Instructions for installation and use

District heating substation

for exhange of Gas Boilers

Akva Lux II TDP Reno

District district heating substation for heating and domestic hot water.

Reno

Exchange of gas

boilers.

www.danfoss.com

Instructions for installation and use Akva Lux II TDP RENO

1.0 Content

2.0 Product introduction ..............................................................................................................................................................................................................3

3.0 Dimensional sketches / Connections ...............................................................................................................................................................................3

4.0 Enduser instructions, General .............................................................................................................................................................................................4

5.0 Enduser instructions, Initial adjustment/setting ..........................................................................................................................................................5

6.0 Installation instructions, Safety and Handling ..............................................................................................................................................................6

7.0 Getting started .........................................................................................................................................................................................................................7

8.0 Installation instructions, General .......................................................................................................................................................................................8

8.1 Height adjustable cover .............................................................................................................................................................................................. 12

9.0 Adjustment and commissioning of the Akva Lux II TDP RENO ........................................................................................................................... 13

10.0 Maintenance........................................................................................................................................................................................................................... 15

10.1 Maintenance schedule (recommendations) ..................................................................................................................................................... 16

11.0 Troubleshooting, Heating.................................................................................................................................................................................................. 17

12.0 Troubleshooting, Domestic hot water .......................................................................................................................................................................... 18

12.0 EU Declaration of Conformity .......................................................................................................................................................................................... 19

13.0 Commissioning Certicate ................................................................................................................................................................................................ 20

2 | © Danfoss | Produced by Danfoss Redan A/S | 2016.03

VI.JV.R1.02

Instructions for installation and use Akva Lux II TDP RENO

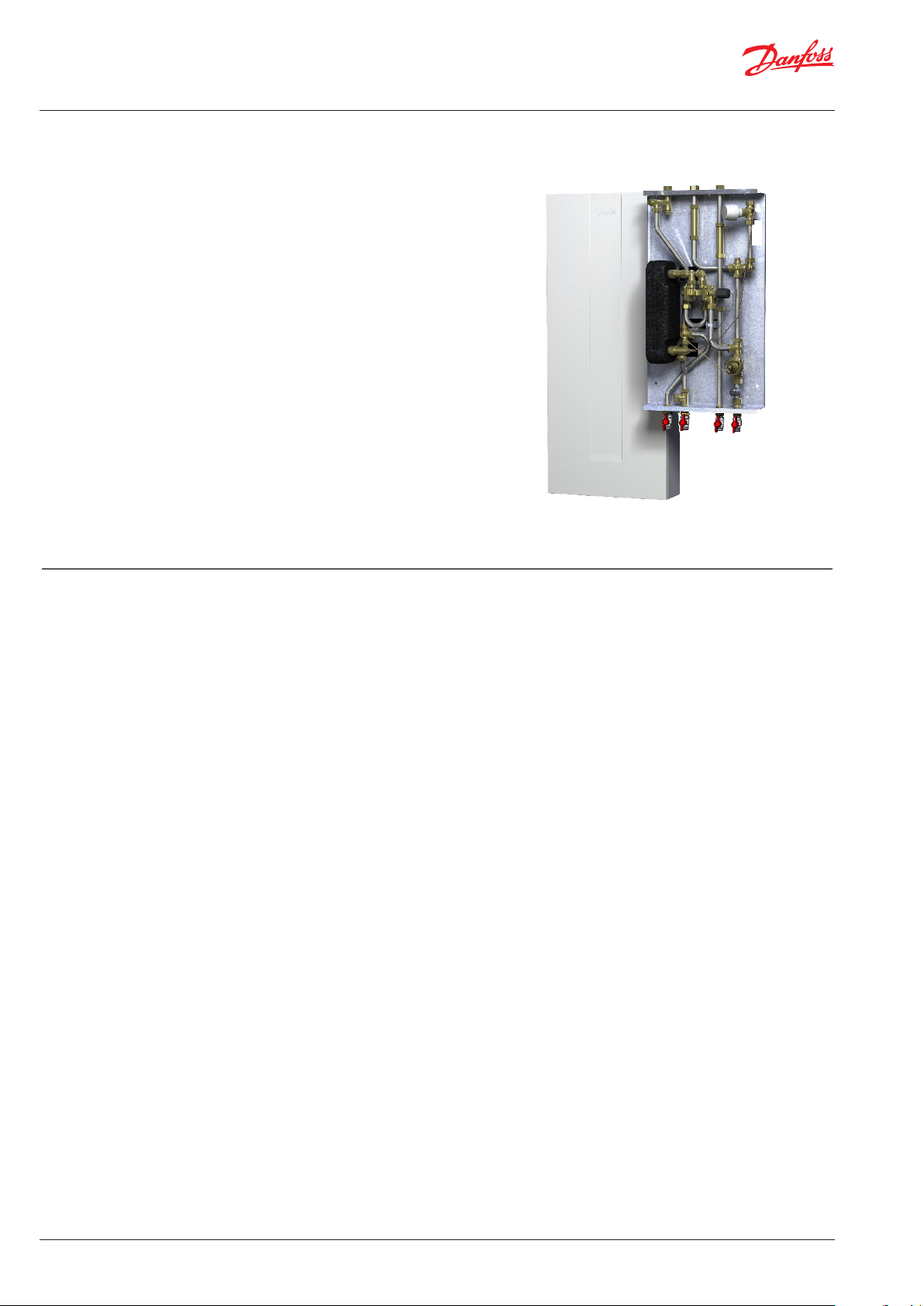

2. PRODUCT INTRODUCTION

DH

Supply

Heating

Supply

DH

Return

2 Plate heat exchanger

4 Dierential pressure controller

Top connection

(DCW connection optional)

5 Strainer

7 Ball valve

23 Sensor pocket for heat meter

24 Fitting piece for heat meter

3/4” x 110 mm

38 PT°C2 controller

40 Danfoss FJVR Thermostat for

Bypass/Circulation

52 Zone valve Danfoss RA-C

------------------------------------------------Optiones:

16A Anti-hammer vessel CAR19 für TWW

52A Thermo actuator Danfoss TWA-A NC

60 Top connection DCW with DCW tting

piece 3/4” x 110 mm

Accessories:

Ball valve 3/4” x 62 mm ET/ET

Bottom connection

Heating

KWWW

Return

2 Plate heat exchanger DHW

4 Dierential pressure controller

5 Strainer

7 Ball valve

23 Sensor pocket for heat meter

24 Fitting piece for heat meter

38 PTC2+P controller

40 Danfoss FJVR thermostat for Bypass/Circulation

52 Zone valve Danfoss RA-C

60 Top connection DCW with tting piece for cold water meter

3/4” x 110 mm (optional)

Please note that the cover is adjustable by 100 mm in height.

Please refer to page 12 for more information.

Please note:

Your substation may look dierent than the substation shown,

as variants with other components may be supplied.

The control function, however, is basically as stated in this

instruction manual.

Instructions for the tted components will be supplied together

with the substation.

Primary

Return

DCW connection

Top (optional)

Primary

Supply

60

40

5

24

2

38

4

52

7

Connections size:

DH, HE, DHW, DCW: G¾” IT

3 | © Danfoss | Produced by Danfoss Redan A/S | 2016.03

HE

Supply

DHW

DCW

HE

Return

VI.JV.R1.02

Instructions for installation and use Akva Lux II TDP RENO

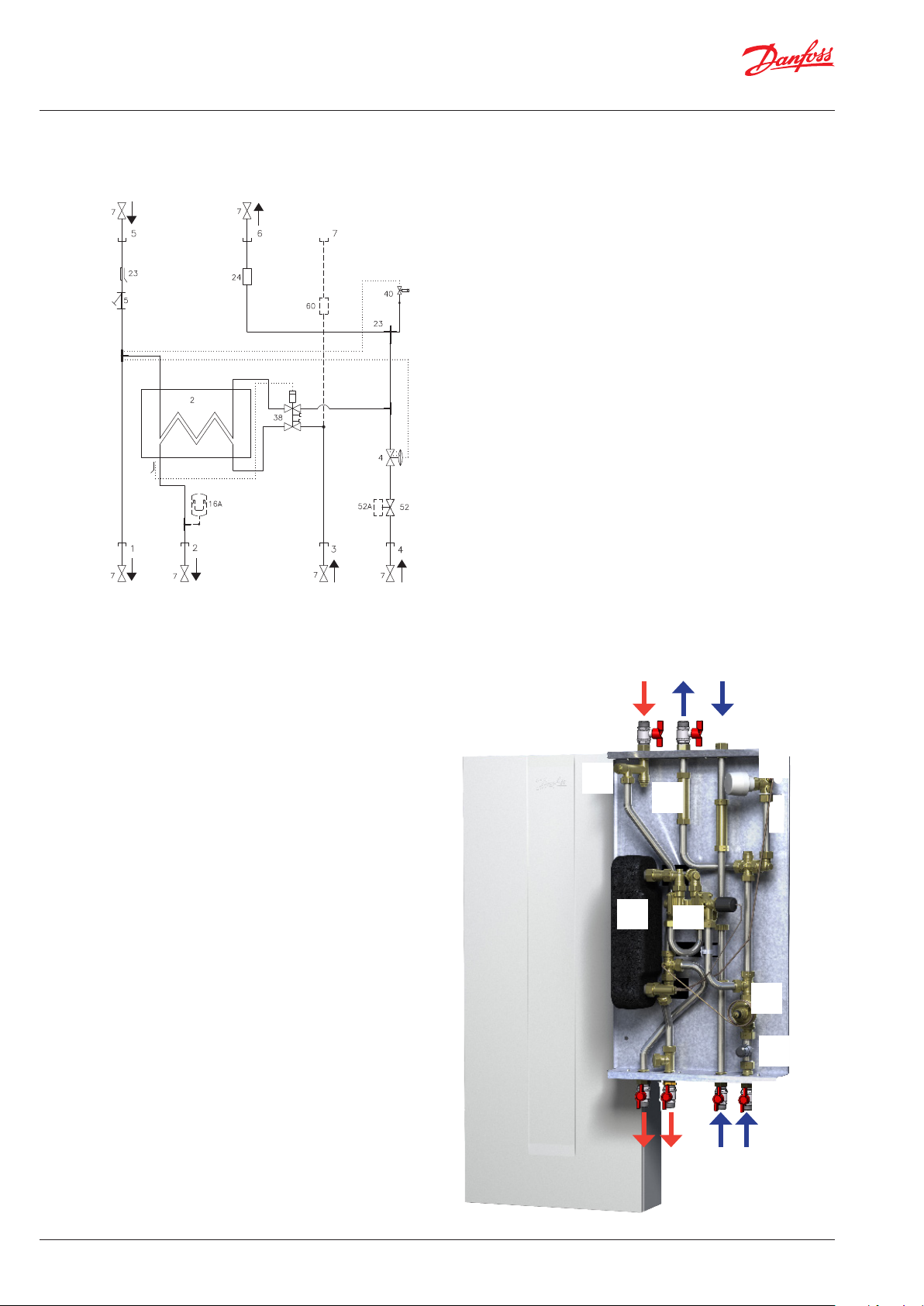

3. ADIMENSIONAL SKETCHES - CONNECTIONS

Connections:

1 Heating (HE) Supply, bottom

2 Domestic hot water (DHW), bottom

3 Domestic cold water (DCW) bottom

4 Heating (HE) Return

5 District heating (DH) Supply, top

6 District heating (DH) Return, top

7 DCW connection, top (option)

Depth incl. of mounting plate:

150 mm

Connections size:

DH, HE, DHW, DCW: G¾” IT

5 6 7

90 100 95

30 30

40

85

40

920

85 750

Dimensions:

Without cover:

H 920 x W 440 x D 150 mm

With cover:

H 1130/1140 x W 480 x D 150 mm

Please note that the cover is adjustable

by 100 mm in height.

Please refer to page 12 for more information.

90 65 130 65 90

440

1 2 3 4

10 mm

1130 mm

44

150

180 mm

80 mm

4 | © Danfoss | Produced by Danfoss Redan A/S | 2016.03

480 mm

VI.JV.R1.02

Instructions for installation and use Akva Lux II TDP RENO

4. ENDUSER INSTRUCTIONS, GENERAL

Instructions

Please read these instructions carefully.

The manufacturer accepts no liability for loss or damage resulting from

failure to comply with these instructions. Read and follow these instructions carefully to prevent the risk of physical injury and/or damage to

property. Exceeding the recommended operating parameters appreciably increases the risk of personal injury and/or damage to property.

Installation, commissioning and maintenance must be carried out

by qualied and authorised personnel (both plumbing and electrical

work).

Once the station has been installed and is operating, there is nor-

mally no need to alter the settings or other functions. The district

heating substation is very reliable and easy to operate.

If necessary, you can change the temperature settings as described

on page 8. For more detailed information about the substation, see

the sections concerning installation and commissioning.

Description

These instructions apply to substation Type Akva Lux II TDP RENO,

which ist a district heating substations, which is especially designed

for the exchange of gas boilers in single-family, semi-detached and

terraced houses as well as ats. With one heating circuit and instantaneous water heater for domestic hot water heating.

Akva Lux II TDP RENO substations are tted with a dierential pressure

controller that maintains a constant pressure in the heating circuit(s).

The supply temperature to the radiators is always identical to the district heating supply temperature. The room temperature is adjusted

solely using the radiator thermostats.

Akva Lux II TDP RENO is designed for wall mounting. For this purpose

it is tted with a height-adjustable cover made of white painted sheet

steel. The existing connections for DHW and DCW as well as supply

and return of secondary heating circuits can be used without major

changes, but it is recommended that the connections for the primary

hot water ow and return are to lead through the chimney. Optionally

the cold water supply can also be connected from above.

As further option it is possible to install a water hammer vessel to

dampen the pressure strokes.

Cooling from the water heater alone:

During tapping, the level of cooling will Typeically be 30–35°C. When

domestic hot water is not being tapped, it is completely normal for

the return temperature from the water heater to rise slightly. In this

situation, the district heating meter will register very modest consumption as the volume of water is very small.

On substations with recirculation, the heat meter registers the heat

loss in the recirculation pipe.

Irregularities

When reading the meters, check all joints and connections for leaks.

If you identify any irregularities/leaks, contact your professional

provider for assistance.

Check the troubleshooting section before contacting your

professional provider.

Warning! Hot surfaces

Parts of the substation may be very hot and can cause burn injuries. Be very careful when you are in the immediate vicinity of

the unit.

Warnings about high pressure and high temperature

The maximum supply temperature in the district heating network can be up to 90°C and the operating pressure can be up

to 10 bar. This may result in a risk of scalding from touching the

substation and from outow of the medium (water/steam). Exceeding the substation design data and operating parameters for

pressure and temperature carries an appreciable risk of personal

injury and/or damage to property.

Emergencies

In the event of re, leaks or other hazards, immediately shut o

all sources of energy to the substation, if possible, and call for

appropriate assistance.

If the domestic hot water is discoloured or malodorous, shut o

We recommend regular inspections of the substation - ideally in connection with readings of the district heating meter.

Pay special attention to any leaks and an excessively high return temperature in the district heating circuit (poor cooling of the district heating water). Cooling – i.e. the dierence between the supply and return

temperature of the district heating water – has a signicant eect on

the overall economy. Therefore, it is important to focus on the supply

and return temperature in the heating system.

The dierence should Typeically be 30–35°C in systems that operate

with radiators. In systems that feature oor heating, the dierence is

Typeically 5–10°C. In these systems, it is important that the supply

temperature does not exceed 35°C.

Please note that a low district heating return temperature is directly

related to the return temperature from the heating/oor heating circuit

and the return temperature of the domestic hot water recirculation (in

systems with domestic hot water recirculation). It is therefore important

to focus on these return temperatures..

VI.JV.R1.02

© Danfoss | Produced by Danfoss Redan A/S | 2015.10 | 5

Instructions for installation and use Akva Lux II TDP RENO

5. Enduser instructions, Initial adjustment/setting

Domestic hot water control

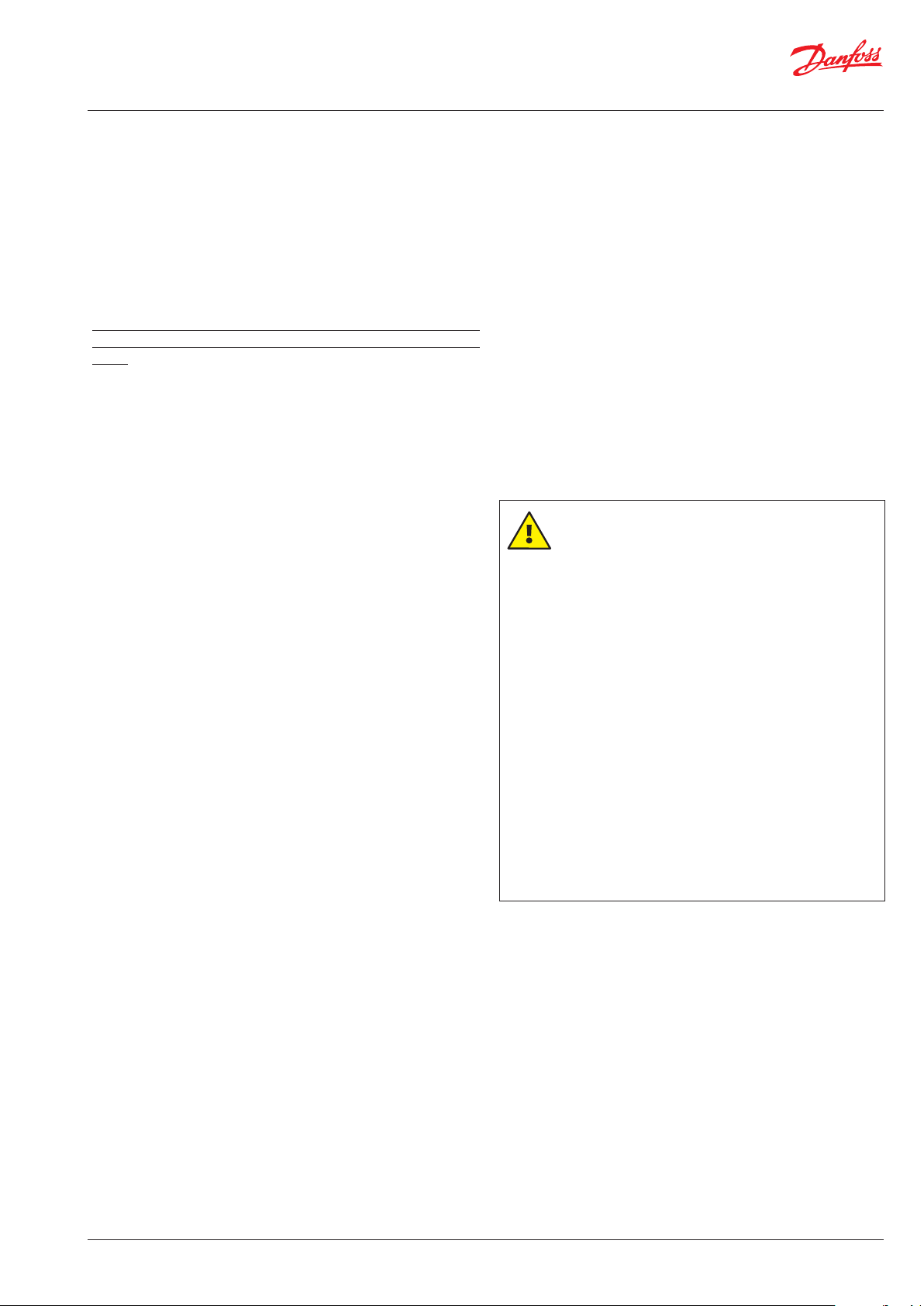

Danfoss PTC2+P controller (Fig. 1) for domestic hot water. Set the

DHW temperature by moving the adjuster lever towards “+” (hotter)

or “-” (colder).

Start by turning the lever clockwise – until it stops/until you cannot

turn it any further. Then turn the lever counter-clockwise until the

temperature of the tap water is approx. 48°C during normal tapping

ow (7–8 litres per min.). The temperature should never exceed 55°C

to prevent limescale deposits building up in the water heater.

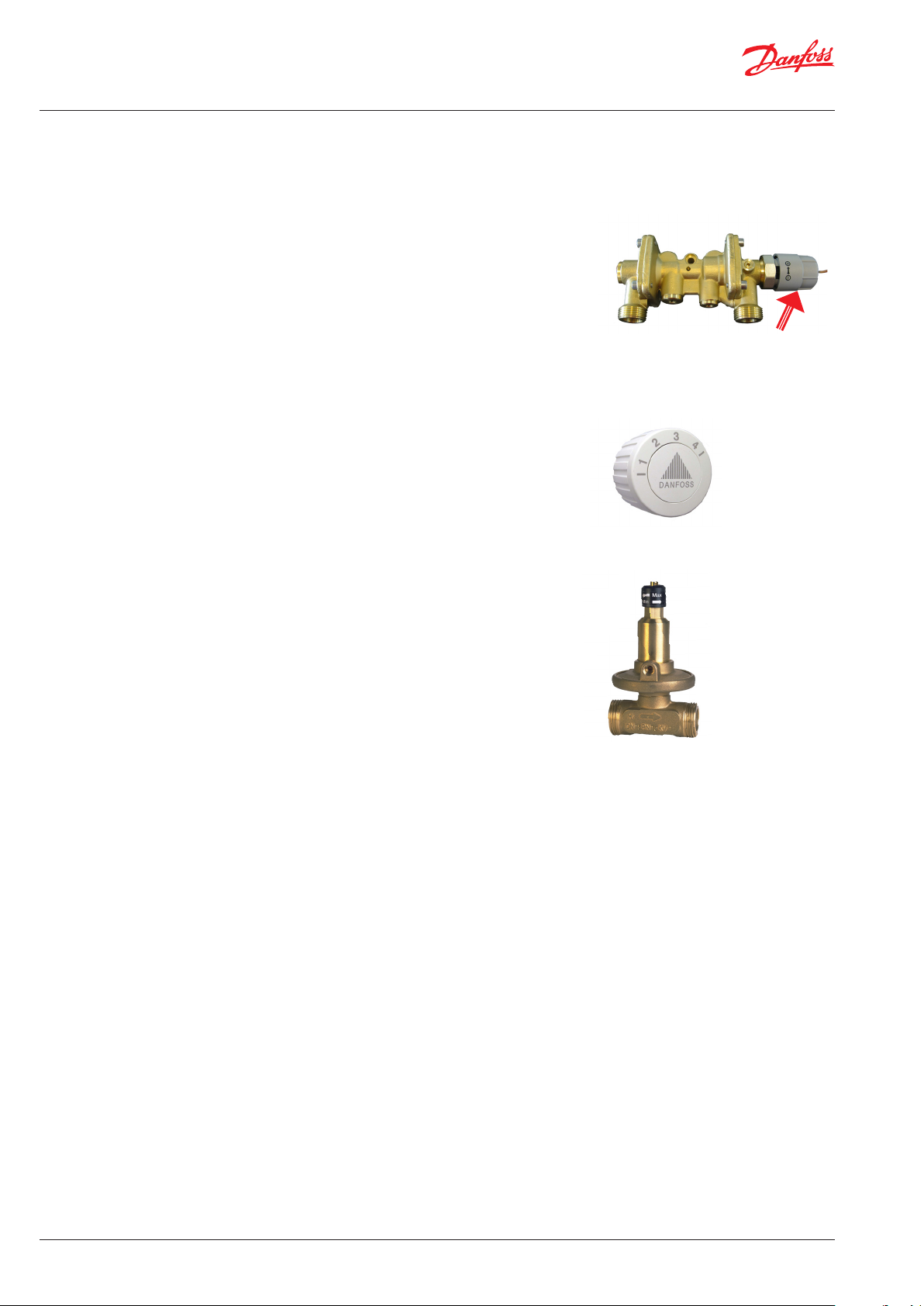

Bypass or circulation thermostat

Thermostat (Fig. 2) that keeps the branch pipe warm in the summer

or regulates the circulation temperature if domestic hot water recirculation has been established in the hot water system.

The thermostat should initially be set to position 3.

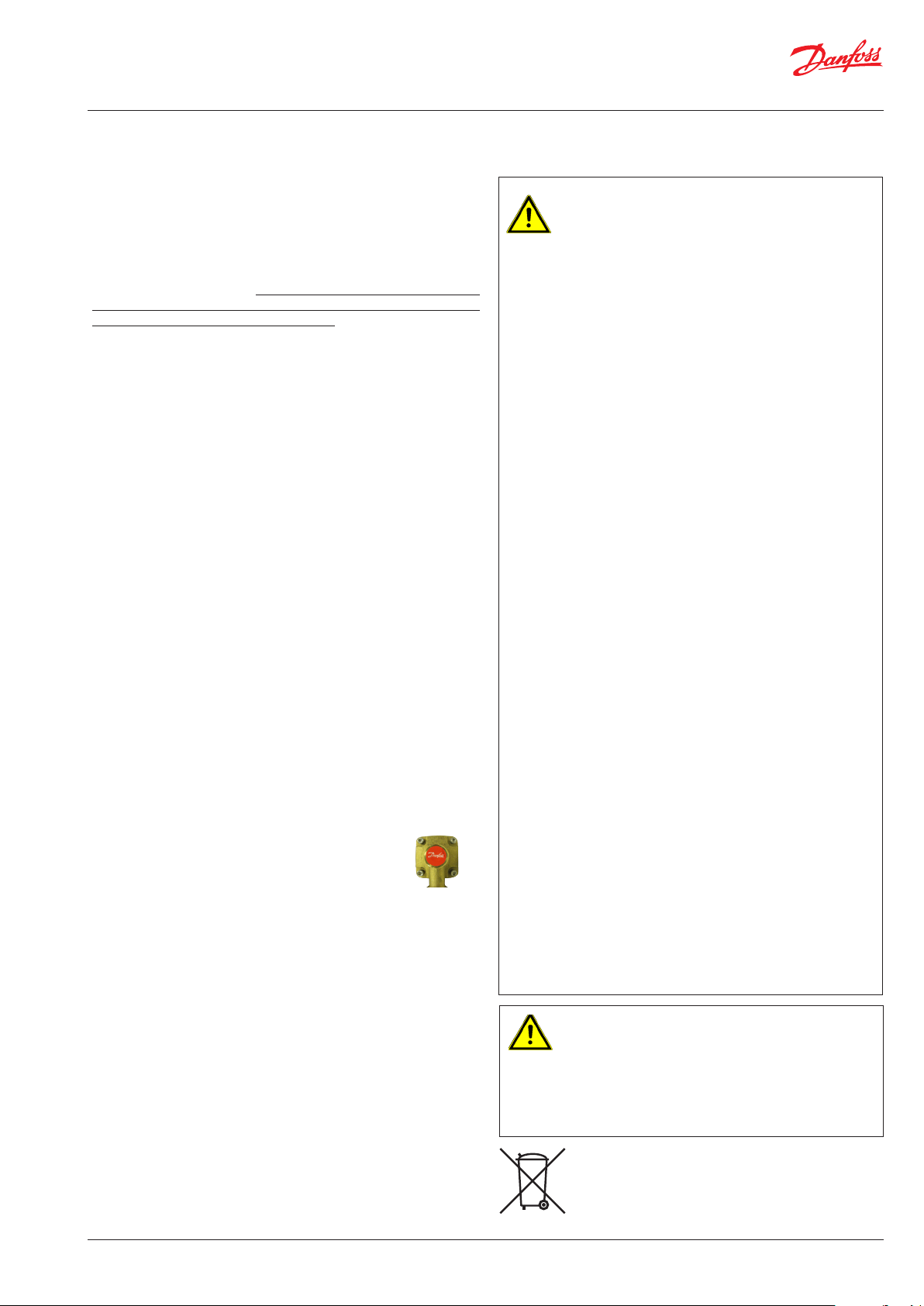

Heating circuit, Dierential Pressure Controller

The dierential pressure controller (Fig. 4) reduces the high, uctuating pressure in the district heating network to a constant operating pressure. The dierential pressure controller is initially set by the

plumber in connection with the commissioning of the substation.

If disruptions to the operation occur: noise in the radiator thermostats or poor regulation capacity, it may be necessary to reset the

dierential pressure controller to a lower or higher operating pressure. We suggest that you contact your local plumber for assistance

Fig. 1

Handle

Fig. 2

Fig. 3

Heating circuit, temperature control

The room temperature is regulated exclusively using the radiator

thermostats.

AVPL

6 | © Danfoss | Produced by Danfoss Redan A/S | 2016.03

VI.JV.R1.02

Instructions for installation and use Akva Lux II TDP RENO

2. INSTALLATION INSTRUCTIONS, SAFETY AND HANDLING

Instructions

Please read these instructions carefully before installing and comissioning this substation. The manufacturer accepts no liability for loss or

damage resulting from failure to comply with these instructions for use.

Read and follow these instructions carefully to prevent the risk of physical injury and/or damage to peroperty. Exceeding the recommended

operating parameters considerably increases the risk of personal injury

and/or damage to property. Installation, commissioning and maintenance must be carried out by qualied and authorized personnel in

compliance with the local safety regulations.

Once the station has been installed and is operating, there is normally

no need to alter the settings or other functions. The district heating

substation is very reliable and easy to operate.

Energy source

The substation is primarily designed for connection to district heating.

Alternative energy sources can be used if the operating conditions are

equivalent to district heating at all times.

Application

The substation is designed only to operate with water or a water-glycol

mixture (up to 40%), and other heating media may not be used.

The substation is to be connected to the household piping in a frost-free

room, where the temperature does not exceed 50 °C and the relative

humidity is not higher than 80%. The substation must no be covered,

bricked in or otherwise cut o from access.

Choise of materials

Only use materials, that comply with local regulations.

Corrosion

The maximum chloride compounds of the medium must not be higher

than 300 mg/l. The risk of corrosion increases considerably if the recommended chloride content is exceeded.

Safety valve(s)

Installation of safety valve(s) must always be in compliance with local

regulations.

Noise level.

≤ 55 dB.

PTC2+P controller for domestic hot water

The controller is preset from factory and sealed with a

red sticker. This sealing must not been broken.

The warranty becomes void if the sealing is broken.

Connection

It must be possible to cut o all energy sources to the unit - including

electrical connections - at all times.

Potential equalization/grounding

Potential equalization is an electrical equalizing connection to secure

against user contact with dangerous voltage, which may occur for example between two piping systems. Potential equalization reduces

corrosion in heat exchangers, water heaters, district heating substations and plumbing installations. Equalization of potentials should be

eected according to local regulations.

Warning! Hot surfaces

Parts of the substation may be very hot and can cause burn injuries. Be

very careful when you are in the immediate vicinity of the substation.

Warning of high pressure and high temperature

The maximum supply temperature in the district heating network can

be up to 90°C and the operating pressure can be up to 10 bar. This may

result in a risk of scalding from touching the substation and from outow of the medium (water/steam). Exceeding the substation design

data and operating parameters for pressure and temperature carries

an appreciable risk of personal injury and/or damage to property.

Emergencies

In the event of re, leaks or other hazards, immediately shut o all

sources of energy to the substation, if possible and call for appropriate

assistance.

If the domestic hot water is discoloured or malodorous, shut o all ball

valves on the substation, notify all users and call for professional assistance immediately.

Warning of damage during transport

On reception of the substation, and before installing it, check for any

evidence of damage during transport.

The substation must be handled and moved with the greatest care and

attention.

Storage

Before installation, the units must be stored in a dry, heated (i.e. frostfree) room.

(Relative humidity max. 80% and storage temperature 5-70 °C).

The units must not be stacked higher than the limit at the factory (max.

8 layers) Units supplied in cardboard packaging must be lifted using the

handles incorporated in the packaging. Units must be placed on pallets

for transport/moving across large distances.

As far as possible, do not lift the substation by the pipes. Lifting by the

pipes may cause leaks. REMEMBER to retighten.

Disposal

Dispose of the packaging in accordance with the local regulations for

disposal of used packaging materials.

The substation is made of materials that cannot be disposed of together

with household waste.

Close all energy sources and disconnect all connection pipes. Disconnect

and dismantle the product for disposal in accordance with the applicable

local regulations for the disposal of the individual components.

VI.JV.R1.02

IMPORTANT - Tightening of connections

Before adding water to the system, ALL pipe connections MUST be

retightened, as vibrations during transport may have caused leaks.

Once the substation has been lled and the system has been put into

operation, ALL pipe connections MUST be tightened once more.

Handling

We recommend that you wear suitable safety footwear while

handling and installing the substation.

© Danfoss | Produced by Danfoss Redan A/S | 2015.10 | 7

Instructions for installation and use Akva Lux II TDP RENO

7. GETTING STARTED

Connect the substation to the household piping in accordance with

the labelling at the bottom and/or in accordance with the instructions in this manual.

GETTING STARTED is a quick guide and some details in connection with

installation and commissioning may require additional information,

which can be found elsewhere in this instruction manual.

Commissioning:

Please note that the “getting started” quick guide presupposes

that shutt-o possibility is established to and from the substation. - We recommend mounting of ball valves.

1. The substation is prepared for wall mounting. Mount the substation on a solid wall using two sturdy bolts, screws, expansion bolts or similar.

2. Make sure that the ball valves are closed, when connnecting

them to the household piping.

3. Mount the district heating mete (see page 9).

4. IMPORTANT! Tighten all pipe connections, as they may have

loosened during transport and handling.

5. Open the ball valve for the HE supply and return ow and ll

the system with water by carefully opening the ball valve for

the district heating supply ow and at the same time venting

the system. Finally, open the ball valve for the district heating

return ow.

6. Check the substation and the household piping thoroughly

for leaks.

7. Pressure test the entire system for leaks in accordance with

the applicable regulations.

08. Connect automatic components, if any, to the electricity supply, but do not switch on the power.

9. Heat the system and vent the radiator circuit/heating side

thoroughly on the radiators and the air valve, if any.

10. For TDP RENO substations, which include zone valve, remember to remove the red split on the position indicator of the

zone valve.

11. Now switch on automatic components, if any.

12. Finish by adjusting the substation in accordance with this

instruction manuals.

WICHTIG! Erwärmung und Abkühlen der Wohnungsstation

kann Leckagen verursachen. Deshalb kann Nachziehen alle

Verschraubungen und Anschlüsse nach der Inbetriebnahme

notwendig sein.

8 | © Danfoss | Produced by Danfoss Redan A/S | 2016.03

VI.JV.R1.02

Instructions for installation and use Akva Lux II TDP RENO

8. MOUNTING INSTRUCTIONS, GENERAL

The installation, connection and maintenance of the substation must

be performed by qualied and authorised personnel.

Installation must always be performed in accordance with the applicable legislation and in compliance with these instructions.

The substation must be installed so that it is freely accessible and can

be maintained without unnecessary disruption. Lift the substation

by its mounting plate/rear section and secure it to a solid wall using

2 sturdy bolts, screws or expansion bolts positioned in the two keyholes in the mounting plate/rear section.

Before commissioning, rinse all the pipes in the household piping

system thoroughly to remove any impurities, and check and clean

the dirt strainers in the substation.

Connect the substation to the household piping in accordance with

the labelling at the bottom and/or in accordance with the instructions in this manual.

Test and connections

Before lling the system with water, retighten all the pipe connections

because vibrations and shocks during transport and handling may

have caused leaks. Once the system has been lled with water, tighten

all the pipe connections once more before performing pressure test

for leaks. After heating of the system, check all the connections and

retighten if necessary.

Please note that the connections features EPDM rubber gaskets!

Therefore, it is important that you DO NOT OVERTIGHTEN the

union nuts. Over-tightening may result in leaks. Leaks caused by

over-tightening or failure to retighten connections are not covered

by the warranty.

Heat meter, tting pieces.

The substation is equipped with tting pieces for heat meter on

the district heating return line.

Fitting of heat meters

- Close the ball valves on the district heating and the heating

sides.

- Loosen the union nuts at both ends of the tting piece and

remove it.

- Fit the heat meter, - remember to insert gaskets.

- Mount sensor, - remember to insert gaskets.

- After mounting of heat meter remember to check and tighten

all pipe connections before commissioning the substation.

The heat meter consists of ow meter, two temperature sensors for

mounting in DH supply and return and a microprocessor calculator

for the calculation of energy consumption. On the LCD display of the

calculator the energy consumption can be read.

*

VI.JV.R1.02

© Danfoss | Produced by Danfoss Redan A/S | 2015.10 | 9

Instructions for installation and use Akva Lux II TDP RENO

Mounting of temperature sensors

As standard the heat meter is supplied with temperature sensors

for measuring the supply and return ow temperatures.

The Akva Lux II TDP-F at station is prepared for mounting of temperature sensors with M10x1 connection (see photo to the right):

The supply ow sensor is mounted in the sensor pocket on DH

supply (pos A.)

- demount M10 plug (Pos. A)

- insert one temperature sensor in the sensor pocket

- tighten temperature sensor union nut

Mount the return ow sensor in the heat meter housing (pos. B).

A

Cold water meter(s), tting pieces.

The substation is equipped with tting piece(s) for cold water

meter(s).

Fitting of cold water meter(s)

- Close the ball valves on the domestic cold water and the domestic hot water supply.

- Loosen the union nuts at both ends of the tting piece and

remove it.

- Fit the cold water meter, - remember to insert gaskets.

- After mounting of cold water meter remember to check and

tighten all pipe connections before commissioning the cold

water meter(s).

10 | © Danfoss | Produced by Danfoss Redan A/S | 2016.03

VI.JV.R1.02

Instructions for installation and use Akva Lux II TDP RENO

088R0248| 15.12.2005 | Version 03

VI.SB.H3.02 12-2005 Produced by Danfoss Industri Service 05.09 JJ-Bi.DS

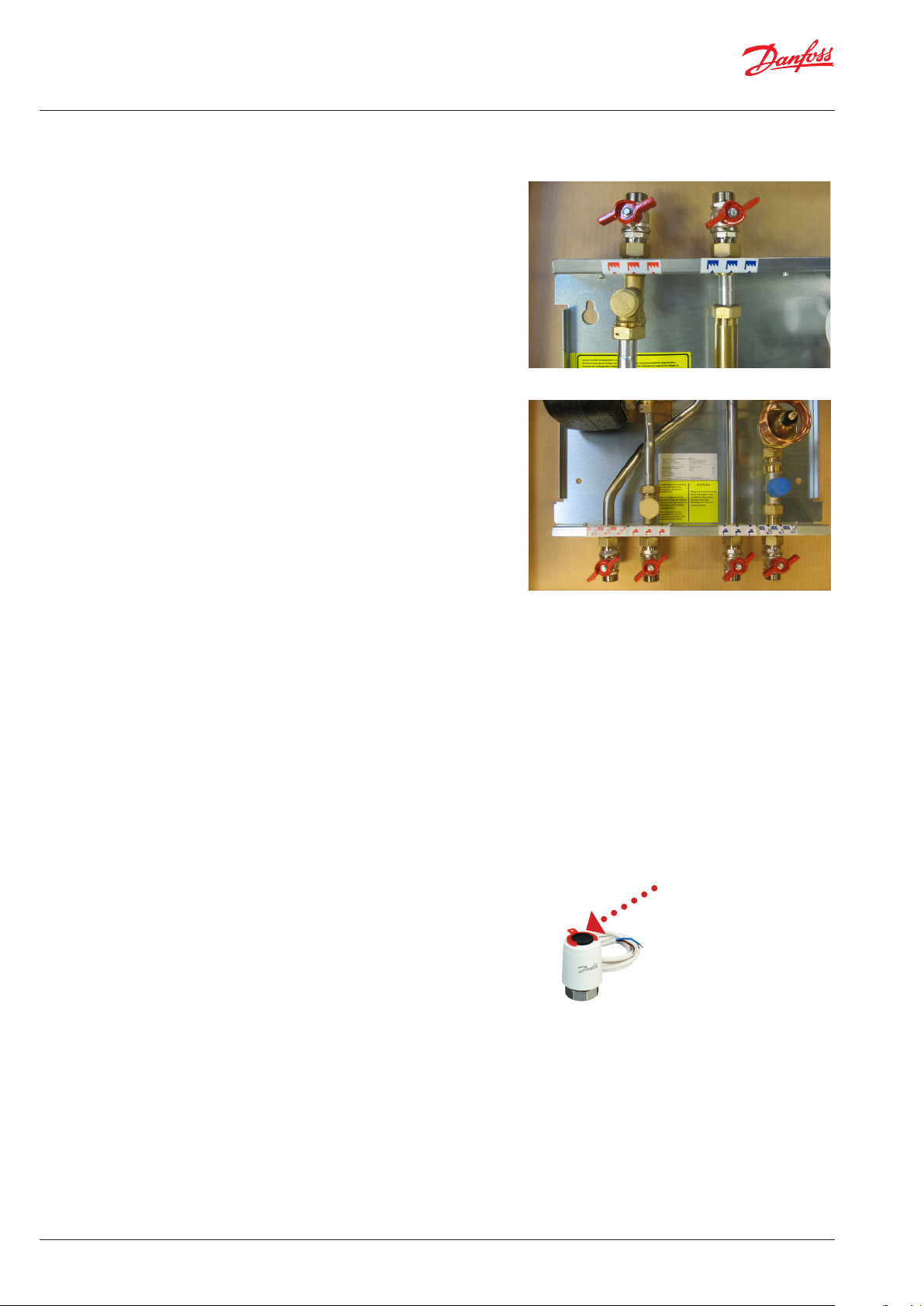

Zone valve / thermal actuator TWA-A

The Akva Lux II TDP-F can be supplied with zone valve/thermal actuator TWA-A, which enables connection to an electronic program-

mable room thermostat.

The thermal actuator of the zone valve is switched on by an external contact from the room thermostat, and starts to open or close

the valve. The actuating movement is achieved by means of an

electrically heated expansion element. When the heating current is

switched o, the actuator shuts or opens the valve.

The actuator is equipped with a visual position indicator to show

the open or closed position of the valve.

INSTRUCTIONS

TWA NC

TWA-A

For Danfoss RA valves

TWA-V

For Danfoss RAV/VMT valves

TWA-L

For Danfoss RAVL valves

TWA-K

For Heimeier/MNG/Oventrop

valves with M30 × 1.5 connection,

generally as per attached drawing.

Other valves must be veried

individually to ensure correct

valve closing measurement and

valve top geometry.

TWA-D

For Danfoss RTD valves

*) 24 V Class II transformer (SELV)

**) 230 V max. 3 A pre-fuse

Thermal actuator TWA-V

Please note: Some variants are

supplied with zone valve only, as

illustrated above, and therefore a

thermal actuator TWA-A must be

mounted on the zone valve before connection to an electronic

Electronic programmable room thermostat (option)

If the substation is connected to a room thermostat the temperature is controlled by the room thermostat and radiator thermostats.

Please note that the room thermostat keeps the temperature at a

constant level in the whole apartment according to the set room

parameters.

Consult additional maintenance instructions for room thermostat

for further information. It is recommended to avoid fully opened

thermostats on some radiators and fully shut-o on others. Higher

temperature at the top and lower temperature at the bottom part

of radiators means that the system operation is correct. To keep correct temperature and friendly microclimate for human beings in the

apartment, it is recommended to ensure regular airing in rooms.

Anti-water hammer membrane tank

The station is prepared for connection of an anti-water hammer

membrane tank, which is to be ordered separately.

The anti-water hammer membrane tank is a pressure equalizing tank,

which absorbs the volume changes of the hydraulic uid between

the minimum and maximum temperature to keep us the pressure

largely constant.

If the system is heated, the anti-water hammer membrane tank

absorbs the expansion volume of the water. If system temperature

drops, the anti-water hammer membrane tank leads the expansion

water back into the system. The water pressure in the system remains

constant.

(Please note that the anti-water hammer tank is not included in the

delivery).

VI.JV.R1.02

© Danfoss | Produced by Danfoss Redan A/S | 2015.10 | 11

Instructions for installation and use Akva Lux II TDP RENO

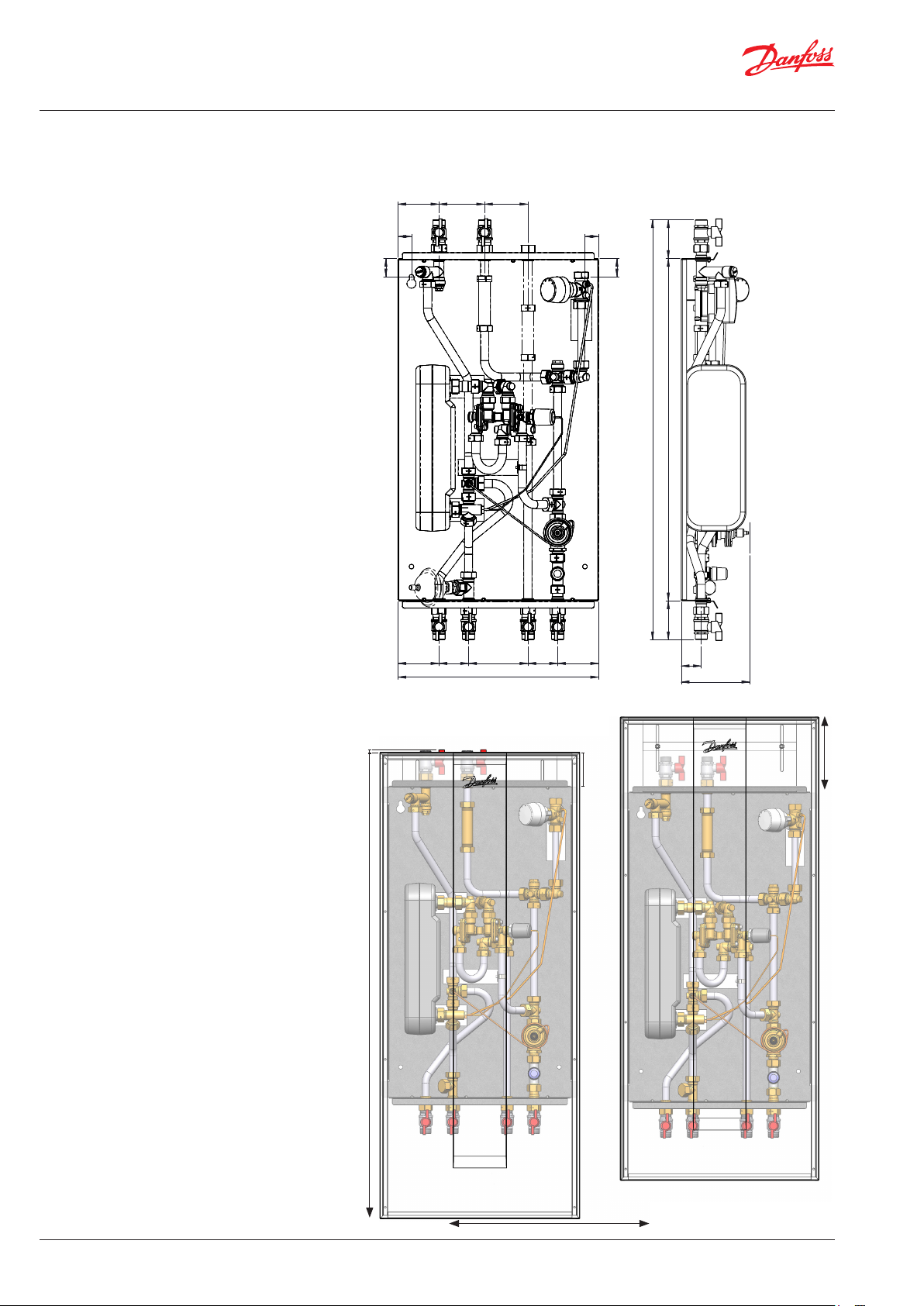

8.1 Height-adjustable cover

The Akva Lux II TDP RENO substations are designed for wall mounting.

Akva Lux II TDP RENO is designed for wall mounting. For this purpose

it is tted with a height-adjustable cover made of white painted sheet

steel.

The cover is adjustable by 100 mm in height, and by oering variable installation possibilities of the cover, installation problems are

prevented.

Figure 1 shows the default position of the cover, by which the cover

is mounted on the mounting plate by means of a plate, which is 80

mm high (see Fig. 1a).

The delivery also includes an extra plate, which can be mounted,

which can be mounted on the existing plate and with this, the cover

can be variably adjusted from 130 to 180 mm in height.

Fig. 1

Plate height 80 mm

Fig. 1a

80 mm 180 mm

Fig. 2

Figure 2 shows the adjustment possibilites with the extra plate.

Figure 2a shows the mounted cover, adjusted to the maximum height.

Plate height 130 mm

Plate heigh 180 mm

Fig. 2a

12 | © Danfoss | Produced by Danfoss Redan A/S | 2016.03

VI.JV.R1.02

Instructions for installation and use Akva Lux II TDP RENO

7369316-0 SIBC VI.CB.T1.6K © Danfoss 05/03 1

Instructions

34 7

9. Adjustment and commissioning of the Akva Lux II TDP RENO

General information

PLEASE NOTE! Some models may have a slightly dierent appearance, but the

control function is in principle the same as described below.

Maintenance and commissioning

Perform maintenance procedures according to the maintenance frequency chart presented in the section entitled “Operation and maintenance”

on pages 15 - 16. Perform adjustment in accordance with the instructions

below.

For cleaning of plate heat exchanger, please see page 15.

Commissioning

Commission the substation in accordance with the instructions on pages 8-14.

Domestic hot water

The domestic hot water is prepared in the heat exchanger based on the

ow principle and the temperature is controlled by a combined hydraulic

and thermostatic self-acting controller PTC2+P (Fig. 1a) with integrated

dierential pressure controller, which blocks the ow of primary and secondary side ow through the heat exchanger immediately after completion of the tapping process.

Regulation of the hot water temperature PTC2+P

Set the DHW temperature by moving the adjuster lever towards “+” (hotter)

or “-” (colder). Start by turning the lever clockwise – until it stops/until you

cannot turn it any further. Then turn the lever counter-clockwise until the

temperature of the tap water is approx. 48°C during normal tapping ow

(7–8 litres per min.).

Fig. 1

Adjuster lever

By-pass function (factory connection).

The Akva Lux II TDP-F substations are supplied with the a Danfoss FJVR bypass thermostat (Fig. 2), so that when water is tapped, the water heater

immediately starts to produce hot water. We re-commend setting of the

thermostat in pos. 3. If you have to wait a long time (i.e. more than 20 sec.)

for hot water, it may be necessary to position the thermostat higher than

pos. 3. If you want to avoid waiting time altogether, you will need to set up

domestic hot water recirculation to the tapping points.

Heating circuit, Dierential pressure controller

The dierential pressure controller (Fig. 3) reduces the high uctuations in

pressure in the district heating network, ensuring constant operating pressure

across the substation.

Dierential pressure controller Type AVPL

The dierential pressure controller is pre-set to 0.1 bar from the factory. To alter

the dierential pressure, use an Allen key – NV3. One full turn is equivalent to

0.01 bar. Turn clockwise to increase the pressure, counter-clockwise to reduce

it.

Recommended setting

Basically, it is recommended to open the controller to its full extent. If disruptions to operation arise, such as noise or uctuations/poor regulation

capacity, it may be necessary to adjust the dierential pressure controller

to a lower operating pressure.

The controller can be adjusted subsequently – see the appendix entitled:

Instructions AVPL 1.0/1.6

Fig.. 2

Fig. 3

Scale setting (indicative)

Pos. 2 = 30°C

3 = 40°C

AVPL 1.0/1.6

1 5

2 6

r kPa

20 25

19 24

18 23

17 22

16 21

15 20

14 19

13 18

12 17

11 16

10 15

9 14

8 13

7 12

6 11

5 10

49

38

27

16

05

VI.JV.R1.02

© Danfoss | Produced by Danfoss Redan A/S | 2015.10 | 13

Instructions for installation and use Akva Lux II TDP RENO

088R0248| 15.12.2005 | Version 03

INSTRUCTIONS

VI.SB.H3.02 12-2005 Produced by Danfoss Industri Service 05.09 JJ-Bi.DS

Electronic programmable room thermostat

The Akva Lux II TDP-F Type 144B2403 is equipped with a zone valve,

and is thereby prepared for tting of a thermal actuator TWA-A,

which enables connection to an electronic programmable room

thermostat.

For Akva Lux II TDP-F Types 144B2434 and 004U8089 zone valve and

thermal actuator are available as an option.

The thermal actuator is switched on by an external contact from

the room thermostat, and starts to open or close the valve. The actuating movement is achieved by means of an electrically heated

expansion element. When the heating current is switched o, the

actuator shuts or opens the valve.

The actuator is equipped with a visual position indicator to show

the open or closed position of the valve.

Please note: Before mounting of

the electronic room thermostat, an

thermal actuator TWA-A for ON/OFF

controls of the heating system must

be mounted on the zone valve.

TWA-A

For Danfoss RA valves

TWA-V

For Danfoss RAV/VMT valves

TWA-L

For Danfoss RAVL valves

TWA-K

For Heimeier/MNG/Oventrop

valves with M30 × 1.5 connection,

generally as per attached drawing.

Other valves must be veried

individually to ensure correct

valve closing measurement and

valve top geometry.

TWA-D

For Danfoss RTD valves

TWA NC

Thermal actuator TWA-A

*) 24 V Class II transformer (SELV)

**) 230 V max. 3 A pre-fuse

If the substation is connected to a room thermostat the temperature is controlled by the room thermostat and radiator thermostats.

Please note that the room thermostat keeps the temperature at a

constant level in the whole apartment according to the set room

parameters.

Consult additional maintenance instructions for room thermostat

for further information. It is recommended to avoid fully opened

thermostats on some radiators and fully shut-o on others. Higher

temperature at the top and lower temperature at the bottom part

of radiators means that the system operation is correct. To keep correct temperature and friendly microclimate for human beings in the

apartment, it is recommended to ensure regular airing in rooms.

14 | © Danfoss | Produced by Danfoss Redan A/S | 2016.03

VI.JV.R1.02

Instructions for installation and use Akva Lux II TDP RENO

10. Maintenance

Maintenance work

Is only to be carried out by qualied and authorised personnel.

Inspection

The water heater should be checked regularly by authorised personnel.

Any necessary maintenance must be performed in accordance

with the instructions in this manual and other sets of instructions.

During service the dirt strainers are to be cleaned – including the lter

on the controller, all pipe connections must be tightened and the safety

valve must be function tested by turning the lever.

Rinsing/cleaning of plate heat exchanger

To clean the plate heat exchanger, rinse it by running clean water through

the exchanger at high speed and in the opposite direction to the normal

ow. This will remove any dirt deposits that may have built up in the

exchanger. If rinsing with clean water is not sucient, the exchanger can

also be cleaned by circulating a cleaning agent approved by Danfoss (e.g.

Kaloxi or Radiner Fl cleaning uid) through the exchanger. Both these

cleaning uids are environmentally friendly and can be disposed o

through the standard sewer system. After use of a cleaning uid, the

plate heat exchanger must be rinsed thoroughly with clean water.

Acid cleaning of plate heat exchanger

Deposits of limesc ale may build up in plate heat exchangers for domestic

hot water on account of the large temperature uc tuations, and because

aerated water is used on the secondary side. If it becomes necessary to

clean the exchanger with acid, this can be done as shown on the drawing

to the right. Brazed plate heat exchangers can withstand rinsing with a

dilute acid sulution - e.g. 5% formic, acetic or phosphoric acid).

Measures after maintenance work

After maintenance work and before commissioning:

– Check that all screwed connections are tight.

– Check that all safety features, covers, that were removed, have been

replaced properly.

– Clean the working area and remove any spilled materials.

– Clear all tools, materials and other equipment from the working area.

– Connect to energy supply and check for leaks.

– Vent the system.

– Carry out any necessary adjustment again.

– Make sure that all safety features on the device and the system work

properly.

Meter reading

The caretaker/owner must perform visual checking and reading of

the district heating meter at short, regular intervals. (The meter is

not a part of the delivery from Danfoss).

Service procedures must only be performed by trained, authorised

personnel.

NB! Excessive consumption for whatever reason is not covered by

the Danfoss warranty.

Cooling / Return temperature reading

Cooling – i.e. the dierence between the supply and return temperature

of the district heating water – has a signicant eect on overall energy

economy. Therefore, it is important to focus on the supply and return

temperature in the heating system. The dierence should Typeically be

30–35°C.

Please note that a low district heating return temperature is directly

related to the return temperature from the heating circuit and the return

temperature of the circulation water.

It is therefore important to focus on these return temperatures.

VI.JV.R1.02

© Danfoss | Produced by Danfoss Redan A/S | 2015.10 | 15

Instructions for installation and use Akva Lux II TDP RENO

Cooling from the water heater alone:

During tapping, the level of cooling will Typeically be 30–35°C. When

hot water is not being tapped, it is completely normal for the return

temperature from the water heater to rise slightly. In this situation,

the district heating meter will register very modest consumption as

the volume of water is very small.

On water heaters with recirculation, the calorie meter registers the

heat loss in the circulation pipe.

Tightening of connections

Retighten all connections after reading of the heat meter. If case of

leaks, contact your professional provider for assistance.

Please note that the connections may feature EPDM rubber gaskets!

Therefore, it is important that you DO NOT OVERTIGHTEN the

union nuts. Over-tightening may result in leaks. Leaks caused by

over-tightening or failure to retighten connections are not covered

by the warranty.

10.1 Maintenance schedule (recommendations)

Interval Maintenance work Comments

If you identify a leak, replace the gaskets and retighten the pipe connections

Check the functionality by turning the lever on the safety valves

In the event of irregularities, lack of functionality or visible faults and

defects in a component, replace the component in question

Visual check. Check whether it is possible to disconnect the current to the

substation.

Visual check. In the event of signs of corrosion, replace pipes or heat

exchanger inconsultance with Danfoss A/S

Follow the instructions in the present manual

At least once a year

Check all connections for leaks

Check that the safety valve on the cold water supply is

functioning correctly.

Check that all components are intact and functioning as

intended

Clean all dirt lters/strainers in the substation Replace any lters that are not intact

Check that any electrical cables are in serviceable condition

and that it is possible to disconnect the electrical power supply to the substation

Check the pipes and exchanger for signs of corrosion

Check that any insulation covers are functioning as intended Check that the insulation ts tightly around the product

Check that the temperature regulators are set in accordance

with the instructions in this manual

Check the functions of all shut-o valves Check that the ball valves open and close as they should

IMPORTANT! Replace gaskets after separation of parts

16 | © Danfoss | Produced by Danfoss Redan A/S | 2016.03

VI.JV.R1.02

Instructions for installation and use Akva Lux II TDP RENO

11. TROUBLESHOOTING - HEATING

If operating disturbances occur, the following basic features

should be checked before carrying out acual troubleshooting:

- the substation is correctly connected,

- the district heating supply temperature is at the normal level

(summer at least 60 °C, winter at least 70 °C),

- the dierential pressure is higher than or equal to the normal

(local) dierential pessure in the district heating network. - If

in doubt, ask the district heating plant,

Problem Possible cause Solution

Dirt strainer clogged on DH or HE side

(radiator circuit.

Filter in district heating meter clogged. Clean the lter (after consulting the

No heat

Uneven heat distribution Air pockets in the system. Vent the installation throughly.

Defective or wrongly set dierential

pressure controller.

Defective room thermostat / actuator Check the funtioning of the room ther-

Air pockets in the system. Vent the installation throughly.

- the substation is connected to electricity (pump and

automatic,

- the dirt strainer in the district heating supply pipe is clean,

- air pockets in the system.

Clean dirt strainer.

district heating plant).

Check the functioning of the dierential

pressure controller - clean valve seat if

required.

mostat / actuator

Supply temperatur too low Dirt strainer clogged Clean dirt strainer

Increase total heating surface

Turn on all the radiators and prevent the

radistors in the system from becoming

Poor cooling

Too small heating surface / too small

radiator in relation to the total heating

requirement of the building

Poor utilization of existing heating

surface

VI.JV.R1.02

© Danfoss | Produced by Danfoss Redan A/S | 2015.10 | 17

Instructions for installation and use Akva Lux II TDP RENO

12. TROUBLESHOOTING - DOMESTIC HOT WATER

Problem Possible cause Solution

Non-return valve on the circulation line

Variations in temperature

Low temperature / variations in temperature at the draining points

defective (leads to mixing - and the

circulation water pipes become cold du-

Non-return valve in thermostatic mixer

tap in the bathroom defective - leads to

mixing of cold and hot water-. Note that

variations in temperature may occur at

other draining points/water taps in the

system!

REMEMBER, to check all the mixer taps in

the house!

Replace non-return valve.

Replace mixer tap, or non-return valve

only.

Not enough pressure on the hot water

Long waiting time

No domestic hot water Dirt strainer on DH supply clogged. Clean dirt strainer.

DHW temperature too low

DHW temperature too high Defective DHW controller.

Dirt strainer in cold water meter or in the

cold water supply line clogged.

Circulation pump out of operation - (not

part of the dly).

See above.

Non-return valve on the circulation line

defective (leads to mixing - and the

circulation water pipes become cold during tapping).

Air in capillary tubes.

Clean dirt strainer (cold water meter

possibly in consulation with the water

supply company).

Check whether the pump is running whether the pump is receiving power.

control that there is no air in the pump

housing - see pump manual.

See above.

Replace non-return valve.

Check the functions of the controller,

and replace if required.

Air and rinse capillary tubes.

Declining temperature during tapping

Poor cooling Calied heat exchanger.

Discoloured water (during a protracted

period)

Lack of hot water pressure Calied plate heat exchanger.

18 | © Danfoss | Produced by Danfoss Redan A/S | 2016.03

Calied heat exchanger.

Short-circuiting of / defective heat

exchanger.

Plate heat exchanger short-circuited. Replace the plate heat exchanger.

Clean heat exchanger with acid solution

or replace heat exchanger.

Replace heat exchanger.

Clean heat exchanger with acid solution

or replace heat exchanger.

Replace the plate heat exchanger or

clean it with acid.

VI.JV.R1.02

Instructions for installation and use Akva Lux II TDP RENO

13. EU DECLARATION OF CONFORMITY

VI.JV.R1.02

© Danfoss | Produced by Danfoss Redan A/S | 2015.10 | 19

Instructions for installation and use Akva Lux II TDP RENO

13. COMMISSIONING CERTIFICATE

The substation is the direct link between the district heating supply network and the household piping system. All supply pipes and the

pipes in the household piping system must be checked and rinsed before commissioning. Once the system has been lled with water, all

pipe connections must be retightened before performing pressure test for leaks. The dirt strainers must be cleaned and the substation

must be adjusted in accordance with the instructions in this manual.

It is important to comply with all technical regulations and the applicable legislation in every respect.

Installation and commissioning must only be performed by trained, authorised personnel.

The substation is checked in the factory for leaks before delivery. Leaks are however possible due to vibrations caused by transport, handling and heating of the system and therefore it is important to check all connections and to retighten if necessarys before commissioning.

Please note that the connections may feature EPDM gaskets! Therefore it is important that you DO NOT OVER-TIGHTEN the connections.

Over-tightening may result in leaks. Leaks caused by ove-rtightening or failure to retighten connections are not covered by the warranty.

To be lled-out by the installer

This substation has been retightened, adjusted and commissioned

on the: by installer:

Date/Year

Company name (stamp)

20 | © Danfoss | Produced by Danfoss Redan A/S | 2016.03

VI.JV.R1.02

Instructions for installation and use Akva Lux II TDP RENO

VI.JV.R1.02

© Danfoss | Produced by Danfoss Redan A/S | 2015.10 | 21

Instructions for installation and use Akva Lux II TDP RENO

22 | © Danfoss | Produced by Danfoss Redan A/S | 2016.03

VI.JV.R1.02

Instructions for installation and use Akva Lux II TDP RENO

VI.JV.R1.02

© Danfoss | Produced by Danfoss Redan A/S | 2015.10 | 23

Danfoss Redan A/S · District Energy · Omega 7, Søften · DK-8382 Hinnerup

Tel. +45 87 43 89 43 · Fax: +45 87 43 89 44 · redan@danfoss.com · www.redan.danfoss.dk

24 | © Danfoss | Produced by Danfoss Redan A/S | 2016.03

VI.IQ.L1.02

Loading...

Loading...