Page 1

Data sheet

Flow-compensated temperature controller

AVTQ DN 15

Description AVTQ prevents high temperatures in the heat

exchanger when no hot water is tapped by

rapidly shutting off the heat supply (e.g. hot

district heating water). AVTQ can be used with

most plate heat exchangers. However, the heat

exchanger manufacturer should be contacted to

ensure that the chosen heat exchanger has been

approved for use with the AVTQ.

• Pressure-controlled opening/closing on

start/stop tapping.

• Infinite adjustment of operating temperature.

AVTQ controller consist of a thermostatic

actuator, diaphragm element, main valve

and pilot valve. Thermostatic actuator with

diaphragm element and main valve are

installed on the district heating (primary) side.

The diaphragm element is, via impulse tubes,

connected to the pilot valve on the domestic hot

water (secondary) side.

Main data:

• DN 15

• kVS 1.6

• PN 16 - Main valve

AVTQ is a self-acting flow-compensated

temperature controller primarily for use in

district heating systems with plate heat

exchangers for instantaneous hot water

production. It closes on rising sensor

temperature.

It has permanent no-load (idle) temperature

setting on about 40 °C which is offset by a

pilot valve using flow-compensation principle

during tapping. Tapping temperature can be set

individually.

PN 10 - Diaphragm element and pilot valve

• Suitable for domestic hot water (DHW)

production in range of 45 … 60 °C

• Permanent no-load (idle) temperature

(approx. 40 °C)

• Temperature (primary):

- Circulation water / glycolic water up to 30 %:

2 … 100 °C

• Connections:

- Ext. thread (weld-on and thread tailpieces)

• Return mounting

Ordering

Example:

Flow-compensated temperature

controller, DN 15, kVS 1.6, PN 16,

setting range 45 … 60 °C,

t

100 °C, ext. thread

max

- 1× AVTQ controlle r, 45 … 60 °C

Code No: 00 3 L70 15

Option:

- 1× Weld-on tailpieces

Code No: 003H690 8

The controlle r package (code 003 L7 015)

does not inclu de copper impulse tubes .

Two standard Ø6 × 0.8 mm copp er

tubes, of the l enght required for the

particula r application, must be obta ined

separately by th e customer in order to

instal the produ ct. The compression

fittings f or mounting the tubes onto the

controller are p rovided in the package.

© Danfoss | 2017.11

AVTQ controller

Picture

* Controller incl. gla nd and compression fitt ings for mounting on Ø6 × 0.8 mm co pper impulse tube (standard cop per impulse tube not

included in th e package).

DN

(mm)

15 1.6 G ¾ A

k

vs

(m3/h)

Main valve ISO 228/1 Pilot valve ISO 228/1

Connection

G 1 A

(DN 20)

Code No .*

003L7015

Accessories

Picture Type designation DN Connection Code No.

Weld-on tailpieces

External thread tailpieces

15

Conical ex t. thread

acc. to EN 10226-1

– 003H6908

R ½” 003H6902

VD.LJ.A2.02 | 1

Page 2

Data sheet Flow-compensated temperature controller AVTQ DN 15

1

4

Ordering (continuous)

Technical data

Service kits

Picture Type designation Code No.

Gasket for diaphragm housing 003L 3154

Thermostatic actuator incl. sensor stuff ing box 003L7100

Compression fittings for Ø6 mm copper tube (4 ferrules and 4 nuts) 003 L7101

Pilot valve excl. compression fittings 003 L7108

Main valve incl. complete valve insert 00 3L7109

Diaphragm element excl. compression fittings 003 L7111

Sensor stuffing box incl. gasket

Nominal diameter DN 15

kVS value m3/h 1.6

Control ratio 100 : 1

Cavitation factor z ≥ 0.6

Leakage acc. to standard IEC 534 < 0.05 %

Nominal pressure

Max. differential pressure

Max. closing pressure 12

PN

bar

Medium

Medium pH Min. 7, max. 10

Medium temperature °C

Connections

valve Ext. thread

tailpieces Weld-on and external thread

Setting range Xs °C 45 … 60

Time constant T acc. to EN 14597 s 4

Max. adm. temperature at sensor °C 130

Max. water velocit y around the sensor m/s 1.5

Capillary tube length m 1

Materials

Valve body RG5, DIN 1705, W.no. 2.1096.01

Valve insert and valve cone

Valve seat, pressure relief cylinder CrNi steel, DIN 17440, W.no. 1.4404

Temperature

controller

Valve spindle CrNi steel, DIN 17440, W.no. 1.4435

Valve plate, O-ring, diaphragm EPDM

Diaphragm housing CrNi steel, DIN 17440, W.no. 1.4435

Diaphragm plate CrNi steel, DIN 17440, W.no. 1.4436

Diaphragm spindle

Diaphragm

housing

stuffing box

Housing

Spindle CrNi steel, DIN 17440, W.no. 1.4401

Sensor

Sensor

Sensor stuffing box EPDM

Gasket Carbon dioxide (CO2)

Charge

Valve body

Valve base

Pilot valve

Valve spindle CrNi steel, DIN 17440, W.no. 1.4401

Setting spring CrNi steel, DIN 17440, W.no. 1.4568

Cone, spring retainer PPS-plastic

O-ring EPDM

1)

Valid for primary side (main valve)

2)

Valid for secondar y side (pilot valve and diap hragm element)

3)

In case of domesti c hot water (secondary side) pH lowe r than 7 -> the hardne ss of the water must be larger than th e sulphate element

4)

at T idle nom. + 10 °C

4)

1)

16

2)

10

6

Circulation water / glycolic water up to 30%

1)

Domestic hot water (chlorine (cl) content max. 200 ppm)

1) ,2) ,3)

1)

2 … 100

2)

2 … 90

Dezincification resistant brass BS 2874

Ecobrass (CW724R)

Ecobrass (CW724R)

Dezincification resistant brass BS 2874

Ecobrass (CW724R)

Ecobrass (CW724R)

Ecobrass (CW724R)

2)

00 3L7120

–HCO

3

〉

––SO

2 | VD.LJ.A2.02

© Danfoss | 2017.11

Page 3

Data sheet Flow-compensated temperature controller AVTQ DN 15

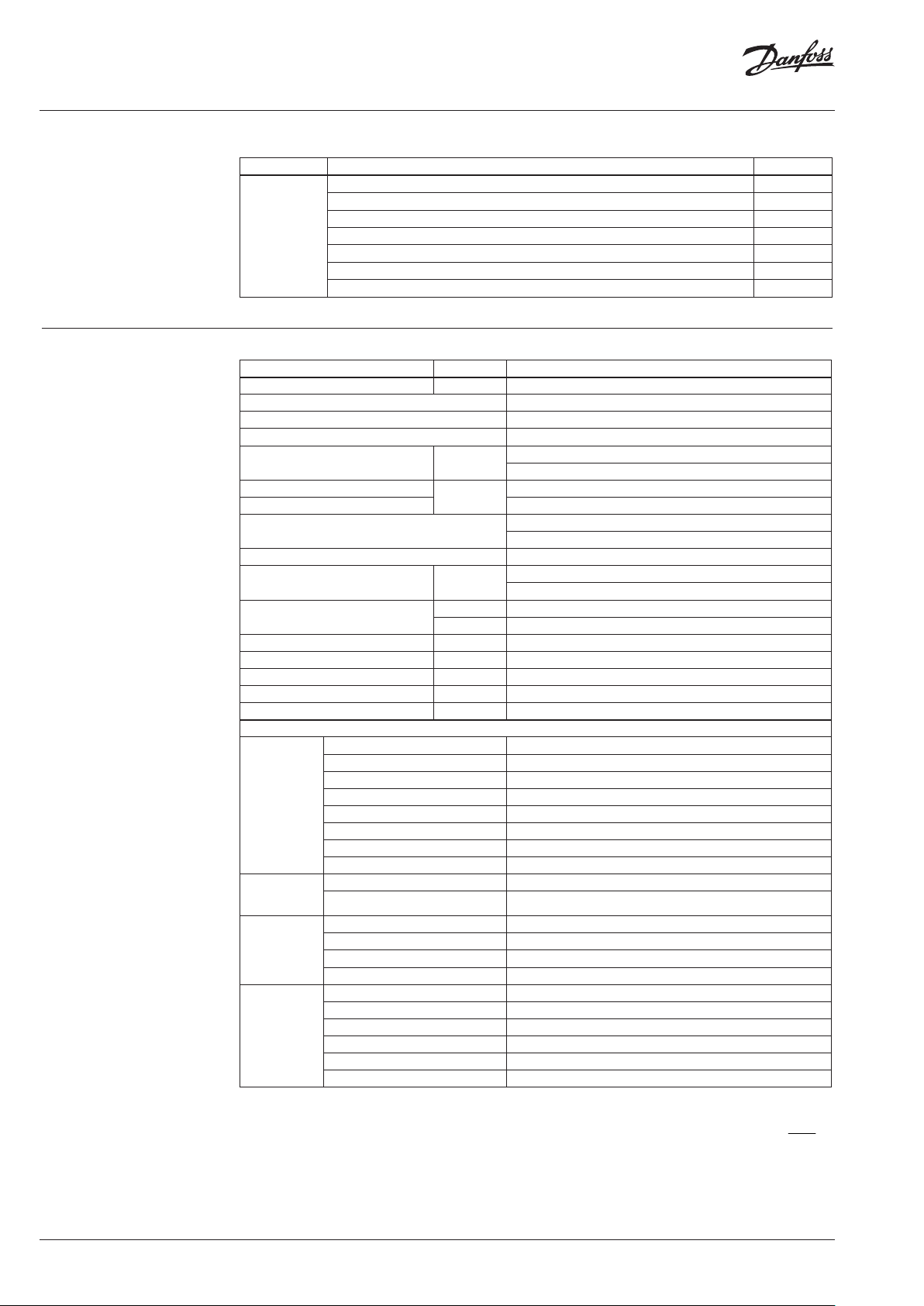

Application principle

The controller AVTQ must be

installed in the return pipeline

only.

Design

1. Thermostatic actuator with

sensor stuffing box

2. Pressure spindle

3. Diaphragm housing

stuffing box

4. Nut

5. Diaphragm housing

6. Diaphragm spindle

7. Control diaphragm

8. Compression connection for

impulse tube

9. Intermediate ring

10. Nameplate

11. Main spring

12. Damping + teflon ring

13. Valve spindle

14. Valve ins ert

15. Pressure relief c ylinder

16. Valve body (main valve)

17. Handle for temperature setting

18. Spindle

19. Valve b ase

20. Spring retainer

21. Setting spring

22. Pressure equalizing hole

23. Valve cone

24. Valve body (pilot valve)

25. Compression connection for

impulse tube

26. Sealing bolt of sensor

stuffing box

27. Gasket of sensor stuf fing box

28. Housing of sensor stuffing box

When domestic hot water (DHW) is tapped, flow

through the pilot valve creates a pressure drop

(force in the diaphragm housing) which is used

to increase the temperature level from no-load

(idle) to set tapping temperature.

This temperature increase causes the main valve

to open for flow on the district heating side and

close when the temperature level again falls to

the no-load operating level. No-load operation

prevents the district heating line becoming cold.

Tapping temperature can be set individually.

© Danfoss | 2017.11

VD.LJ.A2.02 | 3

Page 4

Data sheet Flow-compensated temperature controller AVTQ DN 15

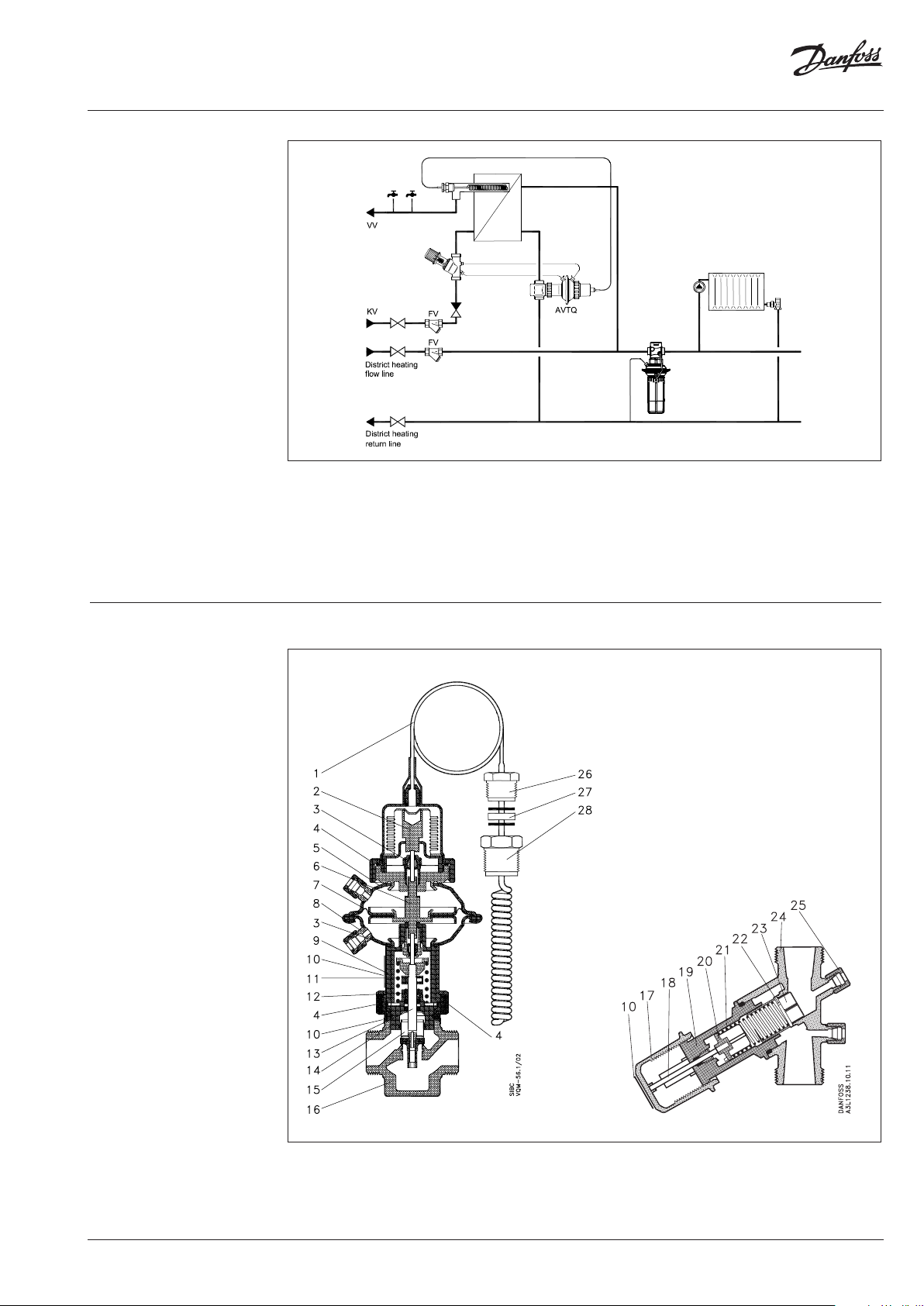

Installation

One-way heat exchanger Two-way heat exchanger Three-way heat exchanger

Fig. 3

AVTQ can be used with most types of plate heat

exchangers.

The AVTQ manufacturer should be contacted to

ensure:

- that the AVTQ is approved for use with the

chosen heat exchanger

- the correct material selection when

connection the heat exchangers

- the correct connection of one pass plate heat

exchangers; layer distribution might occur, i.e.

reduced comfort

The system functions optimal when the sensor

is installed right inside the heat exchanger

(see page 3). However, the sensor head should

be placed approx. 5 mm from the plate which

divides the primary and the secondary side of

the exchanger. If the sensor head is placed too

close to the dividing plate, the sensor might

measure the temperature of the plate and not

the temperature of the medium. For correct noload operation, thermal flow should be avoided

since hot water rises and increases the no-load

consumption.

Note: water velocity around the sensor must be in

accordance with the requirements for copper tube.

The temperature controller (main valve):

- must be installed in the return pipeline on

the district heating (primary) side of the heat

exchanger

- the diaphragm element can be turned in

any position in relation to the valve body so

that impulse tube can be connected in the

required direction

The pilot valve:

- must only be installed in the flow pipeline on

the secondary side of the heat exchanger

- in systems where it cannot be excluded that

drinking water is contaminated with fine dust

from time to time, it is recommended not to

mount the pilot valve with the impulse tube

connections downwards (fig.2) to avoid dirt

ingress in the impulse tubes and diaphragm

housing

The sensor can be installed in any position (fig.1)

It is strongly recommended that:

- the primary and secondary sides of the heat

exchanger should be flushed through before

the heating system is used the first time. In

addition the (+) and (–) side of the diaphragm

should be vented.

- dirt strainers with a mesh size of max. 0.6mm

should be installed in both, the cold tap

water pipeline ahead of the pilot valve and

in the flow pipeline from the district heating

network.

4 | VD.LJ.A2.02

Fig. 1 Fig. 2

© Danfoss | 2017.11

Page 5

Data sheet Flow-compensated temperature controller AVTQ DN 15

()

86.0x42

86.0xP

[

]

Sizing Example

Given data:

T1 = 65 °C

T3 = 50 °C

T4 = 10 °C

Q2 = 0.3, 0.6, 0.9 m3/h (300, 600, 900 l/h)

Primary Secondary

T1 - District heating water flow temperature

T3 - Hot water temperature

T4 - Cold water temperature

Q2 - Hot water service flow

District

heating

flow line

District

heating

return line

Fig. 4

The maximum heating power P

according to formula:

TxQ

p

max

p

max

∆

=

=

=

86.0

()

86.0

86.0

1050x900

−

=

TTxQ

−

43222

kW42

is calculated

max

Based on max. heating power heat exchanger

could be selected. Information about the cooling

across the primary side of heat exchanger

can be acquired either by contacting the

manufacturer of the heat exchanger or by using

the manufacturer’s dimensioning diagram.

In the example chosen cooling on primary side

(ΔT1) is 43 °C, 40 °C or 39 °C, the differential

pressure across the AVTQ main valve (Δpv) is

0.2 bar.

Hot water

C old water

Chosen AVTQ main valve has kvs 3.2 m3/h and

therefore is big enough. Values for flows of 300

and 600 l/h are calculated on the same way and

entered in the table.

Tab.1

Secondary flow Primary flow Cooling

W

(kW)

14 300 280 0.39 43

28 600 600 0.85 40

42 900 925 1.31 39

Q

(l/h)

Q

2

(l/h)

k

1

v

(m3/h)

∆T

(°C)

1

They can be plotted on the diagram overleaf

(fig. 5) and connected. The temperature variation

can be read from the diagram as the difference

between the temperature lines intersected by

the curve

The primary flow Q1 can be calculated according

to formula:

max

Q

=

1

=

T

∆

1

h/l925Q1=

39

Using the above data, the needed capacity of the

main valve (kv) can be calculated:

3

1

=

k

v

[]

∆

barp

v

925.0

h/mQ

=

2.0

kv = 1.31 m3/h

© Danfoss | 2017.11

VD.LJ.A2.02 | 5

Page 6

Data sheet Flow-compensated temperature controller AVTQ DN 15

Sizing (continuous)

The pressure drop across the pilot valve can be

read from the diagram below.

Fig. 6 Pressure drop (Δp

) across pilot valve as a function of the setting value and secondary flow

pilot

Setting

The AVTQ controller can be used with plate heat

exchangers of up to 75 kW. As a result of the flow

compensation principle an actual dimensioning

of the valve is unnecessary, because the

valve will always adjust around the required

temperature without regard to the flow.

This means that if the controller is set to 50 °C

(this is done at 75% of max. tapping flow to

obtain optimum control), then this temperature

will be maintained whether or

not the actual

is 120 l/h, 900 l/h or more. Between 120 l/h and

900 l/h the temperature will vary approx. 4 °C.

Typical settings:

Minimum:

Designation Application values Pilot valve setting

Flow temperature, primary Tp = 65 °C

Dierential pressure across the AVTQ main valve ∆p = 0.5 bar

Hot water temperature, secondary Ts (hot) = 50 °C

Cold water temperature, secondary Ts (cold) = 10 °C

Secondary ow Qs = 800 l/h

3.0

Maximum:

Designation Application values Pilot valve setting

Flow temperature, primary Tp = 100 °C

Dierential pressure across the AVTQ main valve ∆p = 6.0 bar

Hot water temperature, secondary Ts (hot) = 50 °C

Cold water temperature, secondary Ts (cold) = 10 °C

Secondary ow Qs = 750 l/h

The values mentioned above are reference

values and therefore corrections of pilot valve

settings might be necessary in order to obtain

Other approx. setting values:

Tapping temperature = 50 °C

Tapping flow = 800 l/h

2.0

the required temperature.

T

primary

65 °C 3.0 2.5 2.5 2.5

80 °C 2.75 2.5 2.25 2.25

100 ° C 2.5 2.5 2.25 2.0

0.5 1.0 3.0 6.0

∆p (bar)

flow

6 | VD.LJ.A2.02

© Danfoss | 2017.11

Page 7

Data sheet Flow-compensated temperature controller AVTQ DN 15

Dimensions

R 3/4

DN

(mm)

L

1

(mm)

L

(mm)

2

L

3

(mm)aISO 228/1bISO 228/1

Weight

15 65 22.5 35 G ¾ A G ¾ A 3.57

(kg)

© Danfoss | 2017.11

VD.LJ.A2.02 | 7

Page 8

Danf

already on order pro

All trademarks in this material are property of the respec

Data sheet Flow-compensated temperature controller AVTQ DN 15

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

8 | VD.LJ.A2.02

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | DHS-SRMT/SI | 2017.11

Loading...

Loading...