Page 1

Data sheet

Data sheet

APP W HC Pumps

APP W HC 15 - 30

APP pumps

APP 0.6-1.0 / APP 1.5-3.5 / APP (W) 5.1-10.2 /

APP 11-13 / APP 16-22 / APP 21-43

hpp.danfoss.com.

ro-solutions.com

Page 2

Data sheet | APP W HC 15 -30

Table of Contents

1. Introduction ............................................................................3

2. Benefits.................................................................................3

3. Application examples ...................................................................3

4 Technical data ..........................................................................4

4.1 APP W HC 15 - 30........................................................................4

5. Flow at different rpm....................................................................5

5.1 APP W HC 15 - 24 flow curves measured at 120 barg ( 1740 psig ) .........................5

5.2 APP W HC 30 flow curves measured at 120 barg ( 1740 psig ) .............................6

6 Flushing valve curves ...................................................................7

6.1 APP W HC 15 - 30 integrated flushing valve ..............................................7

7. Motor requirements.....................................................................7

7.1 Calculation factor for APP W HC 15 - 30 @ 110 barg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

8. Temperature and corrosion..............................................................8

8.1 Temperature ............................................................................8

9. Installation..............................................................................8

9.1 Filtration................................................................................9

9.2 System with direct supply: ..............................................................9

10. Dimensions and connections...........................................................11

10.1 APP W HC 15 - 30.......................................................................11

11. Dimensions with motor unit............................................................12

11.1 APP W HC 15 -30 .......................................................................12

12. Accessories ............................................................................13

12.1 Accessories for APP W HC 15 - 30 .......................................................13

13. Service.................................................................................13

2

AI283147317727en-000601 | 10.2019

Page 3

Data sheet | APP W HC 15 -30

1. Introduction

This data sheet is valid for APP W HC pumps.

The Danfoss range of APP W HC high-pressure

pumps is designed according to EN 809 for use in

water applications like:

• High pressure RO

• Zero liquid discharge (ZLD)

• Minimal liquid discharge (MLD)

•

Danfoss APP pumps are positive displacement

pumps with axial pistons that move a fixed

amount of water in each cycle.

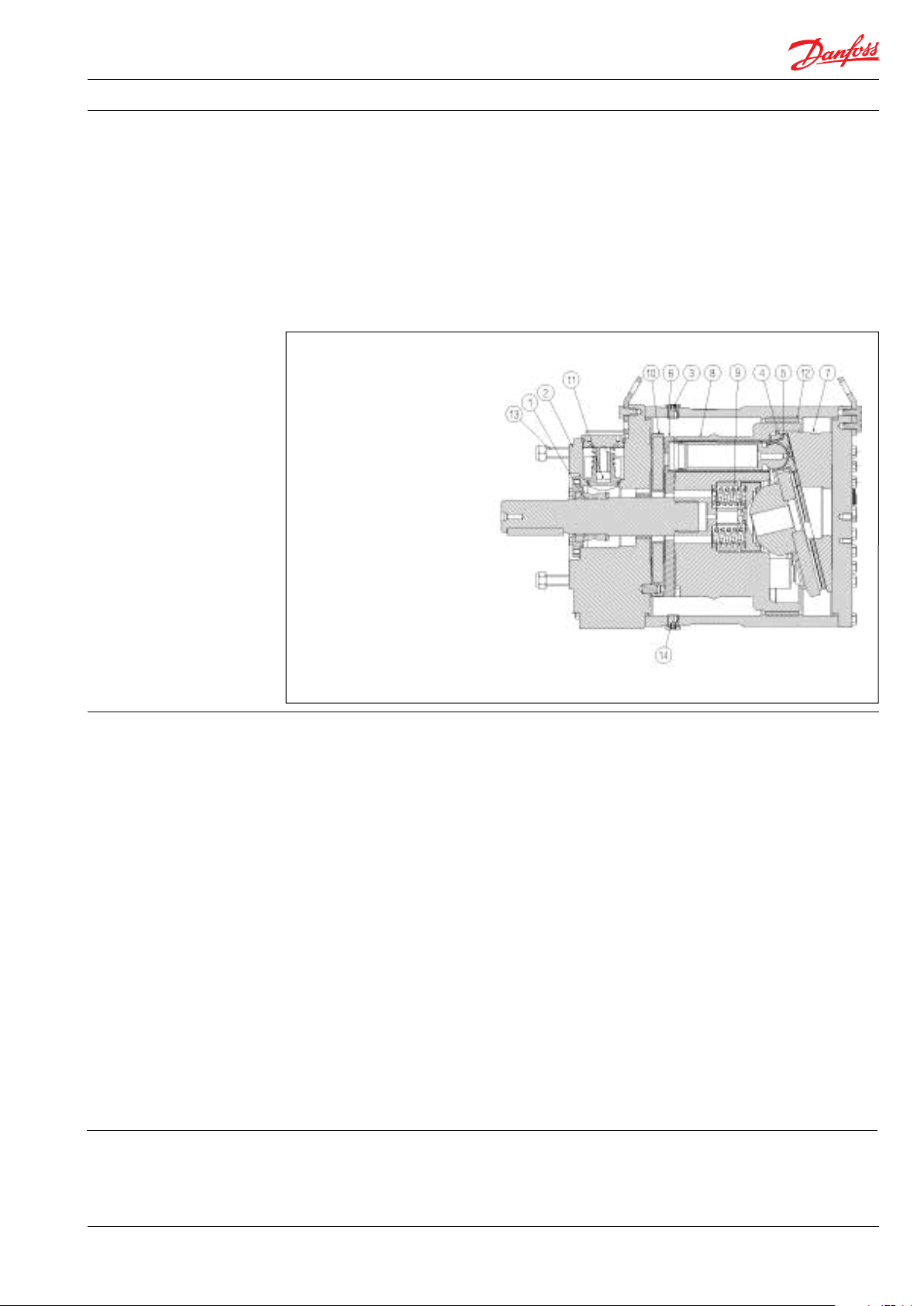

1: Shaft sealing

2: Port flange

3: Bleeding plug

4: Retainer plate

5: Piston/shoe

6: Valve plate

7: Swash plate

8: Cylinder barrel

9: Springs

10: Port plate

11: Flushing valve

(not available on

APP 5.1-10.2)

12: Housing

13: Tail stock screws

14: Drain plug

Flow is propor tional to the number of input shaft

revolutions (rpm). Unlike centrifugal pumps, they

produce

the same flow at a given speed no matter what

the discharge pressure.

Below sectional drawing is an example of an

APP pump. The sectional drawing for the specific

pump sizes are to be found in the pump

instruction.

2. Benefits

3. Application examples

• Zero risk of lubricant contamination:

- Oil lubricants are replaced with the

pumped medium, water, so there is no

contamination risk from the pump.

• Low maintenance costs:

- Efficient design and all-stainless steel

construction ensure exceptionally long

life. When Danfoss specifications are

met, service inspections of 8,000 hours

can be expected. Service is easy, and

can be carried out on-site due to the

simple design and few parts.

• Low energy costs:

- The highly efficient axial piston design

provides the lowest energy

consumption of any comparable pump

on the market.

• Easy installation:

- The most compact and lightest design

available.

- The pump can be installed vertically

and horizontally.

- No pulsation dampeners necessary due

to extremely low pressure pulsation.

Danfoss APP pumps are designed or use in a

broad range of plants around the world for:

- Powered directly by electric motors or

combustion engines (with special

coupling).

- All pumps are supplied with an

integrated flushing valve that allows the

fluid to flow from inlet to the outlet,

when the pump is not running.

• High reliability:

- All parts are made of high corrosion

resistant materials e.g. Duplex

(EN1.4462/ UNS S31803) and

Super Duplex (EN1.4410/UNS S32750)

stainless steel and carbon reinforced

PEEK.

• Certified quality:

- Positive Material Identification (PMI)

report available on request.

- IATF 16949, ISO 9001, ISO 14001.

• High pressure reverse osmosis

• Zero liquid discharge (ZLD)

• Minimal liquid discharge (MLD)

AI283147317727en-000601 | 102019

3

Page 4

Data sheet | APP W HC 15 -30

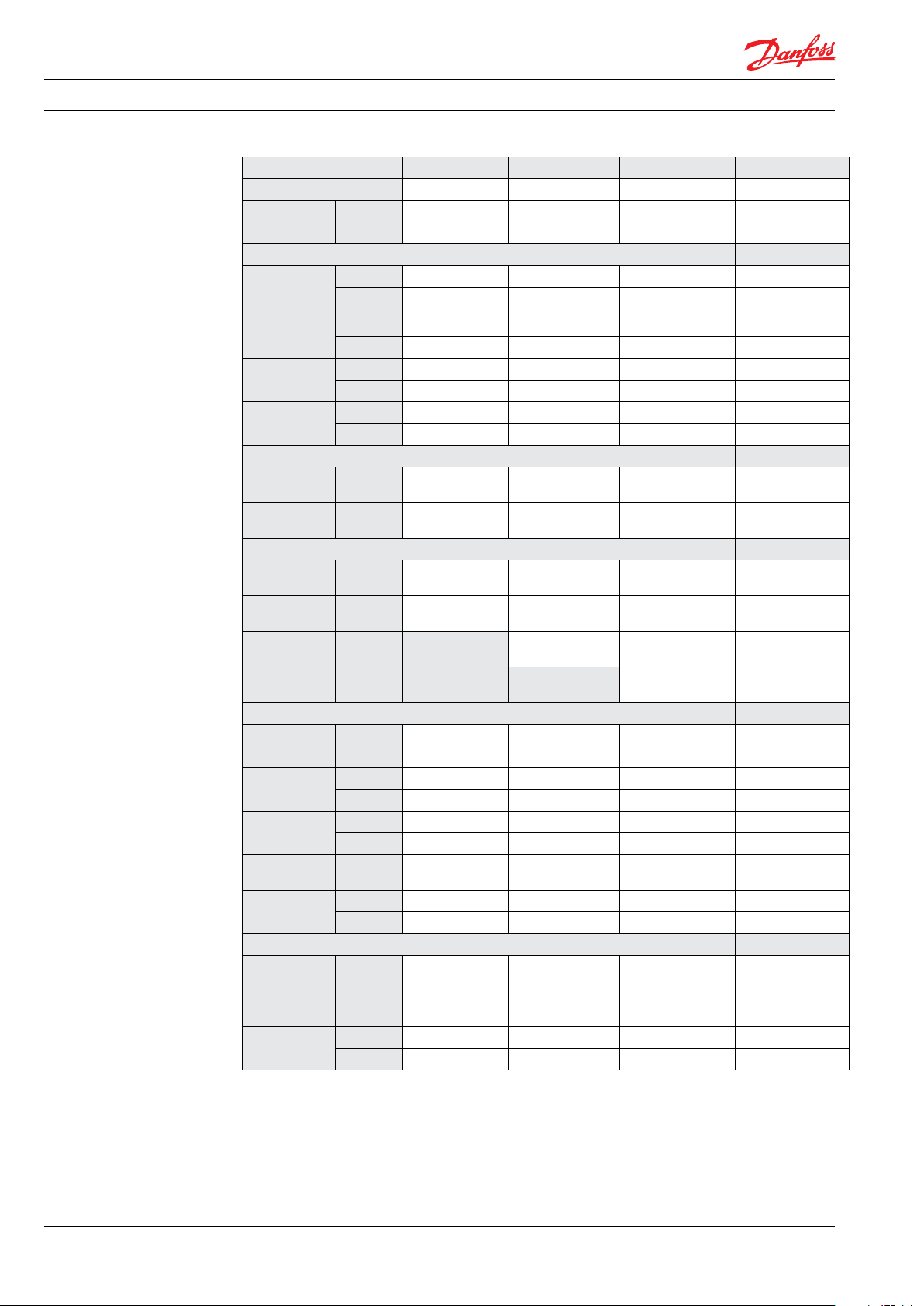

4 Technical data

4.1 APP W HC 15 - 30

Pump size APP W HC 15/750 APP W HC 21/1000 APP W HC 24/1200 APP W HC 30/1200

Code number APP 180B5000 180B5001 180B5002 180B5003

Geometric

displacement

Pressure

Max. outlet

pressure

continuous

Min. outlet

pressure

Inlet pressure

continuous

Max. inlet

pressure peak

Speed

Min. speed

continuous

Max. speed

continuous

Typical flow - Flow curves available in item 5

500 rpm at

max. pressure

750 rpm at

max. pressure

1000 rpm at

max. pressure

1200 rpm at

max. pressure

Technical specifications

2)

Media

temperature

Ambient

temperature

Weight (dry)

Max. sound

pressure level

Footprint with

IEC motor

Typical motor size

Max. speed at

max. pressure

Max. speed at

max. pressure

Torque at max.

outlet pressure

cm³/re v. 362 362 362 444

in³/rev. 22.09 22.09 22.09 27. 09

1)

barg 120 120 120 120

psig 1740 174 0 1740 1740

1)

barg 30 30 30 30

psig 435 435 435 435

barg 2 - 5 2 - 5 2 - 5 2.5-5

psig 29 - 72.5 29 - 72.5 29 - 72.5 36 - 72.5

barg 10 10 10 10

psig 145 145 145 145

rpm 500 500 500 500

rpm 750 1000 120 0 120 0

m³/h 11 11 11 13

m³/h 15 15 15 20

m³/h 21 21 27

m³/h 25 31

°C 2 - 50 2 - 50 2 - 50 2 - 50

°F 36 - 122 36 - 122 36 - 122 36 - 122

°C 0-50 0-50 0-50 0 - 50

°F 32 - 122 32 - 122 32 - 122 32 - 122

kg 105 105 105 105

lb 231 231 2 31 231

dB(A) 85 85 85 85

3)

m² 0.76 0.83 1.10 1.10

4)

foot² 8.18 8.93 11.84 11.84

kW 75 90 110 110

HP 10 0 125 150 150

Nm 740 740 740 761

lbf-ft 546 546 546 561

1)

For lower an d higher pressure , please contact D anfoss.

2)

Depend ent on the NaCI conce ntration - see chap ter 8.

4

AI283147317727en-000601 | 10.2019

3)

A-weigh ted sound pressur e level at 1 m from the pum p unit

surfa ces (reference box) a cc. to EN ISO 20361 section 6 .2. The noise

measurem ents are perf ormed acc. to EN ISO 3744:2010 on a mot or-

pump unit a t max. pressure an d speed.

4)

Max. area covered with recommended motor configuration

(excl. of spa ce to service pump)

Page 5

Data sheet | APP W HC 15 -30

0

5

10

15

20

25

30

m³/h

rpm

0

20

40

60

80

100

120

gpm

rpm

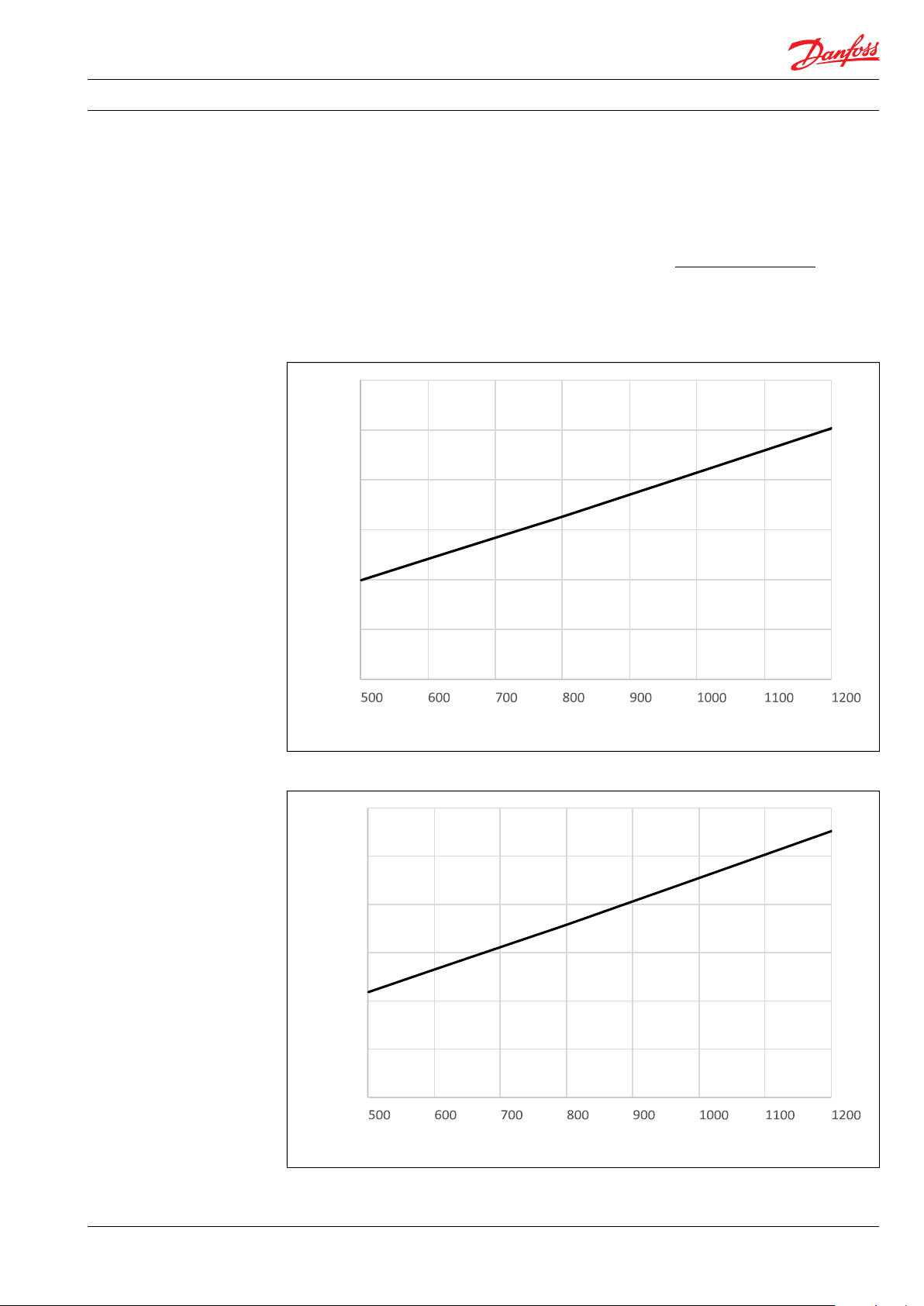

5. Flow at different rpm

If the flow required and the rotation speed (rpm) of the

pump is known, it is easy to select the pump fitting the

application best by using the diagrams below.

Furthermore, these diagrams shows that the

flow can be changed by changing the rotation

speed of the pump. The flow/rpm ratio is

constant, and the “required” flow can be

obtained by changing the rotation speed to a

corresponding value. Thus, the required rpm

can be determined as:

Required rpm =

Rated flow

Required flow x Rated rpm

5.1 APP W HC 15 - 24 flow curves measured at 120 barg ( 1740 psig )

AI283147317727en-000601 | 102019

5

Page 6

Data sheet | APP W HC 15 -30

0

5

10

15

20

25

30

35

m³/h

rpm

0

20

40

60

80

100

120

140

160

GPM

rpm

5.2 APP W HC 30 flow curves measured at 110 barg ( 1595 psig )

6

AI283147317727en-000601 | 10.2019

Page 7

Data sheet | APP W HC 15 -30

Pressure [barg]

ow [l/min]

6 Flushing valve curves

All pumps are supplied with an integrated

flushing valve that allows the fluid to flow from

inlet to the outlet, when the pump is not running.

6.1 APP W HC 15 - 30 integrated flushing valve

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0

0

100

200

300

400

500

Fl

600

The power requirements can be determined using one of the following guiding equations:7. Motor requirements

3

l/min x barg 16.7 x m

/h x barg 0.26 x gpm x psig

Required power = [kW] or [kW] or

Calc. factor Calc. factor Calc. factor

1 hp = 0.75 kW

1 gpm = 3.79 l/min

3

1 m

/h = 4.40 gpm

1 kW = 1.34 hp

1 l/min = 0.26 gpm

1 gpm = 0.23 m

3

/h

7.1 Calculation factor for APP W HC 15 - 30

@ 110 barg

Name rpm Calculation

APP W HC 15 750 545

APP W HC 21 1000 558

APP W HC 24 1200 562

APP W HC 30 1200 545

factor

[hp]

AI283147317727en-000601 | 102019

7

Page 8

Data sheet | APP W HC 15 -30

8. Temperature and

corrosion

8.1 Tem pe ratu re

Fluid temperature:

Min. +2°C to max. +50°C

(Min. +35.6°F to max. +122°F)

Ambient temperature:

Min. +2°C to max. +50°C

(Min. +35.6°F to max. +122°F)

In case of lower operating temperatures, please

contact Danfoss High Pressure Pumps.

8.2 Corrosion

º

80

C

Duplex

70

60

50

316L

40

30

20

100

160 1600

1000

10 000

16000

in order to minimize the risk of crevice corrosion.

The chart below illustrates the corrosive

resistance of different types of stainless steel

related to NaCl concentration and temperature.

The APP water pump is made of Duplex and

Super Duplex.

If the water pump is operated above the Duplex

line, always flush water pump with fresh water at

operation stop in order to minimize the risk of

crevice corrosion.

NaCI vs. temperature

Super Duplex

-

100 000

160000

CI

ppm

NaCI

ppm

9. Installation See example below on how to mount the pump

and connect it to an electric motor or combustion engine (special coupling).

A: Pump

B: Bell housing

C: Flexible coupling

D: Motor shaft

E: Motor

A

B

If alternative mounting is required. please

contact your Danfoss sales representative for

further information.

Note: Do not add any axial or radial loads to the

pump shaft.

EC D

8

AI283147317727en-000601 | 10.2019

Page 9

Data sheet | APP W HC 15 -30

9.1 Filtration

Proper filtration is crucial for the performance.

maintenance and warranty of your pump.

Protect your pump, and the application in which

it is installed, and by always ensuring that all

filtration specifications are met, and by always

changing filter cartridges according to schedule.

Since water has very low vicosity, Danfoss APP

pumps have been designed with very narrow

clearances in order to control internal leakage

rates and improve component performance.

To minimize wear on the pump, it is therefore

essential to filter inlet water properly.

The main filter must have a filtration efficiency

of 99.98% at 10 μm. We strongly recommend

that you always use precision depth filter

cartridges rated 10μm abs. ß

≥5000.

10

Please note that we do not recommend bag

filters or string-wound filter cartridges, which

typically have only 50% filtration efficiency. This

means that out of the 100,000 particles that

enter such filters, 50,000 particles pass right

through; compare this to precision depth filters

that are 99.98% efficient, and only allow 20 of the

same 100,000 particles to pass through.

For more information on the importance of

proper filtration, including explanation of

filtration principles, definitions and guidance on

how to select the right filter for your pump,

please consult our Filtration information and

specifications (Danfoss document number

521B1009).

Noise

Since the pump unit is typical mounted on a

frame or bell housing the overall noise level can

only be determined for a complete system. To

minimize vibrations and noise throughout the

system, it is therefore very important to mount

the pump unit correctly on a frame with

anti-vibration-dampeners, and to use flexible

hoses rather than metal pipes where possible.

• Variable frequency drives (VFD):

Motors regulated by VFDs can produce

more noise if the VFD does not have the

right settings.

9.2 System with direct supply:

Inlet line:

a) Dimension the inlet line to obtain

minimum pressure loss (large flow,

minimum pipe length, minimum number

of b ends/connections, and fittings with low

or no pressure losses). If relevant, please

consult “Parallel coupled pumps and

iSaves” (180R93549

Inlet filter:

b) Install an inlet filter (1) in front of the APP

pump (2). Please consult section 9.1,

“Filtration” for guidance on how to select

the right filter. Thoroughly clean pipes and

flush system prior to start-up.

Low pressure relief valve:

c) Install a low pressure relief valve (9) in order

to avoid system or pump damage in case

the pump stops momentarily or is spinning

backwards.

Monitoring pressure switch:

d) Install a monitoring pressure switch (3)

between the filter (1) and the pump inlet.

Set the minimum inlet pressure according

to specifications described in item 4 about

technical data. If the inlet pressure is lower

than the minimum pressure set, the

monitoring pressure switch must prevent

the pump from starting or from running.

Hoses:

e) Use flexible hoses (4) to minimize

vibrations and noise.

Inlet pressure:

f) In order to eliminate the risk of cavitation

and other pump damage, pump inlet

pressure must always be maintained

according to specifications described in

item 4 about technical data.

The noise level is influenced by:

• Pump speed:

High rpm generates more fluid/structure

borne pulsations/vibrations than low rpm,

because of higher frequency.

• Discharge pressure:

High pressure generates more noise than

low pressure.

• Pump mounting:

Rigid mounting generates more noise than

flexible mounting, because of structureborne vibrations. Be sure to use dampers

when mounting.

• Connections to pump:

Pipes connected directly to the pump make

more noise than flexible hoses, because of

structure-borne vibrations.

AI283147317727en-000601 | 102019

Flushing valve:

g) For easy system filling and flushing, an

integrated flushing valve (6) is in

the APP pump.

Non-return valve:

h) A non-return valve (7) in outlet can be

installed in order to avoid backspin of the

pump. The volume of water in the

membrane vessel works as an accumulator

and will send flow backwards in case of the

pump stops momentarily.

9

Page 10

Data sheet | APP W HC 15 -30

High pressure safety or relief valve:

i) As the Danfoss APP pump begins to create

pressure and flow immediately after

start-up and regardless of any counter

pressure, a safey or pressure relief valve (8)

should be installed after the non-return

valve to prevent system damage and to

avoid high pressure peaks.

Note: If a non-return valve is mounted in the inlet

line, a low-pressure relief valve is also required

between the non-return valve and

pump as protection against high-pressure peaks.

Preferred design - see section 9.2

Feed

Media filter

PI

PI

PI PI

Fresh water

permeat flush

M

PT

PI

Brine

Permeate

PI

10

AI283147317727en-000601 | 10.2019

Page 11

Data sheet | APP W HC 15 -30

10. Dimensions and

connections

10.1 APP W HC 15 - 30

Accessories see section 12. Fore more details on the accessories, please contact the Danfoss High

Pressure Pumps sales organisation.

AI283147317727en-000601 | 102019

APP W C 15 - 30

11

Page 12

Data sheet | APP W HC 15 -30

11. Dimensions with motor

unit

IEC 280-315: 265 [10.433]

APP W HC 15-24: 351 [13.833]

APP W HC 15-24: 304 [11.97]

11.1 APP W HC 15 -30

The examples of assemblies with motor are only

for IEC motors and couplings. Please make sure

to check required motor power and dimensions

when selecting size of pump and motor. For advice and calculation tool, please contact Danfoss.

Pump

APP W HC 15

APP W HC 21

APP W HC 24/30

A mm

(inch)

550

(21.65)

550

(21.65)

660

(25.98)

B mm

(inch)

693

(27.28)

693

(27.28)

861

(33.90)

C mm

(inch)

280

(11.02)

280

(11.02)

315

(12.40)

D mm

(inch)

457

(17.99)

457

(17.99)

508

(20.00)

E mm

(inch)

368

(14.49)

419

(16.50)

406

(15.98)

F mm

(inch)

845

(33.37)

895

(35.24)

1038

(40.87)

IEC Electric motor

75 kW, IEC 280S-4

90 kW, IEC 280M-4

110 kW, IEC 315S-4

12

AI283147317727en-000601 | 10.2019

Page 13

Data sheet | APP W HC 15 -30

12. Accessories

12.1 Accessories for APP W HC 15 - 30

Accessories Typ e Code No.

3” inlet hose kit - 2m (79”) 3” Victaulic 180Z0144

2½” outlet high pressure hose 120 barg

2½” outlet high pressure hose 120 barg

3” inlet connector M60 - 3” Victaulic 180B3208

Non-return valve (outlet) Super Duplex

1)

The installation instruction for Style 77DX is located in the Victaulic document I-100 Field Installation

Handbook (http://static.vicltaulic.com.

When using hoses, please read Design guides: 180R9084 - Right and wrong - Hose assembly routing

tips and 180R9367 - Piping connections.

13. Service Warranty and chemicals disclaimer

Danfoss APP W HC pumps are designed for long

operation, low maintenance and reduced

lifecycle costs.

Provided that the pump has been running

according to the Danfoss specifications, Danfoss

guarantees 8.000 hours service-free operation,

however, max. 18 months from date of production.

All pumps comes with NBR seals and shaft seal,

ideal for water. When pumping water mixed with

chemicals, we recommend assessing or testing

the impact from the chemicals on the pump

materials (see Part List for full overview of

materials). Danfoss product warranty doesn´t

cover cases where chemicals are the root cause

of the failure or claim. Additionally, use of certain

chemicals may lead to increase wear and require

part replacement more often than the Recommended Service Intervals, which are based on

water.

2 ½” Victaulic 1 m

Style 77DX

2 ½” Victaulic 1.78 m

Style 77DX

M60 - 2 ½” Victaulic

Style 77DX

1)

1)

1)

180Z1009

180Z1008

180H0055

Maintenance

Periodic inspections are required to ensure worn

parts (if any), are replaced in due time. Operational conditions such as water quality should be

taken into consideration when determining the

frequency of the inspections. Danfoss recommends yearly inspections.

It is recommended to order the purposedesigned tool kit.

Pump shutdown:

The APP W HC pumps are made of Duplex/Super

Duplex materials with excellent corrosion

properties. It is, however, always recommended

to flush the pump with freshwater when the

system is shut down.

Repair assistance

In case of irregular function of the APP W HC

pump, please contact Danfoss High Pressure

Pumps.

If Danfoss recommendations concerning

system-design are not followed, it will strongly

influence the life of the APP pumps.

Other factors that affect pump performance and

lifetime include:

- Running the pump at speed outside

specifications.

- Supplying the pump with water at

temperature higher than recommended.

- Running the pump at inlet pressure outside

specifications.

- Running the pump at outlet pressure

outside the specifications.

AI283147317727en-000601 | 102019

13

Page 14

Danfoss A/S

High Pressure Pumps

DK-6430 Nordborg

Denmark

Danfoss ca n accept no respons ibility for pos sible errors in ca talogues, bro chures and other pr inted material. Da nfoss reserve s the right to alter its p roducts with out notice.

This also a pplies to produc ts already on ord er provided that su ch alterations ca n be made without su bsequential cha nges being nece ssary in speci fications alread y agreed.

All trade marks in this mate rial are proper ty of the respec tive companies . Danfoss and the Danf oss logotyp e are trademark s of Danfoss A/S. Al l rights reserv ed.

© Danfoss | DCS (im) | 10.2019

AI283147317727en-000 601 | 14

Loading...

Loading...