Data sheet

Actuators for modulating control

AME 13SU, AME 23SU - safety function (spring up)

Description

AME 13SU AME 23SU

Ordering

The actuators with safety function are mainly

used with VZ valve (AME 13SU) or with VS, VM

and VB valves (AME 13SU, AME 23SU). Safety

version is activated automatically in case of

power failure or if the power supply is switched

off by the safety thermostat.

The actuator has some special features:

• The advanced design incorporates load

related ‘switch-off’ to ensure that actuators

and valves are not exposed to overload;

• The advanced design incorporates a

diagnostic LED, operational data capture

and self-adjusting feature;

• Low weight and robust;

• Safety function (spring up).

Typ e

AM E 13SU

AME 23SU 082G3042

Supply voltage

(V)

24

Code No.

082H3044

Main data:

• Nominal voltage:

- 24 Vac, 50 Hz/60 Hz

• Force:

- AME 13 SU.......................300 N

- AME 23 SU ......................450 N

•

Stroke:

-

AME 13 SU .......................

-

AME 23 SU ......................

• Speed:

- AME 13 SU.......................14 s/mm

- AME 23 SU ......................15 s/mm

• Max. medium temperature: 130 °C

• Self stroking

5.5 mm

10 mm

© Danfoss | 2018.12 VD.AB.U5.02 | 1

Data sheet Actuators for modulating control AME 13SU, AME 23SU

Technical data

Typ e AM E 13SU AME 23SU

Power supply Vac 24; +10 to –15 %

Power consumption VA 9

Frequency Hz 50/60

Control input Y

Output signal X Vdc 0 -10 (2-10)

Closing force N 300 450

Max. stroke mm 5.5 10

Speed s/mm 14 15

Max. medium temperature

Ambient temperature 0 … 55

Storage and transpor t temp. –40 … 70

Ambient humidity 5-95 % r.h., non-condensing

Protection Class II I (230V); III(24V)

Grade of enclosure IP 54

Weight kg 0.8 1.45

- marking in accordance with standards

Vdc

mA 0-20 (4 -20)

°C

Low Voltage Directive (LVD) 2014/35/EU: EN 60730-1, EN 60730-2-14

Electromagnetic Compatibility Directive (EMC) 2014/30/EU: EN 61000-6 -2,

EN 61000-6-3

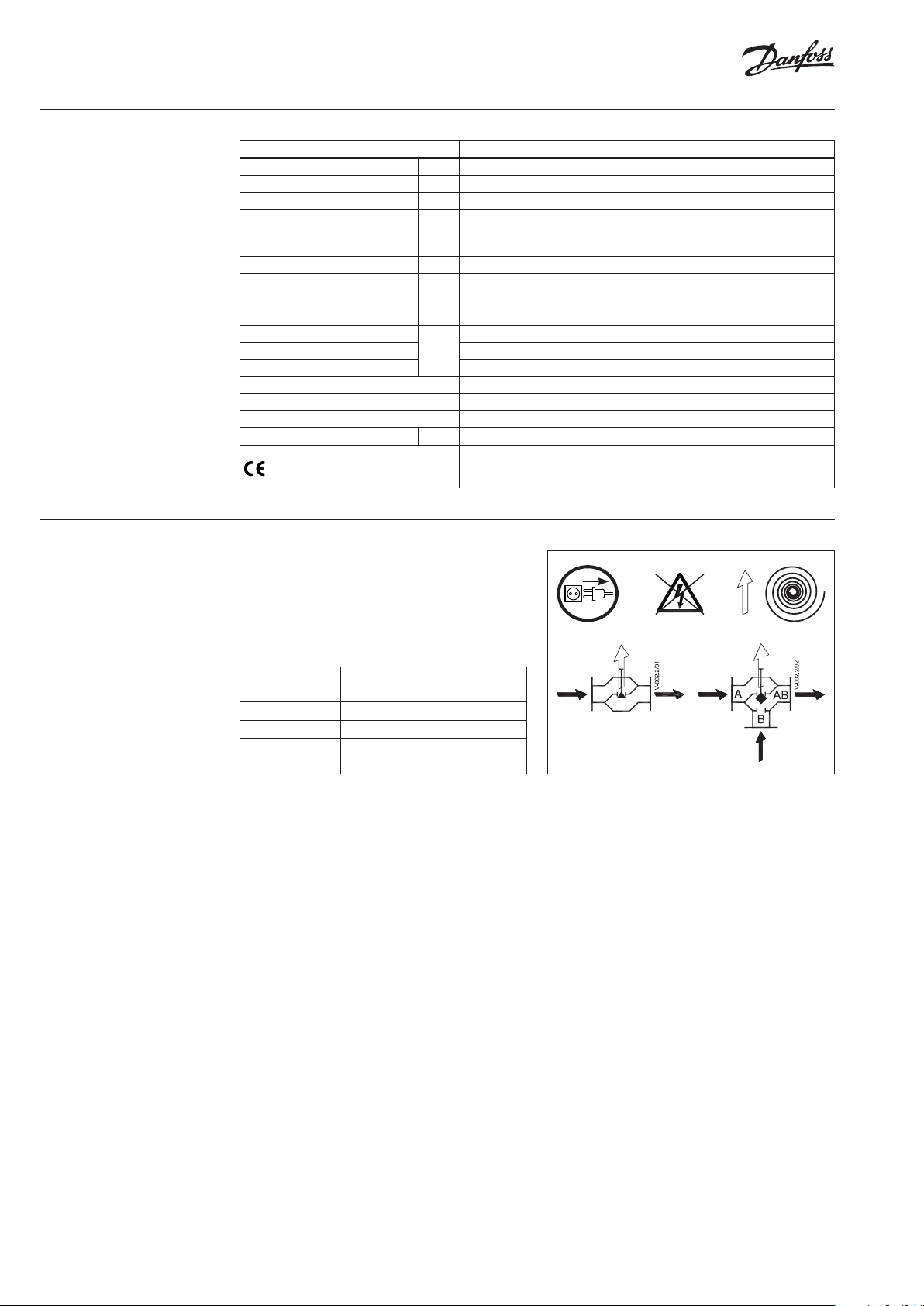

Safety function The safety function will fully open or close the

valve when the power is removed, depending

upon the spring action selected. Valve selection

will also affect the spring action. The safety

function unit is factory fitted to the rear of the

actuator.

0-10 (2 -10)

130

or

=

SU

Note: Do not use safet y activations for

ON/OFF regulation.

Valve t ype

VZ CLOSED

VS OPENED

VM OPENED

VB OPENED

If safety version is activated

than port A-AB will be

2 | VD.AB.U5.02 © Danfoss | 2018.12

Data sheet Actuators for modulating control AME 13SU, AME 23SU

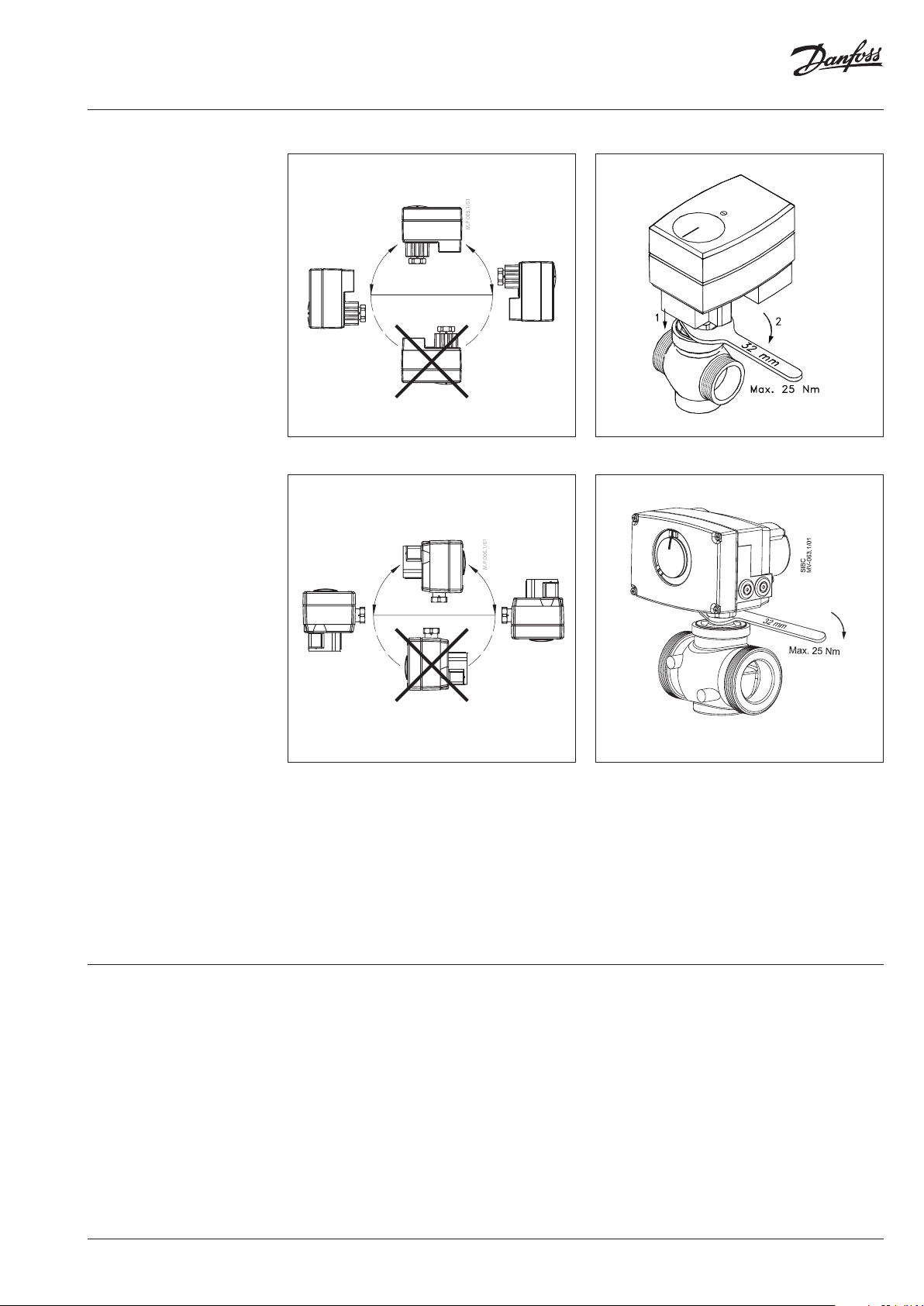

Installation

AME 13 SU

AME 23 SU

Disposal

Mechanical

The actuator should be mounted with the valve

stem in either horizontal position or pointing

upwards.

The actuator is fixed to the valve body by means

of a mounting ring, which requires no tools for

mounting. The ring should be tightened by

hand.

The actuator must be dismantled and the

elements sorted into various material groups

before disposal.

Electrical

Important: It is strongly recommended that the

mechanical installation is completed before the

electrical installation.

Note: Two cable entries are provided for M 16×1.5

cable glands. One entry is provided with a rubber

grommet. Note that in order to maintain the

enclosure’s IP rating, appropriate cable glands must

be used.

VD.AB.U5.02 | 3© Danfoss | 2018.12

Data sheet Actuators for modulating control AME 13SU, AME 23SU

Commissioning Commissioning/testing feature

Complete the mechanical and electrical

installation and perform the necessary checks

and tests:

The actuator can be driven to the fully open or

closed positions (depending on valve type) by

connecting SN to terminals 1 or 3.

- Isolate control medium. (e.g. self-adjusting

in a steam application without suitable

mechanical isolation could cause a hazard).

- Apply the power. Note that the actuator will

now perform the self-adjusting function.

- Apply the appropriate control signal and

check the valve stem direction is correct for

the application.

- Ensure that the actuator drives the valve over

its full stroke, by applying the appropriate

control signal. This action will set the valve

stroke length.

The unit is now fully commissioned.

Manual override

AME 13 SU AME 23 SU

On spring versions manual override is achieved

by disconnecting the power supply, removing

the cover and inserting a 6 mm Allen key for

AME 13 SU, a 5 mm Allen key for AME 23 SU

(not supplied) into the top of the positioning

spindle and turning the key against the spring.

Observe the direction of rotation symbol. To

hold a manual override position, the key must be

wedged.

If manual override has been used then X and

Y signal are not correct until the actuator

reaches its end position. If this is not

accepted reset the actuator.

4 | VD.AB.U5.02 © Danfoss | 2018.12

Data sheet Actuators for modulating control AME 13SU, AME 23SU

DIP switch setting

I

0 …--- V

Inverse

Sequential

5(6) … 10 V

3 point/RL

Reset

LIN fl ow

Red . Kvs

U

- - -

Direct

2 …--- V

0(2) … 5(6) V

Reset

LOG f low

100 % Kvs

Proportional

The actuator has a selection of DIP switches

under the removable cover.

The switch provides the following functions:

OR

6 … 10 V (DIP 2: 2 V … 10)

5 … 10 V (DIP 2: 0 V … 10)

12 … 20 mA (DIP 2: 2 V … 10)

DIP1: U/I - Input signal type selector:

10 … 20 mA (DIP 2: 0 … 10)

• If set to OFF position, input signal Y is set to

voltage (Y).

If set to ON position, input signal Y is set to be

current (mA).

DIP6: Prop./3-pnt - Modulating or 3-point

mode selector:

Actuator can operate in modulating (DIP 6

to OFF) or in “simple” 3-point mode, if the

DIP2: 0/2 - Input signal range selector:

• If set to OFF position, the input signal is in the

range from 2 V to 10 V (voltage input) or from

4 mA to 20 mA (current input). If set to ON

position, the input signal is in the range from

0 V to 10 V (voltage input) or from 0 mA to 20

mA (current input).

3-point function is selected (DIP 6 to ON).

Modulating mode; DIP 6 set to OFF

(factorysetting)

• After the actuator has been connected to

power supply, the actuator will start the

self-adjustment procedure. The indicator LED

flashes until self-adjustment is finished.

• Actuator’s stem will run to its totally extended

DIP3: D/I - Direct or inverse acting selector:

• If set to OFF position, the actuator is direct

acting (actuator’s stem extends by voltage

increase). If actuator is set to ON position the

actuator is inverse acting (actuator’s stem

or retracted position by bridging SN signal

to terminals 1 or 3 and will remain in this

positron as long as potential is present.

It is not allowed to bridge SP to terminal 1

or 3 when DIP 6 is set to OFF .

retracts by voltage increase).

3-point mode; DIP 6 set to On

DIP4: —/Seq - Normal or sequential mode

selector:

• Two actuators can be set to work parallel with

one control signal. If the SEQUENTIAL is set

than an actuator responds to split control

signal (see 0(2) V … 5(6 V) / 5(6) V … 10 V).

Look carefully wiring diagrams as wiring is

different for controllers with triacs output

(ECL) in comparison to controllers with

relay output.

• Connect SN (Neutral) and power supply

(24Vac) via controller to terminals 1 or 3.

• Return signal X (depends on DIP 2, 3, 4 & 5) is

NOTE: This combina tion works in combination w ith DIP 5:

0(2)V… 5(6 V) / 5(6) V … 10 V

SW5: 0-5 V/5 -10 V - Input signal range in

sequential mode:

• This function is available if

DIP4:---/Sequential is set. Actuator can be

set to match the range of the control signal:

2 … 6 V (DIP 2: 2 V … 10)

0 … 5 V (DIP 2: 0 V … 10)

4 … 12 mA (DIP 2: 2 V … 10)

0 … 10 mA (DIP 2: 0 … 10)

possible if connected power supply to SP and

SN.

DIP7: LOG/LIN - Not in use.

DIP8: 100 % KVS/Reduced KVS - Not in use.

DIP9: Reset:

• Changing this switch position will cause the

actuator to go through a self-adjustment

procedure.

VD.AB.U5.02 | 5© Danfoss | 2018.12

Data sheet Actuators for modulating control AME 13SU, AME 23SU

Wiring

24 Vac only.

* Only for ac tuators with safety fu nction

Actuator needs to perform Self stroking

prior chang ing DIP 6 to ON.

Output signa l depends on DIP 2, 3&5

setting.

DIP 6 = OFF

DIP 6 = ON

Wiring for modulating mode

SN 0 V Neutral

SP 24 Vac Power supply

Y

1

3

X 0(2)-10 Vdc Output

0(2)-10 Vdc

0(4) -20 mA

SN Input

Wiring for 3-point floating mode / Controller with relay output

SN 0 V Neutral

SP 24 Vac Power supply

1

SP Input

3

Input

* Only for ac tuators with safety fu nction

* Only for ac tuators with safety fu nction

**R1, **R2=2.6 kΩ (0. 5W)

DIP 6 = ON

X 0(2)-10 Vdc Output

Wiring for 3-point floating mode / Controller with triacs output

SN 0 V Neutral

SP 24 Vac Power supply

1

SP Input

3

X 0(2)-10 Vdc Output

Automatic self-adjustment feature

When power is first applied, the actuator will

automatically adjust to the length of the valve

stroke. Subsequently, the self-adjustment feature

can be re-initialised by changing position of SW9.

Diagnostic LED

The red diagnostic LED is located on the pcb

under the cover. It provides indication of three

operational states:

• Actuator Healthy (Permanently ON),

• Self Stroking (Flashes once per second),

Wiring length

0-50 m 0.75 mm

> 50 m 1.5 mm

Recommended

square of the wiring

2

2

• Error (Flashes 3 times per second - seek

technical assistance).

6 | VD.AB.U5.02 © Danfoss | 2018.12

Data sheet Actuators for modulating control AME 13SU, AME 23SU

Dimensions

Actuator - valve

combinations

- which close port A-AB if

safety version is activated

AME 13 SU AME 23 SU

- which open port A-AB if

safety version is activated)

AME 13 SU +

VZ (DN 15-20)

AME 13 SU +

VS2 (DN 15-25)

VM2 (DN 15-25)

AME 13 SU +

VB2 (DN 15-20)

AME 23 SU +

VS2 (DN 15-25)

VM2 (DN 15-25)

AME 23 SU +

VB2 (DN 15-20)

VD.AB.U5.02 | 7© Danfoss | 2018.12

Data sheet Actuators for modulating control AME 13SU, AME 23SU

© Danfoss | DHS-SRMT/SI | 2018.128 | VD.AB.U5.02

Loading...

Loading...