Page 1

Operating Guide

AME 25, AME 35

ENGLISH

DANSK

DEUTSCH

FRANÇAIS

ESPAÑOL

SUOMI

NEDERLANDS

POLSKI

РУССКИЙ

ROMÂNĂ

AME 25, AME 35 +

Adapter (0 6 5Z 0311) +

VRB 2, VRG 2 (D N 15-50)

AME 25, AME 35 www.danfoss.com Page 5

AME 25, AME 35 www.danfoss.dk Side 6

AME 25, AME 35 www.danfoss.de Seite 7

AME 25, AME 35 www.danfoss.fr Page 8

AME 25, AME 35 www.danfoss.es Página 9

AME 25, AME 35

AME 25, AME 35 www.danfoss.nl Bladzijde 11

AME 25, AME 35

AME 25, AME 35

AME 25, AME 35 www.incalzire.danfoss.com Pagina 14

AME 25, AME 35 +

Adapter (0 6 5Z 0311) +

VRB 3, VR3 2 (D N 15-50)

AME 25, AME 35 +

Adapter (0 6 5Z 0311) +

VF 2, VL 2 (DN 15-50)

www.danfoss.fi Sivu 10

www.danfoss.pl Strona 12

www.danfoss.ru Страница 13

AME 25, AME 35 +

Adapter (0 6 5Z 0311) +

VF 3, VL 3 (DN 15-50)

AME 25, AME 35 +

VFS 2 (DN 15-50)

中文

© Danfoss | 2016.11

AME 25, AME 35 www.danfoss.com.cn 第 16 页

EI.LF.M1.2V | 1

Page 2

AME 25, AME 35

=

AUTO

➊

MAINTENANCE

①

FREE

5-95 % RH

no condensing

②

4×

or

❸

=

4 – 6 mm × 1 mm T 10 2 / 4 mm

③

③

❹

❷

4×

➊

BLUE

RED

B

A

A B

❷

T

≤150 ° C T

max

=150 … 200° C

max

≈5°

065Z 7548

≈5°

2 | © Danfoss | 2016.11

EI.LF.M1.2V

Page 3

AME 25, AME 35

❸

Wiring for modulating mode

Proportional 3 point/ RL

Wiring fo r 3-point flo ating mode

Controll er with relay outpu t

SN 0 V Neutral

SP 24 VAC Power supply

Y

1

3

X 0(2) -10 V Output

0(2)-10 V

0(4) -20 mA

0 V Input

Input

Proportional 3 point/ RL

Wiring fo r 3-point flo ating mode

Controll er with triacs out put

Proportional 3 point/ RL

SN 0 V Neutral

SP 24 VAC Pow er supply

1

24 VAC Input

3

X 0(2)-10 VDC Output

SN

SP

1

3

24 VAC Neutral

0 V Power suppl y

24 VAC Input

EI.LF.M1.2V

X 0(2)-10 V DC Output

© Danfoss | 2016.11 | 3

Page 4

AME 25, AME 35

❹

⑦

④

②①

⑤

⑧

③

⑥

⑨

❺

⑩

155

179

16

47, 5

min . 160

83

EI.LF.M1.2V

© Danfoss | 2016.11 | 4

Page 5

AME 25, AME 35

ClampXO

O

OOO

YokeXO

O

OOO

ENGLISH

Safety Note

To avoid injury of persons and

damages to the device, it is absolutely

instructions carefully.

Necessary assembly, start-up, and maintenance

work must be performed by qualified and

authorized personnel only.

Please comply with the instructions of the

system manufacturer or system operator.

Disposal instruction

Mounting

Fix the actuator on the valve ❶

Admissible Installation Positions ❷

Wiring ❸

Control signal

Control signal from the controller must be

connected to terminals Y (input signal) and SN

(common) on the AME printed board.

Output signal

Output signal from the terminal X can be used

for indication of the current position. Range

depends on the DIP switch settings.

Supply voltage

Supply voltage (24 V~ –15 to +10 %, 50 Hz) must

be connected to the terminals SN and SP.

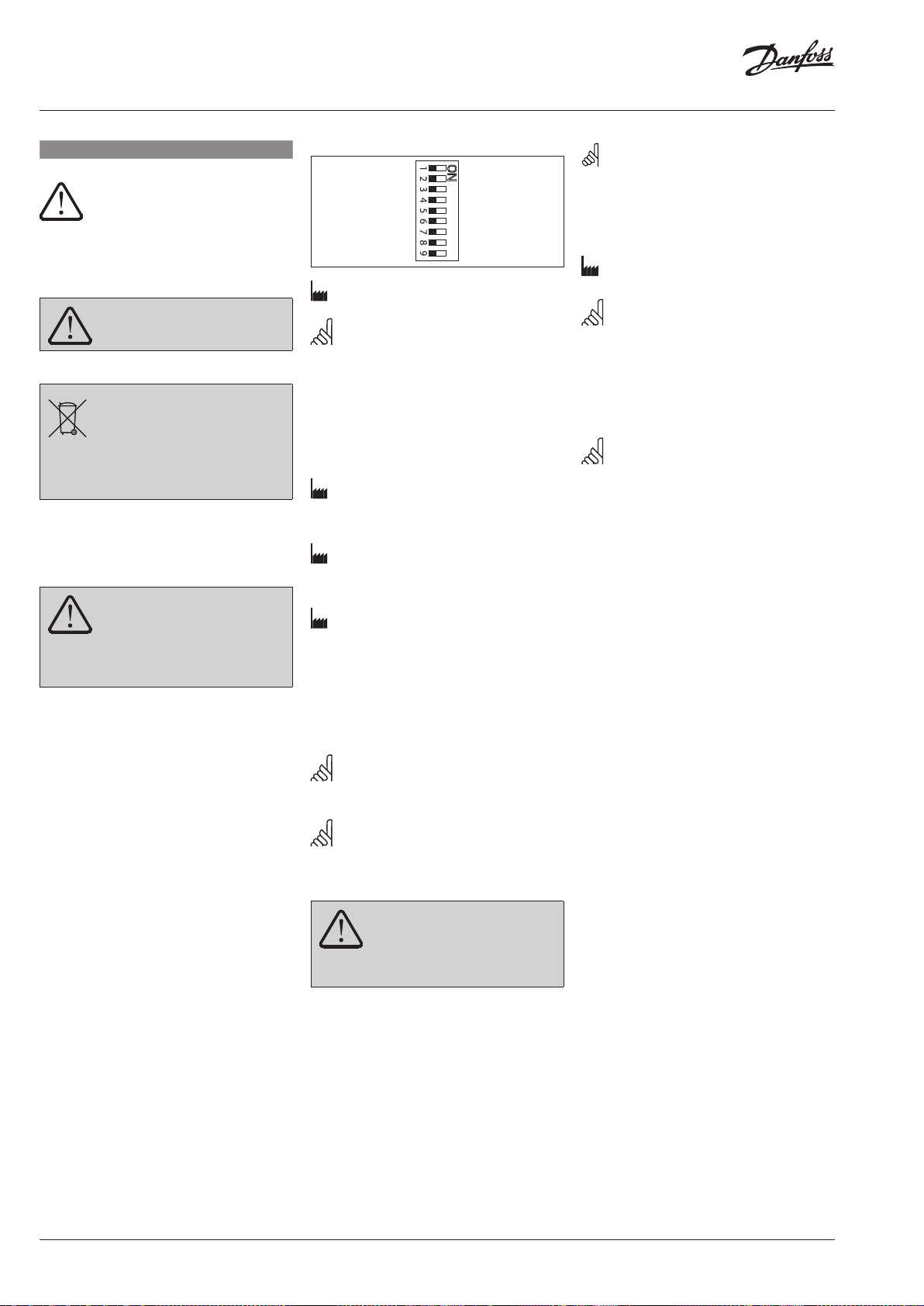

DIP switch settings ❹

necessary to read and observe these

Do not remove the cover before th e

power supply is ful ly switched off.

This product shou ld be dismantled

and its components so rted, if possible,

in various groups befo re recycling or

disposal.

Always follow the local d isposal regulations.

Do not touch anythin g on the PCB!

Switch off the power lin e before wire

the actuator! Lethal voltage!

Wire the actuator according to the wi ring

diagram.

U I

2 V_---V 0 V_---V

Direct Inverse

--- S equential

0(2) V_5(6) V 5(6) V_10 V

Proportional 3 point/RL

LOG. fl ow L IN. flow

100 % k

VS

Reset Reset

RED. k

VS

Factory settings:

ALL switches are on OFF position! ❹①

Note: All combinations of DIP switches are

allowed. All functions that are selected are added

consecutively. There is only one logic override of

functionalities i.e. the switch No.6 Propor tional/3

point, which sets actuator to ignore control signal

and works as a “simple” 3-point actuator.

SW1: U/I ❹②

Factory settings:

Voltage control signal (0-10 V).

SW2: 2-10 V/0-10 V ❹③

Factory settings:

2-10 V.

SW3: Direct/Inverse ❹④

Factory settings:

DIRECT

SW4:---/Sequential ❹⑤

Two actuators can be set to work parallel with

one control signal. If the SEQUENTIAL is set than

an actuator respowwnds to split control signal

(see 0(2)-5(6) V/5(6)-10 V).

Note: This combination works in combination

with switch No.5: 0(2)-5(6) V/5(6)-10 V

SW5: 0(2)-5(6) V/5(6)-10 V ❹⑥

Note: This function is available if switch No.4:

---/Sequential is set.

SW6: Proportional/3 point ❹⑦

Actuator needs to pe rform Self

stroking prior chan ging DIP 6 to ON.

Output signal dep ends on DIP 2, 3&5

setting.

Actuator can operate in modulating (DIP 6 to

OFF) or in “simple” 3-point mode, if the 3-point

function is selected (DIP 6 to ON).

Connect power supply on terminals SN and SP

terminals.

Factory set DIP 6 to OFF for operating actuator

in Modulating mode.

Actuator’s stem will run to its totally extended

or retracted position by bridging SN signal to

terminals 1 or 3 and will remain in this positron

as long as potential is present.

Set DIP 6 to ON for operating actuator in 3 point

mode.

Look carefully wiring diagram as wiring is

different for controllers with triac output (ECL)

in comparison to controllers with relay output.

Return signal X indicates the correct position.

Note: If 3 point function is selected actuator

does not respond to any control signal on port Y.

It only rises and lowers spindle if power is supplied

on port 1 or 3.

SW 7: LOG. flow/LIN. flow ❹⑧

Factory setting is:

LOG. Flow (characteristic of valve is unchanged)

Note: If this function is used in combination

with non-logarithmic valves the characteristic

of motorised valve will be anti-logarithm of

valve’s characteristic (e.g. valve with linear

characteristic will be transformed to quick open

characteristic).

SW 8: 100% KVS/RED. KVS ❹⑨

Note: This function works proper only with

logarithmic (equal percentage) valves.

SW9: Reset ❹⑧

After the actuator has been connected to

power supply, the actuator will start the

self-adjustment procedure. The indicator LED

flashes until self adjustment is finished. The

duration depends on the spindle travel and will

normally last a few minutes. The stroke length

of the valve is stored in the memory after self

adjustment has been completed. To restart

self adjustment, change the position of RESET

switch (switch No.9). If the supply voltage is

switched off or falls below 80 % in more than

0.1 s, the current valve position will be stored

in the memory and all data remain saved in the

memory also after a power supply cut-out.

Function test

The indicator light shows whether the

positioner is in operation or not. Moreover, the

indicator shows the control status and faults.

Constant light

- normal operation

No light

- no operation or no power supply

Intermittent light (1 Hz)

- self adjusting-mode

Intermittent light (3 Hz):

- power supply too low

- insufficient valve stroke (<20 s)

- end-position cannot be reached.

Dimensions ➎

Part Name

Housing X O O O O O

Bushings X O O O O O

O: Indica tes that this hazar dous substance con tained in all of the h omogeneous ma terial for this par t is below the limi t requirement in GB /T 26572;

X: Indica tes that this hazar dous substance co ntained in at least o ne of the homogen eous material fo r this part is above th e limit requirem ent in GB/T 26572;

Lead (P b) Mercur y (Hg) Cadmium (Cd) Hexavalent Chromium (Cr(VI)) Polybrominated biphenyls (PBB) Polybrominated diphenyl ethers (PBDE)

EI.LF.M1.2V

Hazardous Substances Table

© Danfoss | 2016.11 | 5

Page 6

AME 25, AME 35

DANSK

Sikkerhedsbestemmelser

For at undgå skader på personer og

udstyr, er det absolut nødvendigt at

gennemlæse følgende vejledning.

Montering, opstart og vedligeholdelse må

kun foretages af kvalificeret og autoriseret

personale.

Følg fabrikantens eller operatørens

instruktioner.

Fjern ikke dækslet , før

strømforsyning en er helt koblet fra.

Bortskaffelsesinstruktion

Dette produk t skal, om muligt,

adskilles og sor teres i dets forskellige

materialegrupper, før det genbruges

eller bortskaffes.

Følg altid de lokale regulati ver for bortskaffelse .

Montering

Fastgør AME 25, AME 35 på ventilen ❶

Tilladelige installationspositioner ❷.

Elektrisk tilslutning ❸

Rør ikke ved PCB!

Sluk for strømmen ind en elektrisk

tilslutning af motoren! Kan være

livsfarlig!

Tilslut motoren iht. ledningsdiagrammet.

* El-tilslutning for modulerende styring

(Wiring for modulating mode)

** El-tilslutning for 3-punkts styring med

relæudgang i regulator (Wiring for 3-point

floating mode Controller with relay output)

*** El-tilslutning for 3-punkts st yring med

triacudgang i regulator (Wiring for 3-p oint

floatig mode Controller with triacs output)

Styresignal

Styresignalet fra regulatoren skal tilsluttes

terminal Y (indgangssignal) og SN (fælles) på

AME´s klemrække.

Udgangssignal

Udgangssignal fra terminal X kan anvendes til

indikering af aktuel position.

Området afhænger af DIP kontakternes

indstilling.

Forsyningsspænding

Forsyningsspændingen (24 V~ –15/+10 %, 50

Hz) skal tilsluttes klemme SN og SP.

Indstilling af DIP kontakter ❹

U I

2 V_---V 0 V_---V

Direkte Sekventiel

---

0(2) V_5(6) V 5(6) V_10 V

Omvendt 3-punkt/RL

LOG. fl ow L IN. flow

100 % K

VS

Reset Nulstil

Fabriksindstilling:

Alle kontakter er I OFF position! ❹①

Bemærk: Alle kombinationer af

kontaktindstillinger er tilladelige. Alle

funktionsvalg er tilføjet en efter en. Der er kun

en logisk overskridelse af funktionaliteten:

Kontakt Nr. 6 Proportional/3-punkt styring,

som sætter ak tuatoren i stand til at ignorere

reguleringssignalet og arbejde som en ”simpel”

3-punkt motor.

SW1: U/I ❹②

Fabriksindstilling

Spændingssignal (0-10 V).

SW2: 2-10 V/0-10 V ❹③

Fabriksindstilling:

2-10 V.

SW3: Direkte/Indirekte ❹④

Fabriksindstilling:

DIREKTE

SW4: ---/Sekvens ❹⑤

To aktuatorer kan arbejde parallelt med et

reguleringssignal. I SEKVENS indstilling reagerer

aktuatoren på delt styresignal (se 0(2)-5(6)

V/5(6)-10 V).

Bemærk: Denne kombination arbejder

sammen med kontakt Nr. 5: 0(2)-5(6) V/5(6)-10 V

SW5: 0(2)-5(6) V/5(6)-10 V ❹⑥

Bemærk: Denne funktion er tilgængelig hvis

kontakt Nr. 4:---/ekvens er indstillet.

SW6: Proportional/3-punkt ❹⑦

Når DIP 6 er på Ak tuator skal udføre

automatiske kalibrering foru d at

DIP-6.

Udgangssignal afhæ nger af DIP-2, 3 &5

Indstilling.

Aktuator kan køre i modulerende (DIP 6 til OFF)

eller i “simple” 3-punkts funktion, hvis 3-punkt

funktionen er valgt (DIP 6 til ON).

Tilslutte forsyningsspænding på klemme SN og

SP terminaler.

Fabriksindstillet DIP 6 til OFF for at drive

Aktuator i modulerende tilstand.

Aktuator’s stem løber frem til dens fuldt

udstrakt eller tilbagetrukne position ved at

bygge bro mellem SN signal til klemme 1

eller 3 og forbliver i denne positron så længe

potentiale er til stede.

Indstil DIP 6 på ON for Aktuator kører i 3 punkts

funktion.

Proportional

Red. K

VS

Se nøje ledningsdiagram som ledningsføring er

forskellig for regulatorer med triacudgang (ECL)

i caparison til regulatorer med relæudgang.

Bemærk: Hvis 3-punkt funk tionen er valgt,

reagerer aktuatoren ikke på signaler på klemme Y.

Motorspindelen bevæger sig kun opad eller nedad

ved signaler på klemme 1 eller 3.

SW 7: LOG. flow/LIN. flow ❹⑧

Fabriksindstilling:

LOG.flow (ventilkarakteristikken er uændret).

Bemærk: Anvendes denne funktion i

kombination med ikke logaritmiske ventiler, vil

karakteristikken for motorventilen blive modsat

logaritmisk i forhold til ventilkarakteristikken

(d.v.s. en ventil med lineær karakteristik vil blive

transformeret til hurtig åben karakteristik).

SW 8: 100% KVS/RED. KVS ❹⑨

Bemærk: denne funktion virker kun ved

logaritmiske ventiler.

SW9: Reset ❹⑧

Efter tilslutning af forsyningsspænding,

vil aktuatoren starte en selvjusterings

procedure. LED indikatoren blinker indtil

selvjusteringen er færdig. Varigheden afhænger

af spindelvandringen og tager normalt

nogle få minutter. Ventilens spindelvandring

lagres i hukommelsen efter selvjusteringen

er færdig. For at starte selvjustering, skiftes

positionen af RESET kontakten (kontakt Nr. 9).

Hvis forsyningsspændingen svigter eller falder

til under 80 % i mere end 0,1 sekund, vil den

aktuelle ventilposition lagres i hukommelsen

og alle data bliver bevaret i hukommelsen, også

efter at forsyningsspændingen afbrydes.

Funktions test

Lysdioden indikerer, om aktuatoren er i drift,

ligesom den viser driftsstatus og eventuelle fejl.

Konstant lys

- normal drift

Intet lys

- ikke i drift, ingen strømforsyning

Interval blink (1 Hz)

- selvjusteringsmodul

Interval blink (3 Hz)

- strømforsyning for lav

- ventil slaglængde utilstrækkelig

- endestilling kan ikke nås

Mål ➎

6 | © Danfoss | 2016.11

EI.LF.M1.2V

Page 7

AME 25, AME 35

DEUTSCH

Sicherheitshinweise

Um Verletzungen an Personen und

Schäden am Gerät zu vermeiden, ist

diese Anleitung unbedingt zu

beachten.

Montage, Inbetriebnahme und

Wartungsarbeiten dürfen nur von sachkundigen

und autorisierten Personen durchgeführt

werden.

Die Vorgaben des Anlagenherstellers und

Anlagenbetreibers sind zu beachten.

Entfernen Sie die Ab deckung nicht,

bevor die Stromversorgung komplett

ausgeschaltet ist.

Anweisung zur Entsorgung

Dieses Produkt sollte ausgebaut und

in dessen Bestandteile zerlegt werden.

Sortieren Sie die einzelnen

Bestandteile entsprechend der

Entsorgungsgruppen zur Wiederverwertung

oder Entsorgung.

Beachten sie dabei immer die lokalen

Entsorgungsrichtlinien.

Montage

AME 25, AME 35 am Ventil ansetzen ❶

Zulässige Einbaulagen ❷.

Elektrischer Anschluß ❸

Bitte die Platine nicht dire kt

berühren!

Trennen Sie das Netzkabel vor

der Verdrahtung des Stellantriebs! Tödliche

Spannung!

Schließen Sie den Stellantrieb gemäß

dem Verdrahtungsplan an.

* Verdrahtung für die modulierende

Regelung (Wiring for modulating mode)

** Verdrahtung für die 3-Punkt-Regelung mit

Relaisausgang (Wiring for 3-point f loating

mode Controller with relay output)

*** Verdrahtung für die 3-Punkt-Regelung mit

Triac-Ausgang (Wiring for 3-point floatig

mode Controller with triacs output)

Steuersignal

Das Steuersignal des Reglers ist an Klemme

Y (Eingangssignal) und Klemme SN

(Sammelklemme) an der AME-Printplatte

anzuschließen.

Ausgangssignal

Das Ausgangssignal von Klemme X kann zur

Anzeige der aktuellen Position benutzt werden.

Der Bereich hängt von der Brücke ab.

Spannungsversorgung

Die Spannungsversorgung (24 V~ –15 bis +10 %,

50 Hz) ist an Klemme SN und SP anzuschließen.

Einstellung der DIP Brücke ❹

U I

2 V_---V 0 V_---V

Direkte Sekventiel

---

0(2) V_5(6) V 5(6) V_10 V

Omvendt 3-punkt/RL

LOG. fl ow L IN. flow

100 % K

VS

Reset Nulstil

Werkseinstellung:

ALLE Schalter sind in der Position OFF! ❹①

Bemerkung: Alle Kombinationen von DIP

Schalter sind erlaubt. Gewählte Funktionen sind

hintereinandergelegt. Es gibt nur eine logische

Umsteuerung der Funktionen: Brücke Nr.6

proportional/3-Punkt. Dadurch wird der Antrieb so

umgeschaltet, dass das Signal ignoriert wird und

arbeitet als “üblicher” 3-Punkt Anrieb.

SW1: U/I ❹②

Werkseinstellung:

Spannungsregelsignal (0-10V).

SW2: 2-10 V/0-10 V ❹③

Werkseinstellung:

2-10 V .

SW3: Direct/Inverse ❹④

Werkseinstellung:

DIRECT

SW4: ---/Sequentiell ❹⑤

Zwei Antriebe können parallel mit einem

Steuersignal arbeiten. Bei der Einstellung

SEQUENTIAL Antrieb reagiert auf geteilten

Steuersignal (sehe 0(2)-5(6) V/5(6)-10V).

Bemerkung: Diese Kombination funktioniert

mit dem Schalter No.5: 0(2)-5(6) V/5(6)-10 V

SW5: 0(2)- 5(6) V/5(6)-10 V ❹⑥

Bemerkung: Diese Funktion ist wirksam,

wenn der Schalter No.4: --- /Sequentiell eingestellt

ist.

SW6: Proportionäl/3-Punkt ❹⑦

Wenn der DIP- 6 ist auf Stellmotor

muss Ventilhub vor dem Ändern der

DIP 6 auf ON.

Ausgangssignal ist abhängi g von DIP-2, 3 &5

Einstellung.

Stellmotor kann bei jeglichen arbeiten

modulierend (DIP-6, um AUS) oder in “einfacher”

3-Punkt, wenn die 3-Punkt Funktion ausgewählt

ist (DIP-6, um auf).

Anschließen Spannungsversorgung an den

Klemmen SN und SP-Klemmen.

Werkseitig eingestellte DIP 6 auf OFF für den

Betrieb in Stellmotor modulierend Modus.

Stellmotor Antriebsstange ausgeführt

werden soll, der vollkommen erweitert oder

eingefahrener Stellung Audio-Bestandskunden

SN Signal an den Klemmen 1 oder 3 und bleibt

in diesem Elektron-Positron -so lange wie

Potenzial vorhanden ist.

Stellen Sie DIP-Schalter 6 auf EIN für den

Stellmotor in 3 Punkt.

Proportional

Red. K

VS

Bitte schauen Sie Schaltplan als Verdrahtung

ist anders für Regler mit Tricausgang (ECL) in

Prachtdecke durch Controller mit Relaisausgang.

BEMERKUNG: Wenn die 3-Punkt Funktion

gewählt wird, reagier t der Antrieb nicht auf

irgendwelche der Steuersignale Y Klemme. Der

Antrieb bewegt die Motorenspindel nach oben

oder nach unten bei dem Steuersignal auf Klemme

1 oder 3.

SW7: LOG. flow/LIN. flow ❹⑧

Werkseinstellung:

LOG. Flow (Ventilcharakteristik bleibt

unverändert).

Bemerkung: falls diese Funktion mit dem

nicht logarithmischen Ventil verwendet wird,

übernimmt der Antrieb die Anti-Logarithem der

Ventilcharakteristik. (Ventil mit linearer Kennlinie

wird in die Kennlinie umgewandelt).

SW 8: 100% KVS/RED. KVS ❹⑨

Bemerkung: diese Funktion arbeitet richtig

nur mit logarithmischen (gleichprozentigen)

Ventilen.

SW9: Reset ❹⑧

Nach Einschalten der Stromversorgung startet

der Regelantrieb den Selbstanpassungsvorgang.

Die Leuchtdiode blinkt, bis die Anpassung

abgeschlossen ist. Dies dauert normalerweise

einige Minuten, abhängig von der Distanz

der Spindelbewegung. Die Hublänge

des Ventils wird nach abgeschlossener

Selbstanpassung im Speicher registriert. Der

Selbstanpassungsvorgang kann durch Drücken

der RESET-Taste wiederholt werden (Schalter No.

9). Bei Ausfall der Versorgungsspannung - oder

beim Absinken auf einen Wert kleiner 80 % länger als 0,1 s, wird die aktuelle Ventilposition

im Speicher gespeichert. Alle Daten sind also

auch im Falle einer Stromunterbrechung

gesichert.

Funktionstest

Die Leuchtdiode zeigt den Motorbetrieb, den

Betriebszustand und eventuelle Fehler an.

Dauerlicht

- normaler Betrieb

Kein Licht

- nicht in Betrieb oder keine

Stromversorgung

Blinklicht (1 Hz)

- Selbstanpassungsmodus

Blinklicht (3 Hz)

- Versorgungsspannung zu niedrig

- Ventilhublänge ungenügend (<20 s)

- Endposition nicht erreichbar.

Abmessungen ➎

EI.LF.M1.2V

© Danfoss | 2016.11 | 7

Page 8

AME 25, AME 35

FRANÇAIS

Sécurité

Pour éviter des blessures des

personnes et des dégâts au dispositif,

il est absolument nécessaire de lire

attentivement et de respecter ces instructions.

Le montage, la mise en marche et toute

opération de maintenance doivent être

effectués par un service ou une personne de

qualification.

Suivre les instructions du fabricant du système

ou de son service.

Ne pas retirer le capot avant d ’avoir

totalement coupé l’alimentation.

Indications de mise au rebus

Ce produit peut être dém onté et tous

ses composants classés si possible e n

différentes catégor ies en vue de leur

recyclage ou dest ruction

Dans tous les cas , suivre la législatio n locale de

mise au rebus.

Montage

Fixer l’AME 25, AME 35 sur la vanne ❶

Orientations de montage ❷

Branchement éléctrique ❸

Ne pas toucher la car te de circuit

imprimé !

Couper l’alimentation avant de

raccorder l’actionneur ! Dang er de mort !

Raccorder l’actionneur confo rmément au

schéma de branchement électrique.

* Raccordement pour le mode modulant

(Wiring for modulating mode)

** Raccordement pour mode flottant 3 points -

Régulateur avec sortie relais (Wiring for 3-point

floating mode Controller with relay output)

*** Raccordement pour mode flottant 3 points -

Régulateur avec sortie triac (Wiring for 3-point

floatig mode Controller with triacs output)

Signal de commande

Le signal du régulateur doit être branché sur

la borne Y (signal d’entrée) et la borne SN

(commun) sur la carte imprimée de l’AME.

Signal de sortie

Le signal de sortie de la borne X peut servir pour

indiquer la position actuelle. La zone dépend

des réglages du sélecteur de fonction DIP.

Tension d’alimentation

La tension d’alimentation (24 V~ –15/+10 %, 50

Hz) doit être branchée aux bornes SN et SP.

Réglages du sélecteur de fonction DIP ❹

U I

2 V_---V 0 V_---V

Direct Inverse

--- Séquentiel

0(2) V_5(6) V 5(6) V_10 V

Proportionnel 3 points/RL

Débit LO G. Débit LIN.

100 % K

VS

Reset Reset

Réglage d’usine:

TOUTES les commandes sont en position

ARRÊT! ❹①

Remarque: Toutes les combinaisons

des commandes DIP sont possibles. Toutes les

fonctions sélectionnées sont ajoutées l’une à

l’autre. Il y a seulement un pontage logique des

fonctions: commande 6 Proportionnel/ 3 points

qui fait le moteur ignorer le signal de commande et

fonctionne comme un »simple« 3-points moteur.

SW1: U/I ❹②

Réglage de l’usine:

Le signal de commande de tension (0 -10 V).

SW2: 2-10 V/0-10 V ❹③

Réglage de l’usine:

2-10 V.

SW3: Direct/Inverse ❹④

Réglage de l’usine:

DIRECT

SW4: ---/Séquentiel ❹⑤

Deux moteurs peuvent être réglés de telle

manière qu’ils fonctionnent parallèlement

avec un signal de commande. Si la fonction

SÉQUENTIEL est réglée, le moteur répond au

signal de commande »split«

(voir 0(2)-5(6) V/5(6)-10 V).

Remarque: Cette combinaison fonctionne

en combinaison avec la commande 5: 0(2)-5(6)

V/5(6) -10V.

SW5: 0(2)-5(6) V/5(6)-10V ❹⑥

Remarque: Cette fonction est disponible, si la

commande 4: ---/Séquentiel est réglée.

SW6: Proportionnel/3 points ❹⑦

Lorsque le DIP 6 est SUR Act uateur

doit exécuter autorég ulation avant le

DIP en perpét uelle évolution 6 sur

ON.

Signal de sortie dé pend du commutateur DIP 2,

3 et 5 Réglage.

Actuateur permet de fonctionner en modulant

(DIP 6 sur OFF) ou dans “simple” 3-points mode,

si la fonction 3 points est sélectionnée (DIP 6

sur ON).

Alimentation pour alimenter les bornes SN et SP

les bornes.

Réglage d’usine DIP 6 sur OFF pour la mise en

œuvre d’Actuateur en mode modulant.

Actuateur tige continue de fonctionner à sa

position rétractée en établissant totalement

étendue ou signal de SN à la borne 1 ou 3

et resteront dans cette positon tant que le

potentiel est présent.

Red. K

VS

Régler le DIP 6 sur ON pour l’exploitation

Actuateur en mode 3 points.

Schéma de raccordement en tant que regarder

attentivement câblage est différente pour

les régulateurs avec sortie triac (ECL) en

comparaison avec les régulateurs avec sortie de

relais.

REMARQUE: Si la fonction 3 points est

sélectionnée, le moteur ne répond à aucun signal

de commande sur la borne Y. Cette fonction

seulement déplace la broche vers le haut et vers

le bas, s’il y a de l’alimentation en courant sur les

bornes 1 et 3.

SW7: Débit LOG./ débit LIN. ❹⑧

Réglage de l’usine:

débit LOG. (caractéristique de la vanne ne change

pas).

Remarque: Si cette fonction est

utilisée en combinaison avec les vannes

non-logarithmiques, la caractéristique de la

vanne motorisée sera l’anti-logarithme de la

caractéristique de la vanne (p.e. une vanne avec

la caractéristique linéaire sera transformée en

caractéristique »rapidement ouverte«).

SW 8: 100% KVS/RED. KVS ❹⑨

Remarque:

Cela ne fonctionne proprement qu’avec les vannes

logarithmiques (même pourcentage).

SW9: Exploitation ❹⑧

Une fois alimenté, le moteur commence un

procédé d’auto-réglage. La diode lumineuse

clignote jusqu’à ce que l’auto-réglage soit

términé. Cela dure normalement env. 2 minutes,

suivant le déplacement de la broche. La course

de la vanne est conservée en mémoire à la fin

de l’auto-réglage. Le changement de position

de la commande R. À Z. (commande 9) fera

redémarrer l’auto-réglage. Si l’alimentation est

interrompue – ou chute à une valeur inférieure

à 80 % - pendant plus de 0,1 sec., la position

actuelle de la vanne est mémorisée. Toutes les

données seront donc mémorisées, même en cas

de coupure de courant.

Test de fonction

La diode lumineuse indique que le moteur est

en fonction. Elle indique aussi l’état de marche

et les erreurs éventuelles.

Lumière permanente

- marche normale

Pas de lumière

- fonction arrêtée, pas d’alimentation

Clignotements par intervalles (1 Hz)

- mode d’auto-réglage

Clignotement par intervalles (3 Hz)

- alimentation en courant trop faible

- course de vanne insuffisante (<20 s)

- la fin de course ne peut pas être atteinte.

Dimensions ➎

8 | © Danfoss | 2016.11

EI.LF.M1.2V

Page 9

AME 25, AME 35

ESPAÑOL

Nota de seguridad

A fin de evitar lesiones personales o

daños en el dispositivo, es

absolutamente necesario leer y

respetar estrictamente estas instrucciones.

Las operaciones de montaje, puesta en

marcha y mantenimiento deben ser realizadas

únicamente por personal cualificado y

autorizado.

Por favor, respete las instrucciones del

fabricante u operador del sistema.

No retire la cubier ta antes de haber

desconectado el suministro eléctrico

por completo.

Instucciones de eliminación

Este producto deb e ser desmontado y

si es posible, sus componentes d eben

ser separados en varios gru pos antes

de su reciclado o destrucció n.

Siga siempre la regulació n local sobre

eliminación.

Montaje

Montaje del AME 25, AME 35 en la válvula ❶

Posiciones de instalación permitidas ❷

Cableado ❸

¡No toque nada en la pl aca de circuito

impreso! ¡Tensión letal!

¡Desactive la lín ea de suministro

eléctrico antes de conectar el actuador!

Conecte el actuador de acuerdo con el esquema

de cableado.

* Cableado para modo modulante

(Wiring for modulating mode)

** Cableado para modo f lotante de 3

puntos, controlador con salida para

relé (Wiring for 3-point floating mode

Controller with relay output)

*** Cableado para modo flotante de 3 puntos,

controlador con salida triacs (Wiring for 3-point

floatig mode Controller with triacs output)

Seńal de control

La seńal de control proveniente del regulador

deberá ser conectada al terminal Y (seńal de

entrada) y al terminal SN (común) en el circuito

impreso del AME.

Seńal de salida

La seńal de salida del terminal X puede usarse

para indicar la posición actual. El rango

dependerá de la configuración del interruptor

DI P.

Tensión de alimentación

La tensión de alimentación

(24 V~–15/+10 %, 50 Hz) tiene que ser conectada

a los terminales SN y SP.

Las configuarciones del interruptor

DIP ❹

U I

2 V_---V 0 V_---V

Directo Secuencial

--- Proporcional

0(2) V_5(6) V 5(6) V_10 V

Inverso 3 puntos R / L

Flujo LOG . Flu jo LIN.

100 % K

Restablecimiento

VS

Ajuste de fábrica:

Todos los interruptores tienen que estar en la

posición OFF! ❹①

Importante: Todas las combinaciones de los

interruptores están permitidas. Todas las funciones

seleccionadas serán añadidas una a la otra.

Solamente hay una sobreposición de las funciones:

el interruptor No.6 Proporcional/ 3 vías que hace

que el actuador ignore la señal y funcione como

un “sencillo” actuador de 3 vías.

SW1: U/I ❹②

Ajuste de fábrica:

señal de control de tensión (0-10 V).

SW2: 2-10 V/0-10 V ❹③

Ajuste de fábrica:

2-10 V.

SW3: Directo/Inverso ❹④

Ajuste de fábrica:

DIRECTO

SW4: ---/Secuencial ❹⑤

Se pueden ajustar dos acuadores

simultaneamenete que respondan a la misma

señal de control a la vez. Al elegir SEQUENTIAL

el actuador responderá a la señal de control

dividida

(vease 0(2)-5(6) V/5(6)-10 V).

Nota: Esta combinación funciona en

combinación con el interruptor No.5: 0(2)-5(6)

V/5(6)-10 V ).

SW5: 0(2)-5(6) V/5(6)-10 V ❹⑥

Nota: Esta función es posible al elegir el

interruptor No.4:---/Secuencial.

SW6: Proporcional/3 vías ❹⑦

Cuando los interruptores DIP 6 e s de

actuador deb e realizar ajuste

automático de la longitud de ca rrera

antes del conmutador DIP 6 en la p osición ON.

Señal de salida de pende de los interruptores DIP

2, 3 &5 Ajuste.

Actuador puede funcionar en modulante (DIP

6 a OFF) o en modo “simple” 3-puntos, si la

función se selecciona 3 puntos (DIP 6 a).

Conectar la corriente de alimentación SN y SP.

terminales de los terminales.

Ajuste de fábrica los interruptores DIP 6 en la

posición OFF para el funcionamiento actuador

modulante en modo.

Actuador vástago es totalmente extendida

o se ejecutará hasta su posición retraída,

señal de transición SN a los terminales 1 o 3

y permanecerá en tal tomografía mientras

potencial está presente.

Red. K

VS

Restablecimiento

Ajuste los interruptores DIP 6 en

funcionamiento actuador de 3 puntos modo.

Observe atentamente diagrama de

conexionado como cableado es diferente

para los controladores con salida triac (ECL) en

caparison a los controladores con salida de relé.

Importante: Al elegir la función de 3 vías, el

actuador no responerá a ninguna de las señales de

control en el puerto Y. El vástago se moverá hacia

arriba o abajo si hay alimentación en el puerto 1

ó 3.

SW7: LOG.flow/LIN.flow ❹⑧

(LOG.flujo /LIN.flujo)

Ajuste de fábrica:

LOG flow (característica de la válvula no

cambiada)

Imporatante: Al usar esta función con

las válvulas no logarítmicas, la característica

de la válvula motorizada será el antilogaritmo

de la característica de la válvula (por ejemplo

la válvula con la característica linear será

transformada en al caracteristica de apertura

rápida).

SW 8: 100% KVS/RED. KVS ❹⑨

Imporatante:

Esta función funciona correctamente solamente

con las válvulas logarítmicas (de flijo igual

porcentage).

SW9: Funcionamiento ❹⑧

Después de suministrar corriente de

alimentación al actuador, éste inicia un proceso

de auto ajuste. El diodo LED parpadea hasta

que el proceso de auto ajuste haya llegado a

término. Este proceso dura normalmente un

par de minutos dependiendo del recorrido

del vástago. El recorrido de la válvula es

almaceneado en la memoria después de

terminado el auto ajuste. Para empezar de

nuevo el auto ajuste pulsar el interruptor

RESET (interruptor No.9). Si se corta la tensión

de alimentación o en caso de que ésta caiga

por debajo de 80 % durante más de un 0,1 s, la

posición actual de la válvula será guardada en

la memoria. De esta manera, todos los datos

quedarán guardados en la memoria, incluso en

caso de corte de corriente.

Test de funcionamiento

El diodo luminoso indica si el motor está

funcionando. Además indica el estado de

funcionamiento y fallos eventuales.

Luce constantemente

- funcionamineto normal

No luce

- no está en marcha, no hay alimentación

Luce intermitentemente a intervalos (1 Hz)

- estado de auto ajuste

Luce intermitentemente a intervalos (3 Hz)

- corriente de alimentación demasioado baja

- recorrido de la válvula insuficinete

(<20 s)

- el recorrido máximo no puede ser

alcanzado

Dimensiones ➎

EI.LF.M1.2V

© Danfoss | 2016.11 | 9

Page 10

AME 25, AME 35

SUOMI

Turvallisuushuomautus!

Näitä ohjeita on ehdottomasti

noudatettava henkilö- ja

omaisuusvahinkojen välttämiseksi.

Ainoastaan ammattitaitoiset ja valtuutetut

henkilöt saavat tehdä kokoonpano-, käynnistysja huoltotöitä.

Noudata järjestelmän valmistajan ohjeita.

Älä irrota kantta, ennen kui n

virransyöttö on täysin katkaistu.

Tuotteen hävittäminen jätteenä

Mikäli mahdollista tämä tuote tulee

purkaa ja lajitella pure tut osat ennen

niide n kierrät tämistä tai hä vittämistä

jätteenä.

Noudata aina paikallista lainsäädäntöä

ja jätehuoltomääräyksiä jätteiden

hävittämisestä.

Kiinnittäminen

Kiinnitä AME 25, AME 35 venttiiliin ❶

Sallitut asennusasennot ❷

Johdotus ❸

Älä koske mihinkään piirilevyllä!

Käännä virta pois pää ltä ennen

toimimoottorin kytkemistä!

Hengenvaarallinen jännite!

Kytke toimimoottori johdotuskaavion

mukaisesti.

* Jännite- ja virtaohjaus (Wiring

for modulating mode)

** Kytkentä 3-pisteohjatulle säätimelle, jossa

on relelähtö (Wiring for 3-point floating

mode Controller with relay output)

*** Kytkentä 3-pisteohjatulle säätimelle, jossa

on triac-lähtö (Wiring for 3-point floatig

mode Controller with triacs output)

Ohjaussignaali

Ohjaimen ohjaussignaali on liitettävä painetun

AME-piirin liitäntöihin Y (sisäänmenosignaali) ja

SN (tavallinen signaali).

Lähtösignaali

X-liitännän lähtösignaalia voidaan käyttää

nykyisen sijainnin ilmaisemiseen. Alue

määräytyy DIP-kytkinasetusten mukaan.

Käyttöjännite

Käyttöjännite

(24 V~ –15– +10 %, 50 Hz) on yhdistettävä SN- ja

SP-liitäntöihin.

DIP-kytkinasetukset ❹

U I

2 V_---V 0 V_---V

Suora Käänteinen

--- Vaiheittainen

0(2) V_5(6) V 5(6) V_10 V

Verrannollinen 3-piste/RL

LOG. vir taus Lineaarinen virtaus

100 % K

VS

Nollaaminen Nollaaminen

Tehdasasetukset:

Kaikki kytkimet ovat OFF-asennossa! ❹①

Huomautus: Kaikki DIP-kytkinasetusten

yhdistelmät ovat sallittuja. Kaikki valitut toiminnot

yhdistetään keskenään. Vain yksi logiikka ohittaa

toiminnot: ky tkimen nro 5

Suhteellinen /kolmipiste -asetus, joka

määrittää käyttölaitteen jättämään signaalin

huomiotta, jolloin se toimii yksinkertaisena

kolmipistekäyttölaitteena.

SW1: U/I ❹②

Tehdasasetus:

Jänniteohjaussignaali (0–10 V).

SW2: 2–10 tai 0–10 V ❹③

Tehdasasetus:

2–10 V

SW3: Suora tai käänteinen ❹④

Tehdasasetus:

SUORA

SW4: ---/vaiheittainen ❹⑤

Kaksi käyttölaitetta voidaan määrittää

toimimaan rinnakkain samasta

ohjaussignaalista. Jos vaiheittaisuus otetaan

käyttöön, käyttölaite reagoi jaettuun

ohjaussignaaliin. Lisätietoja on kohdassa

0(2)–5(6)V/5(6)–10V.

Huomautus: Tämä yhdistelmä toimii

yhdessä kytkimen 5 kanssa: 0(2)–5(6)V/5(6)–10V

SW5: 0(2)–5(6) V/5(6)–10V ❹⑥

Huomautus: Tämä toiminto on

käytettävissä, jos kytkin 4 - --/vaiheittainen on

määritetty.

SW6: Suhteellinen/3-pisteinen ❹⑦

Jos DIP 6 on ON- asennossa

moottorille tar vitsee ajaa rajat

uudelleen.

Ohjaussignaali riip puu DIP-ky tkimen 2,3 ja 5

asennoista.

Moottori toimii moduloivalla ohjauksella tai

3-piste ohjauksella, jos 3-piste toiminto on

valittu (DIP 6 ON).

Kytke syöttö liittimiin SN ja SP.

Tehdasasetus DIP 6 kytkimelle on modulaatio

asennossa (OFF).

Moottori ajaa karan ääriasentoon auki/kiinni

kytkemällä SN signaalin liittimeen 1 tai 3 ja

jää asentoon niin kauan kuin kytkentä on

paikallaan.

Aseta DIP 6 ON-asentoon halutessasi moottorin

olevan 3-piste ohjauksessa.

Tarkista kytkennät triak (ECL) ja rele tulojen

kytkentöjen osalta. Kytketään eri tavalla.

Pien. K

VS

HUOMAUTUS: Jos 3-pisteinen toiminta

valitaan, käyttölaite ei reagoi portin Y signaaliin.

Se nostaa ja laskee karaa vain, jos portteihin 1 tai 3

syötetään virtaa.

SW 7: Logaritminen tai lineaarinen

virtaus ❹⑧

Tehdasasetus:

Logaritminen virtaus (venttiilin toiminta ei muutu).

HUOMAUTUS: Jos tätä toimintoa

käytetään yhdessä muun kuin logaritmisen

venttiilin kanssa, moottoroidun venttiilin

toiminta muuttuu vastakkaisesti logaritmiseksi,

eli lineaarinen venttiili muuttuu nopeasti

avautuvaksi.

Lisätietoja on tuotetiedotteessa.

SW 8: 100% KVS/RED. KVS ❹⑨

HUOMAUTUS: Tämä toiminto toimii oikein

vain logaritmisissa venttiileissä.

SW9: Nollaaminen ❹⑧

Kun käyttölaite on yhdistetty virtalähteeseen,

se aloittaa itsesäätötoimet. LED-merkkivalo

vilkkuu, kunnes itsesäätötoimet on tehty.

Kestoaika määräytyy karan liikkeen mukaan,

ja on tavallisesti muutama minuutti. Venttiilin

karan liikkeen pituus tallennetaan muistiin,

kun itsesäätötoimet on tehty. Voit aloittaa

itsesäädön uudelleen muuttamalla RESETkytkimen asentoa (kytkin 9). Jos virransyöttö

katkeaa tai putoaa alle 80 prosenttiin yli 0,1

sekunnin ajaksi, nykyinen venttiilin sijainti ja

kaikki tiedot tallennetaan muistiin. Ne säilyvät

siellä sähkökatkon ajan.

Toimintojen testaaminen

Merkkivalo ilmaisee, onko käyttölaite käytössä

vai ei. Lisäksi merkkivalo ilmaisee ohjaustilan ja

viat.

Palaa jatkuvasti

- normaali toiminta

Ei valoa

- ei toiminnassa tai ei virransyöttöä.

1 Hz:n taajuudella vilkkuva valo

- itsesäätötila

3 Hz:n taajuudella vilkkuva valo

- virransyöttö ei riitä

- venttiilin iskunpituus ei riitä (alle 20 s)

- loppusijaintia ei voi saavuttaa.

Dimensions ➎

10 | © Danfoss | 2016.11

EI.LF.M1.2V

Page 11

AME 25, AME 35

NEDERLANDS

Veiligheid

Om verwondingen van personen en

schade aan het apparaat te

voorkomen dient men deze instructies

met aandacht te lezen.

Montage, inbedrijfstelling en

onderhoudswerkzaamheden mogen alleen

door deskundig en erkend personeel uitgevoerd

worden.

Neem alle instructies betreffende

installatiecomponenten van andere fabrikanten

in acht.

Verwijder de afdek kap niet voordat

de voedingsspanning voll edig is

uitgeschakeld

Afvalverwerking

Dit product of d elen ervan dienen te

worden afgevoerd op ee n

milieuverantwoorde wijze.

Apparatuur die elektrische onderdelen

bevat, mag niet samen m et huishoudelijk afval

worden afge voerd.

Deze apparatuur m oet apart worden

ingezameld sam en met ander elektrisch

en elektronisch a fval conform de geldende

wetgeving.

Montage

Plaats de AME 25, AME 35 op de afsluiter ❶

Toegestane montage posities ❷

Elektrische aansluiting ❸

Gevaarlijke spanning, raak n iets aan

op de printplaat! Dodelijke spanning!

Schakel de stroom uit voo rdat

de bedrading van de ser vomotor wordt

aangebracht!

Sluit de servomotor a an volgens het

aansluitschema.

Stuursignaal

Het stuursignaal van de regelaar wordt

aangesloten op klem Y (ingangssignaal) en op

klem SN (gemeenschappelijke nul) van de AME

printplaat.

Uitgangssignaal

Het uitgangssignaal van klem X (t.o.v. klem

SN) kan gebruikt worden als indicatie van de

klepstand. Het bereik hangt af van de instelling

van de DIP schakelaars.

Voedingsspanning

De voedingsspanning (24V~ –15 tot +10 %, 50

Hz) wordt aangesloten op de klemmen SN (nul)

en SP (24 VAC).

DIP schakelaars ❹

U I

2 V_---V 0 V_---V

Direkt Omgekeerd

--- Volgorde

0(2) V_5(6) V 5(6) V_10 V

Proportioneel 3 punts/RL

LOG. fl ow L IN. flow

100 % K

VS

Reset Reset

Fabrieksinstelling:

Alle schakelaars staan in de OFF (uit) positie! ❹①

Opmerking: Alle combinaties van DIP

instellingen zijn toegestaan. Alle gekozen funkties

worden bij elkaar opgeteld. Er is echter één

uitzondering:

Schakelaar 6 Propor tional/3 point, welke de motor

instelt als “simpele” 3-punts servomotor.

SW 1: U/I ❹②

De servomotor kan reageren op een spanningsstuursignaal (U) of een stroom-stuursignaal (I).

Het spanningsbereik is 0-10 V, het stroombereik

is 0-20 mA.

Fabrieksinstelling:

0-10 V stuursignaal

SW 2: 2---- V/0---- V ❹③

Fabrieksinstelling:

2 V (4 mA)

SW 3: Direct/Inverse

(Direkt/Omgekeerd) ❹④

Fabrieksinstelling:

Direct.

SW 4: ---/Sequential (volgorde) ❹⑤

Twee motoren kunnen naar hetzelfde signaal

“luisteren”.

Als Sequential is ingesteld reageert de motor op

een gedeeld signaal.

Deze instelling werkt samen met schakelaar 5.

SW 5: 0(2)-5(6) V/5(6)-10 V ❹⑥

Opmerking: Deze funktie is geldig als

schakelaar 4 op Sequential staat.

SW 6: Proportional/3 point

(Proportioneel/3punts) ❹⑦

De servomotor werkt als een simpele 3-punts

motor als de 3-punts funktie is ingesteld.

Voedingsspanning wordt aangesloten op

de klemmen SN en SP. Op de klemmen 1 en

3 wordt 24 VAC voor “omlaag” en “omhoog”

aangesloten. Uitgangs-signaal X geeft de

werkelijke stand aan.

Opmerking: In de 3-punts funk tie reageert

de servomotor niet op signalen via klem Y. De

spindel beweegt alleen bij spanning op klem 1 of

klem 3.

Red. K

VS

SW 7: LOG. flow/LIN. flow ❹⑧

Fabrieksinstelling:

LOG.flow (afsluiter-karakteristiek ongewijzigd)

Opmerking: Als deze funktie wordt

gebruikt in combinatie met niet-logarithmische

afsluiters dan wordt de karakteristiek van de

gemotoriseerde afsluiter anti-logarithmisch

(bijv. een afsluiter met een lineaire karakteristiek

wordt omgevormd tot een snel open

karakteristiek).

Zie DATABLAD voor meer informatie.

SW 8: 100% KVS/RED. KVS ❹⑨

Opmerking:

Deze funktie werkt alleen nauwkeurig bij

logarithmische (equi-procentuele) afsluiters.

SW 9: Reset ❹⑧

Nadat de servomotor is aangesloten op de

voedingsspanning begint de automatische

afstelprocedure. De indicatie LED knippert

tot de afstelling is beëindigd. De tijdsduur

is afhankelijk van de kleplift en bedraagt

gewoonlijk enkele minuten. De slag van de klep

wordt in het geheugen opgeslagen.

Om de afstelprocedure opnieuw te starten dient

de stand van RESET veranderd te worden.

Wanneer de voedings-spanning wordt

uitgeschakeld of langer dan 0,1s onder 80 %

daalt, wordt de momentele klepstand in het

geheugen opgeslagen en blijven alle gegevens

bewaard, ook na het uitschakelen van de

voeding.

Funktietest

De LED indicator toont het motorbedrijf,

bedrijfstoestand en eventuele fouten.

Continue aan

- normaal bedrijf

Continue uit

- geen bedrijf of geen voedingsspanning

Knipperend (1 Hz)

- automatische afstelprocedure

Knipperend (3 Hz)

- voedingsspanning te laag

- onvoldoende klepslag (< 20 s)

- eindpositie onbereikbaar.

Afmetingen ➎

EI.LF.M1.2V

© Danfoss | 2016.11 | 11

Page 12

AME 25, AME 35

POLSKI

Warunki bezpieczeństwa

Aby uniknąć obrażeń u ludzi oraz

uszkodzenia sprzętu, należy

koniecznie zapoznać się

z tymi informacjami i przestrzegać ich.

Niezbędne prace związane z montażem,

uruchomieniem i konserwacją mogą być

wykonywane wyłącznie przez autoryzowany i

wykwalifikowany personel.

Prosimy stosować się do instrukcji producenta

lub operatora układu.

Nie zdejmować pok rywy pr zed

całkowitym odłączeniem zasilania.

Instrukcja usuwania odpadów

Ten produkt powinien być rozebrany a

jego komponent y posegregowane,

jeśli to możliwe, na różne gru py przed

poddaniem rec yklingowi lub utyli zacji.

Zawsze stosuj się do miejscowych pr zepisów w

zakresie usuwania odpadów.

Montaż

Zamontować siłownik AME 25, AME 35 na

zaworze ❶

Dopuszczalne pozycje montażu ❷

Okablowanie ❸

Nie wolno niczego d otykać na pły tce

drukowanej!

Przed przys tąpieniem do

podłącza nia do siłownika przewodów

elektrycznych należy odłącz yć zasilanie

sieciowe! Zagrożenie życia!

Podłączyć siłownik zgodnie z podanym

schematem.

* Połączenia elek tryczne dla sterowania

analogowego (Wiring for modulating mode)

** Połączenia elektryczne dla sterowania

3-punk towego, sterownik z wyjściem

przekaźnikowym (Wiring for 3-point floating

mode Controller with relay output)

*** Połączenia elektr yczne dla sterowania

3-punk towego, sterownik z wyjściem

na triakach (Wiring for 3-point floatig

mode Controller with triacs output)

Sygnał sterujący

Sygnał sterujący ze sterownika musi być

podłączony do wyprowadzeń Y (sygnał

wejściowy) oraz SN (masa) na płytce drukowanej

siłownika AME.

Sygnał wyjściowy

Sygnał wyjściowy z wyprowadzenia X może być

użyty do wskazania bieżącej pozycji. Zakres

zależy od ustawień przełącznika DIP.

Napięcie zasilania

Napięcie zasilania

(24 V~ –15 do +10 %, 50 Hz) musi być

podłączone do wyprowadzeń SN i SP.

Ustawienia przełącznika DIP ❹

U I

2 V_---V 0 V_---V

Zgodnie Odwrotnie

--- S equential

0(2) V_5(6) V 5(6) V_10 V

Proporcjonalny

LOG. fl ow L IN. flow

100 % K

VS

Reset Reset

Ustawienia fabryczne: ❹①

wszystkie przełączniki są w położeniu OFF!

Uwaga: Dozwolone są wszystkie kombinacje

przełączników DIP. Wszystkie wybierane funkcje są

sumowane. Istnieje t ylko jedno logiczne ominięcie

funkcjonalności: przełącznik nr 6 Proportional

/3 point (Proporcjonalny/3-punktow y), który

powoduje, że siłownik ignoruje sygnał sterujący i

działa jako prosty 3-punktowy siłownik .

SW1: U/I ❹②

Ustawienie fabryczne:

sterowanie sygnałem napięciowym (0-10 V).

SW2: 2-10 V/0-10 V ❹③

Ustawienie fabryczne:

2-10 V.

SW3: Direct/Inverse ❹④

Ustawienie fabryczne:

DIRECT

SW4: ---/Sequential ❹⑤

Dwa siłowniki mogą być sterowane równolegle

jednym sygnałem sterującym. Jeśli wybrana jest

opcja SEQUENTIAL, siłownik reaguje na dzielony

sygnał sterujący (patrz 0(2)-5(6) V/5(6)-10 V).

Uwaga: To ustawienie działa w połączeniu

z przełącznikiem nr 5: 0(2)-5(6) V/5(6)-10 V

SW5: 0(2)-5(6) V/5(6)-10 V ❹⑥

Uwaga: Ta funkcja jest dostępna, gdy

ustawiony jest przełącznik nr 4: ---/Sequential.

SW6: Proportional/3 point ❹⑦

Gdy przełąc znik DIP 6 jest NA

Siłownik musi w ykonywać

samodostrajania pr zed zmianą

ustawień przełąc znika DIP 6 na ON (WŁ. ).

Sygnał wyjściow y zależy od DIP 2, 3 &5 nastawa.

Siłownik może pracować w modulujący (DIP 6

do WYŁĄCZONY) lub w “proste” 3-punktowego,

po wybraniu opcji 3-point (DIP 6 ON).

Podłączyć napięcie zasilania na zaciskach SN i

SP zacisków.

Fabrycznie ustawione na OFF DIP 6 do obsługi

Siłownik w trybie modulujący.

Siłownik jest całkowicie wysunięty trzpień

będzie pracować w jego trakcie wsuwania

trzpienia lub przez możliwość przemierzania

SN sygnał do zacisków 1 i 3 i pozostanie w

tym pozytronowa tak długo, jak jest obecny

potencjał.

Ustawić Siłownik DIP 6 do pracy w trybie

3-punktowy.

Przyjrzyj się uważnie jak połączenia elektryczne

schemat połączeń elektrycznych jest różne w

3-punktowy/RL

Red. K

VS

zależności od regulatorów z wyjścia triakowe

(ECL) w caparison do regulatorów z wyjście

przekaźnika.

UWAGA: Jeśli wybrano opcję 3-point,

siłownik nie reaguje na jakikolwiek sygnał

sterujący na wyprowadzeniu Y. Siłownik

będzie podnosił i opuszczał wrzeciono, jeśli na

wyprowadzenia 1 i 3 zostanie podane napięcie.

SW 7: LOG. flow/LIN. flow ❹⑧

Ustawienie fabryczne:

LOG. Flow (niezmieniona charakterystyka zaworu)

Uwaga: Jeśli ta funkcja jest używana w

połączeniu z zaworami nielogarytmicznymi,

charakterystyka zaworu napędzanego będzie

antylogarytmem charakterystyki zaworu

(np. zawór liniowy przekształci się w zawór

szybkiego otwarcia).

SW 8: 100% KVS/RED. KVS ❹⑨

Uwaga: Ta funkcja działa prawidłowo

wyłącznie z zaworami logarytmicznymi

(stałoprocentowymi).

SW9: Reset ❹⑧

Po podłączeniu siłownika do zasilania

rozpoczyna się procedura samoregulacji.

Dioda LED błyska do momentu zakończenia

tego procedury. Trwa to zazwyczaj parę

minut w zależności od skoku wrzeciona. Po

zakończonym procesie samoregulacji wartość

skoku zaworu jest zachowana w pamięci.

Zmiana pozycji przełącznika RESET (przełącznik

nr 6) ponownie wyzwala proces samoregulacji.

Jeżeli napięcie zasilające zostanie odcięte lub

przez okres ponad 0,1 sekundy spadnie poniżej

80 %, to aktualna pozycja zaworu jest chowana

w pamięci; zapewnia to, zachowana zachowanie

wszystkich danych-również w przypadku

przerw w zasilaniu.

Test działania

Dioda świetlna wskazuje, czy silnik jest aktywny

czy też nie. Co więcej, dioda LED wskazuje też

status sterowania i błędy.

Stałe świecenie

- normalna pracaBrak świecenia

- brak działania lub zasilania

Miganie z częstotliwością 1 Hz

- tryb samoregulacji

Miganie z częstotliwością 3 Hz

- zbyt niskie napięcie zasilania

- niedostateczny skok zaworu (<20 s)

- nie można osiągnąć położenia

krańcowego.

Wymiary ➎

12 | © Danfoss | 2016.11

EI.LF.M1.2V

Page 13

AME 25, AME 35

РУССКИЙ

Техника безопасности

Во избежание получения травм или

повреждений устройства

инструкцию и тщательно ее соблюдайте.

Все необходимые работы по сборке, вводу

в действие и техническому обслуживанию

оборудования должны выполняться только

квалифицированным персоналом, имеющим

соответствующее разрешение.

Следуйте указаниям производителя системы

или оператора системы.

Инструкция по утилизации

Установка

Закрепить электропривод AME 20, AME 30 на

клапане ❶

Монтажные положения регулятора ❷

Схема электрических соединений ❸

Управляющий сигнал

Управляющий сигнал с регулятора подается

на клеммы Y (входной сигнал) и SN (ноль)

платы AME.

Выходной сигнал

Выходной сигнал с клеммы Х может быть

использован для индикации текущего

положения. Диапазон зависит от настроек

переключателя DIP.

Напряжение питания

Напряжение питания (24 В переменного тока

от –15 до +10 %, 50 Гц) подается на клеммы

SN и SP.

Настройки переключателя DIP ❹

обязательно прочитайте настоящую

Не снимайте крышку до того, как

питание будет полностью

отключено.

Данная продукция подлежи т

демонтажу на части, для

раздельной утилизации

составных компонентов.

Всегда соблюдайте местные правила

утилизации.

Не прикасаться к открытым

контактам!

Отключать линию

питания перед монтажом проводк и

электропривода!

Опасное для жизни напряжение!

Смонтируйте проводку привода сог ласно

электрической схеме.

U I

2 V_---V 0 V_---V

Прямо обратно

---

0(2) V_5(6) V 5(6) V_10 V

Аналоговый 3 импульсный/RL

Логарифмическая Линейная характеристика

100 % Kvs Red. Kvs

Сброс Сброс

последовательно

Примечание: Приемлемы все комбинации

переключателей DIP. Все выбранные функции

добавляются друг к другу. Существует

только одно логическое перерегулирование

функций: переключатель № 6 – (аналоговый/

импульсный) настраивать исполни-тельный

механизм таким образом аналоговый, что он

игнорирует управляющий сигнал и работает

как импульсный исполнительный механизм.

SW1: U/I (напряжение/ток) ❹②

Заводская установка:

управляющий сигнал напряжения (0 -10 B).

SW2: 2-10 B/0-10 B ❹③

Заводская установка:

2-10 B.

SW3: Прямо/обратно ❹④

Заводская установка:

ПРЯМО.

SW4: ---/последовательно ❹⑤

Существует возможность установить

два исполнительных механизма так,

что они работают параллельно, с одним

управляющим сигналом. Если настроена

функция ПОСЛЕДОВАТЕЛЬНО, то

исполнительный механизм реагирует на

управляющий сигнал «сплит» (см. 0(2)-5(6)

В/5(6)-10 В).

Примечание: Данная схема работает в

комбинации с переключателем № 5: 0(2)-5(6)

В/5(6) -10 В.

SW5: 0(2)-5(6) В/5(6)-10 В ❹⑥

Примечание: Данная функция имеет

место лишь в случае, если настроен

переключатель № 4: ---/последовательно.

SW6: Аналоговый/импульсный ❹⑦

Если DIP- 6 - это на привод,

исполнительный механизм

необходимо выполнить выходно й

сигнал зависит от DIP-2, 3 5 настройка.а

перед изменением DIP 6.

привод, исполнительный механизм могут

работать в модулирующий (6 в положение

OFF (выкл.)) или в “простой” 3-позиционное

режим, если 3-позиционное функция

выбирается (6).

сеть питания подключается на клеммы SN и

SP. клеммам.

Заводские настройки переключателя DIP

6 в положение OFF (выкл.) для управления

привод, исполнительный механизм в

модулирующий режим.

привод, исполнительный механизм клапана

будет работать в его совершенно продление

или отведенное положение, связывая их SN

сигнал к клеммам 1 или 3 и будет оставаться в

этом positron до тех пор, пока потенциал.

Установите переключатель DIP 6 на привод,

исполнительный механизм для работы в 3

режима точки.

Внимательно посмотрите электрическая

схема как монтаж проводки для регуляторов

с симисторные выходы (ECL) в caparison для

регуляторов с релейный выход.

ПРИМЕЧАНИЕ: В случае, если выбрана

импульсная функция, исполнительный

механизм не реагирует ни на какой

аналоговый управляющий сигнал на входе

Y. Исполнительный механизм поднимает

и опускает шток только в случае, если

электропитание подается на вход 1 или 3.

SW7: Логарифмическая/Линейная

характеристика ❹⑧

Заводские установки:

(Логарифмическая)

характеристика регулирования

клапана не меняется.

Примечание: В случае применения

данной функции в комбинации с

“нелогарифмическими” к лапанами,

характеристика моторного клапана будет

являться антилогарифмом характеристики

клапана (например, клапан с линейной

характеристикой трансформируется в

характеристику быстрого открывания).

SW 8: 100% KVS/RED KVS ❹⑨

Примечание: Данная функция

работает корректно только в случае

применения клапанов с логарифмической

(равнопоцентной) характеристикой

регулирования.

SW9: Reset (Сброс) ❹⑧

После подачи тока на исполнительный

механизм последний начинает процесс

автоподстройки. Об этом свидетельствует

мигание светодиода, которое продолжается

до окончания процесса автоподстройки.

Продолжительность процесса обычно

составляет несколько минут, в зависимости

от перемещения штока. Величина хода

клапана после окончания автоподстройки

регистрируется в запоминающем устройстве.

Процесс автоподстройки возобновляется

нажатием на кнопку сброса «RESET»

(переключатель № 9). При сбросе напряжения

питания или при его падении более чем на 80

% в течение более 0,1 с, текущее положение

клапана регистрируется в запоминающем

устройстве. Таким образом, вся информация

сохраняется в запоминающем устройстве,

в том числе в случаях сбоя напряжения

питания.

Заводские установки:

ВСЕ переключатели находятся в положении

OFF (выключено). ❹①

EI.LF.M1.2V

© Danfoss | 2016.11 | 13

Page 14

AME 25, AME 35

Функциональный тест

Световой диод наряду с индикацией

задействования привода производит также

индикацию рабочего состояния и возможных

ошибок.

Постоянное свечение

- обычное рабочее состояние

эксплуатации

Отсутствие свечения

- выключение, напряжение отключено.

Прерывистое свечение (1 Гц):

- режим автоподстройки

Прерывистое свечение (3 Гц):

- электропитание слишком мало

- недостаточная величина времени хода

клапана (<20 с)

- невозможность входа в исходное

положение.

Габаритные ➎

14 | © Danfoss | 2016.11

EI.LF.M1.2V

Page 15

AME 25, AME 35

ROMÂNĂ

Notă privind siguranţa în funcţionare

cu atenţie aceste instrucţiuni.

Activitatea necesară de instalare, pornire şi

întreţinere trebuie executată numai de personal

calificat şi autorizat.

Vă rugăm să respectaţi instrucţiunile

fabricantului sistemului sau ale operatorului de

sistem.

Scoatere din uz

Montarea

Fixaţi servomotorul AME 25, AME 35, pe vana ❶

Pozitiile admisibile de montare ❷.

Cablarea ❸

* Cablare pentru modul de control modulant

** Cablare pentru modul f lotant în 3 puncte

*** Cablare pentru modul flotant în 3 puncte

Semnal comandă

Semnalul de comandă de la regulator trebuie

conectat la bornele Y (borna de semnal de

intrare) şi SN (borna comună) de pe placa cu

circuite imprimate AME.

Semnal ieşire

Semnalul de ieşire de la borna X poate fi utilizat

pentru indicarea poziţiei curente. Domeniul

depinde de setările comutatorului DIP.

Tensiune de alimentare

Tensiunea de alimentare (24 V~ -15 ÷ +10%, 50

Hz) trebuie conectată la bornele SN şi SP.

Pentru a evita rănirea persoanelor şi

distrugeri ale echipamentului, este

absolut necesar să citiţi şi să respectaţi

Nu îndepărtaţi cap acul până când

alimentarea cu elect ricitate nu este

complet deconectată.

Acest produs trebuie dem ontat şi,

dacă este posibil, compone ntele

acestuia sortate în diverse g rupe,

înainte de reciclare sau scoatere di n uz.

Respectaţi întotdeauna reglementările privind

eliminarea deşeuri lor valabile în regiunea

dumneavoastră.

Nu atingeţi nicio compo nentă de pe

placa circuitelor integrate!

Deconectaţi linia de a limentare

electrică înainte de cone ctarea prin fire a

servomotorului! Tensiune letală!

Conectaţi servom otorul prin fire în conformitate

cu schema de conexiu ni.

(Wiring for modulating mode)

Regulator cu ieșire pe releu (Wiring for 3-point

floating mode Controller with relay output)

Regulator cu ieșire triac (Wiring for 3-point

floatig mode Controller with triacs output)

Setările comutatorului DIP ❸

U I

2 V_---V 0 V_---V

Directă Inversă

--- S ecvenţial

0(2) V_5(6) V 5(6) V_10 V

Proporţional 3 puncte/RL

LOG. fl ow L IN. flow

100 % K

VS

Resetare Resetare

Setări de fabrică:

TOATE comutatoarele se află în poziţia „OFF”

(decuplat)!!

Notă!

Sunt permise toate combinaţiile de comutatoare

DIP. Toate funcţiile selectate sunt adăugate

consecutiv. Există o singură logică de supracontrol

al funcţionalităţilor şi anume, comutatorul

nr. 6 Proporţional / în 3 puncte, care setează

servomotorul să ignore semnalul de comandă şi

să funcţioneze ca servomotor „simplu” în 3 puncte.

SW1: U/I ❹①

Setare de fabrică:

semnal de comandă de tensiune (0 … 10 V).

SW2: 2 V … 10 / 0 V … 10 ❹②

Setarea de fabrică este:

2 … 10 V.

SW3: Directă/Inversă ❹③

Setarea de fabrică este:

DIRECTĂ

SW4: ---/Secvenţial ❹④

Două servomotoare pot fi setate să lucreze în

paralel, cu un singur semnal de comandă. Dacă

este setat SECVENŢIAL, atunci un servomotor

răspunde la semnalul de comandă distribuit

(vezi 0(2) V … 5(6 V) / 5(6) V … 10 V).

Notă!

Această combinaţie lucrează în legătură cu

comutatorul nr5: 0(2)-5(6) V/5(6)-10 V.

SW5: 0(2) V … 5(6 V) / 5(6) V … 10 V ❹⑤

Notă:

Această funcţie este disponibilă în cazul în care

comutatorul nr. 4:

este setat --- / secvenţial.

SW6: Proporţional/în 3 puncte ❹⑥

Cand DIP 6 este ON ser vomotorul

trebuie sa-si faca capetele d e cursa

inainte de schimbarea DI P 6 pe ON.

Semnalul de iesire de pinde de setarea DIP 2, 3

si 5.

Servomotorul poate functiona in modul

modulant (DIP 6 OFF) sau in modul 3 puncte,

daca functia 3 puncte este selectata (DIP 6 ON).

Conectati alimentarea electrica la terminalele

SN si SP.

Setarea de fabrica la DIP 6 este OFF pentru

functionare in modul modulant.

Tija servomotorului se va duce catre pozitia

complet deschis sau inchis dace se face punte

intre SN si 1 sau 3 si va ramane in aceasta pozitie

atat timp cat potentialul persista.

Red. K

VS

Setati DIP 6 la ON pentru functionare in modul

3 puncte.

Verificati cu atentie schema electrica deoarece

cablarea este diferita pentru regulatoare

electronice cu iesire tip triac (ECL) fata de cele cu

iesire tip releu.

NOTĂ: Dacă se selectează funcţia în 3 puncte,

servomotorul nu răspunde la niciun semnal de

comandă de pe portul Y. Doar ridică şi coboară

axul, dacă se alimentează portul 1 sau 3.

SW 7: Debitul LOG./debitul LIN. ❹❹

Setări de fabrică:

Debitul LOG. (caracteristica vanei este

nemodificată)

Notă!

Dacă această funcţie se foloseşte în combinaţie

cu vanele nelogaritmice, caracteristica vanei

motorizate va fi anti-logaritmul caracteristicii

vanei (de ex. vana cu caracteristică liniară se va

transforma într-o caracteristică cu deschidere

rapidă).

SW 8: K

100% / K

VS

REDUS ❹❹

VS

Notă!

Această funcţie lucrează corect numai cu

caracteristici logaritmice (proporţii egale)

ale vanei.

SW9: Resetare ❹⑦

După ce servomotorul a fost conectat la sursa

de alimentare, acesta va porni procedura

de autoreglare. LED-ul indicator se aprinde

intermitent până la terminarea autoreglării.

Durata depinde de cursa axului şi în mod

normal, va dura câteva minute. Lungimea

cursei vanei este stocată în memorie după ce

autoreglarea a fost finalizată. Pentru a reporni

autoreglarea, modificaţi poziţia comutatorului

RESETARE (comutatorul nr. 9). Dacă tensiunea de

alimentare este decuplată sau scade sub 80%

în mai mult de 0,1 s, poziţia actuală a vanei va fi

stocată în memorie şi toate datele rămân salvate

în memorie şi după o oprire a alimentării.

Testul de funcţionare

Lumina indicatoare arată dacă dispozitivul

de poziţionare este sau nu este în funcţiune.

În plus, indicatorul arată starea comenzii şi

defecţiunile:

Lumină continuă

- funcţionare normală

Nicio lumină

- nu funcţionează sau nu este alimentat

Lumină intermitentă (1 Hz):

- modul autoreglare

Lumină intermitentă (3 Hz):

- alimentarea cu energie de nivel prea scăzut

- cursă insuficientă a vanei (<20 s)

- capătul de cursă nu mai poate fi atins.

Dimensiuni ➎

EI.LF.M1.2V

© Danfoss | 2016.11 | 15

Page 16

Danf

already on order pro

All trademarks in this material are property of the respec

AME 25, AME 35

XOOOO

O

XOOOO

O

中文

安全注意事项

为避免发生人身和设备事故,请仔细

阅读本手册。

安装、调试、维修必须由专业人员进行。

请遵循系统制造商或系统操作人员的说明。

电 源 未 完 全 关 闭 前 ,请 勿 取 下 顶 盖

弃置说明

在回收或丢弃前,应当将本产品拆

卸并对元件进行归类

请遵循当地的废弃法规。

安装

将 AME 25,35 驱动器安装到阀体上。❶

允许的安装朝向 ❷

接线 ❸

不要 碰 触 电 路 板 上 的 任 何元件!

接线前请先断开电源!致命的电

请按接线图接线

* 调节模式接线(Wiring for modulating mode)

** 带继电器输出的三点浮动模式控 制

*** 带双控输出的三点浮动模式控制

控制信号

从控制器来的控制信号接到 AME 的 Y 端

( 输 入 信 号 )和 SN 端( 公 共 端 )。

阀位反馈

阀位 反馈信号从 X 端输出,SN 为公共端。

电源电压

电 源 电 压( 24V -15 % 到+10 % ,50 Hz)连 接 到 端

子 SN 和 SP。

DIP 拨动开关的设定 ❹

压!

器 (Wiring for 3-point floating mode

Controller with relay output)

器 (Wiring for 3-point floatig mode

Controller with triacs output)

U I

2 V_---V 0 V_---V

正向 反向动作

---

0(2) V_5(6) V 5(6) V_10 V

比例控制 三点控制 /RL

LOG. fl ow L IN. flow

100 % k

VS

Reset Reset

顺序动作

RED. k

VS

出厂设 定:

所有位都在 OFF 位置。

注意:

允许对 DIP 拨动开关进行任意组合。 所有选定

的功能将依次添加。 只有一种功能逻辑操控,

即拨动开关第 6 位比例控制/三 点 控 制 ,它 将 把

驱动器设为不理会控制信号,而是作为“简单的”

三点驱动器使用。.

SW1: U/I ❹①

出厂设 定:

电压控制信号

SW2: 2-10 V/0-10 V ❹②

出厂设 定:

2- -10 V.

SW3: 正向/反向动作 ❹③

出厂设 定:

正向

SW4: ---/顺序动作 ❹④

两个驱动器可共用一 个控制

信 号 并 联 工 作 。选 择 顺 序 动

作功能后 控制信号将被分割

(0(2)-5(6)V/5(6)-10 V)。

注意:

此项功能与拨动开关第 5 位配合 使用。

0(2)V-5(6V)/5(6)V-10 V。

SW5: 0(2) V-5(6) V/5(6)-10 V ❹⑤

注意:

此项功能当拨动开关第 4 位设为顺序动作时有

效。

SW6: 比例控制/三点控制 ❹⑥

当 DIP 6是在驱动器需要执行行程自检之前

更改 DIP 6为" ON "。

输出信号取决于 DIP 2、3和5设定。

驱 动 器 可 以 运 行 的 调 制( DIP 6为 ”关 闭 ”)或

在”简单的”三点”模式中,如果三点功能( DIP

6为” ON “)。

连 接 电 源端 子上 SP 和 SN 端子接线端连接。

原厂设置 DIP 6为 OFF 来运行驱动器在调制模

式。

驱动器阀杆它仍会运行完全扩展或缩回位置的

衔接 SN 信号端子1或3,将 一 直 保 持 这 种 正 电 子

只要潜力。

设置 DIP 6为 On 用于操作驱动器在3点模式。

仔细观察电路接线图为接线不同控制器带有双

向 可 控 硅 输 出( ECL )在 caparison 控制器与继

电器输出。

注 意: 选择三点控制以后驱动器不对 Y 端

子的控制信号作出反应。

SW 7: 对数流量特性/线性流量特性 ❹⑧

几乎所有丹佛斯阀门的流量特性都是对数特性

的。如果驱动器设定为线性,则驱动器的工作特

性与阀体配合后可得出线性的特性。

出厂设 定:

对数特性

注意:

如果驱动器设定为线形而阀体特性不是对数特

性,则组合后的特性可解为快开特性。

SW 8: 100% KVS 降低 / KVS ❹⑨

选择降低KVS功能后阀门的KVS 值可降为比它小一

号阀门的KVS值与它本身KVS值之间的中间值。

如 :阀 门 本 身 KVS值为16,比它小一号阀门的KVS值

为10,则降低以后的KVS值为13。

注意:

此项功能仅对对数特性的阀门有效。

SW9: 复位 ❹⑦

驱动器第一次通电后将自动进行行程自检,自检

时 LED 指示灯闪烁直到自检结束。

自检的时间根据行程大小和速度快慢各不相同,

大 致 需 几 分 钟 时 间 。自 检 结 束 后 行 程 信 息 被 记 录

到 存 储 器 中 。将 拨 动 开 关 的 第 9 位拨 到复位位置

也可启动自检进程。电源断电或电压降低于 80

% 的时间超过 0.1 秒,所有的当前数据被保存到

存储 器中。

功能测试功能测试

LED 指示灯可提供当前状态和故障指示:

持续亮

- 正常工作

不亮

- 没有任何操作或无电源电压

闪 烁( 1 Hz)

- 自检中

闪 烁( 3 Hz)

- 电源电压过低

- 行 程 不 对(<20 s)

- 不能到达末端位置

尺寸 ➎

部件名称

外壳

轴套管

压板

连接架

O: 表示该有害物质在该部件所有均质材料中的含量均在GB/T 26572规定的限量要求以下。

X: 表示该有害物质至少在该部件的某一均质材料中的含量超出GB/T 26572规 定的限量要求。

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

铅 (Pb) 汞 (Hg) 镉 (Cd)

X O O O O O

X O O O O O

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

16 | © Danfoss | DHS-SRMT/SI | 2016.11

有害物质含量表

六价铬 (Cr (VI)) 多溴 联苯 (PBB) 多溴二 苯 醚 (PBDE )

73692280 / EI.LF.M1.2V

Loading...

Loading...