Page 1

Cooling in trucks

Application Note

Most truck drivers are on the road for many days at a time. To keep

their food and beverages cold they need refrigerators that can be

built into the cab.

The BD 35F and BD 50 F compressors are tailored for the driving

workplaces. They are universal for 12 and 24 V DC power supply.

Besides they are unsurpassed to tolerate changeable climatic

conditions and vibrations under harsh road conditions all over the

world.

The BD 35F and BD 50 F compressors can be used for both refrige-

rators and freezers and use R134a as refrigerant.

The compressors are controlled by an electronic unit including

protection against overload and destructive battery discharge. The

unit also features an internal voltage recording as well as calibra-

tion to the applied voltage (compressor monitoring).

Important features:

• Efcient and reliable operation under extreme conditions

• High efciency/Low current consumption/high COP

• Compact design

• Silent operation, barely perceptible

• Variable capacity (manually adjustable or automatic)

The compressors cover a capacity range from 20 to 180 W.

Low, medium and high back pressure applications.

(See specication sheet on the next page).

Refrigerator sizes up to 160 liters and freezers up to 90 liters.

REFRIGERATION AND

AIR CONDITIONING

More than 25 years of experience with 12-24 V DC compressors

The BD 35F and BD 50F compressors are approved according to

the e4 automotive EMC standard and complies with the CE, UL and

C-tick standards.

For further information please contact Danfoss.

Page 2

Technical data

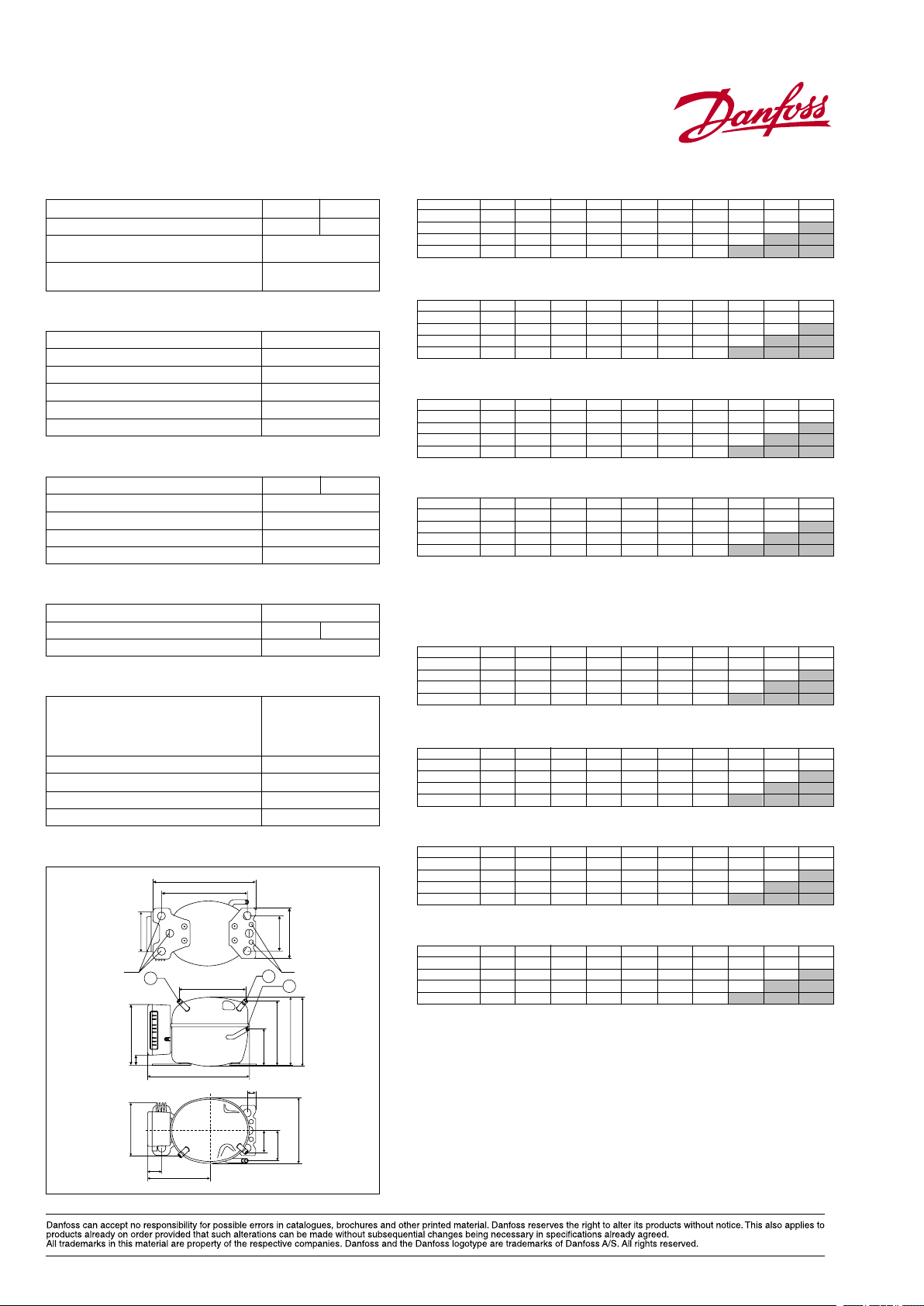

B

A

201

170

70

ø16

C

E

D

130

8269

120

20

105

28

78.

5

204

100

ø9

B2

B1

123

59

46

16

127

BD35F

Performance data

BD35F

General

Compressor BD35F BD50F

Code number: Comp. without electronic unit 101Z0200 101Z1220

Code number: Electronic unit 12-24 V DC,

single packing

Code number: Electronic unit 12-24 V DC,

industrial packing, 30 pcs.

101N0220

101N0221

Application

Application LBP/MBP/(HBP)

Evaporating temperature range °C -30 to 0 (10)

Voltage 12 - 24 V DC

Max. voltage 31.5 V

Max. machine compartment temperature °C 55

Comp. cooling at ambient temp. 43°C S or F1*

* depending on application

Design

Displacement cm3 2.00 2.50

Oil quantity cm3 150

Maximum refrigerant charge g 300

Free gas vol. in compressor housing cm3 870

Weight: Compressor/Electronic unit kg 4.3/0.25

Motor

Motor type Variable Speed

Resistance, all 3 windings (25°C) Ω 2.3 2.0

Approvals E4 72/245 95/54 0277 00

Dimensions

Height mm A 137

B 135

B1 128

B2 73

Suction connector location/I.D. mm C 6.2±0.09

Process connector location/I.D. mm D 6.2±0.09

Discharge connector location/I.D. mm E 5.0 +0.12/+0.20

Compressors on a pallet pcs. 120

Capacity (EN 12900/CECOMAF) Watt

rpm \ °C

2,000

2,500

3,000

3,500

-30

15.8

20.2

22.5

26.2

-25

23.9

29.9

32.4

35.9

-23.3

26.9

33.5

36.5

40.4

-20

33.1

41.2

45.4

50.5

-15

43.8

54.6

61.8

69.8

-10

56.6

70.7

81.7

93.6

-5

71.7

89.7

105

122

89.9

112

133

0

5

10

111

136

139

Power consumption Watt

rpm \ °C

2,000

2,500

3,000

3,500

-30

17.6

23.3

29.9

36.0

-25

23.4

30.9

36.0

42.8

-23.3

25.3

33.3

38.3

45.4

-20

28.7

37.8

43.0

50.8

-15

33.6

44.1

50.7

59.5

-10

38.3

50.2

58.7

68.9

-5

43.0

56.2

66.8

78.5

48.0

62.3

74.8

0

5

10

53.4

59.5

68.7

Current consumption (for 24 V applications the gures must be halved) Amp.

rpm \ °C

2,000

2,500

3,000

3,500

-30

1.5

1.9

2.5

3.0

-25

2.0

2.6

3.0

3.6

-23.3

2.1

2.8

3.2

3.8

-20

2.4

3.2

3.6

4.3

-15

2.8

3.7

4.2

5.0

-10

3.2

4.2

4.9

5.7

-5

0

5

3.6

4.0

4.7

5.2

5.6

6.2

6.5

10

4.5

5.0

5.8

COP (EN 12900/CECOMAF) W/W

rpm \ °C

2,000

2,500

3,000

3,500

-30

0.90

0.87

0.75

0.73

-25

1.02

0.97

0.90

0.84

-23.3

1.06

1.01

0.95

0.89

-20

1.15

1.09

1.06

1.00

-15

1.31

1.24

1.22

1.17

-10

1.48

1.41

1.39

1.36

-5

1.67

1.60

1.58

1.55

1.87

1.80

1.78

0

5

10

2.08

2.29

2.02

Performance data

BD50F

Capacity (EN 12900/CECOMAF) Watt

rpm \ °C

2,000

2,500

3,000

3,500

-30

20.1

27.0

31.0

38.1

-25

31.0

39.0

45.4

53.2

-23.3

34.9

43.4

50.6

59.1

-20

42.8

52.7

61.5

71.9

-15

56.3

68.9

80.7

95.0

-10

42.2

88.9

104

124*

-5

91.6

113

134*

159*

115

144*

171*

0

5

10

144*

178*

181*

Power consumption Watt

rpm \ °C

2,000

2,500

3,000

3,500

-30

25.1

34.1

39.9

50.2

-25

31.8

40.5

49.2

59.3

-23.3

34.0

42.9

52.2

62.5

-20

38.2

47.8

57.8

69.0

-15

44.7

55.8

66.5

80.2

-10

51.3

64.7

76.4

93.4*

-5

58.3

74.3

88.4*

109*

0

65.8

84.8*

104*

5

74.2*

96.1*

10

83.5*

Current consumption (for 24 V applications the gures must be halved) Amp.

rpm \ °C

2,000

2,500

3,000

3,500

-30

2.2

2.9

3.5

4.2

-25

2.6

3.4

4.2

4.9

-23.3

2.8

3.6

4.4

5.2

-20

3.1

4.0

4.9

5.8

-15

3.8

4.7

5.6

6.7

-10

4.4

5.4

6.5

7.8*

5.1

6.2

7.4*

9.0*

-5

0

5

6.4*

7.8*

10

6.9*

5.8

7.0*

8.5*

COP (EN 12900/CECOMAF) W/W

rpm \ °C

2,000

2,500

3,000

3,500

* Fan cooling of electronic unit compulsory

-30

0.80

0.79

0.78

0.76

Test conditions EN 12900/CECOMAF ASHRAE

Condensing temperature 55°C 55°C

Ambient and suction gas temp. 32°C 32°C

Liquid temperature 55°C 32°C

Static cooling, 12 V DC

1 Watt = 0.86 kcal/h

-25

0.98

0.96

0.92

0.90

-23.3

1.03

1.01

0.97

0.95

-20

1.12

1.10

1.06

1.04

-15

1.26

1.24

1.21

1.19

-10

1.41

1.37

1.37

1.32*

-5

1.57

1.53

1.51*

1.45*

0

1.75

1.70*

1.65*

5

1.94*

1.88*

10

2.13*

Danfoss Compressors GmbH

Mads-Clausen-Strasse 7

P.O.Box 1443, D-24939 Flensburg

Phone: +49 461 4941-0

Telefax: +49 461 44715

www.danfoss.com/compressors

CA.46.B1.02

Produced by Danfoss G1 advertising agency 04.03.UF.JN

Loading...

Loading...