Page 1

Data sheet

Thermo. operated water valve

AV TA

Thermo. operated water valves are used for

proportional regulation of ow quantity, depending

on the setting and the sensor temperature.

The Danfoss range of thermo. operated water

valves includes a series of products for both

refrigeration and heating regulation.

The valves are self-acting, i.e. they operate without

the supply of auxiliary energy such as electricity or

compressed air.

The required temperature is maintained constant

without unnecessary use of:

• cooling water in cooling systems,

• hot water or steam in heating systems.

The operating economy and-eciency are

maximized.

AVTA SS for aggressive media.

A valve body in stainless steel means that the

valve can be used for aggressive media in such

applications as the marine sector and the chemical

industry.

Features • Insensitive to dirt

• Insensitive to water pressure

• Needs no power supply – self acting

• Opens on rising sensor temperature

• Dierential pressure: 0 – 145 psi

• Maximum working pressure (MWP): 232 psi

Maximum test pressure: 365 psi

• Maximum pressure on sensor: 365 psi

© Danfoss | DCS (jmn) | 2016.04 IC.PD.500.D4.22 | 520B7244 | 1

• Stainless steel version available

• The valves are pressure-relieved, i.e. the degree

of opening is not aected by dierential pressure

Δp (pressure drop).

• The regulation range is dened for the point at

which the valve begins to open.

• Cooling media temperature range: -13 – 266 °F

• Ethylene glycol as a cooling media up to 40%

Page 2

Data sheet | Thermo. operated water valve, AVTA

3N1103.13

Danf

3N1101.13

How it works

Thermo. operated water valves

consist of three main elements:

1. Setting section with knob,

reference spring and setting

scale.

2. Valve body with orice,

closing cone and sealing

elements.

3. Hermetically sealed

thermostatic element with

sensor, bellows and charge.

When the three elements have been assembled

together, the valve installed and the sensor located

at the point where the temperature is to be

regulated, the function sequence is as follows:

1

1. The pressure changes in the sensor as a result of

a change in temperature - builds up in the sensor.

2. This pressure is transferred to the valve via the

capillary tube and bellows and acts as an

oss

opening or closing force.

3. The knob on the setting section and the spring

exert a force that acts counter to the bellows.

Danfoss

3N1102.12

2

4. When balance is created between the two

opposing forces, the valve spindle remains in its

position.

5. If the sensor temperature changes – or if the

settings are changed – the point of balance

becomes displaced and the valve spindle moves

until balance is re-established, or the valve is fully

3

open or closed.

6. The ow quantity change is approximately

proportional to sensor temperature change.

The illustrations show an AVTA cooling water valve,

but the function principle applies to all types of

thermostatic valves.

Danfoss

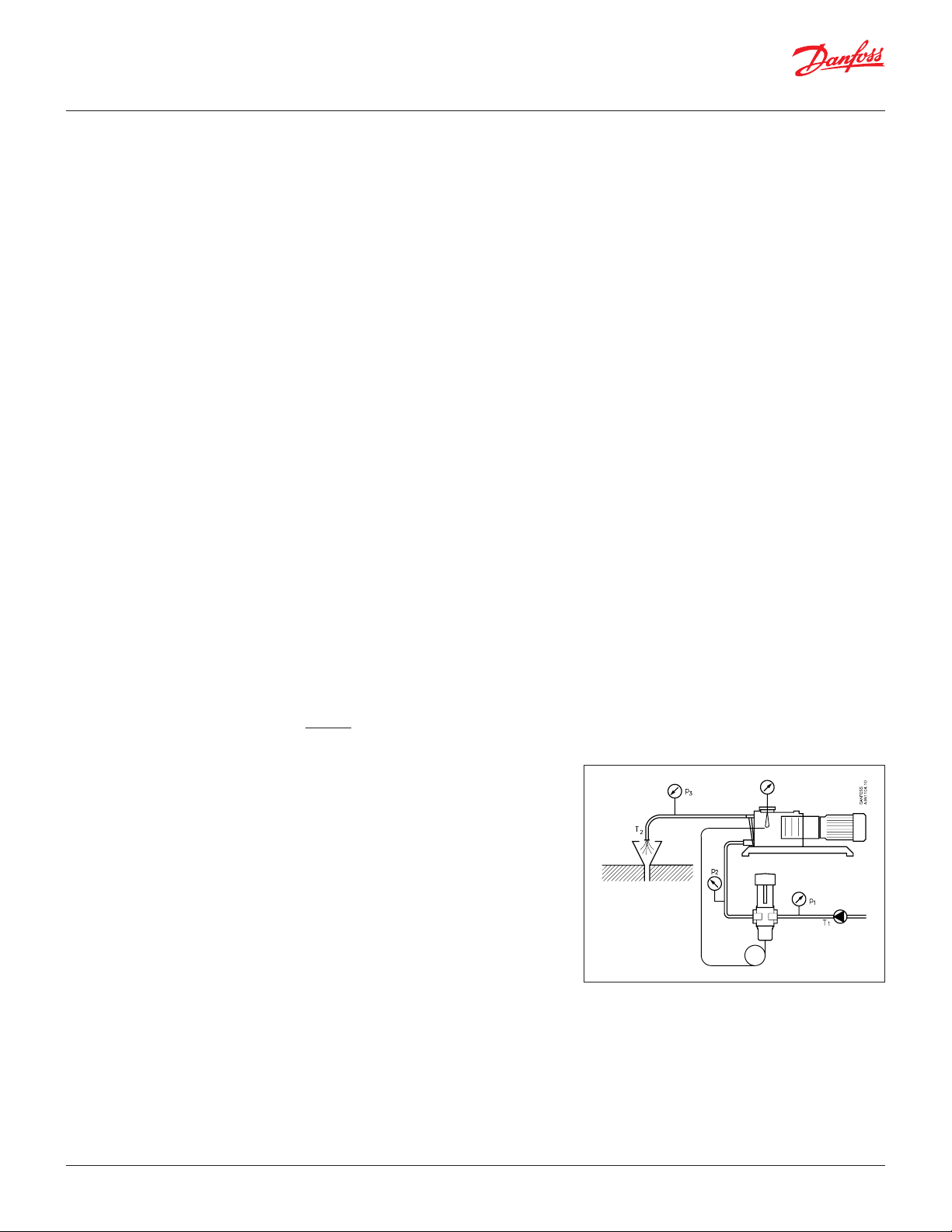

AVTA applications AVTA thermo. operated water valves are widely

used for temperature regulation in many dierent

machines and installations where cooling is

required. AVTA cooling water valves always open to

admit ow on rising sensor temperature.

The valve can be installed in either the cooling

water ow line or the return line.

The standard version of the ATVA thermo. operated

water valve can be used with fresh water or neutral

brine.

Typical application areas:

y Injection moulding machines

y Compressors

y Vacuum pumps

y Dry cleaning machines

y Distillation plants

y Printing machines

y Hydraulic systems

y Roller mills

y Biomass boilers

y Industrial lasers

y Steam sterilizers

y Medical equipment

y Food processing

1. Oil tank

2. Hydraulic machinery

3. Heat exchangers

4. Cooling water supply

5. ATVA thermostatic valve

© Danfoss | DCS (jmn) | 2016.042 | 520B7244 | IC.PD.500.D4.22

Page 3

Data sheet | Thermo. operated water valve, AVTA

Danfoss

Materials

AVTA

6

3N158.11

2

5

3

4

1

2

7

Charges

No. Description Material AVTA Material AVTA SS

1 Spindle Brass Stainless steel

2 Diaphragms Rubber – ethylene – propylene (EPDM).

3 Valve body and other metal parts Forged brass Stainless steel

4 Valve seat Stainless steel

5 Valve cone Nitrile rubber (NBR)

6 Sensor Copper

7 Capillary tube gland Nitrile rubber (NBR) / brass

ATVA thermo. operated water valves with dierent types of charge

Universal charge Mass charge

Adsorption charge

© Danfoss | DCS (jmn) | 2016.04 IC.PD.500.D4.22 | 520B7244 | 3

Page 4

Data sheet | Thermo. operated water valve, AVTA

Ordering AVTA with

adsorption charge

Sensor installation

For immersion pockets, see

“Spare parts and accessories”,

page 8.

The charge consists of active carbon and CO

is adsorbed on falling sensor temperature, thereby

producing a pressure change in the element.

2

which

y Wide regulating range

y Can be installed in any position as far as

orientation and temperature are concerned

y Small sensor dimensions – ø0.4 × 5.9 in

y Max. pressure on sensor 365 psi

Connection

NPT

[in]

½ - 14 50 – 176 266 2.2 7.6 AV TA 15 0 03N6115

¾ - 14 50 – 176 266 4.0 7.6 AV TA 20 003N7120

1 - 11 ½ 50 – 176 266 6.4 7. 6 AV TA 25 003 N8125

1)

Code no. covers complete valve incl. capillary tube gland.

Regulating

range

[°F] [°F] US [gpm] [ft]

Max. temp.

sensor

kv value

Capillary

tube length

Typ e Code no.1)

© Danfoss | DCS (jmn) | 2016.044 | 520B7244 | IC.PD.500.D4.22

Page 5

Data sheet | Thermo. operated water valve, AVTA

Ordering AVTA with

universal charge

Sensor installation Valve body with bypass

For immersion pockets, see

“Spare parts and accessories”,

page 8.

The charge is a mix of liquid and gas where the

liquid surface (regulating point) is always inside the

sensor. Which charge medium is used depends on

the regulation range.

y Sensor dimensions ø0.7 × 8.3 in

y Sensor can be installed in a place where it is

either colder or warmer than the valve

y Sensors must be orientated as shown in the

sketch below

y Max. pressure on sensor 365 psi

Connection

NPT

[in]

½ - 14 32 – 86 135 2.2 6.6 AV TA 15 003N 6132

1 - 11 ½ 32 – 86 135 6.4 6.6 AV TA 25 003N8132

½ - 14 77 – 149 194 2.2 6.6 AV TA 15 003N6162

¾ - 14 77 – 149 194 4.0 6.6 AV TA 20 003N7162

1 - 11 ½ 77 – 149 194 6.4 6.6 AV TA 25 003N8162

½ - 14 122 – 194 257 2.2 6.6 AV TA 15 003 N6182

¾ - 14 122 – 194 257 4.0 6.6 AV TA 20 003N7182

1 - 11 ½ 122 – 194 257 6.4 6.6 AV TA 25 003 N8182

1)

Code no. covers complete valve incl. capillary tube gland.

Regulating

range

[°F] [°F] US [gpm] [ft]

Max. temp.

sensor

Cv value

Capillary

tube length

Typ e Code no.1)

© Danfoss | DCS (jmn) | 2016.04 IC.PD.500.D4.22 | 520B7244 | 5

Page 6

Data sheet | Thermo. operated water valve, AVTA

Ordering AVTA with mass

charge

Sensor installation

The charge is a mix of liquid and gas. Due to the

mixture of liquid and gas the sensor must be

installed in an area or environment that is warmer

than the valve.

Connection1)

Regulating

range

Max. temp.

sensor

Cv value

y Small sensor dimensions – ø0.4× 7.5 in

y Short time constant

y Max. pressure on sensor 365 psi

y Only codes with G thread available

Capillary

tube length

Typ e Code no.1)

[°F] [°F] US [gpm] [ft]

2

G 1⁄

G 3⁄

G 1⁄

G 1⁄

G 3⁄

4

2

2

4

32 – 86 135 2.2 6.6 AV TA 15 003N0042

32 – 86 135 4.0 6.6 AV TA 20 003N0043

32 – 86 135 6.4 6.6 AV TA 15 003N0045

77 – 149 194 2.2 6.6 AV TA 15 003N0034

77 – 149 194 4.0 6.6 AV TA 20 003N0046

G 1 77 – 149 194 6.4 6.6 AV TA 25 003N0047

1)

Code no. covers complete valve incl. capillary tube gland.

© Danfoss | DCS (jmn) | 2016.046 | 520B7244 | IC.PD.500.D4.22

Page 7

Data sheet | Thermo. operated water valve, AVTA

Ordering AVTA in Stainless

Steel with adsorption

charge

Sensor installation

For immersion pockets, see

“Spare parts and accessories”,

page 8.

y Wide regulating range

y Can be installed in any position as far as

orientation and temperature are concerned

y Small sensor dimensions – ø0.4 × 5.9 in

Regulating

Connection1)

2

G 1⁄

4

G 3⁄

G 1 50 – 176 266 6.4 7. 6 AV TA 25 003N4150

1)

Code no. covers complete valve incl. capillary tube gland.

range

[°F] [°F] US [gpm] [ft]

50 – 176 266 2.2 7.6 AV TA 15 003N2150

50 – 176 266 4.0 7.6 AV TA 20 003N3150

Max. temp.

sensor

Cv value

y Max. pressure on sensor 365 psi

y AVTA SS mass and universal charges available on

request

y Only codes with G thread available.

Capillary

tube length

Typ e Code no.1)

© Danfoss | DCS (jmn) | 2016.04 IC.PD.500.D4.22 | 520B7244 | 7

Page 8

Data sheet | Thermo. operated water valve, AVTA

3N1103.13

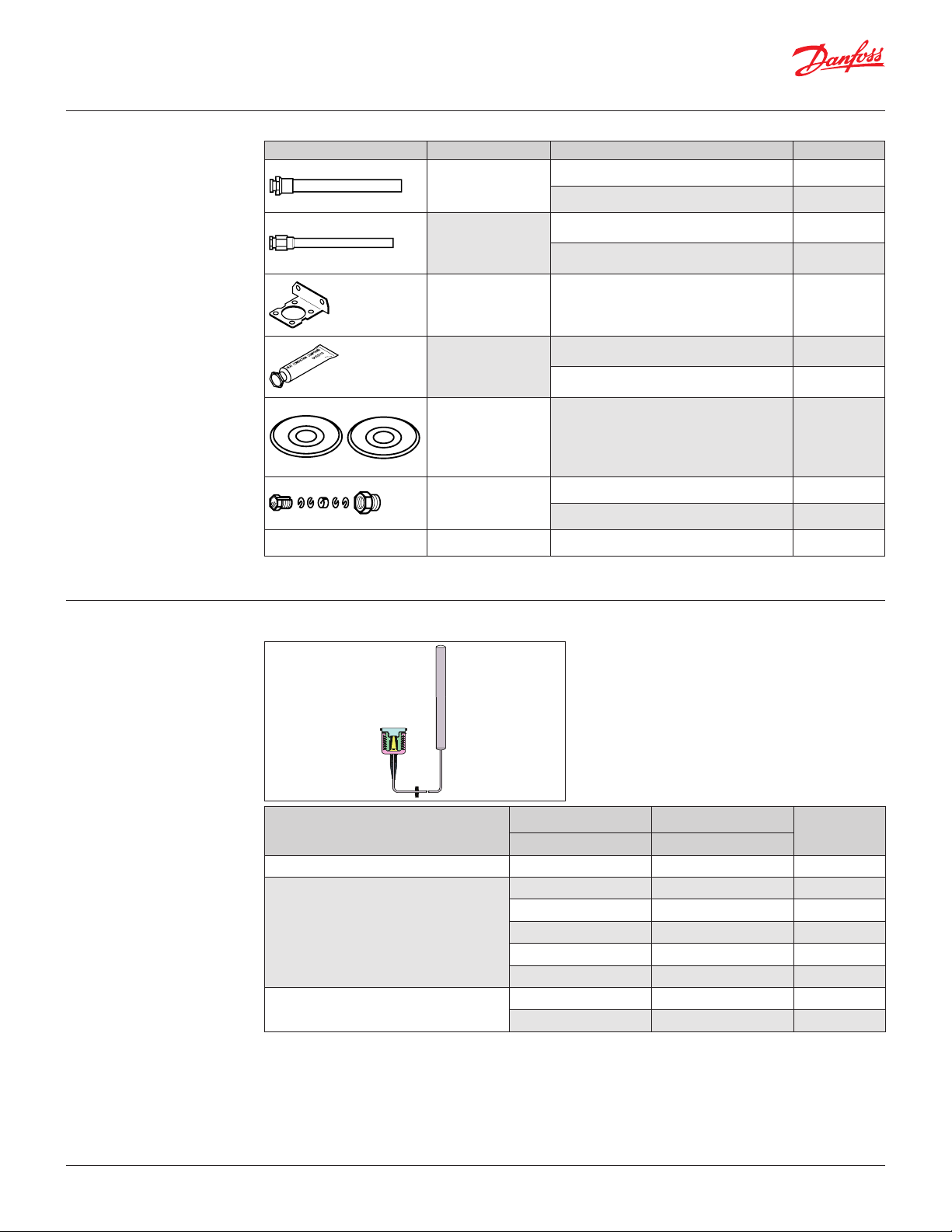

Accessories

1)

W. no. 1.4301.

Designation Description Code no.

Brass for ø0.7 in, sensor ¾ – 14 NPT 003N0051

18/8 steel 1) for ø0.7 sensor, ¾ – 14 NPT 003N0053

Immersion sensor

Brass for ø0.4 sensor G ½ 017-436766

max. pressure 725 psi

L = 7.2 in

18/8 steel1) for ø0.4 sensor R ½ 003N0196

Mounting bracket Fo r AV TA 003N0388

Heat-conductive

compound

0.01 lbs tube 041E 0110

1.75 lbs 041 E0111

Set of 3 nitrile (NBR)

diaphragms sets for

For AVTA 10/15, 20, 25 003N0448

mineral oil

½ – 14 NPT 003N 0157

¾ – 14 NPT 003N0056

Plastic hand knob Fo r AV TA 003N0520

Spare parts Thermostatic elements for AVTA valves

Danfoss

Thermostatic Elements

Adsorption charge – sensor ø0.4 × 5.9 in 50 – 176 7’ 6” 003N0278

Universal charge – sensor ø0.7× 8.3 in

Mass charge – sensor ø0.4 × 7.5 in

Temperature range Capillary tube length

[°F] [ft]

32 – 86 6’ 6” 003N0075

32 – 86 16’ 5” 003N0077

77 – 149 6’ 6” 003N0078

77 – 149 16’ 5” 003N0080

122 – 194 6’ 6” 003N0062

77 – 149 6’ 6” 003N0091

77 – 149 16’ 5” 003N0068

Code no.

© Danfoss | DCS (jmn) | 2016.048 | 520B7244 | IC.PD.500.D4.22

Page 9

Data sheet | Thermo. operated water valve, AVTA

Installation

AVTA with mounting bracket

The valves can be installed in any position.

An arrow on the valve body indicates the direction

of ow.

AVTA valves are marked so that the letters RA are

the right way up when the valve is held as shown.

The installation of an FV lter ahead of the valve is

recommended.

Capillary tube

Install the capillary tube without sharp bends (no

”kinks”). Make sure that there is no strain on the

capillary tube at the ends. Relief is important where

vibration might occur.

Note:

When an AVTA valve is used, the sensor must be

able to react to variations in cooling water

temperature on system start. Therefore a bypass

line with a shut-o valve might be necessary to

ensure ow at the sensor during start-up.

If a mounting bracket is used – see “Spare parts and

accessories”, page 10 – it must always be positioned

between the valve body and the setting section

(see illustration).

© Danfoss | DCS (jmn) | 2016.04 IC.PD.500.D4.22 | 520B7244 | 9

Page 10

Data sheet | Thermo. operated water valve, AVTA

Sizing

When sizing and selecting thermo. operated water

valves, it is most important to ensure that the valve

is able to give the necessary quantity of cooling

water at any time, irrespective of the load.

Therefore, to select a suitable size of valve it is

necessary to know the precise amount of cooling

required. On the other hand, to avoid the risk of

unstable regulation (hunting), the valve should not

be oversized.

The type of charge must be selected on the basis of

the temperature to be maintained, and on an

assessment of the characteristics of each type, as

described in the foregoing.

In general the aim should be to select the smallest

valve capable of giving the required ow.

It is also recommended that the temperature range

be chosen so that the required sensor temperature

lies in the middle of the regulation range.

To help ne-setting the valve, a thermometer

should be installed near the sensor.

Example

A cooling water valve must be selected for the

temperature regulation of a vacuum pump.

Since direct regulation of the oil temperature is

required, an AVTA valve is suitable.

The sensor position is horizontal – and small

dimensions are desired.

Given data:

y Necessary cooling at full load 5 TR.

y Oil temperature to be maintained constant at 113 °F

y Cooling water p1 = 60 psi

y Outlet p3 = 0 psi

3

p1+p

y p2 =

y Cooling water temperature t1 = 88 °F

2

(guess)

y Outlet temperature t2 = 68 °F

Valve size

The following data are used when selecting the

valve size:

y Required cooling water ow, Q [US [gpm]]

y Temperature rise in cooling water, Δt [°F]

y Dierential pressure across valve, Δp [psi].

With fully open valve, the dierential pressure

should be around 50% of the total pressure drop

across the cooling system.

The charts on page 12 are intended to make valve

sizing easier.

Fig. 1 – Relation between heat quantity [kW] and

cooling water quantity

Fig. 2 – Graphs of Cv values

Fig. 3 – Valve operating range

Fig. 4 – Flow quantities as a function of pressure

drop Δp

Operating conditions and other product

requirements in this example mean that a valve

with adsorption charge is the correct choice.

The temperature range 50 – 176 °F is in order.

The table on page 4 gives AVTA 15,

code no.0 03N 6115, which fulll the requirements.

To facilitate the installation a sensor pocket is often

used. A sensor pocket for ø0,4” sensor in brass,

code. no. 017- 436766, or in stainless steel, code no.

003N0196, is listed under “Accessories” on page 10.

1. Using the graph in g.1, you nd the necessary

cooling water quantity at Δt = 20 °F (88 – 68 °F)

for 6 US [gpm].

2. Using the graph in g. 2, you nd the

necessary Cv-value for 6 US [gpm] at Δp = 30 psi

(60 – 0)/2) for 1.17 US [gpm].

3. It can be seen from the columns in g.2 that

all three AVTA valves ca n be used, but the

preferable selection is a valve where the

necessary Cv-value lies in the middle of the

range. So in practice an AVTA 15 ought to be

selected as it fully meets the demand.

© Danfoss | DCS (jmn) | 2016.0410 | 520B7244 | IC.PD.500.D4.22

Page 11

Data sheet | Thermo. operated water valve, AVTA

3N1318.12

Danfoss

3N1319.11

Sizing

(continued)

Fig. 1 Heating or cooling with water.

Example:

Necessary cooling output 5 TR with t = 20 °F.

Required ow is 6 US [gpm].

Fig. 2 Relation bet ween water quantity and pressure drop across valve.

Danfoss

Example:

Flow 6 US gpm with a pressure drop of 30 psi.

The Cv value becomes 1.17 US [gpm].

© Danfoss | DCS (jmn) | 2016.04 IC.PD.500.D4.22 | 520B7244 | 11

Page 12

Data sheet | Thermo. operated water valve, AVTA

Danf

3N1062.12

3N1317.12

Sizing

(continued)

Fig. 3 Nomogram showing the valve Cv ranges.

oss

Cv values are allways water ow in US gpm for a

pressure drop Δp of 1 psi.

The preferable selection is a valve where the

necessary Cv-value lies in the middle of the range,

as a valve with a Cv-value close to either the max. or

min. value is less stable and less precise due to

either a relatively large Δp or ΔQ.

Example:

AVTA 10 and 15 are the most suitable for a Cv value

of 1.17 US [gpm].

Danfoss

Fig. 4 Valve ow quantity in fully open position, as a function of pressure drop Δp.

Options y DZR brass

y Outer thread connecting

y Other lengths of capillary tubes

y Armouring of capillary tubes

y Other combinations of sizes, materials and

ranges

y NPT – connection, see separate datasheet for

USA / Canada

© Danfoss | DCS (jmn) | 2016.0412 | 520B7244 | IC.PD.500.D4.22

Page 13

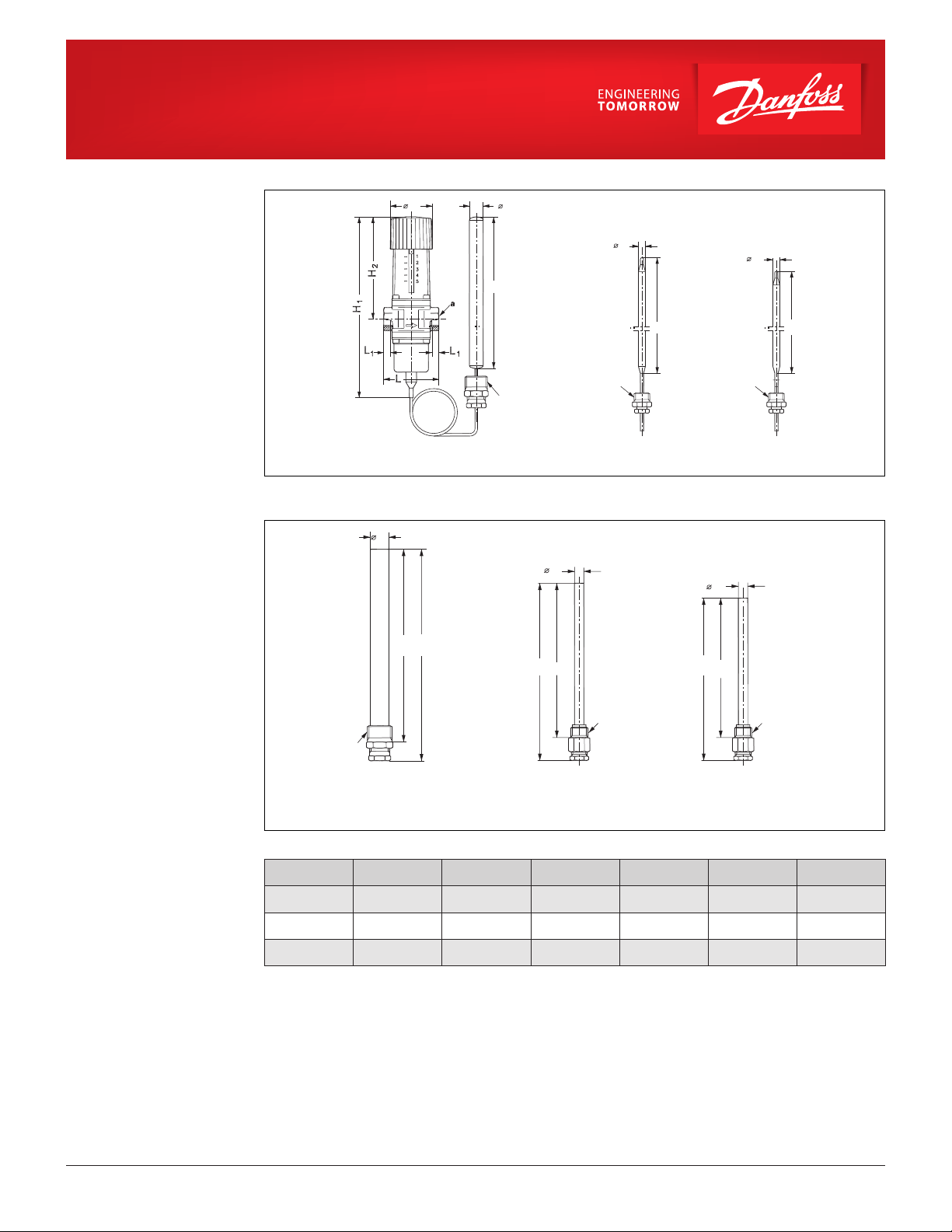

Dimensions [in] and weights

3/4 - NPT

3N1438.10

0.79

2.17

0.7

5.9

[lbs] of AVTA valves in brass

and stainless steel housings

0.4

0.4

8.3

7.5

oss

Universal sensor Mass sensor Adsorption sensor

Brass/Stainless steel pockets

for universal sensor

3/4 - NPT

8.82

8.66

8.7

1/2 - NPT

0.43

7.6

1/2 - NPT

Stainless steel pockets for

mass/adsorption sensor

mass/adsorption sensor

1/2 - NPT

0.43

8.27

7.17

1/2 - NPT

Brass pocket for

Danfoss

Typ e H

1

AV TA 15 9.45 5.24 2.84 0.56 G 1⁄

AV TA 20 9.45 5.24 3.55 0.63 G 3⁄

H

2

L L

1

a Net weight

2

4

3.20

3.31

AV TA 25 9.85 5.43 3. 74 0.75 G 1 3.64

© Danfoss | DCS (jmn) | 2016.04 IC.PD.500.D4.22 | 520B7244 | 13

Loading...

Loading...