Page 1

Data sheet

Actuators for modulating control

AME 01, AME-H 01, AME 02, AME-H 02

Description

AME 01, AME 02

AME 01, AME 02, AME-H 01 and AME-H 02

actuators are used with VZ, VZL, VRBZ or with

AB-QM valves (AME version only). The actuator

can be used with fan coil units, induction units,

small reheaters, recoolers, and zone applications

in which hot/cold water is the controlled

medium.

Main data:

• Proportional version

• The advanced design incorporates no-force

switch-off at stem up position, which enables

use of the actuator on valves with different

nominal strokes and improves the controller

response.

• Force switch-off at stem down position

prevents overload of actuator and valve.

• No tools required for mounting

• Maintenance free during the lifetime

• Low noise operation

• Exercise cycle

• Supplied with 1.5 m cable.

AME-H 01, AME-H 02

Ordering

Technical data

Type

AME 01

AME 02 12 s/mm 082H8006

AME-H 01 24 s/mm 082H8023

AME-H 02 12 s/mm 082H8026

Type AME 01, AME-H 01 AME 02, AME-H 02

Power supply 24 Vac; +10 to –15%

Power consumption 3 VA

Frequency 50 Hz/60 Hz

Close of force 200 N

Max. stroke 5.5 mm

Speed 24 s/mm 12 s/mm

Max. medium temperature inside the pipe 120 °C

Ambient temperature 0 to 55 °C

Storage and transport temperature –40 to +70 °C

Protection code IP 42

Weight 0.34 kg

Supply

voltage

24 V~

- marking in accordance with standards

Speed Code No.

24 s/mm 082H8003

Spare parts

Type Code No.

1.5 m cable for AME, AME-H - 24 V 082H8009

EMC- Directive 89/336/EEC, 92/31/EEC, 93/68/EEC,

EN 50081-1 and EN 50082-1

SIBC VD.JC.N2.02 © Danfoss 08/05 1

Page 2

Data sheet Actuators for modulating control AME 01, AME-H 01, AME 02, AME-H 02

Installation

Disposal The actuator must be dismantled and the

elements sorted into various material groups

before disposal.

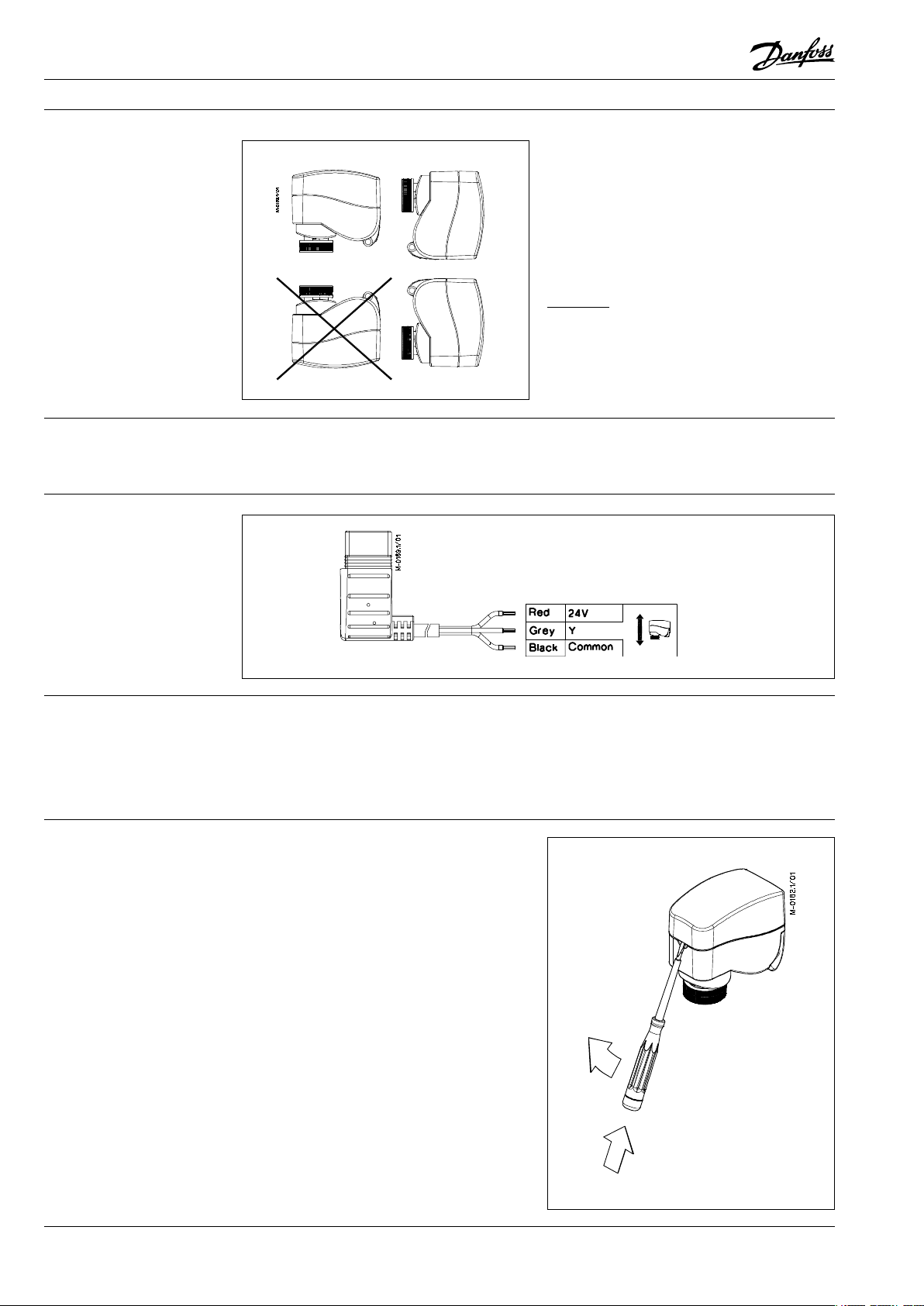

Wiring

Mechanical

The actuator should be mounted with the valve

stem in either horizontal position or pointing

upwards.

The actuator is fixed to the valve body by means

of a mounting ring which requires no tools for

mounting. The ring should be tightened by hand.

Electrical

Important: It is strongly recommended that the

mechanical installation is completed before the

electrical installation.

Each actuator is supplied with the connecting

cable for the controller.

Commissioning

Installation procedure

All actuators are factory tested prior to shipment.

The factory setting of the spindle is the fully

stem up position because of easier mechanical

connection of actuator on valve.

1 Check the valve seat. Ensure that the actuator

is mounted securely on valve body. Before

applying power to the actuator, check for

mechanical obstructions.

2 Ensure that the actuator is electrically isolated.

Remove the cover to set DIP switches (if

required only). See DIP switch settings (page

3) for details. Replace the cover and than

energize the actuator (24 Vac).

3 The load sensitive mechanism requires a

resistance, which is supplied by the valve,

therefore power should not be applied prior

to mounting on the valve. When power is

first applied the actuator begins with the

self-commissioning cycle. At first the actuator

will make a clicking sound. This is normal

and indicates that the actuator's no load

sensor is working properly. After a couple

of seconds this sound will cease. The whole

commisioning cycle will last approximately

6 min (AME 01, AME-H 01) or 3 min (AME 02,

AME-H 02).

Important: Uninstalled actuator will operate

properly only in stem down direction!

If uninstalled actuator is tested than use the Allen

key size 4 mm (or knob for AME-H version) in

order to drive actuator on it's top position.

2 VD.JC.N2.02 © Danfoss 08/05 SIBC

Page 3

Data sheet Actuators for modulating control AME 01, AME-H 01, AME 02, AME-H 02

DIP Switch Setting • SW5: Exercise cycle: If set to ON position,

The actuator has a function selection DIP switch

under the removable cover. In particular, if SW5 is

set to ON, the actuator will perform an automatic

stroke calibration cycle at power on and every

24 hours. The switch provides the following

the actuator performs one complete exercise

cycle every 24 hours to clear possible

accumulation of impurities from the valve

plug and seat and recalibrate the stroke.

functions:

• SW1: U/I - Input signal type selector: If set to

OFF position, voltage input is selected. If set

to ON position, current input is selected.

• SW2: 0/2 - Input signal range selector: If

set to OFF position, the input signal is in the

range from 0 V to 10 V (voltage input) or from

0 mA to 20 mA (current input). If set to ON

position, the input signal is in the range from

2 V to 10 V (voltage input) or from 4 mA to 20

mA (current input).

• SW3: D/I - Direct or inverse acting selector:

If set to OFF position, the actuator is direct

acting (stem lowers as voltage increases).

If set to ON position the actuator is inverse

acting (stem raises as voltage increases).

• SW4: Reset: Changing this switch position

will cause the actuator to go through a self

stroking cycle.

Manual override AME 01, AME 02

1 Remove the small soft plug from the lid.

2 Insert the Allen key size 4 mm into the

opening.

Caution:

Do not manually operate the

drive under the power!

3 Operate the drive manually in the desired

direction.

4 Pull out the key and insert the small soft plug

back.

If manual override has been used than Y signal

is not correct until the actuator reaches it's

end position. If this is not accepted reset the

actuator.

stem up

stem down

SIBC VD.JC.N2.02 © Danfoss 08/05 3

Page 4

Data sheet Actuators for modulating control AME 01, AME-H 01, AME 02, AME-H 02

a b

c

cable

release

slot

mounting

ring

M-diskon/01

Manual override

AME-H 01, AME-H 02

The position indicator is factory calibrated, but if

you need to make incication more precise or have

moved the knob while the actuator is removed

from the valve, then the following advice applies:

1 Energize the actuator with a signal to drive the

stem up (with the actuator fitted to the valve).

2 When it stops, rotate the position indicator

ring while pressing the setting lever , to

the position where the orienting groove

points to the minus sign (-). The knob

should not be turned in this case.

3 Energize the actuator with a signal to drive the

stem down.

Knob

Position indicator ring

Minus sign

Orienting groove

Setting lever

Disconnecting the cable

from the actuator

To disconnect the cable, first ensure that

the actuator is electrically isolated. Insert a

screwdriver into the cable release slot, push the

handle away from the mounting ring, and pull

the connector out of the actuator by hand.

4 VD.JC.N2.02 © Danfoss 08/05 SIBC

Page 5

88

49

83

76

77

M-dimenzije/01

Data sheet Actuators for modulating control AME 01, AME-H 01, AME 02, AME-H 02

Dimensions

AME 01, AME 02

AME-H 01, AME-H 02

Actuator - valve combinations

AME (-H) 01 / 02 +

VZ 2, VZL 2

AME(-H) 01 / 02 +

VZ 3, VZL 3

AME(-H) / 02 +

VZ 4, VZL 4

AME(-H) 01 / 02 +

VRBZ 2/3

AME 01 / 02 +

AB-QM

5 VD.JC.N2.02 © Danfoss 08/05 SIBC

Page 6

Data sheet Actuators for modulating control AME 01, AME-H 01, AME 02, AME-H 02

6 VD.JC.N2.02 © Danfoss 08/05 SIBC

Loading...

Loading...