Operating Guide

Ste m Trav el

5,5 mm

COM

COM

AME 13 SU/SD-1

➊

Travel Speed 11,7 (14) s/mm

MAINTENANCE

FREE

5-95 % RH

no condensing

AME 13 SD-1 +

AB-QM

Washer 003Z0257 Adapter 003Z3960

AME 13 SU-1 +

AB-QM

AUTO

=

=

4 – 6 mm × 1 mm

❷

Do not use as

ON/Off actuator.

AME13 SU/SD-1, Modulang

SN SP Y 1 3 X

~ AC 24V

50/60Hz

0(2)-10VDC

0(4)-20mA

+

DC 0-10V

AME13 SU/SD-1, Floang point

SN SP Y 1 3 X

+

~ AC 24V

50/60Hz

DC 0(2)-10V

+

AQ283757724898en-000301 | 1© Danfoss | 2020.03

AME 13 SU/SD-1

Loss of Power

❸

SD

½”

④

①

②

⑤

Max. 6 Nm/53 in-lb

for AB-QM valves.

③

Loss of Power

SU

½”

④

①

②

Max. 6 Nm/53 in-lb

for AB-QM valves.

⑤

③

AQ283757724898en-000301 2 | © Danfoss | 2020.03

AME 13 SU/SD-1

❹

121 ( 4.76”)

83 (3.27”)

110 (4. 33 ”)

min. 200 (7.87”)

❺

① ② ③

④

⑦

⑤ ⑥

⑧

⑨

© Danfoss | 2020.03 | 3AQ283757724898en-000301

AME 13 SU/SD-1

ENGLISH

Safety Note

To avoid personal injury and damage to

the device or other property, it is

necessary to read and follow these

instructions carefully.

Assembly, start-up, and maintenance work

must be performed by qualified and authorized

personnel.

Comply with the instructions of the system

manufacturer or system operator.

Please comply with the instructions of the

system manufacturer or system operator.

Do not remove the cover before th e

power supply is ful ly switched off.

Disposal

This product shou ld be dismantled

and its components sorted, if

possible, in various grou ps before

Always follow the local d isposal regulations.

recycling or disposal .

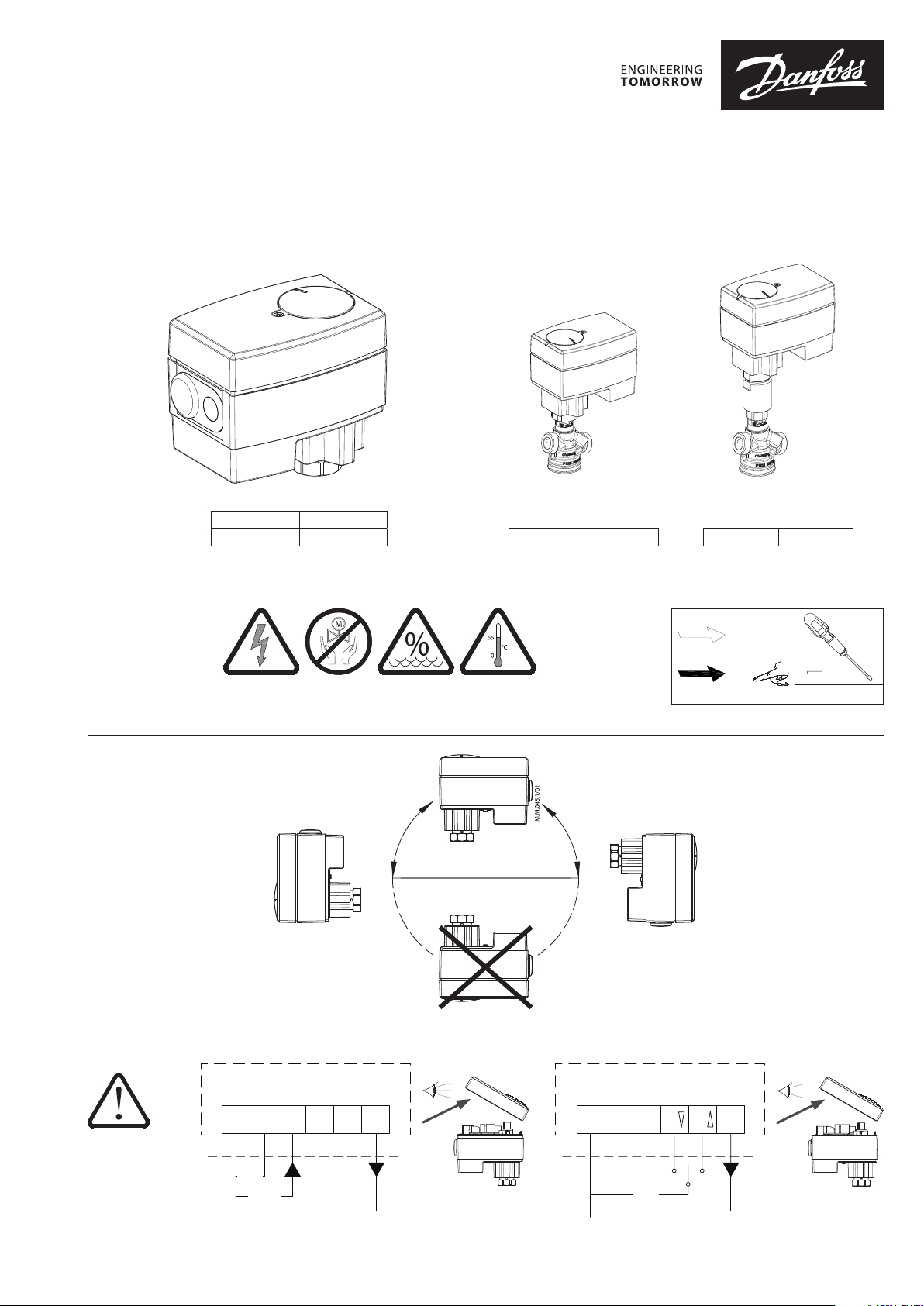

Mounting Position ➊

The actuator should be mounted with the valve

stem in either a horizontal position or pointing

upwards.

Wiring ❷

AC 24 V

Connect via Class 2 (Nor th America)

or Safety E xtra-Low Voltage (SELV)

(Europe). Failure to comply can lead to

equipment damage or personal injury.

Switch off power bef ore wiring the

actuator!

1. Make all wiring connections in accordance

with local, national, or regional regulations.

2. For applications requiring conduit, a field

supplied 1/2” trade size electrician’s fitting

and lock nut can be mounted in the actuator

enclosure. Use flexible metallic tubing or its

equivalent with the field supplied fitting.

3. Insert wiring material through the removable

plug or conduit fitting, and connect to the

terminal block using the applicable wiring

diagram ❷.

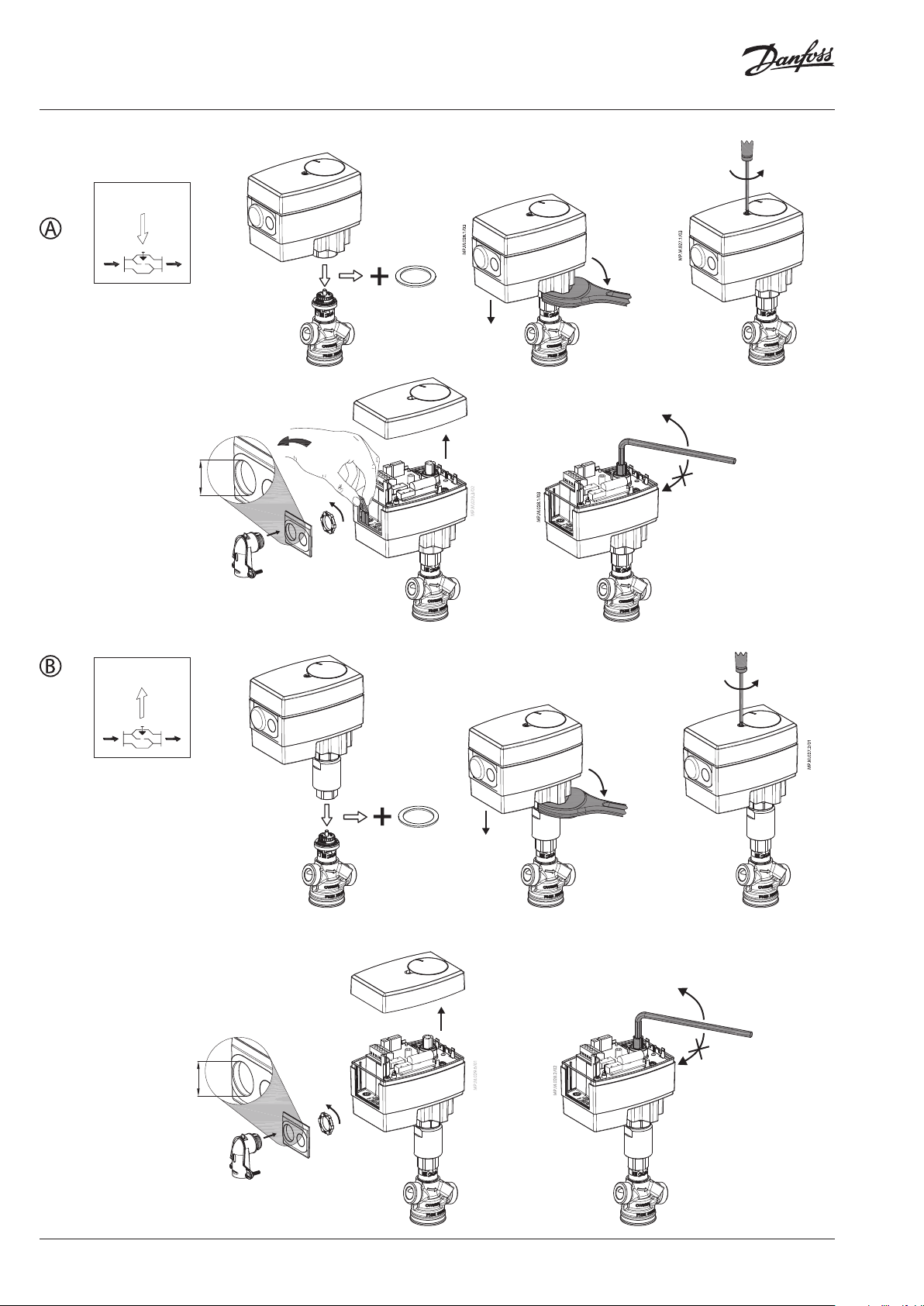

Installation ❸

1. Depending on the version of actuator

(SU/SD) prior to installation an included washer

and adapter is required to be installed:

SD, Washer (003Z0257)

The washer is placed on the valve neck prior to

the installation of the actuator.

SU, Adapter (003Z3960) and washer (003Z0257)

Hand tighten the adapter to the neck of the

valve. The actuator will be installed to the

adapter.

2. The actuator should be in the full up position

① (factory setting). If it is not, refer to the

manual override instructions ❸④.

3. The actuator is fixed to the valve body or

adapter by means of a union nut which requires

an adjustable wrench to assist in tightening the

actuator to the valve.

DIP switch settings ❺

Factory settings:

ALL switches are on OFF position!

(except SW2 which is in ON position)!

NOTE:

All combinations of DIP switches are allowed.

All functions that are selected are added

consecutively. There is only one logic override of

functionalities i.e. the switch No.6 Propor tional /3

point, which sets actuator to ignore control signal

and works as a “simple” 3-point actuator.

SW 1: VDC / mA - Input signal type

selector ①

If set to OFF position, voltage input is

selected. If set to ON position, current input is

selected.

SW 2: 0/2 - Input signal range selector ②

If set to OFF position, the input signal is in the

range from 2-10 V (voltage input) or from 4-20

mA (current input). If set to ON position, the

input signal is in the range from 0-10 V (voltage

input) or from 0-20 mA (current input).

SW3: D/I - Direct or inverse acting

selector ③

If set to OFF position, the actuator is direct

acting (stem retracts as voltage increases). If

the actuator is set to ON position, the actuator

is inverse acting (stem extends as voltage

increases).

SW4:---/Seq - Normal or sequential

mode selector ④

If set to OFF position, the actuator is working

normally in 0(2)-10V or 0(4)-20mA range. If set

to ON position, the actuator is working in a

sequential mode with its range dependent on

the position of SW 4.

SW5: 0-5 V/5-10 V - Input signal range in

sequential mode ⑤

If set to OFF position, the actuator is working in

sequential range 0(2)-5 (6) V or 0(4)-10 (12) mA.

If set to ON position, the actuator is working in

sequential range; 5(6)-10 V or 10(12)-20 mA

SW6: Proportional/Floating point ⑥

If set to ON position, the actuator can operate

as Floating point actuator. Power supply should

be connected on SN and SP ports. On port 1 or 3

24 VAC signal is connected for rising or lowering

of actuator. Return signal X indicates the correct

position.

If set to OFF position, the actuator operates on

modulating input signal.

NOTE:

if 3 point function is selected actuator does not

respond to any control signal on port Y. It only rises

and lowers spindle if power is supplied on port 1

or 3.

SW7: LIN/LOG - Linear or equal

percentage flow through valve selector

⑦

If set to ON position, the flow through the valve

is equal percentage to the control signal.

If set to OFF position, the valve position is linear

acc. to the control signal.

SW8: ⑧

Set to ON for valve bodies 1/2” to 1-1/4” HF. The

actuator will modulate on max stem travel of

4.5mm.

Set to OFF for valve body 1/2” Low flow. The

actuator will modulate on max stem travel of

2.5mm.

SW9: Reset ⑨

Toggling the switch will cause the actuator to go

through an auto-calibration cycle.

Function test

The indicator light shows whether the

positioner is in operation or not. Moreover, the

indicator shows the control status and faults.

Constant light

- normal operation

No light

- no operation or no power supply

Intermittent light (1 Hz)

- self adjusting-mode

Intermittent light (3 Hz):

- power supply too low

- insufficient valve stroke (<20 s)

- end-position cannot be reached.

73694760 / AQ283757724898en-0003014 | © Danfoss | DHS-SMDBT/SI | 2020.03

Loading...

Loading...