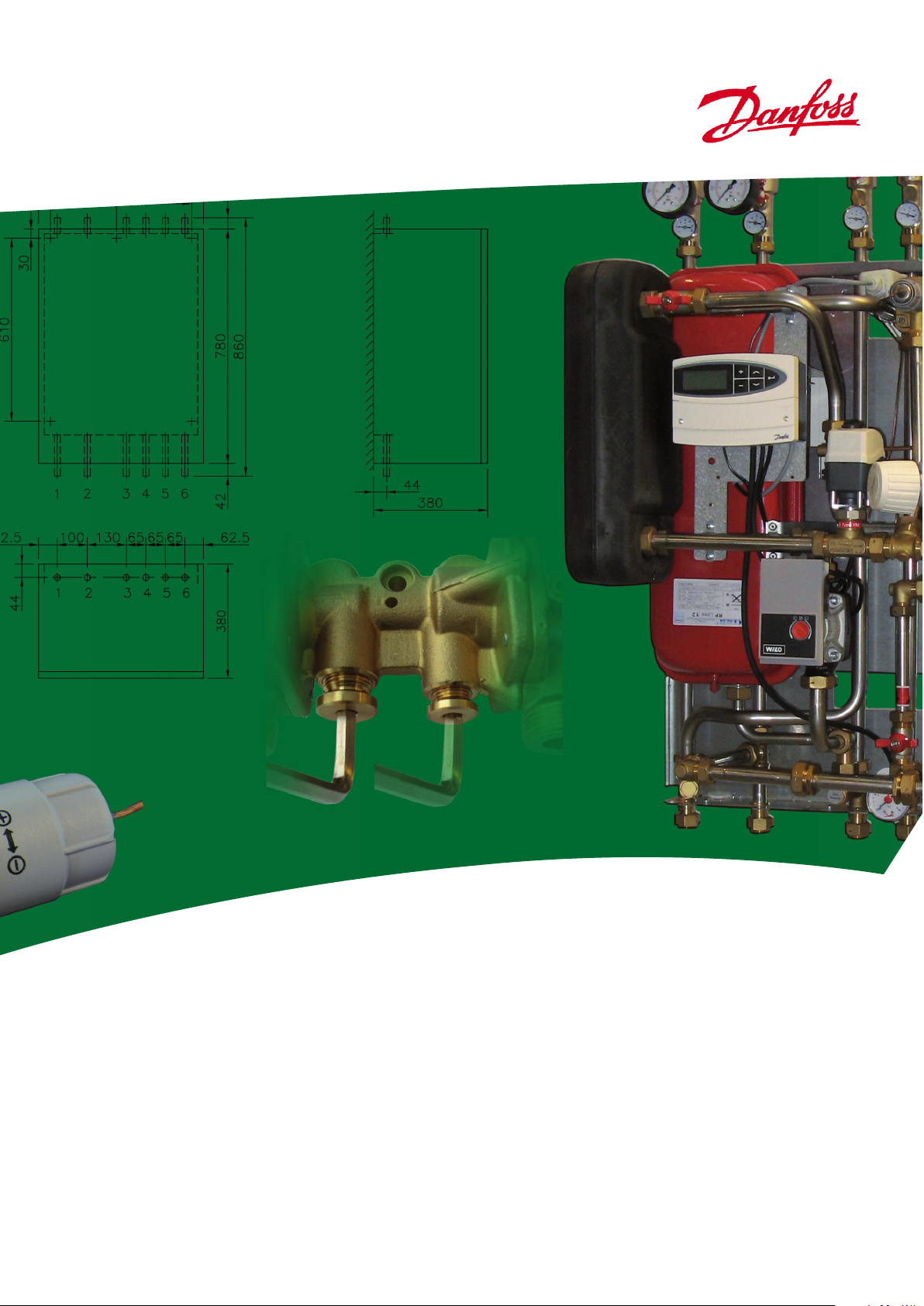

Danfoss Akva Lux II VX2, Akva Lux II VX2-E, Akva Lux II VX3, Akva Lux II VX3-E Operating guide

MAKING MODERN LIVING POSSIBLE

Danfoss District Energy

Akva Lux II VX2, VX2-E, VX3, VX3-E

Instructions for installation and use

Instructions for installation and use Akva Lux II VX substations

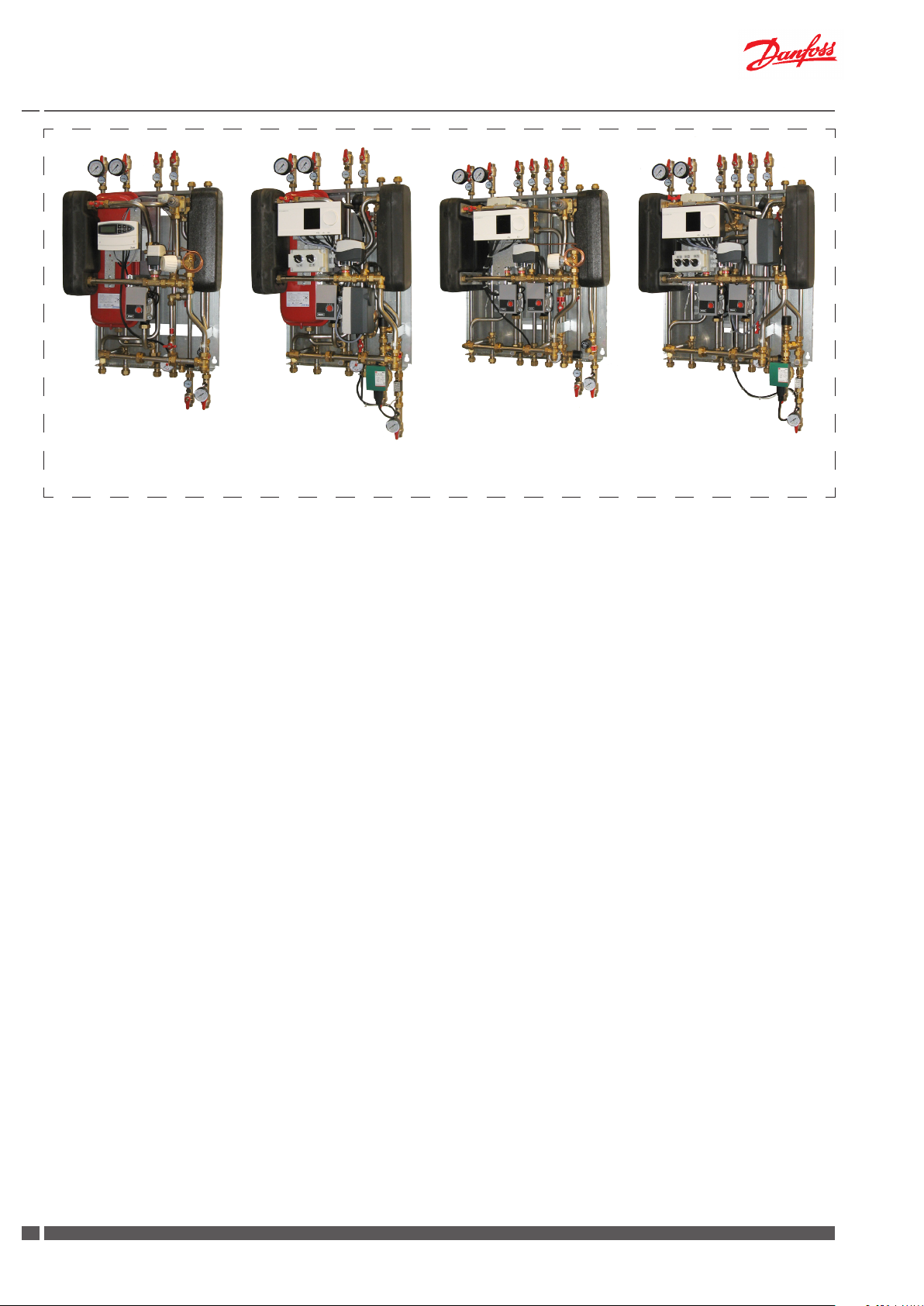

Akva Lux II VX2 Akva Lux II VX2-E Akva Lux II VX3 Akva Lux II VX3-E

1. Contents

1.0 Contents ...................................................................................................................................................................................................................................... 2

2.0 Safety notes ...............................................................................................................................................................................................................................3

3.0 Storage and Handling ............................................................................................................................................................................................................ 3

4.0 Disposal ....................................................................................................................................................................................................................................... 3

5.0 Diagram - Examples ................................................................................................................................................................................................................ 4

5.1 Akva Lux II VX2 ..................................................................................................................................................................................................................4

5.2 Akva Lux II VX2-E ..............................................................................................................................................................................................................5

5.3 Akva Lux II VX3 ..................................................................................................................................................................................................................6

5.4 Akva Lux II VX3-E ..............................................................................................................................................................................................................7

6.0 Main components ................................................................................................................................................................................................................... 8

6.1 Akva Lux II VX2 ..................................................................................................................................................................................................................8

6.2 Akva Lux II VX2-E ..............................................................................................................................................................................................................9

6.3 Akva Lux II VX3 ............................................................................................................................................................................................................... 10

6.4 Akva Lux II VX3-E ........................................................................................................................................................................................................... 11

7.0 Getting started ...................................................................................................................................................................................................................... 12

8.0 Mounting ................................................................................................................................................................................................................................ 13

8.1 Variable connection possibilities ............................................................................................................................................................................ 13

8.2 DHW recirculation Akva Lux II VX2 & Akva Lux II VX3......................................................................................................................................14

8.2.1 Mounting of circulation set for Akva Lux II VX2 & VX3 ......................................................................................................................... 14

8.2.2 Mounting of circulation set Akva Lux II VX2-E and VX3-E ................................................................................................................... 14

8.3 Safety thermostat ........................................................................................................................................................................................................ 15

8.4 Expansion vessel .......................................................................................................................................................................................................... 16

8.5 Heat meter, Fitting piece........................................................................................................................................................................................... 17

8.6 Test and connections ................................................................................................................................................................................................. 17

8.7 Mounting of outdoor temperature sensor ........................................................................................................................................................ 17

8.8 Safety valves .................................................................................................................................................................................................................. 17

9.0 Filling, Start-up ...................................................................................................................................................................................................................... 18

10.0 Manometer and relling .................................................................................................................................................................................................... 18

11.0 Electrical connections ......................................................................................................................................................................................................... 19

12.0 Description of Akva Lux II VX variants ........................................................................................................................................................................... 20

12.1 Akva Lux II VX2 (ECL 110) ......................................................................................................................................................................................... 20

12.2 Akva Lux II VX2-E (ECL 310/A266) ......................................................................................................................................................................... 22

12.3 Akva Lux II VX3 (ECL210/A260) .............................................................................................................................................................................. 25

12.4 Akva Lux II VX3-E (ECL310/A376) .......................................................................................................................................................................... 28

13.0 Circulation pumps - Heating ............................................................................................................................................................................................. 32

14.0 Circulation pumps - Domestic hot water ..................................................................................................................................................................... 33

14.1 Wilo-Stratos ECO-Z (Circulation set 810.441) .................................................................................................................................................... 33

14.2 Wilo-Star-Z NOVA (Circulation set 810.443) ...................................................................................................................................................... 33

15.0 Maintenance ........................................................................................................................................................................................................................... 34

15.1 Maintenance plan (recommendations) .............................................................................................................................................................. 35

16.0 Troubleshooting .................................................................................................................................................................................................................... 36

16.1 Troubleshooting - Heating ...................................................................................................................................................................................... 36

16.2 Troubleshooting - Domestic hot water ............................................................................................................................................................... 38

17.0 EC-Declaration of Conformity .......................................................................................................................................................................................... 40

2

DKDHR VI.GP.V2.02 Danfoss District Energy

Instructions Akva Lux II VX

2.0 Safety notes

Instructions

This operating manual should be read carefully before installation and

start-up of the substation. The manufacturer accepts no liability for

damage or faults that result from non-compliance with the operating

manual.

Please read and follow all the instructions carefully to prevent accidents, injury and damage to property. The risk of persons being injured

and equipment damaged increases considerably if the recommended

permissible operating parameters are exceeded.

Installation, assembly work, rst start-up and maintenance work may

be carried out only by qualied and authorized personnel in compliance with the safety regulations (both heating and electrical work).

Connection

The substation must be equipped with features that ensure that the

substation can be separated from all energy sources (also power

supply).

Warning! Hot surfaces

Parts of the substation may be very hot and can cause burn injuries. Be very careful when you are in the immediate vicinity of the

substation.

Energy source

The substation is designed for district heating as the primary source

of energy. However, also other energy sources can be used where the

operating conditions allow it and always are comparable to district

heating.

Application

The substation is designed only to operate with water or a water-glycol

mixture (up to 40%), and other heating media may not be used.

Connect the substation to the house installation in a frost-free room,

where the temperature does not exceed 50 °C and the humidity does

not exceed 80%. Do not cover or wall up the substation or in any other

way block the entrance to the station.

Choice of material

Choice of materials always in compliance with local legislation.

Corrosion protection

The maximum chloride compounds of the ow medium should not

be higher than 300 mg/l. The risk of equipment corrosion increases

considerably if the recommended permissible chloride compounds

are exceeded.

Safety valve(s)

We recommend mounting of safety valve(s), however, always in compliance with local regulations.

Sound level.

≤ 55 dB.

Warning of high pressure and high temperature

The maximum supply temperature in the district heating network

can be up to 110°C and the operating pressure can be up to 16 bar.

This may result in a risk of scalding from touching the substation

and from outow of the medium (water/steam). Exceeding the

substation design data and operating parameters for pressure and

temperature carries an appreciable risk of personal injury and/or

damage to property.

Emergencies

In the event of re, leaks or other hazards, immediately shut o all

sources of energy to the substation, if possible and call for appropriate assistance. If the domestic hot water is discoloured or malodorous, shut o all ball valves on the substation, notify all users and call

for professional assistance immediately.

Warning of damage during transport

On reception of the substation, and before installing it, check for

any evidence of damage during transport.

The substation must be handled and moved with the greatest care

and attention.

IMPORTANT - Tightening of connections

Before adding water to the system, ALL pipe connections MUST be

retightened, as vibrations during transport may have caused leaks.

Once the substation has been lled and the system has been put

into operation, ALL connections must be tightened once more.

(Do not overstrain! - See item 8.6, page 17)

3.0 Storage and Handling

Before installation, the units must be stored in a dry, heated (i.e. frostfree) room.

(Relative humidity max. 80% and storage temperature 5-70 °C).

The units must not be stacked higher than the limit at the factory . Units

supplied in cardboard packaging must be lifted using the handles incorporated in the packaging. Units must be placed on pallets for transport/

moving across large distances.

As far as possible, do not lift the substation by the pipes. Lifting by the

pipes may cause leaks. REMEMBER to retighten.

Handling

We recommend minimum two people to lift the substation.

We recommend that you wear suitable safety footwear while

handling and installing the substation.

4.0 Disposal

Dispose of the packaging in accordance with the local regulations for

disposal of used packaging materials.

The substation is made of materials that cannot be disposed of together

with household waste.

Close all energy sources and disconnect all connection pipes. Disconnect

and dismantle the product for disposal in accordance with the applicable

local regulations for the disposal of the individual components.

Danfoss District Energy VI.GP.V2.02 DKDHR

33

Instructions Akva Lux II VXInstructions Akva Lux II VX

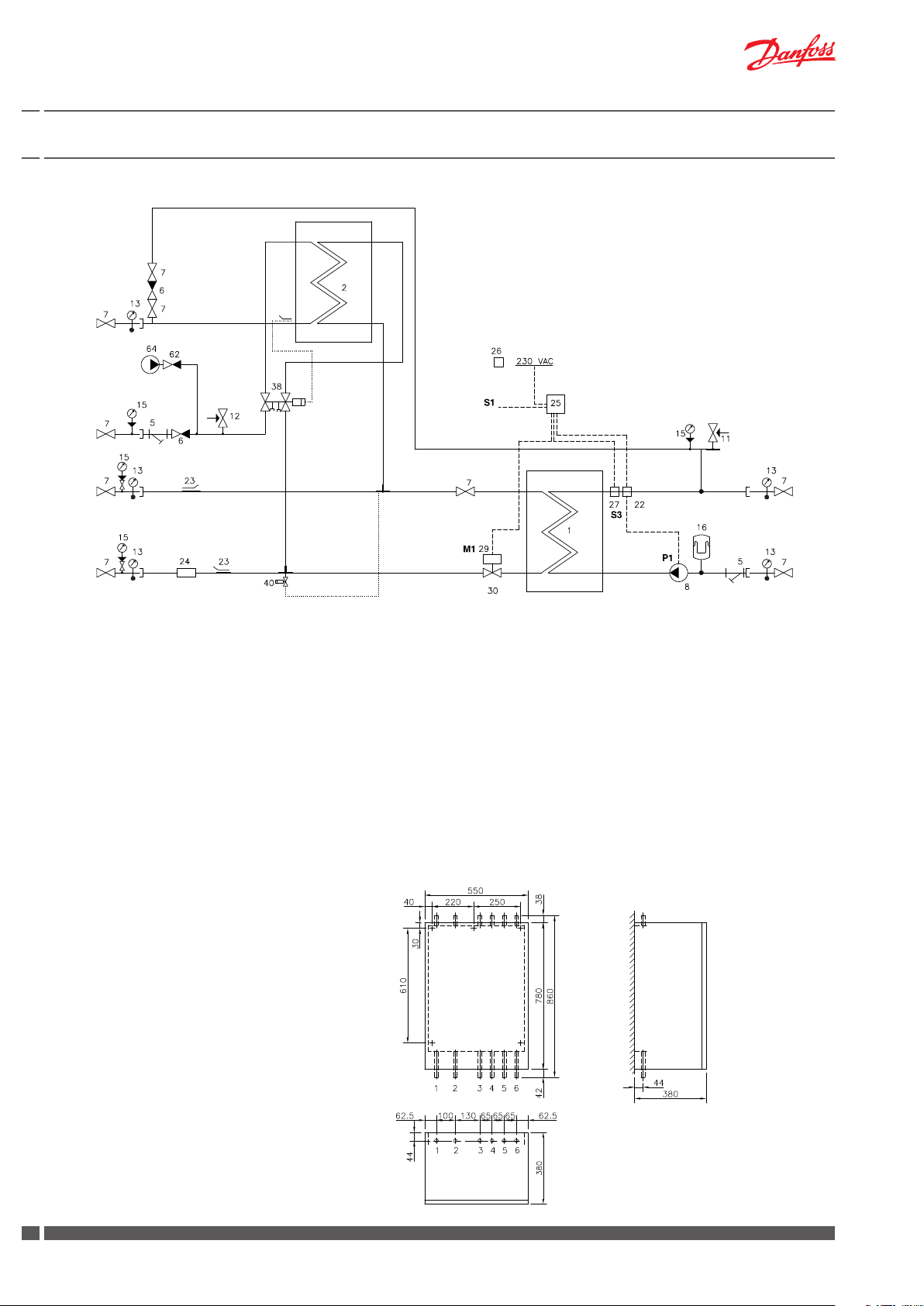

5.0 Diagram - Examples

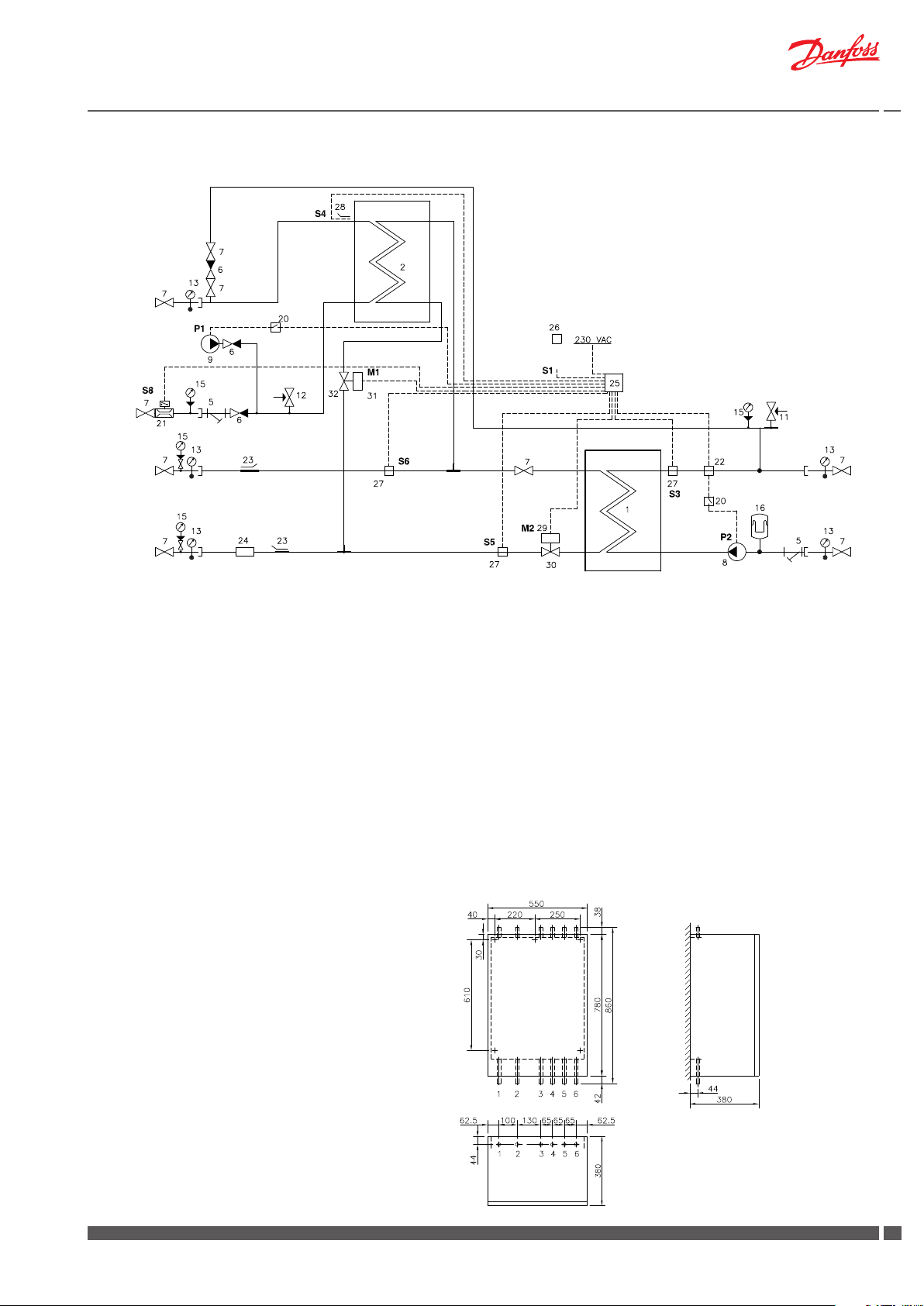

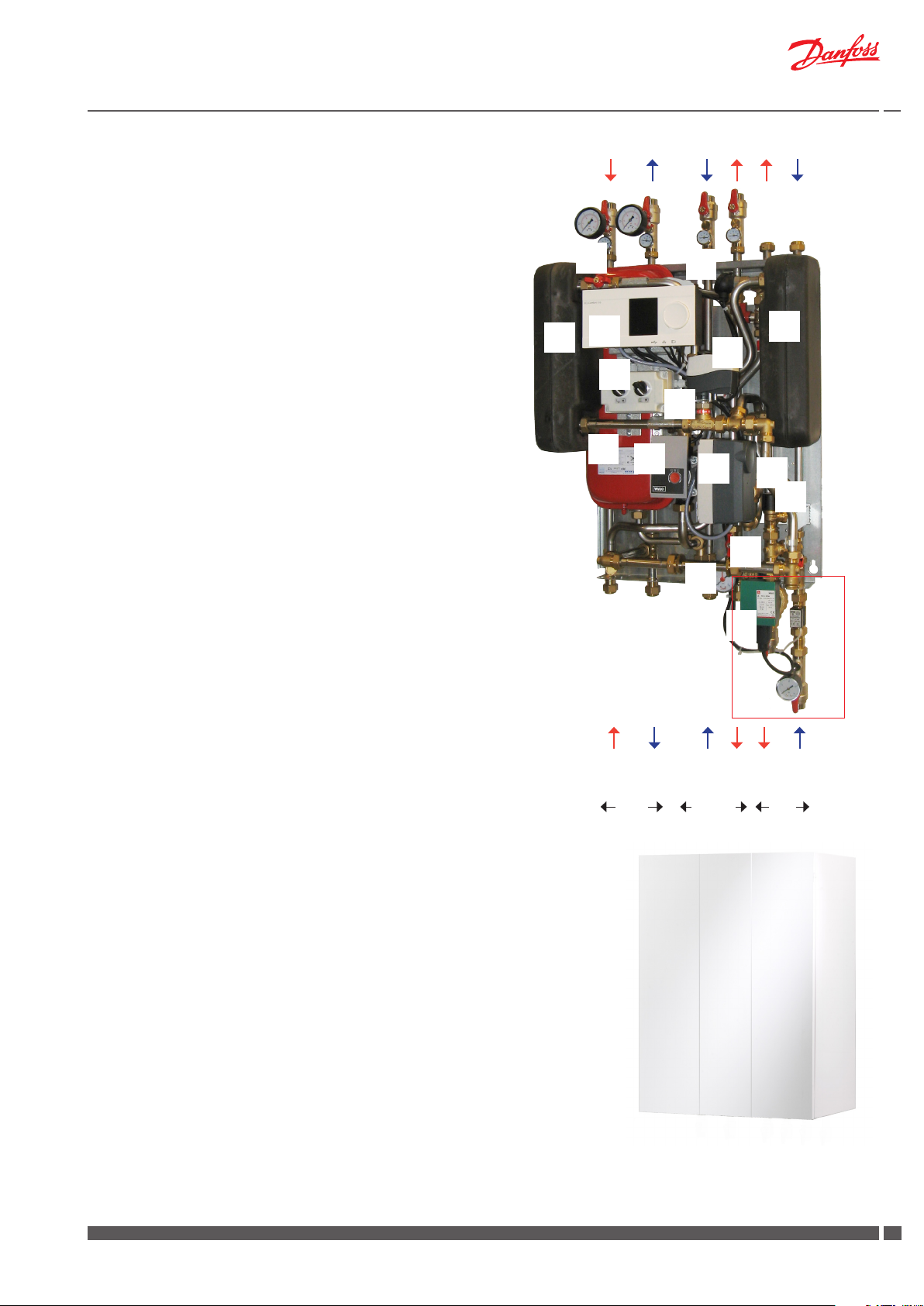

5.1 Akva Lux II VX2

DHW

Circ.

DCW

DH

Supply

DH

Return

Bypass

1 Plate heat exchanger, HE, with insulation

2 Plate heat exchanger, DHW, with insulation

5 Strainer

6 Non-return valve

7 Ball valve

8 Circulation pump HE

11 Safety valve, HE 2,5 bar

12 Safety valve, DHW 10 bar

13 Thermometer

14 Pocket for pressure gauge

15 Manometer

16 Expansion vessel 12 L

17 Air valve

22 Safety thermostat Danfoss AT

23 Sensor pocket for heat meter ½“

24 Fitting piece for heat meter, 1” x 130 mm

Measurements:

HE

Return

HE

Supply

25 Controller Danfoss ECL 110/A130

26 Outdoor sensor Danfoss ESMT

27 Sensor Danfoss ESMC

29 Danfoss actuator AMV 150

30 2-way valve VS2

38 Domestic hot water controller

Danfoss PTC2 +P

40 Danfoss FJVR for bypass/circulation

--------------------------------------------------------------62 Non-return valve (not part of dly)

64 Circulation pump (not part of dly)

Please note that the unit does not include strainer on DH supply.

It is the responsibility of the energy supplier to secure that a strainer,

mesh 0.6 mm, is tted on the primary side.

Dimensions without cover

H730 x W530 x D360 mm

Dimensions with cover

H780 x W550 x D380 mm

Connections:

Order:

1 District heating (DH) supply

2 District heating (DH) return

4 Heating (HE) return

5 Heating (HE) supply

6 Domestic hot water (DHW)

7 Domestic cold water (DCW)

wall

Connection sizes:

DH: G¾ (ET)

HE: G¾ (ET)

DHW, DCW: G¾ (ET)

top view

4

DKDHR VI.GP.V2.02 Danfoss District Energy

Circ.: G¾” (IT )

Instructions Akva Lux II VX

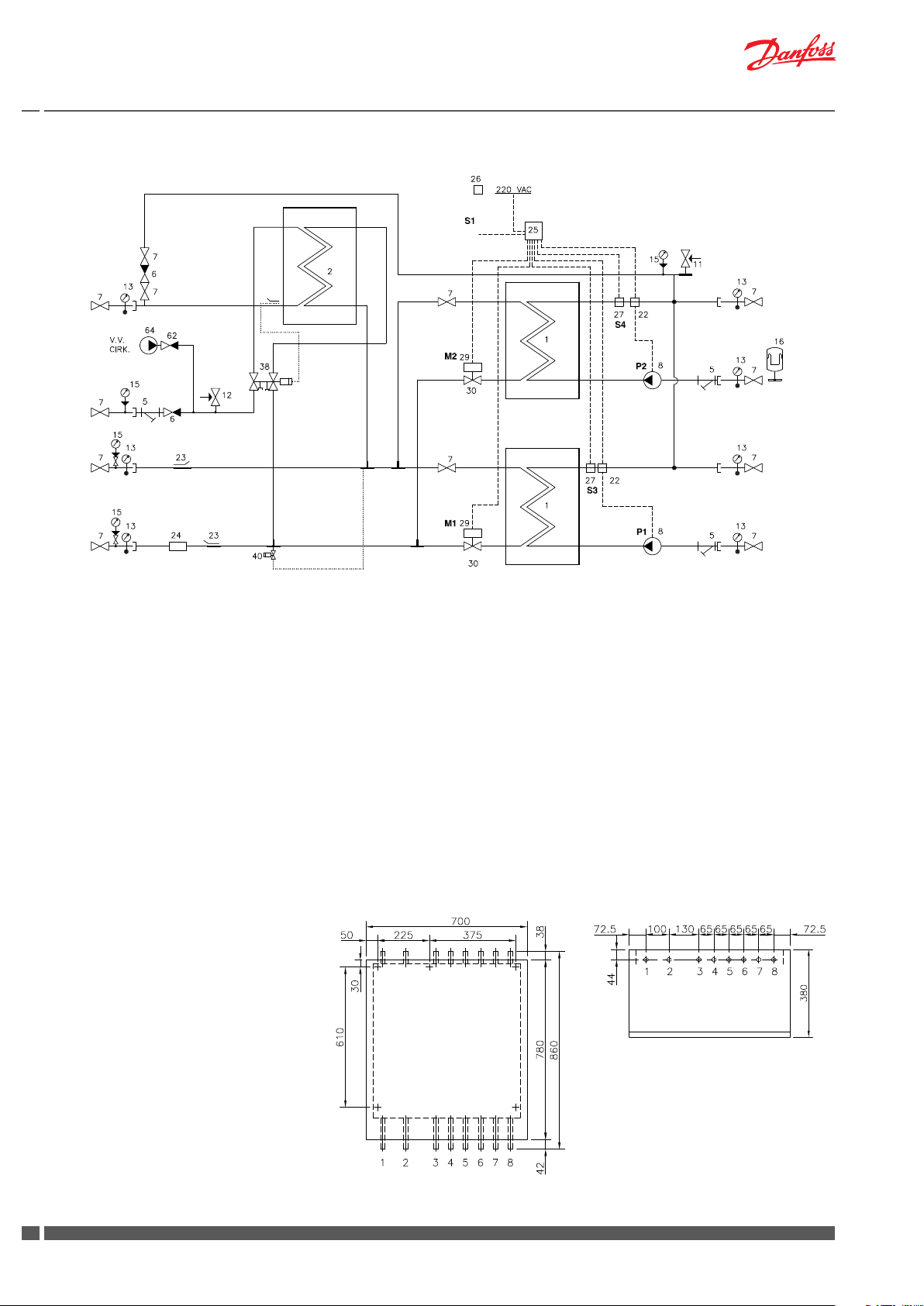

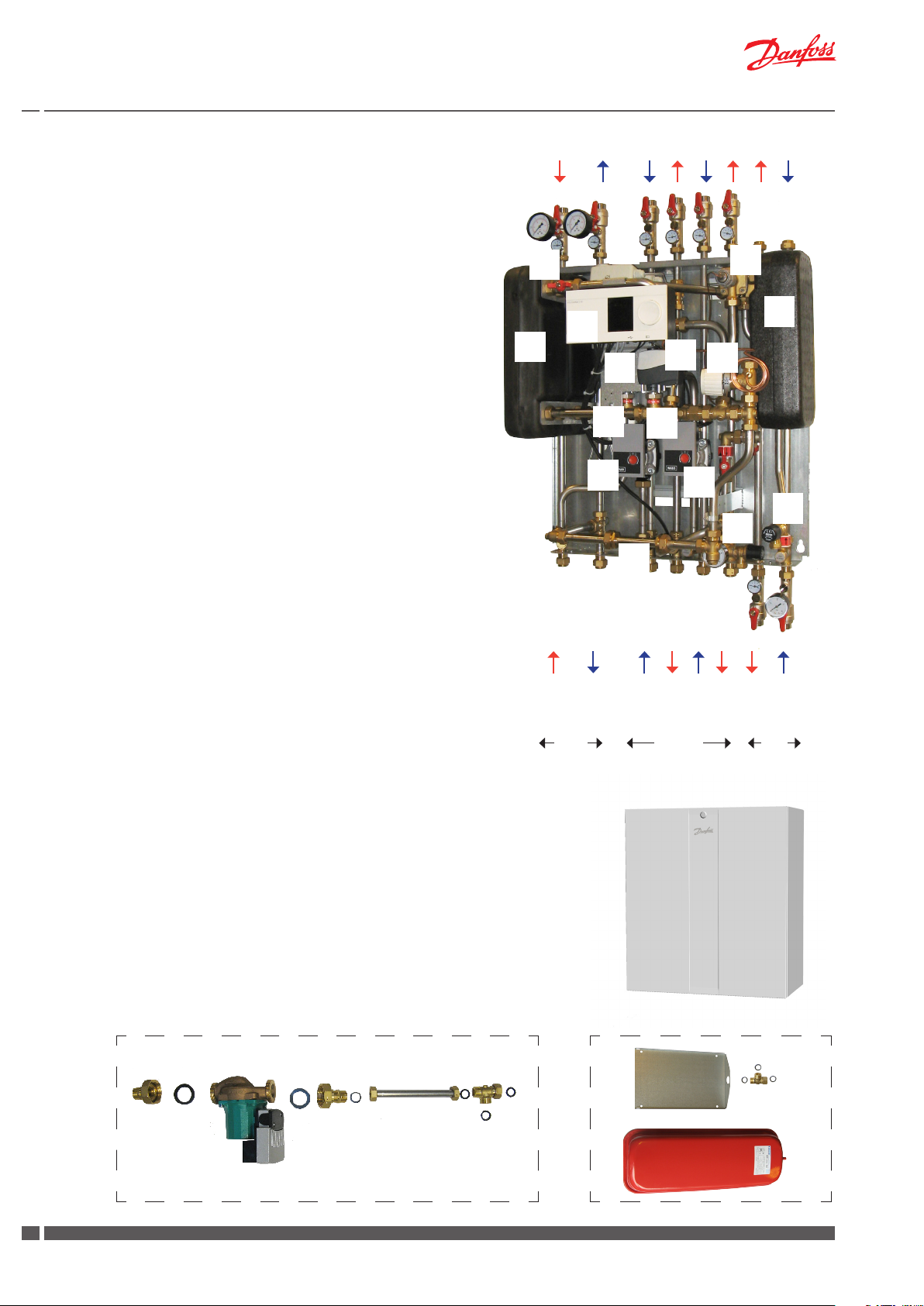

5.2 Akva Lux II VX2-E

DHW

Circ.

DCW

DH

Supply

DH

Return

1 Plate heat exchanger, HE, with insulation

2 Plate heat exchanger, DHW , with insulation

5 Strainer

6 Non-return valve

7 Ball valve

8 Circulation pump HE

9 Circulation pump DHW circ.

11 Safety valve, HE 2,5 bar

12 Safety valve, DHW 10 bar

13 Thermometer

14 Pocket for pressure gauge ½”

15 Manometer

16 Expansion vessel 12 L

17 Air valve

20 Switch box for pumps

HE

Return

HE

Supply

21 Flow switch

22 Safety thermostat Danfoss AT

23 Sensor pocket for heat meter ½“

24 Fitting piece for heat meter, 1” x 130 mm

25 Controller Danfoss ECL 310/A266

26 Outdoor sensor Danfoss ESMT

27 Sensor Danfoss ESMC

29 Danfoss actuator AMV 150

30 2-way valve VS2

31 Danfoss actuator AMV 30

32 2-way valve VM 2

Please note that the unit does not include strainer on DH supply.

It is the responsibility of the energy supplier to secure that a strainer,

mesh 0.6 mm, is tted on the primary side.

Measurements:

Dimensions without cover

H870 x W530 x D360 mm

Dimensions with cover

H870 x W595 x D380 mm

Connections:

Order:

1 District heating (DH) supply

2 District heating (DH) return

4 Heating (HE) return

5 Heating (HE) supply

6 Domestic hot water (DHW)

7 Domestic cold water (DCW)

wall

Connection sizes:

DH: G¾ (ET)

HE: G¾ (ET)

DHW, DCW: G¾ (ET)

top view

Circ.: G¾” (IT )

Danfoss District Energy VI.GP.V2.02 DKDHR

55

Instructions Akva Lux II VX

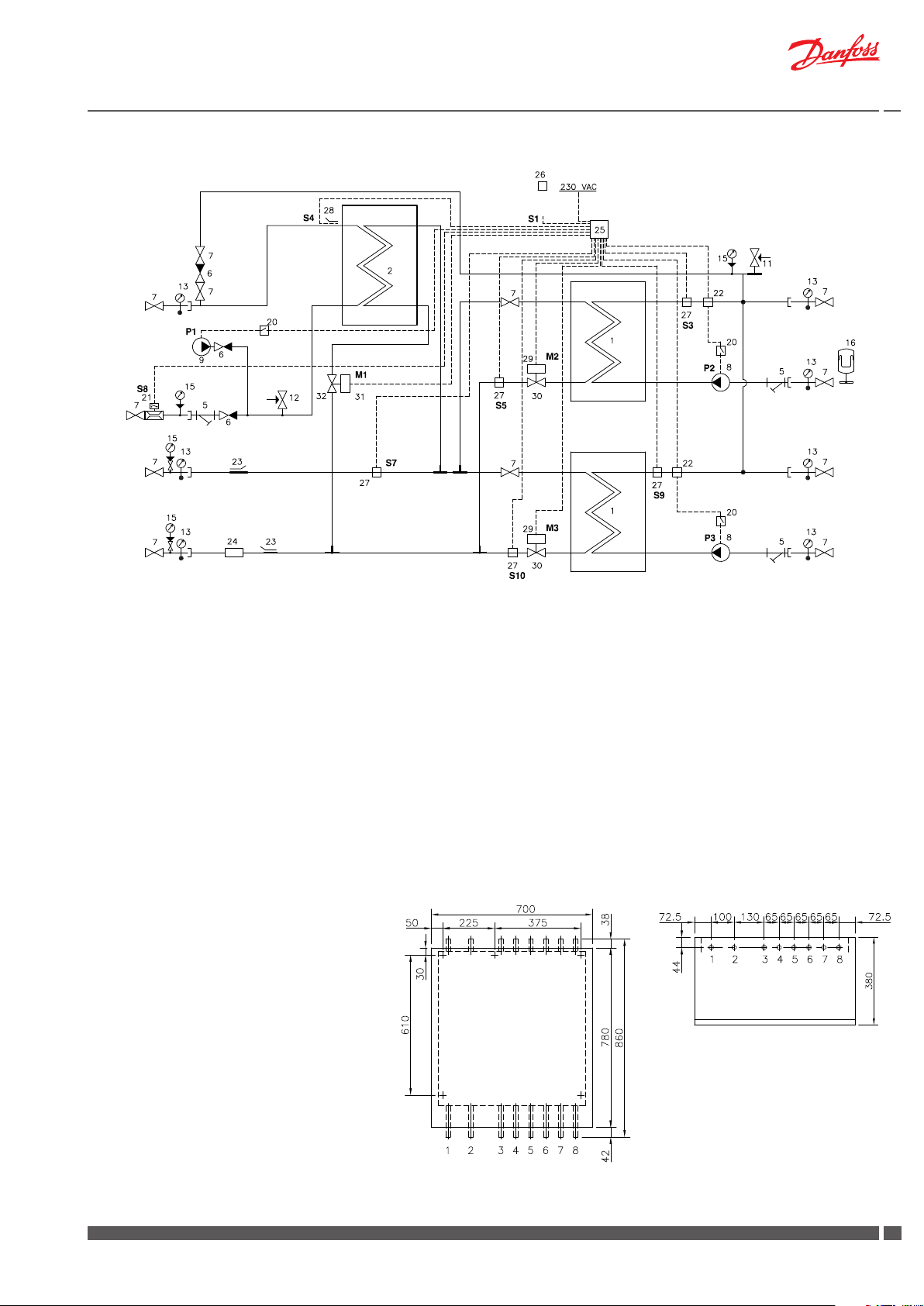

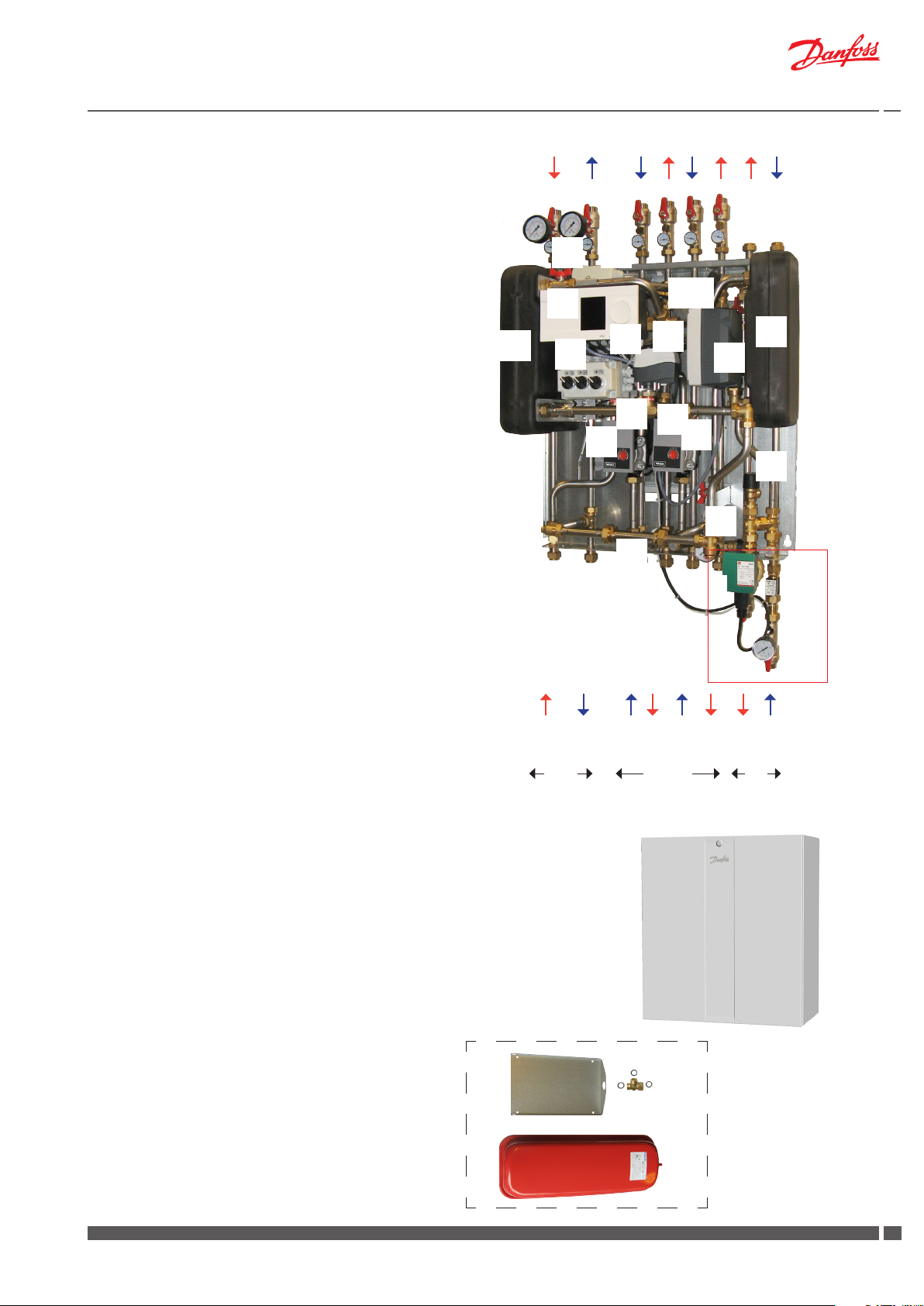

5.3 Akva Lux II VX3

DHW

Circ.

DCW

DH

Supply

DH

Return

Bypass

1 Plate heat exchanger, HE, with insulation

2 Plate heat exchanger, DHW, with insulation

5 Strainer

6 Non-return valve

7 Ball valve

8 Circulation pump HE

11 Safety valve, HE 2,5 bar

12 Safety valve, DHW 10 bar

13 Thermometer

14 Pocket for pressure gauge ½”

15 Manometer

17 Air valve

22 Safety thermostat Danfoss AT

23 Sensor pocket for heat meter ½“

24 Fitting piece for heat meter, 1” x 130 mm

25 Controller Danfoss ECL 310/A260

HE

Return

HE

Supply

HE

Return

HE

Supply

26 Outdoor sensor Danfoss ESMT

27 Sensor Danfoss ESMC

29 Danfoss actuator AMV 150

30 2-way valve VS2

38 Domestic hot water controller

Danfoss PTC2 +P

40 Danfoss FJVR for bypass/circulation

--------------------------------------------------------------16 Expansion vessel 12 L

62 Non-return valve (not part of dly)

64 Circulation pump (not part of dly)

Please note that the unit does not include strainer on DH supply.

It is the responsibility of the energy supplier to secure that a strainer,

mesh 0.6 mm, is tted on the primary side.

Measurements:

Dimensions without cover

H860 x W660 x D360 mm

Dimensions with cover

H860 x W700 x D380 mm

top view

Connections:

Order:

1 District heating (DH) supply

2 District heating (DH) return

3 Heating (HE) return

4 Heating (HE) supply

Connection sizes:

DH: G¾ (ET)

HE: G¾ (ET)

DHW, DCW: G¾ (ET)

Circ.: G¾” (IT )

5 Heating (HE) return

6 Heating (HE) supply

7 Domestic hot water (DHW)

8 Domestic cold water (DCW)

6

DKDHR VI.GP.V2.02 Danfoss District Energy

Instructions Akva Lux II VX

5.4 Akva Lux II VX3-E

DHW

Circ.

DCW

DH

Supply

DH

Return

1 Plate heat exchanger, HE, with insulation

2 Plate heat exchanger, DHW, with insulation

5 Strainer

6 Non-return valve

7 Ball valve

8 Circulation pump HE

9 Circulation pump DHW circ.

11 Safety valve, HE 2,5 bar

12 Safety valve, DHW 10 bar

13 Thermometer

14 Pocket for pressure gauge ½”

15 Manometer

17 Air valve

20 Switch box for pumps

21 Flow switch

22 Safety thermostat Danfoss AT

23 Sensor pocket for heat meter ½“

HE

Supply

HE

Return

HE

Supply

HE

Return

24 Fitting piece for heat meter, 1” x 130 mm

25 Controller Danfoss ECL 310/A376

26 Outdoor sensor Danfoss ESMT

27 Sensor Danfoss ESMC

29 Danfoss actuator AMV 150

30 2-way valve VS2

31 Danfoss actuator AMV 30

32 2-way valve VM2

--------------------------------------------------------------16 Expansion vessel 12 L incl. brackets and T-piece

(supplied loose)

Please note that the unit does not include strainer on DH supply.

It is the responsibility of the energy supplier to secure that a strainer,

mesh 0.6 mm, is tted on the primary side.

Measurements:

Dimensions without cover

H870 x W660 x D360 mm

Dimensions with cover

H870 x W700 x D380 mm

Connections:

top view

Order:

1 District heating (DH) supply

2 District heating (DH) return

3 Heating (HE) return

4 Heating (HE) supply

5 Heating (HE) return

6 Heating (HE) supply

Connection sizes:

DH: G¾ (ET)

HE: G¾ (ET)

DHW, DCW: G¾ (ET)

Circ.: G¾” (IT )

7 Domestic hot water (DHW)

8 Domestic cold water (DCW)

Danfoss District Energy VI.GP.V2.02 DKDHR

77

Instructions Akva Lux II VX

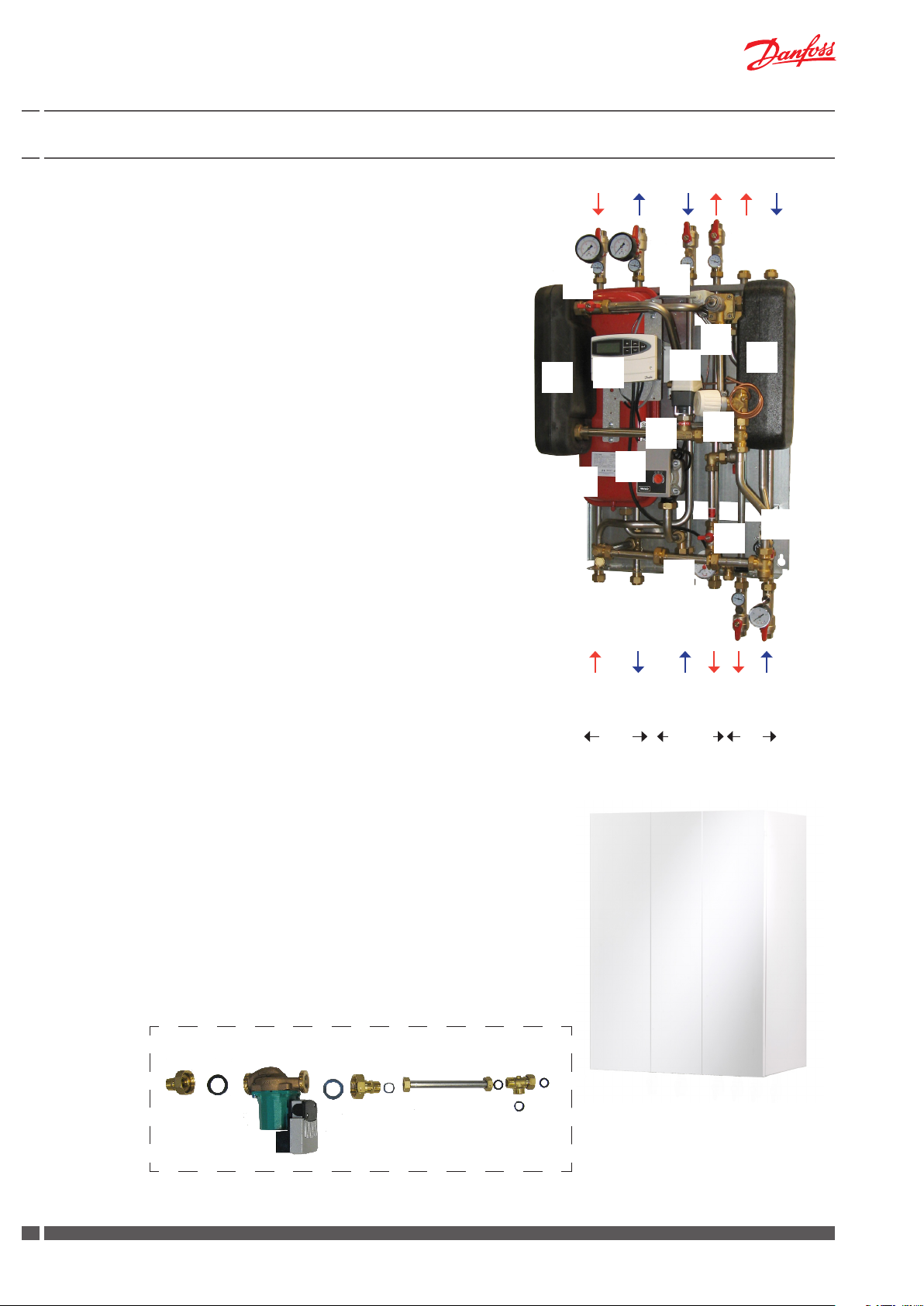

6.0 Main components

6.1 Akva Lux II VX2

1 Plate heat exchanger HE

2 Plate heat exchanger DHW

8 Pump, HE

11 Safety valve HE

12 Safety vale DHW

16 Expansion vessel

17 Air valve

22 Safety thermostat

24 Fitting piece for heat meter

25 Electronic controller ECL110

29 Actuator AMV 150

30 2-way valve VS 2

38 PTC2+P controller

40 Danfoss thermostat for bypass/circulation

The substations oer variable connection possibilities, as connection of pipes can be established both in the top or in the

bottom of the substation.

17

22

38

2

30

29

40

25

1

8

16

Please note:

Your substation may look dierent than the substation shown, as variants with other components may be supplied. The control function,

however, is basically as stated in this instruction manual.

Instructions for the tted components will be supplied together with

the substation.

Accessories to be ordered separately (mounting on site):

Circulation set - Art. No. 810.441

For systems with DHW circulation.

White-lacquered steel-sheet cover

Art. No. 936.0811

DH supply

Primary

11

12

24

DCW

DHW

DH return

HE return

Secondary

HE supply

DHW

810.441

936.0811

8

DKDHR VI.GP.V2.02 Danfoss District Energy

Instructions Akva Lux II VX

6.2 Akva Lux II VX2-E

1 Plate heat exchanger HE

2 Plate heat exchanger DHW

8 Pump HE

9 Circulation pump, DHW circ.

11 Safety valve HE

12 Safety vale DHW

16 Expansion vessel

17 Air valve

20 Switch box for pumps

21 Flowswitch

22 Safety thermostat

24 Fitting piece for heat meter

25 Electronic controller EC310/A266

29 Actuator AMV 150

30 2-way valve VS 2

31 Actuator AMV 30

32 2-way valve VM2

The substations oer variable connection possibilities, as connection of pipes can be established both in the top or in the

bottom of the substation.

17

25

1

22

2

29

20

30

16

8

31

32

12

Please note:

Your substation may look dierent than the substation shown, as variants with other components may be supplied. The control function,

however, is basically as stated in this instruction manual.

Instructions for the tted components will be supplied together with

the substation.

Accessories, which are supplied loose with the substation

(mounting on site):

Circulation set - Art.No. 810.443

The circulation set is supplied assembled and electrically wired

and ready to mount on the substation as shown on the above

photo.

Accessories to be ordered separately (mounting on site):

White-lacquered steel-sheet cover

Art. No. 936.0811

DH supply

Primary

24

DH return

Secondary DHW

HE return

11

9

HE supply

DHW

21

Circulation set

DCW

936.0811

Danfoss District Energy VI.GP.V2.02 DKDHR

99

Instructions Akva Lux II VX

6.3 Akva Lux II VX3

1 Plate heat exchanger HE

2 Plate heat exchanger DHW

8 Pump, HE

11 Safety valve HE

12 Safety valve DHW

17 Air valve

22 Safety thermostat

24 Fitting piece for heat meter

25 Electronic controller ECL 310/260

29 Actuator AMV 150

30 2-way valve VS2

38 PTC2+P controller

40 Danfoss thermostat for bypass/circulation

The substations oer variable connection possibilities, as

connection of pipes can be established both in the top or in

the bottom of the substation.

22

17

38

2

25

1

29

30

30

29

40

Please note:

Your substation may look dierent than the substation shown, as

variants with other components may be supplied. The control function, however, is basically as stated in this instruction manual.

Instructions for the tted components will be supplied together with

Accessories, which are supplied loose with the substation

(mounting on site):

Expansion vessel - Art. No. RES. 178

Accessories to be ordered separately (mounting on site):

Circulation set - Art. No. 810.441

For systems with DHW circulation.

White-lacquered steel-sheet cover

Art. No. 936.1541

8

24

DH return

DH supply

Primary Secondary

HE return

936.1541

HE supply

8

12

11

DCW

DHW

HE return

HE upply

DHW

810.441

10

DKDHR VI.GP.V2.02 Danfoss District Energy

RES.178

Instructions Akva Lux II VX

6.4 Akva Lux II VX3-E

1 Plate heat exchanger HE

2 Plate heat exchanger DHW

8 Pump, HE

9 Circulation pump, DHW circ.

11 Safety valve HE

12 Safety vale DHW

17 Air valve

19 Connection for di. pressure controller

20 Switch box for pumps

22 Safety thermostat

21 Flowswitch

24 Fitting piece for heat meter

25 Electronic controller ECL 310/A376

29 Actuator AMV 150

30 2-way valve VS2

31 Actuator AMV 30

32 2-way valve VM2

The substations oer variable connection possibilities, as

connection of pipes can be established both in the top or in

the bottom of the substation.

17

25

1

20

22

31

29

29

2

32

30

30

8

8

12

11

Please note:

Your substation may look dierent than the substation shown, as

variants with other components may be supplied. The control function, however, is basically as stated in this instruction manual.

Instructions for the tted components will be supplied together with

the substation.

Accessories, which are supplied loose with the substation

(mounting on site):

Expansion vessel - Res. 178

Circulation set - Art.No. 810.443

The circulation set is supplied assembled and electrically wired

and ready to mount on the substation as shown on the above

photo.

Accessories to be ordered separately (mounting on site):

White-lacquered steel-sheet cover

Art. No. 936.1541

RES.178

24

DH return

DH supply

Primary Secondary

HE return

HE supply

936.1541

9

HE return

HE supply

DHW

DHW

21

Circulation set

DCW

Danfoss District Energy VI.GP.V2.02 DKDHR

1111

Instructions Akva Lux II VX

7.0 Getting started

Connect the substation to the household piping in accordance with

the labelling at the bottom and in accordance with the instructions

in this manual.

If the system features DHW recirculation, a recirculation connection

must be established on the substation.

For instructions about recirculation connection, see page 14.

We recommend establishing recirculation BEFORE mounting the

substation on the wall.

Start-up

1. The ball valves are supplied loose with the substation. Mount the

ball valves for DH supply and return as well as the ball valves for

HE supply and return in the top of the substation. Mount the ball

valves for DHW and DCW in the bottom of the substation.

2. Please note that change of connection from bottom to top

for DCW and DHW includes relocation of blind plates BEFORE

mounting the substation on the wall. (See page 13, item 8.1

for further information.

14. Check the substation and the household piping carefully for any

leaks

15. Pressure test the entire system for leaks in accordance with the

applicable regulations.

16. Connect pump(s) and automatic components to the electricity

supply, but do not switch on the power.

3. The substations are for wall mounting, and the mounting sheet

has got holes for installation. Fix the substation on a solid wall

with two sturdy bolts, screws, expansion bolts or the like.

Please note that we recommend min. two people to lift the

substation.

4. Close all shut-o valves at the substation before connecting

them to the household piping.

5. Mount expansion vessel on substation types Akva Lux II VX3 and

Akva Lux II VX3-E, - see page 16.

6. Mount heat meter, - see page 17.

7. IMPORTANT! Tighten all connections, as vibrations during transport and handling may have caused leaks.

CAUTION! Please note that the connections may be supplied

with EPDM rubber gaskets. Therefore take care not to over-

strain the union nuts, as this may result in leaks. The manufacturer accepts no liability for leaks that result from overstrain

of union nuts.

8. On systems that feature a safety valve, establish a drain connection in compliance with the applicable legislation.

9. Set temperature for AT safety thermostat for oor or radiator heating.

10. If the household piping system features domestic hot water

recirculation, the substation must be connected to the recirculation system. See page 14 for more information about DHW

recirculation.

11. Carefully open the ball valves for the HE supply and return ow as

well as the ball valve for DCW. Carefully open the ll valve and ll

the system with water and at the same time vent the system. Fill

the heat exchanger / the system with water until the manometer shows a working pressure, which correspondes to the system

height + 5 m (approx. 1.2 - 1.5 bar), - see page 18.

17. Heat the system and vent the radiator circuit/heating side

thoroughly on the radiators and the air valve, if any.

18. Switch on the pumps and automatic components.

19. Finish by adjusting the substation in accordance with this

instruction manuals.

IMPORTANT! Heating and cooling of the system may cause

leaks. Therefore it may be necessary to retighten the connections in the period after commissioning.

Check list!

1. Remove plug, if DCW connection is established in

top.

2. Remove plug, if DHW connection is established in

top.

3. Set AT thermostat for oor or radiator heating.

4. Adjust the bypass valve.

5. Connect outdoor temperature sensor to the ECL

controller. (ECL 110, terminals 1 and 2), (ECL 310,

terminals 29 and 30).

6. Adjust controller’s min/max. temperature and

heating curve, - for oor or radiator heating.

12. Close the ll valve.

13. Subsequently open the ball valve for the DH supply and return

ow and heat up the system.

12

DKDHR VI.GP.V2.02 Danfoss District Energy

Instructions Akva Lux II VX

8.0 Mounting

The installation, connection and maintenance of the substation must

be performed by qualied and authorised personnel.

Installation must always be performed in accordance with the applicable legislation and in compliance with these instructions.

The substation must be installed so that it is freely accessible and can

be maintained without unnecessary disruption. Lift the substation

by its mounting plate/rear section and secure it to a solid wall using

2 sturdy bolts, screws or expansion bolts positioned in the two keyholes in the mounting plate/rear section.

Before commissioning, rinse all the pipes in the household piping

system thoroughly to remove any impurities, and check and clean

the dirt strainers in the substation.

Connect the substation to the household piping in accordance with

the labelling at the bottom and/or in accordance with the instructions in this manual.

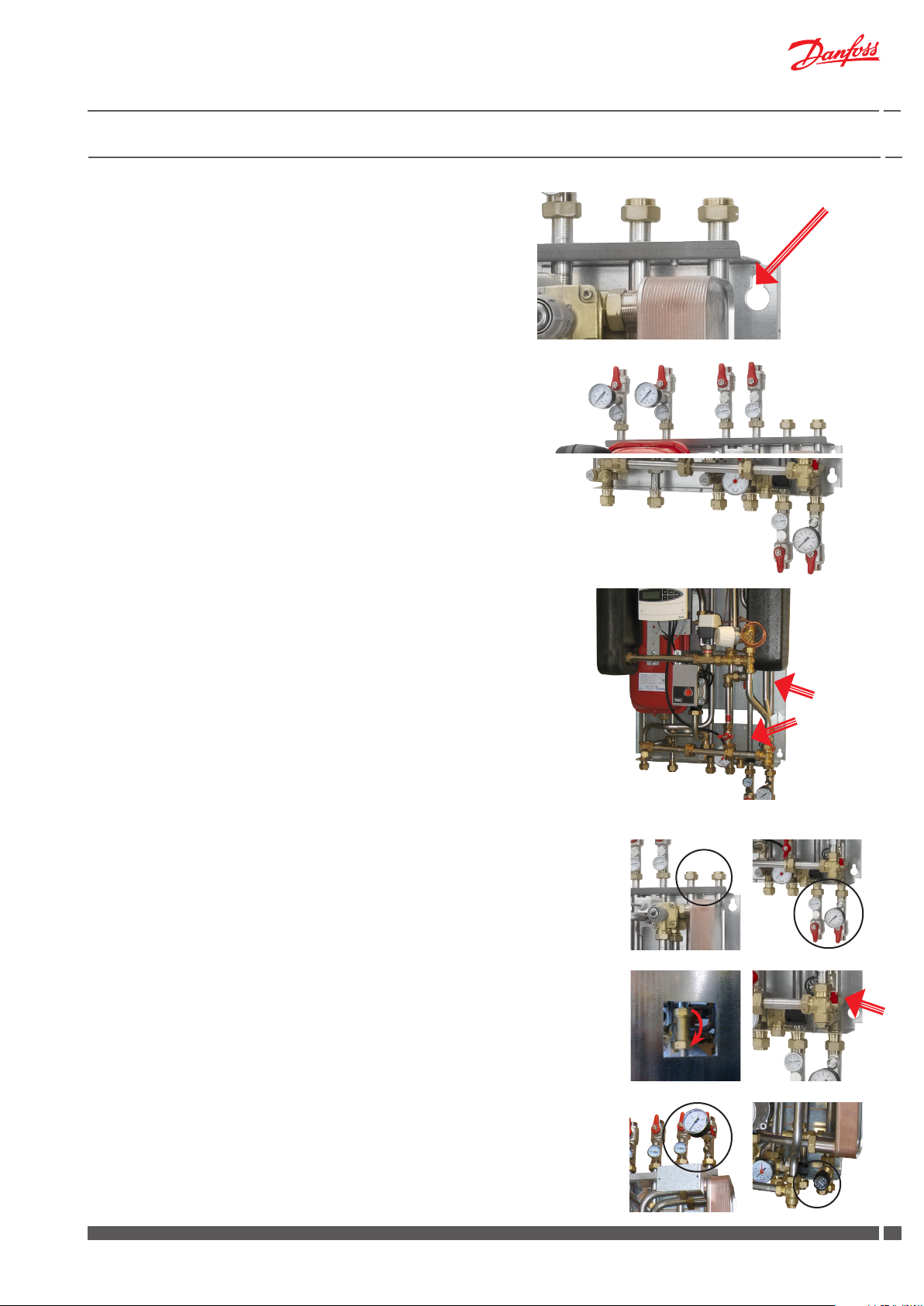

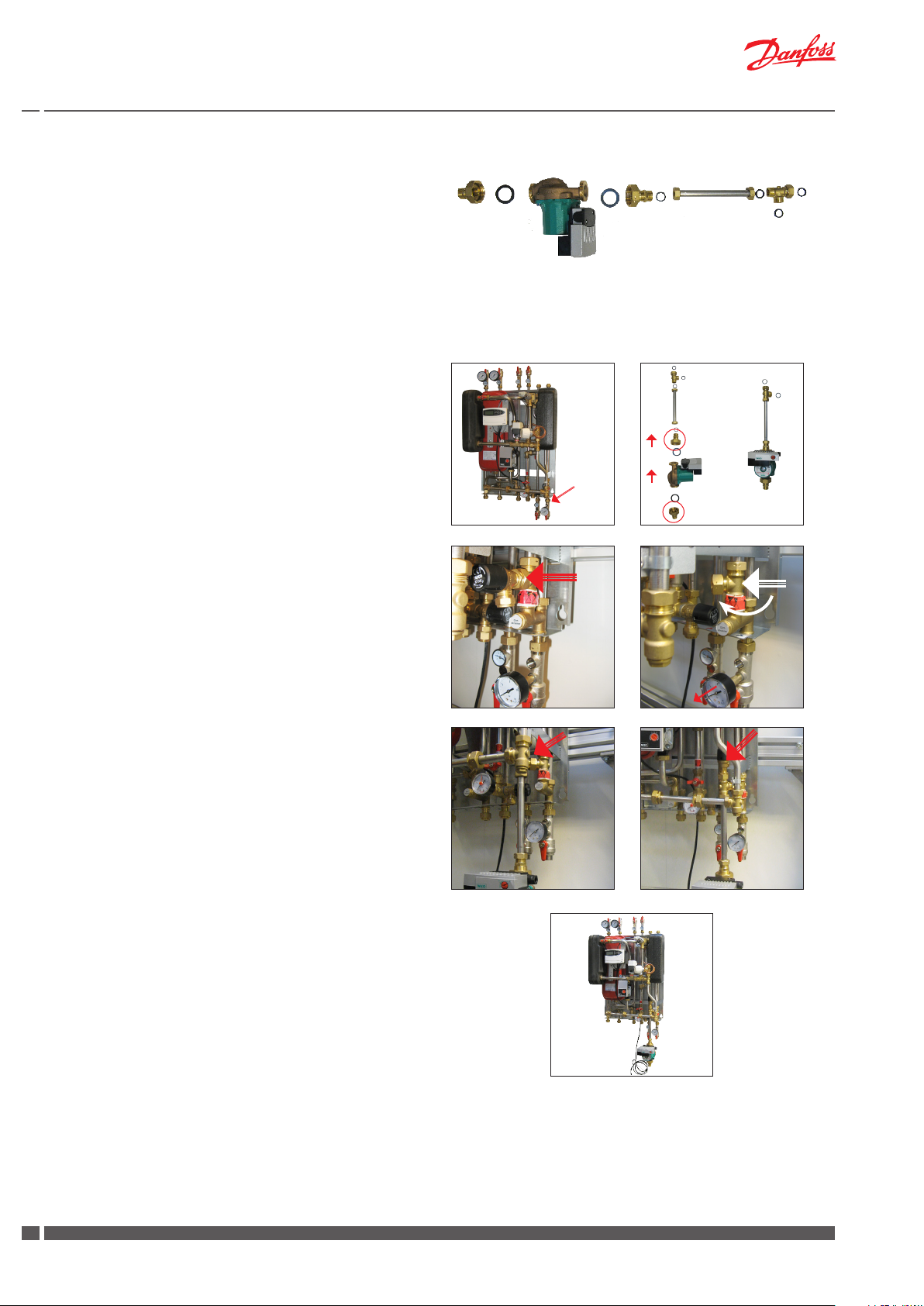

8.1 Variable connection possibilities

The substations oer variable connection possibilities, as connection of pipes can be established in the top or in the bottom of the

substation.

Upon delivery the ball valves are supplied loose with the substation

and the substation is prepared for mounting of the ball valves for DH

supply and return as well as the ball valves for HE supply and return in

top of the substation and for mounting of the ball valves for DHW and

DCW in the bottom of the substation, as illustrated on the photo to your

right (g. B).

For substations, on which the ball valves are mounted according to

the above, it is possible to change the connection order as follows:

Fig. A

Fig. B

DCW

pipe

DHW

pipe

For change of connection from top to bottom for DH supply and return

and HE supply and return, demount plugs on connection pipes in bottom

of substation and ball valves on connection pipes in top of substations

and mount plugs in connection pipes in top of substation and ball valves

on connection pipes in bottom of substation.

For change of connection from bottom to top for DHW and DCW

please follow the below instructions:

Fig. 1: Demount plugs on connection pipes in top of substation

Fig. 2: Demount ball valves on connection pipes in bottom of

substation

Fig. 3: Relocate blind plate in T-piece on DHW pipe as shown on

photo to your right. Please note the easy access to the T-piece

through a cut out in the back plate.

Fig. 4: Demount blind plate on DCW pipe

Fig. 5: Mount ball valves on DCW and DHW connection pipes in top of

substation.

Fig. 6: Mount plugs in DCW and DHW connection pipes in bottom of

substation

Please note Akva Lux II VX3-E is supplied with blind plate on

the DCW pipe only.

Fig. 1 Fig. 2

Fig. 3 Fig. 4

Fig. 5 Fig. 6

Danfoss District Energy VI.GP.V2.02 DKDHR

1313

Instructions Akva Lux II VX

8.2 DHW recirculation Akva Lux II VX2 & Akva Lux II VX3

If the household plumbing system includes hot water recirculation

the substation must be connected to the hot water recirculation

system by using this circulation set.

It is to be recommended to prepare the substation for recirculation

BEFORE mounting it on the wall.

8.2.1 Mounting of circulation set for Akva Lux II VX2 & VX3

Fig. 1. Mount the circulation set on the DCW inlet pipe in the bot-

tom of the substation. The pump must be installed so that

the pump is pumping water towards the substation.

Fig. 2. The circulation set is supplied loose, as illustrated in g. 2a.

Assemble the circulation set as illustrated in g. 2b, and remember to use packing yarn when packing the hexagon

nipple/non-return valve in the 5/4” pump union piece and

make sure that the arrow on the hexagon nipple/non-return

valve points upwards.

Fig. 3. Demount the safety valve (to be reused).

Fig. 4. Turn the T-piece 45°, as illustrated in g. 4.

Fig. 5. Fit the circulation set to the T-piece.

Fig. 6. Remount safety valve on circulation set.

Connect the pump to the household electrical wiring. For

setting and venting of pump, please refer to page 33.

Pack

Pack

Fig. 1 Fig. 2a Fig. 2b

Fig. 3 Fig. 4

Fig. 5 Fig. 6

Akva Lux II VX2 with circulation set

8.2.2 Mounting of circulation set Akva Lux II VX2-E and VX3-E

The circulation set is supplied assembled and electrically wired

and ready to be mounted on the DCW inlet pipe in the bottom of

the substation before start up. See photo on page 9 and 11.

14

DKDHR VI.GP.V2.02 Danfoss District Energy

Instructions Akva Lux II VX

8.3 Safety thermostat

Safety thermostat

The heating circuit is supplied with a safety thermostat, type AT

pipe thermostat, for protection against overheating. The AT thermostat is mounted directly on the pipe with a steel band.

The AT pipe thermostat is used to regulate the medium temperature in the pipe, on which the thermostat is mounted. AT senses the

temperature in the pipe through its contact surface and is therefore

suitable to control the ow temperature, as it - in combination with

the ECL controller - switches of the pump to prevent excessive levels of temperature.

Please see enclosed operating instructions

Thermostat type AT

Data Sheet

Thermostat type AT

Application

Technical Data

Accessories

Danfoss Heating Solutions VDGIA102 © Danfoss 01/2012 1

The AT thermostat can be mounted on the pipe

The AT pipe thermostat is used to regulate the

without emptying the plant of water.

medium temperature in the pipe on which the

thermostat is mounted. AT senses the temperature in the pipe through its contact surface and is

therefore suitable to control boiler or flow temperature in central heating systems.

The AT pipe thermostat comprises a bimetallaic

sensor, a contact system and a setting knob.

On connection to terminals CO and NC the thermostat breaks on a rise in temperature.

On connection to terminals CO and NO the thermostat close on a rise in temperature.

Temperature range 30 to 90 °C

Temperature scale external (type 041E0000)

internal (type 041E0020)

Temperature differential 8 K

Max. temperature plant surface Ts90

Max. ambient temperature 55 °C

Storage temperature -20 to 90 °C

Switch system SPDT

Enclosure IP40

Terminal CO-NC Breaks on temperature rise

Terminal CO-NO Closes on temperature rise

Switch load 6 (2.5) A, 250 Vac

0.1 A, 250 Vdc

Approval according to EMC Standard EN 60730-2-9: 1995

EMC Standard Emission EN 55014

Environment Normal

Installation Installed in any position

Product Code no.

Heat-conductive compound ~ 5 g 041E0110

Heat-conductive compound ~ 1 kg 041E0111

If the supply water temperature rises above the thermostat set

point (for oor heating 50 °C, for radiator heating 80 °C) the heat

pump stops.

The pump starts again as the temperature drops about 6 °C below

the thermostat set point.

Note!

The thermostat set point is changed as follows:

1. Pull the thermostat on the surface of the pipe until it is easily

accessible (g. 1).

2. Demount the thermostat cover cap (g. 2).

3. Turn the spindle to set a new value. Turn the indicator and set

the value according to the embossed thermostat scale on the

thermostat base plate. Scale 30-90 ° C (g. 3).

4. Finally, mount the cover cap and slide the thermostat back in

place.

Remove

Set temperature

80 °C

50 °C

Fig. 1

Fig. 2

Note!

Temperature range for the safety thermostat is 30 - 90 °C.

The temperature is not preset from factory.

For oor heating the value must be set to max. 50 °C.

In case of radiator heating the value must be set to 80 °C.

Fig. 3

Danfoss District Energy VI.GP.V2.02 DKDHR

1515

8.4 Expansion vessel

Expansion vessel, Akva Lux II VX2 and VX2-E

The Akva Lux II VX2 substation is equipped with an expansion vessel, which is factory set to 0.5 bar.

Expansion vessel, Akva Lux II VX3 and VX3-E

An expansion vessel is supplied loose with the Akva Lux II VX3

substations for mounting on site.

The expansion vessel is factory set to 0.5 bar.

The expansion vessel can be connected to the substation either

in the top or in the bottom of the substation, - oppositely to the

pipes connection, which can be established both in the top or in

the bottom of the substation.

Mount the expansion vessel according to the below instructions:

1. Mount the T-piece on the HE supply either in top or bottom of

substation.

2. Mount the bracket on the wall.

3. Place the expansion vessel on the bracket and fasten it with

union nuts or screw nuts (not part of the delivery).

4. Establish pipe connection between T-piece and connecting

piece on expansion vessel. (Please note that a connection

pipe is not part of the delivery).

Expansion vessel

T-piece

Bracket

16

DKDHR VI.GP.V2.02 Danfoss District Energy

Instructions Akva Lux II VX

8.5 Heat meter, Fitting piece

The substations are equipped with tting pieces for heat meter on

the district heating return line.

Fitting of heat meter

- Close the ball valves on the district heating and the heating

sides.

- Loosen the union nuts at both ends of the tting piece and

remove it.

- Fit the heat meter, - remember to insert gaskets.

- Mount sensor, - remember to insert gaskets.

- After mounting of heat meter remember to check and tighten

all pipe connections before commissioning the heat meter.

8.6 Test and connections

Before lling the system with water, retighten all the pipe connections

because vibrations and shocks during transport and handling may

have caused leaks. Once the system has been lled with water, tighten

all the pipe connections once more before performing pressure test

for leaks. After heating of the system, check all the connections and

retighten if necessary.

Please note that the connections may feature EPDM rubber gaskets!

Therefore, it is important that you DO NOT OVERTIGHTEN the

union nuts. Over-tightening may result in leaks. Leaks caused by

over-tightening or failure to retighten connections are not covered

by the warranty.

8.7 Mounting of outdoor temperature sensor

The outdoor temperature sensor is delivered separately and must be

mounted on site according to the enclosed illustrations.

The outdoor sensor is always to be mounted on the coldest side of

the property (normally the north side of the property).

The sensor must not be exposed to the morning sun, and should not

be mounted above windows, doors, air vents or other heat sources,

and not under balconies and roof eaves.

Mounting height approx. 2.5 m above ground.

Temperature range: -50 to 50° C

Electrical connections

Two wire non polarized (can be crossed)

Sensor cable: 2 x 0.4 - 1.5 mm²

ECL 110:

Connect the cable ends to ECL controller in clamps 1 and 2.

ECL 310

Connect the cable ends to ECL controller in clamps 29 and 30.

8.8 Safety valves

A discharge outlet from the safety valves must be established in compliance with local regulations.

Danfoss District Energy VI.GP.V2.02 DKDHR

1717

9.0 Filling, Start-up

Prior to the Akva Lux II VX installation all its pipes and connections

should be cleaned and rinsed. After that the dirt strainers should

be cleaned.

Due to vibrations during transport all connections must be checked

and tightened before lling and start-up.

Before lling up the system and rst start-up, check if:

- pipes are connected according to the circuit diagram,

- expansion vessel is connected,

- heat meter is mounted,

- shut-o valves are closed,

- threaded and anged connections are tightened.

Filling:

The lling valve(s) are used for lling up the heating circuit.

• The pump must be switched o when lling the system with

water.

• Open the ball valves for the HE supply and return ow as well

as the ball valve for DCW.

• Carefully open the ll valve(s) and ll the system with water

and at the same time vent the system.

Filling valves

Akva Lux II VX2

Filling valves

Akva Lux II VX3

Filling valves

Akva Lux II VX2-E

Filling valves

Akva Lux II VX3-E

• Fill heat exchanger / the system with water until the manometer shows a working pressure, which corresponds to the

system height + 5 m (approx. 1.2 - 1.5 bar).

• Close the ll valve(s).

• Then open the ball valves for the DH supply and return ow

and heat up the system.

• After lling and heat- up of the system, it should be vented by

means of the air vents on the substation and on the radiators.

• Then switch on the pump(s).

10.0 Manometer and relling

If the pressure drops below 1 bar, water must be added to the

system. The operating pressure should never exceed 1.5 bar.

(The safety valves open at 2.5 bar)

If the system pressure drops dramatically within a short time, or

if you experience that it is necessary often to rell the system,

the heating system should be examined for leaks, - this includes

checking the factory set pressure of the expansion vessel.

18

DKDHR VI.GP.V2.02 Danfoss District Energy

11.0 Electrical connections

The station is wired and tested in the factory.

Electrical connections between the controller, pump(s), sensor

and actuator(s) are made.

The electrical connection of the substation must be performed

by a qualied and authorised electrician in compliance with all

applicable rules and regulations.

The station should be connected to a 230 V AC power supply.

The power supply connection must be carried out in accordance

with the applicable regulations and instructions.

The station must be wired and connected to an external main

switch so that it can be turned o during maintenance, cleaning

or repair work or in case of an emergency situation.

Component Supply voltage

Controller

ECL 110

Controller

ECL 310

Actuator

AMV 150

Actuator

AMV10/20/30

Pump, Wilo Yonos

Para

Pump, Wilo

Star Z Nova

Pump, Wilo Stratos

Eco Z

230 V a.c., 50 Hz 3 VA

230 V a.c., 50 Hz 5 VA

230 V a.c., 60 Hz 8 VA

230 V a.c., 60 Hz 2 VA

230 V a.c., 50 Hz Max. 45 Watt

230 V a.c., 50 Hz Max. 4.5 Watt

230 V a.c., 50 Hz Max. 59 Watt

Power

consumption

Danfoss District Energy VI.GP.V2.02 DKDHR

1919

Instructions Akva Lux II VX2

12.0 Description of Akva Lux II VX variants

12.1 Akva Lux II VX2 (ECL 110)

Substation for indirect heating for single-family, semi-detatched and

terraced houses as well as ats. With one heating circuit for radiator or

oor heating and instantaneous domestic hot water heater. Designed

for wall-mounting with connections in top and bottom of substation.

The temperature for the heating circuit is controlled by a Danfoss

ECL 110 controller in combination with an electronic actuator. The

supply temperature is calculated by the controller on basis of the

outdoor temperature.

Please note:

Your substation may look dierent than the substation shown, as variants with other components may be supplied.

Instructions for the tted components will always be supplied together with the substation.

Heating circuit

The temperature for the heating circuit is controlled electronically

by the Danfoss ECL controller. The supply temperature is calculated

by the controller on basis of the outdoor temperature.

The factory-setting of the controller ensures that heating is automatically switched o in the summer period.

In periods with higher heat demand the controller settings can be

changed in accordance with the enclosed producer instructions for

the mounted controller.

Installation & Maintenance

Danfoss ECL Comfort 110

Instructions

ECL Comfort 110

Application 116

Constant temperature control

of domestic hot-water systems (DHW)

$2!&4

DH-SMT/DK VI.KT.F2.02 © Danfoss 06/2008

User guide,

Installation & Maintenance

Control of heating circuit

For controlling the heating circuit the Akva Lux II VX 2 (ECL 110) is

supplied with a 2-way valve VS 2 and an electrical actuator AMV 150,

which in combination with the ECL controller controls the heating

circuit.

The electrical actuator has undergone a functional test from factory.

In case of operating disturbances the actuator can be closed manually turning the manual override knob on top of actuator counterclockwise.

Please see enclosed instructions,

Electrical actuator AMV 150

2-way valve VS 2

INSTRUCTIONS

VS2 2-way

065R9075

Instructions

AMV 150

065R9075

Manual override (AMV 150)

AMV 150 + AMV 150 + AMV 150 +

VS2 (DN 15) VMV AVQM (DN 15)

Actuators for three point control AMV 150 www.danfoss.com Page 2

ENGLISH

Motorer til 3-punkts styring AMV 150 www.danfoss.dk Side 3

DANSK

Stellantriebe für 3-Pkt.- Eingangssignal AMV 150 www.danfoss.de Seite 3

DEUTSCH

Motor för 3-punktsreglering AMV 150 varme.danfoss.se Sida 4

SVENSKA

Servomotor met 3-puntssturing AMV 150 www.danfoss.nl Pagina 4

NEDERLANDS

Pavaros trijų padėčių valdymui AMV 150 www.danfoss.lt 5 puslapis

LIETUVIŲ K.

Motori trīs punktu kontrolei AMV 150 www.danfoss.com Lpp. 5

LATVISKI

Szelepmozgatók hárompontos szabályozáshoz AMV 150 www.danfoss.com 6. oldal

DN L (mm)

15 65

20 70

25 75

DN L1(mm)

15 131

20 142

25 159

DN L2(mm)

15 139

20 154

25 159

7369267-9 SIBC R&D EI.97.Q2.00© Danfoss 12/01 1

20

DKDHR VI.GP.V2.02 Danfoss District Energy

MAGYAR

Servopohony s tříbodovým regulačním signálem AMV 150 www.danfoss.cz Strana 6

ČESKY

Siłowniki sterowane sygnałem 3-punktowym AMV 150 www.danfoss.pl Strona 7

POLSKI

Электроприводы для трехпозиционного регулирования AMV 150

РУССКИЙ

DN L3(mm)

15 69

20 74

25 79

www.danfoss.ru Страница 7

VS 2

Press and hold the button (on

the bottom side of the actuator)

during manual override.

Instructions Akva Lux II VX2

Circulation pump, heating circuit

See chapter 13 on page 32 for more information about circulation

pump.

Safety thermostat

The heating circuit is supplied with a safety thermostat, type AT

pipe thermostat, for protection against overheating.

The AT pipe thermostat is used to regulate the medium temperature in the pipe, on which the thermostat is mounted. AT senses the

temperature in the pipe through its contact surface and is therefore

suitable to control the ow temperature, as it - in combination with

the ECL controller - switches of the pump to prevent excessive levels of temperature.

Please see enclosed operating instructions

Thermostat type AT

Note!

Temperature range for the safety thermostat is 30 - 90 °C.

The temperature is not preset from factory.

Data Sheet

Thermostat type AT

Application

Technical Data

Accessories

The AT thermostat can be mounted on the pipe

The AT pipe thermostat is used to regulate the

without emptying the plant of water.

medium temperature in the pipe on which the

thermostat is mounted. AT senses the temperature in the pipe through its contact surface and is

therefore suitable to control boiler or flow temperature in central heating systems.

The AT pipe thermostat comprises a bimetallaic

sensor, a contact system and a setting knob.

On connection to terminals CO and NC the thermostat breaks on a rise in temperature.

On connection to terminals CO and NO the thermostat close on a rise in temperature.

Temperature range 30 to 90 °C

Temperature scale external (type 041E0000)

Temperature differential 8 K

Max. temperature plant surface Ts90

Max. ambient temperature 55 °C

Storage temperature -20 to 90 °C

Switch system SPDT

Enclosure IP40

Terminal CO-NC Breaks on temperature rise

Terminal CO-NO Closes on temperature rise

Switch load 6 (2.5) A, 250 Vac

Approval according to EMC Standard EN 60730-2-9: 1995

EMC Standard Emission EN 55014

Environment Normal

Installation Installed in any position

Product Code no.

Heat-conductive compound ~ 5 g 041E0110

Heat-conductive compound ~ 1 kg 041E0111

internal (type 041E0020)

0.1 A, 250 Vdc

Remove

Set temperature

80 °C

50 °C

For oor heating the value must be set to max. 50 °C.

In case of radiator heating the value must be set to 80 °C.

Domestic hot water

The domestic hot water is prepared in a heat exchanger based on the

ow principle and the temperature is controlled by a combined hydraulic

and thermostatic self-acting controller PTC2+P with integrated dierential pressure controller, which blocks the ow of primary and secondary

side ow through the heat exchanger immediately after completion of

the tapping process.

DHW temperature control

Danfoss PTC2+P controller (1) for DHW. The DHW temperature is adjusted

by turning the lever towards “+” (warmer) or “-” (colder).

Start by turning the handle clockwise - until stop /until the handle can

not be turned anymore. Then turn the handle counter-clockwise until

the temperature of the tap water is approx. 48° C at normal use (7-8 l/

min). The temperature should never exceed 55° C to avoid lime scale

precipitation.

Bypass thermostat

Bypass thermostat (default).

As a standard the Akva Lux II VX2 is equipped with a bypass thermostat,

Danfoss FJVR (2), which ensures that hot water is produced immediately, when tapping starts. It is recommended to set the thermostat

in pos.3. If the water temperature rises too slowly it can be necessary

to set the thermostat at higher value.

Alternatively a DHW circulation system must be installed.

1

Handle for temperature setting

2

Approximate scale settings

2 = 30° C

3 = 40 °C

4 = 45° C

I = 50° C

(max. temperature)

DHW recirculation

For Akva Lux II VX2 switching to recirculation is possible from a

constructional point of view, requiring only an additional circulation set. The circulation set is not included in the delivery and must

be ordered separately and mounted on site.

See instructions for mounting of circulation set on page 14.

You must always t a pump and a non-return valve to the recirculation pipe, with ow direction towards the susbstation.

Danfoss District Energy VI.GP.V2.02 DKDHR

2121

Instructions Akva Lux II VX2-E

12.2 Akva Lux II VX2-E (ECL 310/A266)

Substation for indirect heating for single-family, semi-detatched and

terraced houses as well as ats. With one heating circuit for radiator or

oor heating and instantaneous domestic hot water heater. Designed

for wall-mounting with connections in top and bottom of substation.

The temperature for the heating circuit is controlled by a Danfoss

ECL 310 controller in combination with an electronic actuator. The

supply temperature is calculated by the controller on basis of the

outdoor temperature.

Please note:

Your substation may look dierent than the substation shown, as variants with other components may be supplied.

Instructions for the tted components will always be supplied together with the substation.

Heating circuit

The temperature for the heating circuit is controlled electronically by

the Danfoss ECL controller. The supply temperature ist calculated by

the controller on basis of the outdoor temperature.

The ECL Comfort 310 controller is loaded with a selected application

by means of an ECL Application Key (Plug-&-Play). The Application

Key contains information about application, languages and factory

settings.

The controller is factory preset to turn o the heating automatically

in the summer period.

The controller settings can be changed in accordance with the enclosed producer instructions for the mounted controller.

See ECL Application Key Box with ECL Comfort 210/310 user guide

and mounting guide, for further information.

Control of heating circuit

For control of heating circuit 1 the Akva Lux II VX2-E (ECL 310) is

supplied with a 2-way valve VS 2 and an electrical actuator AMV 150,

which in combination with the ECL controller controls the heating

circuit.

The electrical actuator has undergone a functional test from factory.

In case of operating disturbances the actuator can be closed manually turning the manual override knob on top of actuator counterclockwise.

Please see enclosed instructions,

Electrical actuator AMV 150

2-way valve VS 2

INSTRUCTIONS

VS2 2-way

065R9075

Instructions

AMV 150

065R9075

ECL application key

Manual override (AMV 150)

AMV 150 + AMV 150 + AMV 150 +

VS2 (DN 15) VMV AVQM (DN 15)

Actuators for three point control AMV 150 www.danfoss.com Page 2

ENGLISH

Motorer til 3-punkts styring AMV 150 www.danfoss.dk Side 3

DANSK

Stellantriebe für 3-Pkt.- Eingangssignal AMV 150 www.danfoss.de Seite 3

DEUTSCH

Motor för 3-punktsreglering AMV 150 varme.danfoss.se Sida 4

SVENSKA

Servomotor met 3-puntssturing AMV 150 www.danfoss.nl Pagina 4

NEDERLANDS

Pavaros trijų padėčių valdymui AMV 150 www.danfoss.lt 5 puslapis

LIETUVIŲ K.

Motori trīs punktu kontrolei AMV 150 www.danfoss.com Lpp. 5

LATVISKI

Szelepmozgatók hárompontos szabályozáshoz AMV 150 www.danfoss.com 6. oldal

DN L (mm)

15 65

20 70

25 75

DN L1(mm)

15 131

20 142

25 159

DN L2(mm)

15 139

20 154

25 159

7369267-9 SIBC R&D EI.97.Q2.00 © Danfoss 12/01 1

MAGYAR

Servopohony s tříbodovým regulačním signálem AMV 150 www.danfoss.cz Strana 6

ČESKY

Siłowniki sterowane sygnałem 3-punktowym AMV 150 www.danfoss.pl Strona 7

POLSKI

Электроприводы для трехпозиционного регулирования AMV 150

РУССКИЙ

DN L3(mm)

15 69

20 74

25 79

www.danfoss.ru Страница 7

VS 2

Press and hold the button (on

the bottom side of the actuator)

during manual override.

22

DKDHR VI.GP.V2.02 Danfoss District Energy

Instructions Akva Lux II VX2-E

Circulation pumps, heating circuit

See chapter 13 on page 32 for more information about circulation

pump.

Switch box for pumps

Power switch 1 switches o the DHW/DCW circulation pump.

Power switch 2 switches o the pump for heating circuit 1.

Power switch 3 switches o the pump for heating circuit 2.

Safety thermostat

The heating circuit is supplied with a safety thermostat, type AT

pipe thermostat, for protection against overheating.

The AT pipe thermostat is used to regulate the medium temperature in the pipe, on which the thermostat is mounted. AT senses the

temperature in the pipe through its contact surface and is therefore

suitable to control the ow temperature, as it - in combination with

the ECL controller - switches of the pump to prevent excessive levels of temperature.

Please see enclosed operating instructions

Note!

Thermostat type AT

Temperature range for the safety thermostat is 30 - 90 °C.

The temperature is not preset from factory.

For oor heating the value must be set to max. 50 °C.

In case of radiator heating the value must be set to 80 °C.

Data Sheet

Thermostat type AT

Application

Technical Data

Accessories

The AT thermostat can be mounted on the pipe

The AT pipe thermostat is used to regulate the

without emptying the plant of water.

medium temperature in the pipe on which the

thermostat is mounted. AT senses the temperature in the pipe through its contact surface and is

therefore suitable to control boiler or flow temperature in central heating systems.

The AT pipe thermostat comprises a bimetallaic

sensor, a contact system and a setting knob.

On connection to terminals CO and NC the thermostat breaks on a rise in temperature.

On connection to terminals CO and NO the thermostat close on a rise in temperature.

Temperature range 30 to 90 °C

Temperature scale external (type 041E0000)

internal (type 041E0020)

Temperature differential 8 K

Max. temperature plant surface Ts90

Max. ambient temperature 55 °C

Storage temperature -20 to 90 °C

Switch system SPDT

Enclosure IP40

Terminal CO-NC Breaks on temperature rise

Terminal CO-NO Closes on temperature rise

Switch load 6 (2.5) A, 250 Vac

Approval according to EMC Standard EN 60730-2-9: 1995

EMC Standard Emission EN 55014

Environment Normal

Installation Installed in any position

Product Code no.

Heat-conductive compound ~ 5 g 041E0110

Heat-conductive compound ~ 1 kg 041E0111

0.1 A, 250 Vdc

Remove

1 2 3

Set temperature

80 °C

50 °C

Danfoss District Energy VI.GP.V2.02 DKDHR

2323

Instructions Akva Lux II VX2-E

Domestic hot water

The domestic hot water is prepared in a heat exchanger based on the

ow principle and the temperature is controlled by a two -vay val ve and

an actuator in combination with the ECL controller.

Substations with electronic control of the domestic hot water circuit

are prefabricated with DHW recirculation.

DHW temperature control

For controlling the domestic hot water temperature the Akva Lux

II VX2-E is supplied with 2-way valve VM 2 and an actuator AMV 30,

which in combination with the ECL controller controls the domestic hot water circuit.

The controller closes when set max. ow is exceeded.

The electrical actuator has undergone a functional test from factory.

Please see enclosed instructions,

Electrical actuator AMV 30

2-way valve VM2

Instructions

AMV 20, AMV 30

082R9092

AMV 20, AMV 30 + VM2, VS2 AMV 20, AMV 30 + AVQM AMV 20, AMV 30 + VB2

1

2

3

4

N - 1

N - 3

7369220-2 EI.96.A1.00 © Danfoss 02/02 1

082R9092

065R9074

VM2 VB2

Instructions

VM2, VB2 2-way

DN L (mm)

15 65

20 70

25 75

32 100

40 110

50 130

DN L1(mm)

15 131

20 142

25 159

32 196

40 196

50 228

DN L2(mm)

15 139

20 154

25 159

32 184

40 294

50 330

065R9074

DN L3(mm)

15 69

20 74

25 79

32 104

40 114

50 134

DHW recirculation

Substations with electronic control of the domestic hot water

circuit are prefabricated for DHW recirculation.

The circulation set is supplied assembled, incl. circulation pump

and electrically wired and ready to mount on the substation.

AMV 30

VM2

DHW circulation pump

The Akva Lux II VX2-E substations come standard with a Wilo-Star-Z

NOVA circulation pump, which is electrically connected to the ECL controller from factory.

See chapter 14.2 on page 33 for more information about DHW

pumps.

24

DKDHR VI.GP.V2.02 Danfoss District Energy

Instructions Akva Lux II VX3

12.3 Akva Lux II VX3 (ECL210/A260)

Substation for indirect heating for single-family, semi-detatched

and terraced houses as well as ats. With two heating circuits and

instantaneous domestic water heater. Designed for wall-mounting

with connections in top and bottom of substation.

The temperature for the heating circuits is controlled by a Danfoss ECL

310 controller in combination with electronic actuators. The supply

temperature is calculated by the controller on basis of the outdoor

temperature.

Please note:

Your substation may look dierent than the substation shown, as variants with other components may be supplied.

Instructions for the tted components will always be supplied together with the substation.

Heating circuit

The temperature for the heating circuit is controlled electronically by

the Danfoss ECL controller. The supply temperature ist calculated by

the controller on basis of the outdoor temperature.

The ECL Comfort 310 controller is loaded with a selected application

by means of an ECL Application Key (Plug-&-Play). The Application

Key contains information about application, languages and factory

settings.

The controller is factory preset to turn o the heating automatically

in the summer period.

The controller settings can be changed in accordance with the enclosed producer instructions for the mounted controller.

See ECL Application Key Box with ECL Comfort 210/310 user guide

and mounting guide, for further information.

Control of heating circuit 1

For control of heating circuit 1 the Akva Lux II VX3 (ECL 310) is supplied

with a 2-way valve VS 2 and an electrical actuator AMV 150, which

in combination with the ECL controller controls the heating circuit.

The electrical actuator has undergone a functional test from factory.

In case of operating disturbances the actuator can be closed manually turning the manual override knob on top of actuator counterclockwise.

Please see enclosed instructions,

Electrical actuator AMV 150

2-way valve VS 2

INSTRUCTIONS

VS2 2-way

065R9075

Instructions

AMV 150

065R9075

Manual override (AMV 150)

AMV 150 + AMV 150 + AMV 150 +

VS2 (DN 15) VMV AVQM (DN 15)

Actuators for three point control AMV 150 www.danfoss.com Page 2

ENGLISH

Motorer til 3-punkts styring AMV 150 www.danfoss.dk Side 3

DANSK

Stellantriebe für 3-Pkt.- Eingangssignal AMV 150 www.danfoss.de Seite 3

DEUTSCH

Motor för 3-punktsreglering AMV 150 varme.danfoss.se Sida 4

SVENSKA

Servomotor met 3-puntssturing AMV 150 www.danfoss.nl Pagina 4

NEDERLANDS

Pavaros trijų padėčių valdymui AMV 150 www.danfoss.lt 5 puslapis

LIETUVIŲ K.

Motori trīs punktu kontrolei AMV 150 www.danfoss.com Lpp. 5

LATVISKI

Szelepmozgatók hárompontos szabályozáshoz AMV 150 www.danfoss.com 6. oldal

DN L (mm)

15 65

20 70

25 75

DN L1(mm)

15 131

20 142

25 159

DN L2(mm)

15 139

20 154

25 159

7369267-9 SIBC R&D EI.97.Q2.00 © Danfoss 12/01 1

MAGYAR

Servopohony s tříbodovým regulačním signálem AMV 150 www.danfoss.cz Strana 6

ČESKY

Siłowniki sterowane sygnałem 3-punktowym AMV 150 www.danfoss.pl Strona 7

POLSKI

Электроприводы для трехпозиционного регулирования AMV 150

РУССКИЙ

DN L3(mm)

15 69

20 74

25 79

www.danfoss.ru Страница 7

VS 2

Press and hold the button (on

the bottom side of the actuator)

during manual override.

Danfoss District Energy VI.GP.V2.02 DKDHR

2525

Instructions Akva Lux II VX3

Control of heating circuit 2

For control of heating circuit 2 the Akva Lux II VX3 (ECL 310) is supplied

with a 2-way valve VS 2 and an electrical actuator AMV 150, which

in combination with the ECL controller controls the heating circuit.

The electrical actuator has undergone a functional test from factory.

In case of operating disturbances the actuator can be closed manually turning the manual override knob on top of actuator counterclockwise.

Please see enclosed instructions,

Electrical actuator AMV 150

2-way valve VS 2

INSTRUCTIONS

VS2 2-way

065R9075

DN L (mm)

15 65

20 70

25 75

DN L1(mm)

15 131

20 142

25 159

DN L2(mm)

15 139

20 154

25 159

7369267-9 SIBC R&D EI.97.Q2.00 © Danfoss 12/01 1

Instructions

AMV 150

065R9075

AMV 150 + AMV 150 + AMV 150 +

VS2 (DN 15) VMV AVQM (DN 15)

Actuators for three point control AMV 150 www.danfoss.com Page 2

ENGLISH

Motorer til 3-punkts styring AMV 150 www.danfoss.dk Side 3

DANSK

Stellantriebe für 3-Pkt.- Eingangssignal AMV 150 www.danfoss.de Seite 3

DEUTSCH

Motor för 3-punktsreglering AMV 150 varme.danfoss.se Sida 4

SVENSKA

Servomotor met 3-puntssturing AMV 150 www.danfoss.nl Pagina 4

NEDERLANDS

Pavaros trijų padėčių valdymui AMV 150 www.danfoss.lt 5 puslapis

LIETUVIŲ K.

Motori trīs punktu kontrolei AMV 150 www.danfoss.com Lpp. 5

LATVISKI

Szelepmozgatók hárompontos szabályozáshoz AMV 150 www.danfoss.com 6. oldal

MAGYAR

Servopohony s tříbodovým regulačním signálem AMV 150 www.danfoss.cz Strana 6

ČESKY

Siłowniki sterowane sygnałem 3-punktowym AMV 150 www.danfoss.pl Strona 7

POLSKI

Электроприводы для трехпозиционного регулирования AMV 150

РУССКИЙ

DN L3(mm)

15 69

20 74

25 79

www.danfoss.ru Страница 7

VS 2

Manual override (AMV 150)

Press and hold the button (on

the bottom side of the actuator)

during manual override.

Circulation pumps, heating circuits

See chapter 13 on page 32 for more information about circulation

pumps.

Safety thermostat

The heating circuit is supplied with a safety thermostat, type AT

pipe thermostat, for protection against overheating.

The AT pipe thermostat is used to regulate the medium temperature in the pipe, on which the thermostat is mounted. AT senses

the temperature in the pipe through its contact surface and is

therefore suitable to control the ow temperature, as it - in combination with the ECL controller - switches of the pump to prevent

excessive levels of temperature.

Please see enclosed operating instructions

Thermostat type AT

Data Sheet

Thermostat type AT

Application

Technical Data

Accessories

Danfoss Heating Solutions VDGIA102 © Danfoss 01/2012 1

The AT thermostat can be mounted on the pipe

The AT pipe thermostat is used to regulate the

without emptying the plant of water.

medium temperature in the pipe on which the

thermostat is mounted. AT senses the temperature in the pipe through its contact surface and is

therefore suitable to control boiler or flow temperature in central heating systems.

The AT pipe thermostat comprises a bimetallaic

sensor, a contact system and a setting knob.

On connection to terminals CO and NC the thermostat breaks on a rise in temperature.

On connection to terminals CO and NO the thermostat close on a rise in temperature.

Temperature range 30 to 90 °C

Temperature scale external (type 041E0000)

Temperature differential 8 K

Max. temperature plant surface Ts90

Max. ambient temperature 55 °C

Storage temperature -20 to 90 °C

Switch system SPDT

Enclosure IP40

Terminal CO-NC Breaks on temperature rise

Terminal CO-NO Closes on temperature rise

Switch load 6 (2.5) A, 250 Vac

Approval according to EMC Standard EN 60730-2-9: 1995

EMC Standard Emission EN 55014

Environment Normal

Installation Installed in any position

Product Code no.

Heat-conductive compound ~ 5 g 041E0110

Heat-conductive compound ~ 1 kg 041E0111

internal (type 041E0020)

0.1 A, 250 Vdc

Note!

Temperature range for the safety thermostat is 30 - 90 °C.

The temperature is not preset from factory.

Remove

Set temperature

80 °C

50 °C

For oor heating the value must be set to max. 50 °C.

In case of radiator heating the value must be set to 80 °C.

26

DKDHR VI.GP.V2.02 Danfoss District Energy

Instructions Akva Lux II VX3

Domestic hot water

The domestic hot water is prepared in a heat exchanger based on the

ow principle and the temperature is controlled by a combined hydraulic and thermostatic self-acting controller PTC2+P with integrated

dierential pressure controller, which blocks the ow of primary and

secondary side ow through the heat exchanger immediately after

completion of the tapping process.

DHW temperature control

Danfoss PTC2+P controller (1) for DHW. The DHW temperature is adjusted

by turning the lever towards “+” (warmer) or “-” (colder).

Start by turning the handle clockwise - until stop /until the handle can

not be turned anymore. Then turn the handle counter-clockwise until

the temperature of the tap water is approx. 48° C at normal use (7-8 l/

min). The temperature should never exceed 55° C to avoid lime scale

precipitation.

Bypass or circulation thermostat

Bypass thermostat (default).

As a standard the Akva Lux II VX3 is equipped with a bypass thermostat,

Danfoss FJVR (2), which ensures that hot water is produced immediately, when tapping starts. It is recommended to set the thermostat

in pos.3. If the water temperature rises too slowly it can be necessary

to set the thermostat at higher value.

Alternatively a DHW circulation system must be installed.

DHW recirculation

For Akva Lux II VX3 switching to recirculation is possible from a constructional point of view, requiring only an additional circulation

set.

The circulation set is not included in the delivery and must be ordered separately and mounted on site.

See instructions for mounting of circulation set on page 14.

1

Handle for temperature setting

2

Approximate scale settings

2 = 30° C

3 = 40 °C

4 = 45° C

I = 50° C

(max. temperature)

Remember always to mount circulation pump, non-return valve and

safety valve on the circulation pipe. The pump must be installed so

Danfoss District Energy VI.GP.V2.02 DKDHR

2727

Instructions Akva Lux II VX3-E

12.4 Akva Lux II VX3-E (ECL310/A376)

Substation for indirect heating for single-family, semi-detatched

and terraced houses as well as ats. With two heating circuits and

instantaneous domestic water heater. Designed for wall-mounting

with connections in top and bottom of substation.

The temperature for the heating circuits is controlled by a Danfoss ECL

310 controller in combination with electronic actuators. The supply

temperature is calculated by the controller on basis of the outdoor

temperature.

The domestic hot water temperature is also controlled by the ECL

310 in combination with an electronic actuator.

Please note: