Fact sheet

Akva Therm II LV

Domestic hot water charging system for hospitals, restaurants, sporting centres as well as commercial buildings and apartment blocks

Application

The Akva Therm II LV is a compact and

effective domestic hot water (DHW)

charging system.

It optimally combines the two systems,

storage water heating and instantaneous water heating and is applicable

for hospitals restaurants, sport centres

as well as commercial buildings and

apartment blocks, where a constant

DHW temperature even during peak

consumption periods is needed.

The Akva Therm II LV can be supplied

from district heating supply networks,

from low-temperature or condensing

boilers, solar-, process- and waste heat

systems.

Domestic hot water

The Akva Therm II LV charging system is

delivered as a set consisting of a stainless steel DHW cylinder, a brazed, stainless steel plate heat exchanger, Danfoss

XB37H-1, Danfoss ECL 310 for control

of the charging temperature and temperature in the DHW cylinder, Wilo

low-energy circulation pump, shut-o

valves, balancing valves / ow limiter,

safety valves, thermometers as well as

ready-to-mount pipes and ttings.

Domestic hot water circulation

The Akva Therm II LV charging system

is supplied with connection for DHW

circulation. The DHW circulation pipe

connection is placed directly on the cylinder.

Design

A total of 24 standard applications

are available in the LV series, however,

the possibilities are many, as the heat

exchanger size and cylinder volume can

be combined according to requirement.

The capacities of the heat exchangers

range from 25 and 110 kW and the

tanks are available in sizes from 350 to

1000 liters. The standard executions

supplies 12 to 69 apartments. For other

sizes, please contact our sales

department.

Long life

The use of acid-resistant, stainless steel

for pipes, tank and heat exchanger,

and dezincification-resistant brass for

T-pieces, components and valves, as

well as approved components secures

the charging system a long life.

Good operating economy,

By using Danfoss automatics for the

control of the Akva Therm II LV charging

system the system is optimized in order

to achieve higher efficiency and better

cooling. The LV unit is characterized

by a good stratification in the cylinder.

Circulation is connected to the cylinder

center and the return does not affect

the stratification of the system. The

electronic control and stratification

ensures excellent operating economy.

Serviceability and ease of assembly

The charging unit can easily be

mounted and serviced, as all parts are

assembled with nuts and gaskets.

FEATURES AND BENEFITS

• Charging system for domestic hot water

• Can be supplied from district heating

supply networks, from low-temperature

or condensing boilers, solar, process

and waste heat systems

• Available in standard executions for

supply of 12-69 apartments

• Electronic control - excellent operating

economy

• Pipes, cylinder and heat exchanger

made of stainless steel

www.danfoss.com

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alterations can be made without subsequential changes being necessary eady agreed.

All trademarks in this material are property of the respective companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

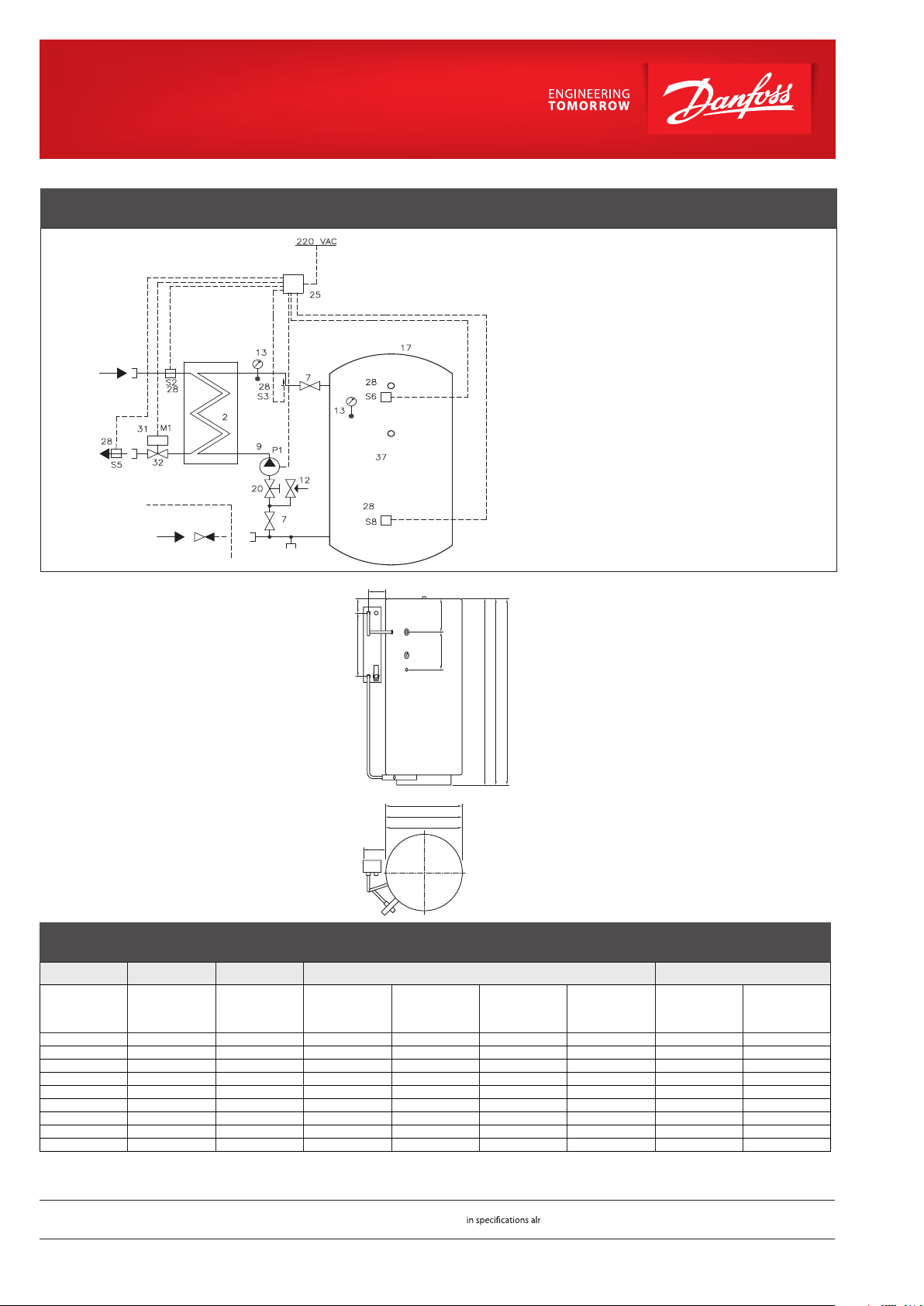

CIRCUIT DIAGRAM - EXAMPLE

DH

Supply

DH

Return

Supply limit

DCW

Technical parameters:

Nominal pressure: PN 16 / PN 10

Max. temperature: 95 °C (construction temp.)

Min. ΔP: See capacity examples

Weight incl. packing: LV16-350 79 kg

LV20-500 95 kg

LV36-750 145 kg

LV50-1000 169 kg

Dimensions, tank:

LV16-350: H 1750 x D 720 mm

LV20-500: H 1890 x D 720 mm

LV36-750: H 2130 x D 920 mm

LV50-1000: H 2180 x D 1060 mm

DHW

Circ.

155

128571

1

6

2

345

1000 L: Dia.1060

750 L: Dia.920

350 - 500 L: Dia.720

200

300

340

350 L: 1750

750 L: 2130

500 L: 1890

1000 L: 2180

2. Brazed plate heat exchanger,

stainless steel AISI 316

7. Ball valve

9. Charging pump

12. Safety valve DHW 10 bar

13. Thermometer

17. Air valve

20. Balancing valve

25. Domestic hot water control

ECL 310, app. 217

28. Sensor

31. Actuator 1

32. Valve 1

37. Fully insulated storage tank, stainless

steel

Connections:

1. District heating (DH) supply

2. District heating (DH) return

3. Domestic cold water (DCW)

4. Domestic hot water (DHW)

5. Circulation (optional)

6. Circulation

Connections (examples):

LV16-350: DCW,DHW 1“ DH., Circ. ¾“

LV20-500: DCW,DHW 1½“ DH ¾., Circ. 1“

LV36-750: DCW,DHW 2“ DH., Circ. 1“

LV50-1000: DCW,DHW 2 “ DH., Circ. 1“

DHW: CAPACITY EXAMPLES 60/15 - 10°C / 50°C

CAPACITY, WEIGHT AND DIMENSIONS

Capacity Primary

Akva Therm II

LV Ty pe

LV16-350 350 15 25 537 800 352 0.19 478

LV20-350 350 18 40 860 1123 406 0.19 76 4

LV20-500 500 22 40 860 1235 518 0.19 764

LV36 -350 350 36 80 172 0 1983 549 0.25 1529

LV36 -50 0 500 41 80 172 0 2095 662 0.25 1529

LV36 -750 750 47 80 172 0 2283 849 0.25 1529

LV50-500 500 58 110 2365 2740 769 0.21 2102

LV50-750 750 63 110 2365 2928 957 0. 21 2102

LV36 -750 1000 69 110 2365 3115 114 4 0. 21 2102

Tan k

volume

No. of

apartments.

(guiding)*

Heat

exchanger

(kW)

Constant,

DHW

(l/h)

Max. capacity

(l/h)

Max. capacity

l/10 min.)

Pressure loss

bar

Danfoss Redan A/S · District Heating · Omega 7, Søften · DK-8382 Hinnerup · Denmark

Tel.: +45 87 43 89 43 · Fax: +45 87 43 89 44 · redan@danfoss.com · www.redan.danfoss.dk

© Danfoss | DHS-SRMT/ PL | 2016. 08

Flow

(l/h)

VL.GE.E3.02

Loading...

Loading...