Data sheet

Actuators for modulating control

AME 110NLX - with position feedback signal

Description

Ordering

The actuator can be used with fan coil units,

induction units, small reheaters, recoolers and

zone applications in which hot/cold water is the

controlled medium.

Main data:

• Position feedback or output signal

(X=0-10 VDC)

• Gap detection at stem up position

• Modulating control

• Force switch-off at stem down position

prevents overload of actuator and valve.

• No tools required for mounting

• Maintenance-free lifetime

• Low-noise operation

• Self-positioning process

The actuators are used together with

• Halogen free cables

automatically balanced combination valve type

AB-QM for DN 10 to DN 32.

Typ e Supply voltage Speed Cable length Code No.

1,5 m 082H8060

AME 110 NLX 24 V~ 24 s/mm

Note: Package of actu ators is Single Pack - each actua tor is packed in separate box.

5,0 m 082H8062

10 m 082H8064

Technical data

© Danfoss | 2019.05

Power supply V 24 ±20 %; AC

Power consumption

Frequency Hz 50/60

Control input Y

Control output X V 0-10 R o

Closing force N 130

Stroke mm 5

Speed s/mm 24

Max. medium temperature

Ambient temperature 0 … 55

Storage and transport temperature –40 … 70

Ambient humidity 95% r.h., non-condensing

Protection class III safet y extra-low voltage

Grade of enclosure IP 42

Weight 0,3 kg

- marking in accordance with standards

running VA 1,5

standby W 0,4

V 0-10 (2-10) Ri = 200 kΩ

mA 0-20 (4-20) Ri = 500 Ω

(min)

120

°C

Low Voltage Directive 2014/35/EU, EN 60730-1:2011, EN 60730 -2-14:1997 +

A1:2001 + A11:2005 + A2:2008

EMC Directive 2014/30/EU, EN 61000-6-2:2005, EN61000 -6-3:2007 + A1:2011

= 38 kΩ

VD.HU.M3.02 | 1

Data sheet AME 110NLX

Installation

Installation procedure

Mechanical

The actuator should be mounted with the valve

stem in either horizontal position or pointing

upwards.

The actuator is fixed to the valve body by means

of a mounting ring, which requires no tools for

mounting. The ring should be tightened by

hand.

Electrical

Important: It is strongly recommended that the

mechanical installation is completed before the

electrical installation.

Auto sleep mode

1. If actuator AME 110NLX is charged by 24 V

supply voltage and if it is not installed on

AB-QM valve, it will stop in lower position and

switch off all LED indicators after 5 minutes.

2. It is mandatory to drive the spindle of the

actuator to upper position before it will be

installed on AB-QM valve (please refer to

manual override drawings)!

3. Auto sleep mode switches back to learning

mode by pressing RESET button or by cycling

power supply.

Each actuator is supplied with the connecting

cable for the controller.

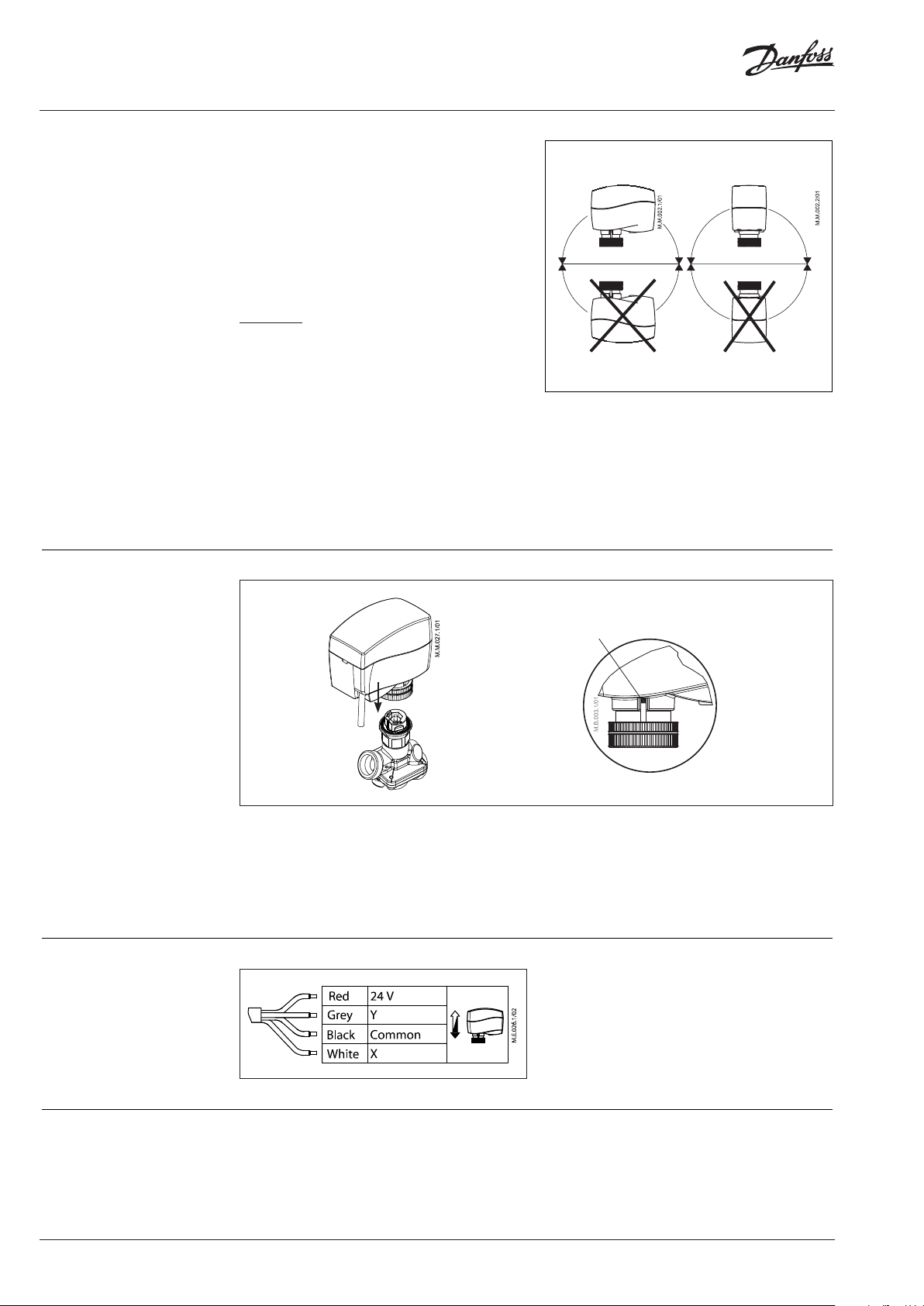

Wiring

1. Check the valve neck. The actuator should be

in stem up position (factory setting).

Ensure that the actuator is mounted securely

on the valve body

position

indicator

2. Wire the actuator according to the

wiring diagram

3. The direction of the stem movement can be

observed on the position indicator

Commissioning

2 | © Danfoss | 2019.05

The factory setting of the spindle is the fully

stem up position because of easier mechanical

connection of the actuator on the valve.

VD.HU.M3.02

Data sheet AME 110NLX

DIP Switch Setting

(for service purposes only)

The actuator has a function selection DIP switch

under the removable cover.

The switch provides the following functions:

• SW1:

0/2 - Input signal range selector

If set to OFF position, the input signal is in the

range from 2-10 V (voltage input) or

from 4-20 mA (current input).

If set to ON position, the input signal is in the

range from 0-10 V (voltage input) or from

0-20 mA (current input).

• SW2:

D/I - Direct or inverse acting selector

If set to OFF position, the actuator is direct

acting (stem contracts as voltage increases). If

the actuator is set to ON position, the actuator

is inverse acting (stem extracts as voltage

increases).

• SW3:

---/Seq - Normal or sequential mode

selector:

If set to OFF position, the actuator is working

in range 0(2)-10 V or 0(4)-20 mA.

If set to ON position, the actuator is working

in sequential range; 0(2)-5(6) V or (0(4)-10(12)

mA) or (5(6)-10 V) or (10(12)-20 mA).

• SW4:

0-5 V/5-10 V - Input signal range in

sequential mode:

If set to OFF position, the actuator is working

in sequential range 0(2)-5(6) V or 0(4)-10(12) mA.

If set to ON position, the actuator is working

in sequential range; 5(6)-10 V or 10(12)-20 mA.

• SW5:

LIN/LOG - Linear or equal percentage flow

through valve selector

If set to OFF position, the flow through the

valve is equal percentage-wise equals the

control signal.

If set to ON position, the flow through the

valve is linear in accordance to the control

signal.

• SW6:

---/ASTK - Anti-blocking function

Exercises the valve to avoid blocking in

periods when the heating/cooling is off.

If set to ON position (ASTK), the valve motion

is switched on. The actuator opens and closes

the valve every 7 days.

If set to OFF position (---), the function is

disabled.

• SW7:

U/I - Input signal type selector

If set to OFF position, voltage input is

selected. If set to ON position, current input is

selected.

Note:

The reset but ton ① will cause the actuator to g o through a self

stroking c ycle (press it for 2 s).

Remark:

When the manua l override has been used, the o utput signal (X) is

not correct unti l the actuator reaches its e nd position.

0-10 V

INV

SEQ

5-10 V

LOG

ASTX

I

ON

OFF

---

DIR

2-10 V

U

---

LIN

0-5 V

Disposal The actuator must be dismantled and the

elements sorted into various material groups

before disposal.

Reset

①

VD.HU.M3.02

© Danfoss | 2019.05 | 3

Danf

already on order pro

All trademarks in this material are property of the respec

Data sheet AME 110NLX

Manual override (for service purposes only)

①

④

Caution:

Do not manually operate the

drive if power is connected!

Do not dismount the actuator

from the valve when it is in a

stem down position!

If dismounted in a stem down

position, there is a high risk

that the actuator gets stuck.

②

⑤

• Remove cover ①

• Press and hold the button ② (on the

bottom side of the actuator) during manual

override ③

• Replace cover ④

• Install actuator on valve ⑤

③

Remark:

A ‘click’ sound after energising the actuator

indicates that the gear wheel has jumped into

normal position.

If manual override has been used, the Y

signal will not be correct until the actuator

has reached its end position. If this is not

accepted, reset the actuator.

Dimensions

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

4 | © Danfoss | DHS-SRMT/SI | 2019.05

92

68

88

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

50

VD.HU.M3.02

Loading...

Loading...