Data sheet

Actuators for modulating control

AME 113 NL SU/SD - with safety function (stem up/down)

AME 113 NLX SU/SD - with feedback signal and safety function

Description

AME 113 is a series of gear actuators for opening

and closing valves for heating and cooling

systems. The predominant area of application

is the energy-efficient control of water-bearing

valves in the area of building services and

automation.

Features • Suitable for AC and DC operation

• Internal energy storage for the safety

function. Positioning in case of supply voltage

failure

• Stroke 8.5 mm or valve path recognition

• Actuating force 125 N

• LC display for status indication

• Function display via LED

• Equal percentage characteristic

• Very fine resolution in valve positioning

• Very short response times

• Max. energy efficiency by means of motor

control via microcontroller

• Self-locking gear in all positions, de-energized

• Antitheft device by removable locking latch

• Special feature for NLX version is feedback signal

• Safety function in case of power failure

The actuator is equipped with a safety function.

If the power supply fails, the valve pressure

plate moves into a parking position. The energy

for this is provided by an internal rechargeable

accumulator.

The actuator has an equal percentage

characteristic, meaning the flow through the

valve is equal percentage to the control signal.

The control is performed by a 0-10 V DC control

signal sent by a central DDC system or a room

thermostat. The current position and the control

voltage are shown on an LC display.

The actuator is supplied with a pluggable

connecting cable and has a manual valve

adjustment which can be used, for example, for

maintenance or installation.

A version with feedback signal is available. The

back channel transmits information about the

current valve position as well as about possibly

occurred errors to the DDC installation.

• Force-dependent deactivation in case of

overload or when the final stop resp. the

closing position is reached

• Manual valve setting

• Very low power consumption

• Valve adapter system

• Simple plug-in installation without tools

• 100 % protection in case of leaky valves (IP 54)

• 360° installation position

• Plug-in connecting cable

• Low-noise and maintenance-free

• High functional safety and long expected

service life

• Control input suitable for 0-10 V

• Automatic valve path recognition / no load

detection

© Danfoss | 2021.08 AI391040222855en-010101 | 1

Data sheet AME 113

Typ e AME 113 NLX SD AME 113 NLX SU AME 113 NL SD AME 113 NL SU

Operating voltage 24 V AC, -10 % ... +20 %, 50-60 Hz 24 V DC, -20 % ... +20 %

Operating power 2.6 VA/ 1.4 W

Charging operating power with battery

(temporarily)

Safety activations / Tag 4

Charging time of int. battery, if empty 16 h

Max. power consumption <160 mA

Standby power consumption <10 mA

Control voltage 0...10 V DC

Working range of the control voltage 0.5...10 V DC

Resistance of control voltage input 100 kΩ

Stroke Max. 8. 5 mm

Actuation force 125 N -20/+40%

Actuation time 15 s/mm

Noise level <30dB/A

LCD (H x W) 10 x 20 mm

LED Multicolour LED

Fluid temperature 0 °C to +100 °C

Storage temperature -20 °C to +70 °C

Characteristic Equal percentage

Ambient temperature 0 °C to +50 °C

Degree of protection IP 54

Protection class III

CE conformity according to EN 60730

Casing

Casing cover

Cable

Dimensions (H x W x D) 65 x 45 x 90 mm

Weight with connection cable (1 m) 155 g

Surge strength according to EN 60730-1 1 kV

Safety function Yes (do wn) Yes (up) Yes (do wn) Yes (up)

Power failure response

Feedback Signal:

1)

In all install ation positions.

Material Polyamide

Colour Signal white (RAL 9003)

Material (polycarbonate)

Colour Transparent

Typ e 4 x 0.22 mm² PVC 3 x 0.22 mm² PVC

Colour white

Length 1 m

Safety function extends the

stem, closes the AB- QM valve

Voltage range 0 - 10 V Output current 1 mA Load impedance 10 kΩ - 1000 kΩ Resolution 0.1 V -

Safety function retrac ts the

stem, opens the AB- QM valve

3.1 VA/ 1.7 W

1)

Safety function extends the

stem, closes the AB- QM valve

Safety function retrac ts the

stem, opens the AB- QM valve

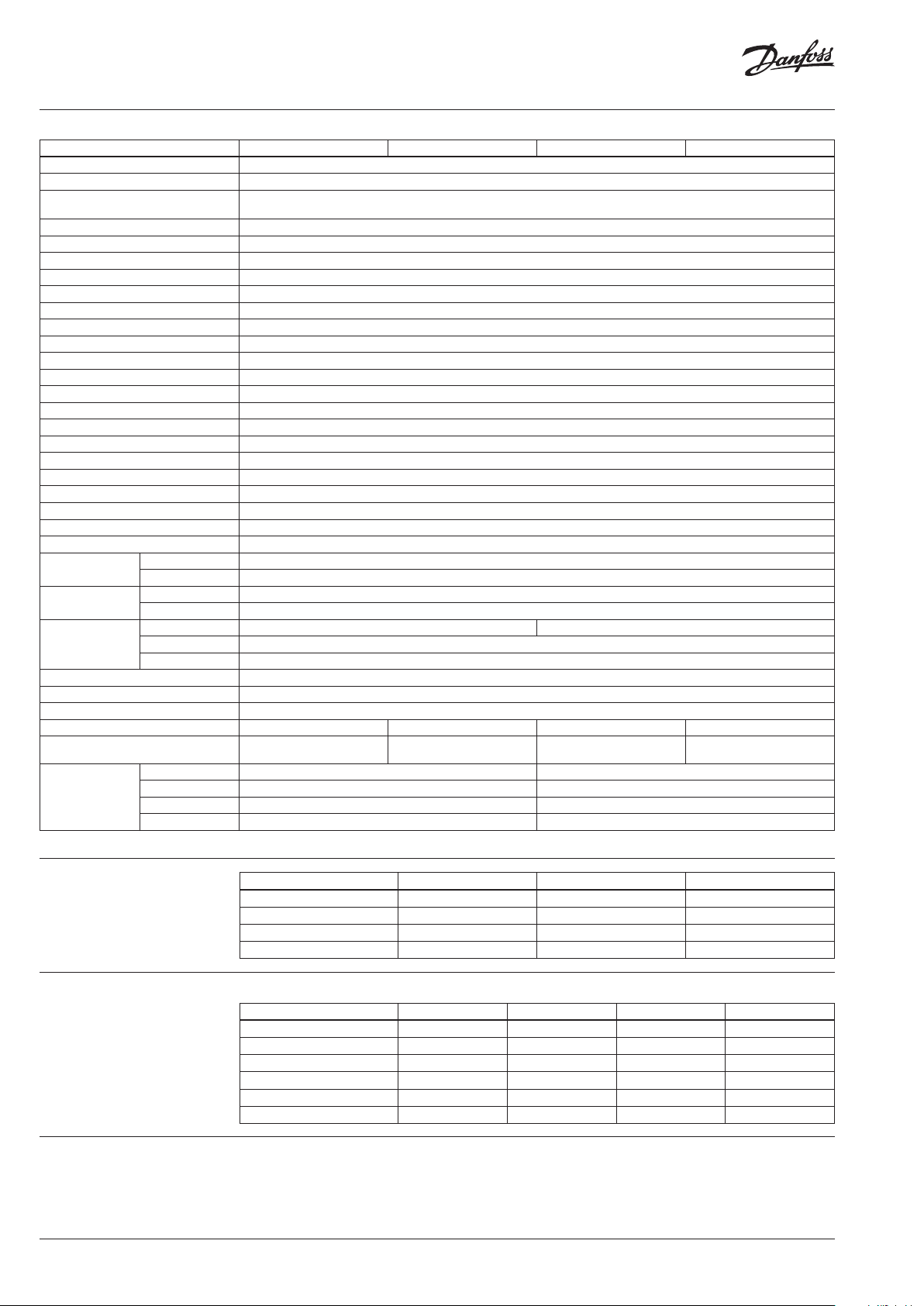

Ordering

Variation

Function

The actuator is available in various versions which differ in their functional features:

LC display

Function display via LED

Valve path recognition

Feedback signal

Manual setting

Safety function display via LED

The actuator mechanism works with a stop motor, a micro controller and a gearing mechanism. After

Typ e Supply voltage Feedback Code no.

AME 113 NLX SD 24 V- AC / DC 0 -10 V 082H5000

AME 113 NLX SU 24 V- AC / DC 0 -10 V 082H5001

AME 113 NL SD 24 V- AC / DC - 082H5007M

AME 113 NL SU 24 V- AC / DC - 082H5008

AME 113 NLX SD AME 113 NLX SU AME 113 NL SD AME 113 NL SU

✓ ✓ ✓ ✓

✓ ✓ ✓ ✓

✓ ✓ ✓ ✓

✓ ✓

✓ ✓ ✓ ✓

✓ ✓ ✓ ✓

switching on the power supply, the actuator carries out an initialization. In the initialization phase, the

traverse path is determined; in the display, alternately “In” (for initialization) and the applied control

voltage are shown. For further descriptions on initialization, refer to the chapter on the actuator.

2 | AI391040222855en-010101 © Danfoss | 2021.08

Data sheet AME 113

valve travel = 100 %

MPR 46845

actuator travel in %

Control

Initialization

Operation

First the valve pressure plate is completely

retracted; the upper end stop of the actuator

is determined by this. The valve pressure plate

then extends completely and determines the

lower end stop, the closing point of the valve.

Subsequently the actual valve path recognition

is performed. For this, the valve pressure plate

retracts at high speed and extends again slowly.

The valve travel is detected during this process.

If the actuator does not detect the valve path,

control is performed using the parameterized

stroke (factory setting: 8.5 mm).

The AME 113 actuator is controlled via a 0-10 V

DC control signal from a room thermostat or a

building management system. The control signal

allows a precise activation and positioning of the

actuator.

Note:

1. For poppet valves with a soft rubber seal, the

compression of the rubber seal is detected as

the valve path.

2. The following diagrams only apply when the

appropriate valve adapter ring is used:

Due to different conditions, the valve travel

for the actuator can change in practice. The

valve has been readjusted or the actuator has

been mounted on a new valve. In both cases,

the values determined during initialization will

change. In order for the actuator to adjust to

the new valve path, the voltage supply and the

control voltage must be interrupted briefly. After

the power supply has been switched on again, a

new initialization phase is carried out.

Note:

The AME 113 needs a maximum of 15 min for an

initialization phase.

100

0

12345678910

UST in V

active voltage control range

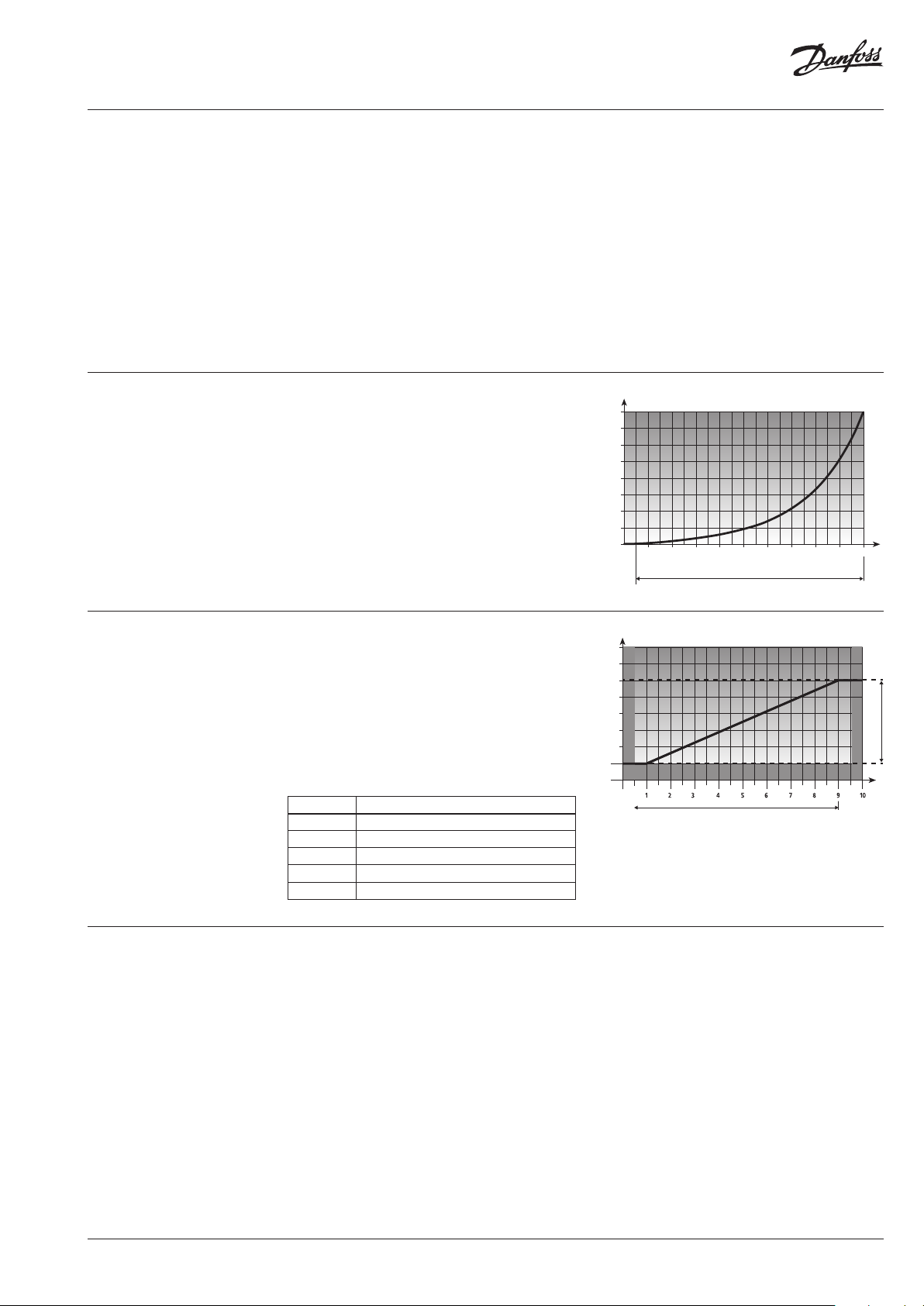

Optional feedback signal

(AME 113 NLX)

The 0-10 V feedback signal of the actuator

enables direct feedback of the current operating

status to the DDC system. Voltages of 1-9 V

provide information about the actuator position.

Voltages <0.5 V and >9.5 V signal any errors

that may occur. The connection of the feedback

signal is volt-age resistant up to 24 V. It outputs

a voltage proportional to the actuator position,

contact error

Stroke in %

actuator error

which is made available to the DDC system.

Safety function

Voltage Description

< 0.5 V No function or no contacting

1-9 V Voltage emitted proportionally to the stroke

1 V Corresponds to a closed valve

9 V Corresponds to an open valve

>9.5 V Internal error

The electronic system of the actuator

continuously monitors the supply voltage. If this

fails for >= 2 seconds, the valve spindle moves

to the specified parking position and closes e. g.

In the event of a power failure during the

initialization phase, the drive stops the

initialization and then moves to the parking

position.

U

the valve. The actuator remains in this parking

position until an operating voltage is applied

again.

• The internal energy storage may only have a small residual charge after longer storage.

• The internal energy storage is designed for at least 4 power failures per day.

• The charging time for a completely empty energy storage is 16 hours.

• When the operating voltage is applied to the failsafe drive again, it starts initialization, see

paragraph Initialization.

• A short start-up can trigger a failsafe event. The valve pressure plate extends and the actuator can

no longer be mounted. In this case, retract the valve pressure plate manually. See paragraph Manual

valve setting.

• Perform the commissioning of the valve.

AI391040222855en-010101 | 3© Danfoss | 2021.08

Data sheet AME 113

5

Function display via LED

Manual valve setting

IP 54

For function signalling of operating statuses, the actuator has two multi-coloured LEDs. Green and

red are used as signal colours.

LED 1

LED 2

55%55%

LED 1 Description

Green (flashes) Initialisation

Red Error1

LED 2 Description

Green (flashes)

Green Device ready

Orange

Red Error1

Failsafe operation, parking

position is approached

Ready for operation, battery

is charging

The manual valve setting allows to bring the valve pressure plate to the desired position in deenergised status. This facilitates e. g. maintenance and installation.

4

Remove the

protective plug and

the connection line,

or switch off the

voltage supply.

LC display

Dimensions

Introduce a

screwdriver (0.3 x 2

mm) into the manual

valve setting device.

When turning to

the right, the valve

pressure plate is

retracted; turning to

the left extracts it.

Note: When the stop

is reached, turn back

by 1/4.

Note

Pull the plug for manual setting. Then wait for

the fail-safe function to end until LED 2 (green)

goes out. See also the chapter “Function

display via LED”.

The LC display alternatively shows the setting

position and the applied control voltage. In case

of a control requirement, the current driving

direction is shown in the LC display by means of

an arrow. In case of an error, the corresponding

error code is shown and the error is indicated by

a steadily lighted LED.

Remove the

screwdriver after

reaching the desired

Install the protective

plug and connect the

connection line.

position.

1)

In case of erro r: Disconnect from voltag e, keep voltage free for

20 minutes and the n reconnect. If this occurs m ore than once,

replace the device.

55%

4 | AI391040222855en-010101 © Danfoss | 2021.08

Data sheet AME 113

4

Electrical connection 24 V

AC/DC L1 (+) L2 (-)

Installation position

AME 11 3

The actuator is controlled via a 0-10 V control unit

or a building management system.

The actuator can be operated in any installation position.

Connection line

We recommend the following maximum

cable lengths for installing a 24 V system:

Cable Section Length

Standard DDC

line

J-Y(ST )Y 0.8 mm² 45 m

NYM / NYIF 1.5 mm ² 136 m

0.22 mm² 20 m

Transformer/power supply unit:

A safety isolating transformer according to

EN 61558-2-6 or a switching power supply

according to EN 61558-2-16 must always be

used.

The dimensioning of the transformer or the

switching power supply results from the

maximum making capacity of the actuators.

Installation with valve

adapter

Note:

The AME 113 needs a

maximum of 15 min for an

initialization phase.

vertical horizontal “overhead”

ATTENTION!

Installation with extracted valve pressure plate

leads to actuator damage.

• Only install the actuator with completely

retracted valve pressure plate.

• Retract an extracted valve pressure plate with

the manual valve setting, or electrically.

Screw the valve

adapter manually

onto the valve.

Position the actuator

manually in vertical

position to the valve

adapter.

The actuator is mounted on the valve using a

valve adapter. The actuator is simply plugged

onto the valve adapter previously installed

manually. The fact that the valve pressure plate is

retracted in factory, allows for easy installation.

Simply latch the

actuator to the valve

Connect the connection

line to the actuator.

adapter manually

by applying vertical

pressure; a clicking

sound can be heard.

AI391040222855en-010101 | 5© Danfoss | 2021.08

Data sheet AME 113

Error codes

Anti-theft device

Certificates

Queued errors are indicated by an error code.

Error code Description Error correction

E8 Indicates an internal error.

The actuator is secured against disassembly by

unauthorised persons by simply removing the

locking button.

The AME 113 has NRTL approval by

TÜV Süd.

The actuator performs a re-initialisation

after 10 seconds. If the error cannot

be eliminated automatically after

a maximum of three attempts, the

indication will become steady. In this

case the customer ser vice must be

called.

ІМПОРТЕР:

UA: ТОВ з ІІ «Данфосс ТОВ», вул. Вікентія Хвойки, 15/15/6, м. Київ, 04080, Україна

© Danfoss | DCS-S/SI | 2021.086 | AI391040222855en-010101

Loading...

Loading...