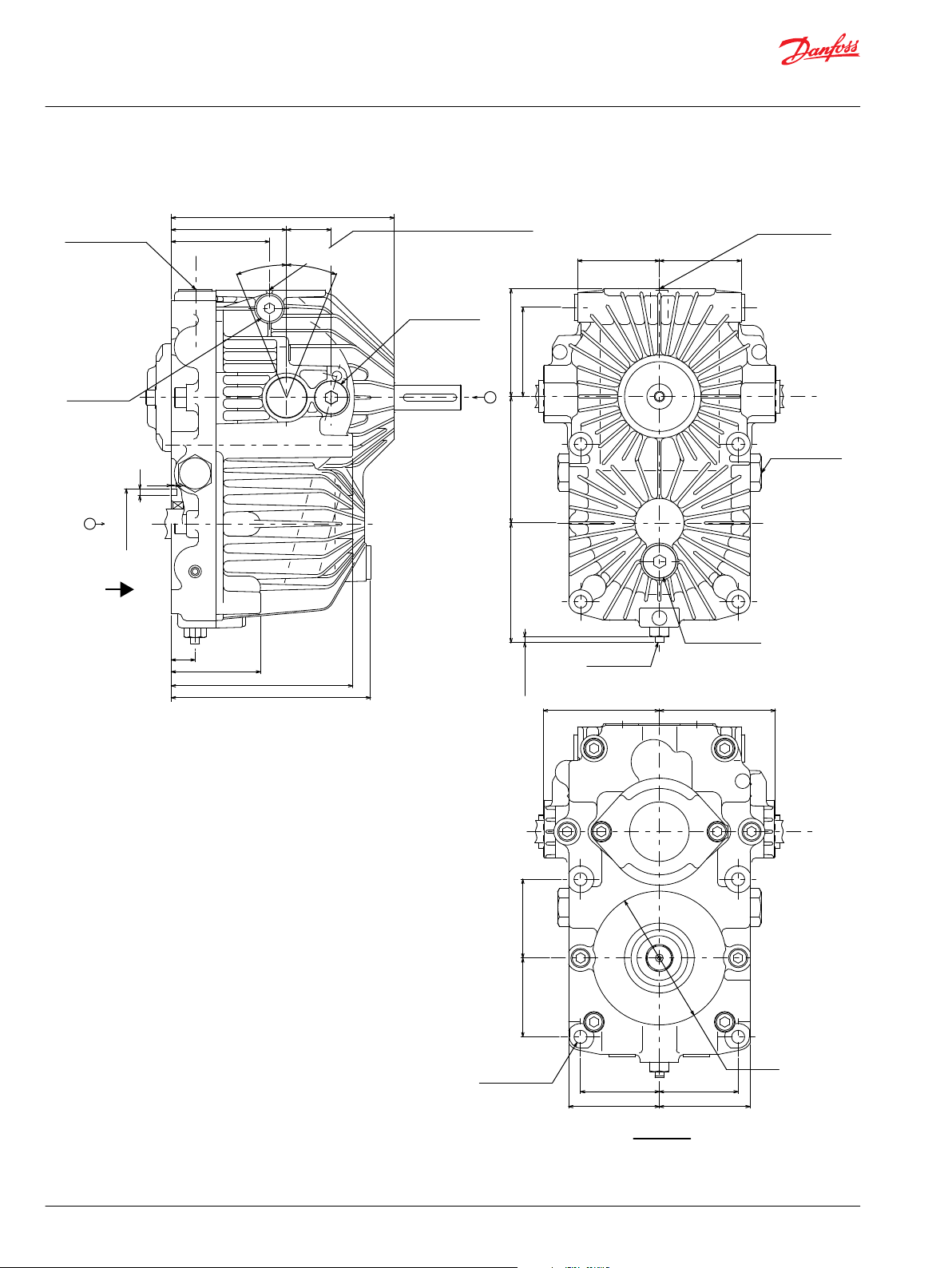

BDU-06S : Ports and Dimensions..............................................................................................................................................35

BDU-06S : Control Arm Location.............................................................................................................................................. 36

BDU-06S : Motor Shaft..................................................................................................................................................................36

BDU-10S/10L : Ports and Dimensions.....................................................................................................................................37

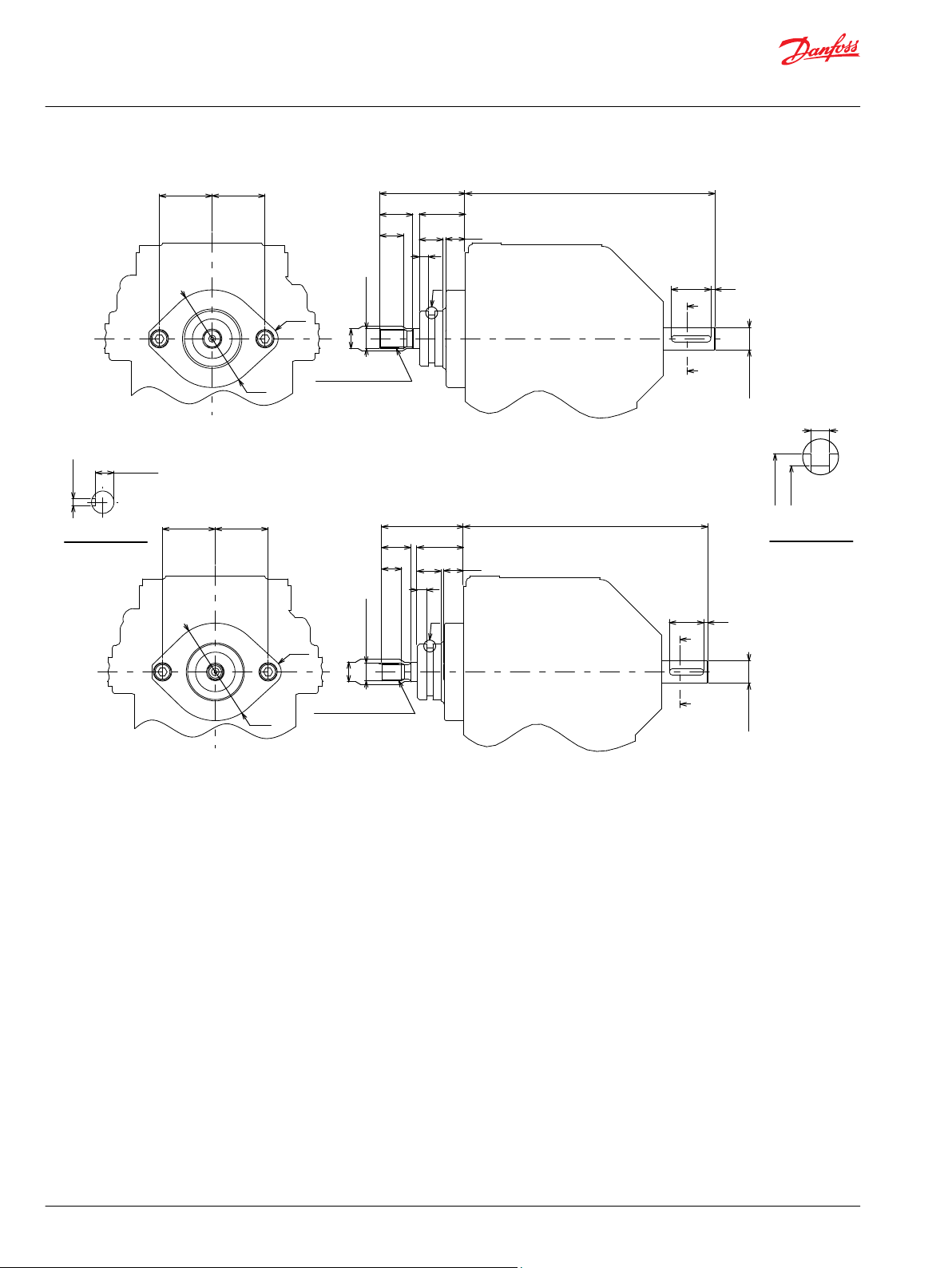

BDU-10S/10L : Control Arm Location..................................................................................................................................... 38

BDU-10S/10L : Motor Shaft.........................................................................................................................................................39

BDU-10S : Shaft Configuration..................................................................................................................................................40

BDU-10L : Shaft Configuration and Charge Pumps Displacement..............................................................................41

BDU-21L/21H : Ports and Dimensions....................................................................................................................................42

BDU-21L/21H : Control Arm Location.....................................................................................................................................43

BDU-21L/21H : Motor Shaft........................................................................................................................................................44

BDU-21L/21H : Shaft Configuration and Charge Pump Displacement...................................................................... 45

Optional Fan.................................................................................................................................................................................... 47

4 | © Danfoss | November 2021 BC152886484098en-000207

Page 5

Technical Information

BDU Series Hydrostatic Transmissions

General Description

BDU Series Family

The BDU transmission is a “ Z” style transmission with a variable displacement pump and a fixed

displacement motor. The variable displacement pump features a cradle swashplate with a direct

proportional displacement control. Reversing the direction of tilt of the swashplate reverses the flow of

oil from the pump and thus reverses the direction of the motor output rotation. The fixed displacement

motor uses a fixed swashplate. The pump and motor are of the axial piston design and utilize

sphericalnosed pistons which are held against a thrust bearing by internal compression springs. The fluid

supply for the BDU-10L/21L/21H transmission is contained in an external reservoir and passes through

an external filter prior to entering the transmission and feeding the fixed displacement gerotor charge

pump. Excess fluid in the charge circuit is discharged over the charge relief valve back to the charge

pump inlet. Constant flow across a small fixed orifice connecting the charge circuit to the transmission

housing supplements the cooling flow.

The BDU-06S/10S transmission has a self-contained fluid supply and an integral filter. The fluid is forced

through the filter by positive “head” on the fluid in the housing reservoir with an assist by the negative

pressure created in the pump pistons as they create a vacuum. Charge check valves in the center section

are used to control the makeup flow of fluid to the low pressure side of the loop. A spool type bypass

valve is utilized in the transmission to permit moving the vehicle over short distances at low speeds

without starting the engine.

Features and Benefits

A complete transmission family to meet the needs of small vehicle application.

•

3 Transmission Frame Sizes: 6, 10, 21

•

PTO Capability on “Z” Style Transmission

•

Cost Effective, Compact, Lightweight Design

•

Low Noise

•

High Efficiency

•

Worldwide Sales and Service

•

©

Danfoss | November 2021 BC152886484098en-000207 | 5

Page 6

1

4

2

P400202

14

15

16

3

11

12

13

5

6

7

8

9

10

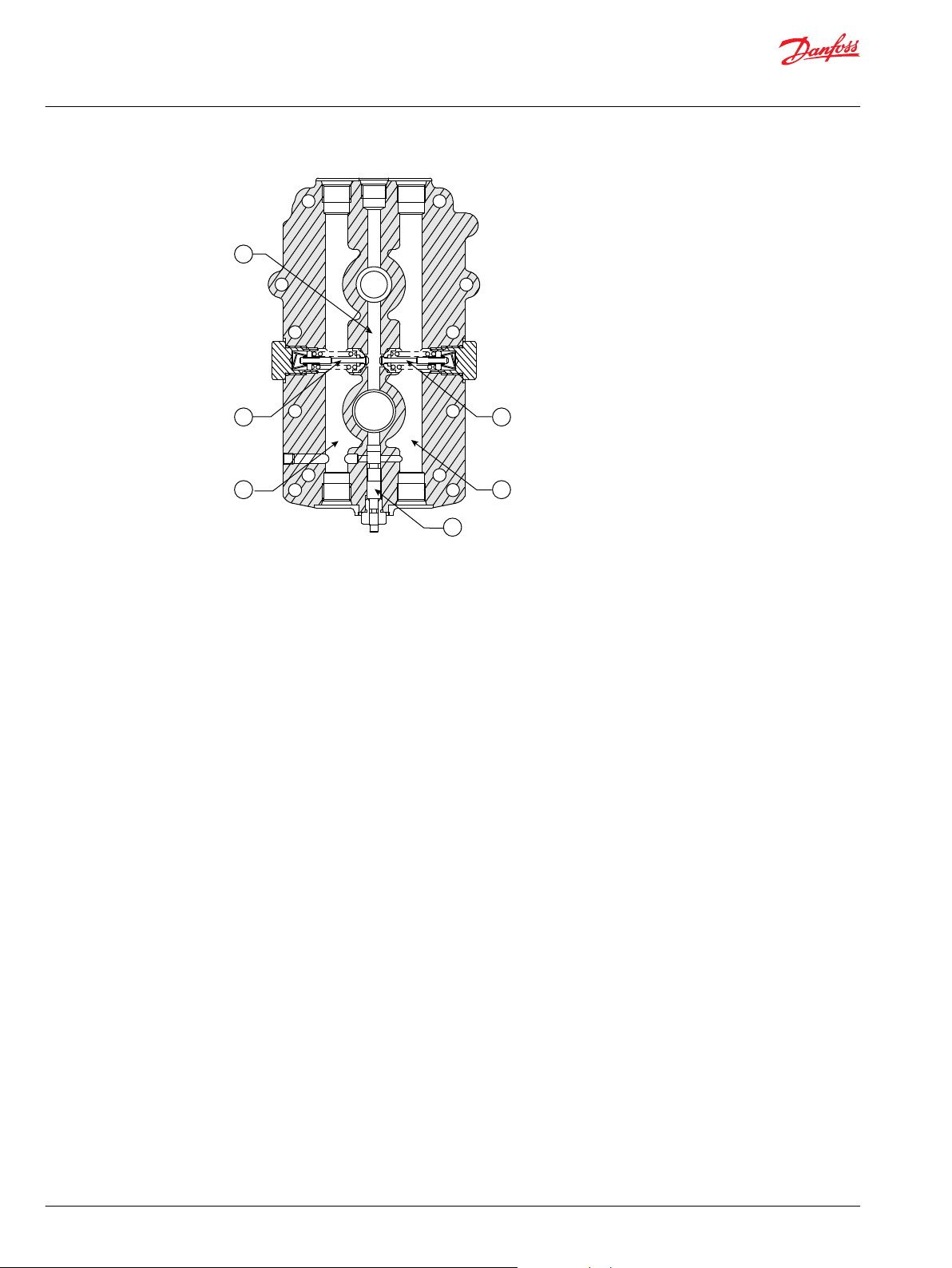

Technical Information

BDU Series Hydrostatic Transmissions

General Description

Design

Cross-Section (BDU-10S)

1. Tank 7. Spool type bypass valve 13. Shaft seal

2. Built-in filter 8. Cylinder block 14. Input shaft

3. Spring 9. Piston 15. Cooling fan

4. Center section 10. Thrust bearing 16. Cradle swash plate

5. Output shaft 11. Housing

6. Spring 12. Ball bearing

6 | © Danfoss | November 2021 BC152886484098en-000207

Page 7

P400203

18

22

3

4

5

11

10

9

8

7

6

20

19

1

17

16

15

14

1312

Technical Information

BDU Series Hydrostatic Transmissions

General Description

1. Suction Circuit 8. Charge Relief 15. Ball Bearing

2. Working Loop 9. Charge Circuit 16. Shaft Seal

3. Charge Check Valve 10. Output Shaft 17. Input Shaft

4. Spool Type Bypass Valve 11. Center Section 18. Cradle Swash Plate

5. Center Section 12. Cylinder Block 19. Piston

6. Suction Port 13. Thrust Bearing 20. Spring

7. Charge Pump 14. Housing

©

Danfoss | November 2021 BC152886484098en-000207 | 7

Page 8

Bypass

Valve

Cylinder

Block

Assembly

Input

Shaft

Variable

Swashplate

Variable

Displacement

Pump

BDU

Housing

Reservor

Built-In

Filter

(BDU-10S)

Check Valve

Check Valve

Cylinder Block

Assembly

Output

Shaft

Displacement

Motor

P400204

Fixed

Swashplate

Fixed

Working Loop

(high pressure)

Working Loop

(low pressure)

Suction Line

Case Drain Fluid

Control Shaft “b”

Control Shaft “a”

Hydraulic Circuit

ø0.7 ø0.8

P400205

Ø0.7 Ø0.8

1

1

2

2

3

3

Technical Information

BDU Series Hydrostatic Transmissions

General Description

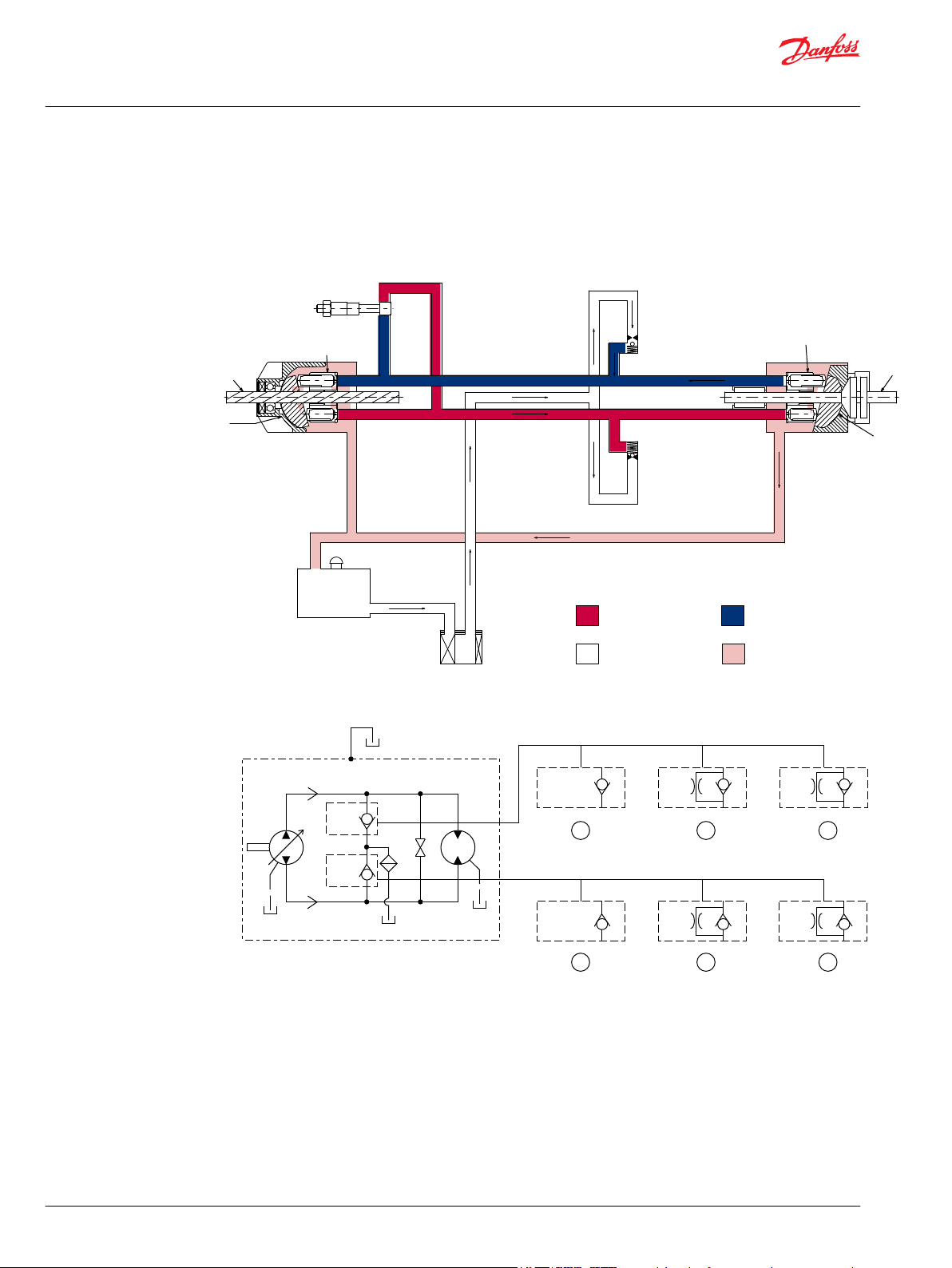

BDU-06/10S

Pictorial Diagram

BDU-06S, BDU-10S

System Schematic

1. Ball Check Valve, Option Code. : BB

2. Check Valve with Ø0.7 Orifice, Option Code : 07

3. Check Valve with Ø0.8 Orifice, Option Code : 08

8 | © Danfoss | November 2021 BC152886484098en-000207

Page 9

Bypass

Valve

Cylinder

Block

Assembly

Input

Shaft

Variable

Swashplate

Variable

Displacement

Pump

Reservor

Filter

Check Valve

Check Valve

Cylinder Block

Assembly

Output

Shaft

Fixed

Swashplate

Cooling

Orifice

Charge

Pump

Charge

Relief

Valve

Displacement

Motor

Fixed

P400206

Working Loop

(high pressure)

Working Loop

(low pressure)

Suction Line

Case Drain Fluid

Control Shaft “b”

Control Shaft “a”

Hydraulic Circuit

Suction Port Drain Port

Ø1.0 Ø1.2

Ø1.0

Ø0.8

Ø1.2

BDU-21L

P400207

1

1

2

2

3

3

Technical Information

BDU Series Hydrostatic Transmissions

General Description

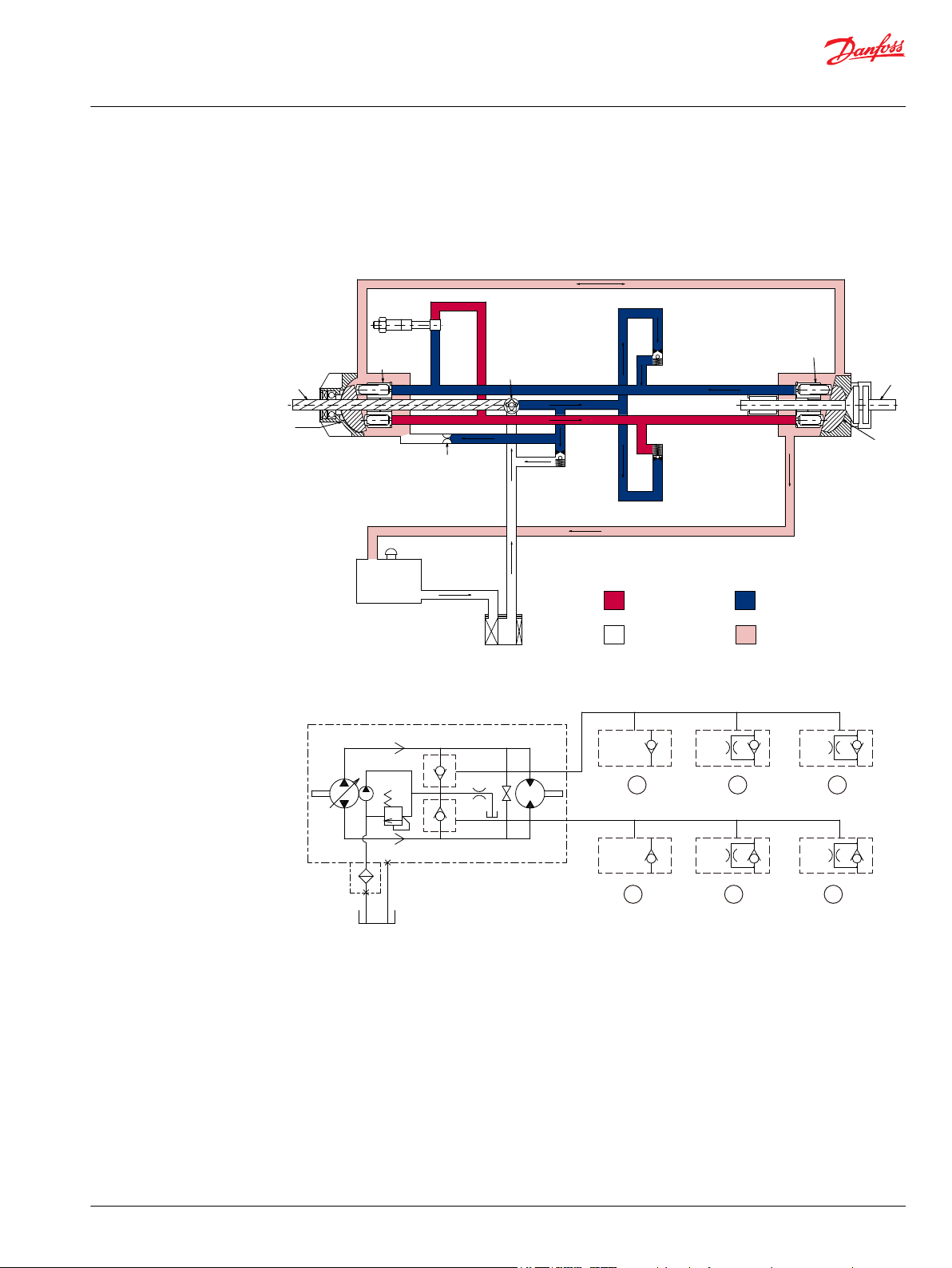

BDU-10L/21L/21H

Pictorial Diagram

BDU-10L, BDU-21L, BDU-21H (part of pump)

System Schematic: BDU-21L

1. Ball Check Valve, Option Code. : BB

2. Check Valve with Ø1.0 Orifice, Option Code : 10

3. Check Valve with Ø1.2 Orifice, Option Code : 12

©

Danfoss | November 2021 BC152886484098en-000207 | 9

Page 10

20.6MPa 17.2MPa 13.7MPa 20.6MPa 20.6MPa

20.6MPa 17.2MPa 13.7MPa 20.6MPa 20.6MPa

Control Shaft “b”

Control Shaft “a”

Hydraulic Circuit

Suction Port Drain Port

Ø0.8

ø0.85

ø0.85

ø0.7

×2

BDU-21H

ø0.7

×2

P400208

1 2 3 4 5

1 2 3 4 5

Technical Information

BDU Series Hydrostatic Transmissions

General Description

System Schematic: BDU-21H

1. Check Valve with Relief Valve, Option Code. : R0

2. Check Valve with Relief Valve, Option Code. : R1

3. Check Valve with Relief Valve, Option Code. : R2

4. Check Valve with Relief Valve and Ø0.7 Twin Orifice, Option Code. : RA

5. Check Valve with Relief Valve and Ø0.85 Orifice, Option Code. : RB

10 | © Danfoss | November 2021 BC152886484098en-000207

Page 11

Technical Information

BDU Series Hydrostatic Transmissions

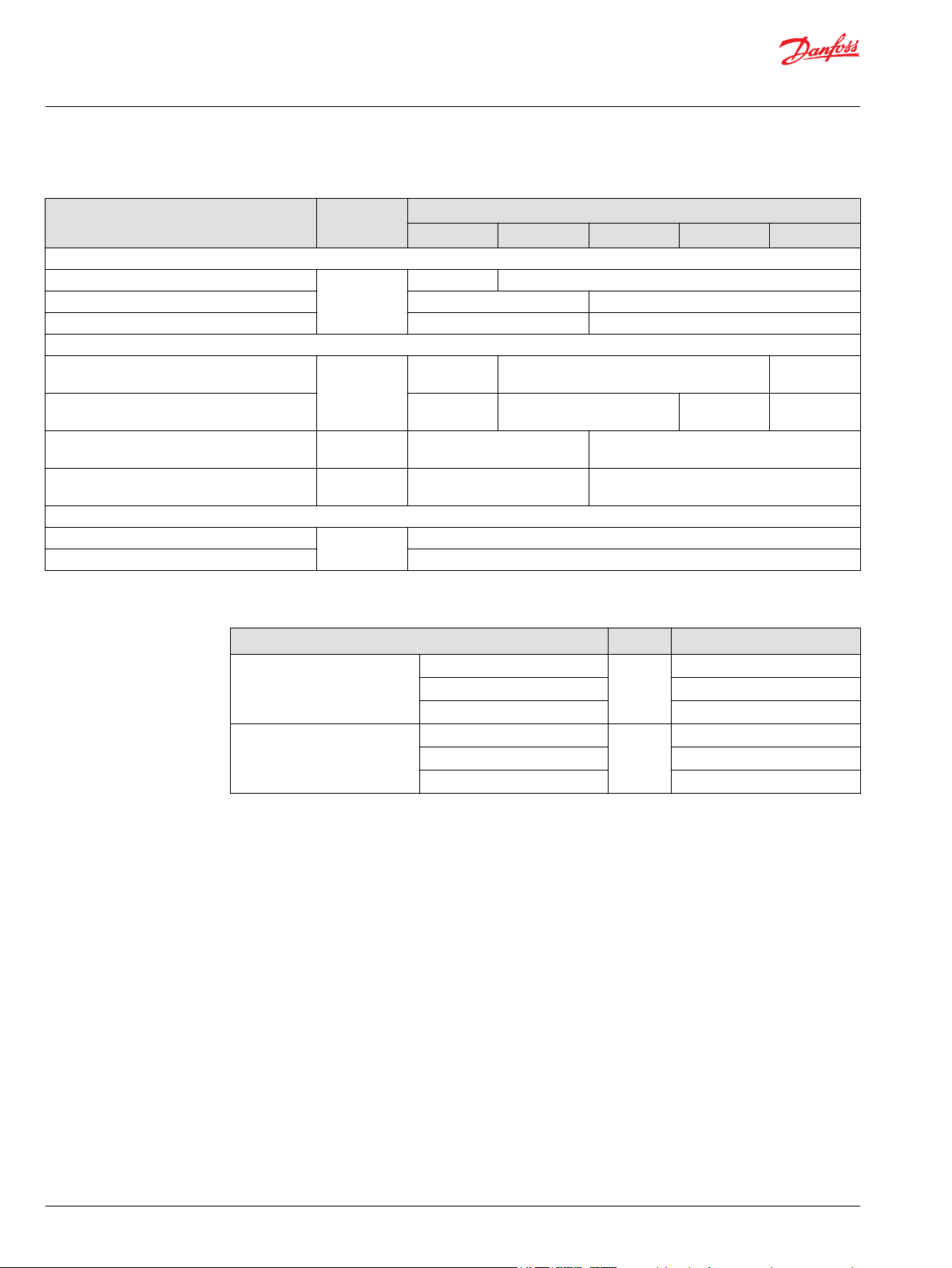

Technical Specifications

Features and Options

Features Unit

Displacement cm3 [in3]

Pump

Motor

Charge Pump Displacement cm3 [in3] NA NA

Output Speed

Maximum Output Torque (Theoretical) Nm [lbf•in]

Input Power (Maximum) kW [ps]

Weight kgf [lbs]

Control Torque Required to Stroke Pump

(Maximum)

Mounting See Installation Drawings

Rotation Clockwise or Counterclockwise

Suction/Oil Tank Port (SAE O-ring Boss) 7/8-14 UNF 7/16-20 UNF 9/16-18 UNF

Other ports See Installation Drawings

Shaft See Installation Drawings

Bypass Valve OP STD STD STD STD

Neutral Valve/Orifice NA/NA NA/OP NA/OP OP/OP OP/OP

High Pressure Relief Valve NA NA NA NA STD

Filtration W/O built-in External External (Option, Integrated)

Reservoir Integrated Integrated External External

Space for the oil in the housing cm

Swashplate Angle degree 15 15 15 15 15

Control Shaft degree 15 21 21 22 22

Displacement cm3 [in3]

Swashplate Angle degree 15 15 15 15 15

Rated

Maximum

(intermittent)

-1

min

Nm [lbf•in]

3

BDU-06S BDU-10S BDU-10L BDU-21L BDU-21H

6

[0.37]

6

[0.37]

3000 3000 3600 3600 3600

3200 3200 3800 3800 3800

9.8

[87]

1.1

[1.5]

4

[9]

8.8

[78]

450 550 550 700 700

Product Type & Frame

10

[0.61]

10

[0.61]

23.4

[208]

2.2

[3.0]

6.3

[14]

19.6

[174]

10

[0.61]

10

[0.61]

1.9

[0.12]

23.4

[208]

3.7

[5.0]

6.5

[14]

19.6

[174]

21

[1.28]

21

[1.28]

2.1

[0.13]

49.2

[436]

7.4

[10.0]

10

[22]

22.5

[200]

21

[1.28]

21

[1.28]

3.0

[0.18]

72.1

[639]

11.0

[15.0]

10

[22]

24.5

[217]

SAE J1926-1 / ISO 11926-1

©

Danfoss | November 2021 BC152886484098en-000207 | 11

Page 12

Technical Information

BDU Series Hydrostatic Transmissions

Technical Specifications

Operating Parameters

Parameter Unit

Input Speed

Minimum

Rated 3000 3600

Maximum 3200 3800

System Pressure

Maximum Working

Maximum

Charge Pressure

Charge Inlet Pressure

Case Pressure

Rated

Maximum (Cold Start) 0.7 [10]

min

[psi]

[psi]

[psi]

[psi]

Fluid Specifications

Features Units BD Series

Viscosity

Temperature

bar

bar

bar

bar

Product Type & Frame

BDU-06S BDU-10S BDU-10L BDU-21L BDU-21H

1000 600

-1

105

[1530]

150

[2185]

NA 3 [44] - 5 [73]

NA 0.8 [12] abs

Minimum

Continuous 12-60 [66-280]

Maximum 1600 [7500]

Minimum

Maximum Continuous 82 [180]

Maximum 104 [219]

[2549]

175

150

[2185]

0.3 [4]

mm2/sec.

[ SUS]

°C [°F]

210

[3059]

210

[3059]

245

[3569]

7 [49]

-10 [14]

12 | © Danfoss | November 2021 BC152886484098en-000207

Page 13

100

Efficiency %

90

80

70

60

50

40

30

20

10

0

3 5 7

Theoretical Output Torpue Nm

40%

40%

50%

50%

55%

55%

60%

60%

65%

65%

70%

70%

45%

45%

10

5

0 1000 2000 3000

Output Torque Nm

Output Speed min

-1

P400210

100

90

80

70

60

50

40

30

20

10

0

5 9 11 13 17

Efficiency %

Theoretical Output Torpue Nm

40%

45%

50%

55%

60%

65%

70%

73%

73%

70%

65%

60%

55%

50%45%

40%

20

10

0 1000 2000 3000

Output Torque Nm

Output Speed min

-1

P400211

100

90

80

70

60

50

40

30

20

10

0

5 5 7 9 11 13 15 16 18 20 22

Efficiency %

Theoretical Output Torpue Nm

40%

45%

50%

55%

60%

65%

70%

73%

73%

70%

65%

60%

55%

50%45%

40%

20

10

0

1000 2000 3000

P400212

Output Torque Nm

Output Speed min

-1

Technical Information

BDU Series Hydrostatic Transmissions

Technical Specifications

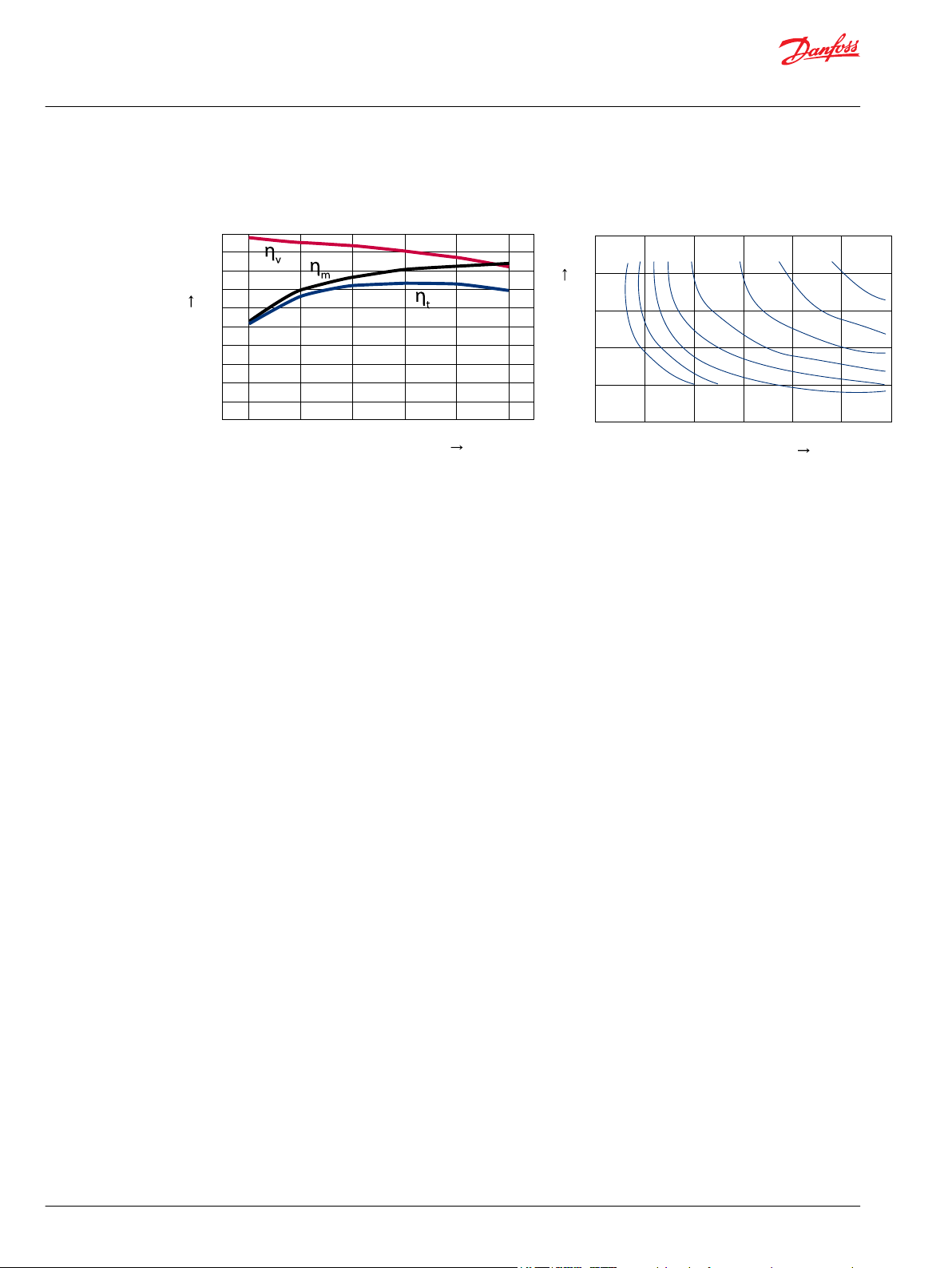

Efficiency

Input speed: 3000 min-1, Oil temperature: 50 °C, Full Displacement

BDU-06S

Efficiency (ηv:Volumetric, ηm:Mechanial, ηt:Overall)

BDU-10S

Efficiency (ηv:Volumetric, ηm:Mechanial, ηt:Overall)

BDU-10L

Efficiency (ηv:Volumetric, ηm:Mechanial, ηt:Overall)

©

Danfoss | November 2021 BC152886484098en-000207 | 13

Page 14

100

90

80

70

60

50

40

30

20

10

0

11 23 34 46 57 65

Efficiency %

Theoretical Output Torpue Nm

40%

45%

50%

55%

60%

65%

70%

75%

70%

75%

65%

60%

55%

50%

45%

40%

50

40

30

20

10

0

1000 2000 3000

Output

Torque Nm

Output Speed min

-1

P400213

Technical Information

BDU Series Hydrostatic Transmissions

Technical Specifications

BDU-21L/21H

Efficiency (ηv:Volumetric, ηm:Mechanial, ηt:Overall)

14 | © Danfoss | November 2021 BC152886484098en-000207

Page 15

W

Technical Information

BDU Series Hydrostatic Transmissions

Operating Parameters

Overview

Maintain operating parameters within prescribed limits during all operating conditions. This section

defines operating limits given in the table Operating Parameters.

Input Speed

Minimum speed is the lowest input speed recommended during engine idle condition. Operating below

minimum speed limits pump’s ability to maintain adequate flow for lubrication and power transmission.

Rated speed is the highest input speed recommended at full power condition. Operating at or below

this speed should yield satisfactory product life.

Maximum speed is the highest operating speed permitted. Exceeding maximum speed reduces product

life and can cause loss of hydrostatic power and braking capacity. Never exceed the maximum speed

limit under any operating conditions.

Operating conditions between rated speed and maximum speed should be restricted to less than full

power and to limited periods of time. For most drive systems, maximum unit speed occurs during

downhill braking or negative power conditions.

System Pressure

Charge Pressure

Warning

Unintended vehicle or machine movement hazard.

Exceeding maximum speed may cause a loss of hydrostatic drive line power and braking capacity. You

must provide a braking system, redundant to the hydrostatic transmission, sufficient to stop and hold the

vehicle or machine in the event of hydrostatic drive power loss.

System pressure is the differential pressure between system ports A & B. It is the dominant operating

variable affecting hydraulic unit life. High system pressure, which results from high load, reduces

expected life. Hydraulic unit life depends on speed and normal operating—or weighted average—

pressure that you can only determine from a duty cycle analysis.

Maximum Working Pressure is the highest recommended Application pressure. Maximum working

pressure is not intended to be a continuous pressure. Propel systems with Application pressures at, or

below, this pressure should yield satisfactory unit life given proper component sizing.

Maximum pressure (peak) is the highest intermittent pressure allowed under any circumstances.

Applications with applied pressures between rated and maximum require factory approval with

complete application, duty cycle, and life expectancy analysis.

All pressure limits are differential pressures referenced to low loop (charge) pressure. Subtract low loop

pressure from gauge readings to compute the differential.

The charge pressure setting listed in the technical specifications is based on the charge flow across the

charge pressure relief valve at fluid temperature at 50˚C [120˚F].

Charge Inlet Pressure

Charge pump inlet conditions must be controlled in order to achieve expected life and performance. A

continuous inlet vacuum of no less than 0.8 abs bar is recommended. Normal vacuums less than 0.7 abs

bar would indicate inadequate inlet design or stricted filter.

©

Danfoss | November 2021 BC152886484098en-000207 | 15

Page 16

C

C

Technical Information

BDU Series Hydrostatic Transmissions

Operating Parameters

Case Pressure

Under normal operating conditions, the maximum continuous case pressure must not exceed 0.3 bar

(4PSI). Maximum allowable intermittent case pressure during cold start must not exceed 0.7 bar (10PSI).

Caution

Possible component damage or leakage

Operation with case pressure in excess of stated limits may damage seals, gaskets, and/or housings,

causing external leakage. This condition may also affect performance since charge and system pressure

are referenced to case pressure.

Hydraulic Fluids

Ratings and data are based on operating with hydraulic fluids containing inhibitors to prevent oxidation,

rust, and foam. These fluids must possess good thermal and hydrolytic stability to prevent wear, erosion,

and corrosion of the internal components.

Caution

Never mix hydraulic fluids of different types.

Temperature and Viscosity

Temperature and viscosity requirements must be concurrently satisfied. The data shown in the table Fluid

Specifications on page 12, assume petroleum-based fluids are used.

The high temperature limits apply at the hottest point in the transmission, which is normally the motor

case drain. The system should generally be run at or below the rated temperature. The maximum

temperature is based on material properties and should never be exceeded.

Cold oil will generally not affect the durability of the transmission components, but it may affect the

ability of oil to flow and transmit power; therefore temperatures should remain 16 °C [30 °F] above the

pour point of the hydraulic fluid. The minimum temperature relates to the physical properties of

component materials.

For maximum unit efficiency and bearing life the fluid viscosity should remain in the recommended

operating range. The minimum viscosity should be encountered only during brief occasions of

maximum ambient temperature and severe duty cycle operation. The maximum viscosity should be

encountered only at cold start.

Heat exchangers should be sized to keep the fluid within these limits. Testing to verify that these

temperature limits are not exceeded is recommended.

16 | © Danfoss | November 2021 BC152886484098en-000207

Page 17

W

Technical Information

BDU Series Hydrostatic Transmissions

System Design Parameters

Fluid and Filtration

To prevent premature wear, it is imperative that only clean fluid enters the hydrostatic transmission

circuit. Therefore an inlet filter better than β20=1.4 is required in the charge pump inlet line. This filter

should not have a bypass and should be changed regularly to ensure system reliability. The BD series

hydrostatic transmission requires system filtration capable of maintaining fluid cleanliness at ISO

4406-1999 class 22/18/15 or better.

Reservoir

The BDU-06S and BDU-10S are designed with optional integrated reservoir. A reservoir for BDU-10L larger

than the 2 liter tank size is recommended. A reservoir for BDU-21L/H larger than the 5 liter tank size is

recommended. The hoses or piping size is recommended to be larger than 3/8 inch normal tube OD.

Control Shaft Force

The BDU transmission is designed with direct displacement control (DDC). DDC can be located at either

side of the housing. It provides a simple, positive method of control. Movement of the control shaft

causes a proportional swashplate movement, thus varying the pump’s displacement from full

displacement in one direction to full displacement in the opposite direction.

The approximate maximum control torque necessary to rotate the control shaft is shown in the table of

technical specifications. A stopper to prevent over-stroke is required at the end of maximum angle of

control shaft. The control shaft force should be kept at or below the force in the table below.

Independent Braking System

Features Unit

Allowable maximum force for control shaft Nm 10 20 25

Vehicle propel applications may require a provision for non-linear control input to reduce control

sensitivity near neutral. Damping or frictional forces may be necessary to produce the desired control

feeling.

These units do not include any neutral centering device for the swashplate. It is necessary to provide a

force in the machine’s control system that will hold the swashplate at the desired angle. A “ fail safe

“ which will return the swashplate to the neutral in the event of linkage failure is recommended.

Warning

Unintended vehicle or machine movement hazard.

The loss of hydrostatic drive line power, in any mode of operation (forward, neutral, or reverse) may cause

the system to lose hydrostatic braking capacity. You must provide a braking system, redundant to the

hydrostatic transmission, sufficient to stop and hold the vehicle or machine in the event of hydrostatic

drive power loss.

BDU-06S BDU-10S BDU-21L

Product type & Frame

©

Danfoss | November 2021 BC152886484098en-000207 | 17

Page 18

No Load

No Load

No Load

T

out

(No Load)

T

in

Distance (L)

P400215

R

e

BDU-21L/21H

200

400

600

800

1000

1200

1400

0 10-10 20 30 40 50

BDU-10S/10L

200

400

600

800

0 10 20 30 40 50

0 10

200

400

600

BDU-06S

20 30

distance (L) mm → distance (L) mm → distance (L) mm →

Re N →

Re N →

Re N →

P400216

Technical Information

BDU Series Hydrostatic Transmissions

Features and Options

Shaft Load

The maximum allowable radial road of input shaft (Re) is based on the maximum external moment and

the distance from the housing surface to the input shaft. The limit of radial load of input shaft is shown

the figure below:

Shaft Options

The maximum shaft thrust in (Tin) of input shaft is 18% of allowable radial road (Re) of the input shaft.

The shaft thrust out (Tout) of the input shaft should be no load. The radial and thrust load of the output

shaft should be no load.

The BDU transmissions are available with a variety of straight key, JIS Spline, JIS Serration, SAE Spline

shaft for input shaft, PTO shaft and output shaft. Details are shown in the Installation Drawings on page

35.

18 | © Danfoss | November 2021 BC152886484098en-000207

Page 19

A

B

C

P400217

D

d

D

Technical Information

BDU Series Hydrostatic Transmissions

Features and Options

Shaft Options : BDU-06S/10S/10L

Output Shaft Options

Output Shaft Code BDU-06S BDU-10S BDU-10L

Shafts:

A = Output Shaft

B = PTO Shaft

C = Input Shaft

15 x 13 x 1.0 J13

JIS Spline

20 x 18 x 1.0 K18

SAE Spline 32/64-16T S16

PTO Shaft / Input Shaft Options

PTO Shaft Input Shaft Code BDU-06S BDU-10S BDU-10L

KA0

KB0

None

Straight-Keyed D =

15 mm

KB1

PB1

Straight d =

12.7 mm

Straight-Keyed D =

15 mm

PB3

©

Danfoss | November 2021 BC152886484098en-000207 | 19

Page 20

D

A

P400355

B

C

Technical Information

BDU Series Hydrostatic Transmissions

Features and Options

PTO Shaft / Input Shaft Options (continued)

PTO Shaft Input Shaft Code BDU-06S BDU-10S BDU-10L

PB2

JIS Serration

12 x 23 x 0.5

Shaft Options : BDU-21L/21H

Output Shaft Options

Straight-Keyed D =

15 mm

This charge pump housing is applied only for BDU-10L.

Output Shaft Code BDU-21L BDU-21H

PB4

Shafts:

A = Output Shaft

B = PTO Shaft

C = Input Shaft

20 x 14 x 1.25 J14

JIS Spline

20 x 18 x 1.0 J18

SAE Spline 32/64-22T S22

20 | © Danfoss | November 2021 BC152886484098en-000207

Page 21

D

D

D

Technical Information

BDU Series Hydrostatic Transmissions

Features and Options

PTO Shaft / Input Shaft Options

PTO Shaft Input Shaft Code BDU-21L BDU-21H

KC1

None

JIS Spline

15 x 13 x 1.0

SAE Spline

32/64-16T

Bypass Valve

Straight-Keyed D =

17 mm

Straight-Keyed D =

17 mm

Straight-Keyed D =

17 mm

KC2

PC1

PC2

PC3

PC5

In some applications, it is desirable to move the vehicle over short distances at low speed without

starting the engine. A bypass valve allows oil to be routed from one side of the pump/motor circuit to the

other, thus allowing the motor to turn. The bypass valve must be fully closed during normal vehicle

operation. BDU series transmissions utilize a spool-type bypass valve. The bypass valve plunger must be

depressed manually to open the valve. This connects both sides of the main hydraulic circuit to the

housing case and allows fluid to circulate without rotating the pump, prime mover and motor. A spring

closes this valve on the 6S, 10L and 10S transmissions, while charge pressure closes the valve on the 21L

and 21H transmissions.

High Pressure Relief Valve (hprv) and Charge Check (Overpressure Protection)

The BDU-21H transmission is available with a combination charge check and high pressure relief valve

assembly. High pressure relief valves are available in a range of settings as shown in the Model Code on

page 31. Individual port pressure settings may be specified. The high pressure relief valve settings are a

differential pressure (referenced to charge pressure).

Check and Relief Valve for BDU-21H

Option Code

R0 210 R1 175 R2 140 RA 210 0.7 Twin

RB 210 0.85

©

Danfoss | November 2021 BC152886484098en-000207 | 21

Pressure setting

bar [psi]

Orifice

Page 22

P400219

1

2

3

6

5

4

Technical Information

BDU Series Hydrostatic Transmissions

Features and Options

1. Charge circuit

2. Check and relief valve

3. Working loop (Main hydraulic circuit

4. Bypass valve

5. Working loop (Main hydraulic circuit)

6. Check and relief valve

22 | © Danfoss | November 2021 BC152886484098en-000207

Page 23

with Orifice

Reverse

DB-OR

Neutral-OR

Neutral-STD

DB-STD

Control Shaft Angle

Forward

Output Flow

P400220

Technical Information

BDU Series Hydrostatic Transmissions

Features and Options

Charge Check Valve with Orifice

The BDU transmissions are equipped with charge check valves. In some applications, it is desirable to use

charge check valve with orifice for expanding null dead band, giving both the safety measure to prevent

the vehicle movement in the neutral position of the control shaft and easy adjustment of neutral position

when connected to vehicle linkage. The orifice connects the working loop, which is a main hydraulic

circuit, to a charge circuit. It always allows some internal leakage to ensure the expanding null dead band

around neutral position of control shaft. However, it decreases the volumetric efficiency, particularly at

high system pressure in the working loop. It is recommended to install the orifice in a specific working

loop, which is pressurized when the vehicle moves in reverse. The orifice diameter improves the null

dead band but decreases the volumetric efficiency. A cross section and characteristics are shown below.

The charge check valves with orifice are available in a range of orifice diameters as shown in the Model

Code on page 31.

Input Speed: 3000min-1, Oil Temp: 50 °C , No Load

Features Unit

Deadband of Control Shaft Angle

(DB-STD)

©

Danfoss | November 2021 BC152886484098en-000207 | 23

Features Unit

Deadband of Control Shaft Angle

(DB-OR)

[degree] Approx. 0.1

BDU-10S/10L BDU-21L BDU-21H

Ø 0.7 Ø 0.8 Ø 1.0 Ø 1.2 Ø 0.85 Ø 0.7 twin

[degree]

Approx.

0.5

Approx.

BDU-10S/10L/21L/21H

Without Orifice

Orifice diameter [mm]

0.7

Approx.

0.5

Approx.

0.7

Approx.

0.35

Approx.

0.5

Page 24

P400221

P400222

P400223

P400224

Orifice

P400225

P400226

P400227

Orifice

P400228

P400229

P400230

Orifice

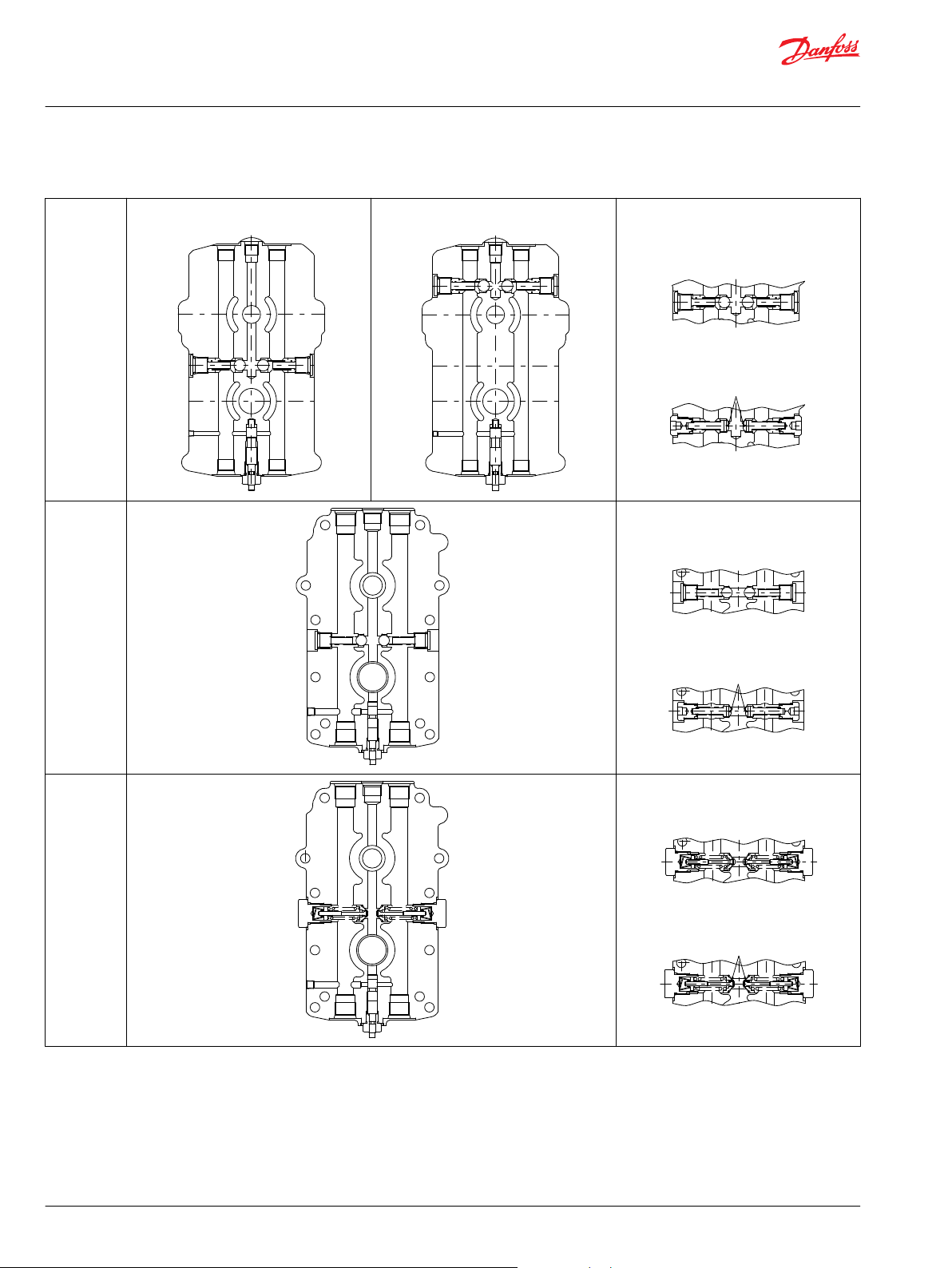

Technical Information

BDU Series Hydrostatic Transmissions

Features and Options

Charge Check with Orifice

BDU-10S

BDU-10L

BDU-21L

BDU-10L Check Valve

BDU-10S Check Valve

Check Valve (Ball) without Orifice

Check Valve with Orifice

Check Valve (Ball) without Orifice

Check Valve with Orifice

Check & Relief without Orifice

BDU-21H

Check & Relief with Orifice

24 | © Danfoss | November 2021 BC152886484098en-000207

Page 25

25.51415

7/8-14UNF

P400231

30

-0.8

0

Dimensions of

Widths Across

Flats of Hexagon

Ø 71

Ø 60

75.5 ± 1.5

P/N BDU-10S-TANK

70.8

69

32

3/4-16 UNF screw

3/4-16 UNF screw

Screwed Type

P/N H-3101069

P/N 05EL-BD

Steel Pipe Fitting

Ø 37

Ø 59.7

Ø 84

P400232

Technical Information

BDU Series Hydrostatic Transmissions

Features and Options

Optional Integrated Reservoir

The BDU-06S and BDU-10S are designed with optional integrated reservoir. The optional Integrated

reservoir is shown in the figure on the right.

Filter

The BDU-10S is designed with Built-in filter. BDU-21L/H is designed with optional Integrated filter, which

is shown in the figure on the right. The filter connection is designed with consideration given to the

screwed type steel pipe fitting that is an option. An external filter is required in the charge pump inlet line

for BDU- 10L. This filter should not have a bypass and should be changed regularly to ensure system

reliability.

©

Danfoss | November 2021 BC152886484098en-000207 | 25

Page 26

CCW

31.8

Rotation

Wind

Ø 7.1

Ø 177.8

P400233

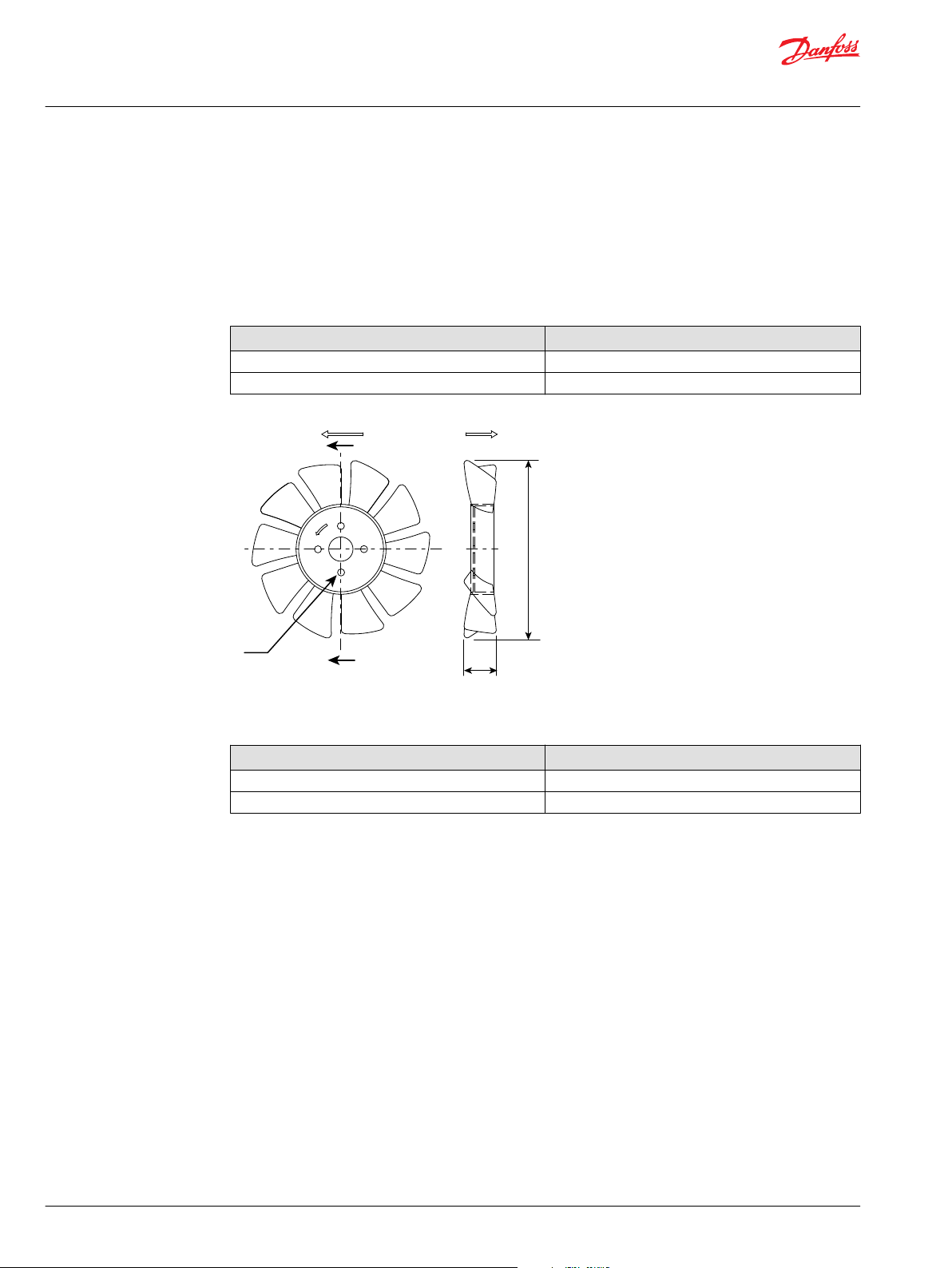

Technical Information

BDU Series Hydrostatic Transmissions

Features and Options

Fan

The operating temperature of the BDU transmission becomes hot when operated at a heavy load for

long, continuous time. To avoid a reduction in the life of the BDU transmission or risking immediate

failure, a cooling fan may be installed on the input shaft or external reservoir to be effective as heat

exchanger may be installed. The BDU transmission is available with optional fan integrated with the belt

drive device for the input shaft. The detailed outlines are shown in the Installation Drawings on page 35.

Optional Fan for Cooling

P/N Rotation

H-1030826 CW

H-1030827E CCW

Optional Fan for Cooling

P/N Rotation

H-1030826 CW

H-1030827E CCW

26 | © Danfoss | November 2021 BC152886484098en-000207

Page 27

Technical Information

BDU Series Hydrostatic Transmissions

Component Selection

Selecting the proper transmission for a vehicle begins with determining the maximum system pressure

by using tractive effort of the vehicle and the maximum vehicle speed required. The transmission

selected must meet both requirements.

Maximum System Pressure

Maximum operating system pressure should be calculated at maximum tractive effort condition.

Maximum tractive effort condition is assumed at vehicle with maximum weight transfer from pushing or

pulling implements at maximum grade of slope. First, calculate BDU motor torque by using the following

equation:

Equation-1

MTQ_ME = Output torque of BDU motor at maximum tractive effort condition in Nm

•

PR_ME = Pull Ratio at maximum tractive effort (See below)

•

VW_ML = Gross vehicle weight with maximum loaded weight in kgf

•

LR = Tire Radius in meters

•

FDR = Transaxle Final Drive Ratio

•

EFF_FD = Transaxle Final Drive Efficiency

•

The hydrostatic transmissions in many applications are used in conjunction with readily available

transaxles. In order to meet both requirements of high output torque at operating mode and high speed

at traveling mode, the transaxles with two kinds of shifts, Hi and Lo are used in some applications. In such

transaxles, use Lo shift ratio as FDR in equation-1 and -4 to calculate maximum system pressure.

A useful parameter for determining tractive effort is "Pull Ratio". Pull Ratio is a dimensionless term that is

the ratio of tractive effort to gross vehicle weight. It is generally constant for each class of vehicle. These

values may be used when actual vehicle tractive efforts are not known. In a typical agriculture application

for BDU application, Pull Ratio for the highest load mode can be calculated from the primary components

of pull ratio: rolling resistance, grade motion resistance by a function of slope, machine function motion

resistance and drive configuration motion resistance. In such cases, pull ratio is determined by using the

following equation:

Equation-2

•

RR = Rolling resistance. See SD Application manual

•

GR = Motion resistance of Grade. See SD Application manual

•

MF = Machine function motion resistance, See SD Application manual

•

DC = Drive configuration motion resistance, See SD Application manual

Then, maximum system pressure can be calculated by using MTQ_ME and the following quation:

Equation-3

©

Danfoss | November 2021 BC152886484098en-000207 | 27

Page 28

Technical Information

BDU Series Hydrostatic Transmissions

Component Selection

•

SPR_ME = Maximum BDU system pressure operated at Maximum tractive effort mode in bar

•

DP = Motor Displacement of selected BDU transmissions in cm

•

MEF_MO = Motor Mechanical Efficiency of BDU transmission in this mode

Select appropriate BDU size which will give SPR_ME, not to exceed the value of maximum system

pressure allowed in the technical specification, because BDU is generally applied without system

pressure relief valves.

If appropriate BDU size satisfies maximum system pressure, determine the BDU output speed at

maximum tractive effort mode by using the following equation:

Equation-4

•

MSP_ME = The BDU output speed at maximum tractive effort condition in min-1 (rpm)

•

VSP_ME = The vehicle speed requested for maximum tractive effort mode in m/s

Confirm the BDU output speed calculated to satisfy the maximum output speed (intermittent) in the

technical specification.

3

Input Power

Calculate required input power of BDU by using the following equation:

Equation-5

PW_ME = BDU Input power required for maximum tractive effort mode in kW

•

OEF_BDU = BDU unit overall efficiency for this mode

•

If PW_ME is larger than Input power (Maximum) of selected BDU, VSP_ME should be limited to satisfy

maximum BDU input power. If the calculated speed exceeds the technical specification, the transaxle

final drive ratio or tire size may need to be changed.

Maximum vehicle speed is generally recommended in traveling mode. Calculate maximum BDU speed by

using the following equation:

Equation-6

•

MSP_TR = The BDU output speed for traveling mode in min-1 (rpm)

•

VSP_TR = The vehicle speed requested for traveling mode in m/s

Use Hi shift ratio as FDR in Equation-6 if the Transaxle Final Drive has two shifts.

Confirm MSP_TR to satisfy the maximum output speed (intermittent) in the technical specification. If

MSP_TR is not satisfied, FDR (Hi shift) may need to be changed. It is also necessary to determine the

system pressure for traveling mode (SPR_TR) to satisfy maximum system pressure (intermittent) allowed

in the technical specification. SPR_TR is calculated by using equation -1, -2 and -3 with parameters of

traveling mode.

28 | © Danfoss | November 2021 BC152886484098en-000207

Page 29

Technical Information

BDU Series Hydrostatic Transmissions

Component Selection

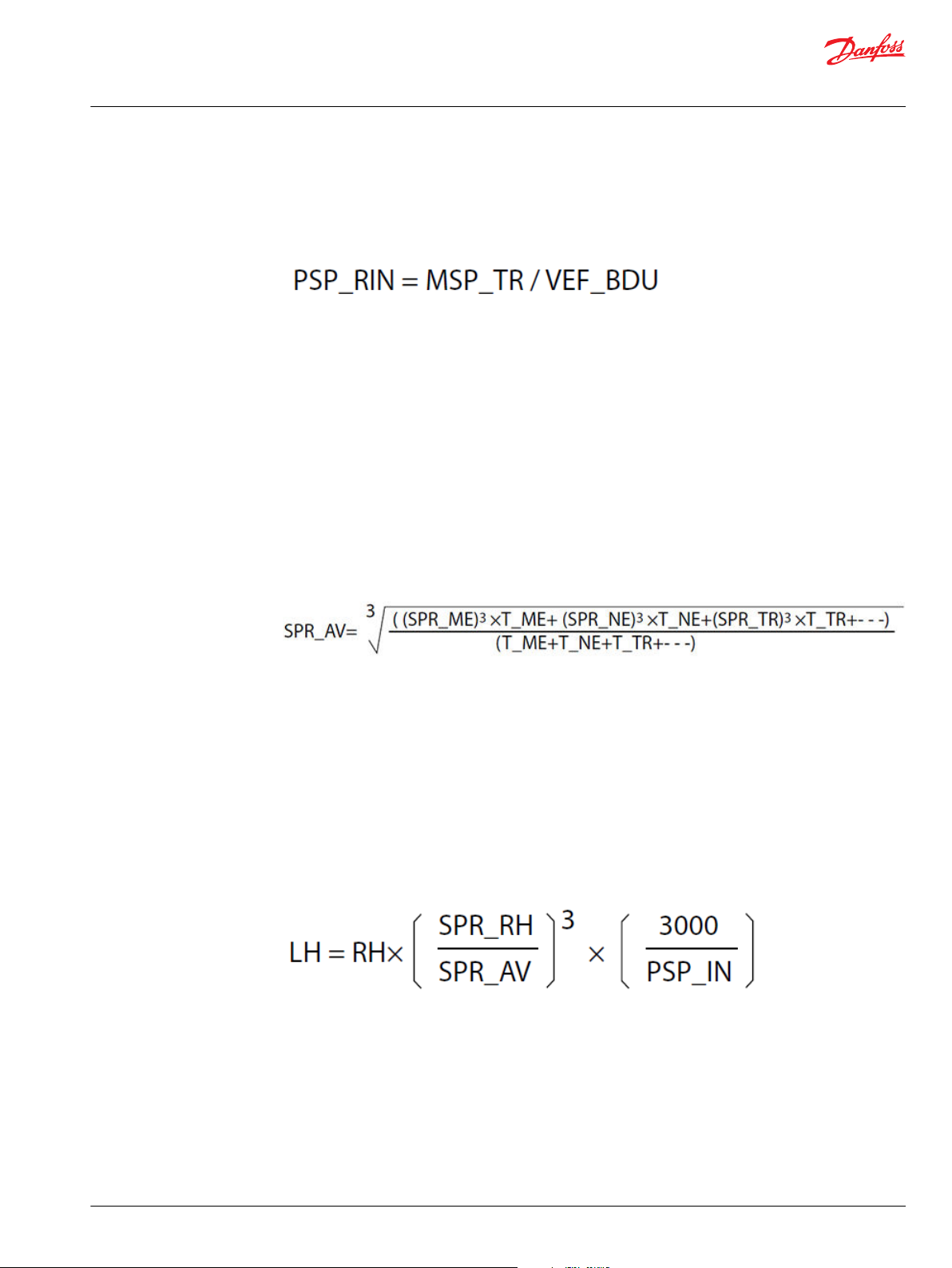

Calculate the required BDU input shaft speed to satisfy maximum BDU output shaft speed by using the

following equation:

Equation-7

•

PSP_RIN = required BDU input shaft speed in min-1 (rpm)

•

VEF_BDU = BDU volumetric efficiency for this mode

Confirm BDU input shaft speed is larger than PSP_RIN.

Unit Life

The unit life of selected BDU transmissions should be determined by using average system pressure

under overall operating modes, because vehicles generally operate in their maximum tractive effort

mode for a small percentage of their life. If a duty cycle for a transmission is known, weighted average

system pressure can be calculated and can estimate the life expectancy of the transmission selected. The

duty cycle can be assumed for instances including several modes. Calculate weighted average system

pressure by using the following equation:

Equation-8

SPR_AV = weighted average system pressure. This is the mean pressure of the duty cycle in bar

•

SPR_ME = the system pressure for maximum tractive effort mode and T_ME is its time in the duty

•

cycle

SPR_NE = the system pressure at the normal tractive effort which means with normal weight and at

•

0% Grade and T_NE is its time in the duty cycle

SPR_TR = the system pressure for traveling mode and T_TR is its time in the duty cycle

•

If needed, define other system pressures at other operating conditions and add them to the equation.

The BDU Unit Life hours at weighted average pressure is determined by using the following equation:

Equation-9

•

LH = Unit Life hours of selected BDU at the duty cycle estimated

•

SPR_RH = The system pressure at Rated Unit Life (See table A)

•

PSP_IN = The input shaft speed of BDU unit. Normally, input shaft speed of BDU is constant

Confirm LH of selected BDU to satisfy the Life requirement. If LH is shorter than the requested

specification, the next larger size transmission may be needed and the repeat the calculation for

Component Selection on other BDU using Equation -1 through -9. Contact Danfoss for assistance in

correct transmission selection.

©

Danfoss | November 2021 BC152886484098en-000207 | 29

Page 30

Technical Information

BDU Series Hydrostatic Transmissions

Component Selection

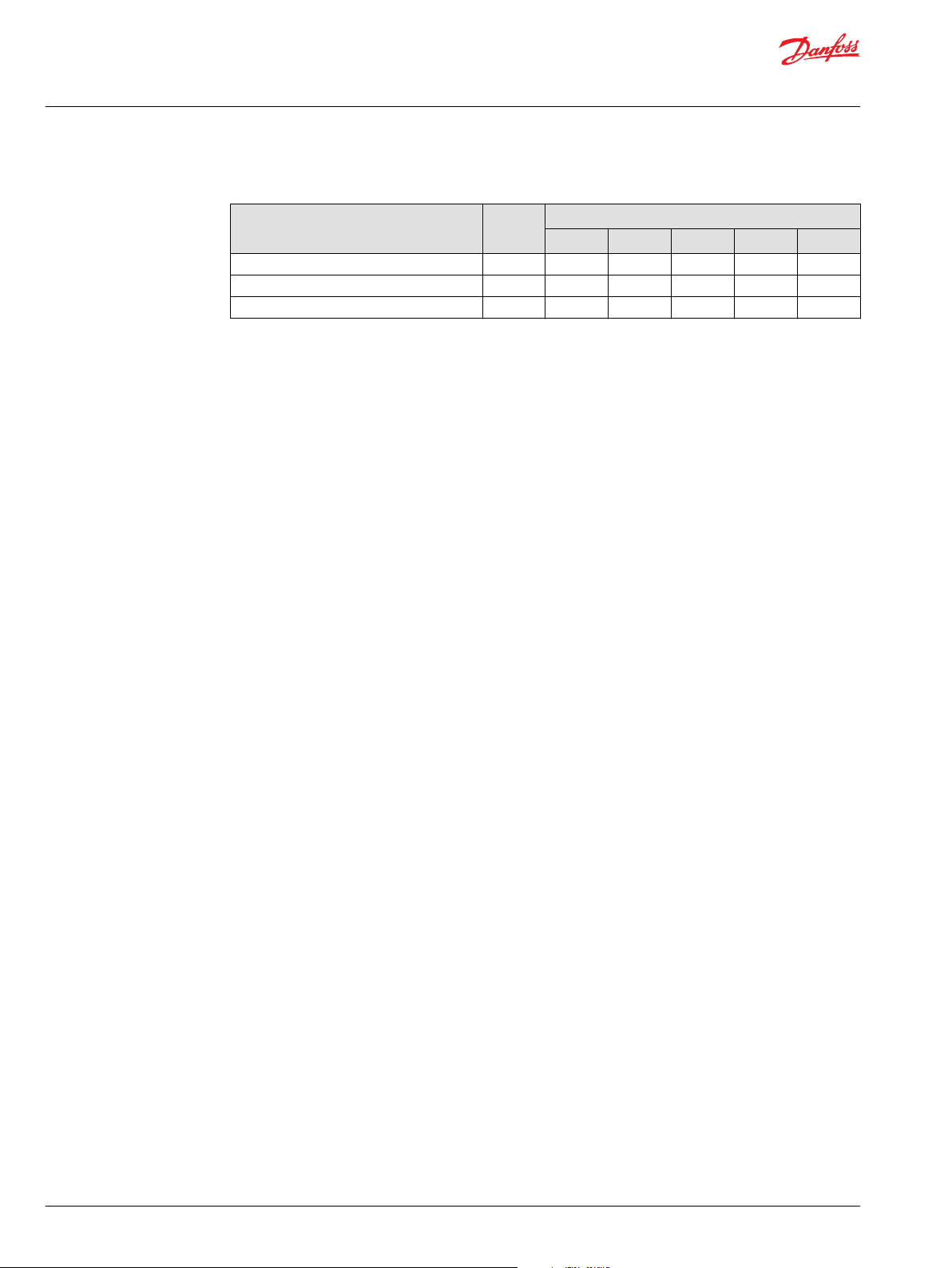

Table A

Parameter Unit

RH hour 300 300 1000 1600 2500

SPR_RH bar 55 70 70 70 70

BSP_OP min

BDU-06S BDU-10S BDU-10L BDU-21L BDU-21H

-1

3000 3000 3000 3000 3000

Frame

30 | © Danfoss | November 2021 BC152886484098en-000207

Page 31

JF GE H K

BDU -

B DCA

Technical Information

BDU Series Hydrostatic Transmissions

Model Code

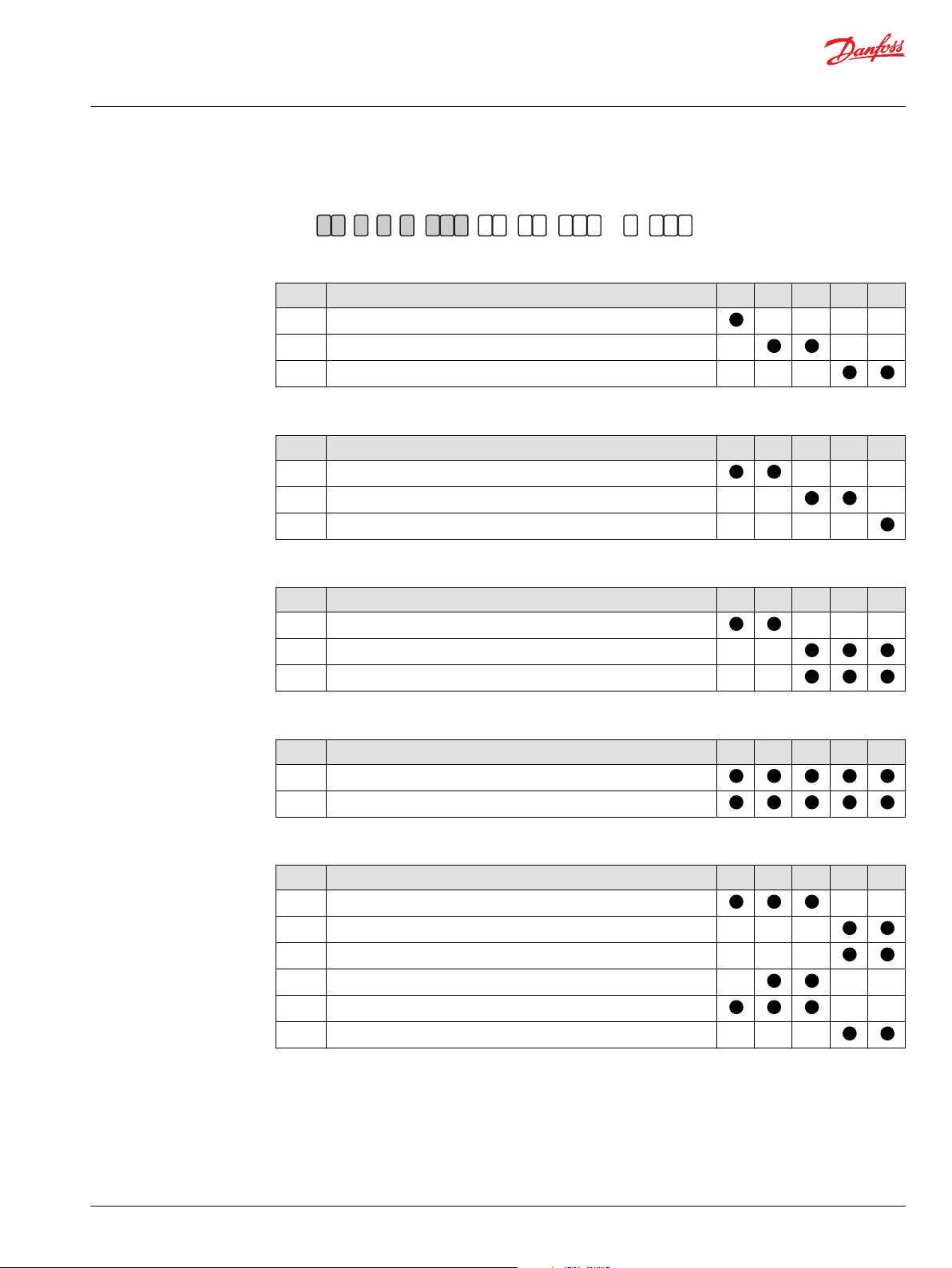

BDU : Model Code (A - B - C - D - E)

A - Displacement

Code Description 06S 10S 10L 21L 21H

06 6 cm

10 10 cm

21 21 cm

B - Design

Code Description 06S 10S 10L 21L 21H

S Standard

L Long Life

H High Pressure

3

3

3

C - Rotation

Code Description 06S 10S 10L 21L 21H

W Bi-directional rotation

R Clockwise rotation

L Counter-Clockwise rotation

D - Contrl Arm Location

Code Description 06S 10S 10L 21L 21H

R Right-hand side viewing from input shaft (pump located upside)

L Left-hand side viewing from input shaft (pump located upside)

E - Output Shaft

Code Description 06S 10S 10L 21L 21H

J13 JIS Spline 15×13×1.0

J14 JIS Spline 20×14×1.25

J18 JIS Spline 20×18×1.0

K18 JIS Spline 15×18×0.75

S16 SAE Spline 32/64 - 16T

S22 SAE Spline 32/64 - 22T

©

Danfoss | November 2021 BC152886484098en-000207 | 31

Page 32

JF GE H K

BDU -

B DCA

Technical Information

BDU Series Hydrostatic Transmissions

Model Code

BDU : Model Code (F - G)

F - Check & Relief Valve (Left-hand side viewing from Housing)

Code Description 06S 10S 10L 21L 21H

BB Ball Check Valve

00 Poppet-type Check Valve

07 Check Valve w/dia = 0.7 orifice

08 Check Valve w/dia = 0.8 orifice

10 Check Valve w/dia = 1.0 orifice

12 Check Valve w/dia = 1.2 orifice

R0 Check and High Pressure Relief Valve 210 bar

R1 Check and High Pressure Relief Valve 175 bar

R2 Check and High Pressure Relief Valve 140 bar

RA Check and High Pressure Relief Valve 210 bar w/dia=0.7 twin orifice

RB Check and High Pressure Relief Valve 210 bar w/dia=0.85 orifice

G - Check & Relief Valve (Right-hand side viewing from Housing)

Code Description 06S 10S 10L 21L 21H

BB Ball Check Valve

00 Poppet-type Check Valve

07 Check Valve w/dia = 0.7 orifice

08 Check Valve w/dia = 0.8 orifice

10 Check Valve w/dia = 1.0 orifice

12 Check Valve w/dia = 1.2 orifice

R0 Check and High Pressure Relief Valve 210 bar

R1 Check and High Pressure Relief Valve 175 bar

R2 Check and High Pressure Relief Valve 140 bar

RA Check and High Pressure Relief Valve 210 bar w/dia=0.7 twin orifice

RB Check and High Pressure Relief Valve 210 bar w/dia=0.85 orifice

32 | © Danfoss | November 2021 BC152886484098en-000207

Page 33

JF GE H K

BDU -

B DCA

Technical Information

BDU Series Hydrostatic Transmissions

Model Code

BDU : Model Code (H - J - K)

H - Input shaft / PTO shaft Configuration & Charge Pump Displacement

Code Description 06S 10S 10L 21L 21H

KAO Straight-keyed D=15mm shaft / None & w/o Charge Pump

KBO Straight-keyed D=15mm shaft / None & w/o Charge Pump

KB1 Straight-keyed D=15mm shaft / None & w/1.9cm3 Charge Pump

KC1 Straight-keyed D=17mm shaft / None & w/2.1cm3 Charge Pump

KC2 Straight-keyed D=17mm shaft / None & w/3.1cm3 Charge Pump

PB1 Straight-keyed D=15mm shaft /Straight 12.7 mm shaft & w/o Charge

Pump

PB2 Straight-keyed D=15mm shaft /JIS Serration 12 x 23 x 0.5 shaft & w/o

Charge Pump

PB3 Straigt-keyed D=15mm shaft /Straight 12.6 mm shaft & w/2.4cm

Charge Pump

PB4 Straight-keyed D=15mm shaft /JIS Serration 12 x 23 x 0.5 shaft & w/

2.4cm3 Charge Pump

PC1 Straight-keyed D=17mm shaft /JIS Spline 15 x 13 x 1.0 shaft & w/2.1cm

Charge Pump

PC2 Straight-keyed D=17mm shaft /JIS Spline 15 x 13 x 1.0 shaft & w/3.1cm

Charge Pump

PC5 Straight-Keyed D=17mm shaft /SAE Spline 32/64 -16T & w/2.1cm

Charge Pump

PC6 Straight-Keyed D=17mm shaft /SAE Spline 32/64 -16T & w/3.1cm

Charge Pump

3

3

3

3

3

J - Bypass & Nuetral Valve

Code Description 06S 10S 10L 21L 21H

N None

A w/Nuetral Valve Pressure 35 bar w/dia=1.0 orifice

B w/Bypass Valve

K - Special Hardware

Code Description 06S 10S 10L 21L 21H

NNN None

WOL Oil-filled in case

©

Danfoss | November 2021 BC152886484098en-000207 | 33

Page 34

Technical Information

BDU Series Hydrostatic Transmissions

Recommended Installation and Maintenance

Housing Installation

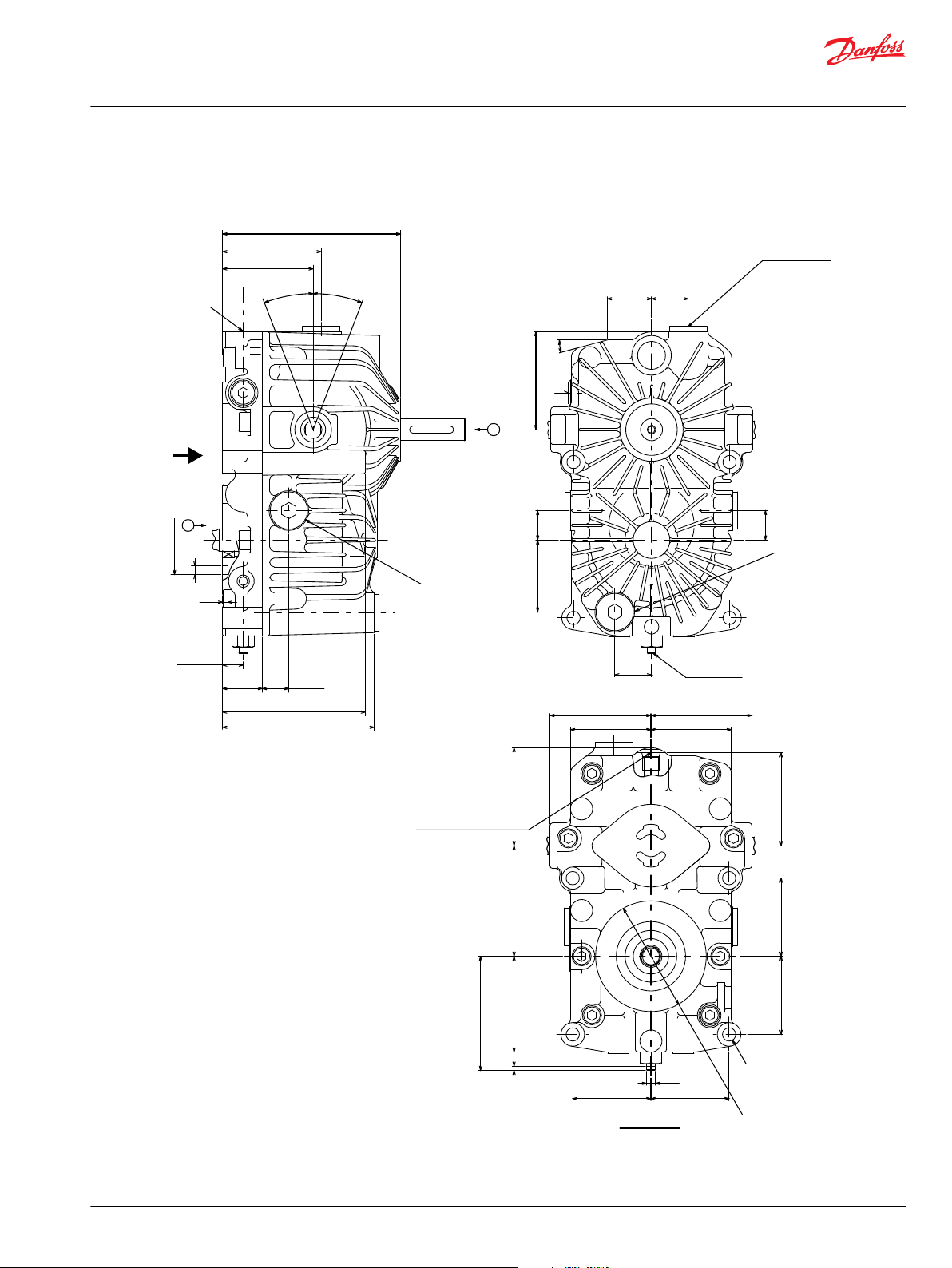

The center section of BDU transmission has 4 holes for fixing screws. The screws should be inserted in the

holes and tightened to specifications.

*Fitting Torque 1569 ~ 2058 N·cm

Shaft Installation

The input shaft of the BDU transmission should be connected to the prime mover by a belt drive device,

sheave or coupling. When using a belt drive device, the radial load on the input shaft should not exceed

the maximum allowable load shown in Shaft Load on page 18.

When installing the BDU motor shaft to the gearbox or to other devices directly, utilize the groove on the

center section of the BDU transmission, which is located concentric to the motor shaft, to ensure the

accuracy of concentricity. When using the coupling for connection of the shaft, ensure the accuracy of

concentricity is kept in the region of ±0.025mm. Do not beat the coupling strongly into the shaft with a

hammer.

It is recommended the shaft to be lubricated when using a spline shaft.

Start Up Procedure

After installing the BDU transmission and corresponding pipeline connection, remove the case drain port

plug from the housing. Fill the BDU transmission case with the recommended oil through the drain port.

Operation

Maintenance

BDU-10S is filled with oil at the plant shipment.

Make sure the control shaft of the BDU transmission is set to the neutral position. The BDU transmission

pump must be at zero position. Depress the bypass valve plunger manually to connect both side of the

main hydraulic circuit to housing case. Allow the prime mover to turn at idling speed. Turn the control

shaft and oil fills into main circuits. Stop depressing the bypass valve plunger. Then, the output shaft will

start to turn. Check the oil tank or reservoir level and refill the oil to the proper level if necessary. Repeat

the control shaft movement from full displacement in one direction to full displacement in the opposite

direction. Oil should not contain air trapped in the oil during the initial operation.

Check all joints and connections for leaks, and check that the oil tank or reservoir level is proper at the

time of first operation and every day.

Start the prime mover turning in the neutral position of the control shaft of the BDU transmission.

If some water, dust or grease are mixed in, with the transmission oil, change to new recommended oil.

Always keep at less than 0.1 % water in the transmission oil. It is recommended to change oil and filter

every year or at the every 500 operating hours.

34 | © Danfoss | November 2021 BC152886484098en-000207

Page 35

C

2.4

3.5

22 3

4.1

R7.5

A

a b

B

A

A

27 ± 0.5

15

19

Bypass Valve

68 ± 0.5

11.9 ± 0.1

56 ± 0.5

26.5 ± 0.5

14 ± 0.2

51 ± 0.4

Rese rvoir Fitting

7/8-14UNF-2B

SAE Straig ht THD.

O Ring Boss

(Both Sides)

55 ± 0.5

65.5 ± 0.4

52

48

R7.5

48

65.5 ± 0.4

55 ± 0.5

Rese rvoir Fitting

7/8-14UNF-2B

SAE Straig ht THD.

O Ring Boss

60 ± 0.565 ± 0.05

45 ± 0.1845 ± 0.18

62.4 ± 0.7

51 ± 0.82.9

45 ± 0.1845 ± 0.18

25.5

20

Bypass Valve

Open

Bypass Valve

Close

Section A-A

View C

Ø 65

Ø 35

Ø 47

+0.03

0

56

+0.8

-0.5

91

+0.8

-0.5

97

+1

-0.15

Ø 15

0

0.036

114

+1

-0.15

15°

+0.5

-2.5

15°

+0.5

-2.5

(30)

144

+2

-1

5

+0.03

0

4- Ø 8.7

Ø 71

Ø 6

52

+0.2

0

P400234

Technical Information

BDU Series Hydrostatic Transmissions

Installation Drawings

BDU-06S : Ports and Dimensions

.

©

Danfoss | November 2021 BC152886484098en-000207 | 35

Page 36

THRTHR

Left-hand side viewing from input shaft

(when pump located upside)

Option Code : L

Right-hand side viewing from input shaft

(when pump located upside)

Option Code : R

View B-B

B

B

10 ± 0.2

12

7.57.5

8181

-0.006

-0.024

13.5

+0.8

0

13.5

+0.8

0

Ø 5

+0.12

0

Ø 5

+0.12

0

P400235

17

4 ± 0.5

Involute Spline

Fillet Root Side Fit

SAE 1963 class 1

Pitch Diameter = 12.7

Pressure Angle = 30°

Number of Teeth = 16

Spline Pitch = 32/64

Involute Spline

JIS 15x13x1.0 class a

Tooth Profile Short Teeth

Module = 1.0

Pressure Angle = 20°

Number of Teeth = 13

Pitch Diameter = Ø13.0

Addendum Modification Coefficient = 0.8

30

0

-2.5

30

0

-2.5

20

0

-2.5

5

0

-2.5

Ø 14.8

Ø 15

Ø 15

0

-0.15

Ø 13.495

0

-0.15

P400236

Technical Information

BDU Series Hydrostatic Transmissions

Installation Drawings

Option Code R L

Input Rotation as Seen From A Direction CW CCW

Control Shaft Rotation a b a b

Output Rotation as Seen From B Direction CCW CW CW CCW

The tightening torque to install HST is 1569 to 2058 N·cm.

BDU-06S : Control Arm Location

BDU-06S : Motor Shaft

36 | © Danfoss | November 2021 BC152886484098en-000207

Page 37

103

20

20

3.5

6

a b

54.5 54.5

63

2.9

B

A

BDU-10L

Charge Pump

Suction Port

Reservoir Fitting

7/8- 14UNF-2B

SAE Straight THD.

O Ring Boss

(Both Sides)

67 ± 0.5

61.5 ± 0.4

21°

15°

+0.5

-2.5

21°

+0.5

-2.5

121

+1

-0.15

14 ± 0.2

27 ± 0.5

18 ± 0.3

97

+0.8

-0.5

Ø 47

+0.03

0

C

25 ± 0.5

66.75 ± 0.5

49 ± 0.5

66.5 ± 0.575 ± 0.0565 ± 0.8

77.4 ± 0.7

Bypass Valve Close

Bypass Valve

Open

30

Reservoir Fitting

7/8- 14UNF-2B

SAE Straight THD.

O Ring Boss

Reservoir Fitting

7/8- 14UNF-2B

SAE Straight THD.

O Ring Boss

BDU-10L

Charge Pump

Suction Port

7/8- 14UNF-2B

SAE Straight THD.

O Ring Boss

25 ± 0.5

68.5 ± 0.5 68.5 ± 0.5

Bypass Valve

View C

53 ± 0.18 53 ± 0.18

53 ± 0.18 53 ± 0.18

Ø 6

Ø 75

4- Ø 9 THR

Mounting Holes

0

-0.3

P400237

Technical Information

BDU Series Hydrostatic Transmissions

Installation Drawings

BDU-10S/10L : Ports and Dimensions

.

©

Danfoss | November 2021 BC152886484098en-000207 | 37

Page 38

7.5

84

7.5

84

E

E

E

E

Left-hand side viewing from input shaft

(when pump located upside)

Option Code : L

Right-hand side viewing from input shaft

(when pump located upside)

Option Code : R

13.5

+0.8

0

13.5

+0.8

0

5

+0.12

0

5

+0.12

0

Ø12

-0.006

-0.024

Ø12

-0.006

-0.024

10 ± 0.15

View E-E

P400238

Technical Information

BDU Series Hydrostatic Transmissions

Installation Drawings

Option Code R L

Input Rotation as Seen From A Direction CW CCW

Control Shaft Rotation a b a b

Output Rotation as Seen From B Direction CW CCW CCW CW

The tightening torque to install HST is 1569 to 2058 N·cm.

BDU-10S/10L : Control Arm Location

38 | © Danfoss | November 2021 BC152886484098en-000207

Page 39

17

4

Involute Spline

JIS 15x13x1.0 class a

Tooth Profile = Short Teeth

Module = 1.0

Pressure Angle = 20°

Number of Teeth = 13

Pitch Diameter = Ø13.0

Addendum Modification Coefficient = 0.8

Involute Spline

JIS 15x18x0.75 class a

Tooth Profile = Short Teeth

Module = 0.75

Pressure Angle = 20°

Number of Teeth = 18

Pitch Diameter = Ø13.5

Addendum Modification Coefficient = 0.5

Shaft : JIS 15x18x0.75

Option Code : K18

Shaft : JIS 15x13x1.0

Option Code : J13

Shaft : SAE 32/64-16T

Option Code : S16

Involute Spline

Fillet Root Side Fit

SAE 1963 class 1

Pitch Diameter = 12.7

Pressure Angle = 30°

Number of Teeth = Ø16

Spline Pitch = 32/64

4 ± 0.5

Ø14.8

Ø15

Ø15

0

-0.15

Ø13.495

Ø15

0

-0.15

Ø14.8

0

-0.15

30

0

-2.5

30

0

-2.5

24

0

-2.5

2.5

0

-2.5

5

0

-2.5

2.5

0

-2.5

P400239

Technical Information

BDU Series Hydrostatic Transmissions

Installation Drawings

BDU-10S/10L : Motor Shaft

©

Danfoss | November 2021 BC152886484098en-000207 | 39

Page 40

F

F

G

G

F

F

3030

8

8

18

8

30

F

F

3

9.6 ± 0.1

11.9 ± 0.1

Pump Sha ft : 15mm Straigh t Keyed

PTO Shaft : None

Charge Pump : None

Option Code : KB

Pump Sha ft : 15mm Straigh t Keyed

PTO Shaft : 12.7mm Straight Keyed

Charge Pump : None

Option Code : PB1

Pump Sha ft : 15mm Straigh t Keyed

PTO Shaft : Serration 12x23x0.5

Charge Pump : None

Option Code : PB2

Model Involute Serration

Module = 0.5

Pressure Angle = 45°

Number of Teeth = 23

Pitch Diameter = Ø11.5

(Effective Length of Spline)

165

+2

-1

165

+2

-1

165

+2

-1

24

+1

-2

30

+1

-2

22

+0.5

0

Ø15

0

-0.036

Ø15

0

-0.036

5

+0.03

0

5

+0.03

0

Ø12

0

-0.05

Ø15

0

-0.036

Ø12.7

0

-0.011

Section F-F

Section G-G

P400241

Technical Information

BDU Series Hydrostatic Transmissions

Installation Drawings

BDU-10S : Shaft Configuration

40 | © Danfoss | November 2021 BC152886484098en-000207

Page 41

H

H

I

I

30

R1

3

18

1.65

14

17

MAX.

MAX.

25

J

8

33 33

2-R7

H

H

30

16

8

10

33 33

2-R7

2-R7

33 33

8

30

J

25

H

H

2-R0.2

2-R0.5

1.65

1.4

1.7

R1

165

+2

-1

165

+2

-1

2.7

+0.23

0

165

+2

-1

50.1

+1

-2

55

+1

-2

22

+0.5

0

Ø15

0

-0.036

Ø15

0

-0.036

Ø31.8 ± 0.05

(Ø35)

Ø15

0

-0.036

5

+0.03

0

5

+0.03

0

Ø42Ø42

Ø35

-0.02

-0.05

Ø35

-0.02

-0.05

Ø12

0

-0.05

Ø12.6

0

-0.018

View J

11.9 ± 0.1

9.6 ± 0.1

Section H-H

Section I-I

Pump Sha ft : 15mm Straigh t Keyed

PTO Shaft : None

Charge Pump : 1.9 cc/rev

Option Code : KB1

Pump Sha ft : 15mm Straigh t Keyed

PTO Shaft : Serration 12x23x0.5

Charge Pump : 2.4 cc/rev

Option Code : PB4

Pump Sha ft : 15mm Straigh t Keyed

PTO Shaft : 12.7mm Straight Keyed

Charge Pump : 2.4 cc/rev

Option Code : PB3

Ø56

Ø58

Ø58

Ø41

(Effective Length of Spline)

Model Involute Serration

Module = 0.5

Pressure Angle = 45°

Number of Teeth = 23

Pitch Diameter = Ø11.5

P400240

Technical Information

BDU Series Hydrostatic Transmissions

Installation Drawings

BDU-10L : Shaft Configuration and Charge Pumps Displacement

©

Danfoss | November 2021 BC152886484098en-000207 | 41

Page 42

4.5

3.5

66

77.5

16

30

a b

Bypass Valve Close

Bypass Valve

Open

4

6161

7878

Bypass Valve

B

A

73

60

Ø 47

+0.03

0

C

150 ± 1.0

60 ± 0.7

122 ± 1.0

134 ± 1.5

Charge Pump

Suction Port

9/16- 18UNF-2B

SAE Straight THD.

O Ring Boss

In case of

External Filter

Charge Pump

Suction Port

9/16- 18UNF-2B

SAE Straight THD.

O Ring Boss

W/Option Filter

(Both Side)

Charge Pump

Suction Port

3/4- 16UNF-2B

SAE Straight THD.

O Ring Boss

In case of

External Filter

Drain Port

3/4- 16UNF-2B

SAE Straight THD.

O Ring Boss

(Both Side)

Drain Port

3/4- 16UNF-2B

SAE Straight THD.

O Ring Boss

Plug for C & HPRV

Only for BDU-21H

(Both Side)

Charge Pump Suction Port

In case of External Filter

View C

22°

+0° 40’

-2° 10’

22°

+0° 40’

-2° 10’

55 ± 0.555 ± 0.5

85 ± 0.07

53 ± 0.1853 ± 0.18

53 ± 0.18

53 ± 0.18

80.5

4- Ø 8.5 THR

Ø 90

Mounting Holes

P400243

Technical Information

BDU Series Hydrostatic Transmissions

Installation Drawings

BDU-21L/21H : Ports and Dimensions

42 | © Danfoss | November 2021 BC152886484098en-000207

Page 43

9

9

97

E

E

E

E

97

Left-hand side viewing from input shaft

(when pump located upside)

Option Code : L

Right-hand side viewing from input shaft

(when pump located upside)

Option Code : R

P400242

15

+0.8

0

15

+0.8

0

Ø6

+0.12

0

Ø6

+0.12

0

Ø15

-0.006

-0.030

Ø15

-0.006

-0.030

12 ± 0.2

View E-E

Technical Information

BDU Series Hydrostatic Transmissions

Installation Drawings

Option Code R L

Input Rotation as Seen From A Direction CW CCW

Control Shaft Rotation a b a b

Output Rotation as Seen From B Direction CCW CW CW CCW

The tightening torque to install HST is 1569 to 2058 N·cm.

BDU-21L/21H : Control Arm Location

©

Danfoss | November 2021 BC152886484098en-000207 | 43

Page 44

Model Involute Spline

20x14x1.25 class a

Tooth Profile = Short Teeth

Module = 1.25

Pressure Angle = 20°

Number of Teeth = 14

Pitch Diameter = Ø17.5

Addendum Modification Coefficient = 0.8

Model Involute Spline

Fillet Root Side Fit

SAE 1963 class 1

Pressure Angle = 30°

Number of Teeth = 22

Pitch Diameter = Ø17.643

Spline Pitch = 32/64

Model Involute Spline

20x18x1.0 class a

Tooth Profile = Short Teeth

Module = 1.0

Pressure Angle = 20°

Number of Teeth = 18

Pitch Diameter = Ø18.0

Addendum Modification Coefficient = 0.8

21.5

0

-0.5

16

2

32

32

5

4

37

Shaft : JIS 20x18x1.0

Option Code : J18

Shaft : JIS 20x14x1.25

Option Code : J14

Shaft : SAE 32/64-22T

Option Code : S22

Ø20

Ø19.75

0

-0.15

Ø20

0

-0.1

Ø18.263

0

-0.15

Ø20

Ø19.8

(Effective Length of Spline)

P400244

Technical Information

BDU Series Hydrostatic Transmissions

Installation Drawings

BDU-21L/21H : Motor Shaft

44 | © Danfoss | November 2021 BC152886484098en-000207

Page 45

7

R10

40 40

18

G

F

F

25 ± 0.25

15

26

3

185 ± 2.0

13.9 ± 0.1

3

36

F

F

16

40 40

R7

10

R7

40 40

3

36

F

F

18

12

Ø17

0

-0.036

Ø17

0

-0.036

Ø40

60

°

Ø72

Ø40

Ø72

Ø74

Pump Shaft : 17mm Straight Keyed (Key Length 36mm)

PTO Shaft : None

Charge Pump : 3.1cc/rev (for 21H)

Option Code : KC2

Pump Shaft : 17mm Straight Keyed (Key Length 36mm)

PTO Shaft : None

Charge Pump : 2.1cc/rev (for 21L)

Option Code : KC1

Pump Shaft : 17mm Straight Keyed (Key Length 26mm)

PTO Shaft : Involute Spline JIS 15x13x1.0

Charge Pump : 2.1cc/rev (for 21L), 3.1 cc/rev (for 21H)

Option Code : PC1 (2.1cc/rev), PC2(3.1 cc/rev)

195 ± 2.0

195 ± 2.0

65 ± 2.0

35

0

-0.5

18

+0.5

0

Ø15

Ø14.8

0

-0.1

Ø17

0

-0.036

5

+0.03

0

Ø42

Ø36

0

-0.039

4.7

+0.25

0

Model Involute Spline

JIS 15x13x1.0 Class a

Tooth Profile = Short Teeth

Module = 1.0

Pressure Angle = 20°

Number of Teeth = 13

Pitch Diameter = Ø13.0

Addendum Modification

Coefficient = 0.8

View G-G

Section F-F

P400245

Technical Information

BDU Series Hydrostatic Transmissions

Installation Drawings

BDU-21L/21H : Shaft Configuration and Charge Pump Displacement

©

Danfoss | November 2021 BC152886484098en-000207 | 45

Page 46

189 ± 2.0

3

30

65 ± 2.0

25 ± 0.25

22

18

15

F

F

40 40

R10

7

G

G

7

R10

40 40

F

F

15

62± 2.0

26

3

185 ± 2.0

13.9 ± 0.1

18

15

5

+0.03

0

Section F-F

Ø42

Ø36

0

-0.039

4.7

+0.25

0

View G-G

Ø74

Ø74

Pump Shaft : 17mm Straight Keyed (Key Length 30mm)

PTO Shaft : Involute Spline JIS 15x13x1.0

Charge Pump : 2.1cc/rev (for 21L), 3.1 cc/rev (for 21H)

Option Code : PC3 (2.1 cc/rev), PC4(3.1 cc/rev)

Pump Shaft : 17mm Straight Keyed (Key Length 26mm)

PTO Shaft : Involute Spline SAE 32/64-16T

Charge Pump : 2.1cc/rev (for 21L), 3.1 cc/rev (for 21H)

Option Code : PC5 (2.1 cc/rev), PC6(3.1 cc/rev)

Model Involute Spline

JIS 15x13x1.0 Class a

Tooth Profile = Short Teeth

Module = 1.0

Pressure Angle = 20°

Number of Teeth = 13

Pitch Diameter = Ø13.0

Addendum Modification

Coefficient = 0.8

Model Involute Spline

Fillet Root Side Fit

SAE 1963 Class 1

Module = 1.0

Pressure Angle = 30°

Number of Teeth = 16

Pitch Diameter = Ø12.7

Spline Pitch = 32/64

35

0

-0.5

35

0

-0.5

18

+0.5

0

+0.5

0

Ø15

Ø14.8

0

-0.1

Ø15

Ø13.495

0

-0.15

Ø17

0

-0.036

Ø17

0

-0.036

P400247

Technical Information

BDU Series Hydrostatic Transmissions

Installation Drawings

46 | © Danfoss | November 2021 BC152886484098en-000207

Page 47

CCW

A

2.5

23