Data sheet

Temperature controller AVTB (PN 16)

Description AVTB is self-acting temperature controller used

to control the water temperature in hot water

tanks, heat exchangers, oil preheaters, etc.

Controller closes on rising temperature.

The controller has a control valve, thermostatic

actuator and handle for temperature setting.

Thermostatic actuator consist of a bellows,

capillary tube and sensor.

Main data:

• DN 15, 20, 25

• kVS 1.9; 3.4; 5.5m3/h

• PN 16

• Setting range:

0 … 30°C/20 … 60°C/30 … 100°C

• Temperature:

- Circulation water/glycolic water up to 30%:

2 … 130°C

• Connections:

- Int. thread

- Ext. thread (weld-on and ext. thread

tailpieces)

• Flow or return mounting, depending on

sensor type.

Ordering

1)

Complete control ler including sensor

stuffi ng box. The immersion p ocket is

an accessor y.

2)

Including sma ll sensor Ø 9.5 × 180.

The sensor is to be m ounted where the

system tempe rature is warmer than

the temperatu re in the valve housing.

Insulaton disk is fac tory mounted on

the controller.

3)

Including sma ll sensor Ø 9.5 × 150.

Capillar y tube length 2.3 m.

4)

Including se nsor Ø 18 × 210; available

on request

Example:

Temperature controller; DN 15;

kVS 1.9; PN 16; setting range

30 … 100°C; T

- 1× AVTB DN 15 Controller

Code No: 0 0 3N5141

Option:

- 1× Imm. pocket, brass

Code No: 013U 029 0

- 1× Weld-on taipieces

Code No: 003H6908

130 °C; ext. thread

max

AVTB Controller

DN

15

20

25

Capillary tube length: 2 m.

Setting

range

(°C)

0 … 30

20 … 60 90 003N8229

30 … 100 130 003N 8141

0 … 30

20 … 60 90 003N8230

30 … 100 130 003 N8142

0 … 30

20 … 60 90 003N8253

30 … 100 130 003N8143

k

VS

(m3/h)

1.9

3.4

5.5

Max. se nsor

temp.

(°C)

55

55

55

Internal thread External thread

Connection

IS O 7/1

Rp ½

Rp ¾

Rp 1

Code No.

003N2232

003N3232

003N4232

1)

4)

2)

3)

4)

2)

3)

4)

2)

3)

Connection

ISO 228/1

Service kits

Type designation for Code No.

Repair set

Two diaphragms, two O-rings, one rubber cone,

one tube of grease and eight valve cover screws

Thermostatic actuator 0 … 30 °C, sensor Ø 18 × 210, 2m 003N0075

Thermostatic actuator 20 … 60 °C, sensor Ø 9.5 × 180, 2m 00 3N0130

Thermostatic actuator 30 … 100 °C, sensor Ø 9.5 × 150, 2.3m 00 3N0131

Housing of sensor stuffing box, R ½ × M14 × 1 mm, rubber EPDM Ø 12.6 × 4 × 6 mm 013U 8102

1)

For thermostatic a ctuators 20 … 60°C and 30 … 100° C; code includes housing an d gasket of sensor stuffi ng box

Code No.

003 N5101

G ¾ A

G 1 A

G 1¼ A

DN 15 003N4006

DN 20 003N4007

DN 25 003N4008

00 3N 5114

00 3N5141

003 N5102

00 3N 5115

00 3N5142

003 N5103

00 3N 5116

003N5143

1)

4)

2)

3)

4)

2)

3)

4)

2)

3)

1)

© Danfoss | 2018.04 VD.JK.Z4.02 | 1

Data sheet Temperature controller AVTB (PN 16)

Ordering (continuous)

Technical data

Accessories

Picture Type designations DN Connection Code No.

15

Weld-on taipieces

External thread taipieces

Immersion pocket

Insulation disk

1)

For details see “ Installation positions” sec tion

Nominal diameter DN 15 20 25

k

value m3/h 1.9 3.4 5.5

VS

Cavitation factor z 0.4

Nominal pressure PN 16

Max. differential pressure bar 10

Medium Circulation water/glycolic water up to 30%

Medium pH Min. 7, max. 10

Medium temperature

Connections

Materials

Valve body

Valve seat Cr Ni steel, DIN 17440, W.No. 1.4301

Valve cone NBR-rubber

Spindle Dezincing-free brass, BS 2872/CZ132

Other metal parts Dezincing-free brass, BS 2874/CZ132

Diaphragms, O-rings EPDM-rubber

Temperature sensor Copper

Sensor charge

1)

o

valve Internal and external thread

tailpieces Weld-on and external thread

internal thread MS 58, hot-pressed, DIN 17660, W.No. 2.0402, CuZn40Pb2

external thread Dezincing-free brass, BS 2872/CZ132

20 003H6909

25 00 3H6910

15

20 R ¾” 003H6903

25 R 1” 003H6904

Rp ½ × M14 × 1 mm, brass 182 mm, without sens.stuff. box

Rp ½ × M18 × 1.5 mm, st. steel 182 mm, with sens.stuff. box

Rp ¾ × M22 × 1 mm, brass 220 mm, with sens.stuff. box

Rp ¾ × M22 × 1 mm, st. steel 220 mm, with sens.stuff. box

C 2 … 130

0 … 30 oC R 152 A, C2H4F2

20 … 60 oC Butane R600, C4H10

30 … 100 oC Carbon dioxide, CO2

Con. ext. thread acc. to

EN 10226 -1

-

R ½” 003H6902

003H6908

013U 0290

003 N0196

003N0050

003 N0192

003N4022

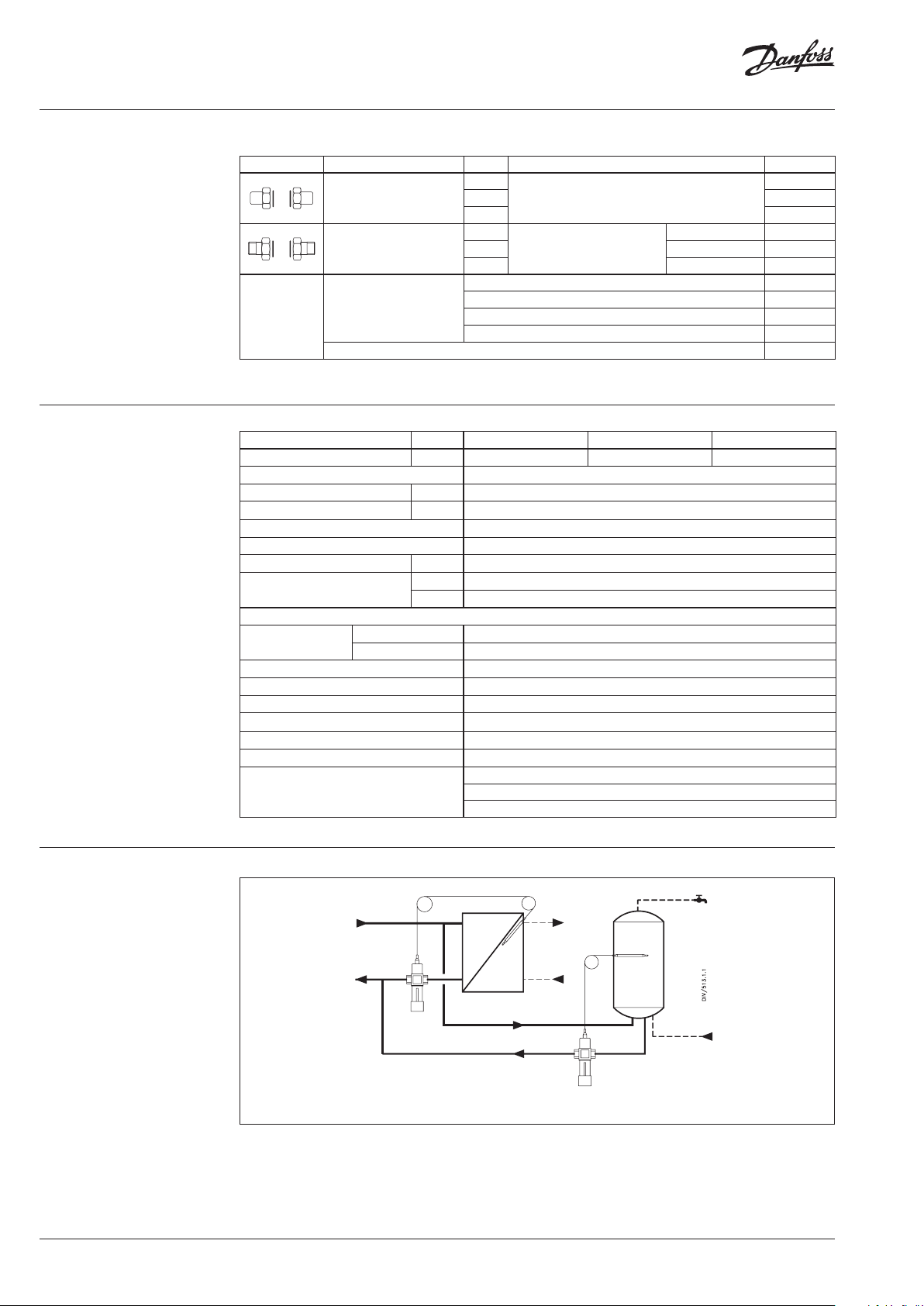

Application principle

Slow control system, setting range 30 …100°C

Fast control system, setting range 0 … 30°C/20 … 60°C

2 | VD.JK.Z4.02 © Danfoss | 2018.04

Data sheet Temperature controller AVTB (PN 16)

Installation positions Temperature controller

The controller can be installed in any position,

with flow in the direction of the cast-in arrow.

AVTB 20 … 60 must always be installed in the

return line (sensor warmer than valve).

If AVTB 20 … 60 has been installed in the return

line from a service water heat exchanger (where

for certain periods the return temperature

approaches the sensor temperature) the

installation of insulation disk is recommended

(003N4022).

Insulation disk is factory mounted

on the product.

Temperature sensor

AVTB 0 … 30 and 30 …100 can be installed either

in flow or in return line.

With AVTB 30 … 100, if temperature variations

of more than 20°C occur at the valve, insulation

disk (003N4022) must be installed between

thermostatic actuator and valve body.

o

f

r

r

m

e

a

p

t

s

e

B

n

c

e

Sizing

Sensor Ø 18 × 210 mm

2)

Sensor Ø 9.5 × 180 mm1) Sensor Ø 9.5 × 150 mm

(AVTB 0 … 30 °C) (AVTB 20 … 60 °C) (AVTB 30 … 100 °C)

1)

The sensor is to be m ounted where the system temp erature is warmer than the temp erature in the valve body

2)

The sensor can be m ounted where the system temp erature is either warmer or col der than the temperature in th e valve body

2)

VD.JK.Z4.02 | 3© Danfoss | 2018.04

Data sheet Temperature controller AVTB (PN 16)

hm 1,3

20

0,8631

3

hm 1,0

1,7

3,1

p

Q

k

3

v

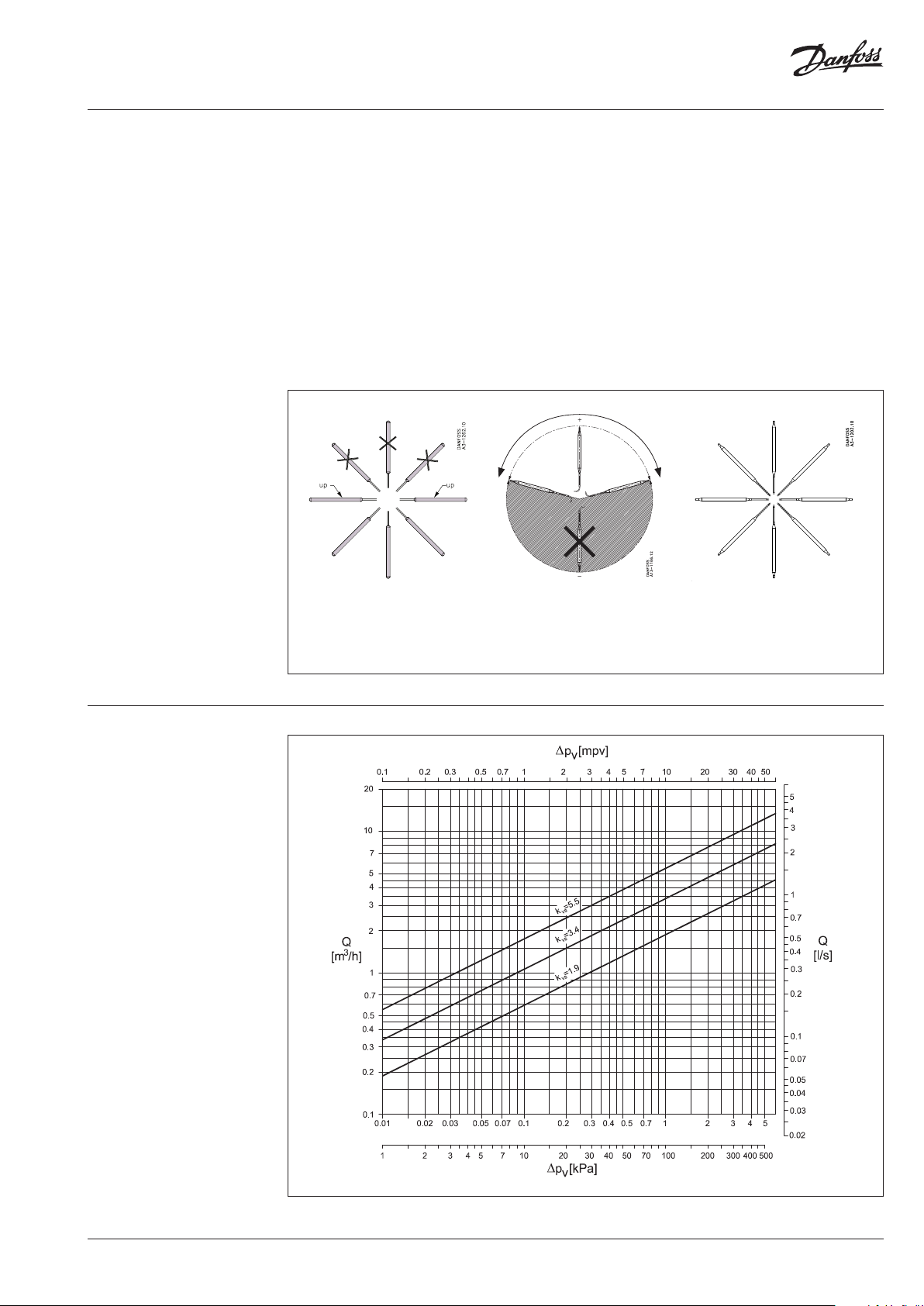

Sizing (continuous) Temperature range and P-band

Example

Hot water temperature control in hot water

tanks.

Primary medium: Water

Given:

Load: 31 kW (26500 kcal/h)

Primary temperature

drop Δt: 20 K

Differential pressure

Δp across the valve: 1.7 bar

Max. hot water

temperature: 55°C

Water volume Q:

Calculated kv value is 1m3/h.

From this value on the kV scale in the AVTB

diagram, take a line horizontally to intersect

the columns for recommended sizing range.

Select the smallest possible valve, here an AVTB

15. A temperature range of 30 …100°C can be

assumed as suitable for this example.

The P-band (XP) and final temperature range

can also be read from the AVTB diagram. The

required closing temperature can be read from

the scale for the valve selected. However, there

are two temperature ranges that meet the

requirement for a closing temperature of 55°C.

XP is 9 K for the range 30 …100°C, which means

that the controller will yield the calculated

capacity at a sensor temperature of 55°C minus 9

K = 46°C. For the range 20 … 60°C XP = 4 K. This

Required:

The correct valve size

means that the controller will yield the calculated

capacity at 55°C minus 4 K = 51°C.

To ensure the most stable control an AVTB 15

with a range 30 … 100 °C should be chosen. The

water in the hot water tank will reach the closing

temperature (55°C) only when there has been no

hot water demand for some time.

AVTB diagram to determine valve size, temperature range and proportional band (XP).

Note: The values stated are mean values

4 | VD.JK.Z4.02 © Danfoss | 2018.04

Data sheet Temperature controller AVTB (PN 16)

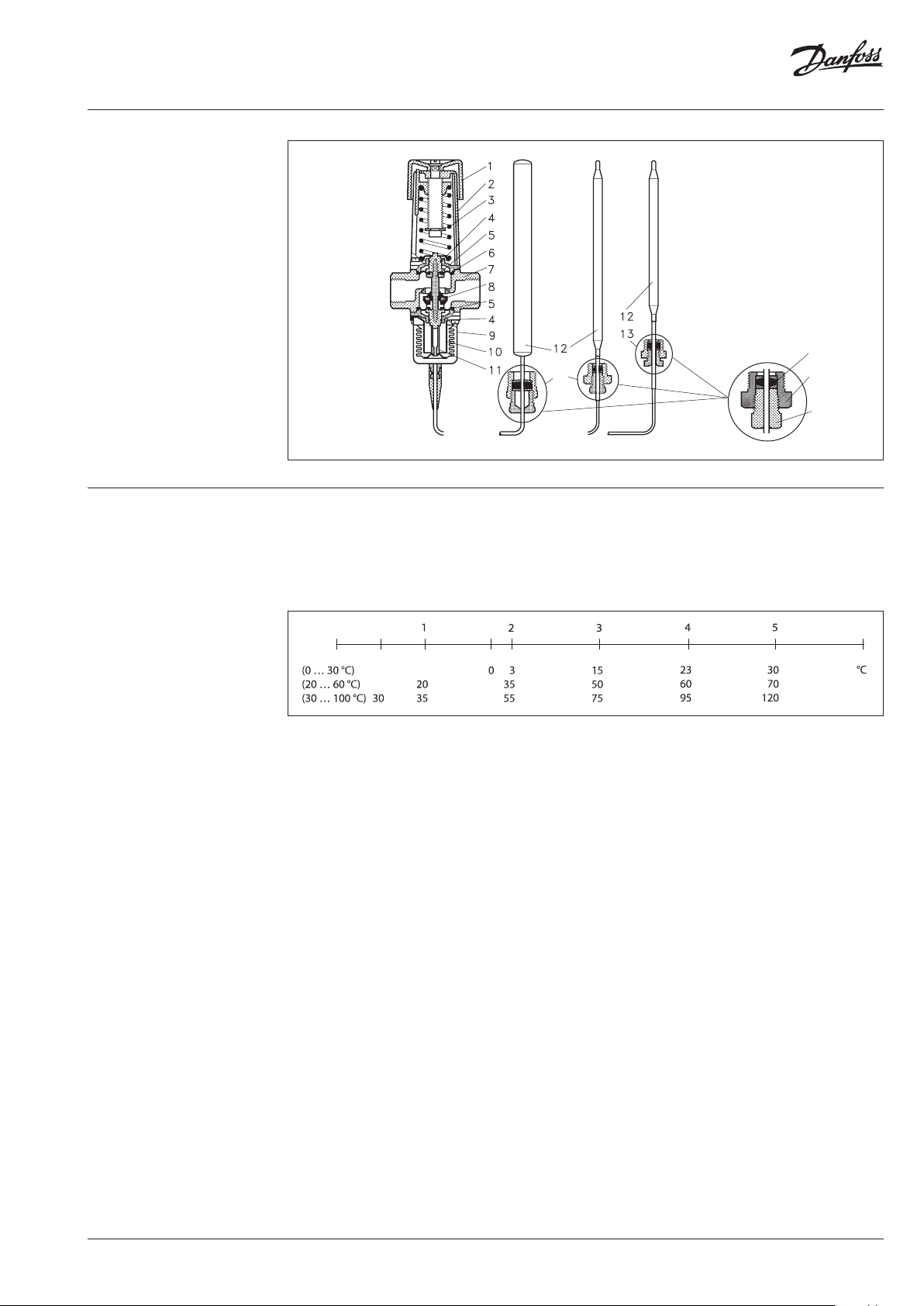

Design

1. Handle for temperature

setting

2. Spring housing

3. Setting spring

4. O-ring

5. Diaphragm

6. Spindle

7. Valve body

8. Valve cone

9. Bellows

10. Bellows stop

11. Pres sure stem

12. Temperature sensor

13. Sensor stuffing box

14.

Housing of sensor stuffing

box

15. Gasket of sensor stuffing box

16. Sealing bolt of sensor

stuffing box

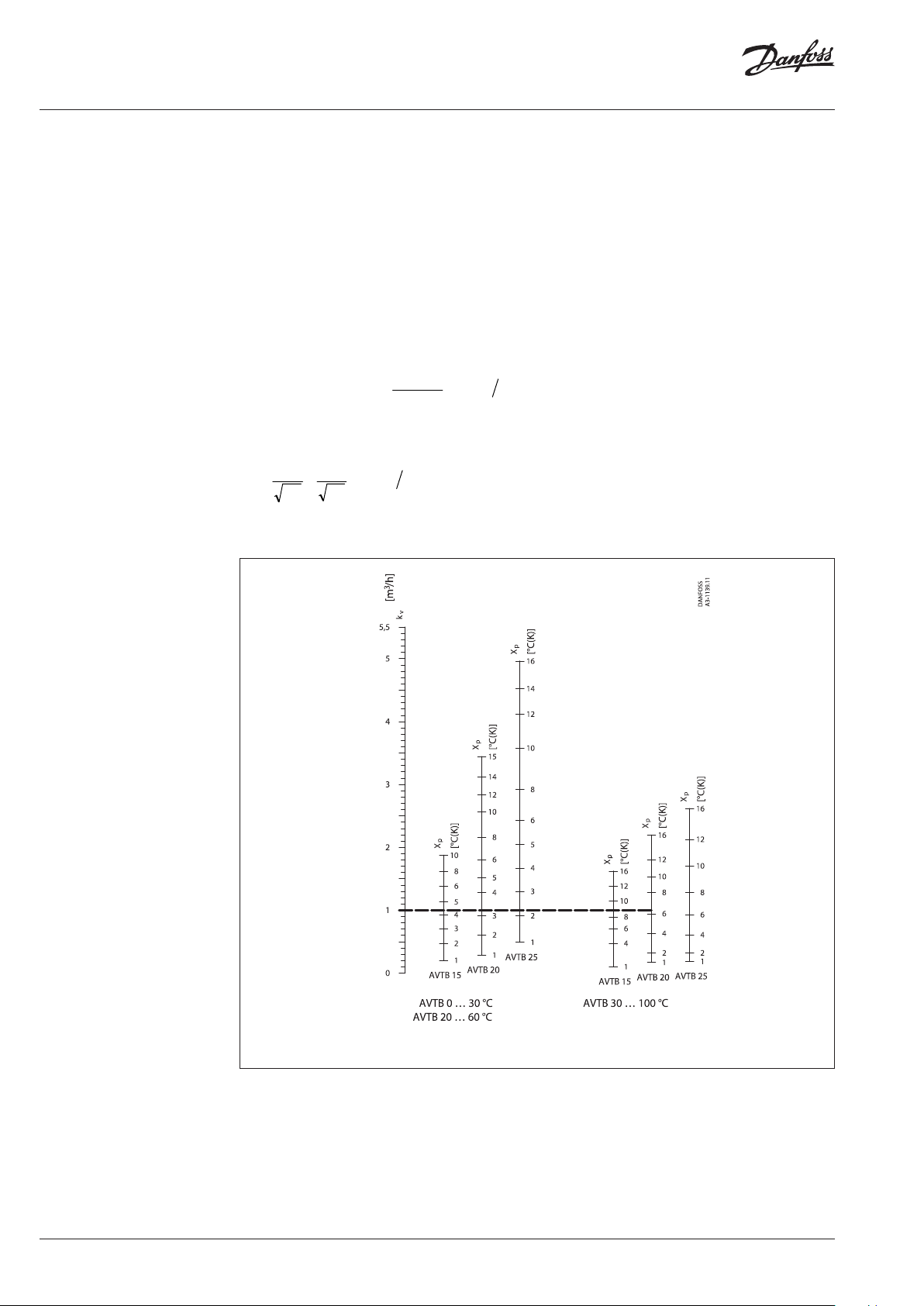

Settings Temperature setting

Relation between scale numbers 1-5 and the

closing temperature.

15

13

14

16

The values given are approximate.

Scale settin g

Closing temperature

VD.JK.Z4.02 | 5© Danfoss | 2018.04

Data sheet Temperature controller AVTB (PN 16)

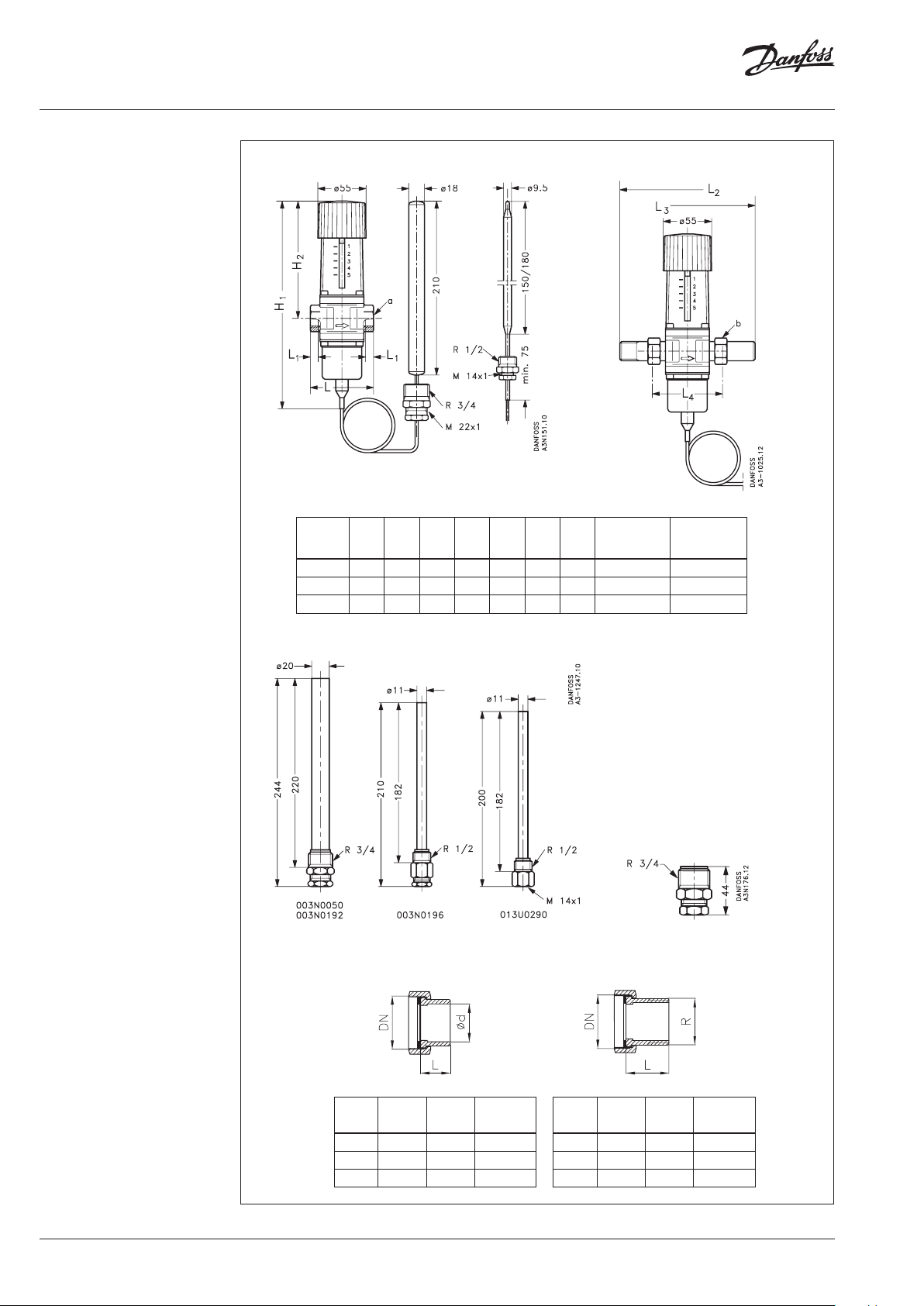

Dimensions

AVTB with internal thread AVTB with external thread

H

H

1

Typ e

AV TB 15 217 133 72 14 141 149 75 Rp ½ G ¾A

AVT B 20 217 133 90 16 154 164 80 Rp ¾ G 1A

AVT B 25 227 138 95 19 16 8 167 83 Rp 1 G 1¼ A

mm

2

mmLmm

L

1

mmL2mmL3mmL4mm

a

IS O 7/1

(int. thread)

b

ISO 228/1

(ext. thread)

Immersion pockets Sensor stuffing box

Weld-on tailpieces External thread tailpieces

G Ød L Weight

(mm) (mm) (mm) (kg)

15 15 35 0.18

20 20 40 0.26

25 27 40 0.38

G R L Weight

(“) (“) (mm) (kg)

¾ ½ 25.5 0 .17

1 ¾ 2 7. 5 0.27

1 ¼ 1 32.5 0.45

6 | VD.JK.Z4.02 © Danfoss | 2018.04

Data sheet Temperature controller AVTB (PN 16)

VD.JK.Z4.02 | 7© Danfoss | 2018.04

Danfos

produc

Al

Danfoss A/S

Heating Segment

Data sheet Temperature controller AVTB (PN 16)

s can accept no responsibility for possible errors in catalogues, brochures and o ther printed material. Danfoss reserves the right to alter its pro ducts without notice. This also applies to

ts already on order provided that such alterations can be m ade without subsequential changes being necessary in specications already agreed.

l trademarks in this material are property of the r espective companies. Danfoss and all Danfoss logotypes are trademark s of Danfoss A/S. All rights reserved.

• heating.danfoss.com • +45 7488 2222 • E-Mail: heating@danfoss.com

© Danfoss | DHS-SRMT/SI | 2018.048 | VD.JK.Z4.02

Loading...

Loading...