Page 1

Data sheet

TR(TW)700

Temperature controller for heating (PN 25)

AVT / VG - external thread

AVT / VGF - flange

Description

AVT / VGF

AVT / VG

The AVT / VG(F) controller is a self-acting

proportional temperature controller developed

primarily for domestic hot water (DHW)

production:

- Hot water tanks

- Storage charge systems

- Instantaneous domestic hot water production

(AVT 255 mm version)

It can be used in mixing loops and room heating

systems as well.

Controller closes on rising temperature.

The controller has a control valve VG(F),

thermostatic actuator and handle for

temperature setting. Thermostatic actuator

consist of bellows, capillary tube and sensor.

The temperature controller is type-tested

according to EN 14597 and can be used in

combinations with safety temperature monitors

STM and safety temperature limiters STL.

Main data:

• DN 15-50

• kVS 0.4 -25 m3/h

• PN 25

• Setting ranges:

−10 … 40 °C / 20 … 70 °C / 40 … 90 °C / 60 … 110 °C

and

10 … 45 °C / 35 … 70 °C / 60 … 100 °C / 85 … 125 °C

• Temperature:

- Circ. water / glycolic water up to 30 %:

2 … 150 °C

• Connections:

- Ext. thread (weld-on, thread and flange

tailpieces)

- Flange

• Flow and return mounting.

Ordering

Example:

Temperature controller, DN 15;

kVS 1.6 ; PN 25; setting range 40…90°C

T

150 °C; ext. thread

max

- 1× VG DN 15 valve

Code No: 065B0772

- 1× AVT thermostatic actuator,

40 … 90 °C

Code No: 065-0598

Option:

- 1× Weld-on tailpieces

Code No: 003H6908

© Danfoss | 2020.08

VG, VGF valve

;

Picture

DN k

(mm) (m3/h)

15

20 6.3 G 1 A 065B0775

25 8.0 G 1¼ A 065B0776

32 12.5 G 1¾ A 065B0777

40 16 G 2 A 065B0778

50 20 G 2½ A 065B0779

15 4.0

20 6.3 065B0781

25 8.0 065B0782

32 12.5 065B0783

40 20 065B0784

50 25 065B0785

VS

0.4

1.0 065B0771

1.6 065B0772

2.5 065B0773

4.0 065B07 74

Cylindrical external thread acc. to

Connection Code No.

065B0770

G ¾ A

ISO 228 / 1

065B0780

Flanges PN 25, acc. to EN 1092-2

AI173286467274en-000503 | 1

Page 2

Data sheet Temperature controller AVT / VG(F) (PN 25)

Ordering (continuous)

AVT thermostatic actuator

Picture For valves

1)

conic male thre ad EN 10226

2)

without immersion pocket

DN 15-2 5

DN 32-50

DN 15-50

Setting range

(°C)

−10 … +4 0

20 … 70 065-0597

40 … 90 065-0598

60 … 110 065-0599

−10 … +4 0

20 … 70 065-0601

40 … 90 065-0602

60 … 110 065-0603

10 … 45

35 … 70 065-0605

60 … 100 065-0606

85 … 12 5 065-0607

Temperature sensor with brass immersion

pocket, length, connection

170 mm, R ½

210 mm, R ¾

255 mm, R ¾

1)

1)

1) 2)

Accessories for valves

Picture Type designation DN Connection Code No.

15

20 003H6909

Weld-on tailpieces

External thread tailpieces

Flange tailpieces

25 00 3H6910

32 0 03 H69 11

-

40 065B2006

50 065B2007

15

R ½ 003H6902

20 R ¾ 003H6903

25 R 1 003H6904

Conical ex t. thread acc. to EN

32 R 1¼ 003H6905

10226-1

40 R 1½ 065B2004

50 R 2 065B2005

15

20 003H6 916

Flanges PN 25, acc. to EN 1092-2

25 0 03H6 917

Code No.

065-0596

065-0600

065-0604

003H6908

003H6 915

2 | AI173286467274en-000503

Accessories for thermostats

Picture Type designation PN For valves Material Code No.

Brass 06 5-4 414

Brass

Immersion pocket 25

DN 15-2 5

DN 32-50

Stainless steel, mat. No. 1.4571 065- 4415

Stainless steel, mat. No. 1.4435 06 5-4 417

Combination piece K2 003H6855

Combination piece K3 003H6856

1)

Not for AV T thermostatic actuator code numbers: 065-0604, 065- 0605, 065-0606, 065-0607

Service kits

Picture Type designation DN (mm) kVS (m3/h) Co de No.

0.4 003H6869

1.0 003H6870

15

Valve insert

1.6 003H6871

2.5 003H6872

4.0 0 03H6873

20 6.3 003 H6874

25 8.0 003H6 875

32 / 40 / 50 125 / 16 / 20 / 25 003H6876

for sensors Code No.

Housing of sensor stuffing box

AVT 170 R 1/ 065- 4420

AVT 210, 255 R / 065-44 21

© Danfoss | 2020.08

065- 4416

1)

1)

1)

1)

Page 3

Data sheet Temperature controller AVT / VG(F) (PN 25)

Technical data

Valves

Nominal diameter DN 15 20 25 32 40 50

k

value m3/h 0.4 1.0 1. 6 2.5 4.0 6.3 8 12.5 16 / 20 1)20 / 25

VS

Stroke mm 3 5 10

Control ratio > 1:50

Control characteristic linear

Cavitation factor z ≥ 0.6 ≥ 0.55 ≥ 0.5

Leakage acc. to standard IEC 534 % of k

VS

Nominal pressure PN 25

Max. differential pressure bar 20 16

Medium Circulation water / glycolic water up to 30 %

Medium pH Min. 7, ma x. 10

Medium temperature

°

C 2 … 150

valve

Connections

tailpieces

Materials

Valve body

thread Red bronze CuSn5ZnPb (Rg5)

flange - Ductile iron EN -GJS-400-18-LT (GGG 40.3)

Valve seat Stainless steel, mat. No. 1.4571

Valve cone Dezincing free brass CuZn36Pb2As

Sealing EPDM

Pressure relieve system Piston

1)

Flange valve bod y

≤ 0.02 ≤ 0.05

External thread

- Flange

Weld-on and external thread

Flange -

Ductile iron

EN-GJS-400-18-LT (GGG

40. 3)

1)

Application principles

Thermostatic actuator

Setting range X

s

°C

Time constant T acc. to EN 14597 s max. 50 (170 mm, 210 mm), max. 30 (255 mm)

Gain K

s

mm / °K

Max. adm. temperature at sensor 50 °C above maximum setpoint

Max. amb. temperature at sensor

Nominal pressure sensor

Nominal pressure immersion pocket

°C

PN 25

Capillary tube length 5 m (170 mm, 210 mm), 4 m (255 mm)

Materials

Temperature sensor Cooper

Ms design Brass, nickel-plated

Immersion pocket

1)

Stainless steel design Mat. No. 1.4571 (170 mm), mat. No. 1.4435 (210 mm)

Handle for temp. setting Polyamide, glass fiber-reinforced

Scale carrier Polyamide

1)

for sensor 170 and 210 mm

−10 … 40 / 20 … 70 / 40 … 90 / 60 … 110

10 … 45 / 35 … 70 / 60 … 100 / 85 … 125

0.2 (170 mm), 0.3 (210 mm), 0.7 (255 mm)

0 … 70

© Danfoss | 2020.08

AI173286467274en-000503 | 3

Page 4

Data sheet Temperature controller AVT / VG(F) (PN 25)

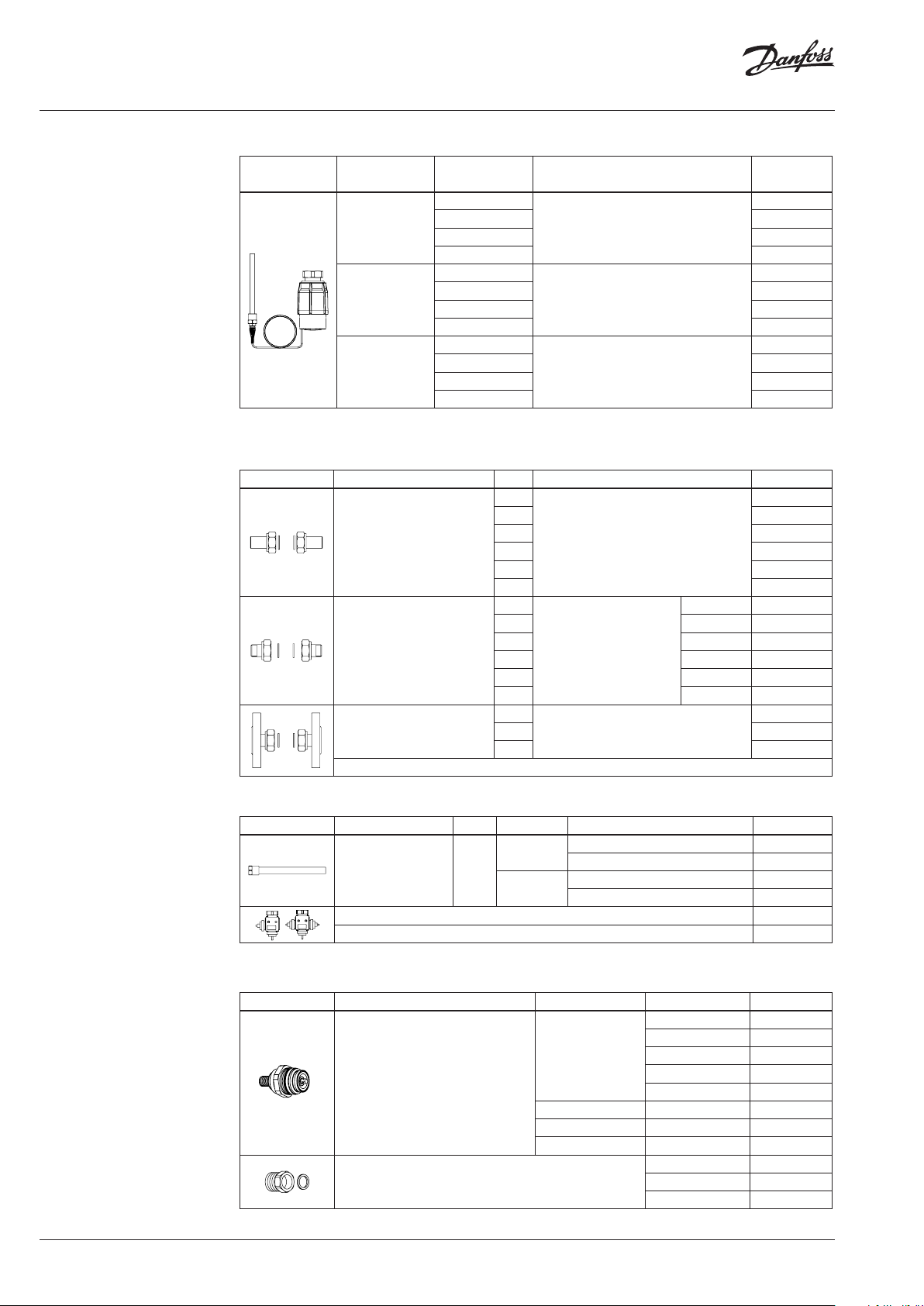

Combinations

Example:

Temperature controller with safety

temperature monitor, DN 15; kVS 1.6 ;

PN 25; setting range 40 … 90 °C;

T

150 °C; ext. thread

max

- 1× VG DN 15 valve

Code No: 065B0772

- 1× AVT thermostatic actuator,

40 … 90 °C

Code No: 065-0598

- 1× STM thermostat, 30 … 110 °C

Code No: 065-0608

- 1× K2 combination piece

Code No: 003H6855

Products will b e delivereed separatly

Note:

For safety temperature monitor

STM / VG(F) data and safet y

temperature limiter STLV data see

relevant data sheet.

AVT / VG

- temperature controller

AVT / AVT / VG

- two temperature controllers

Installation positions

STM / AVT / VG

- temperature controller with

safety temperature monitor

Temperature controller

Temperature controller AVT / VG(F) can be

installed in any position.

STM / AVT / AVT / VG

- two temperature controllers with

safety temperature monitor

4 | AI173286467274en-000503

© Danfoss | 2020.08

Page 5

Data sheet Temperature controller AVT / VG(F) (PN 25)

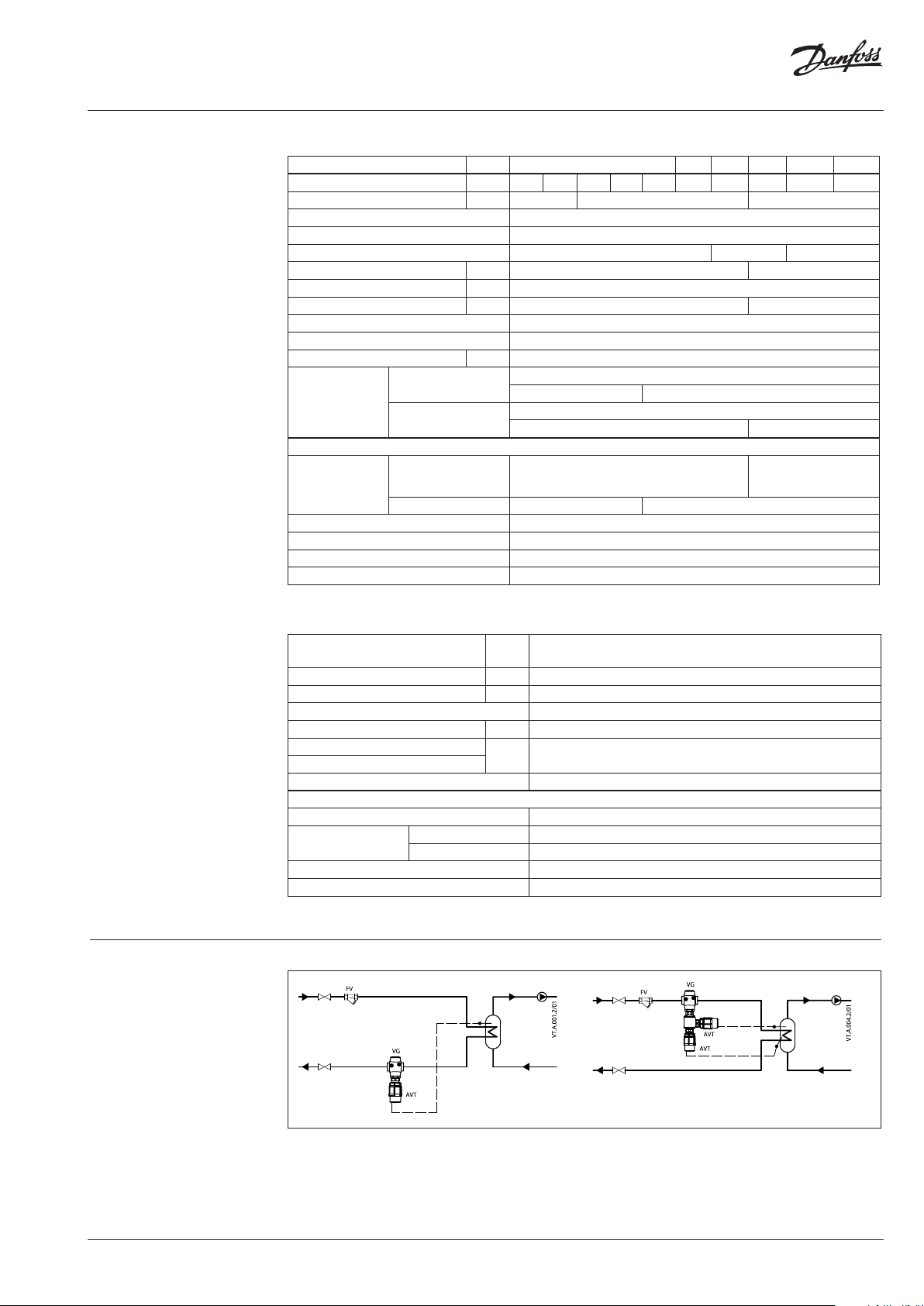

Installation positions

(continuous)

Temperature sensor

The place of installation must be chosen in a way

that the temperature of the medium is directly

taken without any delay. Avoid overheating of

temperature sensor. The temperature sensor

must be immersed into the medium in its full

length.

Temperature sensors 170 mm R ½ and 210 mm R ¾

- The temperature sensor may be installed in

any position.

Temperature sensor 255 mm R ¾

- The temperature sensor must be installed as

shown on the picture.

Pressure temperature

diagram

EN-GJS-400-18-LT (GGG 40.3) PN 25

CuSn5ZnPb (Rg5) PN 25

Maximum allowed operating pressure as a function of medium temperature (according to EN 1092-2 and EN 1092-3).

© Danfoss | 2020.08

AI173286467274en-000503 | 5

Page 6

Data sheet Temperature controller AVT / VG(F) (PN 25)

Valve sizing

Given data:

P

= 14 kW

max

∆t = 20 K

∆pv = 0.15 bar

P

- heating power (kW)

max

∆t -temperature difference (K)

∆pv - differential pressure across the valve

Maximum flow Q

calculated according to formula:

max

= 0.6 m3/h

max

max

Q

Q

(m3/h) through the valve is

max

8 6 , 0P

t

86,014

20

kv value is calculated according to formula:

Q

max

k

v

p

6,0

1 5, 0

V

kv = 1.5 m3/h

Chosen kVS = 1.6 m3/h

or read from the sizing diagram by taking a

line through Q scale (0.6 m3/h) and ∆pv scale

(0.15 bar) to intersect kv-scale at 1.5 m3/h

Chosen kVS = 1.6 m3/h

Solution:

The example selects

1) ext. thread valve VG DN 15, kVS value 1.6 or

2) flange valve VGF DN 15, kVS value 1.6

6 | AI173286467274en-000503

© Danfoss | 2020.08

Page 7

Data sheet Temperature controller AVT / VG(F) (PN 25)

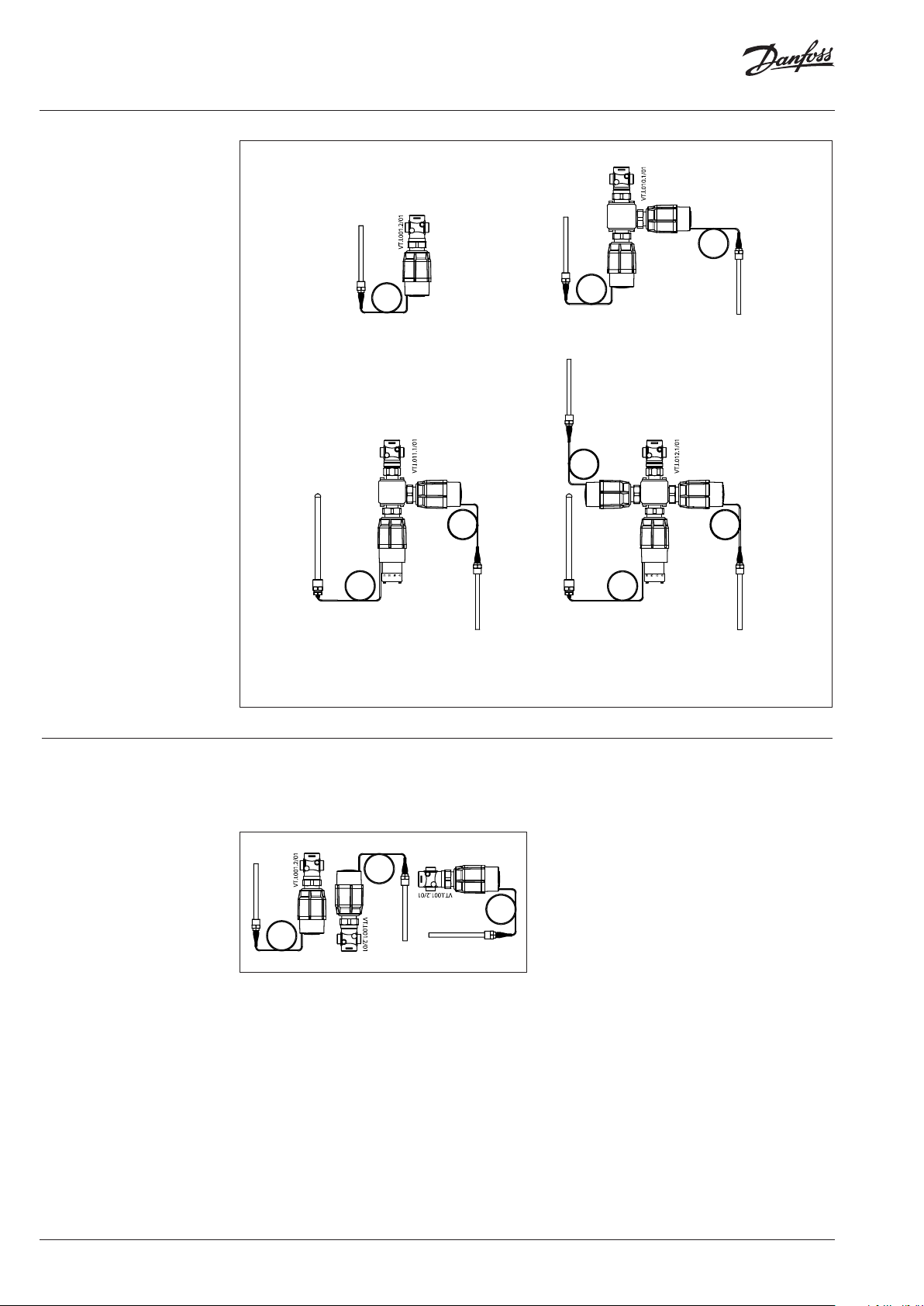

Design

1. Valve VG(F)

2. Valve insert

3. Pressure relieved valve cone

4. Valve stem

5. Union nut

6. Thermostatic actuator AVT

7. Thermostat stem

8. Bellows

9. Setting spring for

temperature control

10. Handle for temperature

setting, prepared for sealing

11. Scale carrier

12. Capillary tube

13. Flexible protected pipe

(only at AVT 255 mm)

14. Temperature sensor

15. Immersion pocket

16. Sensor stuffing box

17. Housing of sensor stuffing

box

Function

AV T 170

AVT 255

AV T 210

Medium temperature changes cause pressure

changes in temperature sensor. Resulting

pressure is being transferred through the

capillary tube to the bellows. Bellows moves

thermostat stem and opens or closes the valve.

By increasing of medium temperature valve

cone moves towards the seat (valve closes), by

decreasing of medium temperature valve cone

moves away from the seat (valve opens).

Handle for temperature setting can be sealed.

Settings

Temperature setting

Temperature setting is being done by the

adjustment of the setting spring for temperature

control. The adjustment can be done by means

of handle for temperature setting and/or

temperature indicators.

Adjustment diagram Temperature setting

Relation between scale numbers 1-5 and closing

temperature.

Note: The values given are approximate

AVT Thermostat ... 170 mm, 210 mm

AVT Thermostat ... 255 mm

© Danfoss | 2020.08

AI173286467274en-000503 | 7

Page 8

Data sheet Temperature controller AVT / VG(F) (PN 25)

Dimensions

L

1

L

2

H

H

L L1H H1H2H

DN

mm

15 65 130 18 0 229 34 47

20 70 15 0 180 229 34 52

25 75 16 0 18 0 229 37 57

32 100 180 2 21 2 21 62 70

40 110 200 221 221 62 75

50 130 230 2 21 2 21 62 82

Note: other flange dimensions - see table for tailpieces

L

L

1

H

2

H

1

H

2

H

H

3

H

1

H

150

Ø 76

AVT

3

1

H

H

2

H

Typ e Weight

sensor 170 mm

sensor 210 mm 1.5

sensor 255 mm 1.6

L

1

H

H

2

H

1.3

kg

L

H

8 | AI173286467274en-000503

VG DN 15-25 VGF DN 15-25 VGF DN 32-50VG DN 32-50

VG

L H H1 H2

DN

15 65 80 34 46 0.7

20 70 80 34 46 0.8

25 75 83 37 46 0.9

32 10 0 151 63 88 3.0

40 110 151 63 88 3.1

50 13 0 151 63 88 3.8

mm

Weight

(kg)

VGF

L H H1 H2

DN

mm

15 130 14 4 48 96 3.3

20 150 149 53 96 4.1

25 160 15 4 58 96 4.7

32 18 0 158 70 88 7. 5

40 200 163 75 88 9.0

50 230 17 1 83 88 11.1

Note: other flange dimensions - see table for tailpieces

Weight

(kg)

© Danfoss | 2020.08

Page 9

Data sheet Temperature controller AVT / VG(F) (PN 25)

Dimensions (continuous)

L

L2L

1

k d

3

2

L

3

d

DN R

R

1)

L

2

SW d L

2)

1

mm

d

2

k

n

15 ⁄ 32 (G ⁄A) 21 130 131 139 65 14 4

20 ⁄ 41 (G 1A) 26 150 144 154 75 14 4

25 1 50 (G 1⁄A) 33 160 16 0 159 85 14 4

32 1⁄ 63 (G 1¾A) 42 - 17 7 18 4 100 18 4

40 1 ⁄ 70 (G 2A) 47 - 195 204 110 18 4

50 2 82 (G 2½A) 60 - 252 234 125 18 4

1)

Conical ex t. thread acc. to EN 10226-1

2)

Flanges PN 25, acc. to EN 1092-2

Ø 16

Ø 16

Ø 19

174

SW 17

AV T 170

SW 22 (R ½)

SW 27 (R ¾)

R ½; R ¾

Ø 9.5

170

6

M14×1

AV T 170

Immersion p ocket

M 14×1 (R ½)

M 22×1 (R ¾)

Housing of sensor

stuffing box

Ø 12

SW 22

30 (R ¾)

25 (R ½)

R ½

Combination piece K2

223

SW 22

AV T 210

85

M22×1

109

215

10

SW 27

R ¾

AV T 210

Immersion p ocket

Combination piece K3

108

SW 22

AVT 255

266

R ¾

109

© Danfoss | 2020.08

AI173286467274en-000503 | 9

Page 10

Data sheet Temperature controller AVT / VG(F) (PN 25)

10 | AI173286467274en-000503

© Danfoss | 2020.08

Page 11

Data sheet Temperature controller AVT / VG(F) (PN 25)

© Danfoss | 2020.08

AI173286467274en-000503 | 11

Page 12

Data sheet Temperature controller AVT / VG(F) (PN 25)

12 | AI173286467274en-000503

© Danfoss | DHS-SRMT/SI | 2020.08

Loading...

Loading...