Fact sheet

Akva Vita II

Instantaneous water heater for single-family houses and flats

Application

The Akva Vita II is an instantaneous water

heater featuring high performance and

simple operation. It is especially suitable for

single-family houses and for systems with a

similar domestic hot water requirement.

The Akva Vita II can be used directly on district heating networks with a differential

pressure of max. 2.5 bar.

Construction

The Akva Vita II water heater is prefabricated with a brazed, highly efficient Danfoss

plate heat exchanger for domestic hot water production, a domestic hot water controller Danfoss PM2+P, as well as a Danfoss

FJVR thermostat for control of the bypass/

circulation temperature. All pipes are made

of stainless steel and the connections are

made by nuts and gaskets. As an option and

if approved by local regulations the water

heater can be supplied with a Danfoss AVE

expansion unit to avoid having to establish

a discharge pipe.

Design

The Akva Vita II is designed for wall-mounting and the design emphasizes a user-friendly placement of the controllers. The Akva

Vita II can be supplied with a brushed or white-lacquered stainless steel cover in an elegant and modern design.

Bypass (thermostatic circulation)

The water heater is supplied with a thermostatically controlled bypass, which ensu

res that hot water is produced immediately,

when tapping starts. The bypass temperature is set with due consideration of the best

possible DHW comfort and economy.

Domestic hot water circulation

The water heater is prepared for domestic

hot water circulation. If the household piping includes hot water recirculation the

water heater must be connected to the hot

water recirculation system and a circulation pump and a non-return valve must be

mounted on the circulation pipe and a safety valve must be mounted in the DCW inlet. The pump must be installed so that it

pumps towards the water heater. Domestic

hot water circulation ensures that hot water

is available at the tapping point without waiting time and waste of water. The circulation temperature is set independently of the

set DHW temperature. This ensures the best

possible DHW comfort, very low standby

losses and thus a very good district heating

economy. Please note that Akva Vita II with

AVE expansion unit should not be used on

systems with domestic hot water recirculation.

Heat exchanger for DHW heating

The water heater is based on a brazed, highly

efficient plate heat exchanger type XB 06H-1

26, which is controlled by a pressure controlled DHW controller, Danfoss PM+P with integrated differential pressure controller and

e

save

exchanger is cold during standby. After

function, which ensures that the heat

TM

completion of the tapping process, the controller immediately blocks the district heating flow, to avoid standby losses and to

protect the heat exchanger from the formation of lime scale and growth of bacteria.

The heat exchanger is cold during standby,

so the heat loss is very low. The integrated

differential pressure controller compensates

for variations in supply temperature and varying differential pressure and thereby ensures a constant hot water temperature at

all times.

Service and maintenance

The water heater is very service-friendly and

easy to install. It is mounted on the wall and

as all pipes are placed in pipe bracket distance, it is possible to establish a nice piping.

FEATURES AND BENEFITS

• COLD heat exchanger during standby, no standby losses

• DHW controller PM2+P with integrated

differential pressure controller and energy- saving function

• Pipes and heat exchanger made of

stainless steeel, connections with EPDM

gaskets

• Minimized risk of lime scale and bacteria

formation, no Legionella

• Capacity: 35 kW

www.danfoss.com

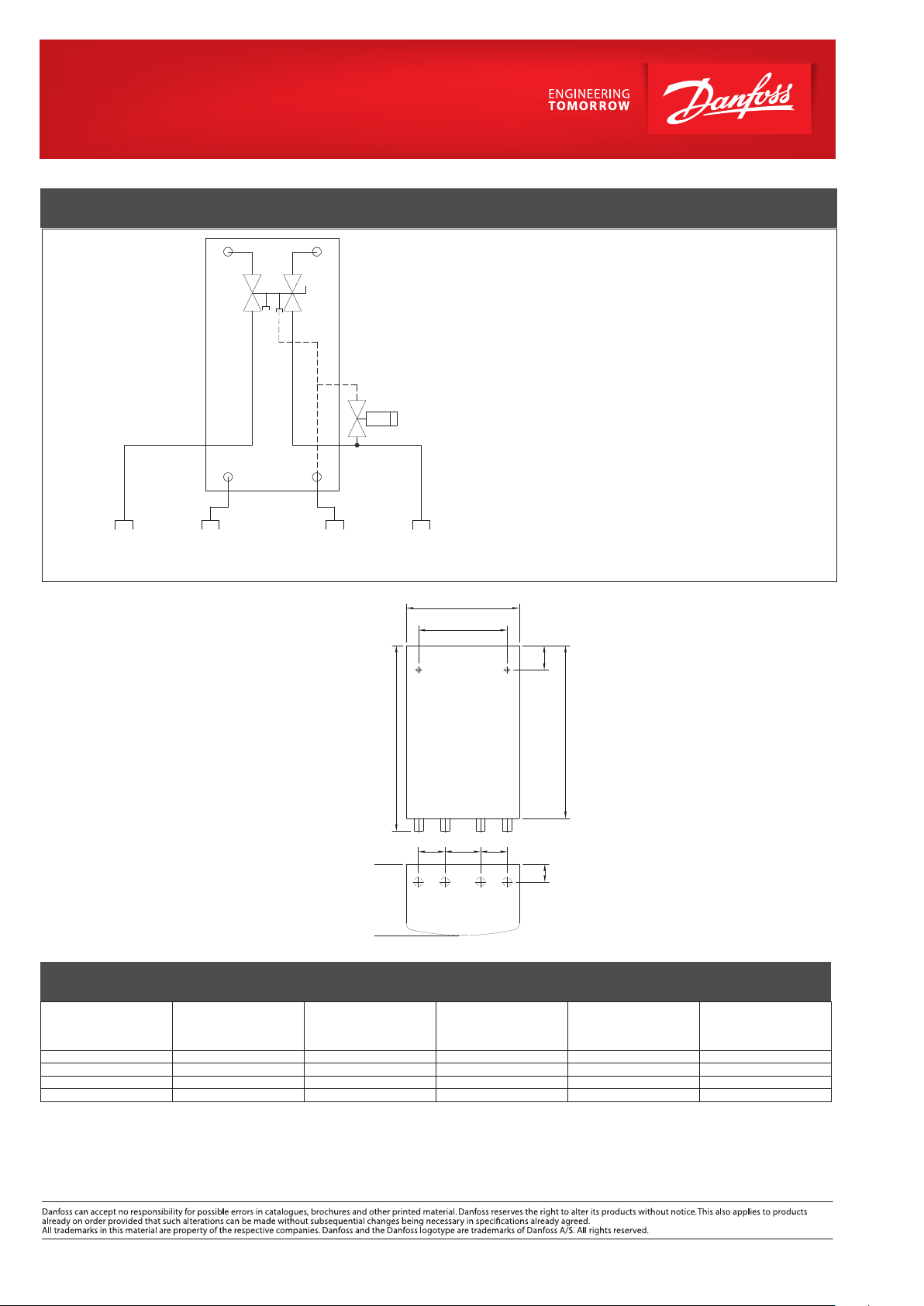

CIRCUIT DIAGRAM – EXAMPLE

DHW circ.

DCW

DHW DH

Bypass

Supply

DH.

return

1. Danfoss copper brazed plate heat exchanger

in stainless steel AISI 316, type XB 06H-1 26.

2. Domestic hot water controller type Danfoss

PM2+P.

3. Bypass/circulation thermostat Danfoss FJVR.

4. Connection of capillary tube from Danfoss

FJVR acting as bypass thermostat (standard

function).

5. Connection of capillary tube from Danfoss

FJVR acting as circulation thermostat (DHW

recirculation).

6. Connection piece for circulation pipe, if any.

Note: Circulation set is not part of the delivery and must

be ordered separately and mounted on site.

Design specifications:

Nominal pressure (prim/sec.): PN 16 / PN 16

Max. supply temperature: 120 ºC

DCW static pressure: p

Min. ∆P: See capacity examples

= 2.0 bar

min

Chloride compounds: Max. 300 mg/l

Weight incl. cover: 9 kg

(incl. packing)

Cover: Brushed steel

Dimensions (mm):

Without cover: H420xW250xD150

With cover: H420xW255xD160

Connections sizes:

DH, DCW, DHW: R ½“ ET (ext. thread)

Circulation: R ½“ ET (ext. thread))

CAPACITY, WEIGHT AND DIMENSIONS

DHW: CAPACITY EXAMPLES, 10°C/45°C

DHW

Capacity

kW

32.3 55 21. 8 13.16 0.28 840

32.3 60 18.9 13.16 0.18 680

41.0 60 20.4 16.96 0 .31 900

41.0 70 16.8 16.86 0.17 670

*) Stated pressure loss values are complete, incl. pipes, heat exchanger and valves.

Supply flow

Primary

°C

Return flow

160

Primary

°C

420

1 2 3 4

60 80 60

1 2 3 4

Top view

255

200

(5)

DHW

tap load

l/min

Recirculation:

Remember to order circulation set for systems

that feature DHW recirculation.

55

40

Connections:

1. District heating (DH) supply

2. District heating (DH) return

3. Heating (HE) return

4. Heating (HE) supply

5. Domestic hot water (DHW)

391

6. Domestic cold water (DCW)

Options:

• Cover, white-lacquered steel, with door

• Electronic controller Danfoss ECL310

• Circulation set for DHW recirculation

• Safety function - safety thermostat + actuator

• Connection of pipes can be established in the top

or in the bottom of the substation

• Pipe insulation

• Mounting of heat meter (supplied by customer)

• Supplementary fitting set for change of fitting

piece size ¾ x 110 mm to fitting piece size 1“ x 190

mm

Pressure loss*

Primary

bar

Flow rate

Primary

l/h

Danfoss Redan A/S · District Energy · Omega 7 · DK-8382 Hinnerup

Tel.: +45 87 43 89 43 · Fax: +45 87 43 89 44 · redan@danfoss.com · www.redan.danfoss.dk

© Danfoss | DHS-SRMT/ PL | 2016 . 05

VL.GP.J2.02

Loading...

Loading...