Page 1

Data sheet

Actuators for modulating control

AME 130, AME 140, AME 130H, AME 140H

DH-SMT/SI VD.KG. Z1.02 © Danfoss 06/20 06 1

Description

AME 130, AME 140, AME 130H and AME 140H

actuators are used with VZ, VZL or VRBZ valves.

The actuator can be used with fan coil units,

induction units, small reheaters, recoolers, and

zone applications in which hot/cold water is the

controlled medium.

Main data:

• Modulating control

• Force switch-off at stem down position

prevents overload of actuator and valve.

• No tools required for mounting

• Maintenance free during lifetime

• Low noise operation

• Self-positioning process

• Supplied with 1.5 m cable.

Ordering

Type

Supply

voltage

Speed Code No.

AME 130

24 V~

24 s/mm 082H8044

AME 140 12 s/mm 082H8045

AME 130H 24 s/mm 082H8046

AME 140H 12 s/mm 082H8047

Technical data

Type AME 130, AME 130H AME 140, AME 140H

Power supply 24 Vac; +10 to –15%

Power consumption 1.3 VA

Frequency 50 Hz/60 Hz

Close of force 200 N

Stroke 5.5 mm

Speed 24 s/mm 12 s/mm

Max. medium temperature inside the pipe 130 °C

Ambient temperature 0 … 55 °C

Storage and transport temperature –40 … +70 °C

Protection code IP 42

Weight 0.3 kg

- marking in accordance with standards

EMC- Directive 89/336/EEC, 92/31/EEC, 93/68/EEC,

EN 61000-6-1 and EN 61000-6-3

Spare parts

Type Code No.

Cable (5 m) 082H8053

AME 130H, AME 140H

AME 130, AME 140

Page 2

2 VD.KG. Z1.02 © Danfoss 06/20 06 DH-SMT/SI

Data sheet Actuators for modulating control AME 130, AME 140, AME 130H, AME 140H

Data sheet

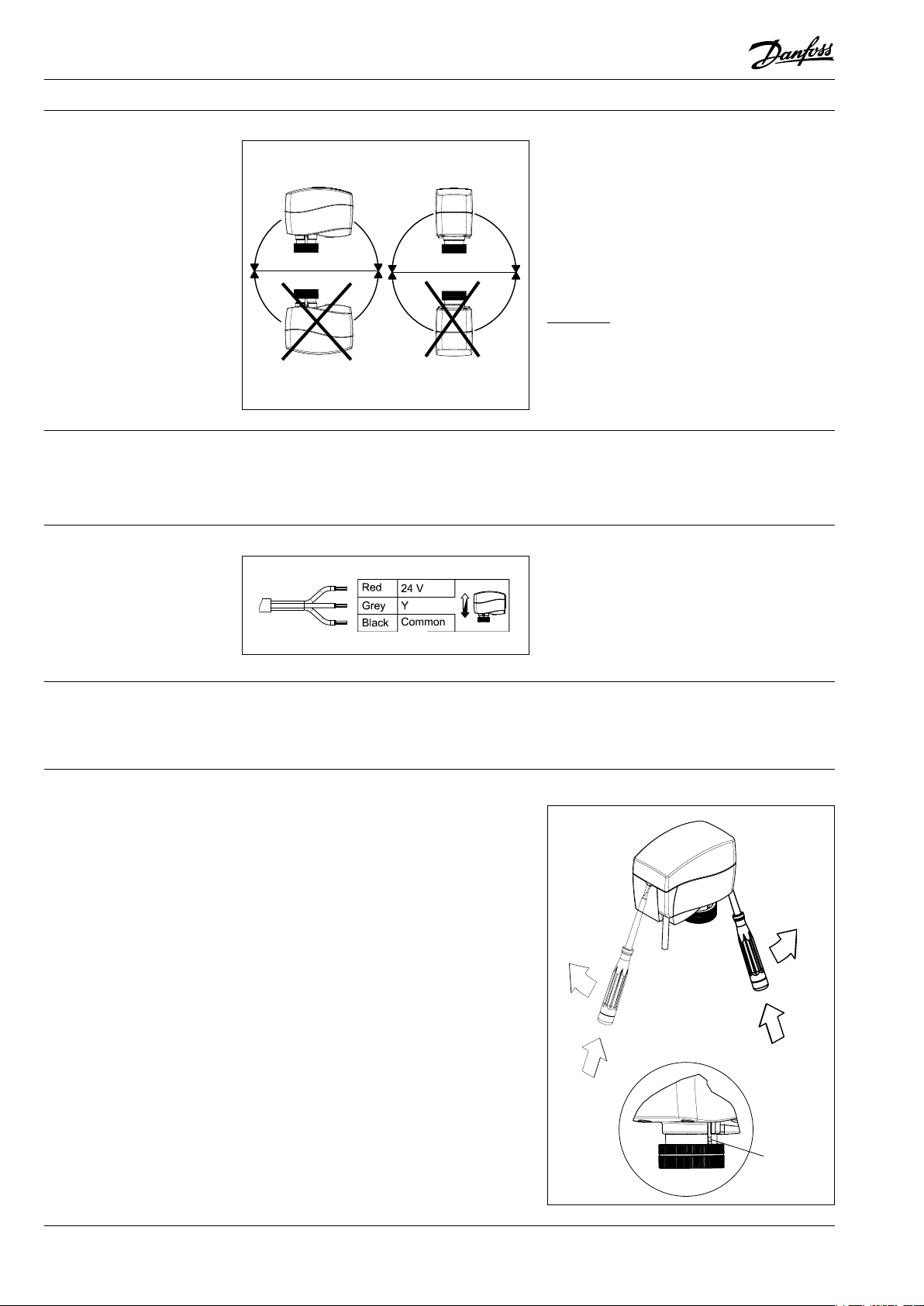

Installation

Commissioning

Mechanical

The actuator should be mounted with the valve

stem in either horizontal position or pointing

upwards.

The actuator is fixed to the valve body by means

of a mounting ring which requires no tools for

mounting. The ring should be tightened by

hand.

Electrical

Important: It is strongly recommended that the

mechanical installation is completed before the

electrical installation.

Each actuator is supplied with the connecting

cable for the controller.

The factory setting of the spindle is the fully

stem up position because of easier mechanical

connection of the actuator on the valve.

Wiring

1 Check the valve’s neck. The actuator should

be in steam up position (factory setting).

Ensure that the actuator is mounted securely

on valve body.

2 Energise the actuator according to the wiring

diagram - see page 2.

3 The direction of stem movement can be

observed on the positon indicator.

Installation procedure

Disposal The actuator must be dismantled and the

elements sorted into various material groups

before disposal.

position

indicator

Page 3

DH-SMT/SI VD.KG. Z1.02 © Danfoss 06/20 06 3

Data sheet Actuators for modulating control AME 130, AME 140, AME 130H, AME 140H

DIP Switch Setting

(for service purposes only)

The actuator has a function selection DIP switch

under the removable cover.

The switch provides the following functions:

• SW1:

Reset

Changing this switch position will cause the

actuator to go through a self stroking cycle.

• SW2:

0/2 - Input signal range selector

If set to OFF position, the input signal is in the

range from 2 V … 10 V (voltage input) or from

4 mA … 20 mA (current input). If set to ON

position, the input signal is in the range from

0 V … 10 V (voltage input) or from

0 mA … 20 mA (current input).

• SW3:

D/I - Direct or inverse acting selector

If set to OFF position, the actuator is direct

acting (stem lowers as voltage increases). If

the actuator is set to ON position, the actuator

is inverse acting (stem raises as voltage

increases).

• SW4:

---/Seq - Normal or sequential mode

selector:

If set to OFF position, the actuator is working

in range 0(2)..10V or 0(4)..20mA. If set to ON

position, the actuator is working in sequential

range; 0(2)..5 (6)V or (0(4)..10 (12)mA) or

(5(6)..10V) or (10(12)..20mA).

• SW5:

0 … 5 V/5 … 10 V - Input signal range in

sequential mode:

If set to OFF position, the actuator is working

in sequential range 0(2)..5 (6)V or 0(4)..10 (12)mA.

If set to ON position, the actuator is working

in sequential range; 5(6)..10V or 10(12)..20mA.

• SW6:

U/I - Input signal type selector

If set to OFF position, voltage input is

selected. If set to ON position, current input is

selected.

Manual override

(for service purposes only)

AME 130, AME 140

1 Remove the cover.

2 Insert the Allen key 6 into the spindle.

3 Press and hold the button (on the bottom

side of the actuator) during manual override.

4 Pull out the tool.

5 Place cover back on the actuator.

Caution:

Do not manually operate the

drive under power!

Remark:

A ”click” sound after energizing the actuator

means that the gear wheel has jumped into

normal position.

If manual override has been used, then Y

signal is not correct until the actuator reaches

it’s end position. If this is not accepted, reset

the actuator.

push

Page 4

4 VD.KG. Z1.02 © Danfoss 06/20 06 DH-SMT/SI

Data sheet Actuators for modulating control AME 130, AME 140, AME 130H, AME 140H

AME 130H, AME 140H

1 Press and hold the button (on the bottom

side of the actuator) during manual override.

Remark:

A ”click” sound after energizing the actuator

means that the gear wheel has jumped into

normal position.

Manual override (continuous)

AME 130(H) / 140(H) +

VZ 3, VZL 3

AME 130(H) / 140(H) +

VZ 4, VZL 4

AME 130(H) / 140(H) +

VZ 2, VZL 2

AME 130(H) / 140(H) +

VRBZ 2/3

Dimensions

AME 130, AME 140 AME 130H, AME 140H

Actuator - valve

combinations

Loading...

Loading...