Danfoss AK-SM 800A User guide

User Guide

AK-System Manager

AK-SM 800A series

ADAP-KOOL® Refrigeration Control System

www.danfoss.com

User Guide | AK-System Manager, AK-SM 800A series

Contents

1. Product Introduction

1.1 Product Introduction ..............................................................................3

1.2 Specifications.............................................................................................4

2. Installation and start-up configuration

2.1 Installation ..................................................................................................6

2.2 Connections ...............................................................................................8

2.3 Network topology ....................................................................................8

2.3.1 Lon RS485 topology ...................................................................9

2.3.2 MODBUS topology .................................................................. 10

2.4 First time startup .................................................................................. 11

2.5 IP Configuration and suggested security settings .................... 12

3. Navigation and use (Local screen)

3.1 Log in screen ........................................................................................... 14

3.2 Home screen / Dashboard ................................................................. 15

3.3 Home Screen – Menu Bar ................................................................... 17

4. Navigation and use (SvB5 browser)

4.1 StoreView Browser 5 (SvB5) ............................................................... 19

4.2 AK-SM 800A Utilities ............................................................................ 19

4.3 Utilities – Software update ................................................................ 21

4.4 File menu ..................................................................................................25

4.5 Dashboard ............................................................................................... 25

4.6 Managing alarms ................................................................................... 26

4.7 System view ............................................................................................ 27

4.8 Device detail ........................................................................................... 27

4.9 Schedule view ........................................................................................ 28

4.10 History (Logs) ......................................................................................... 28

4.11 AK-SM 800A Host Network Configuration ................................... 30

4.12 Secondary device configuration ..................................................... 30

4.13 Device Upload / Download ............................................................... 31

4.14 Device Management ............................................................................32

(Configuration/System/Device Management) ........................... 32

5. Configuration

5.1 Configuration Wizards ....................................................................34

5.2 Copy Wizard ............................................................................................ 38

5.3 Configuration Time ......................................................................... 39

5.4 Configuration System ..................................................................... 39

5.5 Configuration Comm ...................................................................... 41

5.6 Configuration Alarms ..................................................................... 42

5.7 Offline ........................................................................................................ 46

5.8 Control tab ...............................................................................................47

5.9 Configuration Network Nodes .................................................... 50

5.10 Configuration History ................................................................... 51

5.11 Configuration History ................................................................... 52

6. Master Control Functions

6.1 Rail Heat .................................................................................................... 53

6.2 Schedules ................................................................................................. 56

6.3 Customized control .............................................................................. 58

6.4 Suction Pressure Optimization .........................................................59

6.5 Configuration of suction optimization .......................................... 60

6.6 Adaptive Liquid Management ......................................................... 61

6.7 AKC ON (Evap shutdown when injection off)............................. 62

6.8 Coordinated Adaptive Defrost ......................................................... 63

7. Advanced features and configurations

7.1 Managers Override ............................................................................... 64

7.2 Light 65

7.2.1 Lighting Configuration ...........................................................65

7.2.2 Addresses .................................................................................... 67

7.2.3 Alarms........................................................................................... 67

7.3 Dimming control via AK I/O .............................................................. 68

7.4 HVAC Configuration ............................................................................. 70

7.5 Miscellaneous Configuration ............................................................ 73

7.6 Energy ....................................................................................................... 84

7.7 Energy Measurement / Load shed .................................................. 88

7.8 Detail Energy ..................................................................................... 90

7.9 Enterprise Load Shed (via Danfoss EDS Service)........................ 91

7.10 Demand Limiting ................................................................................. 92

7.11 Boolean Logic / Calculations ........................................................... 93

8. Device support

8.1 Danfoss AKC Support (Via AK-PI 200) ............................................ 95

8.2 Service Tool Support ............................................................................ 99

8.3 CoreSense™ (MODBUS) Support ...................................................100

8.4 AK-SM 800A Device support guidelines .....................................101

9. Ordering ................................................................................................102

10. Document History ............................................................................ 102

11. Glossary of terms .............................................................................. 102

2 | BC337629891709en-000201

© Danfoss | DCS (vt) | 2021.03

User Guide | AK-System Manager, AK-SM 800A series

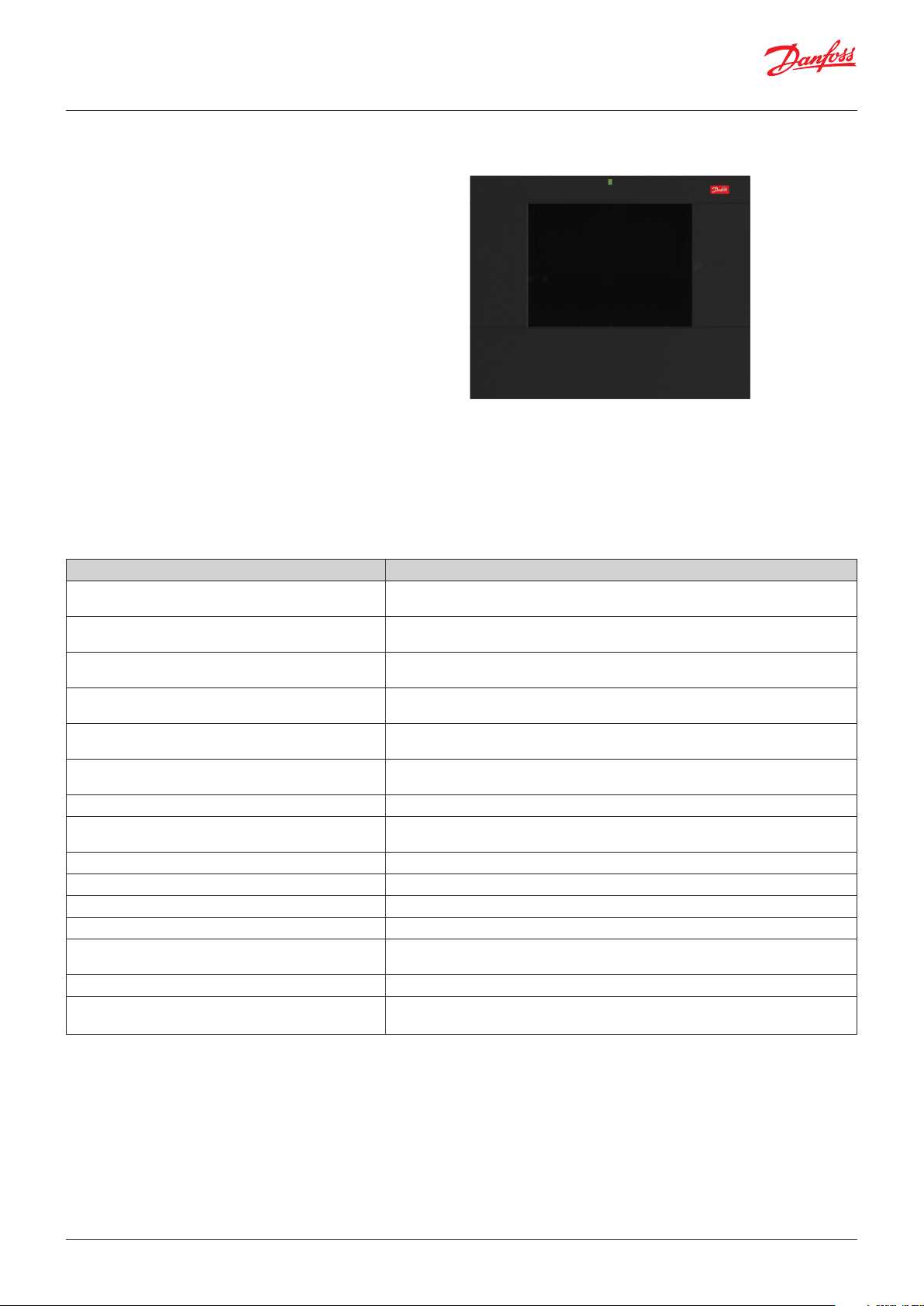

Chapter 1: Product Introduction

1.1 Product Introduction

Introducing the new Danfoss System Manager 800A series. The

System Manager AK-SM 800A series is an evolution of the global

System Manager 800 and represents a significant investment by

Danfoss in the Food Retail market. The AK-SM 800A maintains

familiarity and a deep application feature set but is enhanced via

several significant updates.

Product headline features

• All new Electronics platform supporting new Operating System

(based on Linux)

• Implementation of IT industry standard security protocols

(HTTPS, SSL/TSL 1.2, WPA2 encryption)

• Enhanced UI/UX - new yet familiar touch screen

• Full HTML5 web browser, known as StoreView Browser 5 (SvB5)

• New Utilities App (integrated in SvB5)

• Support of Mobile devices (Utilities App only)

• Retro-fit ready – includes EoL and legacy control functions

supporting smooth upgrade path

• Extended history capacity

• Secure Wi-Fi Access point – for site connection without

disrupting WAN network

Series Features (Model dependent) Benefits

Built in standard IT security best practice and protocols Secure web connection (HTTPS), Secure e-mail, Encrypted data and secure software

Full Web browser interface Reduce tool complexity, utilization of modern web technology (HTML5), full view and

Mobile ready utilities Key functions broken into discrete apps, making task more user friendly and mobile

Refrigeration Control (centralized and de-centralized) Control your refrigeration application via built in Rack control or via de-centralized

Lighting Control (centralized and de-centralized) Control your lighting application via built in control or via de-centralized distributed

HVAC Control (centralized and de-centralized) Control your HVAC application via built in control or via de-centralized distributed

Energy saving technology (built in) Energy saving functions built in - no additional licenses to enable savings

Master Schedules Schedules Groups Central Defrost, Case lighting, Store / Outside Lighting, Night setback,

Flexible Alarm Routing / output Flexible Alarm Routing / Output e-mail, IP address, relay

Built in field bus options Modbus, LonWorks®, SNMP IP, CANbus (future update)

Full color VGA Local touch screen Full access to system

Built in Buzzer & 2-tone LED Easy local level alarm notification

Custom graphics Local screen custom graphics Create simple & clear graphic screen with only ‘key

Extended History logging More memory for more history point collection and save

Danfoss Enterprise Services ready Supported by Danfoss Enterprises Services, offering multiple digital services and

update packages

access to your system

device supported (software updates, backup..)

distributed network controls

network controls

network controls

Shutdown

parameters’ shown - simply the

reporting

© Danfoss | DCS (vt) | 2021.03

BC337629891709en-000201 | 3

User Guide | AK-System Manager, AK-SM 800A series

1.2 Specifications

The mounting location should be flat, dry and free of major

vibrations. The AK-SM 800A should be mounted at eye level.

Environmental Range:

Operating temperature:

-10 – 50˚C (14 – 122˚F)

@ 95% RH (non condensing) IP20

Approvals

UL file: E31024

61B5

Class 2 or LPS in accordance with NEC.

Enclosure rating type 1

FCC ID: X02SPB209A

IC ID: 8713A-SPB209A

Electrical range:

For supply connections, use 16 AWG or larger wires rated for at

least 75 °C (167 °F). Use copper conductors only.

~ 100 – 240 V AC 50/60 Hz, 12 W Built in alarm relay,

Contact voltage:

Up to 240 V, Load: AC-1 (Ohmic) Current rating.

5 Amp AC-15 (inductive) Current rating. 3 Amp

LCD Touch Screen

Active TFT touch (thin-film transistor), SVGA 800 x 600

LCD Touch Screen – cleaning

• Use a soft lint-free cloth.

• The cloth may be used dry, or lightly dampened with a mild

soap cleaner or Ethanol.

•

Cleaner with Ammonia can be used, but with percentage max of 4%.

• Be sure the cloth is only lightly dampened, not wet. Never apply

cleaner directly to touch panel surface.

• Never use acidic or alkaline cleaners, or organic chemicals such

as: paint thinner, acetone, tolulene, xylene, propyl or isopropyl

alcohol, or kerosene.

International Certifications

Este equipamento não tem direito à proteção contra interferência

prejudicial e não pode causar interferência em sistemas

devidamente autorizados. Para maiores informações, consulte o

site da ANATEL - www.anatel.gov.br

Size

Unit Width 295 mm (11.6”), Unit Height 235 mm (9.3”),

Unit Depth 65 mm (2.5”)

Mounting holes 246 mm (9.7”) Width

Mounting holes 175 mm (6.9”) Height

Approvals:

Declaration of conformity info

- Regulation 2005/37/EC

- EN 12830, 07-1999

- EN 13485, 11-2001

- HACCP 080R1215

- CE 080R1213

- C-Tick 080R1214

- UL E31024

WARNING: To avoid risk of injury from electric shock,

ensure correct electrical isolation is made before working

within the enclosure.

4 | BC337629891709en-000201

© Danfoss | DCS (vt) | 2021.03

User Guide | AK-System Manager, AK-SM 800A series

Statements for the AK-SM 800A

FCC COMPLIANCE STATEMENT

CAUTION: Changes or modifications not expressly approved could void your authority to use this equipment

This device complies with Part 15 of the FCC Rules. Operation to the following two conditions: (1) This device may not cause harmful interference, and (2)

this device must accept any interference received, including interference that may cause undesired operation

INDUSTRY CANADA STATEMENT

This device complies with Industry Canada license-exempt RSS standard(s). Operation is subject to the following two conditions: (1) this device may not

cause interference, and (2) this device must accept any interference, including interference that may cause undesired operation of the device.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts de licence. L'exploitation est autorisée aux deux

conditions suivantes : (1) l'appareil ne doit pas produire de brouillage, et (2) l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi,

même si le brouillage est susceptible d'en compromettre le fonctionnement.

NOTICE

FCC COMPLIANT NOTICE

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Modifications: Any modifications made to this device that are not approved by Danfoss may void the authority granted to the user by the FCC to operate

this equipment.

Any regulatory related concerns contact: global_approvals@danfoss.com

Danfoss Cooling

11655 Crossroads Circle

Baltimore, Maryland 21220

United States of America

global_approvals@danfoss.com

www.danfoss.com

EU CONFORMITY NOTICE

Hereby, Danfoss A/S declares that the radio equipment type AK-SM 800A is in compliance with Directive 2014/53/EU.

The full text of the EU declaration of conformity is available at the following internet address: www.danfoss.com

Danfoss A/S

Nordborgvej 81

6430 Nordborg

Denmark

global_approvals@danfoss.com

www.danfoss.com

© Danfoss | DCS (vt) | 2021.03

BC337629891709en-000201 | 5

User Guide | AK-System Manager, AK-SM 800A series

80Z817

Danfoss

80Z818

100 - 240 V

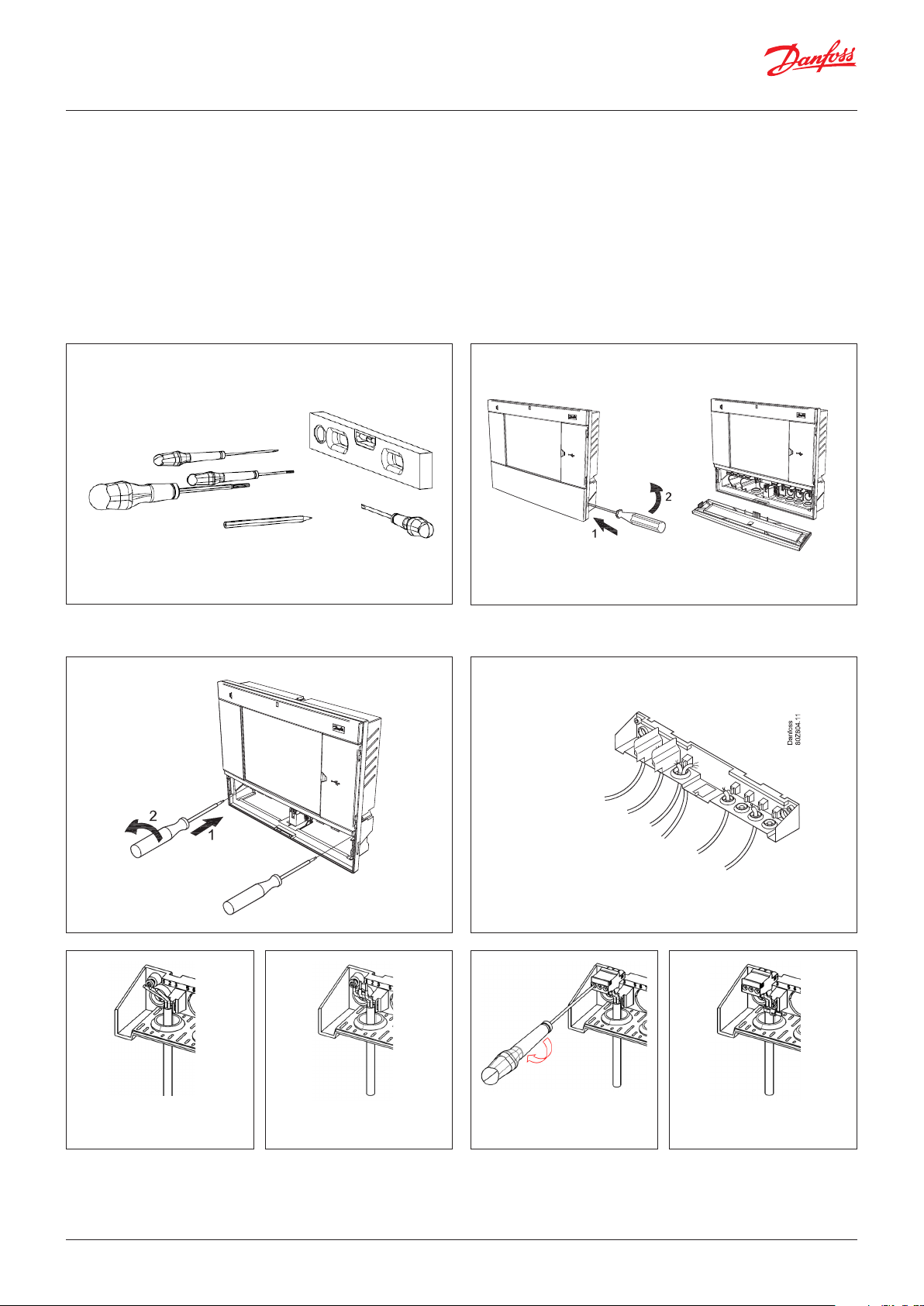

Chapter 2: Installation and start-up configuration

2.1 Installation

Tools needed

1. Bubble level

2. Small slotted screwdriver for connector screws

3. Torx 8 screwdriver for releasing the electronic unit and for

fastening the unit when recessed mounted

4. Screwdriver for fixating the AK-SM 800A

5. Pen for marking the 2 lower fixation holes

6. Larger slotted screwdriver for releasing the Technician lid

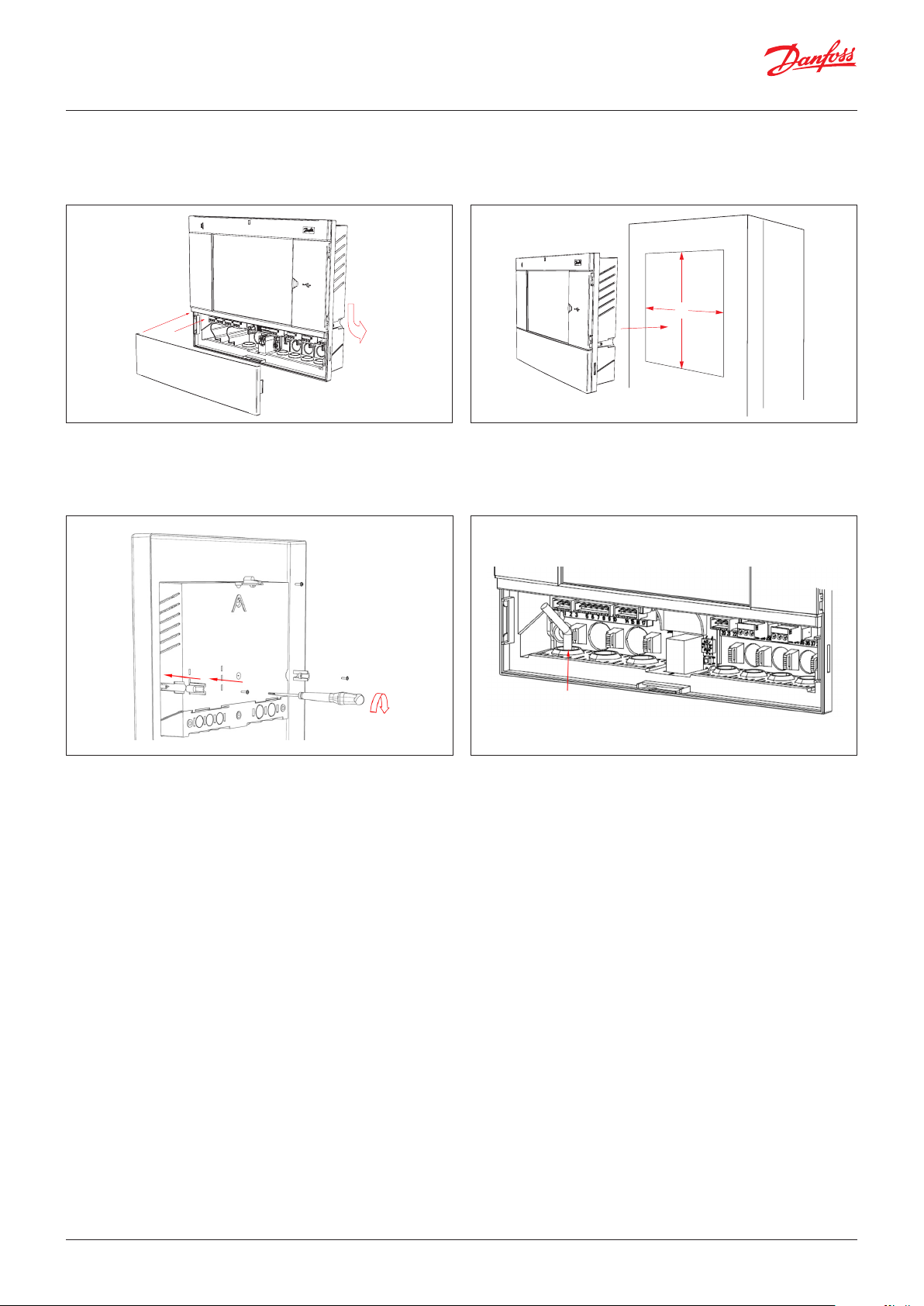

Wall Mounting- box1)

1. Attach screw to the wall

2. Mount AK-SM 800A to the screw

3. Loosen Technician lid (three sides)

4. Remove Technician lid

5. Level the AK-SM 800A

6. If drilling is necessary, mark up 2 screws in Connector part.

7. Attach the Connector part to the wall using another 2 screws

Danfoss

T10

Wall Mounting- wiring

Insert cables through the rubber grommets

AC

Relay 1/2

Canbus

Ethernet 0

MODBUS 1/2

LON / TP78

Strip the cables Strip the wires

1

) For installation in countries where UL Listing is required, please refer to the installation instruction provided with the product.

6 | BC337629891709en-000201

Secure wires in

connectors by screwdriver

Strain relief the cables

© Danfoss | DCS (vt) | 2021.03

User Guide | AK-System Manager, AK-SM 800A series

Carefully replace the keypad, ensure that it securely snaps into

place

Danfoss

80G8144

From the backside:

Slide the 3 fastener into the housing part.

The screws are inserted into the fasteners.

Secure the unit by tightening the screws

Wall Mounting- Panel recessed

From the front:

A hole of the size 280 x 220mm is machined.

The AK-SM 800A is inserted in the hole.

a

Danfoss

80G8145

b

Remove Technician lid

From the back, push cables inside the housing

© Danfoss | DCS (vt) | 2021.03

BC337629891709en-000201 | 7

User Guide | AK-System Manager, AK-SM 800A series

)

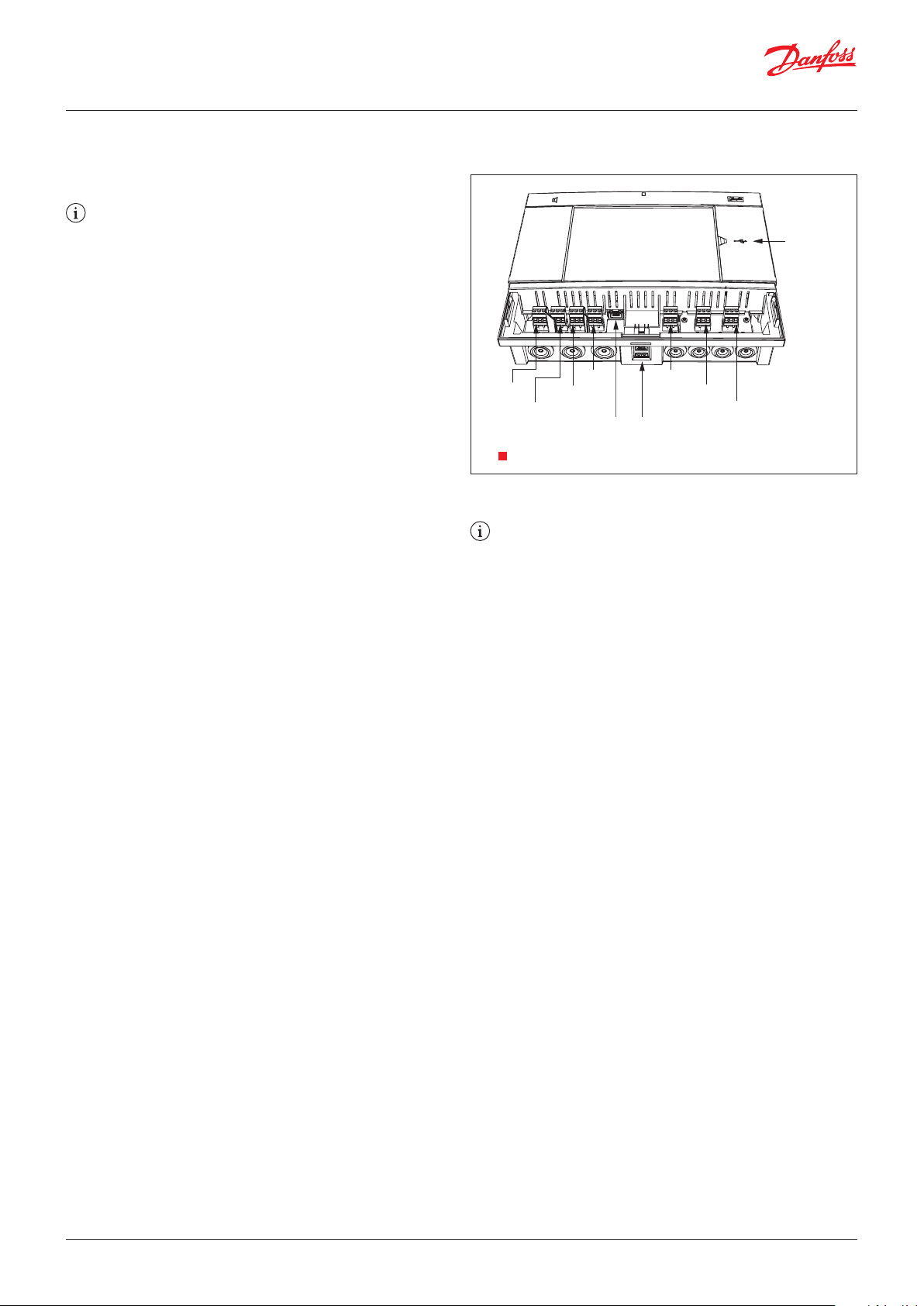

2.2 Connections

The following chapter describes the available connections on your AK-SM

800A.

Please note that not all connection points are currently active, please

refer to the drawing below for more details

Danfoss

80Z8105

USB 2.0 (x2

2.3 Network topology

Your AK-SM supports both MODBUS and Lon RS485 local

bus connections. For further detailed description of network

connections please refer to document ‘Data Communication

between ADAP-KOOL® Refrigeration controllers_RC8AC802’ Lon

RS485.

Follow standard topology guidelines for Lon RS485, with particular

respect to maximum cable length, when to use a repeater and

ensuring suitable resistors are in place.

Cable type

Cables twisted in pairs must be used, and they may be provided

with a screen. Some types of communication require a cable with

a screen to be used.

Examples:

For Lon RS485, MODBUS, RS485 Third party - General ‘EIA 485’

recom- mendation:

– Belden 9841, 24 AWG, 1 pair with screen

– Belden 3107A, 22 AWG, 2 pairs with screen

– Smartwire 043006AL, 22 AWG, 1 pair with screen

– Alpha wire 6453, 22 AWG, 1 pair with screen

– Carol C4841A, 24 AWG, 1 pair with screen

– Dätwyler Uninet 3002 4P 4 pairs with screen (CAT5 cable)

Power

Alarm Relay 1

Future use

Alarm Relay 2

Eth0 (WAN) Eth1 (Field)

Modbus 1CANbus

Modbus 2

LON (RS 485) or

LON (TP78)

USB 2.0 Host (800 mA)

When using the Lon RS485 network, ensure the Term. Switch

on the AK-SM is in the ‘ON’ position (enable internal resistor).

Any repeaters must also have 120 Ohm resistor in place.

Finally, ensure that the last controller on the network run also

has its end of line on line resistor enabled.

For Lon TP78 communication - Level 4 cable general

recommendation:

– Belden 7703NH, 22 AWG, 1 pair with screen

– Belden 7704NH, 22 AWG, 2 pair with screen

– Smartwire 106500, 22 AWG, 1 pair with screen

Wires with larger cross-section than AWG 22 is not recommended

Cable length

A cable length must not exceed 1200 m (4000 foot). A repeater

(Part # 084B2241 ) must be used for longer lengths.

8 | BC337629891709en-000201

© Danfoss | DCS (vt) | 2021.03

User Guide | AK-System Manager, AK-SM 800A series

MODBUS

max. 1200 m

R=120 ohm

AK-SM

R=120 ohm

RS 485

84B3288

AK-SM

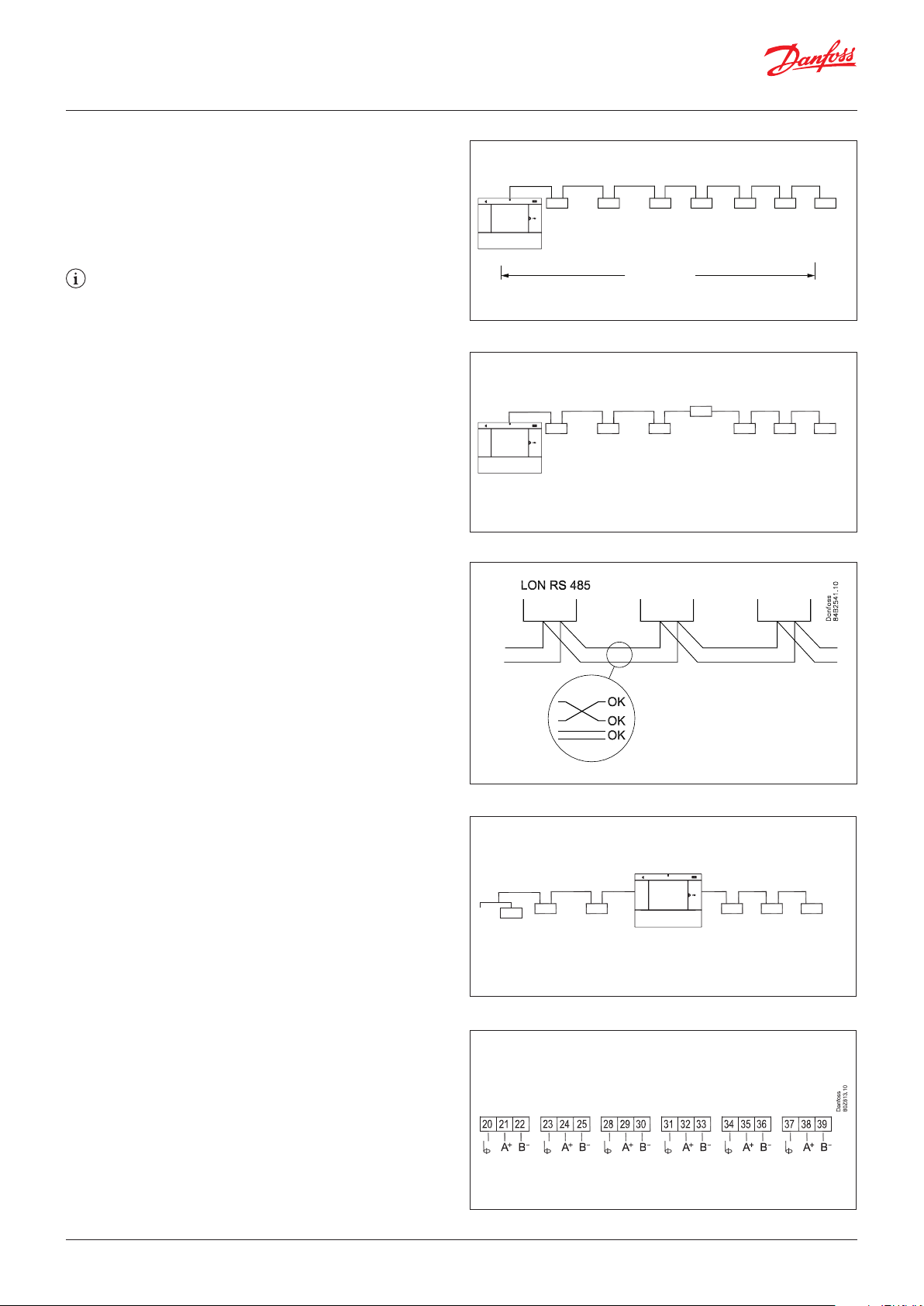

2.3.1 Lon RS485 topology

The cable connection must be connected from controller to

controller, and no branches are allowed on the cable. If the cable

length exceeds 1200 m a repeater must be inserted. If the data

communication cable runs through an electrically noisy

environment which impairs the data signal, one or more repeaters

must be added to stabilise the signal.

When configuring Lon devices on the control bus, the highest

device address that can be can be used is 127 (max. 120

controller in total).

Remember to use 120 Ohm terminators on the last filed bus

controller device. Note also to enable (ON) the Term. Switch,

located above each network connection point on the AK-SM 800A,

this will enable the built in terminator(s) for each network point on

the AK-SM 800A.

Conductors

he two wires are looped from device to device. There are no

polarisation requirements. (On some controllers, the clamps are

designated A and B. On others there is no designation. Otherwise

the connections are identical.) If a screen is used, it must be

connected to the system device and any repeaters. A screen must

always be looped from device to device.

AK-SM

Danfoss

Danfoss

84B3286

84B3287

The screen must not be connected to anything else. (The screen is

earthed inside the screen and must not be earthed in any other way.)

Mid network connection

This example shows the AK-SM 800A series RS485 version used

in the middle of a network run. In this example ensure that both

ends of the controller run are fitted with 120 Ohm terminators.

Over the past several years Danfoss has offered versions of the

AK-SC 255 and AK-SC 355 which has a LonWorks® option of TP78.

As a physical layer of the LonWorks® protocol these older systems

offered x5 network connection points. Due to the global phase

out of the TP78 option by the OEM, Danfoss has made available

a special order version of the AK-SM 880A (080Z4029), which

will come pre-installed with a LonWorks® TP78 options card.

This ‘special’ version of the AK-SM 880A is designed to support

customers who wish to migrate from existing AK-SC 255 and AKSC 355 and AK-SM 800 TP78 systems.

Note: this version of the AK-SM 880A is not intended or available

in Europe and offers x4 TP 78 connection points.

RS 485 RS 485

R=120 ohm

Danfoss

R=120 ohm

© Danfoss | DCS (vt) | 2021.03

TP 78-Version

1

(Danfoss)

MODBUS 2

(for future use)

(RS485)

TP 78

LON 1

TP 78

LON 2

TP 78

LON 3

TP 78

LON 4

BC337629891709en-000201 | 9

User Guide | AK-System Manager, AK-SM 800A series

84B3289

AK-SM

84B3290

max. 1200 m

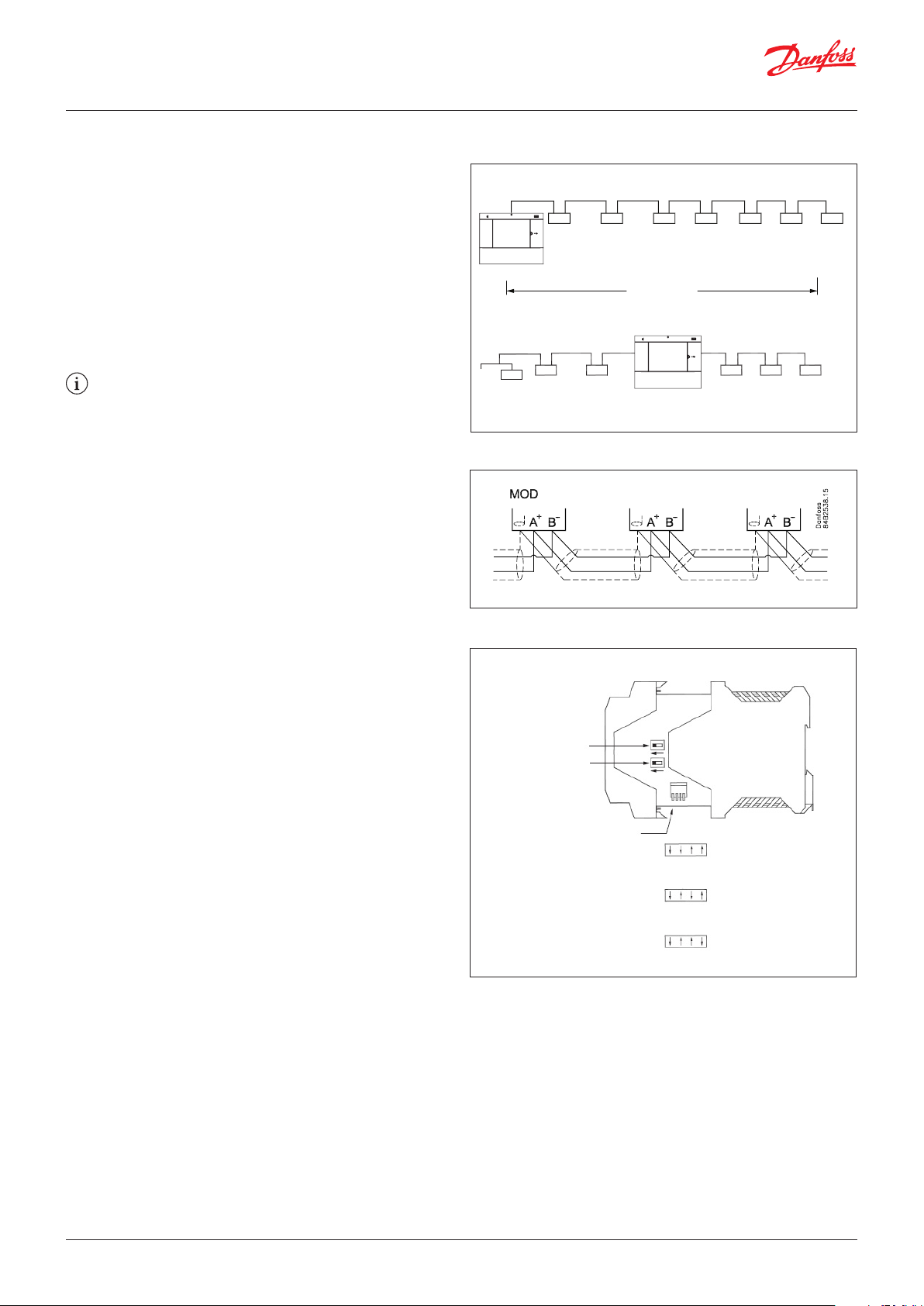

2.3.2 MODBUS topology

The AK-SM 800A has two Modbus ports, at the time of writing

Modbus #2 is not currently enabled. The below information relates

to Modbus#1

The cable must be with screen. The cable is connected from

controller to controller, and no branches are allowed on the cable.

If the cable length exceeds 1200 m a repeater must be inserted. If

the data communication cable runs through an electrically noisy

environment which impairs the data signal, one or more repeaters

must be added to stabilise the signal.

‘The System Manager can be inserted in middle of network, ensure

System Manager termination is OFF. Refer to Danfoss document

‘RC8AC802 Data Communication’.

When configuring MODBUS devices on the control bus, the

highest device address that can be used is 199 (max. 120

controller in total)

The wires are looped from device to device.

A is connected to A.

B is connected to B.

The screen must be connected to the system device, all controller

and any repeaters.

A screen must always be looped from device to device.

The screen must not be connected to anything else.

AK-SM

MODBUS

R=120 ohm

MODBUS

R=120 ohm

Danfoss

Danfoss

Be sure to configure the MODBUS repeater AKA 222

(code#084B2240) to the correct baud rate.

See notes section at the back of this guide for MODBUS device

baud rate properties.

Refer to Danfoss Instructions RI8KN402 for further details on the

AKA 222 repeater’

Termination

ON

ON

Baudrate:

DANBUSS:

MODBUS: 19.2

MODBUS: 38.4

Repeater

OFF

ON

ON

OFF

ON

OFF

OFF

ONONON

OFF

10 | BC337629891709en-000201

© Danfoss | DCS (vt) | 2021.03

User Guide | AK-System Manager, AK-SM 800A series

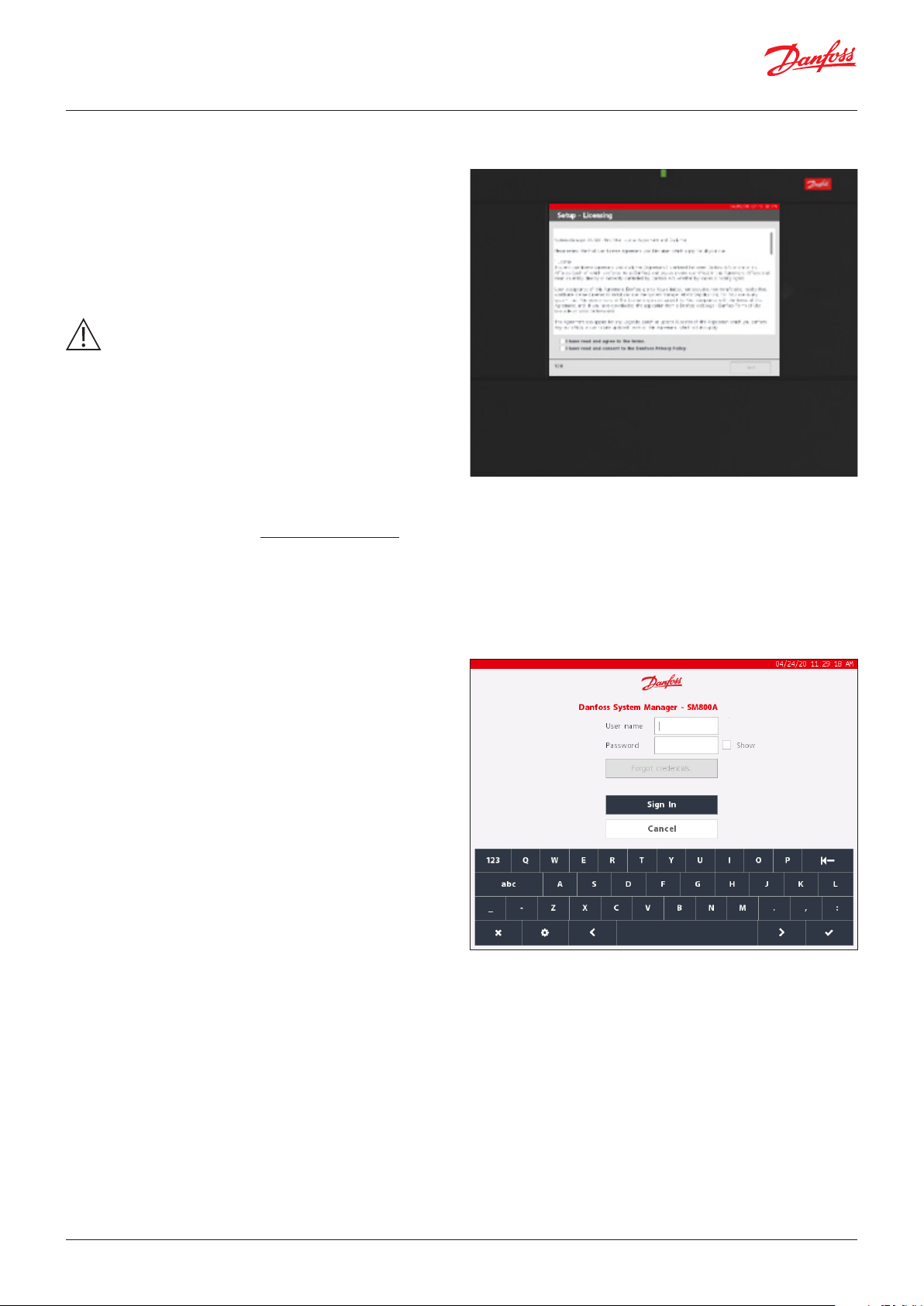

2.4 First time startup

To establish basic settings, an initial wizard is presented upon first

powering up your AK-SM 800A. This wizard appears only once

upon first time power up from new (out of the box) or if the system

database has been cleared (an option in the system configuration).

The following screens are presented;

1/8 Licensing (review and acknowledge terms and conditions)

2/8 Language (set required primary unit language)

3/8 Setup Administrator (create highest level user who later can

then create additional users.

Caution: Take note of user/password as Danfoss does not

have access to user profiles or passwords. Danfoss is not

responsible for the management of user passwords. If the

user/password is forgotten the ‘forgot password’ workflow

will need to be applied).

4/8 Setup Date/Time/Format

5/8 Setup system units

6/8 Notification of connectors (take note of connector locations

and what connectors are available)

7/8 Setup Network

8/8 Important software update notification.

(To ensure optimum operation, security and the latest features

ensure your AK-SM 800A is updated with the latest software.

Follow on screen prompts or visit ak-sm800a.danfoss.com for

the latest software packages. Also refer to chapter 4.3 for more

information on how to update your AK-SM 800A.)

After completion of the settings wizard the AK-SM 800A Series will

request a reset, where settings will saved. Commissioning activities

can now continue using Web wizards and control screens.

Local screen login

For security purposes, no system information or status is available

on the AK-SM 800A until a valid username and password has been

entered. To assist in the confirmation of inputting of credentials,

use the ‘show’ check box – this will show each character as you

input.

Forgot Credentials

This button can be used if you have forgotten your user name

or password. Danfoss cannot access or recover any user name

or password in the system, as these are stored in an encrypted

format. If your log in credentials are forgotten you will need

to enter new credentials, previous user credentials are not

recoverable. Please note that it is expected that one administrator

can always gain access to the system and thereby delete the

original user profile of the user who has forgotten their credentials

and create a new one, where the user would input a new

password.

If the administrator is not available or cannot perform this action,

the reset password workflow will need to be initiated. Follow the

on-screen prompts and press the ‘Reset password’ button, see

section 3.1 for more details.

Note: For security purposes, resetting of the password requires

specific unit information that is ONLY possible when in front of the

local AK-SM 800A screen.

© Danfoss | DCS (vt) | 2021.03

BC337629891709en-000201 | 11

User Guide | AK-System Manager, AK-SM 800A series

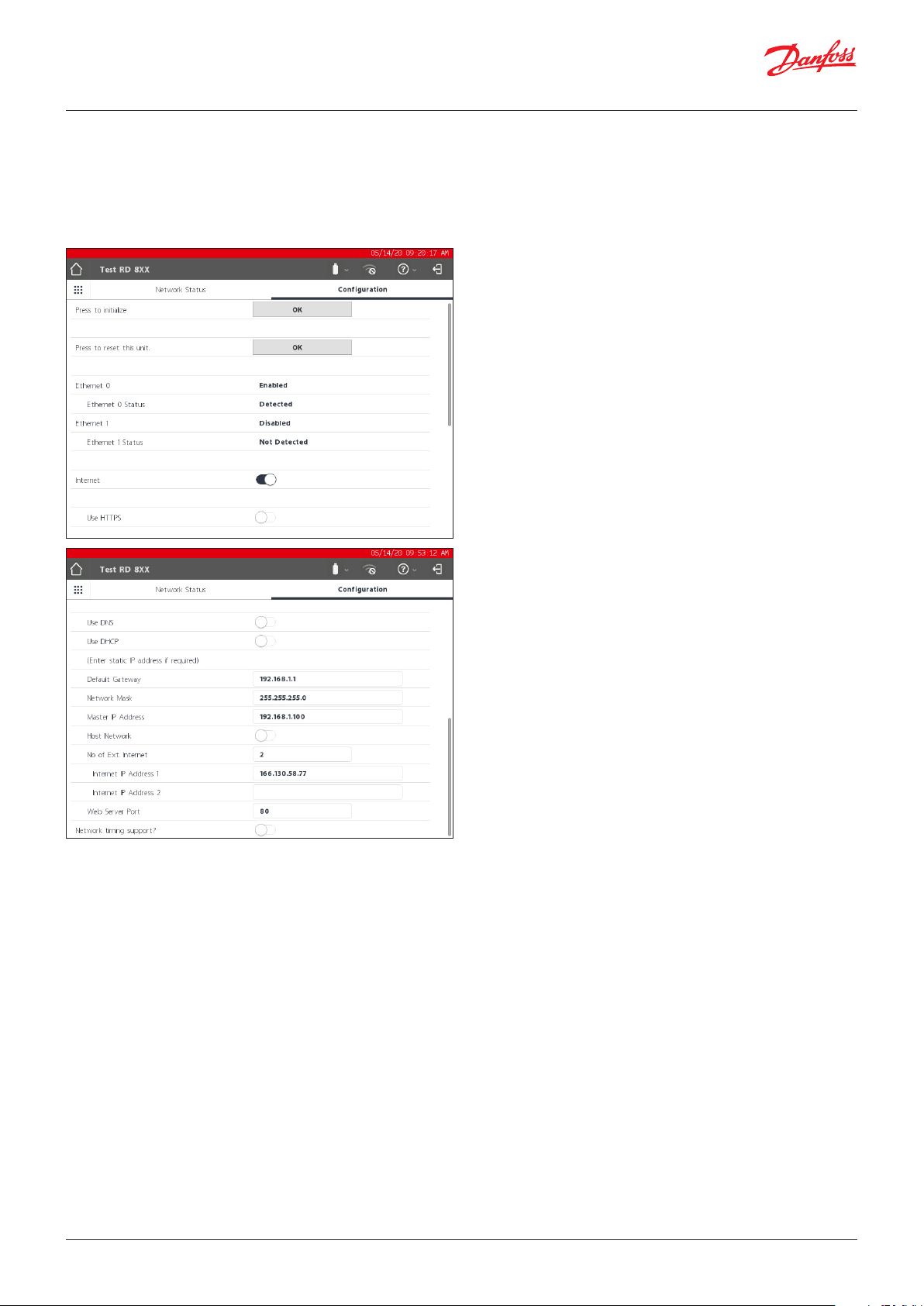

2.5 IP Configuration and suggested security

settings

The Configuration Comm screen allows important routing and

IP configuration to be set. With correct settings you will be able to

remotely connect to your AK-SM 800A series controller.

Use DHCP (On/Off)

Dynamic Host Configuration Protocol (DHCP) is a standard

network protocol that dynamically distributes network

configuration parameters, such as IP addresses. If you connect

the AK-SM 800A controller to a valid DHCP server the controller

will obtain an address automatically. The management (renewal,

binding and lease) of the IP address is fully automatic. It is strongly

recommended that DNS is used in conjunction with DHCP so to

keep track of dynamic addressing.

Use IP address as backup if DHCP fails (Yes/No)

If a non-reliable DHCP service is suspected, you can insert a fixed

IP address that will be used in the event of a DHCP failure. Under

normal network conditions this feature would not normally be

required.

Primary IP address

Your AK-SM 800A series controller is a so called ‘Primary’ when the

rotary address switch (located behind keyboard cover) is set to 0.

This automatically assigns the unit as a Primary and is used when

operating with multiple AK-SM 800A units (host network)

Preferred Hostname

If DNS is set to YES then a preferred hostname line appears.

Selecting YES to the preferred hostname will enable Primary node

name line (see below). If DNS is set to No, the site name and unit

name (site name-unit name) will be used by default.

Note: Site Name and Unit name should be configured under the

Configuration System screen.

Press to initialize

Use this function when a change to IP address or other IP related

modification has occurred. An initialization will not physically resset the AK-SM 800A

Press to reset unit

This function will physically cause the AK-SM 800A to reset, use

this when configuring Primary/Secondary host network

Ethernet 0 / 1

This reflects if an active Cat5 ethernet connection is seen

Eth(0) must be used for WAN/LAN communications

Internet (slider on/off)

Slide ON if remote communications is required via IP, then view

options under this

Use DNS (On/Off)

Domain Name System- select to YES to enable this feature and

take advantage of your networks naming service. When answering

YES (and with DHCP set to NO), the preferred host name line

appears together with Domain Server IP address. There are two

lines for the domain server IP or DNS name. Note that if DHCP is

set to yes, the domain server IP address lines are not visible.

Primary node name

Enter a name here, used to identify the AK-SM 800A controller on

the router.

Host Network (Enabled / Disabled)

If your AK-SM 800A will be part of an interconnected host network

of AK-SM 800A units, select ‘Enabled’ to this question. If there is

only 1 AK-SM 800A controller then leave set as Disabled.

SM800A on network (1-10) – Enter how many units will be on

host network.

Node to be used as (Primary / Secondary) – Select

‘Secondary’ for all units with rotary address switch set to 1 or

above.

No of external Internet (1-3)

If your AK-SM 800A series controllers will be made accessible via

an external IP address (i.e. on a 4G router/modem or INTERNET

connection) please ensure this is set to at least 1. This will allow the

insertion of an IP address that is the public facing address.

Note: the requirement to enable External Internet is ONLY

applicable for a host network configuration (AK-SM 800A units

that are interconnected via host network).

Type (IP/ Name) – Select IP for static addressing or Name if

using DHCP

Internet IP / Name address – Enter IP or Name (based on

above selection)

Web server port (user configurable)

Used to allow HTTPS traffic / support browser access to your AKSM 800A controller.

12 | BC337629891709en-000201

© Danfoss | DCS (vt) | 2021.03

User Guide | AK-System Manager, AK-SM 800A series

Network timing support (NTP)

Use this function (if supported by your network) to sync the AK-SM

800A real time clock over the network, known as NTP. Requires

NTP sever address and Time Zone offset to be programed.

Note: Time Zone offset can be configured under the

Configuration Time screen

General IT security / Recommendations

The AK-SM 800A series device is an embedded controller designed

to be installed behind an appropriate router and firewall. Whilst

the AK-SM 800A offers many IT industry security technologies

(HTTPS, encrypted Wi-Fi, encrypted passwords...) Danfoss strongly

recommends the deployment using IT security best practices and

protocols.

The AK-SM 800A controller supports auto negotiated 10/100

Ethernet speeds.

The AK-SM 800A controller supports auto negotiated full / half

duplex Ethernet communications.

Port Description Use User configurable (in SM800A interface)

443 HTTPS Web communications Yes

80 Redirect only It redirects to current https post when IP address is typed No

1041, 254 Service tool Service tool communications No

5136 SNMP SNMP communications No

1041 PI200 PI200 communications Yes

2812 Localhost Local processes monitoring No

5003, 5004, 5005, 5006 Host network

Only used when host network is enabled. For host

network communication

No

© Danfoss | DCS (vt) | 2021.03

BC337629891709en-000201 | 13

User Guide | AK-System Manager, AK-SM 800A series

Chapter 3: Navigation and use (Local screen)

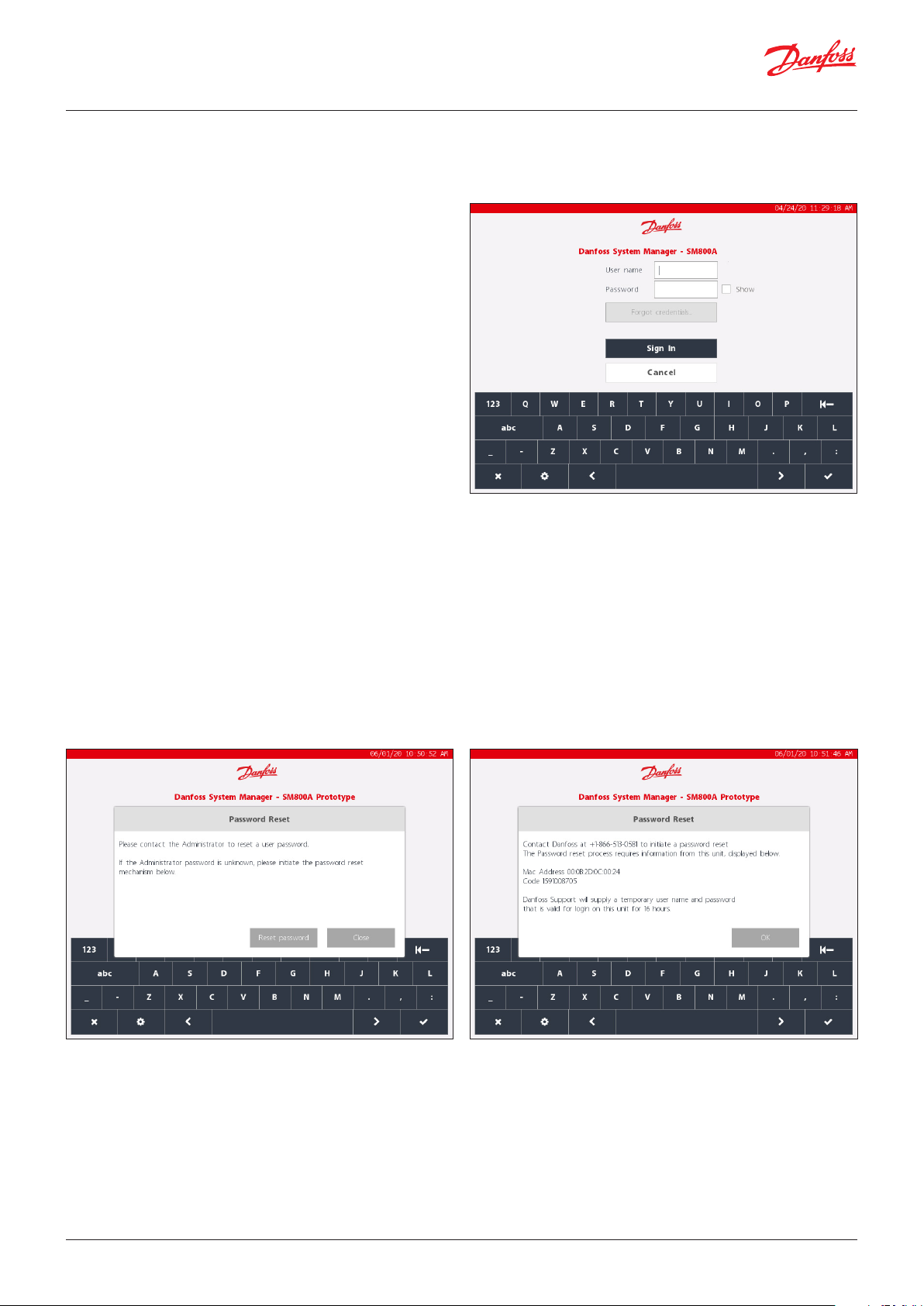

3.1 Log in screen

For security purposes, no system information or status is available

on the AK-SM 800A until a valid username and password has been

entered. To assist in the confirmation of inputting of credentials,

use the ‘show’ check box – this will show each character as you

input.

Forgot Credentials

This button can be used if you have forgotten your user name or

password. Danfoss cannot access or recover any user name or

password in the system, as these are stored in an encrypted

format. If your log in credentials are forgotten you will need

to enter new credentials, previous user credentials are not

recoverable.

Please note that it is expected that one administrator can always

gain access to the system and thereby delete the original user

profile of the user who has forgotten their credentials and create

a new one, where the user would input a new password. If the

administrator is not available or cannot perform this action, the

reset password workflow will need to be initiated. Follow the onscreen prompts following ‘Reset password’ button.

Note: For security purposes, resetting of the password requires

specific unit information that is ONLY possible when in front of the

local AK-SM 800A screen.

Note: For the North American region, Danfoss Enterprise Services

(DES) can be called to initiate a password reset. The phone number

will be shown in the reset popup window, as shown below.

Depending on the AK-SM 800A region (country) configuration, the

initial contact point may differ. In essence, your first action is to

contact Danfoss Technical support for your region. Upon receipt

of your request to reset a password, Danfoss Technical support

will raise a support ticket capturing relevant details and ultimately

will provide a one off, time restricted (16 hours) user/password so

entry can be established. Upon using this code to gain access to

the AK-SM 800A you must update your user credentials with a new

password.

14 | BC337629891709en-000201

© Danfoss | DCS (vt) | 2021.03

User Guide | AK-System Manager, AK-SM 800A series

3.2 Home screen / Dashboard

After logging in, by default the dashboard screen will be

presented. Note that a system preference is available under the

Configuration System screen where the option to define

either Dashboard, Equipment or Graphics as home screen is

available.

The home screen (indicated by the home icon) offers access to

different functions, described below;

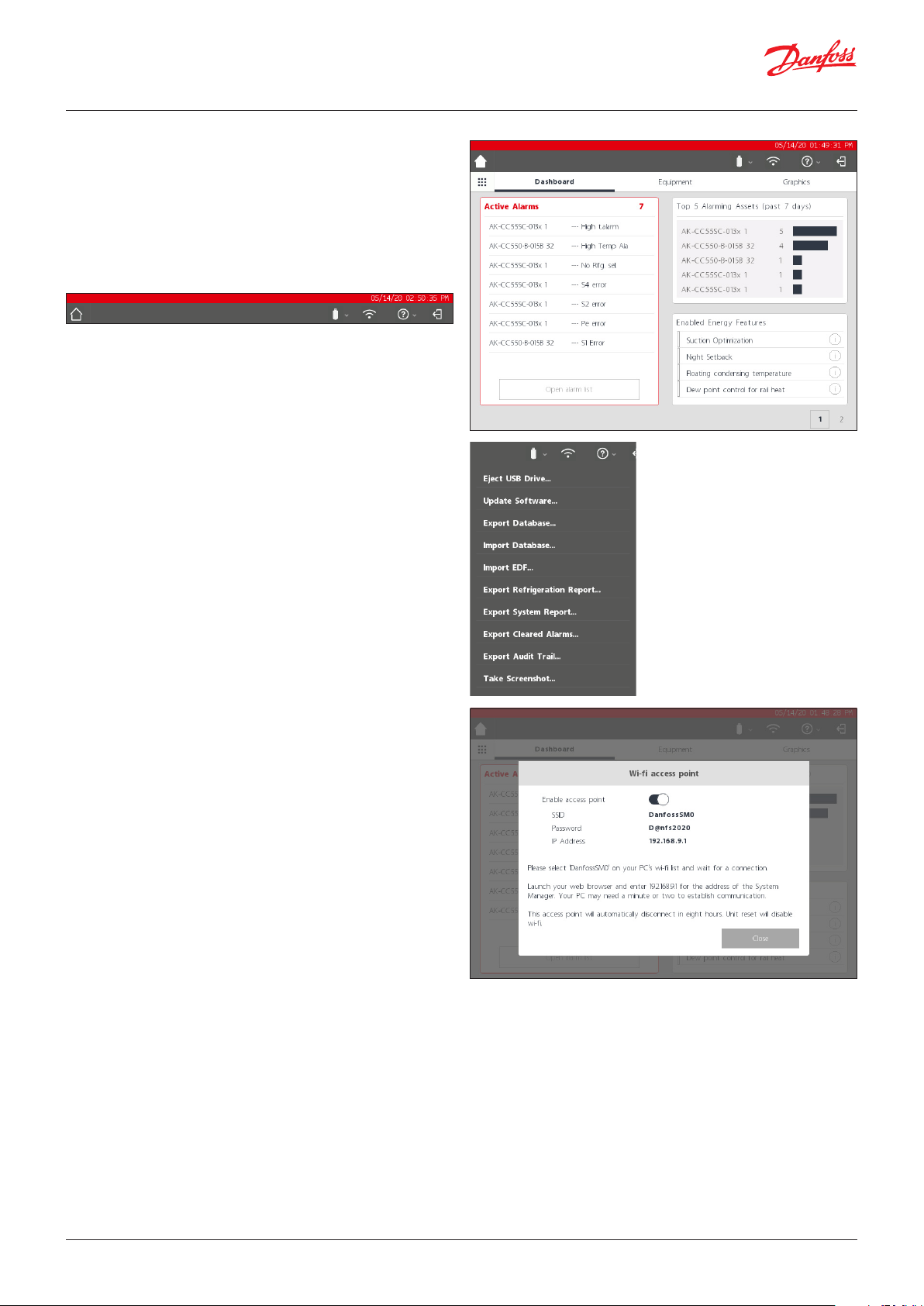

USB Flash Drive

Access to the USB Flash drive (when inserted) is via the USB flash

drive icon. When a compatible USB flash drive (max. 32MB) is

inserted into any one of the three USB ports, the USB icon changes

to solid, indicating successful detection. Pressing this icon will

bring up the USB menu options.

Note: Be sure to correctly eject the USB drive, via the top menu

selection, corruption to the USB may occur if this is not done.

USB Flash Drive menu options

• Eject USB Drive: use this to correctly eject flash drive

• Update Software: Use this option to update the AK-SM 800A

via compatible software package (obtained via Danfoss ADAPKOOL support site)

• Export Database

• Import Database

• Import EDF

• Export Refrigeration report: CSV file format

• Export System Report: txt file format

• Export Cleared alarms: CSV file format

• Export Audit Trail: CSV file format

AK-SM 800A Wi-Fi Access Point

The AK-SM 800A is equipped with built in Wi-Fi access, designed

to support direct unit/user access. By default, Wi-Fi is disabled,

only authorized users can enable this feature. The AK-SM 800A

Wi-Fi access point can be used to connect a mobile device (smart

phone, tablet) or laptop/PC and when enabled will remain active

for 8 hours.

When connecting to the AK-SM 800A Wi-Fi, look for the wireless

network SSD name and select. The SSD name will reflect the host

address (rotary switch), since this is a point to point connection

only (host network view not supported).

Once connection to the AK-SM 800A network has been

established, open a compatible web browser (Google Chrome™ /

Apple Safari™, Chromium based Microsoft Edge™) and enter the IP

address shown on the Wi-Fi screen, the AK-SM 800A.

© Danfoss | DCS (vt) | 2021.03

BC337629891709en-000201 | 15

User Guide | AK-System Manager, AK-SM 800A series

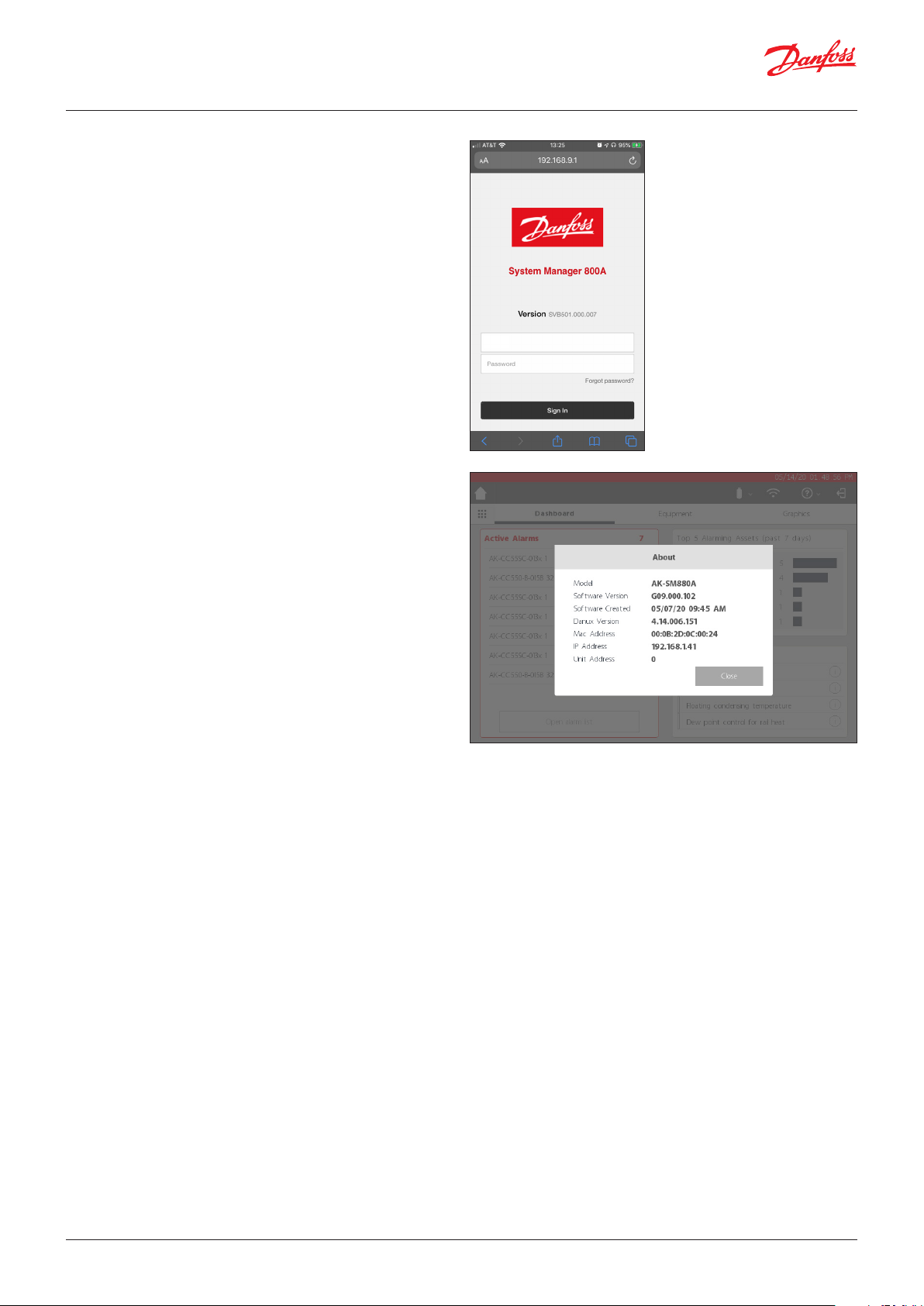

Web log on screen will be shown. Enter the AK-SM 800A user name

and password.

When connecting with a mobile device (i.e. smart phone) the AKSM 800A will auto detect this platform and will only present the

unit Utilities. If accessing with a desktop class browser, StoreView

browser 5 will be presented.

Note: If the Wi-Fi is enabled and the AK-SM 800A resets, for security

purposes, Wi-Fi will revert to disabled.

Info button

The info button hosts a drop down menu selection, where the

following is available;

About:

Shows unit information, software version, MAC and IP address

Licensing:

This screen will show any applied licenses

Terms:

End user terms and disclosure

Connections:

A technical view of active connections available on the AK-SM

800A.

Log out

Press the log out icon to exit and log out of the AK-SM 800A.

Note: The AK-SM 800A will detect inactivity and will auto log

off after a period of 20 minutes. This can be changed via the

Configuration->System screen (Idle timeout).

16 | BC337629891709en-000201

© Danfoss | DCS (vt) | 2021.03

User Guide | AK-System Manager, AK-SM 800A series

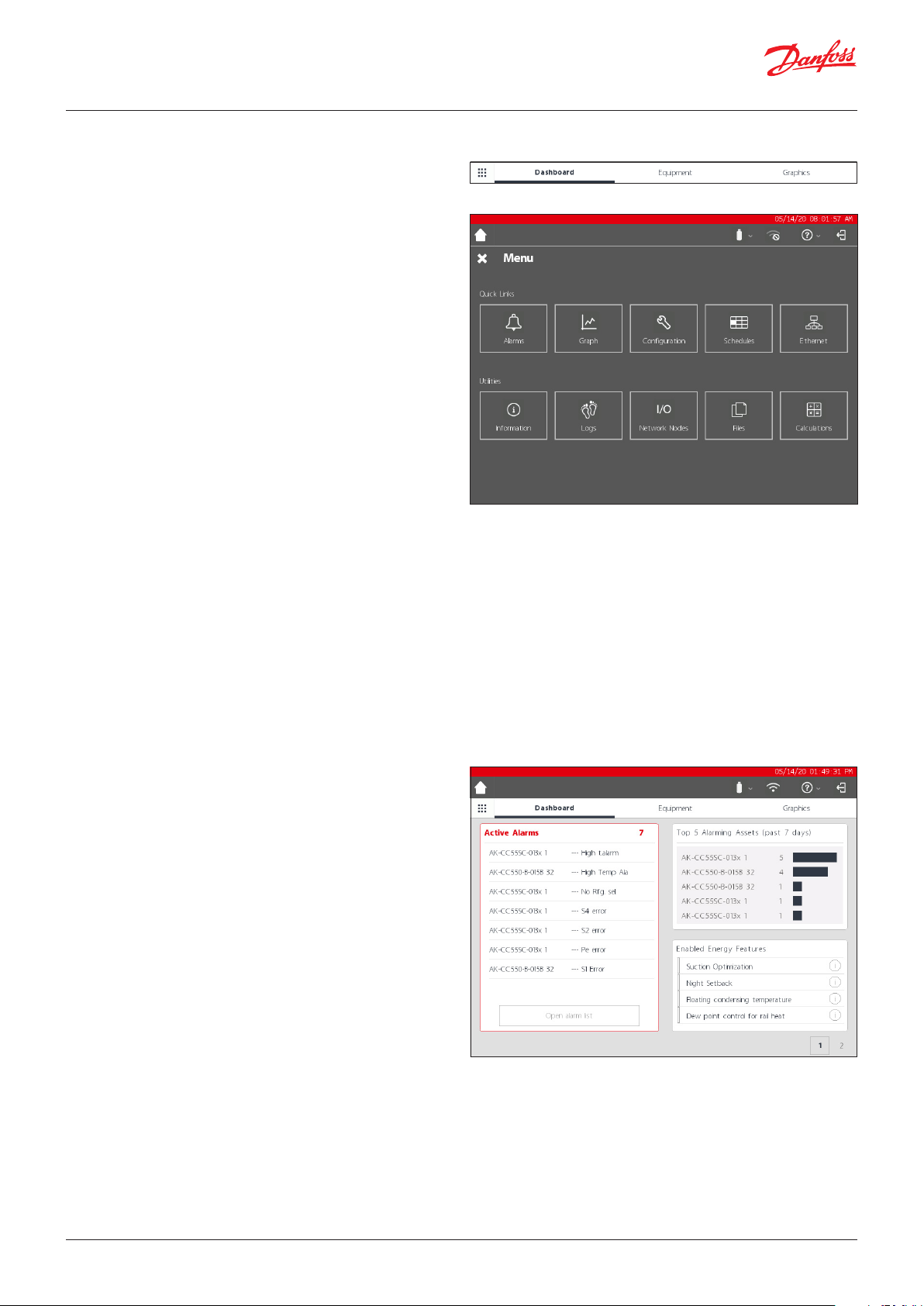

3.3 Home Screen – Menu Bar

The second level of meu bar on the home screen offers the

following;

Fly-in Menu

Pressing the ‘grid button’ will trigger the fly-in menu. The purpose

of this menu is to provide quick links / utilities to important areas

of the AK-SM 800A.

Dashboard

With the Dashboard in focus (note grey focus line under

Dashboard), the left hand section of the screen will display

active alarms. The active alarm count will be shown as a red digit,

followed by the active alarm list. Press the ‘Open Alarm list’ button

to open a dedicated alarm screen.

The active alarm screen will show all current active alarms in the

AK-SM 800A unit. An active alarm is one where no user action has

occurred, for example the alarm(s) have not been acknowledged.

Use the check boxes to select or de-select different application

types (HVAC, Refrigeration, Lighting, Misc.). A search field can be

used to quickly search on device name.

Alarms on this list can be acknowledged individually or on bulk.

To perform a bulk acknowledgement ‘check’ the device box and

all entries will be selected – press the Acknowledge button to

execute this action. Note that this will be recorded in the Audit

trail.

Additional functions can be found along the top of the screen,

Cleared, service, status and info

Cleared

This screen will show all alarms that have been set to cleared.

Service

This screen allows the user to send test alarms, suspend alarms,

clear alarm log and delete alarm configuration. In addition, the

internal relay (found on the AK-SM 800A) can be configured.

Status

Provides a quick status view (offline) of your connected devices.

Top 5 alarming assets (past 7 days)

The upper right segment of the screen shows a rolling analysis of

what devices (top 5) are highest in terms of alarm occurrences.

This is for information only and may help guide the operator on

what to focus on to reduce alarm counts.

Enabled Energy Features

The AK-SM 800A includes several energy functions that provide

autonomous control and continuous savings of operational

efficiency, when combined with Danfoss controls. Any built-in

energy feature enabled in the system will show green in the list.

This information panel is designed to prompt users in ensuring

enablement of these included features, thus maximizing energy

efficiency of the store.

© Danfoss | DCS (vt) | 2021.03

BC337629891709en-000201 | 17

User Guide | AK-System Manager, AK-SM 800A series

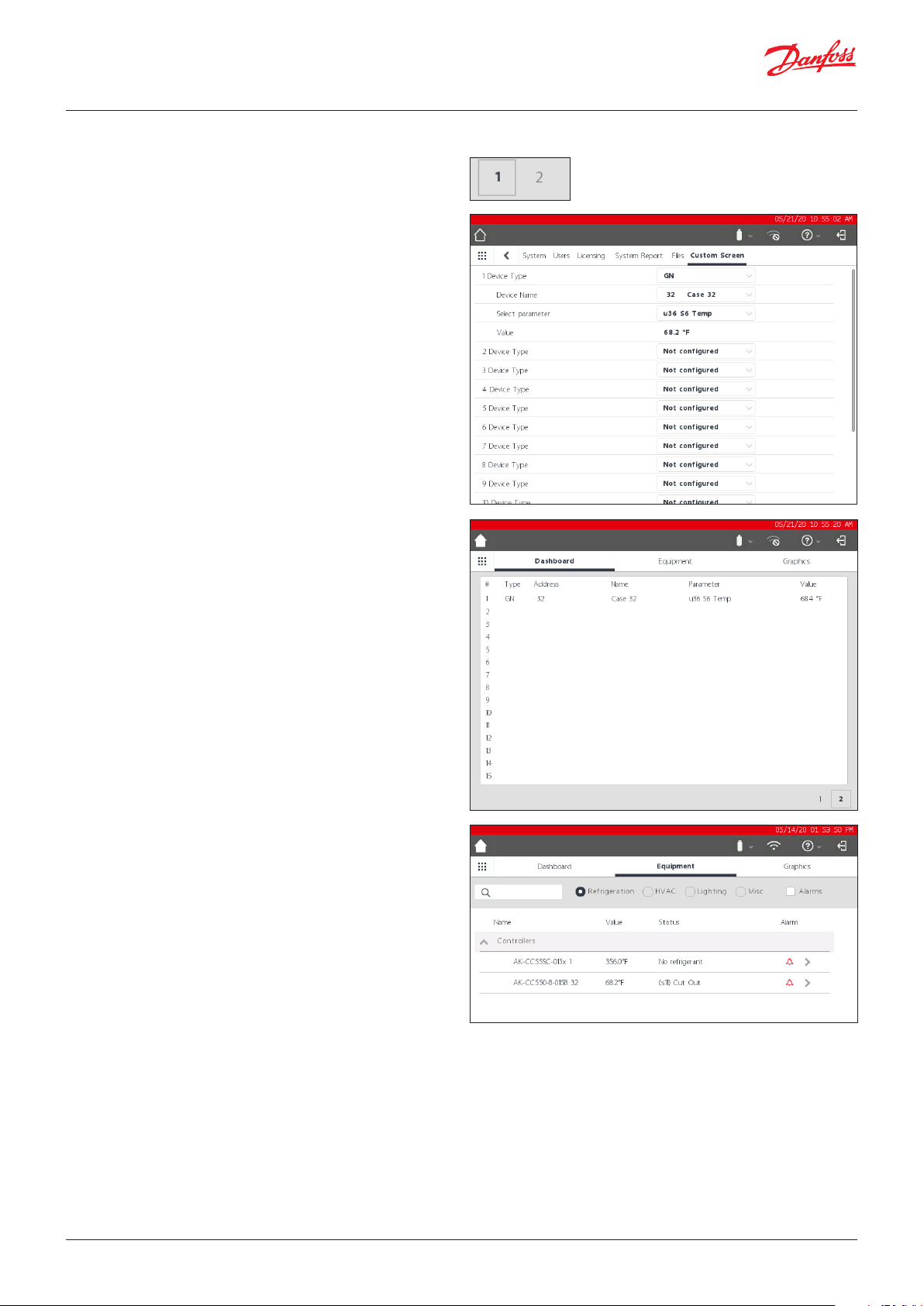

Custom Screen

The AK-SM 800A offers the ability to create a custom screen,

populated with up to 15 points (OI, RO, SI, VO, Generic device).

Once configured, the custom screen can be seen by pressing

the second screen (2) button, found at the bottom right of the

dashboard screen.

Note: To configure datapoints to show in the custom screen,

navigate to the Configuration System Custom Screen. Here a

selection can be made – in the example opposite, point 1 has been

defined as a generic device (GN), Case 32 and the parameter u36

S6 Temp is selected.

Repeat this process for additional datapoints, upon completion

press the 2 button to view the points. The values on this screen will

auto refresh to provide an up to date status.

Equipment

To view a list of installed equipment, navigate to the equipment

screen from the dashboard (grey bar will be indicated under

Equipment menu).

Use the radio buttons to select which application type should

be listed (Refrigeration, HVAC, Lighting, Misc) – by default

Refrigeration is preselected.

A list of devices, grouped into Rack / Packs will be shown

(reflecting the configuration).

To view more information on a particular device, press the >

button, which will then show the device detail screen.

Graphics

To view any graphics loaded in the AK-SM 800A, navigate to the

graphics screen from the dashboard (grey bar will be indicated

under graphics menu)

Note: See the section on Utilities to get an overview on how to

configure and deploy graphics on your AK-SM 800A.

18 | BC337629891709en-000201

© Danfoss | DCS (vt) | 2021.03

User Guide | AK-System Manager, AK-SM 800A series

Chapter 4: Navigation and use (SvB5 browser)

Once your AK-SM 800A has been configured, general navigation

and daily use is done via the Dashboard screen. The Dashboard

screen acts as the central system home page, where further system

details can be reached. The Dashboard and subsequent device

screens have been developed to provide an easy to use navigation

environment for the user, where typical status and setting can be

found.

Dashboard view / Menus

Once the correct user name and password has been entered the

Dashboard screen will load. The Dashboard screen will only reflect

what your application configuration has been set to. For example,

if your application does not have any HVAC configured the

Dashboard will not show the HVAC panel. Dashboard panels are

automatically generated depending on the configuration, no user

action is required to build the panels.

Utilities (fly in) menu

Press the ‘grid icon’ to view the utilities.

4.1 StoreView Browser 5 (SvB5)

This section describes the (web) browser interface of the AK-SM

800A, known as the StoreView Browser 5 or SvB5 for short.

Your AK-SM 800A includes web server technology that ‘serves’ data

that is then displayed in a compatible web browser. SvB5 provides

full access to all system screens and in some instances provides

additional features not available in the local touch screen due to

the preferred user interface (i.e. wizards are only found in SvB5)

SvB5 is a software module utilizing HTML 5, included in the AKSM 800A software package, the version of which can be seen in

the info screen(s) of your AK-SM 800A. For ease of use, no special

tools and setup is required, simply open a supported browser and

type the HTTPS address of your AK-SM 800A unit, for example;

https://192.168.1.50

Note: At the time of user guide publication, Google Chrome™

Chromium based Microsoft Edge™ and Apple Safari™ are

supported browsers for the AK-SM 800A.

Communications between your device/browser and the AK-SM

800A is encrypted using HTTPS technology.

Note: You may observe that your browser provides a warning,

suggesting that the connection to this site is not secure. In fact,

the browser is providing this user warning as it has detected a selfsigned certificate which it cannot verify from a public database. In

this instance you will need to continue to connect via the ‘proceed

to…’ option (depending on your browser choice).

4.2 AK-SM 800A Utilities

This section describes the various AK-SM 800A Utilities, seen when

connecting via a compatible browser. The Utilities are hosted in

the AK-SM 800A, as an individual software component and are

part of the AK-SM 800A software package.

When logging onto your AK-SM 800A via a (desktop grade)

compatible browser you will have access via the fly-in menu

(based on user permissions), located next to the File Menu. The

AK-SM 800A will recognize the browser type (mobile/desktop) and

will react accordingly. For example, when accessing your AK-SM

800A via a mobile platform, only the Utilities will be shown, if a

desktop grade browser is detected the full SvB5 interface will be

shown, with access to the Utilities as described.

© Danfoss | DCS (vt) | 2021.03

BC337629891709en-000201 | 19

User Guide | AK-System Manager, AK-SM 800A series

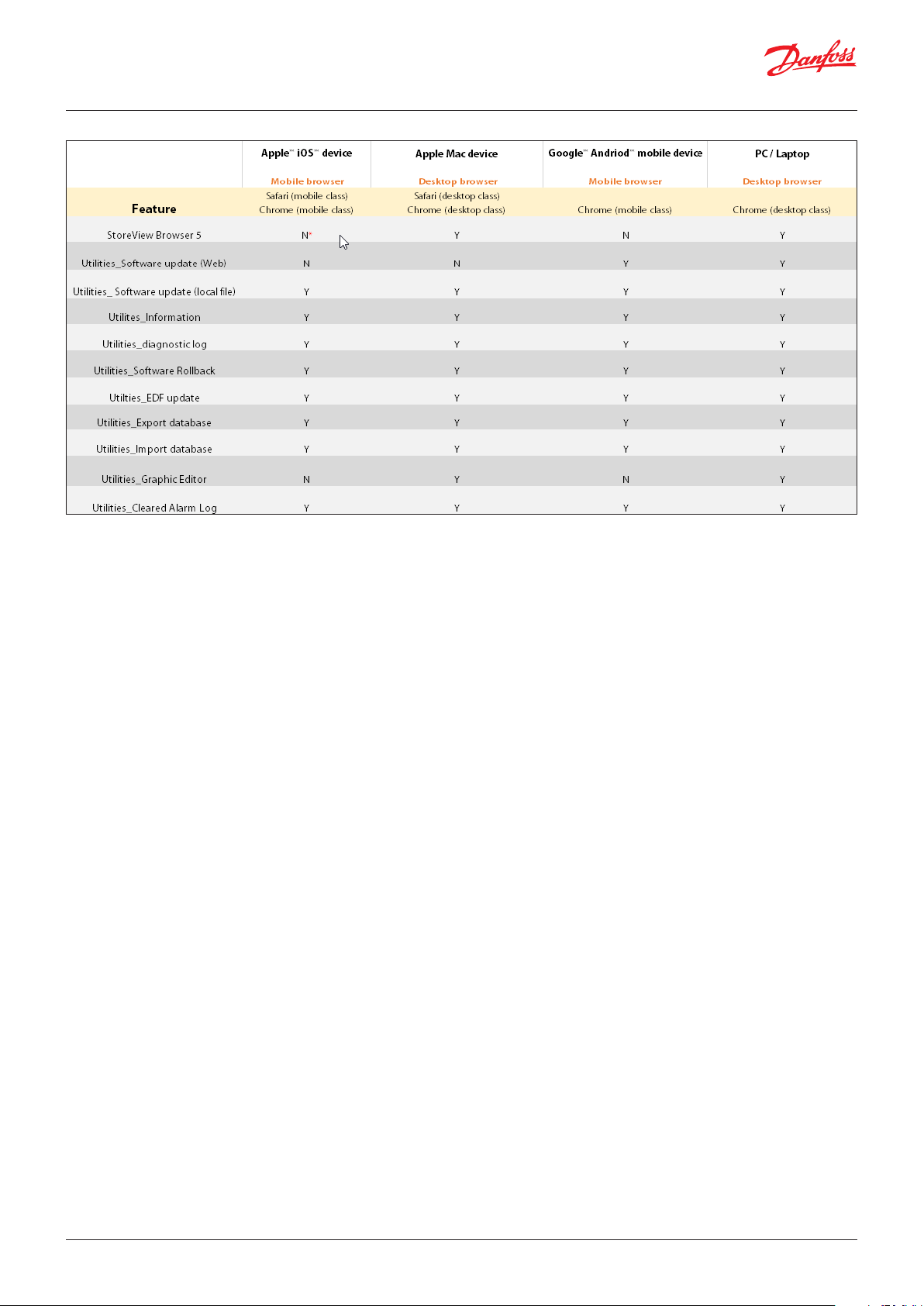

At the time of publication, the AK-SM 800A and SvB5 supports

Google Chrome™, Chromium based Microsoft Edge™ and Apple

Safari™ mobile and desktop browsers. Refer to the chart below for

a detailed overview of platform and associated feature support.

Note: Whilst SvB5 is not currently engineered to support

responsive web design, enabling full mobile use, it is possible

to view and use SvB5 in a mobile tablet device that supports

browser Desktop mode (i.e. Apple iPad™ 10.2” and above). For best

SvB5 experience Danfoss recommends and supports PC/Laptop

configuration only.

Utilities - Information function

Selecting the information button will retrieve and show AK-SM

800A unit information. The most commonly used information

is located at the top of the screen. The Information screen also

contains version numbering for other technical software aspects

that may mostly be relevant to Danfoss.

To easily record / share unit information, use the download

icon, located in the upper right of the screen. This will initiate a

download, presented as a Comma Separated Value (.CSV) file (the

file will automatically be named YYYY/MM/DD/HHMMSS).

Utilities – Diagnostic Log

The diagnostic log is intended to capture technical information

about unit operation or system events. This log is designed

for Danfoss Technical support and is intended to gather large

amounts of data and is not intended to present a daily user audit

trail. An export feature is available that will easily download a

diagnostic log file, which can be sent to Danfoss for analysis.

20 | BC337629891709en-000201

© Danfoss | DCS (vt) | 2021.03

User Guide | AK-System Manager, AK-SM 800A series

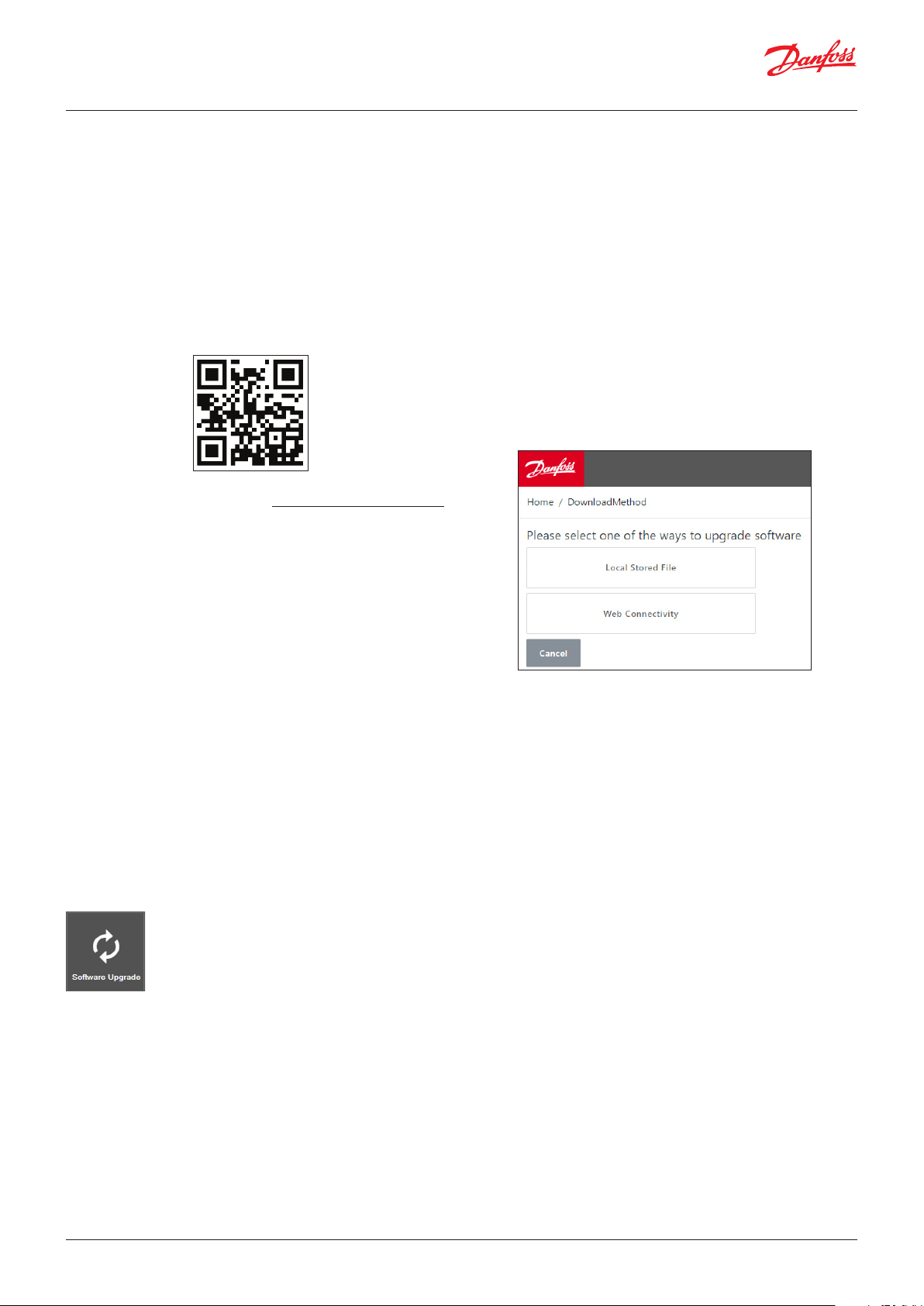

4.3 Utilities – Software update

Introduction

Like many other modern electronic devices, it is important that

you maintain your AK-SM 800A with up to date software. Danfoss

has a policy of continued improvement and enhancement and will

regularly offer updates to your system. These updates may include

bug fixes, new enhancements and important updates for security

vulnerabilities. Updates can be categorized as ‘recommended’

or ‘mandatory’, with supporting documentation describing the

categorization. The following section describes the Software

Upgrade feature, found in utilities. Use this feature to remotely

update your AK-SM 800A series controller.

Important: To download the latest software package for your

AK-SM 800A series controller, visit www.ak-sm800a.danfoss.com

Operational scope and Important notes:

Once connected to your AK-SM 800A series controller you will

have access to the Utilities App. The Software Upgrade function

is currently designed for single SM800A units only. For example, if

you have a host network of multiple units, ensure you connect to

the actual unit (IP address) that you intended to update. To update

other units on the host network, be sure to log into that units

unique IP address and follow the same workflow.

Local Stored File

This method assumes you have previously downloaded a software

package from www.sm800a.danfoss.com and this package is

located on the device you are using to access your AK-SM 800A /

SvB5.

1. Click on the Local Stored File option and select the software

package via the ‘Choose File’ button. The file type is SPK

(software Package)

2. Press the Upgrade SM800A button to initiate the package

download to the SM800A

3. After the package has been downloaded and checked for

integrity, press the install button to execute the update. Note:

During the update process, your AK-SM 800A will reset, this

will temporarily disconnect your connection. Press the browser

refresh to reconnect after ~3 minutes.

4. An upgrade Log will appear, with the final status ‘Software

upgrade SUCCESSFUL!’, press the Home button to get back to

the Utilities.

The software packages available for your AK-SM 800A have unique

assigned ‘digital signatures’, this signature is then validated by the

AK-SM 800A to ensure the file has not be altered or tampered with.

Any software package that is modified will be rejected by the AKSM 800A and update will not be possible.

Important: Whilst upgrading your system, power must not be

interrupted at any time during the update process. Any power loss

during the update procedure may cause permanent damage or

corruption to your AK-SM 800A series controller.

Important: In host network applications (multiple interconnected

AK-SM 800A units) it is required that ALL units have the same

software installed. Failure to do so may result in unexpected

behavior and may affect control and monitoring of your store.

Utilities - Software update function

The software update utility offers two methods of

updating, Local Stored File and Web Connectivity

(note, in addition to using the Utilities, any of the

USB ports on your AK-SM 800A can also be used to

update software via a flash memory stick).

© Danfoss | DCS (vt) | 2021.03

BC337629891709en-000201 | 21

User Guide | AK-System Manager, AK-SM 800A series

Web Connectivity

This method assumes you have connected to your AK-SM 800A

via a device that has access to the Internet. Selecting this option

will use your Internet connection to retrieve the latest AK-SM 800A

software package (from secure Danfoss software server) and with

the live browser connection to the AK-SM 800A unit, will update

software. Follow the screen prompts to perform a software update

via a web connected device. (Note: At this time Apple® based

platfrom(s) do not support the web connectivity function, if using

an Apple® device, use the Local stored file option described above)

Utilities- Operating System (Danux)

This function follows the same principle as described above for

software update, but is supporting the updating of the System

Managers operating system (OS). Your AK-SM 800A utilizes a Linux

based distribution, specifically for Danfoss and like all software

systems, updates may be required for feature or security reasons.

Utilities- Software Rollback

The Software Rollback function is designed to support the use

case where the operator wishes to revert to the last (previous)

version of AK-SM 800A software. The last/previously installed AKSM 800A software package (firmware, EDF’s, HTML..) will be reinstalled and your AK-SM 800A will run normally with this version

of software package.

Utilities- EDF Update

EDF files are digital files that represent actual hardware/control

products connected to your AK-SM 800A. When connecting

devices to the AK-SM 800A it is required to have the correct EDF

file to support that device, model, type and software version. As

part of ongoing operations, it will likely be needed to update

the EDF files or library of EDF files as new products or software

variants enter the market. Typically, each time Danfoss issues new

AK-SM 800A software update it will include the latest EDF files.

However, during software release cycles it may be required to

update individual or a group of EDF files that did not come or were

not available at time, in this instance you can update the library of

EDF files in your AK-SM 800A. Using the same principles as seen

in software updates, you have a section of local stored file or Web

connectivity.

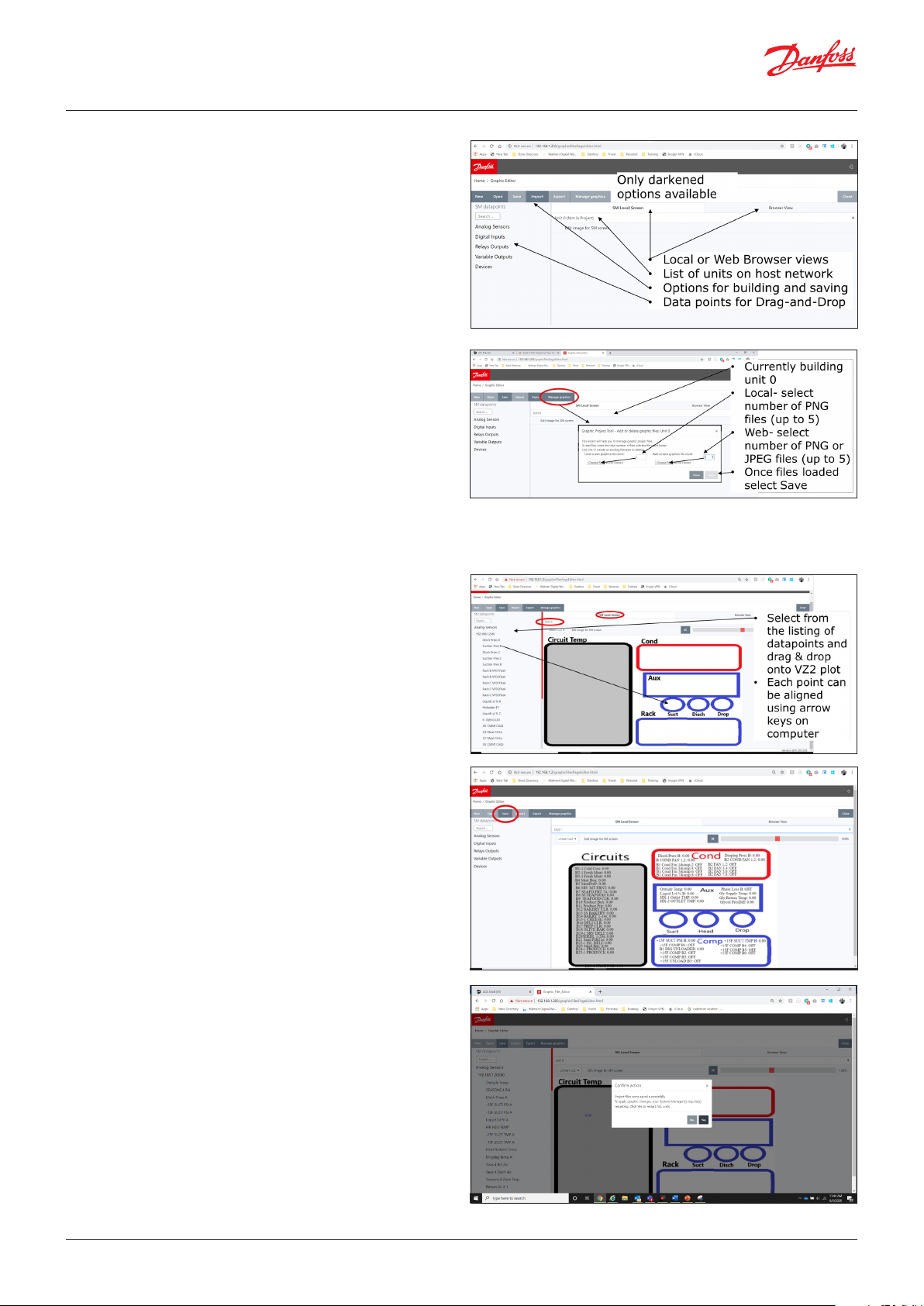

Utilities - Graphic Editor

Using the Graphic Utility

The graphic utility allows custom graphics to be viewed at the

local AK-SM 800A display or when communicating via Web.

These graphics must be built and loaded in the controls on a host

network.

Basic operation

This utility will only function on controls that are programmed and

communicating. The host network must be operational for data

from all controls to be retrieved into the Graphic utility.

Once graphics are built the files are transmitted to all controls.

Local graphics will only be applicable to match the unit

communication address number.

The local SM800A graphics screen can only display data points

programmed on this specific control. The Web graphics will display

data points programmed on any SM800A on the host network.

The initial files, Jpeg and PNG, have size requirements that must be

adhered to. The graphics files are not imbedded in the database

when exported or imported.

The DPJ file, project file, should be stored in a location allowing

for future access. You can modify overlaying points at any time

by opening the graphic utility, but the original Jpeg or PNG is not

available.

The AK-SM 800A browser (using Google Chrome) will support

a total of 5 web graphic views supporting custom Jpeg or PNG

drawings, and 5 custom PNG views for each local AK-SM 800A unit.

In addition to these graphical drawing the system parameters are

mapped to display current sensor readings and status of digital

inputs and relays. This may serve as an easy means to display data

on the local and web screens. If no graphic is loaded the screen

will be blank. If no graphic is loaded for the web application the

tab for “View Graphics” is not available.

Select Graphic Editor from Utility menu.

To access EDF packages manually (when using the local stored file

option), use the following link ak-sm800a.danfoss.com.

Note: To ensure the integrity of the AK-SM 800A only approved,

digitally singed software packages will be allowed to be installed

in the AK-SM 800A. Be sure that the tool chain you are using (i.e.

MCX Shape) has the ability to export digitally signed files.

Available EDF packages will have the format of ‘SM800A_EDF_

YYYYMMDD.epk

Utilities- Export Database

This utility allows for the export of the AK-SM 800A database.

When initiated, the database will download to your browser

download folder. The file will have a YYYYMMDD format with file

format .dpk

Utilities- Import Database

This utility allows the user to select a compatible database file,

and then import. The import procedure is done in a simple two

step process. Step one is to download the selected database file to

the AK-SM 800A, a file security check is performed, and the file is

uncompressed. The next step is the actual installation, where the

unit will reset.

22 | BC337629891709en-000201

© Danfoss | DCS (vt) | 2021.03

User Guide | AK-System Manager, AK-SM 800A series

Prior to starting a build, these basic size requirements must be

adhered to per the pop up screen shown

JPEG or PNG for web graphics: < 1 MB

PNG for local graphics: 800x450 pixels and 8 or 24 bit (no alpha

channel).

On initial entry into the graphic utility all data points are

automatically retrieved for overlaying

Selection of drawing

Step 1: Import the Jpeg or PNG file to be used for both web

graphics and SM 800A graphics.

Select “Manage graphics” and using pop-up window select

number of drawings to be used for Web (up to 5) and number of

drawings to be used for SM 800A (up to 5 per control). Use the

browse option to select the Jpeg or PNG drawings to import.

The SM800A PNG will be specific to the unit as indicated below Ie;

Unit 0. The SM800A graphics will need to be selected for the other

controls on the host network by first selecting another control ie;

Unit 1 followed by selecting/importing the PNG files.

When all drawings have been imported select “Save” to continue.

Step 2: Open the datapoints that will be overlaid.

The imported drawings will be displayed one at a time by the

selection of either the “Browser View” or “SM Local Screen”. When

using the local screen option the drawings will be specific to the

SM800A unit number. See below

Using the data tree on left select the data type ie; Analog sensor,

Digital input, etc. Select the IP addresses for the SM 800A’s to drag

and drop the point on overlay.

For the SM Local Screen graphics there will be only one IP address

as you can only select points for that control.

Step 3: Aligning layout

Any datapoint overlaid can be individually setup. Once the

datapoint is placed on the drawing, and highlighted blue, a

doubleclick of the left mouse button will display a pop up. This

allows for the datapoint to be displayed in different formats.

When the data point is highlighted blue the arrow keys on

keyboard can now move the point for alignment.

Step 4: Loading the files in controls.

With datapoint overlay complete the package must be transmitted

to the controls.

The “Save” button will transmit all the files to each controller in the

host network.

A pop up window details the download status.

When the download is complete a pop up window notifies that

the units must be reset for the new graphics to be implemented.

© Danfoss | DCS (vt) | 2021.03

BC337629891709en-000201 | 23

User Guide | AK-System Manager, AK-SM 800A series

Step 5: Import and export the graphic package

All the files used to build graphics are stored in a xxx.dpj file

When selecting “export” a pop up asks for file name and the

complete graphic package will placed in the download folded.

Ensure the naming identifies the store.

When selecting “Import” a pop up asks for file to be loaded to all

controllers. This file must be specific to the store or data points will

not be will be incorrectly labeled.

Utilities – Cleared Alarm Log

This utility presents a visual list of ALL previously cleared alarms

from the AK-SM 800A. The cleared alarm log screen also allows the

download of the units cleared alarms in .CSV file for easy sorting

Note: Clearing the Alarm Log via the Alarm->Service screen does

NOT delete this list. The cleared alarm log remains active and will

continue to append to the list as alarms clear.

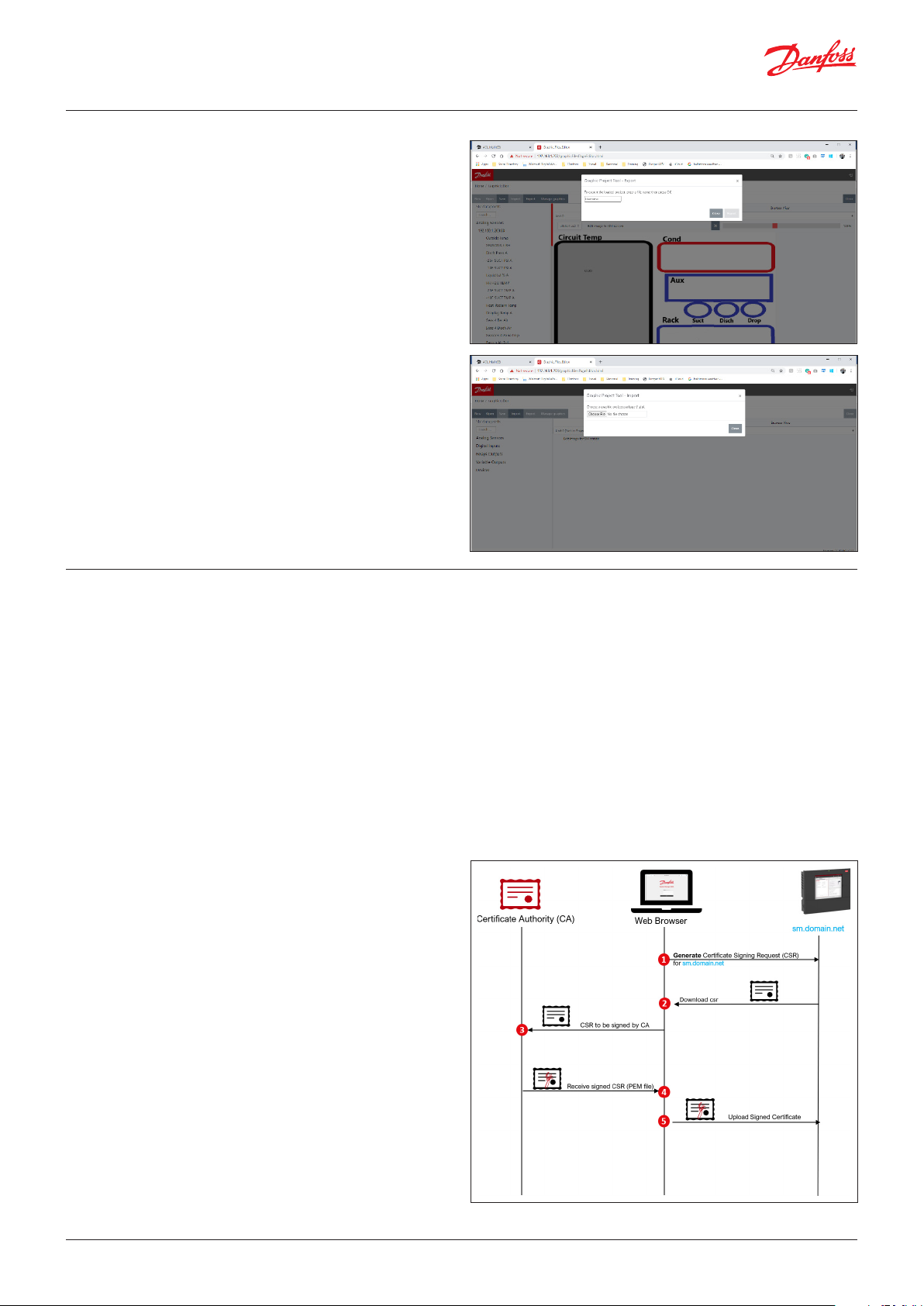

Utilities- Browser Certificate

Browser certificate management tool

Communication with the system manager via web interface is

encrypted when (as default) HTTPS is enabled. The AK-SM800A

uses a self-signed certificate (SSC) and whilst the connection is

secure, your web browser will likely mark the connection as not

trusted. To facilitate a trusted connection between your web

browser and the AK-SM800A, the SM800A browser certificate must

be signed by an authority known to the browser.

The browser certificate feature under the Utilities section is a

tool intended for customer use and allows the creation of a CRS

(Certificate Signing Request) allowing the customer to self-sign or

obtain a Certificate Authority (CA) signed certificate. Once signed,

the certificate is uploaded back to the SM800A - thus creating a

root of trust between SM800A and browser.

Key notes:

• When the generate request is made, a new private key with

2048 bits is created using RSA

• The hash function uses 256 bits

• The certificate will expire after 365 days

The following procedure can be followed for the browser

certificate management tool, where a Certificate Signing Request

(CSR) will be initiated, resulting in a configuration file containing a

new private key with 2048 bit RSA encryption.

1. Navigate to the Utilities section of the SvB5 and select browser

certificate

2. The info screen will be shown

3. Navigate to the ‘Generate’ screen and fill in the following

information

4. Country

5. Domain

6. IP Address

7. Organization

8. Press the generate button which will output a csr file

9. This crs file then must be signed by a trusted authority, usually

via the following options

10. The user pays an internationally trusted CA (e.g. VeriSign,

DigiCert) to sign the certificate. In this case the browser already

has the root and intermediate certificate installed.

11. The user acts as a certificate authority to sign the CSR, installs

root and intermediate certificates in user browser

12. Once the CSR is signed the user uploads the file through the

web interface (Upload menu). The system manager first checks

if the uploaded certificate is valid and ensures that a matching

<domain>.key file exists. Finally, it runs a test to check if the

uploaded certificate matches the private key (<domain>.key)

that was created along with CSR. If the test passed, the current

certificate is replaced, else the changes are rolled back and an

error is returned. If the update was successful a summary of

the new certificate is sent back as response.

The image below is a graphical representation of this workflow.

24 | BC337629891709en-000201

© Danfoss | DCS (vt) | 2021.03

User Guide | AK-System Manager, AK-SM 800A series

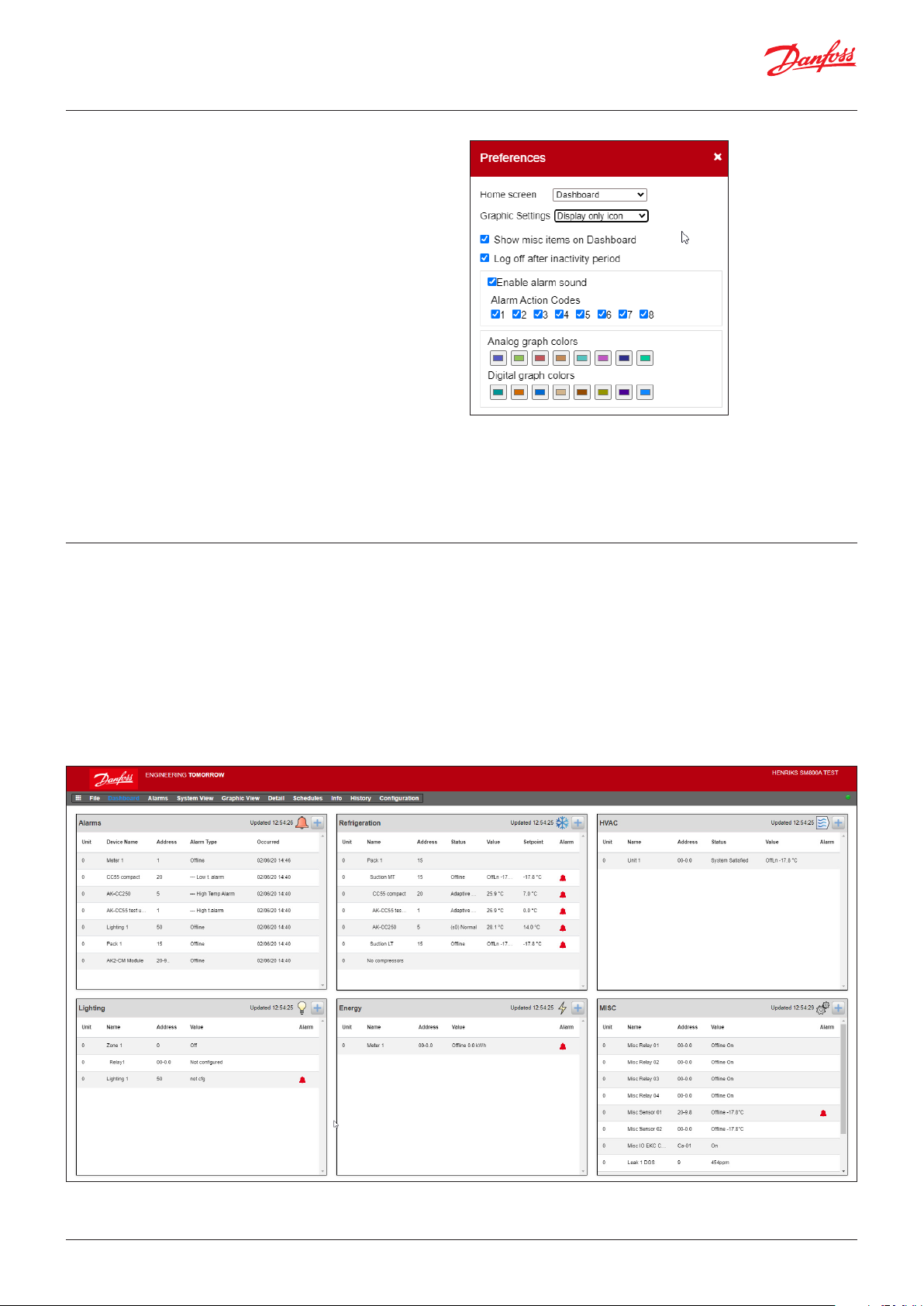

4.4 File menu

Preferences

Under this selection custom settings can be made for the

SvB5 via the Preferences pop up window.

Refrigeration report

When selecting the Refrigeration Overview report it is possible

to output a current status report of configured refrigeration. The

report will display current value, setpoint, alarm, defrost and

device address. The report can be exported to PDF, CSV and Print.

Note: It is also possible to export the Refrigeration report to a USB

flash drive in simple text format, which is mounted in the AK-SM

800A USB port (user must be authorized).

Download report

It is possible to download a text file which contains AK-SM 800A

information and configuration. The report includes information

about the whole unit setup, alarms, schedules, scanned devices,

audit trail and the controller database.

Note: Report setup (what to include) can be made under

Configuration System System Report screen.

Log Off

As described.

4.5 Dashboard

The Dashboard screen will only reflect what your application

configuration has been set to. For example, if your application

does not have any HVAC configured the Dashboard will not show

the HVAC panel. Dashboard panels are automatically generated

depending on the configuration, no user action is required to

build the panels.

Upon the Dashboard loading, if any active alarms are present the

built in alarm buzzer can be heard. To silence the alarm press the

silence button. This does not acknowledge or clear any alarms.

The Dashboard allows for a consolidated ‘system’ view, where any

configured AK-SM 800A on a host network will be shown.

Tips: Use the + buttons to zoom into a dedicated application

panel.

If there is more than one AK-SM 800A configured on a host

network, access to the individual unit can be done via the

configuration menu (a drop-down list of configured units will be

shown). Single click a line item to jump into more / additional

details.

© Danfoss | DCS (vt) | 2021.03

BC337629891709en-000201 | 25

User Guide | AK-System Manager, AK-SM 800A series

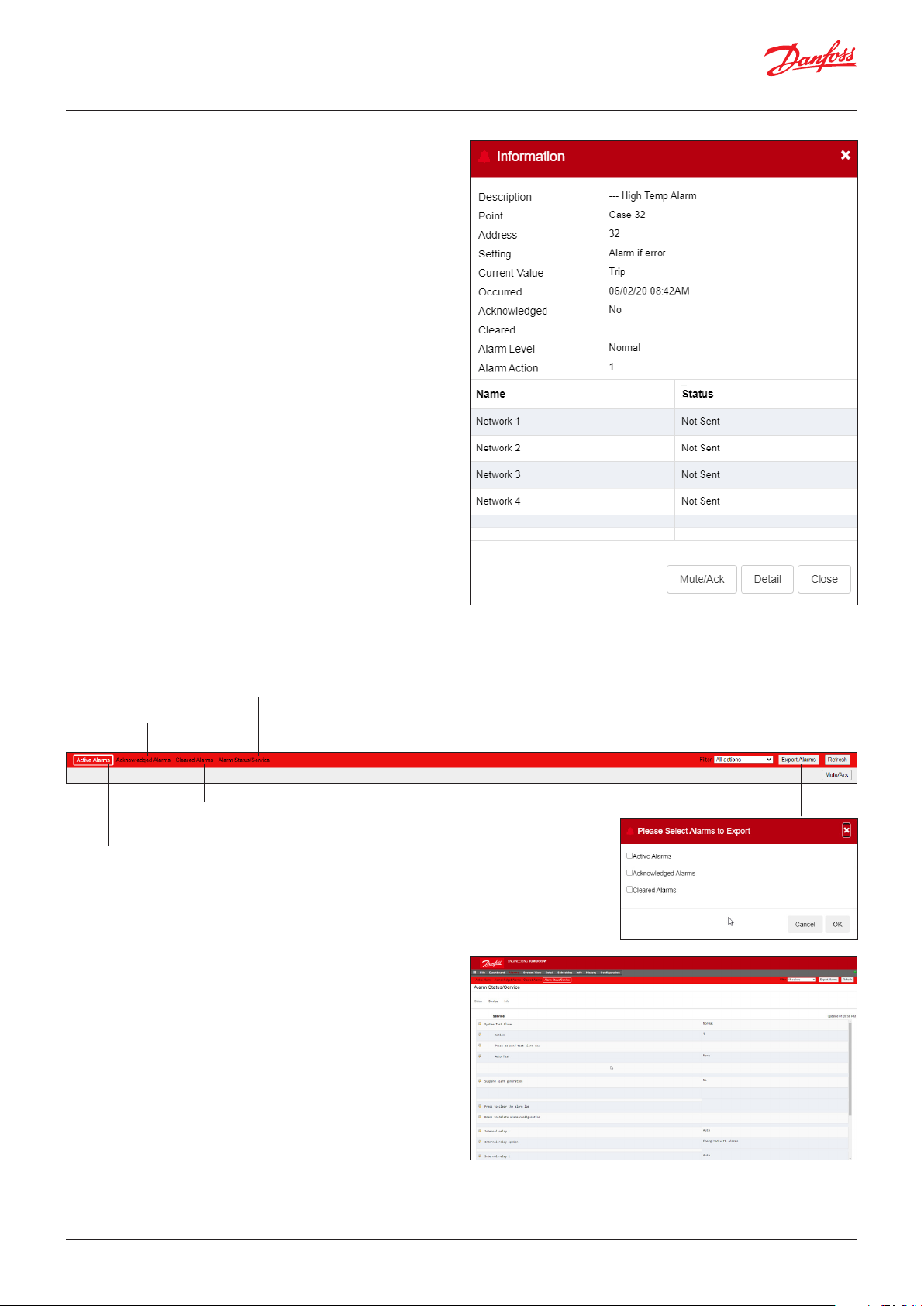

4.6 Managing alarms

Any active alarms will be shown in the Dashboard alarm panel.

To view more details regarding the alarm, click the relevant alarm

line. An alarm info box will appear with further details regarding

the alarm.

In addition to more information, the info box also allows the

authorized user to Mute/Acknowledge the alarm and to jump to

the device detail screen.

Use the Mute/Ack button to acknowledge the alarm. When

pressed the alarm will ‘move’ to the Acknowledge list.

To view all system alarms (known as global alarms) use the Alarms

tab (found on the main menu).

Status and Service screens

Global acknowledge list

Global cleared alarm list

Global active alarm list

Service screen

Under the service screen tab, test alarms can be configured and set.

26 | BC337629891709en-000201

© Danfoss | DCS (vt) | 2021.03

User Guide | AK-System Manager, AK-SM 800A series

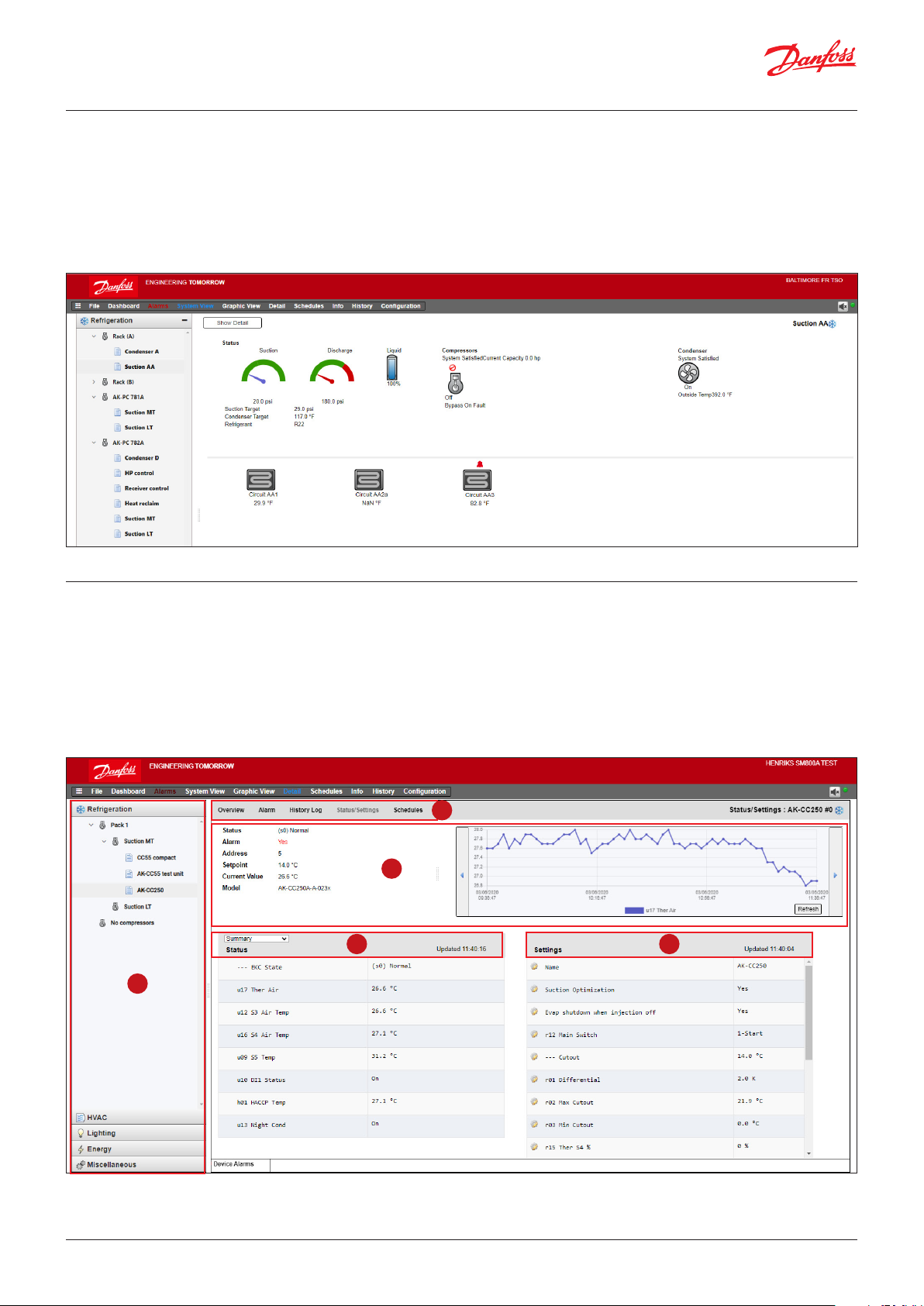

4.7 System view

The system view provides a generic yet graphical view of your

configured controls.

The same principle of the navigation tree can be seen in the left

side of the screen. The system view screen shows any configured

Rack or Pack, with associated evaporator circuits. To see additional

System View (Refrigeration)

information, hover your mouse pointer over an icon, a pop up box

will appear showing additional information. To view additional

information and gain access to settings click the ‘show Detail’

button. A dashboard will slide across, where a Status, Settings

and Manual operation can be seen. Simply click an asset to

highlight and the detail table will update with reference to this

selected device. Once complete with the device settings, close the

dashboard by clicking the ‘Hide Detail’ button.

4.8 Device detail

Whilst the Dashboard screen will show basic asset information

(AK-SM 800A unit address, Asset Name, Value, Status and alarm),

more detailed information can be found by clicking an asset line

in the Dashboard. The resulting device detail screen will reflect

more details and settings. The device detail screen is designed to

provide key status and operational settings for the selected device.

Easy navigation to other assets is done via the navigation tree.

2

3

4 5

1

The screen image below highlights some of the main areas of the

device detail screen:

1. Application / device selection tree

2. Device Detail Menu (select overview menu for manual

operation selections-if available)

3. Device details and history plot

4. Device menu (depending on menu selection in section 2)

5. Device Settings

© Danfoss | DCS (vt) | 2021.03

BC337629891709en-000201 | 27

User Guide | AK-System Manager, AK-SM 800A series

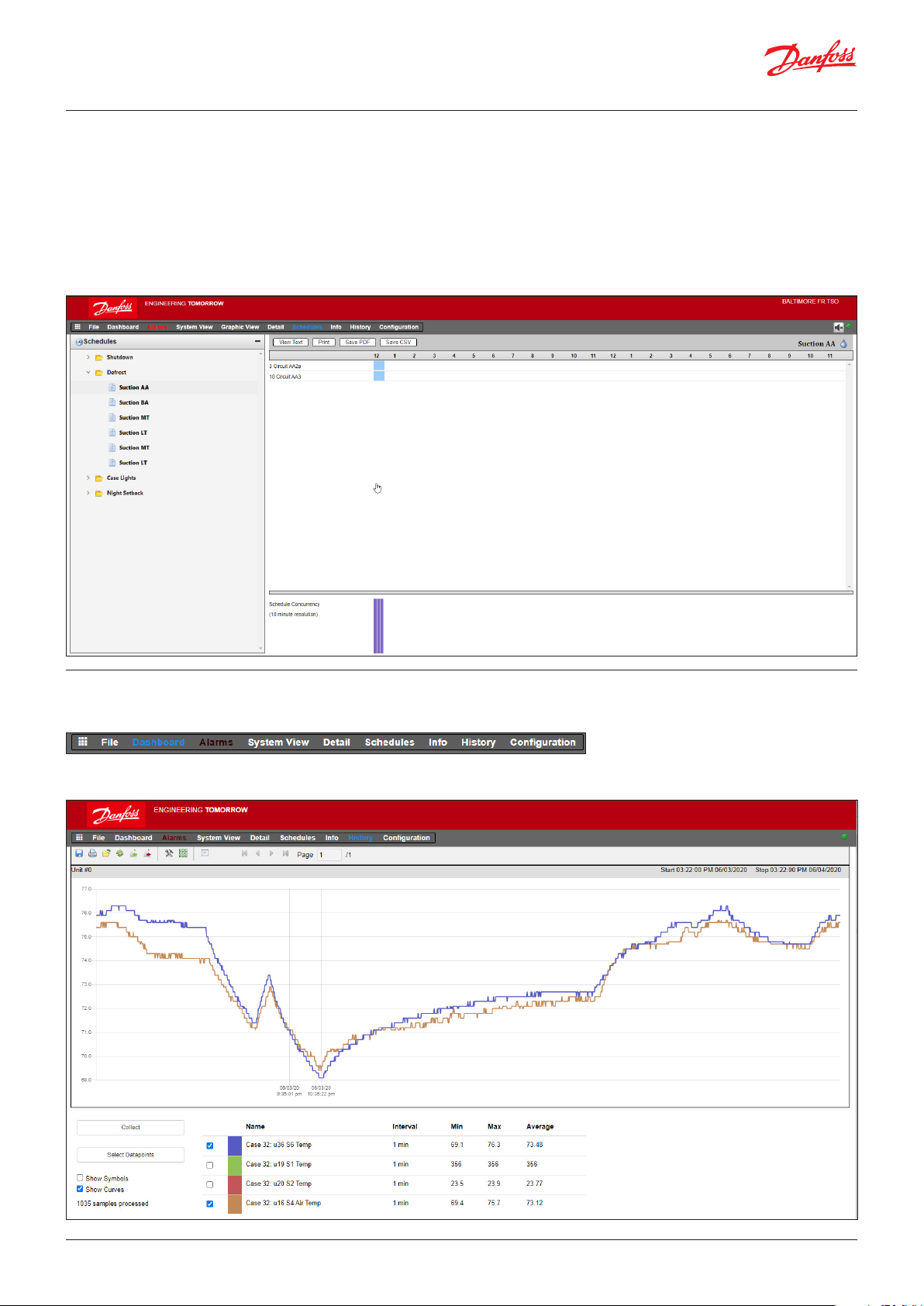

4.9 Schedule view

The schedule view provides a system wide view of schedules

(previously configured) in your AK-SM or host of controllers. The

following schedules are currently supported under the schedule view.

Shutdown (Generic controllers - i.e. AK-CC)

Defrost (Generic controllers - i.e. AK-CC)

Case Lights (Generic controllers - i.e. AK-CC)

Night Setback (Generic controllers - i.e. AK-CC)

If a host network of AK-SM units are configured, a full system view

can be seen by selecting the folder icon, for a (AK-SM) unit display

click the relevant heading under the folder view. The schedule

screen includes a mouse hover over, that indicates (per circuit) the

schedule times.

Change the graphical view to text (table) form, Print, save as PDF

or save as CSV.

4.10 History (Logs)

To access your AK-SM history, select the history tab.

Upto 8 datapoints can be viewed at any given time on the history

screen.

28 | BC337629891709en-000201

© Danfoss | DCS (vt) | 2021.03

User Guide | AK-System Manager, AK-SM 800A series

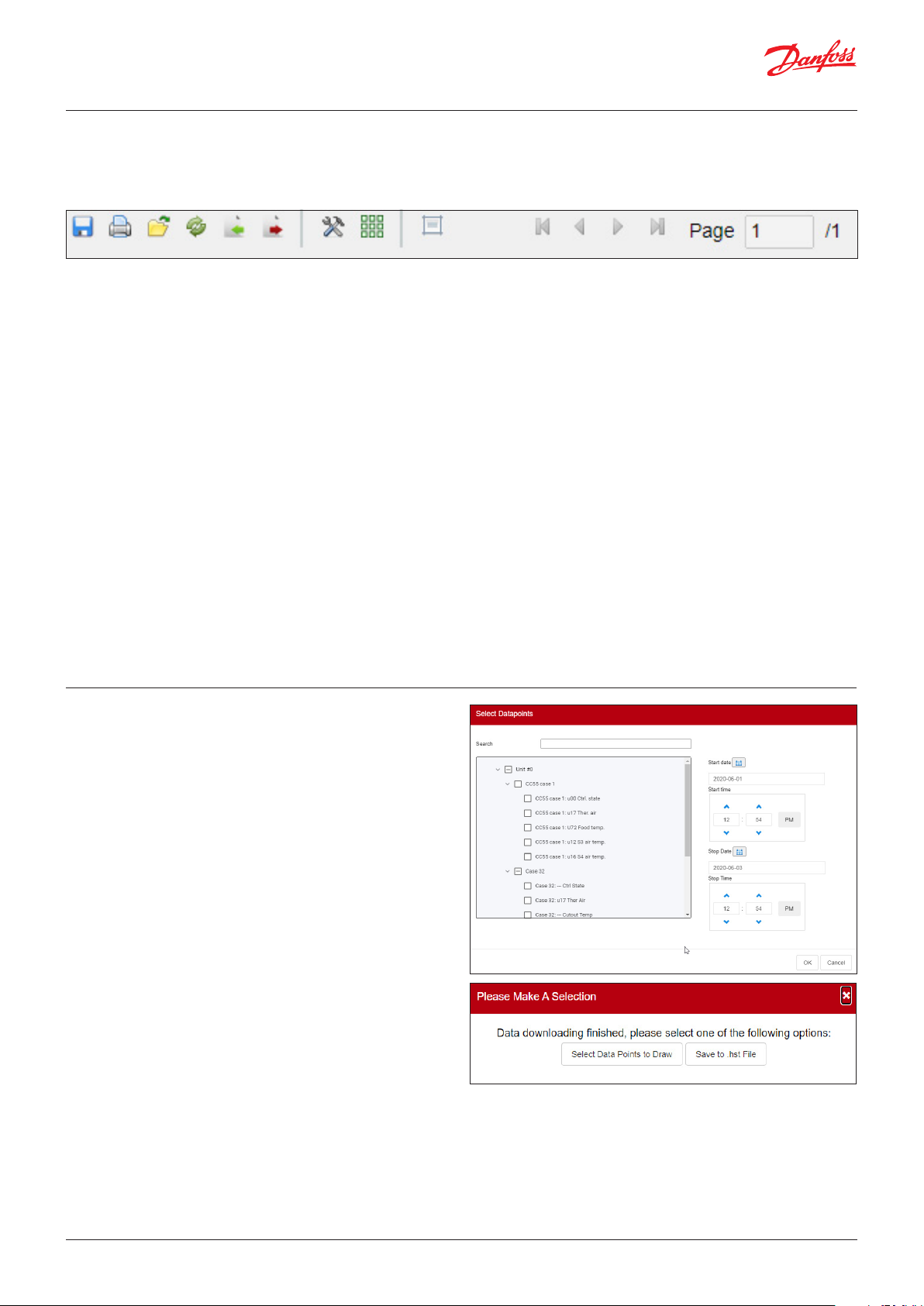

History Tool bar

When viewing data in the history view the tool bar has a set of

functions to enable various actions to be performed. From left to

right, the following functions are available.

Export history function

This feature allows the user to export the previously collected

history data.

A pop up window asks the user to select a file format, the

following formats are possible.

.hst (Danfoss history file format)

.csv (Excel compatible spreadsheet)

Saving any collected history as a file allows for future loading

and view, use the ‘Load history from file’ button to load any saved

history files.

Note: A .hst file is a compressed history file created and used by

the AK-SM 800A.

Print

Print (printer or PDF) your graph view

Load History from file

Use in conjunction with the export function.

Convert .hst filr to .csv file format

To view history data in a spreadsheet, use this function to convert

from the .hst format to .CSV

Collecting and viewing history

1. From the history page, press the collect button.

2. Select the required datapoints and time/date range. Multiple

points can be collected but only 8 can be later shown in the

history screen at any given time. After the datapoints have

been downloaded, a dialogue box will appear which provides

two options:

- Select points to draw

- Save to .hst file (for later view)

3. The graph will be presented for view and analysis. Use the

zoom buttons or hold the left mouse button and hold for zoom

area. Moving the mouse pointer will show a tool tip with point

description, time/date and value.

Load history group from file

Used in conjunction with the save history feature. Use this

feature to load any previously save datapoint groups. When

opening the history group file the system will prompt for the

file location. Once loaded a ‘select datapoint’ box will appear with

the datapoints already pre-selection.

Save history group from file

This feature allows the user to save a set of history datapoints.

Typically, this feature would be used when a set of datapoints

is frequently needed to be loaded and viewed. Once the

datapoints are saved, this history group can then be easily loaded thus saving time in selecting datapoints.

Preferences

Date, time and unit preferences for graph presentation.

Show/Hide Grid

Reset Zoom

Click and hold the left mouse button and drag to create zoom

area. This function resets zoom coordinates.

Page controls

When displaying large volume of data use the pages buttons to

move forward, back or jump forward / back.

© Danfoss | DCS (vt) | 2021.03

BC337629891709en-000201 | 29

User Guide | AK-System Manager, AK-SM 800A series

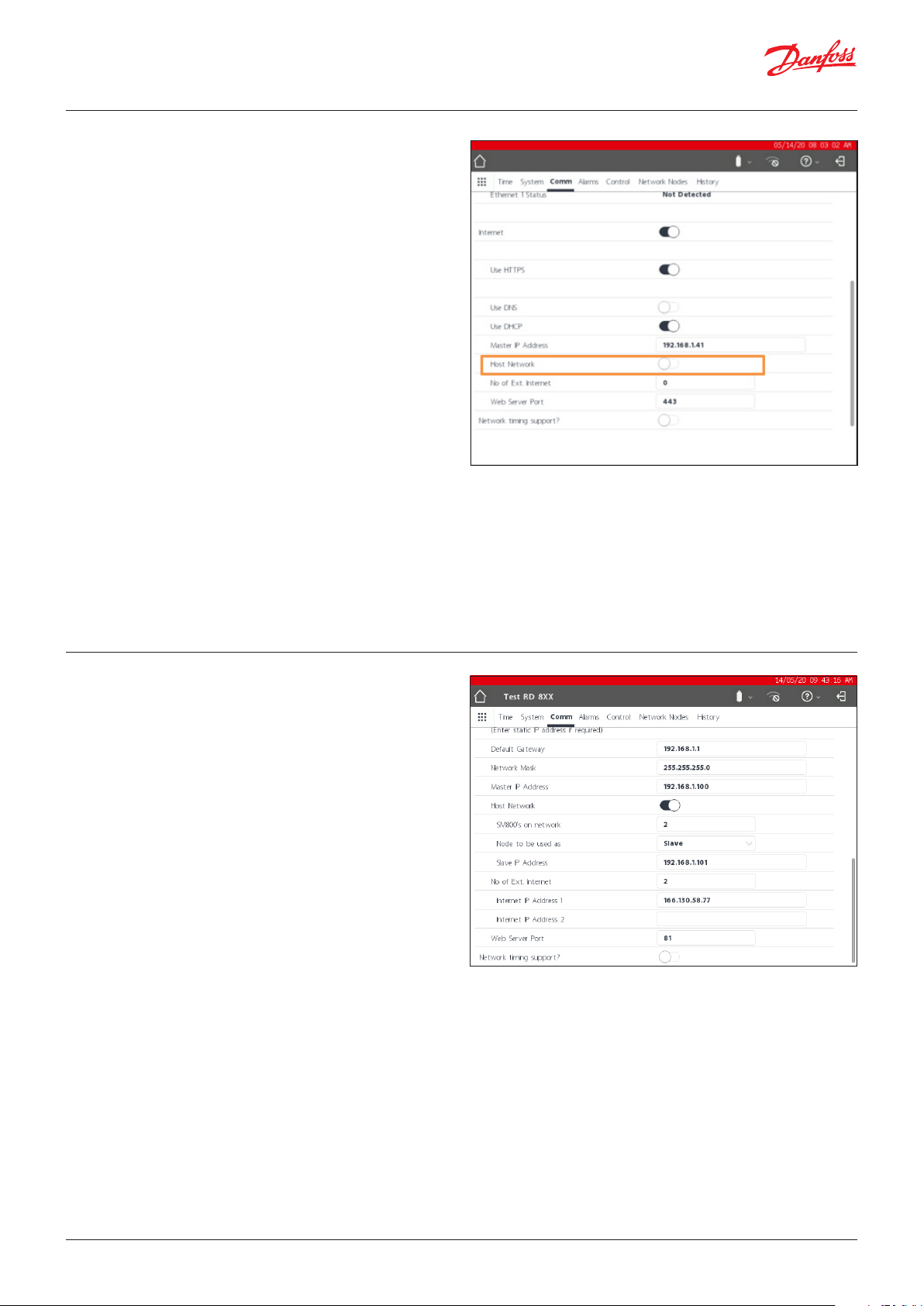

4.11 AK-SM 800A Host Network Configuration

The following section describes how to configure your AK-SM

800A to facilitate a host network. The AK-SM 800A host network

can support up to a max of 10 interconnected AK-SM 800A units.

The practice of interconnecting on a host network allows for

support of larger applications or to separate discrete control

applications onto dedicated AK-SM 800A units. For example, HVAC

and Refrigeration control could be done via dedicated AK-SM

800A units. The host network requires an IP Ethernet connection to

each AK-SM 800A unit. Once configured all AK-SM 800A units can

be viewed in a consolidated format via a web browser.

Note: Ensure a common user / password is applied to all units in

the host network. A consolidation view is only available via SvB5,

not local screens.

Primary device configuration

Make sure you have suitable fixed IP or DHCP addresses for each

of your AK-SM 800A units you wish to deploy on the host network.

Also ensure all Ethernet cables are connected.

Make sure the rotary address switch (located behind cover plate)

is set to 0 (Zero), which will define your AK-SM 800A as the Primary

node on the host network.

Navigate to the Configuration/Comm screen and check your unit

has a valid Primary IP address. Set the ‘Host Network’ question to

Enabled. Enter the number of System Manager units you intend to

have on the host network.

After all changes are complete reset the Primary AK-SM 800A unit.

4.12 Secondary device configuration

Make sure the rotary address switch (located behind cover plate)

is set to the appropriate number. For example, setting the switch

to 1, will define the unit as a Secondary device address 1. All units

in the host network must have unique host network addresses

(address 0 is always Primary).

Once you have set the rotary address switch, reset the unit and

allow the AK-SM 800A to boot up. Navigate to the Configuration/

Comm screen and check your unit shows the Primary IP address.

Set the ‘Host Network’ slider to Enabled. Enter the number of

System Manager units you intend to have on the host network

(matching what you have already set in the Primary unit)

Make sure the Secondary unit has a valid IP address.

30 | BC337629891709en-000201

© Danfoss | DCS (vt) | 2021.03

Loading...

Loading...