Operating Guide

AME 130(H), AME 140(H)

AME 130, 140

AME 130H, 140H

ENGLISH

DANSK

DEUTSCH

NEDERLANDS

LIETUVIŲ K.

LATVISKI

MAGYAR

ČESKY

POLSKI

AME + VZ 2 / VZL 2 AME + VZ 3 / VZL 3 AME + VZ 4 / VZL 4

Actuators for modulating control

AME 130, AME 140, AME 130H, AME 140H

Motorer til modulerende styring AME 130, AME 140, AME 130H, AME 140H www.danfoss.dk Side 6

Stellantriebe für stetiges Eingangssignal

AME 130, AME 140, AME 130H, AME 140H

Servomotoren voor modulerende regeling

AME 130, AME 140, AME 130H, AME 140H

Tolygaus valdymo pavaros AME 130, AME 140, AME 130H, AME 140H www.danfoss.lt 9 puslapis

Modulēšanas vadības izpildmehānismi

AME 130, AME 140, AME 130H, AME 140H

AME 130, AME 140, AME 130H, AME 140H szelepmozgató motorok

arányos szabályozáshoz

Servopohony s modulačním regulačním signálem

AME 130, AME 140, AME 130H, AME 140H

Siłowniki do sterowania modulacyjnego

AME 130, AME 140, AME 130H, AME 140H

www.danfoss.com Page 5

www.danfoss.de Seite 7

www.danfoss.nl Pagina 8

www.danfoss.com Lpp. 10

www.danfoss.com 11. oldal

www.danfoss.cz Strana 12

www.danfoss.pl Strona 13

AME + AHQM

© Danfoss | 2017.07

VI.KU.M6.9O | 1

AME 130(H), AME 140(H)

❶

❷

MAINTENANCE

FREE

5-95 % RH

no condensing

30°

30°

4 – 6 mm × 1 mm 6 mm

❸

①

Red

Gray

Black

24 VAC

Y 0 - 10 VDC

Common

2 | © Danfoss | 2017.07

VI.KU.M6.9O

AME 130(H), AME 140(H)

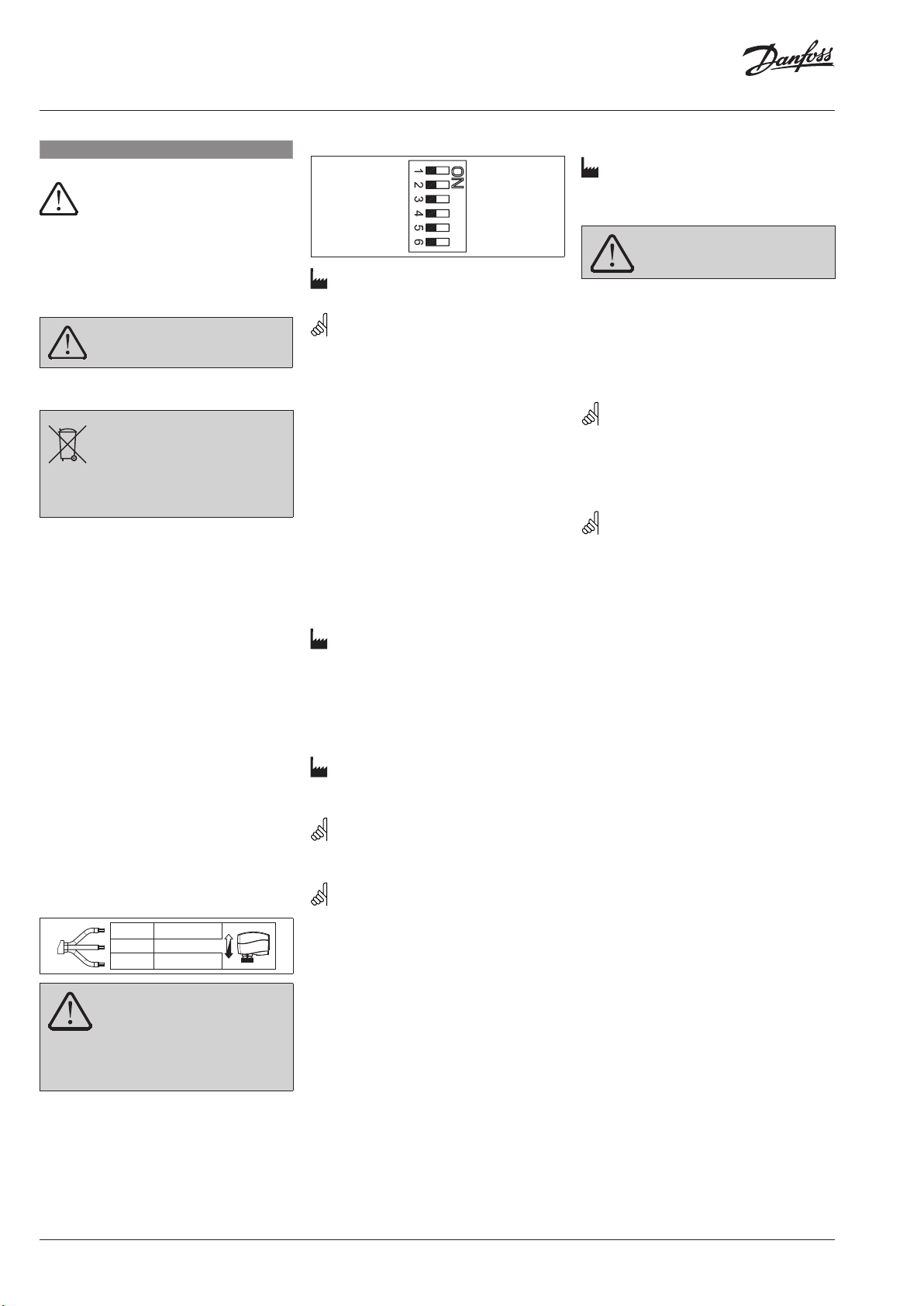

Reset

0V…---V

Inverse

Sequential

5(6)…10 V

I

➍

Reset

①

U I

--- S equential

Reset

Direct Inverse

2 V...---V 0V...---V

0(2)...5(6)V 5(6)...10V

② ③

④ ⑤

➎

⑥

AME 130, 140

①

②

⑦

6 mm

⑤

④

VI.KU.M6.9O

③

© Danfoss | 2017.07 | 3

AME 130(H), AME 140(H)

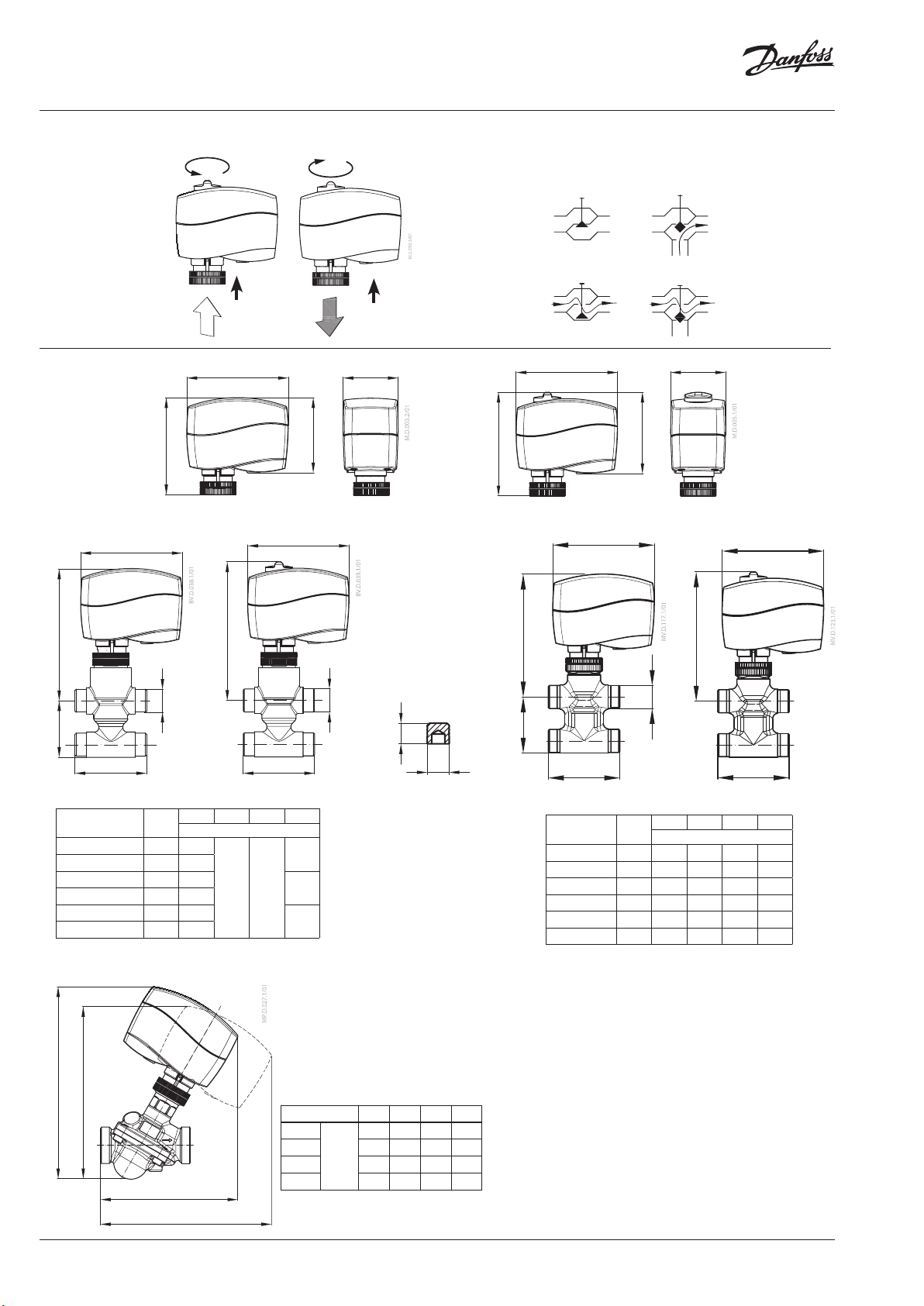

mm

mm

AME 130H, 140H

❻

stem up

2 port

3 or 4 port

➐

92

H

h

L

AME 130/140 +

VZ (DN 15, 20)

Valve t ype d

VZ 2 / DN 15 G ½” 65

VZ 2 / DN 20 G ¾” 77

VZ 3 / DN 15 G ½” 65

VZ 3 / DN 20 G ¾” 77

VZ 4 / DN 15 G ½” 65

VZ 4 / DN 20 G ¾” 77

88

H

d

L H H1h

①

92

68

AME 130, 140

92

1

L

AME 130H/140H +

VZ 2, VZ 3, VZ 4 (DN 15, 20)

26.5

119 125

35

65

①

stem down

50

94

d

4.7

Ø5

Stem extension

plug

h

92 50

74

AME 130H, 140H

92

H

1

L

AME130/140 + VZL

+ stem exte nsion plug

Valve t ype d

VZL 2 DN 15 G ½” 65 111 117 29.5

VZL 2 DN 20* G ¾” 77 117 123 34.0

VZL 3 DN 15 G ½” 65 111 117 35.0

VZL 3 DN 20 G ¾” 77 117 12 3 35.0

VZL 4 DN 15 G ½” 65 111 117 51.0

VZL 4 DN 20* G ¾” 77 117 123 65.0

* conex valve s DN 20 - G 1 ¹/₈” 14 TPI

1

H

d

L H H1h

92

L

AME130H/140H + VZL

+ stem exte nsion plug

1

1

2

H

H

L

4 | © Danfoss | 2017.07

DN 15 20 25 32

L

1

L

2

H

1

H

1

L

2

2

118 125 141 160

148 156 174 194

mm

168 178 19 6 216

152 162 180 200

VI.KU.M6.9O

AME 130(H), AME 140(H)

Gray

Y 0-10 VDC

Black

Common

Reset

0V…---V

Inverse

Sequential

5(6)…10 V

I

ENGLISH

Safety Note

To avoid injury of persons and

damages to the device, it is absolutely

necessary to read and observe these

instructions carefully.

Necessary assembly, start-up, and maintenance

work must be performed by qualified and

authorized personnel only.

Please comply with the instructions of the

system manufacturer or system operator.

Do not remove the cover before th e

power supply is ful ly switched off.

Disposal instruction

This product shou ld be dismantled

and its components so rted, if possible,

in various groups befo re recycling or

disposal.

Always follow the local d isposal regulations.

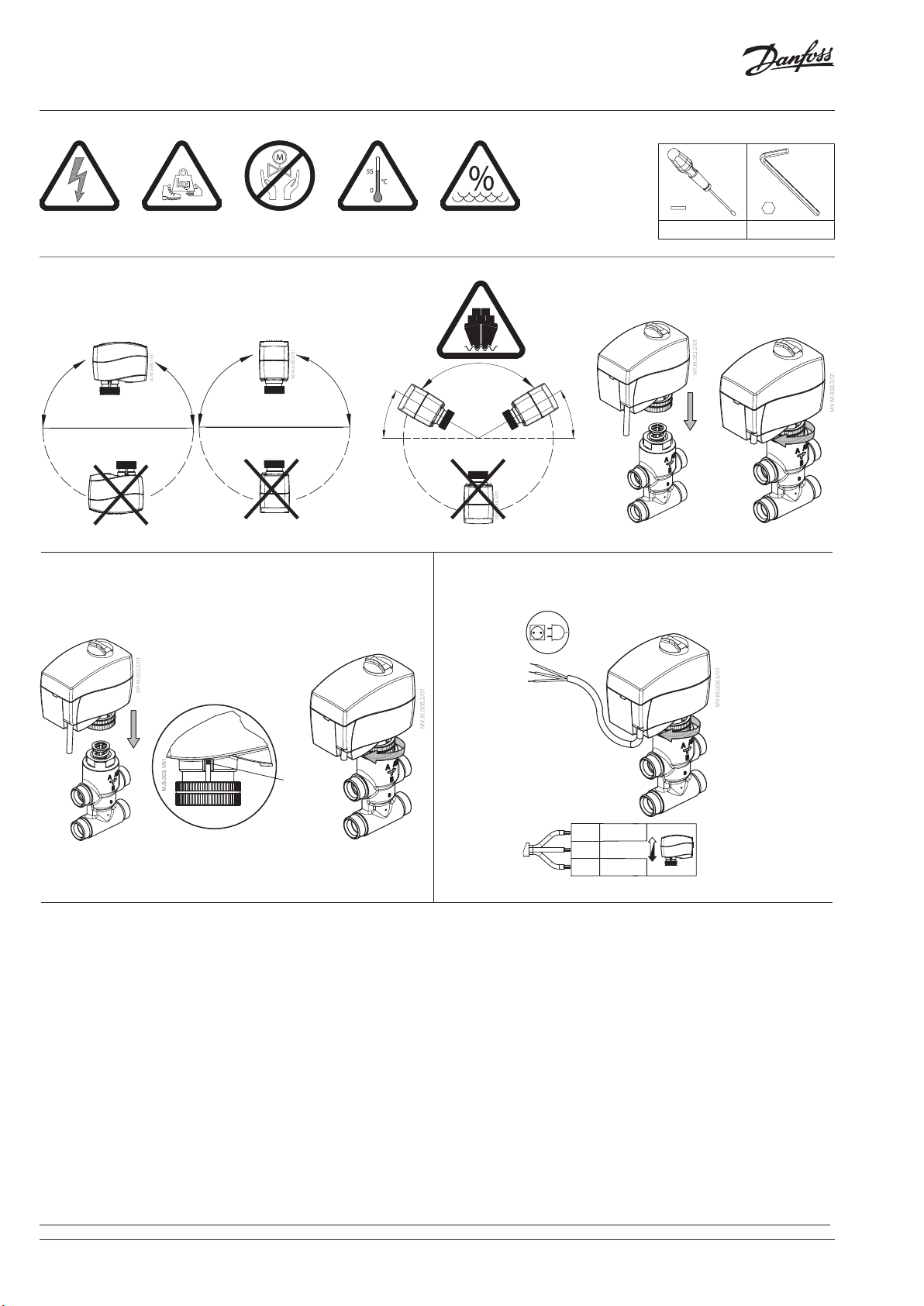

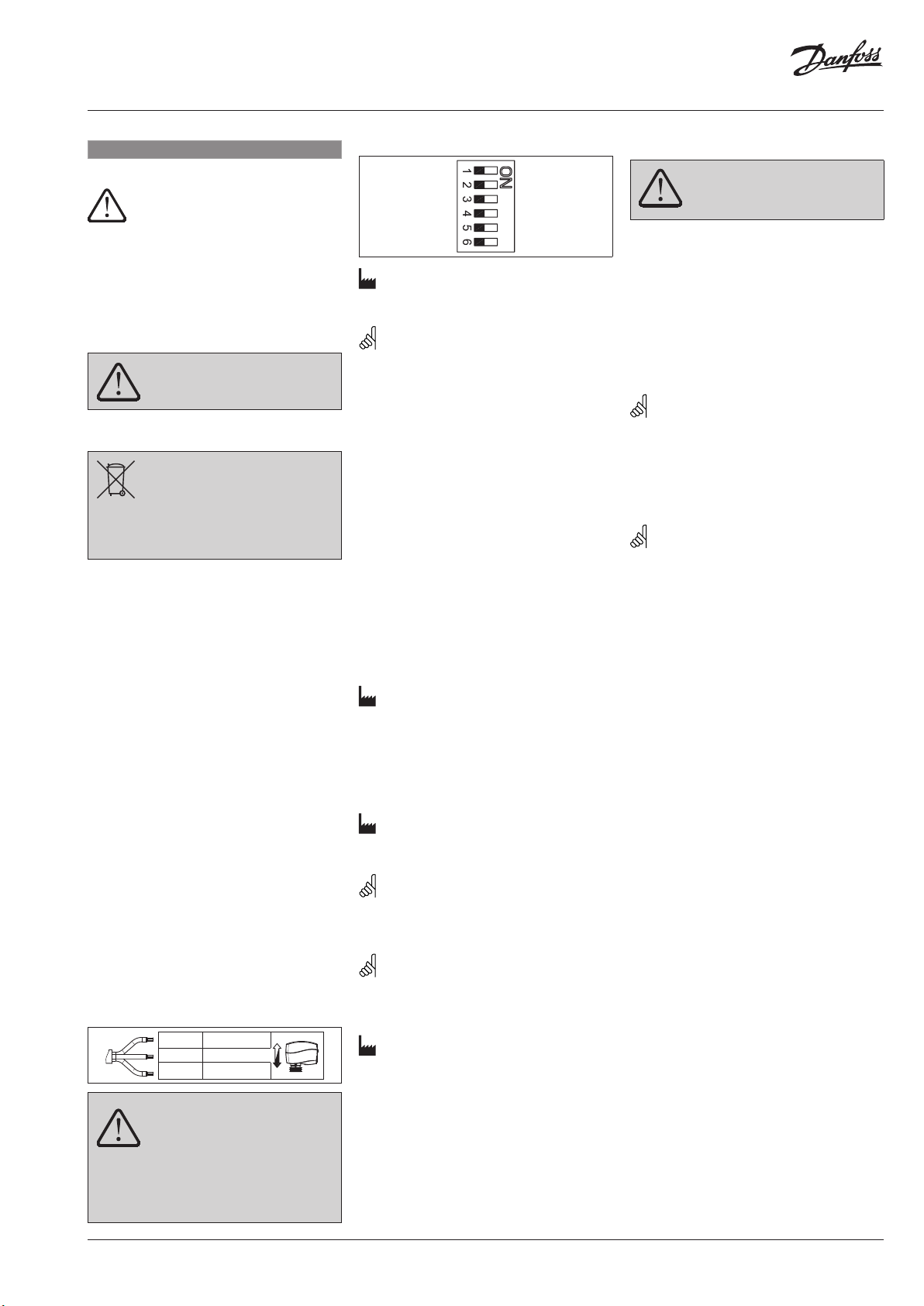

Mounting ➊

In case of ship applications (on water) actuator

should be mounted with the valve stem in

either 30° above horizontal position or pointing

upwards.

In case of building applications actuator should

be mounted with the valve stem in either

horizontal position or pointing

upwards.The actuator is fixed to the valve body

by means of a ribbed nut which requires no

tools for mounting. The ribbed nut should be

tightened by hand.

Installation ❷

1. Check the valve neck. The actuator should

be in steam up position (factory setting).

Ensure that the actuator is mounted securely

on the valve body

2. Wire the actuator according to the wiring

diagram

3 The direction of stem movement can be

observed on the position indicator ①

Wiring ❸

Red 24 VAC

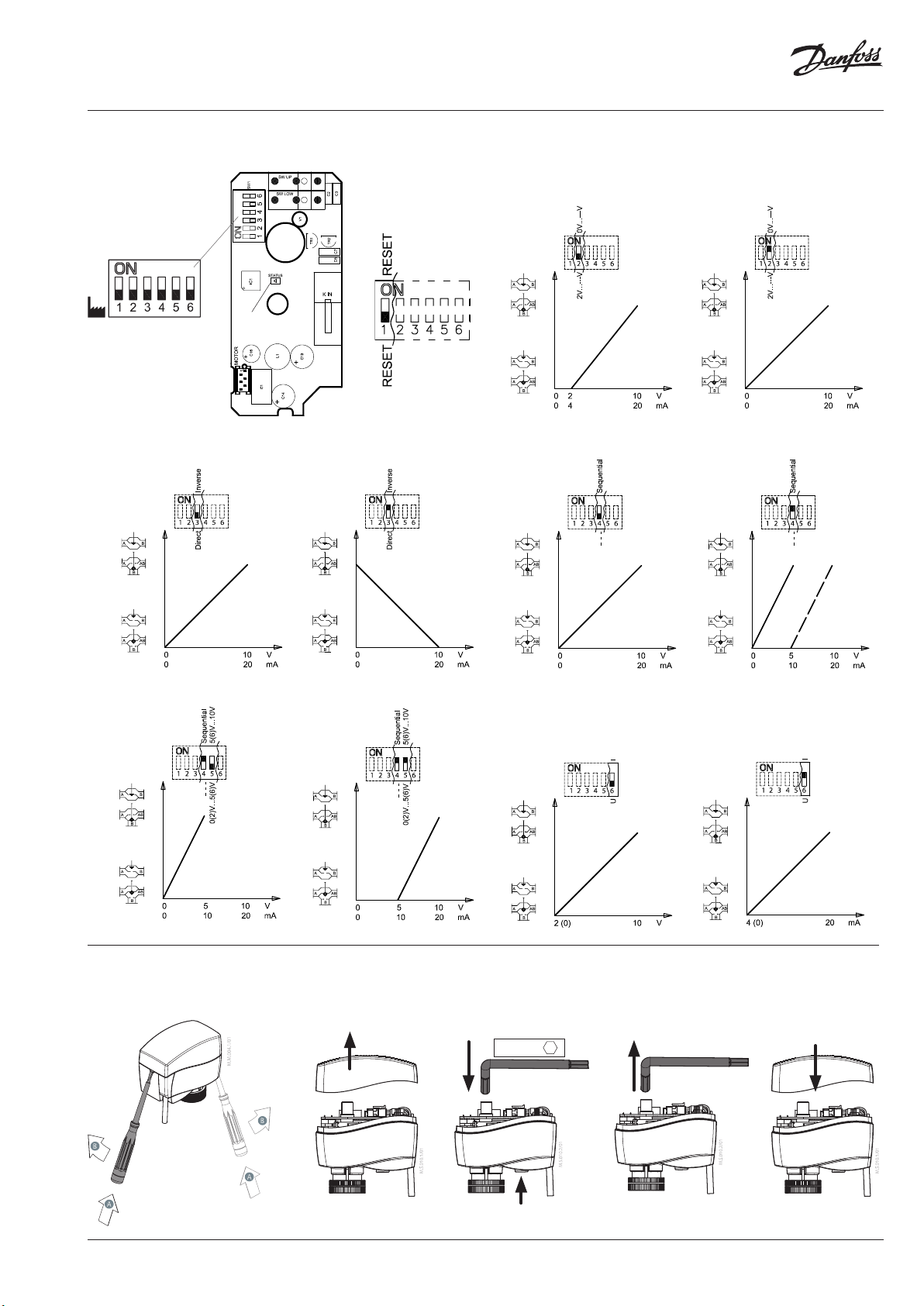

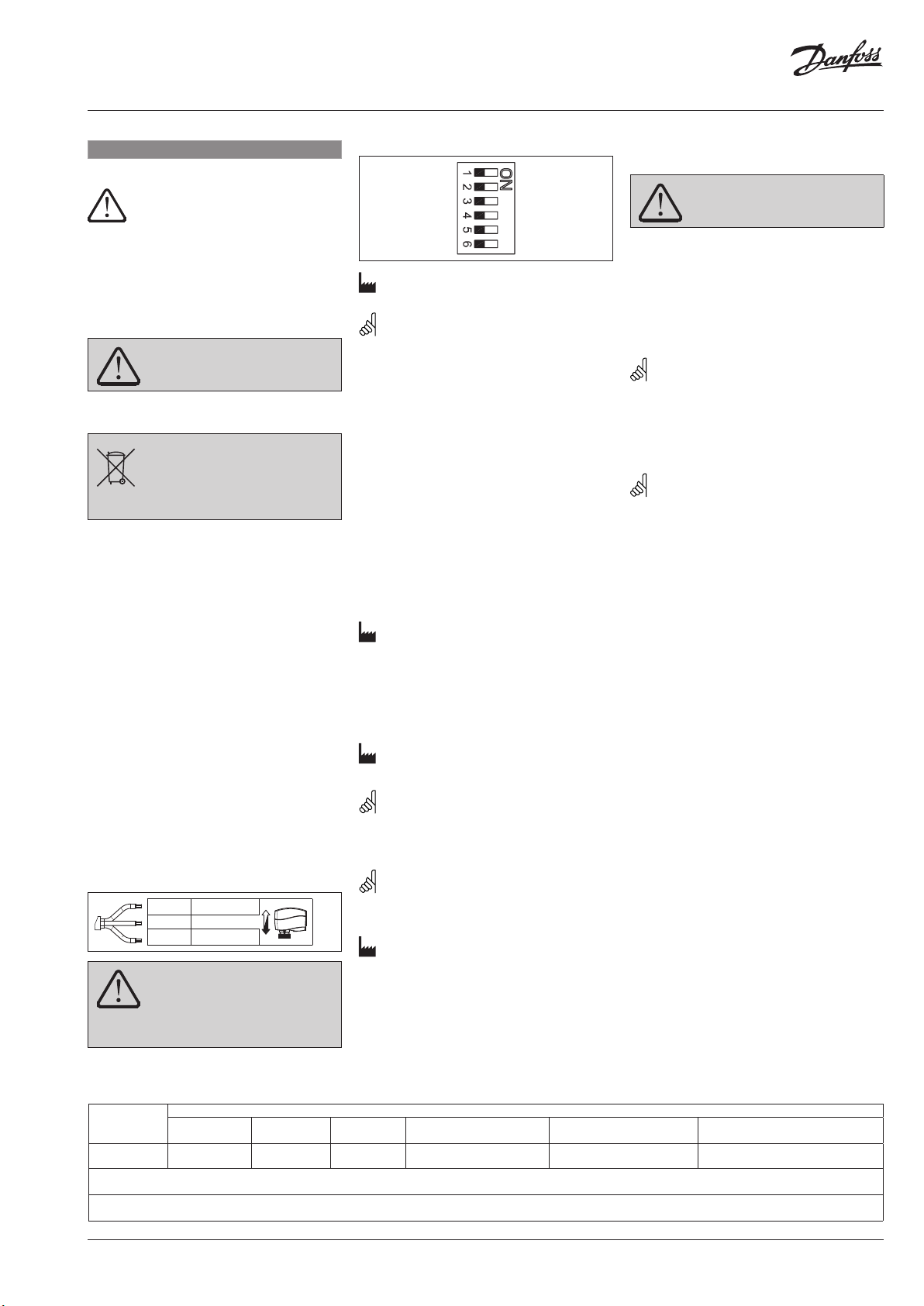

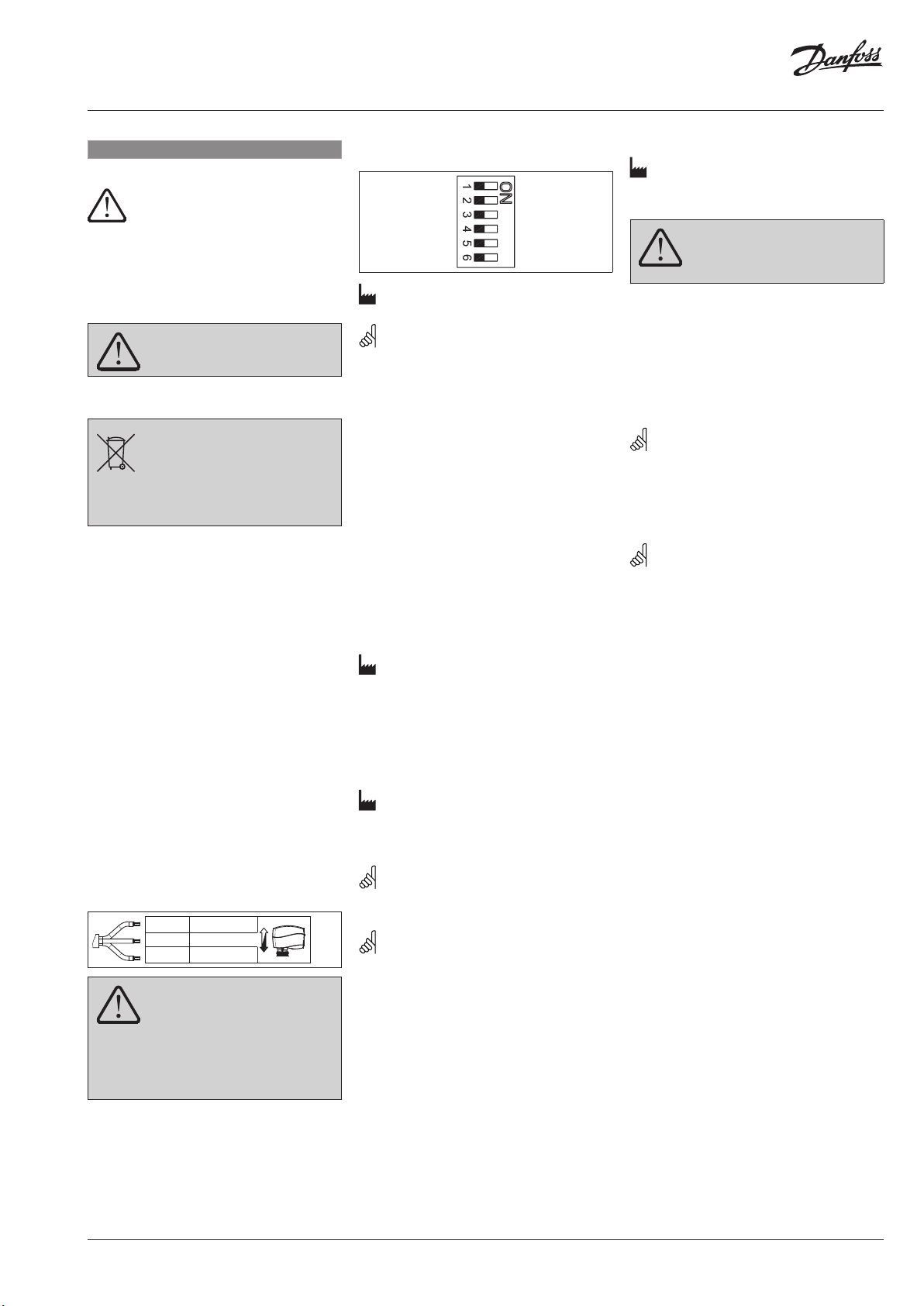

DIP switch settings ➍

Reset

2 V...---V 0V...---V

Direct Inverse

--- S equential

0(2)...5(6)V 5(6)...10V

U I

Factory settings:

ALL switches are on OFF position!

NOTE: All combinations of DIP switches are

allowed. All functions that are selected are

added consecutively.

SW1: Reset ②

After the actuator has been connected to

power supply, the actuator will start the selfadjustment procedure. The indicator LED ①

flashes until self adjustment is finished. The

duration depends on the spindle travel and will

normally last a few minutes. The stroke length

of the valve is stored in the memory after self

adjustment has been completed. To restart self

adjustment, change the position of the RESET

switch (switch No.1). If the supply voltage is

switched off or falls below 80 % in more than

0.1 s, the current valve position will be stored

in the memory and all data remain saved in the

memory also after a power supply cut-out.

SW2: 2-10 V/0-10 V ③

Factory setting is:

2-10 V.

SW3: Direct/Inverse ④

The actuator can be set for the spindle to

travel downwards on the rising control signal

(DIRECT), OR for the spindle to travel upwards

on the rising control signal (INVERSE)

Factory setting is:VI.KU.M6.9ODIRECT

SW4: ---/Sequential ⑤

NOTE: This combination works in

combination with switch No.5: 0(2)-5(6) V/5(6)10 V.

SW5: 0(2)-5(6) V/5(6)-10 V ⑥

NOTE: This function is available if switch

No.4: ---/Sequential is set.

SW6: U/I ⑦

Reset

Manual override

(for service purposes only)

Do not manually operate the drive

under power!

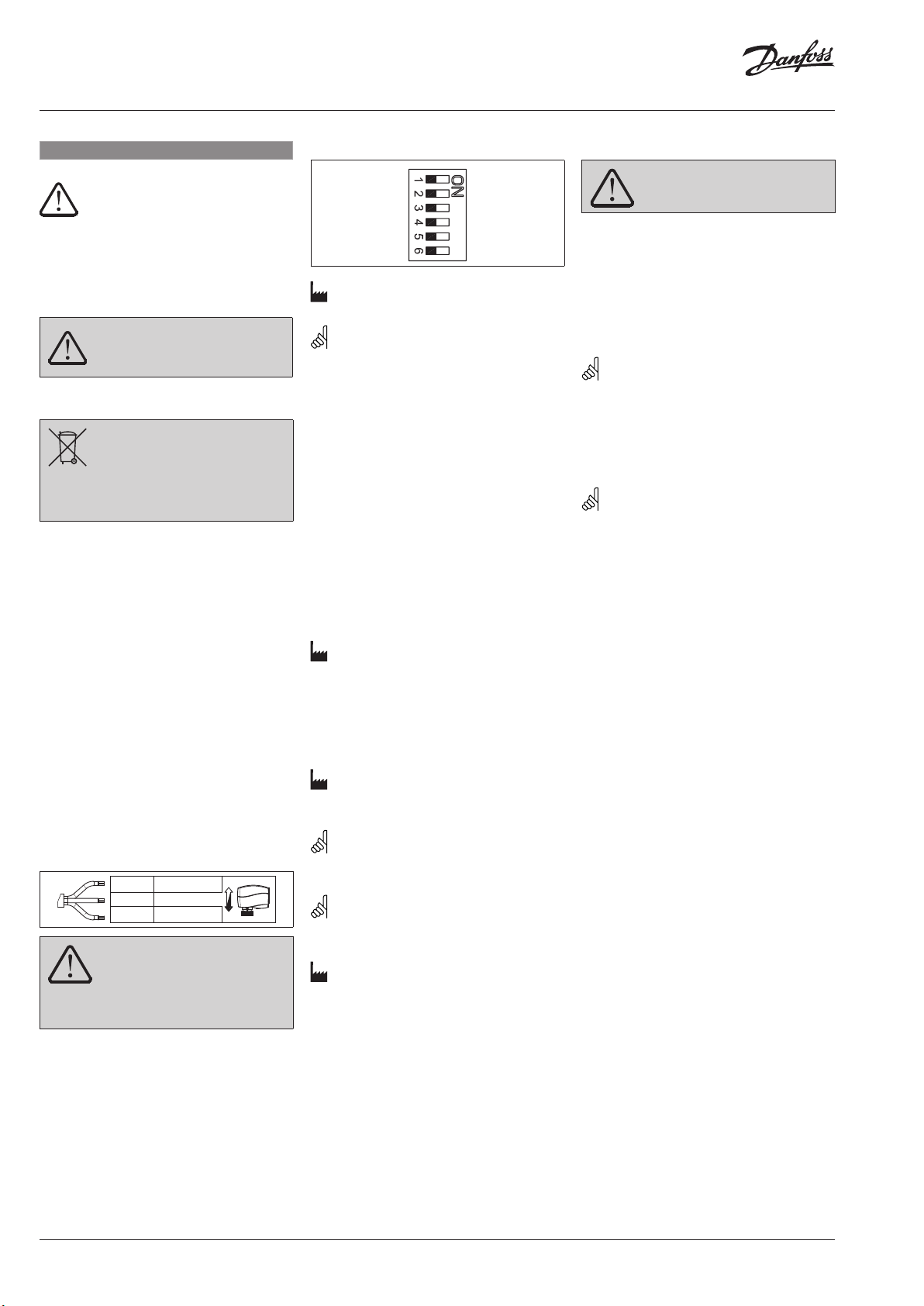

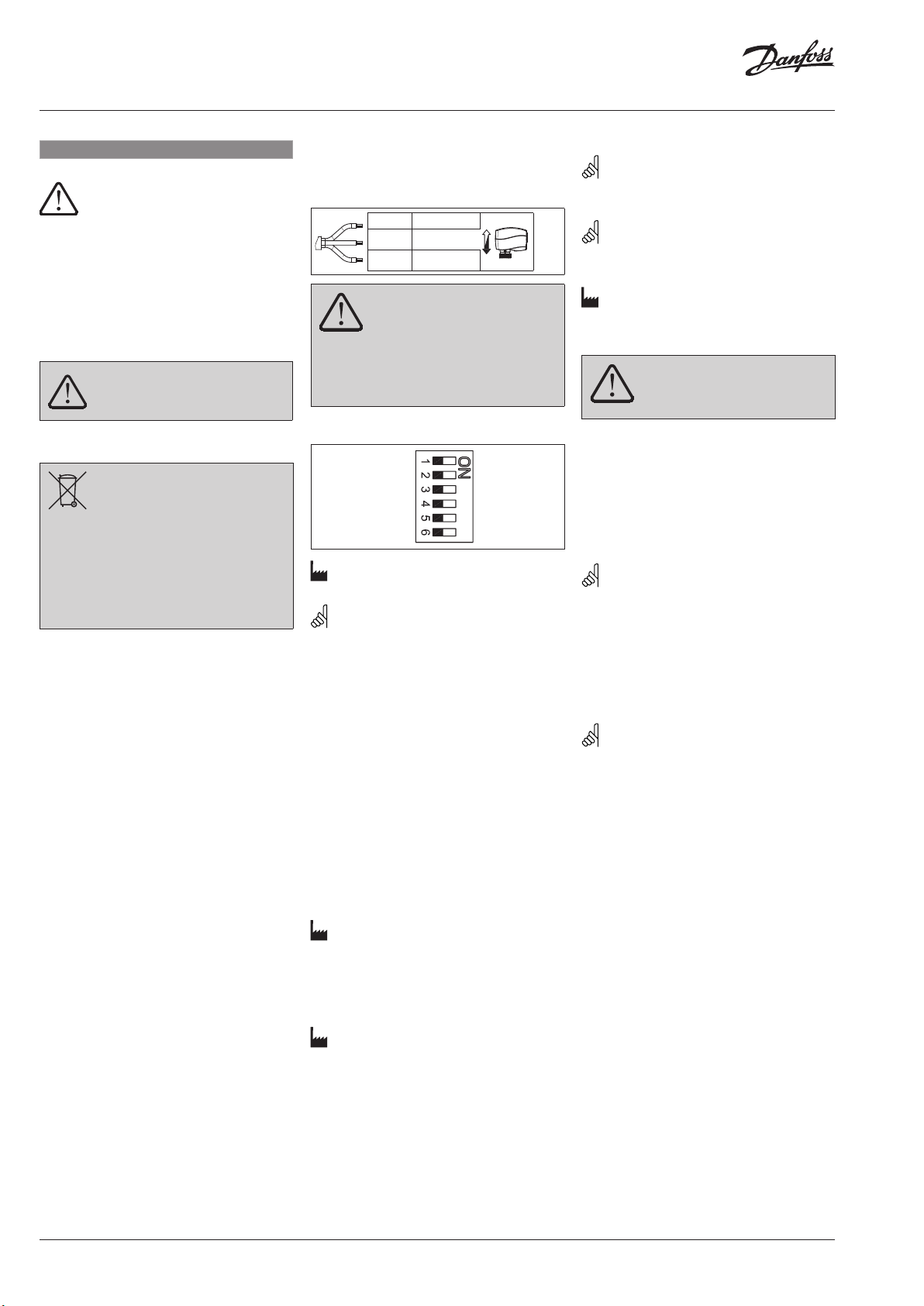

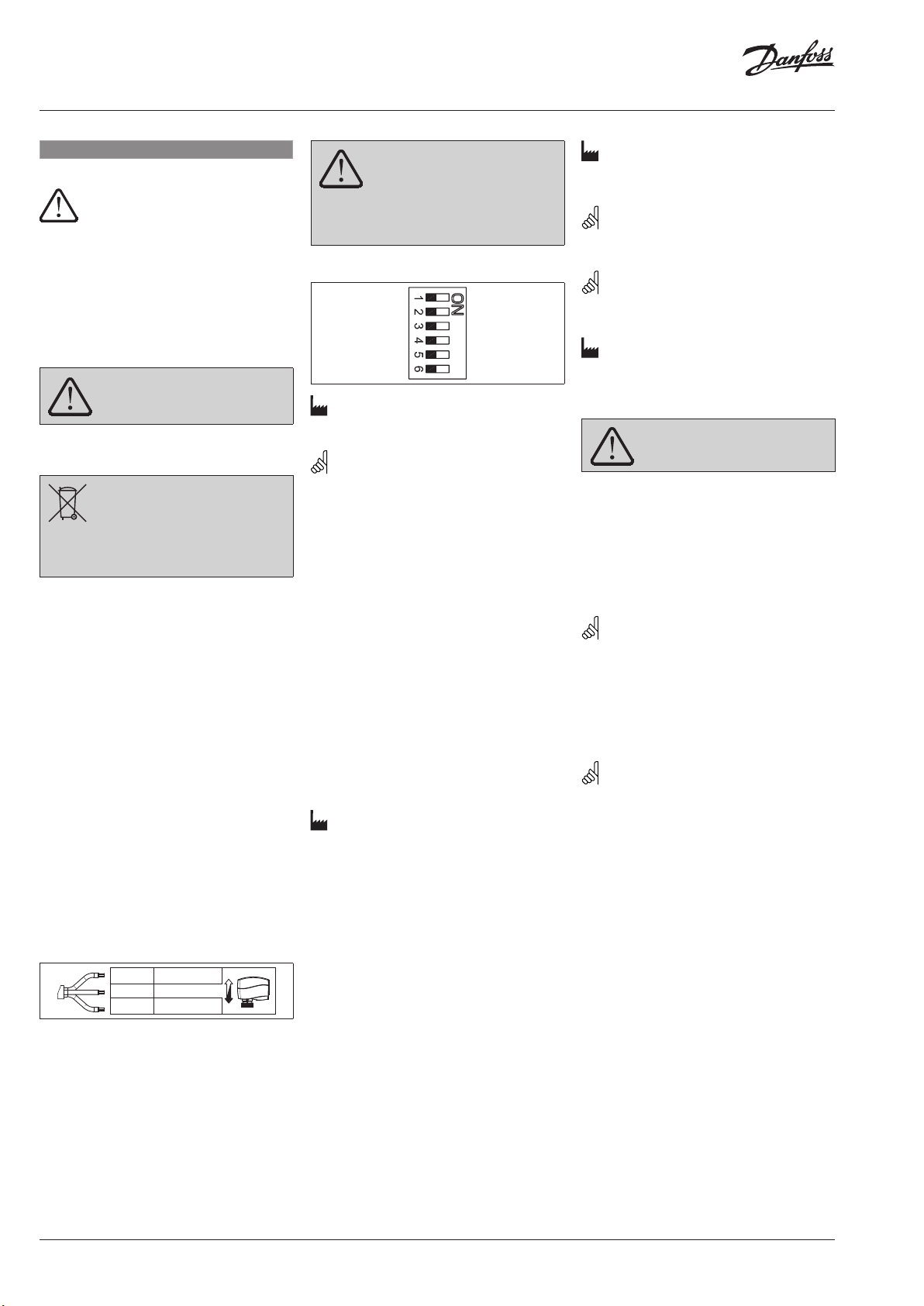

AME 130, AME 140 ➎

① Remove the cover

② Insert the Allen key 6 into the spindle

③ Press and hold the button (on the bottom

side of the actuator) during manual override

④ Pull out the tool

⑤ Replace cover

Remark: A ‘click’ sound af ter energising

the actuator means that the gear wheel has

jumped into normal position.

AME 130H, AME 140H ❻

Press and hold the button ① (on the bottom

side of the actuator) during manual override.

Remark: A ‘click’ sound af ter energising

the actuator means that the gear wheel has

jumped into normal position.

Function test

The light emitting diode (LED) ❹① indicates

whether the actuator is in operation or not, the

operating status, and failures, if any.

• No light

- no operation or no power supply

• Constant light

- normal operation

• Flashing light (1 Hz)

- self-adjusting mode

• Flashing light (~ 3 Hz):

- power supply too low

- initial self-adjusting time to short due too

short valve’s stroke must last more than 12

sec.

Dimensions ❼

Factory setting:

Do not touch anythin g on the PCB!

voltage control signal (2-10 V).

Switch off the power lin e before

wiring the actuator! Lethal voltage!

Wire the actuator according to the

wiring diagram.

Part Name

部件名称

Connecting nut

连接螺母

O: Indica tes that this hazar dous substance con tained in all of the h omogeneous ma terial for this par t is below the limi t requirement in GB /T 26572;

O: 表示该有害物质在该部件所有均质材料中的含量均在GB/T 26572规定的限量要求以下。

X: Indica tes that this hazar dous substance co ntained in at least o ne of the homogen eous material fo r this part is above th e limit requirem entw in GB/T 26572;

X: 表示该有害物质至少在该部件的某一均质材料中的含量超出GB/T 26572规 定的限量要求。

VI.KU.M6.9O

Lead (P b)

铅 (Pb)

X O O O O O

Mercur y (Hg)

汞 (Hg)

Cadmium (Cd)

镉 (Cd)

Hazardous Substances Table/有害物质含量表

Hexavalent Chromium (Cr(V I))

六价铬 (Cr (VI))

Polybrominated biphenyls (PBB)

多溴联 苯 (PB B)

Polybrominated diphenyl ethers (PBDE)

多溴二 苯醚 (PBDE)

© Danfoss | 2017.07 | 5

AME 130(H), AME 140(H)

Rød

24 VAC

Grå

Y 0-10 VDC

Reset

0V…---V

Inverse

Sequential

5(6)…10 V

I

DANSK

Sikkerhedsbestemmelser

For at undgå skader på personer og

udstyr, er det absolut nødvendigt at

gennemlæse følgende vejledning.

Montering, opstart og vedligeholdelse må kun

foretages af kvalificeret og autoriseret

personale.

Følg fabrikantens eller operatørens

instruktioner.

Dækslet må ikke ernes, før

strømforsyningen er ernet fra

stikkontakten.

Bortskaffelse

Før genbrug eller b ortskaffelse skal

dette produk t skilles ad, og

komponenterne skal sor teres i

forskellige materialegrupper.

Der henvises til de lokal e regulativer for

bortskaffelse.

Montering ➊

I tilfælde af anvendelser ombord på et skib skal

motoren monteres med ventilspindelen i enten

30° over vandret stilling eller pegende opad.

I tilfælde af anvendelser i bygninger skal

motoren monteres med ventilspindelen i enten

vandret eller pegende opad.

Motoren monteres på ventilhuset med en riflet

møtrik, der kan monteres uden værktøj. Den

riflede møtrik skal spændes med håndkraft.

Installation ❷

1. Kontroller ventilens hals. Motoren skal stå

i en position med spindelen trukket op.

(fabriksindstilling). Kontroller, at motoren er

monteret solidt på ventilhuset.

2. Tilslut motoren iht. ledningsdiagrammet – se

ovenfor.

3. Spindelens bevægelsesretning kan ses på

positionsindikatoren ①.

Wiring ❸

El-tilslutning ❹

Nulstilling

2 V...---V 0V...---V

Direkte Omvendt

--- Sek ventiel

0(2)...5(6)V 5(6)...10V

U I

Fabriksindstillinger:

ALLE omskiftere er stillet på OFF!

BEMÆRK: Alle kombinationer af

funktionsomskifterindstillinger er tilladt.

Alle funktioner, der vælges, tilføjes i den

rækkefølge, hvori de vælges.

SW1: Nulstilling ②

Når motoren er tilsluttet netspænding, starter

den en selvjusteringsprocedure. LED-dioden ①

blinker, indtil selvjusteringen er gennemført.

Varigheden afhænger af spindelens vandring

men tager normalt nogle få minutter. Ventilens

slaglængde gemmes i hukommelsen, når

selvjusteringen er gennemført. Selvjusteringen

kan genstartes ved at ændre RESETomskifterens position (omskifter nr.1). Hvis

forsyningsspændingen afbrydes eller falder til

under 80 % i mere end 0,1 sek., vil den aktuelle

ventilposition blive gemt i hukommelsen, og

alle data forbliver gemt i hukommelsen.

SW2: 2-10 V/0-10 V ③

Fabriksindstillingen er:

2-10 V.

SW3: Direkte/omvendt ④

Motoren kan indstilles, så spindelen vandrer

nedad, når styresignalet er stigende (DIREKTE),

ELLER så spindelen vandrer opad, når

styresignalet er stigende (OMVENDT)

Fabriksindstillingen er:

DIREKTE

SW4: ---/Sekventiel ⑤

BEMÆRK: Denne funktion indstilles med

omskifter nr. 5: 0(2)-5(6) V/5(6)-10 V.

SW5: 0(2)-5(6) V/5(6)-10 V ⑥

Nulstilling

Manuel overstyring

Drevet må ikke betjenes manuelt,

når det modtager strømforsyning!

AME 130, AME 140 ❺

① Tag dækslet af.

② Sæt en unbrakonøgle nr. 6 i spindelen.

③ Tryk på knappen (på undersiden af motoren)

og hold den inde under en manuel

overstyring.

④ Træk værktøjet ud.

⑤ Sæt dækslet tilbage på plads på motoren.

Bemærk: Hvis der høres en klik-lyd, efter

at strømforsyningen er sluttet til motoren,

betyder det, at tandhjulet er drejet i normal

position.

AME 130H, AME 140H ❻

Tryk på knappen ① (på undersiden af motoren)

og hold den inde under en manuel overstyring.

Bemærk: Hvis der høres en klik-lyd, efter

at strømforsyningen er sluttet til motoren,

betyder det, at tandhjulet er drejet i normal

position.

Funktionstest

LED-dioden ❹① angiver, om motoren er i

drift eller ej, dens driftsmæssige status samt

eventuelle fejl.

• Lyser ikke

- ude af drift eller ingen forsyningsspænding

• Lyser konstant

- normal drift

• Blinkende lys (1 Hz)

- selvjusteringstilstand

• Blinkende lys (~ 3 Hz):

- spændingen er for lav

- selvjustering-stidsrummet er for kort, fordi

ventilens vandring er for kort. Vandringen

skal have en varighed af over 12 sek.

Mål ❼

livsfarlig!

Tilslut motoren iht. ledningsdiagrammet.

6 | © Danfoss | 2017.07

Sort Fæ lles

Rør ikke ved PCB!

Sluk for strømmen inden elektrisk

tilslutning af motoren! Kan være

BEMÆRK: Denne funktion er tilgængelig, hvis

omskifter nr. 4: ---/Sekventiel er indstillet.

SW6: U/I ⑦

Fabriksindstilling:

styresignal (2-10 V).

VI.KU.M6.9O

AME 130(H), AME 140(H)

Grau

Y 0-10 VDC

Schwarz

Nullleiter

Reset

0V…---V

Inverse

Sequential

5(6)…10 V

I

DEUTSCH

Sicherheitshinweise

Um Verletzungen an Personen und

Schäden am Gerät zu vermeiden, ist

diese Anleitung unbedingt zu

beachten.

Montage, Inbetriebnahme und

Wartungsarbeiten dürfen nur von sachkundigen

und autorisierten Personen durchgeführt

werden.

Die Vorgaben des Anlagenherstellers und

Anlagenbetreibers sind zu beachten.

Abdeckung erst e ntfernen, wenn die

Stromversorgung komplett

ausgeschaltet ist.

Anweisung zur Entsorgung

Dieses Produkt sollte ausgebaut und

in dessen Bestandteile zerlegt werden.

Sortieren Sie die einzelnen

Bestandteile entsprechend der

Entsorgungsgruppen zur Wiederverwertung

oder Entsorgung.

Beachten sie dabei immer die lokalen

Entsorgungsrichtlinien.

Montage ❶

Bei Schiffsanwendungen (auf dem Wasser) sollte

der Stellmotor so installiert werden, dass die

Ventilspindel entweder 30° steiler als horizontal

ausgerichtet ist oder nach oben zeigt

Beim Einsatz in Gebäuden sollte der Stellmotor

so installiert werden, dass die Ventilspindel

entweder horizontal ausgerichtet ist oder nach

oben zeigt.

Der Stellantrieb wird am Ventilgehäuse mittels

einer Rändelschraube befestigt, für die kein

besonderes Werkzeug nötig ist. Diese Schraube

wird mit der Hand angezogen.

Einbau ❷

1. Überprüfen Sie den Anschluss am Ventil.

Die Antriebsstange des Stellantriebs sollte

eingefahren sein. Stellen Sie sicher, dass

der Stellantrieb fest auf dem Ventilkörper

montiert ist.

2. Schließen Sie den Stellantrieb entsprechend

dem Verdrahtungsplan (unten) an.

3. Die Bewegungsrichtung der Antriebsstange

kann an der Positionsanzeige überprüft

werden ①.

Verdrahtung ❸

Rot 24 VAC

Einstellung der DIP-Schalter ❹

Reset

2 V...---V 0V...---V

Direct Inverse

--- S equential

0(2)...5(6)V 5(6)...10V

U I

Werkseinstellung:

ALLE Schalter stehen auf OFF!

HINWEIS: Alle Kombinationen der DIP-

Schalter sind erlaubt.

SW1: Reset ②

Nachdem der Stellantrieb an die

Stromversorgung angeschlossen wurde,

startet eine Selbstjustierungs-routine. Die

LED-Anzeige ① blinkt, bis die Anpassung

abgeschlossen ist. Dies dauert je nach Hub ein

paar Minuten. Der maximale Hub des Ventils

wird gespeichert, sobald die Selbstjustierung

vollendet ist. Zum Neustart der Selbstjustierung

muss nur die Position des RESET-Schalters

(Schalter Nr. 1) verändert werden. Wenn die

Stromversorgung ausfällt oder länger als

0,1 Sek. unter 80 % sinkt, wird die aktuelle

Ventilposition gespeichert. Alle Daten werden,,

auch nach einem Stromausfall, gespeichert.

SW2: 2-10 V/0-10 V ③

Werkseinstellung:

2-10 V.

SW3: direkt/invers ④

Der Stellantrieb kann so eingestellt werden, dass

die Antriebsstange bei steigendem Steuersignal

ausfährt (direkt) oder dass sie bei steigendem

Steuersignal einfährt (invers).

Werkseinstellung: direkt

SW4: - --/sequentiell ⑤

HINWEIS: Die Kombination arbeitet im

Zusammenspiel mit dem Schalter 5: 0(2) -5(6 )

V/5( 6)-10 V.

SW5: 0(2)-5(6) V/5(6)-10 V ⑥

HINWEIS: Diese Funktion steht zur

Verfügung, wenn Schalter 4 (---/Sequentiell)

eingestellt wurde.

SW6: U/I ⑦

Werkseinstellung:

Spannungssignal (2-10 V)

Reset

Manuelle Hubverstellung

Verstellen Sie den Antrieb nicht von

Hand, solange er unter Strom steht!

AME 130, AME 140 ❺

1. Deckel abnehmen ①.

2. Den Inbusschlüssel in die Antriebsstange

stecken ②.

3. Knopf (auf der Unterseite des Stellantriebs)

drücken ③ und während der manuellen

Hubverstellung gedrückt halten.

4. Werkzeug entfernen ④.

5. Deckel wieder auf den Stellantrieb setzen ⑤.

Anmerkung: Der hörbare „Klick“ nach

dem Einschalten der Stromzufuhr zeigt, dass

das Getriebe in Normalstellung eingerastet ist.

AME 130H, AME 140H ❻

Knopf ① (auf der Unterseite des Stellantriebs)

drücken und während der manuellen

Hubverstellung gedrückt halten.

Die Hubverstellung erfolgt durch das

Drehen des Handrades auf der Oberseite des

Stellantriebs.

Anmerkung: Der hörbare „Klick“ nach

dem Einschalten der Stromzufuhr zeigt, dass das

Getriebe in Normalstellung eingerastet ist

Funktionstest

Die LED ❹① zeigt, ob der Stellantrieb arbeitet

oder nicht, den Betriebszustand und Fehler,

sofern vorhanden.

• kein Licht

– nicht in Betrieb oder keine Stromversorgung

• Dauerlicht

– Normalbetrieb

• Blinklicht (1 Hz)

– Selbstjustierungsmodus

• Blinklicht (~ 3 Hz)

– Spannungsversorgung zu niedrig; die Zeit

für den Selbstjustierungsmodus ist zu kurz

(dieser muss mehr als 12 Sek. betragen), da

der Ventilhub zu kurz ist.

Abmessungen ❼

Bitte die Platine nicht direkt

berühren!

Trennen Sie das Netzkabel vor

der Verdrahtung des Stellantriebs! Tödliche

Spannung!

Schließen Sie den Stellantrieb gemäß

dem Verdrahtungsplan an.

VI.KU.M6.9O

© Danfoss | 2017.07 | 7

AME 130(H), AME 140(H)

rood

Y (0-10V

stuursignaal)

pelijk (nul )

Reset

Reset

0V…---V

Inverse

Sequential

5(6)…10 V

I

Reset

2 V...---V

0V...---V

Direkt

Omgekeerd

---

Volgorde

0(2)...5(6)V

5(6)...10V

U

I

NEDERLANDS

Veiligheid

Om verwondingen van personen en

schade aan het apparaat te voorkomen

dient men deze instructies met

aandacht te lezen.

Montage, inbedrijfstelling en

onderhoudswerkzaamheden mogen alleen

door deskundig en erkend personeel uitgevoerd

worden.

Neem alle instructies betreffende

installatiecomponenten van andere fabrikanten

in acht.

Verwijder de afdek kap niet voordat de

voedingsspanning volle dig is

uitgeschakeld.

Afvalverwerking

Dit product of delen ervan dienen te

worden afgevoerd op een

milieuverantwoorde wijze.

Apparatuur die elektrische onderdelen bevat,

mag niet samen met huishoudelijk afval

worden afgevoerd.

Deze apparatuur moet apart worden

ingezameld samen met ander elek trisch

en elektronisch afval conform de geldende

wetgeving.

Montage ❶

Wanneer de servomotoren op een schip

worden toegepast dan dient de positie van

de afsluiterspindel minimaal 30° boven het

horizontale vlak gemonteerd te zijn.

Wanneer de servomotoren in een gebouw

worden toegepast dan dient de afsluiterspindel

tussen een horizontale- en een naar boven

wijzende positie gemonteerd te zijn.

De servomotor wordt op de afsluiter

gemonteerd d.m.v. het aandraaien van de

gekartelde ring onder de servomotor. Deze ring

mag uitsluitend met de hand worden vastgezet.

Installatie ❷

1. Controleer of de servomotor op de afsluiter

past. De servomotor dient in de geopende

stand te staan. (fabrieksinstelling) Controleer

of de servomotor goed is bevestigd op de

afsluiter.

2. Sluit de servomotor aan volgens het

onderstaande aansluitschema.

3. De richting van de spindel kan afgelezen

worden aan de positie van de indicator aan

de onderzijde van de servomotor ①.

Elektrische aansluiting ❸

24 V

grijs

gemeenschap-

zwart

Gevaarlijke spanning, raak niets aan

op de printplaat! Dodelijke

spanning!

Schakel de stroom uit voordat de bedrading

van de servomotor wordt aangebracht!

Sluit de servomotor aan volgens het

aansluitschema.

Dip schakelaars ❹

Fabrieksinstellingen:

alle schakelaars staan in de OFF (uit) positie.

Opmerking: Alle combinaties van DIP

instellingen zijn toegestaan.

Alle gekozen functies worden bij elkaar

opgeteld.

SW1: Reset ②

Nadat de servomotor is aangesloten op de

voedingsspanning begint de automatische

afstelprocedure. De indicatie LED ① knippert

tot de afstelling is beëindigd. De tijdsduur

is afhankelijk van de kleplift en bedraagt

gewoonlijk enkele minuten. De slag van de

klep wordt in het geheugen opgeslagen. Om

de afstelprocedure opnieuw te starten dient de

stand van RESET veranderd te worden. Wanneer

de voedingsspanning wordt uitgeschakeld

of langer dan 0,1 sec onder 80 % daalt, wordt

de momentele klepstand in het geheugen

opgeslagen en blijven alle gegevens bewaard.

SW2: 2-10 V/0-10 V ③

Fabrieksinstelling is:

2-10 V.

SW3: Direct/Inverse ④

Direct: spindel omlaag bij stijgend stuursignaal.

Inverse: spindel omhoog bij stijgend

stuursignaal.

Fabrieksinstelling is:

Direct

SW4: ---/Sequential ⑤

OPMERKING: Deze instelling werkt samen

met schakelaar 5: 0(2)-5(6) V/5(6)-10 V.

SW5: 0(2)-5(6) V/5(6)-10 V ❽⑥

Opmerking: Deze functie is geldig als

schakelaar 4 op Sequential staat.

SW6: U/I ⑦

Fabrieksinstelling:

Spanningssignaal (2-10 V)

Handbediening

Maak geen gebruik van de

handbediening wanneer de

servomotor onder spanning staat.

AME 130, AME 140 ❺

① Verwijder de afdekkap.

② Steek de imbussleutel 6 in de spindel.

③ Houd de knop aan de onderzijde van de

servomotor ingedrukt gedurende het

verdraaien van de spindel.

④ Verwijder de sleutel.

⑤ Plaats de afdekkap terug op de servomotor.

Opmerking: Wanneer de servomotor weer

onder spanning wordt ge zet, is er een ˝ klik˝

hoorbaar, dit wil zeggen dat de aandrijving

weer in de normale positie staat.

AME 130H, AME 140H ❻

Houd de knop aan de onderzijde van

de servomotor ingedrukt gedurende het

verdraaien van de handbediening aan de

bovenzijde van de servomotor ①.

Opmerking: Wanneer de servomotor weer

onder spanning wordt ge zet, is er een ˝ klik˝

hoorbaar, dit wil zeggen dat de aandrijving

weer in de normale positie staat.

Funktietest:

De LED ❹① geeft aan of de servomotor loopt

of stil staat, de bedrijfstoestand en eventuele

fout.

• Geen licht (uit)

- geen actie of geen voedingsspanning

• Continu licht (aan)

- normaal bedrijf

• Knipperlicht (1 Hz)

- automatische afstelprocedure

• Knipperlicht (3 HZ)

- voedingsspanning te laag

- tijd van afstelprocedure te kort (min. 12

sec.) vanwege te kleine spindelslag.

Afmetingen ❼

8 | © Danfoss | 2017.07

VI.KU.M6.9O

AME 130(H), AME 140(H)

Raudona

24 VAC

Pilka

Y 0-10 VDC

Reset

0V…---V

Inverse

Sequential

5(6)…10 V

I

LIETUVIŲ K.

Saugos informacija

Siekiant išvengti traumų ir įrenginio

gedimų, būtina atidžiai perskaityti šias

instrukcijas ir jomis vadovautis.

Būtiną montavimą, paleidimą ir techninį

aptarnavimą turi atlikti tik kvalifikuotas

įgaliotasis personalas.

Rekomenduojame laikytis sistemos gamintojų

sistemos operatoriaus instrukcijų.

Nenuimkite dangtelio, kol

maitinimas bus visiškai išjungtas.

Sunaikinimo instrukcija

Šis gaminys turi būti išmontuotas ir jo

dalys surūšiuotos, jei įmanoma, pagal

atskiras medžiagų grupes, prieš

sunaikinant.

Vadovaukitės vietinėmis sunaikinimo

nuostatomis.

Montavimas ❶

Naudojant pavarą laivų sistemose (vandenyje),

ją reiktų montuoti taip, kad pavaros stiebas būtų

30° virš horizontalios padėties arba nukreiptas

į viršų.

Naudojant pavarą pastatų sistemose, ją reiktų

montuoti taip, kad pavaros stiebas būtų

horizontalioje padėtyje arba nukreiptas į viršų.

Pavara prie vožtuvo korpuso prisukama

rantuota veržle, todėl montavimui nereikalingi

jokie įrankiai. Rantuota veržlė priveržiama ranka.

Montavimas ❷

1. Patikrinkite vožtuvo ir pavaros jungimą.

Pavara montuojama vožtuvo stiebą

nukreipiant aukštyn gamintojo nustatyta).

Įsitikinkite, ar pavara saugiai pritvirtinta prie

vožtuvo korpuso.

2. Prijunkite pavarą pagal elektrinių sujungimų

schemą.

3. Stiebo judėjimo kryptį galima stebėti pagal

padėties indikatorių ①.

Elektriniai sujungimai ❸

arba

Funkcijų pasirinkimo jungiklių

nustatymas ❹

Pradinis nustatymas

2 V...---V 0V...---V

Tiesioginis veikimas Atvirkštinis veikimas

--- Nu oseklusis

0(2)...5(6)V 5(6)...10V

U I

Gamintojo nustatymas:

Visi jungikliai yra išjungtoje (OFF) padėtyje.

PA STABA : Leidžiami visi funkcijų pasirinkimo

jungiklių deriniai. Visos pasirinktos

funkcijos pridedamos viena po kitos.

SW1: Pradinis nustatymas ②

Prijungus pavarą prie elektros maitinimo,

prasideda savaiminio nustatymo procedūra.

Kol vyksta ši savaiminio nustatymo procedūra,

mirksi indikatorius, pažymėtas simboliu ①.

Trukmė priklauso nuo stiebo eigos, dažniausiai

ši procedūra užtrunka kelias minutes. Pasibaigus

savaiminio nustatymo procedūrai, atmintyje

išsaugomas vožtuvo stiebo ilgis. Norėdami iš

naujo pradėti savaiminio nustatymo procedūrą,

perjunkite pirmąjį jungiklį, pažymėtą “RESET”.

Jei maitinimo įtampa nutrūksta arba daugiau

negu 0.1s jos reikšmė būna žemesnė už 80 %

nominalios reikšmės, atmintyje išsaugoma

esama vožtuvo padėtis, o nutrūkus maitinimui,

atmintyje išlieka ir visi duomenys.

SW2: 2-10 V/0-10 V ③

Gamintojo nustatymas:

2-10 V.

SW3: Tiesioginis arba atvirkštinis

veikimas ④

signalui didėjant, pavaros kotas judėtų žemyn

(tiesioginis veikimas) arba, valdymo signalui

didėjant, pavaros kotas judėtų aukštyn

(atvirkštinis veikimas).

Gamintojo nustatymas:

TIESIOGINIS VEIKIMAS

SW4: ---/Veikimo pagal seką

nustatymas ⑤

PA STABA : Šią funkciją reikia derinti su

penktuoju jungikliu: 0(2)-5(6) V/5(6)-10 V.

SW5: 0(2)-5(6) V/5(6)-10 V ⑥

Pradinis nustatymas

SW6: U/I ⑦

Gamintojo nustatymas:

Įtampos valdymo signalas (2-10 V).

Rankinis valdymas

Rankiniu būdu nevaldykite pavaros,

prie kurios prijungtas elektros

maitinimas!

AME 130, AME 140 ❺

① Nuimkite dangtelį.

② Į vožtuvo stiebą įstatykite 6 numerio “Allen”

raktelį.

③ Rankiniu būdu sukdami pavarą, paspauskite

ir laikykite mygtuką, esantį pavaros apačioje.

④ Ištraukite įrankį.

⑤ Vėl uždėkite pavaros dangtelį.

Pastaba: Įjungus pavarą, spragtelėjimas

rodo, kad pavaros krumpliaratis įėjo į

normalią padėtį.

AME 130H, AME 140H ❻

Rankiniu būdu sukdami pavarą, paspauskite ir

laikykite mygtuką, esantį pavaros apačioje ①.

Pastaba: Įjungus pavarą, spragtelėjimas

rodo, kad pavaros krumpliaratis įėjo į

normalią padėtį.

Veikimo patikrinimas

Šviesos diodas, pažymėtas simboliu ❹①

rodo, ar pavara veikia, jos darbinę būklę

ir pasitaikančius gedimus.

• Diodas nešviečia

- Pavara neveikia arba nėra elektros

maitinimo.

• Diodas šviečia nuolat

- Pavara veikia normaliai.

• Diodas mirksi 1 Hz dažniu

- Savaiminio nustatymo režimas.

• Diodas mirksi maždaug 3 Hz dažniu:

- Per žema maitinimo įtampa.

- Pradinio savaiminio nustatymo laikas per

trumpas dėl per mažos vožtuvo eigos.

Šis laikas turi būti ne mažesnis kaip

12 sekundžių.

Matmenys ❼

Juoda B endras

Nelieskite jokių dalių, esančių ant

montažines plokštės!

Prieš prijungdami prie pavaros

laidus, išjunkite maitinimą! Įtampa pavojinga

gyvybei!

Prijunkite pavarą pagal elektrinių sujungimų

schemą.

VI.KU.M6.9O

PA STABA : Ši funkcija veikia, jei nustatomas

4-asis jungiklis “---/Sequential”.

© Danfoss | 2017.07 | 9

AME 130(H), AME 140(H)

Sarkans

24 VAC

Pelēks

Y 0-10 VDC

Reset

0V…---V

Inverse

Sequential

5(6)…10 V

I

LATVIEŠU

Drošība

Lai novērstu traumu gūšanas un ierīces

bojājumu risku, obligāti rūpīgi jāizlasa

un jāievēro šie norādījumi.

Nepieciešamā montāža, palaišana un apkope

jāveic tikai kvalificētiem un pilnvarotiem

darbiniekiem.

Lūdzu, ievērojiet sistēmas izstrādātāja vai

sistēmas operatora norādījumus.

Nenoņemiet vāku, p irms strāvas

padeve nav pilnībā izslēgta.

Utilizācijas instrukcija

Šis produkts ir jādemontē pa daļām

un tā komponentes ir jāšķiro dažādās

grupās pirms otreizējās pārstrādes vai

utilizācijas.

Vienmēr ievērojiet vietējo likumdošanu

attiecībā uz atkritumu apsaimniekošanu.

Uzstādīšana ❶

Pielietojuma gadījumā uz kuģa (uz ūdens)

izpildmehānisms jāuzstāda ar vārsta pamatni

30° virs horizontālā stāvokļa vai virzienā uz

augšu.

Pielietojuma gadījumā būvniecībā

izpildmehānisms jāuzstāda ar vārsta pamatni

horizontālā stāvoklī vai virzienā uz augšu.

Izpildmehānisms tiek piestiprināts pie vārsta ar

rievotu uzgriezni, kuram nav nepieciešami citi

instrumenti. Rievotais uzgrieznis ir jāpievelk ar

roku.

Instalācija ❷

1. Pārbaudiet vārsta kātu. Izpildmehānismam

ir jāatrodas ar vārsta kātu uz augšu.

Pārliecinieties, ka izpildmehānisms ir droši

piemontēts pie vārsta.

2. Pieslēdziet izpildmehānismu, izmantojot

elektroinstalācijas diagrammu – skat.

iepriekš.

3. Mehānisma kustības virzienu var noteikt pēc

indikatora stāvokļa ①.

Elektroinstalācija ❸

DIP slēdža uzstādīšana ❹

Ieregulēšana

2 V...---V 0V...---V

Tiešs Pretējs

--- S ecīgs

0(2)...5(6)V 5(6)...10V

U I

Rūpnīcas uzstādījumi:

Visiem slēdžiem ir jābūt izslēgtiem.

Piezīme:

Visas DIP slēdžu kombinācijas ir atļautas. Visas

funkcijas tiek secīgi un atbilstoši atlasītas un

pievienotas.

SW1: Ieregulēšana ②

Pēc motora pieslēgšanas strāvai, tas sāks

pielāgošanās procedūru. LED indikators ① degs

tik ilgi, kamēr pielāgošanās tiks pabeigta. Tās

ilgums ir atkarīgs no vārpstas pārvietošanās

un parasti ilgst dažas minūtes. Virzuļa gājiena

intervāls tiek saglabāts atmiņā pēc tam, kad

pabeigta pielāgošanās. Lai atsāktu pielāgošanu,

mainiet atiestatīšanas slēdža (reset ) stāvokli.

(slēdzis nr. 1). Ja motora spriegums ir atslēgts vai

nokrītas zem 80 % par vairāk nekā 0.1 s, strāvas

vārsta stāvoklis tiks saglabāts atmiņā un arī

visa informācija tiks saglabāta atmiņā arī tad, ja

strāvas padeve tiks pārtraukta.

SW2: 2-10 V/0-10 V ③

Rūpnīcas iestatījums ir:

2-10 V.

SW3: Tiešs/Pretējs ④

Motoru var iestatīt, lai vārpsta virzītos lejup

pieaugot kontrolsignālam (tiešs), vai lai tā

virzītos augšup pieaugot kontrolsignālam

(pretējs )

Rūpnīcas iestatījums ir:

Tiešs

SW4: - --/secīgs ⑤

Piezīme: Šāda kombinācija darbojas kopā ar

slēdža nr. 5 kombināciju: 0(2)-5(6) V/5(6)-10 V.

SW5: 0(2)-5(6) V/5(6)-10 V ⑥

Piezīme: Šī funkcija ir pieejama, ja ir ieslēgts

slēdzis nr.4: ---/secīgs ir ieslēgts.

Ieregulēšana

SW6: U/I ⑦

Rūpnīcas iestatījums:

Sprieguma kontrolsignāls (2-10 V).

Instrukcijas neievērošana

Neaiztieciet ar rokām dzinēju, kas

atrodas zem sprieguma!

AME 130, AME 140 ❺

① Noņemiet vāciņu.

② Ievietojiet vārpstā 6. atslēgu.

③ Piespiediet un paturiet pogu (pārveidotāja

apakšdaļā)

④ Izņemiet instrumentu.

⑤ Novietojiet vāciņu atpakaļ uz motora.

Piezīme: Klikšķa skaņa pēc motora

pieslēgšanas nozīmē, ka zobrats ir pārlecis

normālā stāvoklī.

AME 130H, AME 140H ❻

Piespiediet un paturiet pogu

(motora apakšdaļā) ①

Piezīme: Klikšķa skaņa pēc motora

pieslēgšanas nozīmē, ka zobrats ir pārlecis

normālā stāvoklī.

Darbības pārbaude

Gaismiņa, kas izstaro ❹① norāda, vai motors

darbojas, vai nē, darbības stāvokli un kļūmes, ja

tādas ir.

• Gaismiņa nedeg

- nenotiek darbība vai nav strāvas padeves

• Pastāvīga gaismiņa

- Normāla darbība

• Mirgojoša gaismiņa (1 Hz):

- pielāgošanās režīms

• Mirgojoša gaismiņa (~ 3 Hz):

- pārāk maza strāvas padeve

- sākotnējam pielāgošanās laikam pārāk īsā

virzuļa gājiena dēļ ir jābūt vairāk par 12

sekundēm.

Izmēri ❼

Dzivibai bistams spriegums!

Pievienojiet vadus saskana ar pievienosanas

shemu.

10 | © Danfoss | 2017.07

Melns Kopējs

Neaiztikt PCB plati!

Atsledziet stravu pirms vadu

pievienosanas aktuato ram!

VI.KU.M6.9O

AME 130(H), AME 140(H)

Szürke

Y 0-10 VDC

Fekete

Közös

Reset

0V…---V

Inverse

Sequential

5(6)…10 V

I

MAGYAR

Biztonsági megjegyzések

Az itt szereplő utasítások gondos

elolvasása és betartása feltétlenül

fontos a személyi sérülések és

berendezés károsodások elkerülésére.

A szükséges szerelési, beállítási és

munkákat kizárólag szakképzett

személyzet végezheti el.

Kérjük, tartsa be a rendszer gyártójának és

üzemeltetőjének rendelkezéseit!

Ne távolítsa el a fedelet a

tápfeszültség teljes lekapcsolása

előtt.

Hulladék tárolási instrukció

Ezt a terméket szét kell szerelni és

annak alkatrészeit szét válogatni

amennyiben lehetséges különböző

csoportok szerint az újrahasznosítás vagy a

szemétbe dobás előtt.

Mindig keresse a helyi szemét lerakási helyeket!

Beépítés ❶

Hajózási alkalmazásoknál, a hajtás a vízszintestől

minimum 30°-os szögben elforgatva vagy

felfelé nézően függőleges helyzetben építhető

be.Épületgépészeti alkalmazásoknál a hajtás

vízszintes helyzetben ill. a vízszintes helyzettől

felfelé irányulóan építhető be.

A szelepmozgató a szeleptesthez egy recézett

anyával van rögzítve, - szerszán nélküli szerelés.

A recézett anyát kézzel kell meghúzni.

Beépítés ❷

1. Ellenőrizze a szelepnyak helyzetét.

A szelepmozgatót felfelé mutató

szelepszárra kell felszerelni.(gyári beállítás).

Bizonyosodjon meg a szelepmozgató

szeleptestre történő biztonságos

rögzítéséről.

2. Kösse be a szelepmozgatót a huzalozási rajz

szerint – lásd fent

3. A szelepszár mozgás iránya megfigyelhető a

pozíció kijelzőn ①.

Elektromos bekötés ❸

Piros 24 VAC

karbantartási

és megbízott

Mikrokapcsolók beállításai ❹

Visszaállítás

2 V...---V 0V...---V

Egyenes Fordított

--- Sze kvenciális

0(2)...5(6)V 5(6)...10V

U I

Gyári beállítás:

Mindegyik kapcsoló OFF/KI állásban van!

MEGJEGYZÉS: A mikrokapcsolók

helyzeteinek minden kombinációja

megengedett. Minden kiválasztott funkció

egymás után hozzáadódik a korábbiakhoz.

SW1: Visszaállítás ②

Az egység tápfeszültségre kapcsolása után, a

szelepmozgató elkezdi az önbeállítást. Az ①

LED az önbeállítás befejezéséig villog. Az

időtartam az orsómozgás nagyságától függ, és

normál esetben a folyamat eltart néhány percig.

Az önbeállítás befejezésekor a szeleplöket

hossza eltárolásra kerül a memóriában. Az

önbeállítás újrakezdéséhez változtassa meg

a RESET mikrokapcsoló (1. kapcsoló) állását.

Ha a tápfeszültség lekapcsolódik, vagy 0,1

másodpercnél tovább 80 % alá esik, akkor

az aktuális szeleppozíció elmentésre kerül a

memóriában. Energiaellátás kimaradásakor az

összes adat a memóriában elmentve marad.

SW2: 2-10 V/0-10 V ③

Gyári beállítás:

2-10 V.

SW3: Egyenes/Fordított működés ④

A szelepmozgató beállítható úgy, hogy növekvő

vezérlő jelre az orsó lefelé mozogjon (EGYENES

működés), vagy felfelé mozogjon (FORDÍTOTT

működés).

Gyári beállítás:

EGYENES

SW4: ---/Szekvenciális ⑤

MEGJEGYZÉS: Ez a kombináció az 5. számú

mikrokapcsolóval együtt működik: 0(2)-5(6)

V/5(6)-10 V ).

SW5: 0(2)-5(6) V/5(6)-10 V ⑥

MEGJEGYZÉS: Ez a funkció akkor áll

rendelkezésre, ha a 4 számú mikrokapcsoló:

---/SZEKVENCIÁLIS helyzetben van.

Visszaállítás

SW6: U/I ⑦

Gyári beállítás:

feszültség vezérlőjel (2-10 V).

Kézi működtetés

Feszültség alatti állapotban kéz zel

ne működtesse a szelepet!

AME 130, AME 140 ❺

① Távolítsa el a szelepmozgató fedelét

② Helyezze a 6mm-es imbusz-kulcsot az

orsóba.

③ Kézi működtetés során nyomja meg és

tartsa nyomva a szelepmozgató alsó részén

elhelyezett gombot.

④ Húzza ki az imbusz-kulcsot.

⑤ Helyezze vissza a fedelet a szelepmozgatóra.

Megjegyzés: A szelepmozgató

tápfeszültségre kapcsolása utáni „kattanás”

azt jelenti, hogy a fogaskerék normál

pozícióba ugrott.

AME 130H, AME 140H ❻

Kézi működtetés során nyomja meg és

tartsa nyomva a szelepmozgató alsó részén

elhelyezett gombot ①.

Megjegyzés: A szelepmozgató

tápfeszültségre kapcsolása utáni „kattanás”

azt jelenti, hogy a fogaskerék normál

pozícióba ugrott.

Működés vizsgálat

Az ❹① számú LED jelzi a szelepmozgató

működését, az üzemállapotot, és az esetleges

meghibásodásokat.

• Nincs fényjelzés

- nem működik, vagy nincs energiaellátás

• Állandó fényjelzés

- normál működés

• Villogó fény(1 Hz)

- önbeállító mód

• Villogó fény(~3Hz)

- tápfeszültség túl alacsony

- a kezdeti önbeállítási idő túl rövid,

- a szelep rövid lökete miatt. (minimum 12

másodperc mozgásidő szükséges)

Méretek ❼

Ne érintsen meg semmit a PCB-n!

Kapcsolja ki a tápellátást mielőtt

beköti az állítóművet! Élet veszélyes

feszültség!

Csatlakoztassa az állítóművet az elektromos

bekötési rajz szerint.

VI.KU.M6.9O

© Danfoss | 2017.07 | 11

AME 130(H), AME 140(H)

Cervená

24 V

Šedá

Y 0-10 VDC

Reset

0V…---V

Inverse

Sequential

5(6)…10 V

I

ČESKY

Bezpečnostní pokyny

Abyste předešli zranění osob a

poškození zařízení, před montáží a

uváděním zařízení do provozu si

musíte přečíst tyto pokyny a bezpečnostní

instrukce.

Nedemontujte servopohony s funkcí

bezpečnostní pružiny! Při nesprávné manipulaci

hrozí nebezpečí zranění nebo usmrcení!

Servopohon je těžký. Manipulujte s ním opatrně,

abyste předešli zranění osob nebo poškození

produktu.

Nesundávejte kryt, dokud není

napájení

zcela vypnuto.

Pokyny pro likvidaci

Tento výrobek by měl být před

recyklací nebo likvidací rozebrán na

součástky a ty u místěny do různých

skupin odpadu.

Vždy dbejte aktuál ních pokynů místní

legislativy.

Montáž ❶

V případě lodních aplikací (na vodu) by měl být

pohon instalován s vřetenem ventilu buď 30%

nad horizontální pozicí nebo směrem nahoru.

V případě aplikací v budovách by měl být pohon

instalován s vřetenem ventilu buď v horizontální

pozici nebo směrem nahoru.

Servopohon je k tělesu ventilu připojen pomocí

drážkované převlečné matice. K montáži není

potřeba používat žádné nářadí.

Instalace ❷

1. Zkontrolujte připojovací hrdlo ventilu.

Servopohon je potřeba montovat s

vřetenem nastaveným do horní polohy

(tovární nastavení). Ujistěte se, že

servopohon je k tělesu ventilu správně

namontován.

2. Servopohon zapojte dle schéma zapojení-viz

nahoře.

3. Směr pohybu vřetena je možné sledovat

pomocí indikátoru polohy ①.

Zapojení ❸

Cerná Spolecný

V žádném případě se nedotýkejte

žádné součásti desky s plošnými

spoji!

Před zapojováním servopohonu vypněte

elektrické vedení! Pozor na vysoké napětí!

Servopohon zapojte podle schématu zapojení.

Nastavení DIP spínače ❹

Resetování

2 V...---V 0V...---V

Přímý Inverzní

--- S ekvenční

0(2)...5(6)V 5(6)...10V

U I

Tovární nastavení:

VŠECHNY spínače jsou nastaveny do VYPNUTÉ

polohy!

POZNÁMKA: Na DIP spínači je možné

nastavovat všechny možné kombinace.

Všechny funkce, které byly navoleny, jsou

přidávány postupně.

SW1: Resetování ②

Po zapojení ke zdroji napájecího napětí se

servopohon začne automaticky nastavovat. LED

kontrolka ① bude během tohoto nastavování

blikat. Doba nastavování závisí na délce dráhy

vřetena a obvykle trvá několik minut. Velikost

dráhy zdvihu je po dokončení nastavování

uložena do paměti. Chcete-li nastavování

zopakovat, tak stačí změnit polohu spínače

RESET (spínač č. 1). Jestliže dojde k výpadku

dodávky elektrické energie nebo poklesne-li

napětí pod 80 % nominální hodnoty na dobu

delší než 0,1 sec, zaznamená se do paměti

aktuální poloha kuželky ventilu. Tyto hodnoty

zůstanou v paměti uloženy i v tom případě, kdy

bude servopohon odpojen od zdroje elektrické

energie.

SW2: 2-10 V/0-10 V ③

Tovární nastavení:

2-10 V.

SW3: Přímý/Inverzní ④

Servopohon je možné nastavit tak, aby při

rostoucím regulačním signálu docházelo buď

k pohybu hřídele ventilu směrem dolů (PŘÍMÝ)

NEBO k pohybu hřídele směrem nahoru

(INVERZNÍ).

Resetování

Tovární nastavení:

PŘÍMÝ

SW4: ---/Sekvenční ⑤

POZNÁMKA: Tato kombinace pracuje spolu

se spínačem č.5: 0(2)-5(6) V/5(6)-10 V.

SW5: 0(2)-5(6) V/5(6)-10 V ⑥

POZNÁMKA: Tato funkce je použitelná pouze

s nastaveným spínačem č. 4: ---/Sekvenční.

SW6: U/I ⑦

Tovární nastavení:

Napěťový regulační signál (2-10 V).

Ruční ovládání

Je-li servopohon pod napětím, tak se

ho nikdy nesnažte ovládat ručně!

AME 130, AME 140 ❺

① Sejměte kryt servopohonu.

② Do vřetena zasuňte imbusový klíč číslo 6.

③ Na spodní straně servopohonu stiskněte

tlačítko a držte ho stisknuté po celou dobu

ručního ovládání.

④ Vytáhněte klíč.

⑤ Kryt nainstalujte zpět na servopohon.

Poznámka: Ozve-li se po připojení na zdroj

elektrické energie slyšitelné cvaknutí, tak

to znamená, že převodové kolo zapadlo do

správné polohy.

AME 130H, AME 140H ❻

Na spodní straně servopohonu stiskněte tlačítko

a držte ho stisknuté po celou dobu ručního

ovládání ①.

Poznámka: Ozve-li se po připojení na zdroj

elektrické energie slyšitelné cvaknutí, tak

to znamená, že převodové kolo zapadlo do

správné polohy.

Funkční test

Světelná dioda ❹① signalizuje, zda je či není

servopohon v provozu, provozní stav a v

případě vzniku poruchy i poruchu.

• Nesvítí

- není v provozu nebo není pod napětím

• Svítí trval

- normální provozní podmínky

• Bliká (Frekvence 1 Hz, tzn. 1 × za sekundu)

- automatický nastavovací režim

• Bliká (~ 3 Hz, tzn. asi 3 × za sekundu):

- příliš nízké napětí

- počáteční doba samonastavování příliš

krátká z důvodu krátkého zdvihu ventilu a

musí trvat alespoň 12 sekund.

Rozměry ❼

12 | © Danfoss | 2017.07

VI.KU.M6.9O

AME 130(H), AME 140(H)

Szary

Y 0-10 VDC

Czarny

Wspólny

Reset

0V…---V

Inverse

Sequential

5(6)…10 V

I

POLSKI

Warunki bezpieczeństwa

Aby uniknąć obrażeń u ludzi oraz

uszkodzenia

zapoznać się

z tymi informacjami i przestrzegać ich.

Niezbędne prace związane z montażem,

uruchomieniem i konserwacją mogą być

wykonywane wyłącznie przez autoryzowany

wykwalifikowany personel.

Prosimy stosować się do instrukcji producenta

lub operatora układu.

Nie zdejmować obudowy przed

całkowitym odłączeniem napięcia

zasilania.

Instrukcja usuwania odpadów

Ten produkt powinien być rozebrany

a jego komponent y posegregowane,

jeśli to możliwe, na różne grupy przed

poddaniem recyklingowi lub utylizacji.

Zawsze stosuj się do miejscowych pr zepisów w

zakresie usuwania odpadów.

Montaż ❶

W przypadku aplikacji do instalacji na statku (na

wodzie) siłownik powinien być zamontowany

tak, aby trzpień zaworu był w położeniu pod

kątem 30° powyżej poziomu lub był skierowany

do góry.

W przypadku aplikacji do instalacji w budynkach

siłownik powinien być zamontowany tak, aby

trzpień zaworu był w pozycji poziomej lub

skierowany do góry.

Siłownik jest montowany na zaworze za

pomocą karbowanej nakrętki, nie wymagającej

stosowania narzędzi. Nakrętkę należy dokręcić

ręcznie.

Montaż ❷

1. Sprawdzić szyjkę zaworu. Siłownik powinien

być w pozycji podniesionego trzpienia

zaworu (ustawienie fabryczne). Upewnić

się, że siłownik został zamontowany we

właściwy sposób.

2. Podłączyć do siłownika zasilanie elektryczne

zgodnie z podanym schematem (patrz

poniżej).

3. Sprawdzić kierunek ruchu trzpienia

obserwując wskaźnik położenia

(pozycjoner) ①.

Podłączenia elektryczne ❸

sprzętu, należy koniecznie

i

Czerwony 24 V

Ustawianie mikroprzełączników ➍

Reset

2 V...---V 0 V...---V

Zgodnie Odwrotnie

--- Sek wencyjnym

0(2)...5(6)V 5(6)...10V

U I

Nastawa fabryczna:

WSZYSTKIE przełączniki ustawione są w pozycji

OFF (wyłącz).

UWAGA : Dopuszczalne są dowolne

kombinacje ustawień mikroprzełączników.

Wszystkie wybrane funkcje są odpowiednio

aktywowane.

SW1: Reset ②

Po podłączeniu do zasilania elektrycznego

siłownik rozpoczyna procedurę

samoustawienia. Dioda LED ① błyska do chwili

zakończenia procedury. Czas tej operacji zależy

od drogi (skoku) trzpienia – zazwyczaj zajmuje

to kilka minut. Wielkość skoku zaworu (grzybka)

zostaje zapamiętana po zakończeniu procedury

samoustawienia. Aby ponownie uruchomić

procedurę samoustawienia należy zmienić

położenie przełącznika RESET (przełącznik nr 1).

Jeżeli napięcie zasilające zostanie odłączone

albo spadnie poniżej 80 % wartości nominalnej

przez okres dłuższy niż 0,1 sekundy, w pamięci

zostaje zachowane aktualne położenie zaworu

oraz wszystkie bieżące dane. Podobnie dzieje

się w przypadku wyłączenia zasilania.

SW2: 2-10 V/0-10 V ③

Nastawa fabryczna:

2-10 V.

SW3: Direct/Inverse ④

Siłownik może być ustawiony tak, aby jego

trzpień poruszał się w dół przy wzroście

wartości sygnału sterującego (DIRECT –

Zgodnie) albo w górę (INVERSE – Odwrotnie).

Nastawa fabryczn:

DIRECT (Zgodnie).

SW4: ---/Sequential ⑤

UWAGA : Ustawienie to działa w połączeniu

z ustawieniem przełącznika Nr 5:

0(2)V-5(6) V/5(6)-10 V.

SW5: 0(2)-5(6) V/5(6)-10 V ⑥

UWAGA : Funkcja ta jest dostępna po

włączeniu (ON) przełącznika Nr 4: -- -/

Sequential.

SW6: U/I ⑦

Nastawa fabryczna:

sygnał napięciowy (2-10 V).

Reset

Sterowanie ręczne.

Nie wolno używać sterowania

ręcznego, jeżeli siłownik jest pod

napięciem!

AME 130, AME 140 ❺

① Zdjąć pokrywę.

② Wsunąć klucz imbusowy 6 do otworu we

wrzecionie.

③ Podczas sterowania ręcznego kluczem

imbusowym przycisnąć i przytrzymać

przycisk znajdujący się pod spodem

siłownika.

④ Wyciągnąć klucz imbusowy.

⑤ Założyć pokrywę na siłownik.

Uwaga: „Kliknięcie” po załączeniu zasilania

elektrycznego oznacza, że koło zębate

wskoczyło w normalną pozycję roboczą.

AME 130H, AME 140H ❻

Podczas sterowania ręcznego przycisnąć

i przytrzymać przycisk znajdujący się pod

spodem siłownika ①.

Uwaga: „Kliknięcie” po załączeniu zasilania

elektrycznego oznacza, że koło zębate

wskoczyło w normalną pozycję roboczą.

Wskaźnik działania

Dioda świecąca ❹① sygnalizuje stan pracy

siłownika, jego normalne lub nieprawidłowe

działanie.

• Dioda nie świeci się

– siłownik nie pracuje lub brak zasilania.

• Dioda świeci się ciągle

– normalne działanie.

• Dioda błyska (1 Hz)

– tryb samoustawiania.

• Dioda błyska (~3 Hz)

– za niskie napięcie zasilania lub

– za krótki czas początkowego

samoustawiania spowodowany zbyt

małym skokiem zaworu (czas przejścia od

pełnego zamknięcia do pełnego otwarcia

zaworu powinien wynosić, co najmniej 12

sekund).

Wymiary ❼

Nie wolno niczego dotykać na pł ytce

drukowanej!

Przed przystąpieniem do

podłączania do siłownika

przewodów elektrycznych należy odłączyć

zasilanie sieciowe! Zagrożenie życia!

Podłączyć siłownik zgodnie z podanym

schematem.

VI.KU.M6.9O

© Danfoss | 2017.07 | 13

AME 130(H), AME 140(H)

14 | © Danfoss | 2017.07

VI.KU.M6.9O

AME 130(H), AME 140(H)

VI.KU.M6.9O

© Danfoss | 2017.07 | 15

Danf

already on order pro

All trademarks in this material are property of the respec

AME 130(H), AME 140(H)

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

16 | © Danfoss | DHS-SRMT/SI | 2017.07

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

73690990 / VI.KU.M6.9O

Loading...

Loading...