Page 1

Data sheet

Actuators for modulating control

AME 25, AME 35

Description

AME electric actuators are used with, VRB, VRG,

VF, VL valves

065Z0311, not supplied) and VFS valves up to

DN 50 diameter.

Ordering Actuators

Typ e

AME 25

AME 35 082G3022

with additional adapter (Code No.

Supply voltage

(Vac)

24

Code No.

082G3025

The actuator automatically adapts its

stroke to valve end positions which reduces

commissioning time.

The actuator has some special features:

• The advanced design incorporates load

related ‘switch-off’ to ensure that actuators

and valves are not exposed to overload;

• The advanced design incorporates a

diagnostic LED, operational data capture and

self stroking feature;

• Low weight and robust.

Main data:

• Nominal voltage:

- 24 Vac, 50 Hz/60 Hz

• Control input signal:

- 0(4)…20 mA

- 0(2) … 10 V

• Stroke: 15 mm

• Max. medium temperature: 150 °C

• Self stroking

• Output signal

Accessories

Typ e Code No.

Adapter for VFS 2 valve DN 15-50

(for media temp. over 150 °C)

Adapter for VRB/VRG/VF/VL valves

(gen.2009) DN 15-50

Stem heater for VFS valve DN 15-50 06 5B2171

Clutch AMV(E) 25, AMV(E) 35 003G6396

* Needs to be orde red separately.

065Z 7548

06 5Z03 11*

Technical data

Typ e AME 25 AME 35

Power supply V 24 ac; +10 to –15%

Power consumption VA 4 9

Frequency Hz 50/60

Control input Y

Output signal X V 0 -10 (2-10)

Closing force N 1000 600

Max. stroke mm 15

Speed by 50(60) Hz s/mm 11 ( 8. 8) 3 (2.4)

Max. medium temperature

Ambient temperature 0 … 55

Storage and transpor t temp. –40 … 70

Grade of enclosure IP 54

Weight kg 1.70

- marking in accordance with standards

V 0-10 (2-10) Ri = 24 kΩ

mA 0-20 (4-20) Ri = 500 Ω

150 (200 - with adapter or mounted horizontally)

°C

Low Voltage Directive 73/23/EEC,

EMC-Directive 2006/95/EEC:

- EN 60730-1, EN 60730-2-14

© Danfoss | 2020.11 AI117586476321en-010302 | 1

Page 2

Data sheet Actuators for modulating control AME 25, AME 35

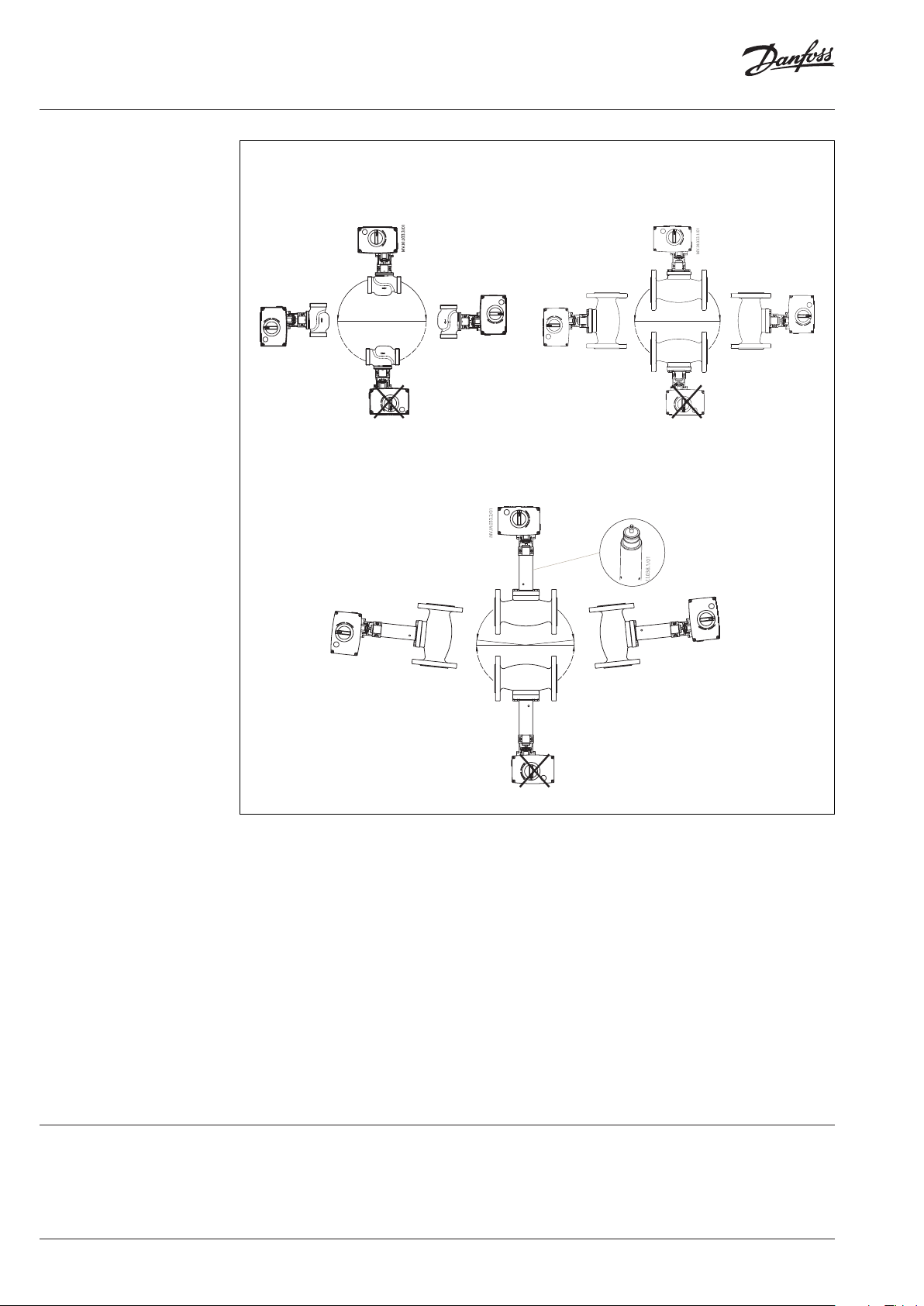

Installation

T

≤150°C for AME 25, 35

max

and VRB, VRG, VF and VL

T

= 200°C for AME 25, 35

max

and VFS

T

≤150°C for AME 25, 35

max

and VFS

Adapter for VFS

(Code No. 065Z7548)

o

≈5

Mechanical

Use 4 mm Allan key (not part of actuator delivery)

to mount actuator on the valve. Installation

of the valve with the actuator is allowed in

horizontal position or upwards. Installation

downwards is not allowed.

The actuator must not be installed in an

explosive atmosphere, at ambient temperature

lower than 0 °C or at ambient temperature higher

than 55 °C. It must not be subject to steam jets,

water jets or dripping liquid as well.

Note: the actuator may be rotated up to 360° with

respect to the valve stem by loosening the retaining

fixture. Once the actuator is placed, retighten

thefixture.

o

≈5

Electrical

Electrical connections can be accessed by

removing the actuator cover. Two cable gland

entries with thread (M20 x 1.5 and M16 x 1.5) are

prepared for cable glands.

Note: Cable and cable gland used must not

compromise the actuator’s IP rating, and must

ensure the connectors are fully strain relieved.

Please observe local rules and regulations as well.

Disposal The actuator must be dismantled and the

elements sorted into various material groups

before disposal.

2 | AI117586476321en-010302 © Danfoss | 2020.11

Page 3

Data sheet Actuators for modulating control AME 25, AME 35

DIP switch setting

vs

I

0 …--- V

Inverse

Sequential

5(6) … 10 V

3 point/RL

Reset

LIN fl ow

Red. K

U

- - -

Direct

2 …--- V

0(2) … 5(6) V

vs

Reset

100 % K

LOG f low

Proportional

The actuator has a function selection DIP switch

under the removable cover. In particular, if SW6

is set to ON, the actuator will perform as 3-point

actuator.

The switch provides the following functions:

•

SW1: U/I - Input signal type selector:

If set to OFF position, voltage input is selected. If

set to ON position, current input is selected.

•

SW2: 0/2 - Input signal range selector:

If set to OFF position, the input signal is in

the range from 2-10 V (voltage input) or from

4-20mA (current input). If set to ON position, the

input signal is in the range from 0-10 V (voltage

input) or from 0-20 mA (current input).

•

SW3: D/I - Direct or inverse acting selector:

If set to OFF position, the actuator is direct acting

(stem lowers as voltage increases). If actuator is

set to ON position the actuator is inverse acting

(stem raises as voltage increases).

•

SW4: —/Seq - Normal or sequential mode

selector:

If set to OFF position, the actuator is working

in range 0(2)-10 V or 0(4)-20 mA. If set to ON

position, the actuator is working in sequential

range; 0(2)-5(6) V or (0(4)-10(12) mA) or

(5(6)-10 V) or (10(12)-20 mA).

•

SW5: 0-5 V/5-10 V - Input signal range in

sequential mode:

If set to OFF position, the actuator is working in

sequential range 0(2)-5(6) V or 0(4)-10(12) mA.

If set to ON position, the actuator is working in

sequential range; 5(6)-10 V or 10(12)-20 mA.

•

SW6: Prop./3-pnt - Modulating or 3-point

mode selector:

If set to OFF position, the actuator is working

normally according to control signal. If set to

ON position, the actuator is working as 3-point

actuator.

For this operation please refer to page 4

(wiring 3-point control).

When DIP switch SW6 is set to ON than all

functions from other DIP switch become inactive.

•

SW7: LOG/LIN - Equal percentage or linear

flow through valve selector 1):

If set to OFF position, the flow through valve

is equal percentage. If set to ON position, the

flow through valve is linear according to control

signal.

•

SW8: 100% KVS/Reduced KVS - Flow reduction

through valve selector 1):

If set to OFF position, the flow through valve

is not reduced. If set to ON position, the flow

through valve is reduced by half of increment

between standard KVS values. Example: valve

with KVS 16 and SW8 set to ON – maximum flow

through the valve is K

standard KVS 16 and next lower standard KVS 10).

1)

NOTE: To be used only in comb ination with valves with equal

percentage characteristic.

•

SW9: Reset:

13 (middle between

VS

Changing this switch position will cause the

actuator to go through a self stroking cycle.

AI117586476321en-010302 | 3© Danfoss | 2020.11

Page 4

Data sheet Actuators for modulating control AME 25, AME 35

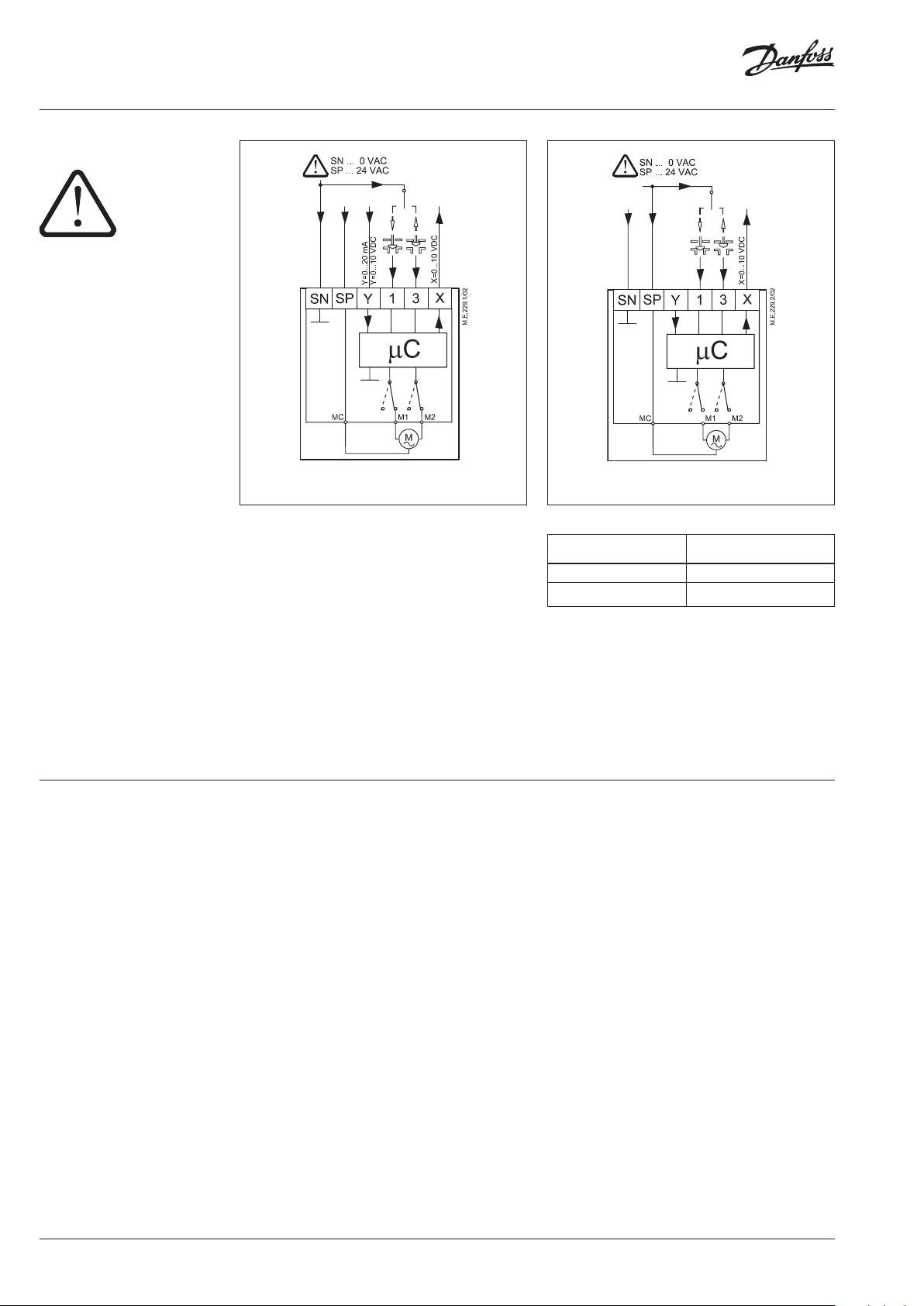

Wiring

24 Vac

Note:

If switch SW6 is set to ON tha n use this wiring.

Wiring for modulating control Wiring for 3-point control

Commissioning

Automatic self stroking feature

When power is first applied, the actuator will

automatically adjust to the length of the valve

stroke. Subsequently, the self stroking feature

can be re-initialised by changing position of SW9.

Diagnostic LED

The red diagnostic LED is located on the pcb

under the cover. It provides indication of three

operational states:

• Actuator Healthy (Permanently ON),

• Self Stroking (Flashes once per second),

• Error (Flashes 3 times per second - seek

technical assistance).

Complete the mechanical and electrical

installation and perform the necessary checks

and tests:

•

Isolate control medium. (E.g. self stroking

in a steam application without suitable

mechanical isolation could cause a hazard).

•

Apply the power.

Note that the actuator will now perform the

self stroking function.

•

Apply the appropriate control signal and

check the valve stem direction is correct for

the application.

•

Ensure that the actuator drives the valve over

its full stroke, by applying the appropriate

control signal. This action will set the valve

stroke length.

Wiring length

0-50 m 0.75 mm

> 50 m 1.5 mm

Recommended

square of the wiring

2

2

SP 24 V ac .........................................Power supply

SN 0 V ........................................................ Common

Y 0-10 V .............................................. Input signal

(2-10 V)

0-20 mA

(4-20 mA)

X 0-10 V ...........................................Output signal

(2-10 V)

Commissioning / testing feature

The actuator can be driven to the fully open or

closed positions (depending on valve type) by

connecting SN to terminals 1 or 3.

The unit is now fully commissioned.

4 | AI117586476321en-010302 © Danfoss | 2020.11

Page 5

Data sheet Actuators for modulating control AME 25, AME 35

Manual override The manual override is achieved by turning the

manual knob to the required position.

Observe the direction of rotation symbol.

If manual override has been used then X and Y

signal are not correct until the actuator reaches

its end position. If this is not accepted, mount

accessory active return signal kit.

Procedure

• Press rubber button

• Adjust valve position using control knob

• Set valve to closed position

• Restore power supply

Actuator - valve

combinations

AME 25, AME 35 +

Adapter (065Z0311)

VRB 2, VRB 3 ext. thread (DN 15-50)

VRG 2, VRG 3 ext. thread (DN 15-50)

AME 25, AME 35 +

Adapter (065Z0311)

VRB 2, VRB3 Int. thread

(DN 15-50)

AME 25, AME 35 +

VFS 2 (DN 15-50)

AME 25, AME 35 +

Adapter (065Z0311)

VF 2, VF 3 (DN 15-50)

VL 2, VL 3 (DN 15-50)

AI117586476321en-010302 | 5© Danfoss | 2020.11

Page 6

Data sheet Actuators for modulating control AME 25, AME 35

Dimensions

Adapter 065Z0311

for VRG, VRB, VF, VL (DN 15-50)

Adapter 065Z7548

for VFS (DN 15-50)

for media temperatures over 150 oC

6 | AI117586476321en-010302 © Danfoss | 2020.11

Page 7

Data sheet Actuators for modulating control AME 25, AME 35

AI117586476321en-010302 | 7© Danfoss | 2020.11

Page 8

Data sheet Actuators for modulating control AME 25, AME 35

© Danfoss | DHS-SRMT/SI | 2020.118 | AI117586476321en-010302

Loading...

Loading...