Page 1

Quick Setup Guide

AK-System Manager

AK-SM 800

ADAP-KOOL® Refrigeration Control System

Page 2

Quick Setup Guide | System Manager, AK-SM 800

Contents

Document History .......................................................................3

Mounting Specications .............................................................4

Installation ...................................................................................5

Connections .................................................................................7

Network topology .......................................................................7

Remote Management Tool (RMT) .............................................10

Initial Conguration - language ...............................................12

Initial Conguration - Wizard ...................................................13

Conguration .............................................................................16

Service Tool Support .................................................................34

General navigation, operation and use (via web) ...................35

Connecting to your AK-SM: .................................................................35

Dashboard view: ..................................................................................... 35

Managing alarms: ................................................................................... 36

Device detail: ............................................................................................ 37

System view: ............................................................................................. 38

Schedule view: .........................................................................................39

History (Logs) .............................................................................40

Collecting and viewing history .......................................................... 41

Updating Software (via USB Flash Drive) ................................42

2 | USCO.PI.R1.H2.02 |

© Danfoss | ADAP-KOOL® | 2015.10

Page 3

Quick Setup Guide | System Manager, AK-SM 800

Document History

Document Notes

USCO.PI.R1.H1.02

Document revision

First document release

© Danfoss | ADAP-KOOL® | 2015.10

USCO.PI.R1.H2.02 | 3

Page 4

Quick Setup Guide | System Manager, AK-SM 800

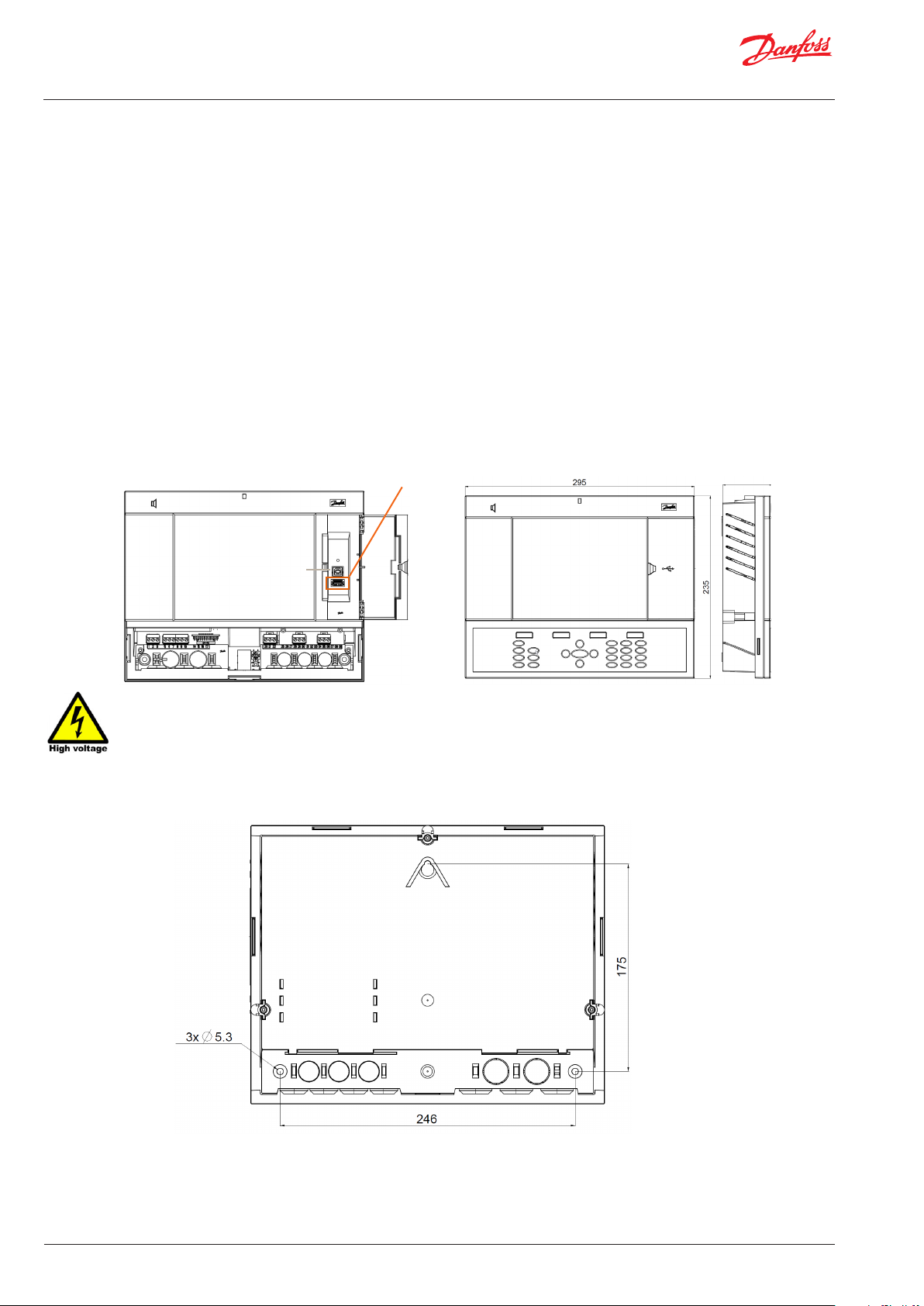

Mounting Specications

The mounting location should be at, dry and free of major vibrations. The AK-SM 800 should be mounted at eye level.

Dimenstions:

Unit Width 295 mm (11.6”)

Unit Height 235 mm (9.3”)

Unit Depth 65 mm (2.5”)

Mounting holes 246 mm (9.7”) Width

Mounting holes 175 mm (6.9”) Height

Operating temperature:

Screen: -10 to +55˚C (14 to 131˚F)

@ 90% RH (non condensing)

Electrical range: ~ 100 - 240 V a.c. (+ / - 10%) 50/60 Hz

Built in alarm relay 240 V a.c. Class II 3 Amp inductive, 5 Amp.

ohmic

Approvals: CE

IP 20

USB Access door

Active USB Flash drive (use for load/save database and AK-SM software)

65

Not currently Used

WARNING: To avoid risk of injury from electric shock, ensure correct electrical isolation is made

before working within the enclosure.

4 | USCO.PI.R1.H2.02 |

© Danfoss | ADAP-KOOL® | 2015.10

Page 5

Quick Setup Guide | System Manager, AK-SM 800

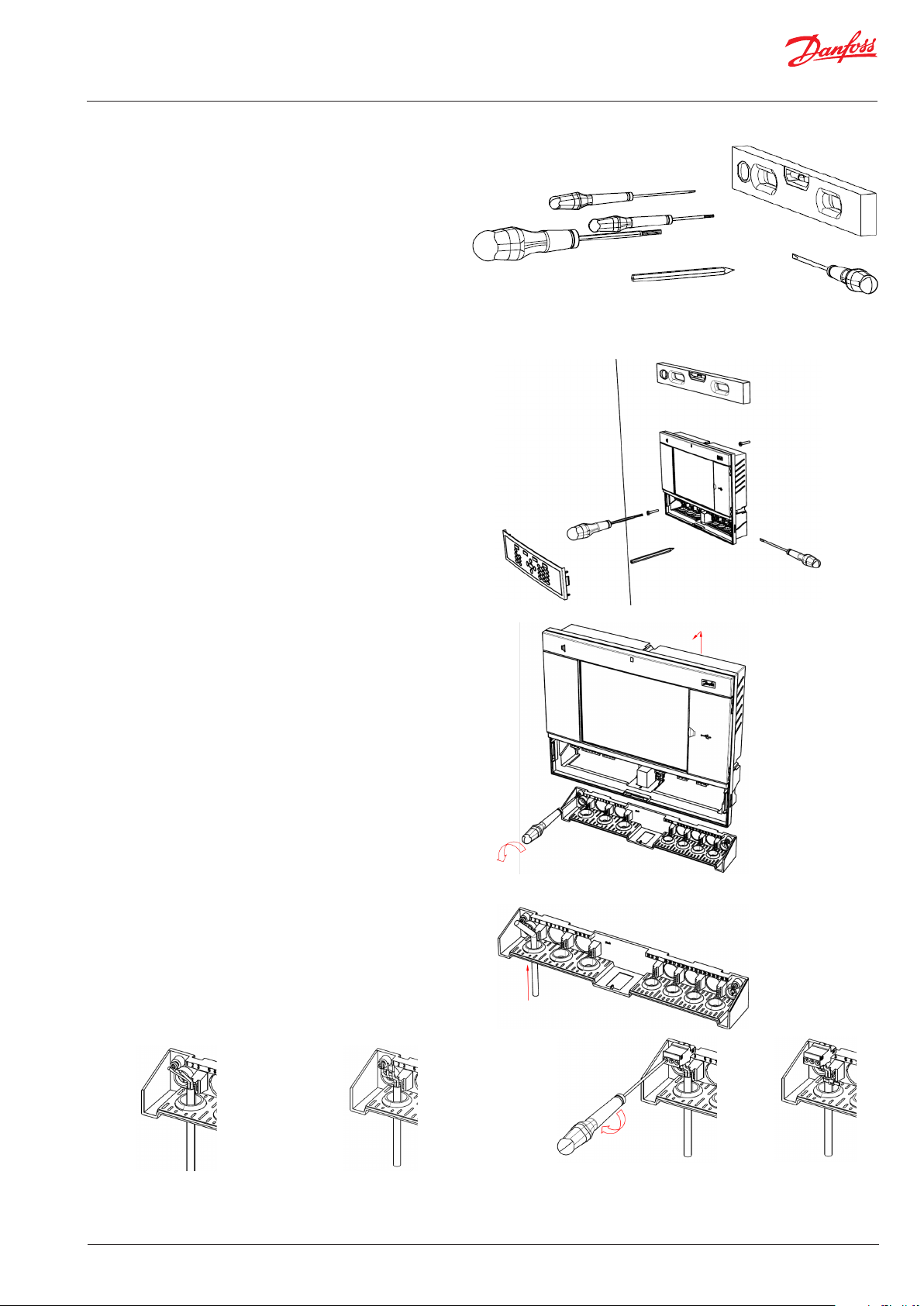

Installation

Tools needed

Bubble level

Small slotted screwdriver for connector screws

Torx 8 screwdriver for releasing the electronic unit and for

fastening the unit when recessed mounted

Screwdriver for xating the AK-SM 800

Pen for marking the 2 lower xation holes

Larger slotted screwdriver for releasing the Technician lid

Wall Mounting- box

Attach screw to the wall

Mount AK-SM 800 to the screw

Loosen Technician lid (three sides)

Remove Technician lid

Level the AK-SM 800

If drilling is necessary, mark up 2 screws in Connector part.

Attach the Connector part to the wall using another 2 screws

Wall Mounting- wiring

Insert cables through the rubber grommets

Strip the cables Strip the wires

© Danfoss | ADAP-KOOL® | 2015.10

Secure wires in connectors by screwdriver

Strain relief the cables

USCO.PI.R1.H2.02 | 5

Page 6

Quick Setup Guide | System Manager, AK-SM 800

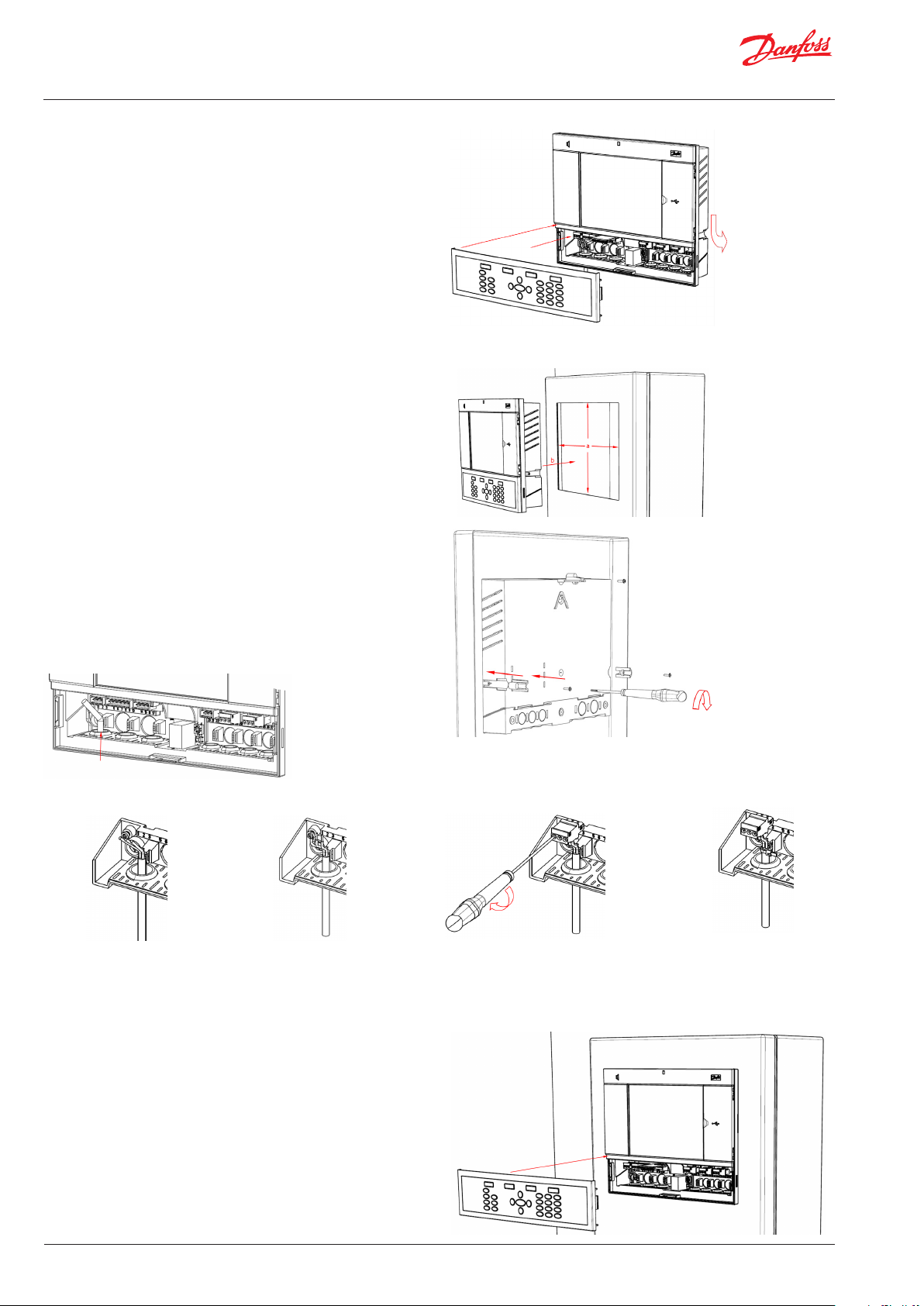

Carefully replace the keypad, ensure that it securely snaps into

place

Wall Mounting- Panel recessed

From the front:

A hole of the size 280 x 220 mm is machined

The AK-SM 800 is inserted in the hole

From the backside:

Slide the 3 fastener into the housing part

The screws are inserted into the fasteners

Secure the unit by tightening the screws

Remove Technician lid

From the back, push cables inside the housing

Strip the cables Strip the wires

Secure wires in connectors by screwdriver

Strain relief the cables

Carefully replace the keypad, ensure that it securely snaps into

place

6 | USCO.PI.R1.H2.02 |

© Danfoss | ADAP-KOOL® | 2015.10

Page 7

Quick Setup Guide | System Manager, AK-SM 800

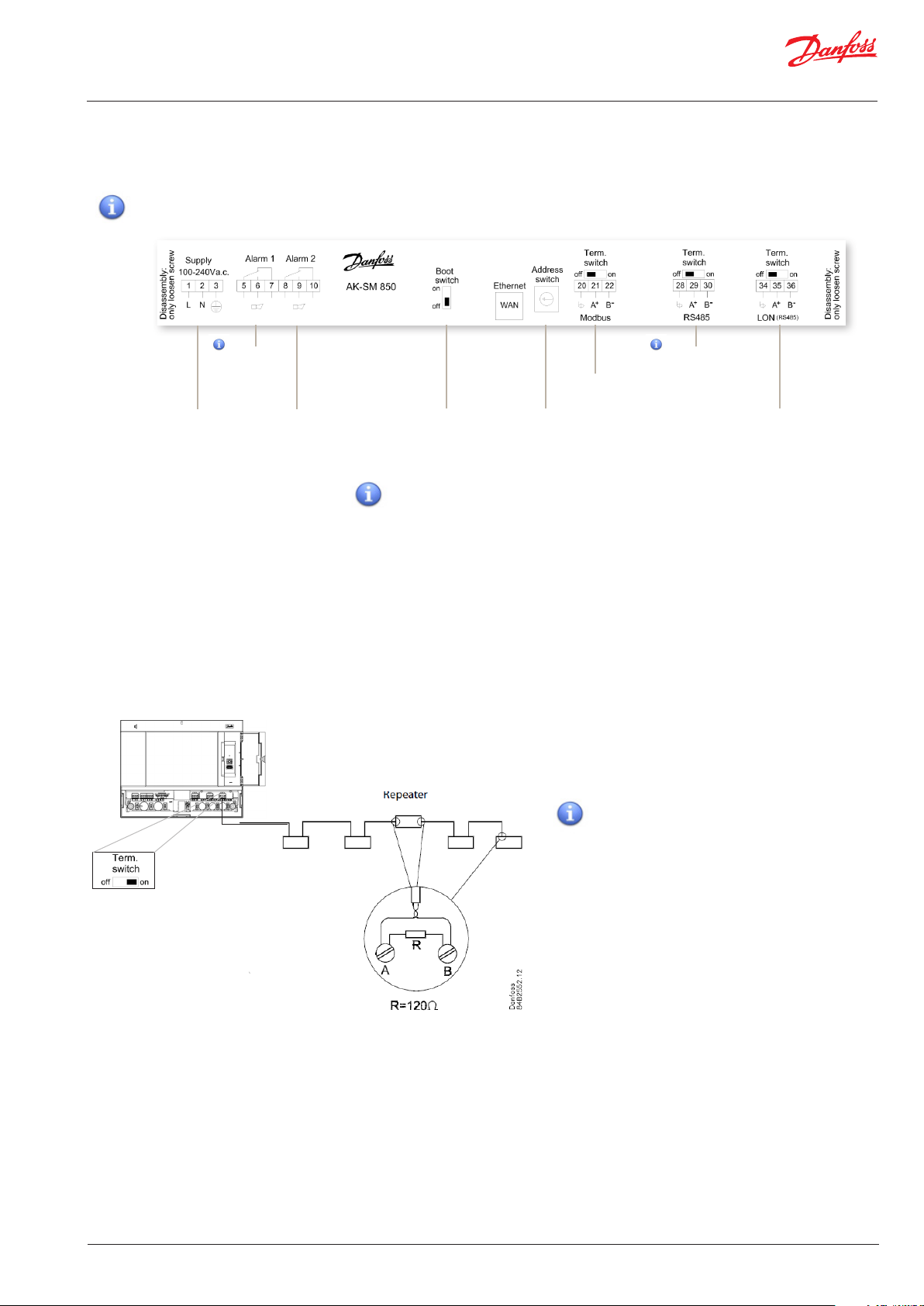

Connections

The following chapter describes the available connections on

your AK-SM 800.

Please note that not all connection points are currently

active, please refer to the drawing below for more details

not currently

used

Power Supply Alarm relay

Boot switch

(used to place unit in

boot loader mode)

RJ 45 LAN, Use shielded Ethernet cable

Network topology

Your AK-SM supports both Modbus and Lon RS485 local bus

connections. For further detailed description of network

connections please refer to document ‘Data Communication

between ADAP-KOOL® Refrigeration controllers_RC8AC602’

Lon RS485

Follow standard topology guidelines for Lon RS485, with

particular respect to maximum cable length, when to use a

repeater and ensuring suitable resistors are in place.

Modbus eld

bus

Address swicth

(used when conguring

multiple SM units

When using the Lon RS485 network, ensure the

Term. Switch on the AK-SM is in the ‘ON’ position

(enable internal resistor). Any repeaters must

also have 120Ohm resistor in place. Finally, ensure that the last controller on the network run

also has its end of line on line resistor enabled.

not currently

used

Lon (RS485)

eld bus

Cable type

Cables twisted in pairs must be used, and they may be provided

with a screen. Some types of communication require a cable with

a screen to be used. The conductor’s cross section must be at

least 0.60 mm. Examples of cable types:

Belden 7701NH, single-thread 1 x 2 x 0.65 mm, without screen

Belden 7702NH, single-thread 2 x 2 x 0.65 mm, without screen

Belden 7703NH, single-thread 1 x 2 x 0.65 mm, with screen

Belden 7704NH, single-thread 2 x 2 x 0.65 mm, with screen

LAPP UNITRONIC Li2YCY (TP), multi-thread 2 x 2 x 0.65 mm, with

screen

Dätwyler Uninet 3002 4P, single-thread 4 x 2 x 0.6 mm, with

screen

© Danfoss | ADAP-KOOL® | 2015.10

USCO.PI.R1.H2.02 | 7

Page 8

Quick Setup Guide | System Manager, AK-SM 800

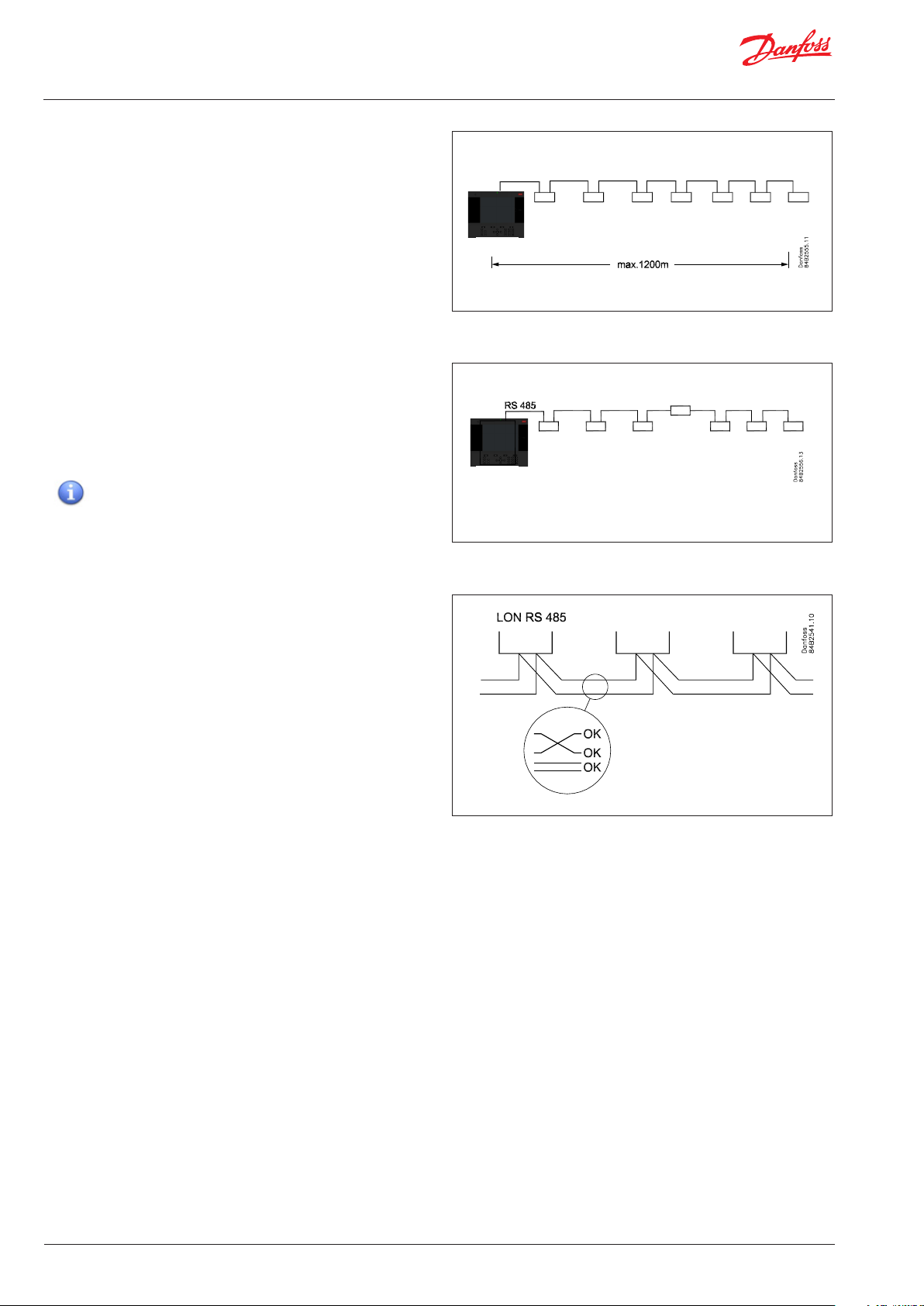

Cable length

A cable length must not exceed 1200m (4000 foot). A repeater

(Part # 084B2241 ) must be used for longer lengths.

Lon RS485 Topology

The cable connection must be connected from controller to

controller, and no branches are allowed on the cable. If the cable

length exceeds 1200 m a repeater must be inserted. If the data

communication cable runs through an electrically noisy environment which impairs the data signal, one or more repeaters must

be added to stabilise the signal.

When conguring Lon devices on the control bus, the

highest device address that can be can be used is 127 (max. 120

controller in total)

AK-SM

AK-SM

Conductors

The two wires are looped from device to device. There are no

polarisation requirements. (On some controllers, the clamps are

designated A and B. On others there is no designation. Otherwise

the connections are identical.) If a screen is used, it must be

connected to the system device and any repeaters. A screen must

always be looped from device to device.

The screen must not be connected to anything else.

(The screen is earthed inside the screen and must not be earthed

in any other way.)

8 | USCO.PI.R1.H2.02 |

© Danfoss | ADAP-KOOL® | 2015.10

Page 9

Quick Setup Guide | System Manager, AK-SM 800

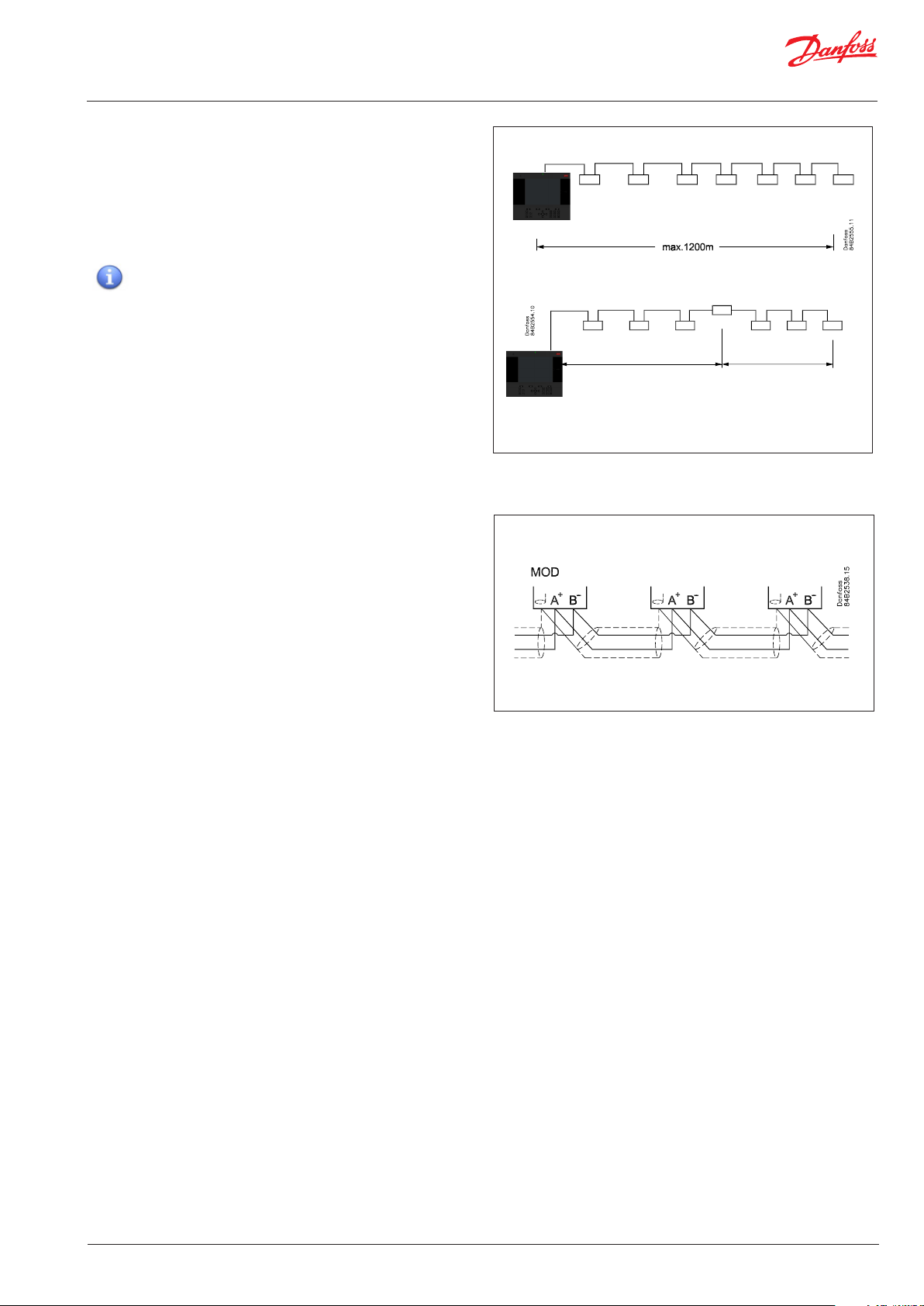

Modbus topology

The cable must be with screen. The cable is connected from controller to controller, and no branches are allowed on the cable.

If the cable length exceeds 1200 m a repeater must be inserted

One repeater must be added for every 32 controllers. If the data

communication cable runs through an electrically noisy environment which impairs the data signal, one or more repeaters must

be added to stabilise the signal.

When conguring Modbus devices on the control bus,

the highest device address that can be used is 127 (max. 120

controller in total)

AK-SM

The wires are looped from device to device.

A is connected to A

B is connected to B.

The screen must be connected to the system device, all controller

and any repeaters.

A screen must always be looped from device to device.

The screen must not be connected to anything else.

AK-SM

32

32

© Danfoss | ADAP-KOOL® | 2015.10

USCO.PI.R1.H2.02 | 9

Page 10

Quick Setup Guide | System Manager, AK-SM 800

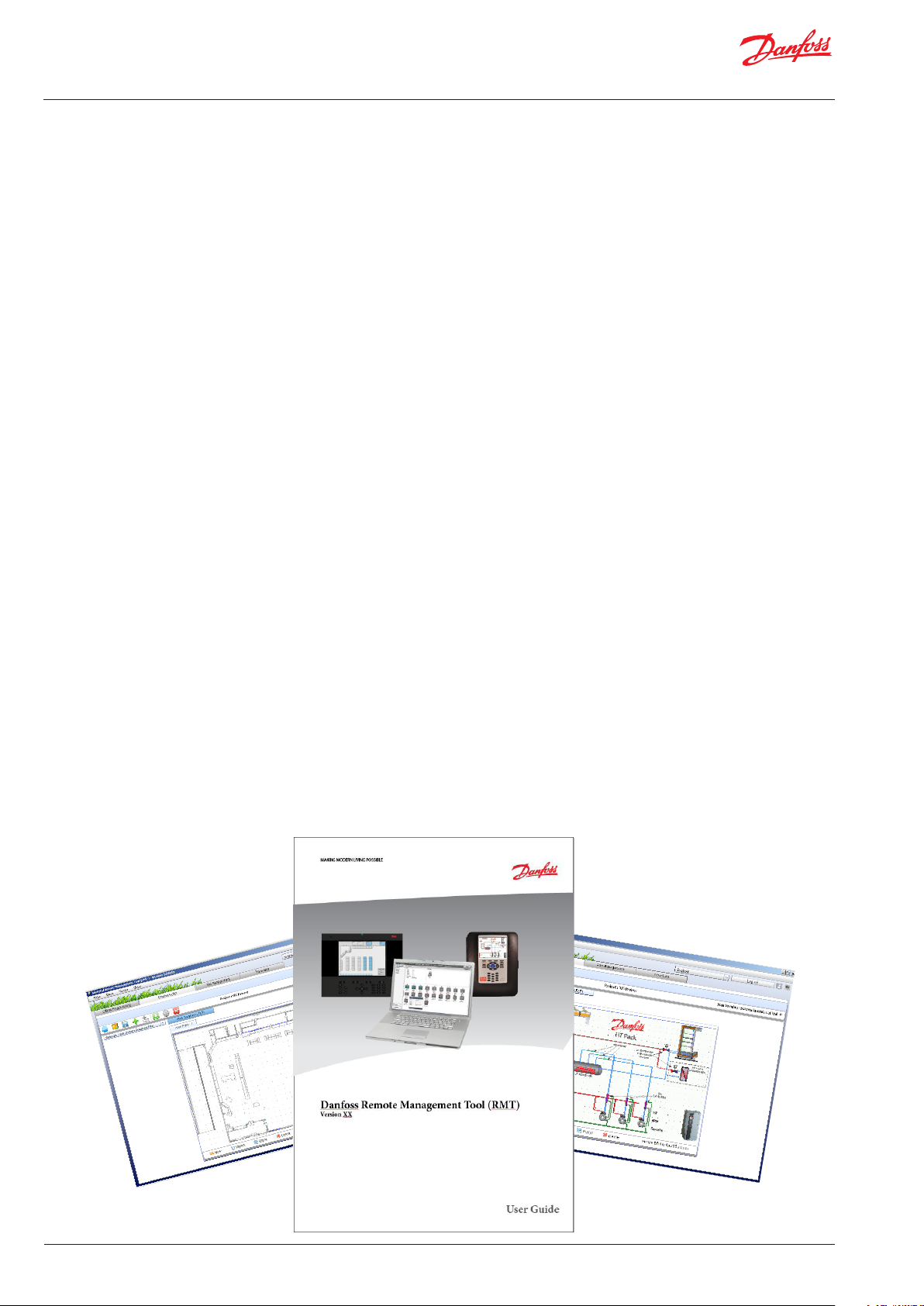

Remote Management Tool (RMT)

The Remote Management Tool (RMT) is a PC software application

tool that is designed to support the AK-SM, both in commissioning and service. The RMT is a powerful tool that allows full oine

programming and simulation of AK-SM databases, providing the

opportunity to save considerable on site commissioning times.

In addition, the RMT tool has various remote management

features, facilitating complete system management. Creating

custom images for the AK-SM web browser is also another

function of the RMT tool. The following features can be seen in

th e RMT;

• Oine web Programming

Launch oine web simulator(s) to allow full oine AK-SM

database programming, with controller simulation you can

fully pre-program your application and save the resulting

database to USB for on site install.

• Program simulation

From within the web browser session simulate board and

point variables to test calculations and system behaviour

• Custom Graphics

Use your own Jpeg or bitmap le to crate custom images,

mapped with any congured system data point

• F TP (File Transfer Protocol)

Remotely connect, load and access system les (html web &

EDF device les) Retrieve data points

• Address Book

Save your most commonly connected site details to allow

for one click connection

• Tools

Download System software, backup (save) & load database

les.

• Language

Compatible in multi- languages

The RMT tool is available from your Danfoss sales oce with

associated supporting documentation.

10 | USCO.PI.R1.H2.02 |

© Danfoss | ADAP-KOOL® | 2015.10

Page 11

Quick Setup Guide | System Manager, AK-SM 800

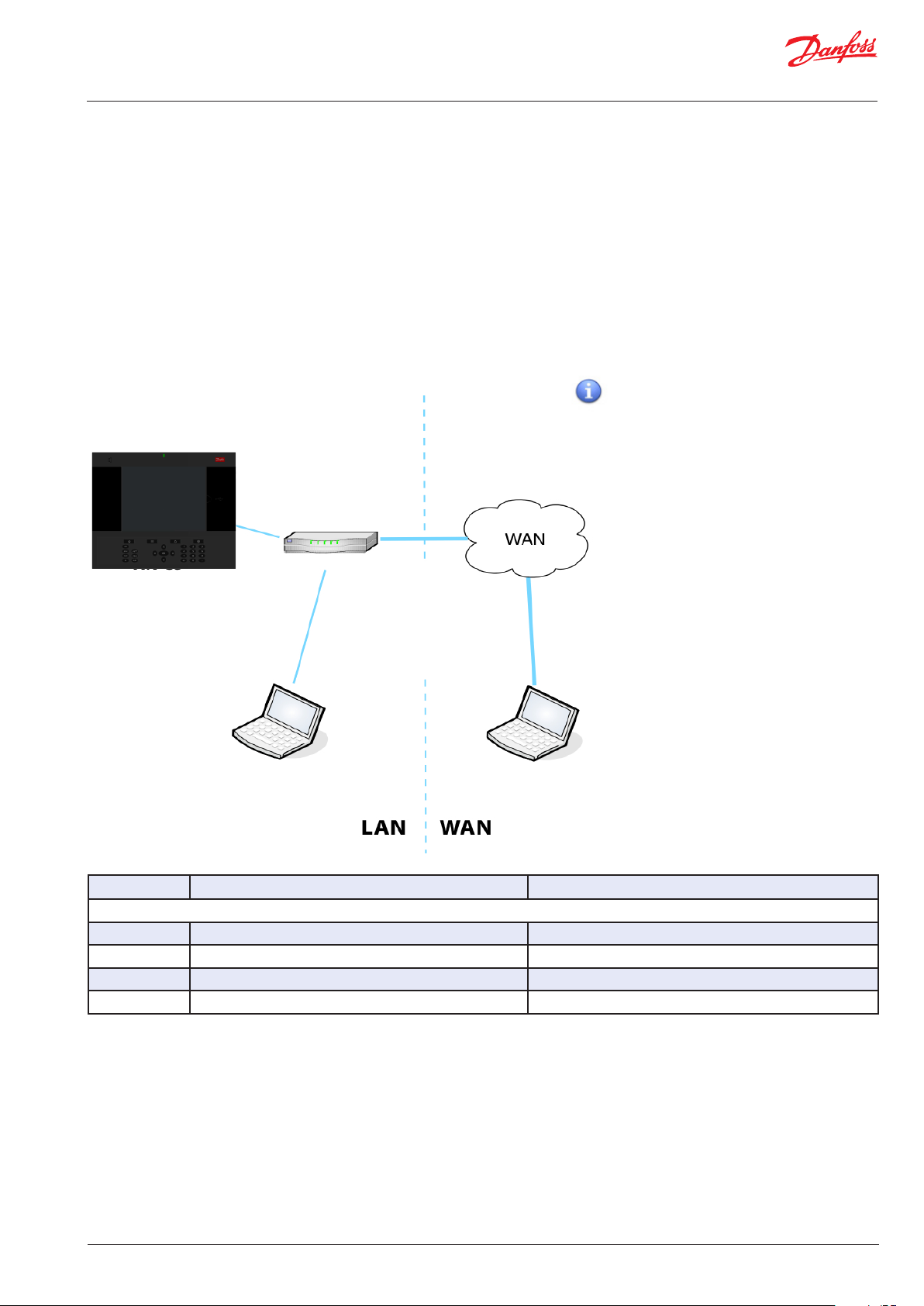

Required IP ports

As the AK-SM uses IP networking standards to create remote

access it may be necessary to congure any site routers to allow

incoming connections, either from a LAN or WAN view. The gure

below shows a simple IP connection with the AK-SM connected to

a standard network router with a typical factory IP address range.

From within the LAN any remote connections should ‘point’ to

the master IP address of the AK-SM, in this example

http://192.168.1.100. If however the remote connection is on a

WAN then the LAN router may need to be congured to allow this

inbound connection, with the addition of the web port added tot

he end of the http sting.

Please refer to the port allocation table below for remote IP

connections

Ma ste r IP 192 .168.1.10 0

De fault Gatew ay 192.16 8.1.1

Network Mask 255.255.255.0

(AK-SM factory set http port = 80)

LAN Network Router

IP 192 .168.1.1

LAN Network Router

AK-SM

WAN IP 172.28.6.108

For WAN access port

forwarding is required

1. The port number is required to be typed

into the URL address ONLY if the web port is

NOT congured as 80. For example, if the port

number is congured as 8080, then Computer

A needs to type in ht tp: //192.168.1.100:8 080,

while Computer B needs to type in

http://172.68.6.108:8080 to access the website

of the unit.

2. If the port number is dened as default

number 80, then it is not necessary to type in

“:80” in the URL address, this is because the

HTTP protocol uses 80 as default port. If the

router port forwarding is correctly congured,

it is not required in WAN access either.

Computer A

type ‘http://192.168.1.100’ to access AK-SM

Computer B

type ‘http://172.28.6.108 to access AK-SM

Port allocation table

IP Port Use Notes

- LAN side -

80 web browser This port is user congurable but factory set to 80

21 RMT tool This port is user congurable but factory set to 21

25 e-mail e-mail output

3001 XML Used for XML communications

Notes for FTP port forwarding in AK-SM units

In AK-SM units, FTP service is a convenient way to download/

upload les and updating database/code. Open FTP server

ports to the public internet is not considered as a safe network

practice. To avoid these issues, Danfoss strongly suggests FTP

functionality in LAN network only . This would reduce the risk

of open FTP ports and enhance network security. However, to

make the FTP work on WAN side, it must have configured FTP

server port opened and forwarded to the public internet.

© Danfoss | ADAP-KOOL® | 2015.10

USCO.PI.R1.H2.02 | 11

Page 12

Quick Setup Guide | System Manager, AK-SM 800

Initial Conguration - language

The following section describes the recommended actions

to get your AK-SM up and running.

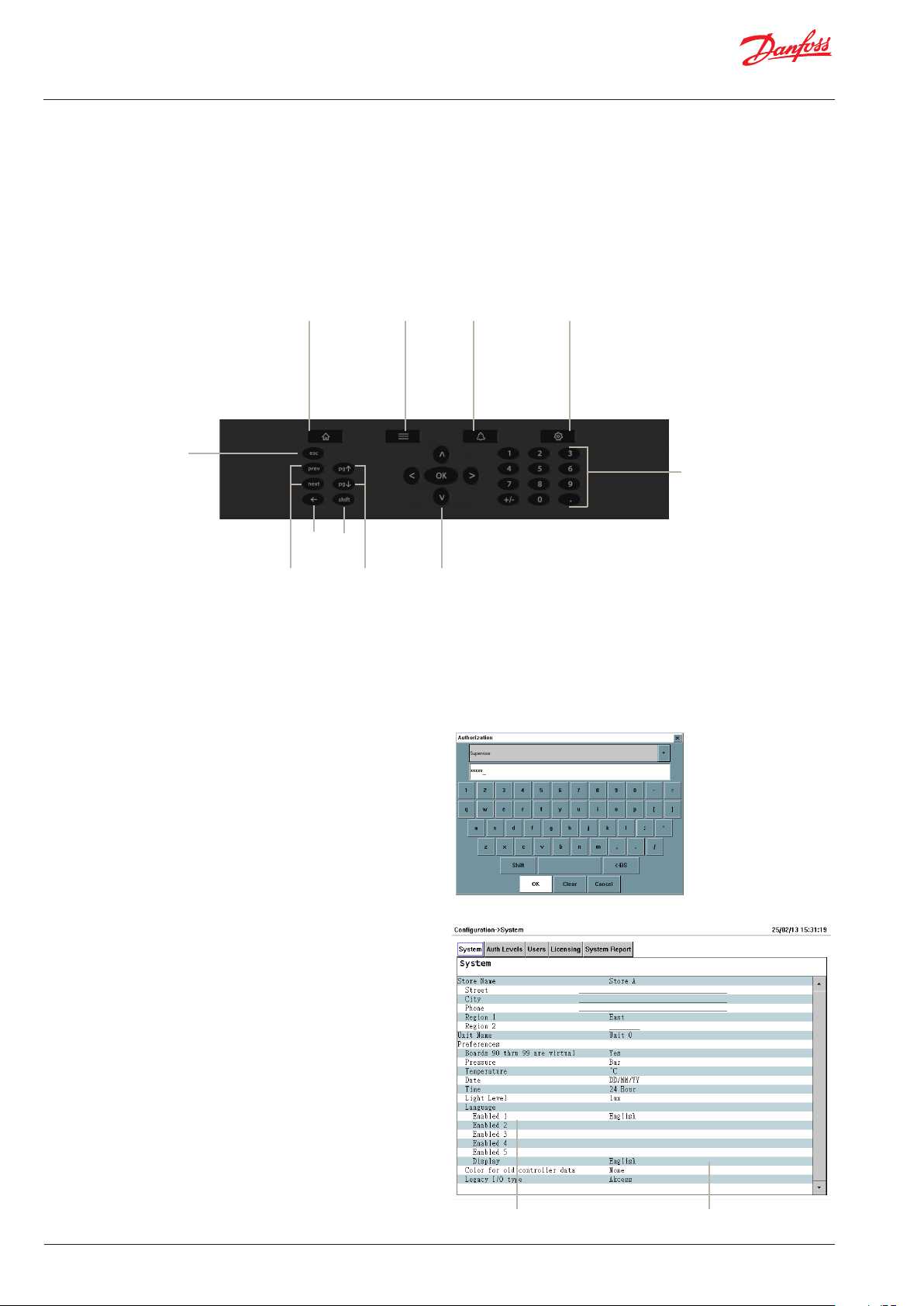

Local keypad - button layout

Home

(System View)

Menu

Escape

Back Shift

Previous

Next

Setting language for local SM display

Your AK-SM can display several different languages. The

factory default the unit will display English, in addition your

required language can also be enabled. Follow the simple

steps below to display your preferred language in the local

screen;

1/ Press the Configuration button, and if required enter the

factory default user name and password (Supervisor, 12345)

Page Up

Page Down

Alarms Configuration

Numeric keypad

Menu Navigation

2/ Using the arrow keys, navigate to the ‘System’ memu.

3/ Using the down arrow, navigate to the Language line and

select your required language

4/ Select your language for ‘Display’. The unit will then request

a re-set.

12 | USCO.PI.R1.H2.02 |

Select language

Display language

© Danfoss | ADAP-KOOL® | 2015.10

Page 13

Quick Setup Guide | System Manager, AK-SM 800

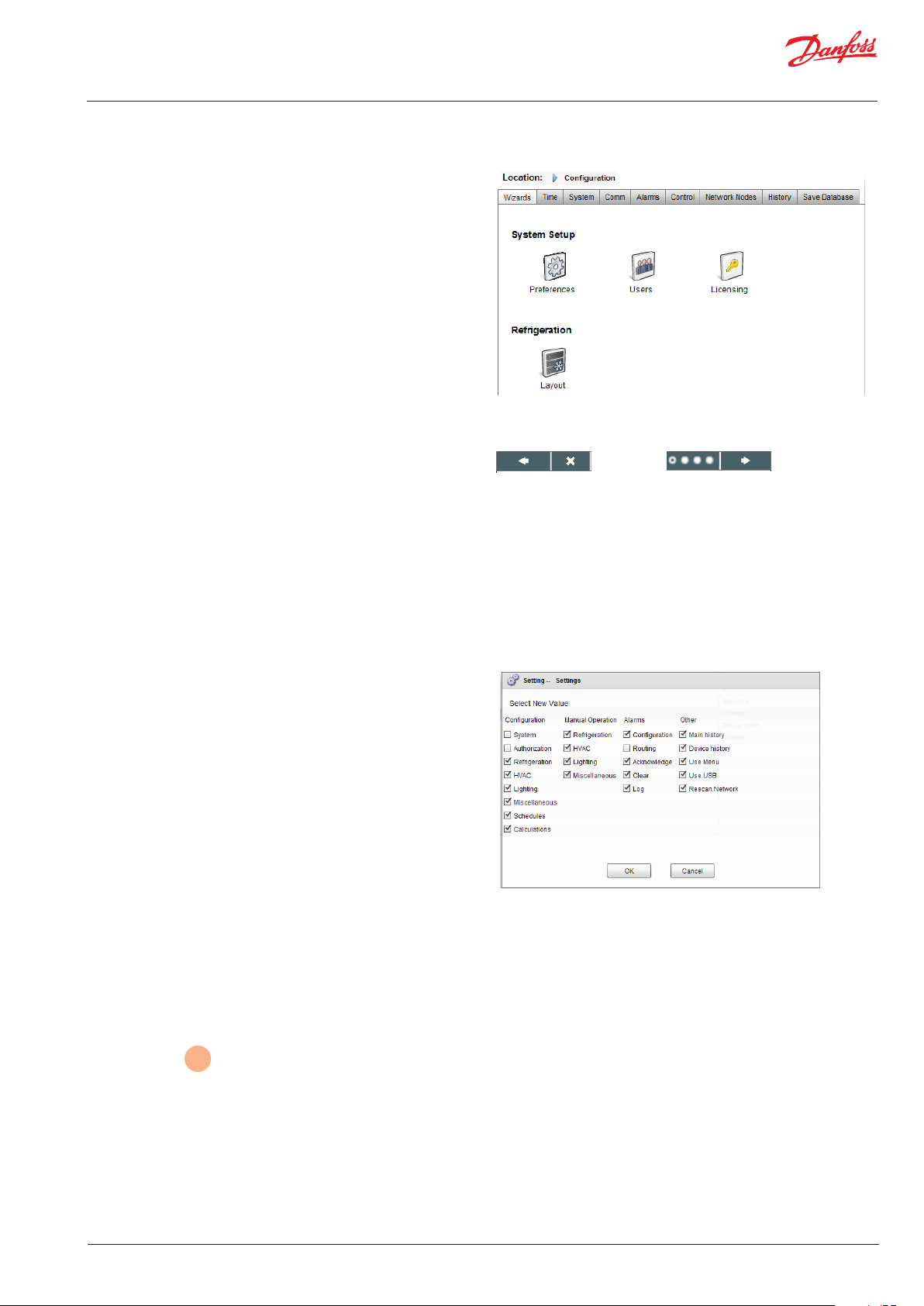

Initial Conguration - Wizard

The following section describes the current Web Wizards, used

for simplifying initial settings and Refrigeration layout. The Web

Wizards can be used in an oine or online conguration.

Danfoss recommends using the AK-SM web environment for

commission tasks.

Establish a web connection to your AK-SM (if working online,

enter the valid IP address of the AK-SM and apply the factory user

name and password). Navigate to the Configuration menu

Preferences Wizard (Language, store names, units, preferences,

time, date, daylight savings)

1/ To easily congure your units preferences, launch the Prefer-

ences wizard. Use the Wizard navigation controls to move

thought the Wizard screens.

2/ To make changes, double click on the relevant line and

continue until the nal screen.

3/ Press the nish button to complete and close the wizard

(return to main wizard screen)

Web Wizard Navigation

Back Close Progress Forward

Users Wizard (Create, modify users, user groups, authorization

levels)

1/ Enter number of users required (max 22), set password and

browser language for each user

2/ Enter the number of authorization types (max 7), against the

settings line double click to modify the scope of system access

3/ Press the Finish button to complete the Web Wizard

Licensing Wizard (Enter new license functionality)

Not currently used

Refrigeration layout Wizard (used to dene your refrigeration

layout, grouping case with packs, forming associations)

One of the main features of the refrigeration layout wizard allows

the user to make use of a network scan. The principle is that the

wizard is initially used to initiate a network scan, discover and list

what is found. This discovery is then used to easily dene the

Pack and Case controller relationships (suction groups). The

wizard allows for easy drag and drop association, the net result is

that once completed the refrigeration layout is built in the AK-SM.

The Refrigeration layout Wizard can be used during a live connection to your AK-SM or can be used when programming oine.

limitations: Whilst the wizard will layout the Pack and Case

relationships, further controller conguration may be required.

Refer to section

any remaining conguration areas required. Currently the wizard

is intended for Pack and Case devices, any controls not designated as such will have to be congured using traditional cong

methods (see Conguration section).

6

under ‘ Conguration’ for guidance on

© Danfoss | ADAP-KOOL® | 2015.10

USCO.PI.R1.H2.02 | 13

Page 14

Quick Setup Guide | System Manager, AK-SM 800

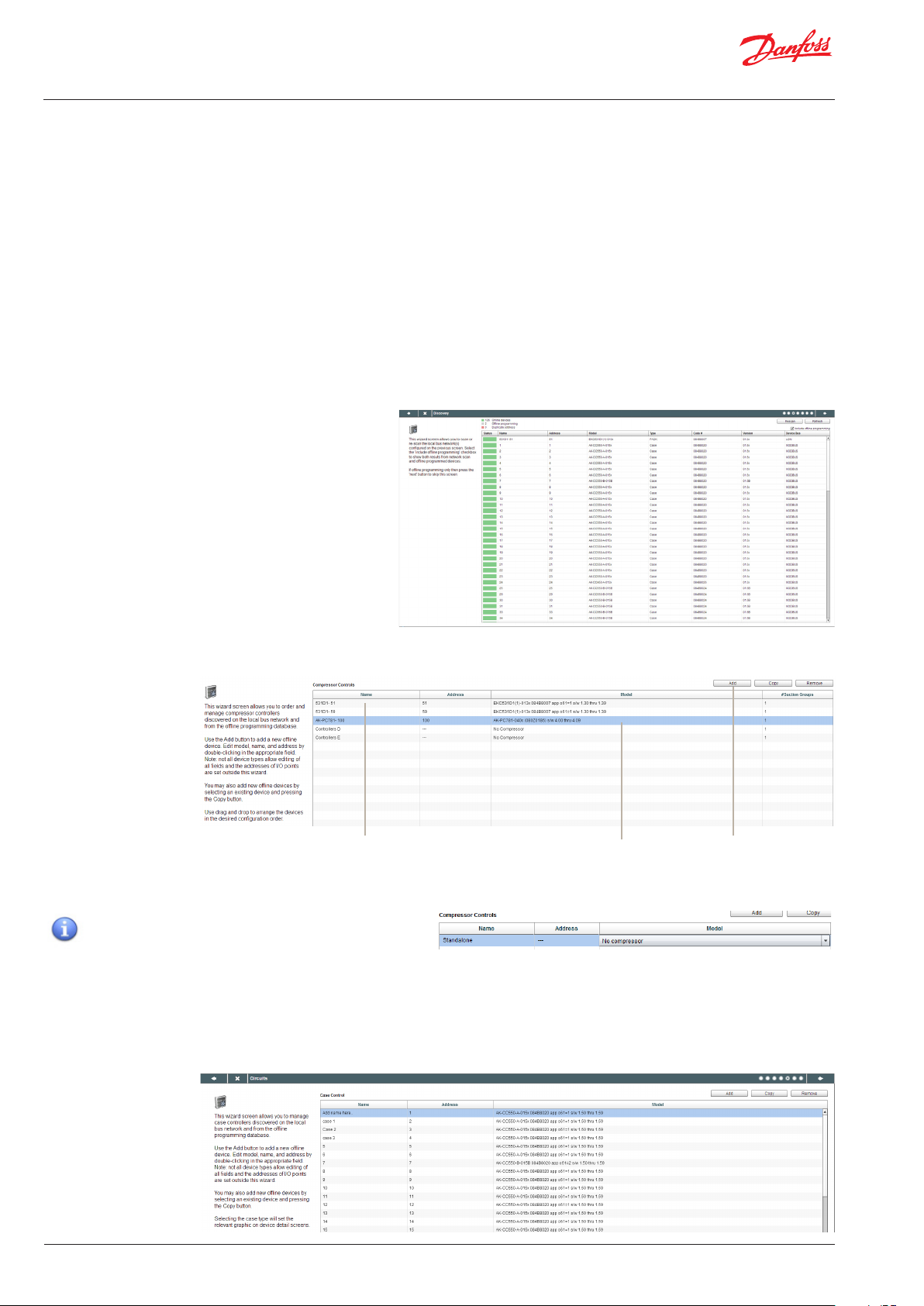

Open the Refrigeration layout wizard and follow the described

steps, each step has some description for the available actions.

The following wizard screens are available in sequential order;

Network (select and perform network scan)

Discovery (list scanned devices)

Compressors (Input Pack controller name, view address, model,

add, copy, remove)

Circuits (Input Evaporator controller name, view address, model,

add, copy, remove)

Suction Group mapping (Drag and drop your evap controllers

under each pack)

Summary (view your groupings before nishing wizard and thus

processing your selections to the AK-SM)

After the relevant networks have been selected an scanned the

‘Discovery’ screen will show all detected devices. Once satised

with the correct content press the forward button to continue

the wizard.

The ‘Compressors’ screen allows for custom text input. If working

oine (programming a database not being connected to a

AK-SM) the Add, Copy and Remove buttons can be used.

Double click the ‘Name’ line to enter a custom description for the

device. Pressing return will automatically focus on the next

device name in the list.

If your scanned list has known devices that are standalone (not associated with a Pack) these must be

mapped under ‘No Compressor’. Manually add a new

compressor and double click the model line and select

‘No Compressor’. When the nal wizard screen is

presented any standalone controls can be mapped under

this ‘No Compressor’ group.

The ‘Circuits’ screen follows the same principle as the Compressors screen.

Use the Add button when creating oine nodes. Double

click the ‘model’ line to bring up a selection of nodes

14 | USCO.PI.R1.H2.02 |

© Danfoss | ADAP-KOOL® | 2015.10

Page 15

Quick Setup Guide | System Manager, AK-SM 800

The ‘Suction group mapping’ screen allows for the dened

evaporator devices to be ‘mapped’ under the required Pack

controller. This mapping forms a relationship or grouping

between the pack and the evaporator devices. This grouping

association will then be seen in the AK-SM conguration and

dashboard screens (and can be used to easily set up master

control functions like Suction optimization).

As the user description indicates, use a drag and drop action to

group your controls. Use the CTRL key and multi-select cases to

save time when making bulk actions. You can remove any case

devices by simply dragging back to the available case list.

The check box labelled ‘Allow multi-case circuit creation’ is to

support Centralized refrigeration control conguration, where

multiple case circuits are available’. Leave this check box empty if

you are using a de-centralized control strategy (i.e. Case and pack

controllers)

Once satised with the mapping, press the forward button and

the summary screen will be shown. Pressing the nish button

will then send your conguration layout to the AK-SM. During

this time a progress bar will be shown and nally a status

dialogue box.

This completed wizard process will layout your refrigeration

application. Typically some additional conguration tasks will

then need to be completed (i.e. dene alarms, setpoint changes,

congure history), please refer to the following section for further

details on detailed conguration.

© Danfoss | ADAP-KOOL® | 2015.10

USCO.PI.R1.H2.02 | 15

Page 16

Quick Setup Guide | System Manager, AK-SM 800

Conguration

The following section describes the typical steps required for

commissioning and conguration of your AK-SM. Although site

applications can dier from one site to another, many setup

procedures are common. This setup section assumes the AK-SM

is mounted and all necessary power, network cabling and

controllers are in place. The described work ow is based around

the AK-SM web browser interface, but would equally apply if

being done via the local screen. Further detailed commissioning

instructions are found though out this user guide.

De-Centralized

Pack & Case

The AK-SM oers unique control exibility in that both centralized

and de-centralized control methods are supported. The term

‘centralized’ is used to describe the control of refrigeration Racks

via I/O (Danfoss Input / Output modules). Under this method of

control the refrigeration control is managed directly from the

front end (AK-SM), with eld bus I/O. De-centralized control is the

term used to describe the full support of Danfoss Pack and Case

controllers. Under this method, each Pack or Case controller on

the network can be seen as self contained, with control logic built

in. The front end (AK-SM) under this type of application is more of

a network manager, providing full read / write access and energy

saving functions.

When conguring your application, have in mind

which control strategy you wish to utilise.

Centralized

Rack I/O

When starting your system conguration you will have the opportunity to select either Centralized or De-centralized (or a mix of

both) control methods.

The following areas of system conguration will be covered in this

section;

Network Nodes (Network scan/ Node overview, Points, scan /cong status, duplicates, upload/download)

1

Time (Set time/date, time zone, operating Hours, Daylight savings, Holidays)

2

System (Store / Region Names, Units preferences, Authorization levels and users)

3

Communication (DNS, DHCP, IP Ports)

4

5

Alarms (XML, e-mail, Routing)

6

Control (Congure Refrigeration, Lighting, Miscellaneous, Energy meters and Gas detection)

Once successfully logged into the AK-SM (web) and assuming you

have the required authorization, system conguration is done via

the central ‘Configuration tab’. Clicking this tab reveals the

conguration ‘sub tabs’. Depending on your selection, these sub

tabs will change dependent on content.

Using the menu structure seen in the ‘Conguration’ page, a step

by step process can be applied when setting up your AK-SM.

Navigation ‘bread-crumb’

16 | USCO.PI.R1.H2.02 |

Central conguration menu

© Danfoss | ADAP-KOOL® | 2015.10

Page 17

Quick Setup Guide | System Manager, AK-SM 800

Network Nodes

1

If your application already has controllers and/or I/O modules

set and powered you may wish to perform a network scan to

validate their connection to the AK-SM. Follow this section to

perform a network scan

From the Conguration tab select the ‘Network Nodes’ sub-tab.

When your eld network is complete and all controllers are on

line a network scan can be initiated. The operation of a network

scan allows the AK-SM to be aware of any controller devices on

the network, allowing the AK-SM to communicate and function

with the controllers on the eld bus.

Use this screens to

perform network

scan

Relays | Sensors | On/Off | Variable Output

This tab relates to any AK I/O congured

points, the term points relates to AK I/O

relay, sensors, On/O Inputs and variable

outputs. Any control questions that have

required AK I/O control will be seen in

these tabs. The purpose of these tabs is to

allow the viewing of the I/O point status.

All nodes | Controllers | I/O boards | Other nodes

The scan status menu/tabs allows the user to view any scanned

nodes found on the network.

All Nodes: Central list will display congured devices and points.

Only congured controllers will be visible in this list.

Controllers: view any scanned generic controllers. This screen

will also reect address and controller type

I/O Boards: Display AK Board & Point status.

Other Nodes: List of other nodes

Ensure the appropriate network channel is selected, and press

the ‘complete rescan’ line. The AK-SM will now scan the network

to identify any connected and addressed controller nodes. The

text on the screen will reect the scan progress, after a scan the

time & date will be shown (indicating last scan)

For SLV support, select Modbus channel

‘Use this screens to

view status of your

assets (Online)

Duplicates Tab

Check this list to make sure no two devices have been assigned

the same network address. Any duplicate address will be

shown in this list. Correct any address issues and re-scan.

Upload Tab

The upload tab will list any controllers that have been uploaded.

The upload function can be performed in the Conguration>Control area (one controller at a time) or here (multiple devices

with one command). The process of an upload takes the

current parameter settings and values from the controller(s) and

loads them into the AK-SM database. This operation ensures

that the AK-SM database is synchronised with any pre-congured controllers on the control network. Any upload failure will

be shown on this screen, else a time / date stamp will be shown

when successful

Download Tab

The download tab will list any controllers that have been

processed for download (where the AK-SM sends parameter

data to the device). The download function can be performed

individually under the Conguration->Control page or here,

where multiple controllers can be selected for download (using

one command). The process of a download takes the AK-SM

database values and downloads them to the selected

controller(s). Any upload failure will be shown on this screen,

else a time / date stamp will be shown

© Danfoss | ADAP-KOOL® | 2015.10

USCO.PI.R1.H2.02 | 17

Page 18

Quick Setup Guide | System Manager, AK-SM 800

After the network scan has completed, any resulting count will be

seen against the Nodes Scanned on Network line - this reects

the number of found nodes on the scan just completed. The

corresponding line below (Nodes congured in database)

reects the current total of network nodes actually congured in

the AK-SM database.

The last group in this table refers to the following node types;

OI (Output|Input)

RO (Relay output)

SI (Sensor Input)

V02 (Variable output)

Utility Meter (WattNode, Veris, Carlo Garvazzi)

Generic (Danfoss case / pack controllers)

AK-CM (AK- Communication Modules)

Calculations

Each node (type) has a column that reects any congured or

scanned status.

2

System conguration (Time settings / preferences)

The Time tab allows the system time, time zone, operating hours,

daylight savings and holidays to be congured. Double click a

line to make any changes.

The following examples can be seen for the time zone;

London (GMT) = 000

Central Europe = 100

East Coast USA = -500

The operating hours can be set that reect your store operating

hours. Any times set in this section can then be referenced to

via a ‘Relative schedule’ . Relative schedules are found under the

‘Lighting’ and ‘HVAC’ application areas and apply a (user selectable) oset which references the operating hours schedule.

3

System conguration (Time settings / preferences)

18 | USCO.PI.R1.H2.02 |

© Danfoss | ADAP-KOOL® | 2015.10

Page 19

Quick Setup Guide | System Manager, AK-SM 800

After completing the required settings in the ‘time’ tab, navigate

to the ‘system’ tab. Under the system tab add the store name and

region / preference setting and information.

Use this screen to congure

‘Store name/details, unit

name, preferences, system

language’. Double click the

appropriate line to make

changes

‘Color for old controller data’ is

an option to reect data that

has yet been updated via a

network poll. Data with a *

indicates either an oine

condition or that the AK-SM is

waiting for a fresh update

from the device

Legacy I/O type is used to set

legacy supported devices

The Auth (Authorization) Levels tab allows the denition of up to

7 authorization types. Custom authorization types can be

congured with certain system privileges / access. In the

example below, 4 auth levels have been dened (factory setting

is 3). Level 1 (Supervisor) cannot have the settings changed. To

change the level of access of other auth levels, navigate to the

desired line and select from the Authorization pop up dialog box.

As factory standard, 3 levels are predened (Supervisor, Service,

Daily User), the service and daily user levels can be changed as

required.

The Auth (Authorization) screen allows

the denition of up to 7 authorization

types.

Reects what license is

congured for your AK-SM.

Dierent license allow

additional functionality

The Users screen allows the

denition of up to 20 users

The system report screen allows the user to dene

what content should be included.

Alarms, Schedules, scanned devices, Audit trail and

controller database are available options.

To generate a system report go the main web menu

and select File/Download Report

© Danfoss | ADAP-KOOL® | 2015.10

To add/delete auth levels select the ‘Number of

authorization types’ line (max 7 levels)

The Supervisor name can be changed but the level

of access / privileges are factory set.

Adding new auth levels allows new users to have

specic access to key system areas. Once new auth

types have been created, enter custom name and dene

level of access by selecting the Settings line (Authorization pop up box will appear)

USCO.PI.R1.H2.02 | 19

Page 20

Quick Setup Guide | System Manager, AK-SM 800

The following areas of authorization are available;

Conguration

System: Access to the System tab

Authorization: Access to the Authorization tab

Refrigeration: Access to Refrigeration conguration

HVAC: Access to HVAC conguration

Lighting: Access to Lighting conguration

Miscellaneous: Access to Misc conguration

Schedules: Access to Schedule conguration

Calculations: Access to Calculations conguration

Manual Operation (seen under Service tab in device detail

page)

Refrigeration: Allow user to perform the following operations

on Danfoss case controllers ;

Main Switch, Defrost, Cleaning, Lights, Night Setback, Shutdown

HVAC: Allow user to perform the following operations to Relay,

Inputs & sensor overrides

Lighting: Allow user to perform the following operations

-override relay

Miscellaneous: Allow user to perform the following operations

-override relay, sensor inputs

Alarms

Conguration: Allow user to congure alarms

Routing: Access to the alarm routing

Acknowledge: Allow user to acknowledge

Clear: Allow user to clear alarms

Log: Allow user to set alarm level to log

Other

Main Menu: Allow user to access main menu

Device History: Allow user to access device history

Use Menu: Allow access to Menu function

Use USB: Allow use of USB ash

Rescan Network: Allow user to rescan network

Users tab

The next tab (user tab) allows the denition of up to 20 users. A

custom name and password can be given for each user. The

appropriate level (dened in Auth Level tab) can be assigned to

each user. The AK-SM always maintains a single user in the

system prole and this level is factory set to the Supervisor level.

To add users simply enter the required value in the ‘number of

users’ line. The Browser language line reects what language will

be displayed in the web browser upon this user logging on [via

browser access].

To add users select the ‘Number of users’ and enter

required number

20 | USCO.PI.R1.H2.02 |

Enter custom name, password and auth level for

user.

Browser Language: This denes the language that

will be displayed when the user log on via the web

browser access.

© Danfoss | ADAP-KOOL® | 2015.10

Page 21

Quick Setup Guide | System Manager, AK-SM 800

Communication

4

The Comm (Communications) screen allows for IP network

settings to be congured. Follow the question lines on the screen

to congure your AK-SM according to site requirements. Any

changes in IP conguration will require an AK-SM system reset.

Select ‘Yes’ if a DNS service is to be used. Prefered host

name can be entered if setup in router cong

Select ‘Yes’ if AK-SM is to be connected to a DHCP server

Select yes and manually enter the IP address that the

AK-SM will use if DHCP fails.

Master IP address - if using multiple AK-SM controllers in

a host network, enter the Master (unit address 0) IP

address

Internet IP address - Specify public IP address which is

used to contact your AK-SM via an Internet based

connection. Factory web (HTTP) port is 80 & FTP port is

20 and 21, both can be changed to suit your network

application.

If your network supports NTP, select ‘yes’ to the

question ‘Network timing support?’

Alarms

5

The Alarms screen has a sub set of screen [Connections, Service, Alarm Routing, Relays, System, I/O Comm]. Go through each sub tab to

ensure all areas are correctly congured as per site requirements.

Dene the number of

connections (typically

network should be selected),

then select the connection

type [e-mail, Remote (Danfoss

Retail Care), XML)

The service tab is designed to

allow test alarms to be

generated. There is also an

auto alarm test that can either

be on a scheduled or repeated

basis.

The AK-SM utilizes an

Alarm Action Matrix that

allows a high degree of

exibility for various

alarm routing options.

At the heart of the alarm

conguration is the

‘Alarm Routing’ page,

where dierent routing

options can be dened,

along with time delays

and alarm output stop

conditions.

AK-SM system

based alarm

conditions

should be set

under the

System tab.

If the alarm output

includes relay(s) the

Relays tab should be

accessed to congure

the board & point

address for these relays

If Controllers (Danfoss Evap &

Pack, Power meters) and I/O

has been used in the control

conguration (Lighting, HVAC,

Refrigeration etc.), these

devices can be seen under the

I/O Comm tab.

© Danfoss | ADAP-KOOL® | 2015.10

USCO.PI.R1.H2.02 | 21

Page 22

Quick Setup Guide | System Manager, AK-SM 800

Connections screen - Dene the number of connections, then

select the connection type. Your AK-SM can oer the following

alarm IP based alarm output;

e-mail, Remote (Danfoss Electronic delivered services) and XML.

Depending on your conguration the screen will reect the

required inputs in order to satisfy the output. In order for any

alarms to be routed out of your AK-SM please ensure a schedule is

congured. Failure to set a schedule will inhibit any alarm output.

To congure a netwrok connection select

‘Number of network connections’

Type (e-mail | Remote | XML)

Ensure a schedule is dened to allow alarm

ouput

Example of e-mail conguration

Enter valid server name (or IP) for e-mail server

If your e-mail service requires user authorization, enter user name and password

Send to: Add the e-mail address for intended

recipients

Reply to: A mandatory eld that must

have a valid entry (address with same domain

name). An abbreviated message would have

reduced text in the alarm message

Congure a schedule to enable the alarm

e-mail output

22 | USCO.PI.R1.H2.02 |

3G Wireless routers

3G technology oers many benets over standard dial up

connections. Utilizing a 3G connection the full range of AK-SM

services can be used, including web browser, and RMT. Where

Internet / Intranet connection is not available, Danfoss recommends considering 3G as a means of oering IP connectivity.

Please consult your local Danfoss sales oce with regard to 3G

connectivity.

© Danfoss | ADAP-KOOL® | 2015.10

Page 23

Quick Setup Guide | System Manager, AK-SM 800

Service tab

Use the service screen to send test alarms. You may congure the

alarm type and alarm action logic (1-8). In addition, scheduled or

repeat test alarms can be congured on this screen. The internal

alarm relay cam also be tested from this screen.

Disabled = No alarms will activate on this point

Log Only = When an alarm occurs on this alarm point it will only

register in the AK-SM alarm log - no physical alarm output

Normal = When alarm is active the output will be sent once

(alarm may get re-triggered if the stop condition is set for repeat)

Severe = When alarm is active the output will get re-sent every

xx min

Critical = Same as Severe but with separate re-trigger time when alarm is active the output will get re-sent every xx min

Delete = Removes any applied alarm settings

Routing tab

The AK-SM utilizes an Alarm Action Matrix that allows a high

degree of exibility for various alarm routing options. At the heart

of the alarm conguration is the ‘Alarm Routing’ page, where different routing options can be dened, along with time delays and

alarm output stop conditions.

The central alarm action matrix allows various output options

(known as alarm actions) and alarm handling conguration to be

centrally assigned. Once the alarm action matrix has been

dened, any controller or I/O point can be given an alarm action

number. The alarm action number corresponds to the appropriate output. (as dened in the alarm routing page). Alarm output

options include;

• 5 external (AK I/O) relay outputs

• Local AK-SM buzzer

• Local AK-SM front LED

• Internal alarm relay

• 2 Network connections

• 6 IP / e-mail addresses

• Serial printer output.

Select Alarm Action type (dened under Alarm routing)

Auto Test:

Scheduled: Congure days & time for test alarm

Repeated: Congure interval time for test alarm

Suspend alarms generation (suspend All alarms in the

system from being sent): Set time period (min/Hrs) to

stop alarms being sent

Any relays congured for alarm output can be forced on /

o for testing purposes.

Remember to leave in Auto position after

testing

The following example can be seen as a guide to conguring your

AK-SM alarm logic options;

© Danfoss | ADAP-KOOL® | 2015.10

USCO.PI.R1.H2.02 | 23

Page 24

Quick Setup Guide | System Manager, AK-SM 800

To congure an alarm action, navigate to the required output line

(I.E. Relay A) and press enter. The resulting screen allows the

conguration of the alarm actions, any pre delays, duration times

and stop conditions. The results of this conguration will be

shown in the alarm routing page.

Alarm Actions (1-8)

Up to 8 alarm actions can be dened. Each alarm action can have multiple outputs, making

the AK-SM alarm output options very exible. ‘Look down’ each alarm action number column

Component Column (alarm output)

and any associated outputs will be seen in the left hand column

Select from the options seen in this

column;

• Relay A-E

• Front LED

• Buzzer

• Int. Relay

• Network 1

• Network 2

Stop

The stop condition denes when the alarm output will stop or return to congured

position. The following denitions apply;

Time = Stop on time (set under duration)

Ack = Stop on alarm being acknowledged

Clear = Stop when alarm clears

Time/Rep = Stop after time delay but repeat if alarm is still active

Ack/Rep = Stop after alarm is acknowledged. If alarm still

active after acknowledge repeat

alarm action (repeat

Alarm Actions (1-8)

Custom text that better

reects the alarm relays

can be entered.

Use the ‘component

name display’ to toggle

between custom text &

factory name (Relay A,

Relay B...)

Alarm output options

Select the appropriate

‘component’ (i.e relay,

network) and congure

by double clicking on

the appropriate line

Each alarm action can have multiple relays, IP address, etc assigned

Delay

Once an alarm action is dened the

associated time delay for the action can be

set. This delay is in addition to any delay

already dened in any controller (i.e. EKC) or

monitoring points (i.e. I/O) dened in the

system.

Duration

A duration time is available when either

Time or Time/Repeat are selected as stop

conditions. The duration setting denes

the length of time the alarm output will be

active for (irrespective if the alarm is still

active or acknowledged or not)

Available in second or minute selections. 0

Sec/Min duration will result in the alarm

output remaining o.

Min = 0 Sec/Min

Max = 99 Sec/Min

Delays & Stop conditions

Set pre delay, duration and

stop conditions (for each

alarm output selection)

24 | USCO.PI.R1.H2.02 |

© Danfoss | ADAP-KOOL® | 2015.10

Page 25

Quick Setup Guide | System Manager, AK-SM 800

Example conguration

This example will describe the steps to congure an alarm

actions. Alarm action 1 will be dened according to the follow-

ing;

• Relay A should trigger after a 10 second pre delay. This relay

will energize any time and will only reset when the alarm

clears.

• The Front LED should activate (de-activate LED when alarm

clears)

• The Buzzer should only activate during the Day (Buzzer

stops when alarm is Acknowledged)

• Alarm message should also be sent out via e-mail

The above alarm outputs are associated with action 1 - ‘look

down’ the alarm action 1 column and the relevant outputs can be

seen in the left of the page.

To dene the alarm output options navigate down the page and

double click the relevant line.

This opens another page that allows the conguration for that

output to be set. In the example below Relay A and the

Buzzer can be seen. Follow the same process for the

other outputs. For e-mail output, navigate to the

Network 1 line and press enter. Here, set the action,

time delay & stop conditions. (The actual e-mail

conguration is done in the Alarm ‘Connections’ page).

‘Look down’ Alarm action 1 column

The results of the alarm output conguration can

be seen in the central Alarm Routing page. Follow

this process for other actions.

Relay A Conguration page

Action settings:

Once in the actual output page, navigate through the lines and

set the relevant Action. Each action can have the following

settings;

Not Selected: No action

Enabled: Will enable this output action (any time of day)

Day: Enable this output during day status (based on store

opening times (Conguration->Time)

Night: Enable this output during night status (based on time

Delay, Units & Stop settings:

outside of store opening times (Conguration->Time)

To complete the output conguration set the time delay,

units & stop conditions should be set. Stop conditions;

Time = Stop on time (set under duration)

Ack = Stop on alarm being acknowledged

Clear = Stop when alarm clears

Time/Rep = Stop after time delay but repeat if alarm is still active

Ack/Rep = Stop after alarm is acknowledged. If alarm still active

active after acknowledge repeat

© Danfoss | ADAP-KOOL® | 2015.10

USCO.PI.R1.H2.02 | 25

Page 26

Quick Setup Guide | System Manager, AK-SM 800

Relay tab

If the alarm output includes relay(s) the Relays tab should be

accessed to congure the board & point address for these relays.

The example below shows relay A & C, with the associated (AK

I/O) board & point address.

System tab

Enter the AK I/O board & point location for the

relay(s)

Select N-Open / N-Closed as required

AK-SM system based alarm conditions should be set under the

System tab. The alarms seen in this page are factory set but can

be changed as per site requirements. Navigate down each line

and congure (pressing the enter key) as required. The following

items can be seen and changed under the System tab;

I/O Network Fail: Alarm if communications to AK I/O fails

Flash Memory fail: Alarm if AK-SM system memory fails

Database Cleared: Alarm if AK-SM database is cleared

File Error: Alarm if critical les do not load / not present on

AK-SM system (I.E. Device list missing)

Alarm send fail: Alarm if any active alarms were unable to be

sent out

NTP Failure: Alarm if the network time protocol fails

Host Comm: Alarm If host communication fails

Host Count: Alarm if one or more AK-SM units disconnect from

host netwok

Ram Disk Full: Alert alarm if Ram is getting full (due to EDF les)

Factory settings can be changed as per customer

requirements.

26 | USCO.PI.R1.H2.02 |

Alarm level & Actions can be changed

© Danfoss | ADAP-KOOL® | 2015.10

Page 27

Quick Setup Guide | System Manager, AK-SM 800

I/O Comm tab

If Controllers (Danfoss Evap & Pack, Power meters) and, I/O has

been used in the control conguration (Lighting, HVAC, Refrigeration etc.), these devices can be seen under the I/O Comm tab.

The I/O Comm tab allows any oine communication alarms to be

congured. The example below shows an evaporator controller

(address 1) with the alarm level set to ‘Normal’ & alarm action ‘1’.

These factory settings can be changed in this page.

Any AK I/O points used in the AK-SM system can be found on this

page, with the associated alarm level and actions set. The factory

settings can be changed as required.

Calculations & Other

If any calculations have been dened in the AK-SM

system, alarms can be associated with these. Use

the Calculations tab to set appropriate alarm levels

and actions.

© Danfoss | ADAP-KOOL® | 2015.10

USCO.PI.R1.H2.02 | 27

Page 28

Quick Setup Guide | System Manager, AK-SM 800

Control tab

6

The control tab is the central conguration page for your control

requirements. It lays out the dierent application areas and

allows the Commissioning Engineer to dene what applications

are on site. Once the application areas are dened on this page,

more detailed commissioning is done in the dedicated application tabs (covered in following section). Note that depending on

your license version, dierent applications may be visable (or not).

Please also note that the SM provides the ability to congure

centralized or de-centralized control. Centralized control is

where your SM has the control logic built in and uses Danfoss I/O

to provide refrigeration control. De-centralized is the control

method via the use of Danfoss Pack and case controllers

For de-centralized control, ensure the control type is

set to your required controller type (via drop down

menu)

For centralized control, ensure the control type is set to

IO (input/Output). This alerts the SM that you wish to

use Danfoss Board and Point conguration for your

refrigeration application

De-Centralized

Pack & Case

Show only scanned devices:

Select ‘yes’ if your controller devices are already on the

network, with valid addresses and connected to the

AK-SM. By setting to ‘yes’ and after a network scan

(covered in next section) only discovered devices will be

shown in the drop down boxes. If your controllers are not

yet on the network, keep this selection to no.

Centralized

Rack I/O

Number of Racks / Packs (max 12):

Enter the required amount of suction groups.

Rack type (Use I/O selection for centralized

control, select controller type if using de-centralized)

AK IO = built in control via AK I/O

No Compressor = No Compressor control

Device selection = select required controller

Note: Variable Speed can be selected as a pack controller.

28 | USCO.PI.R1.H2.02 |

Suction groups (Suction group or Evaporator

control)

Add your required quantity of suctions groups

(centralized logic) OR enter how many evaporator controls are available under your Pack

(de-centralized)

Note: suction group / evap conguration is then

done under the Refrigeration tab

© Danfoss | ADAP-KOOL® | 2015.10

Page 29

Quick Setup Guide | System Manager, AK-SM 800

The following screen shots below represent an example of

de-centralized conguration (Pack and Case control).

The AK-SM has been congured for two pack controllers (AK-PC

730 and the AK-PC 840), with 5 Evaporator controllers under each

pack. Selection for each Pack controller was made via the pop up

box that appears when the Rack line is double clicked.

Once the Pack controllers have been dened and the number of

case controllers under each pack have been set, continue to the

Refrigeration tab for detailed conguration.

Double click to select your

required Pack device

First, navigate to the ‘Address’ tab. Enter a valid network address,

corresponding to the address already set in the eld controllers.

Note: If your eld controllers have already been congured with

the relevant parameters set, you may wish to perform an ‘Upload’.

This function forces the AK-SM to pull back the controller settings

and thus synchronize the AK-SM database. Only use the ‘Download’ function if you have nished controller conguration on the

AK-SM and you wish then to send these settings ‘down’ to the

controller.

A one click option for this (upload/download) can be found under

the Conguration->Network Nodes tab

Set a custom name for your control devices

Enter address that matches the physical

address in the pack and case controllers

See above note about Download / Upload

© Danfoss | ADAP-KOOL® | 2015.10

USCO.PI.R1.H2.02 | 29

Page 30

Quick Setup Guide | System Manager, AK-SM 800

Once all the addresses and custom naming is complete escape

out of the addresses menu and navigate to the ‘Suction’ tab. This

will allow for conguration of the Pack Controller(s). Use the drop

down (Suction) menu to access each Pack controller and the

corresponding menus. Please note that any online controller

devices will invoke a dialogue box which asks if you wish to

retrieve the data from this controller. This dialogue box is

intended to direct the choice of either uploading data from a

controller (overwriting any previous settings held in the AK-SM

database) or not. If you have existing controllers on the network

which have already been congured, choose the upload option

(this need only be done once for each controller you view).

Controller menu selection. Use

this drop down list to access the

dierent controller menus.

When to use Upload / Download function:

The AK-SM holds a database in which all the system conguration

is held. This includes any actual controller devices connected or

just devices that have been selected ready for conguration. It is

important to recognise when to perform an upload or download

function so that any preset conguration is not overwritten by

automatic upload by the AK-SM.

Upload

This function may be required where the case and pack controllers have already been congured and all parameters are set

according to customer specications. In this instance the need is

to typically perform an upload function, thus updating the AK-SM

database to fully reect the controllers commissioned settings.

Once this has been done, changes to the controller settings can

be done directly from the AK-SM.

Download

The opposite to this would be where the controller devices have

not been set per customer specication and the AK-SM should be

used as the commissioning tool or window into the controllers.

By navigating through all the controller screens in the AK-SM it is

possible to congure the controller parameters and then send

these setting to the connected controllers via the download

function.

Controller parameters, to modify or

change double click line and press the

enter key. The new value will be sent to

the controller*

*Controller must be online

*Some controller types require the main

switch (R12 parameter) to be o before

certain changes can be made

30 | USCO.PI.R1.H2.02 |

© Danfoss | ADAP-KOOL® | 2015.10

Page 31

Quick Setup Guide | System Manager, AK-SM 800

Copy function

To aid the commissioning process, the AK-SM oers a settings

copy function which can be used to copy one device settings and

alarm conguration to other (similar) device(s). This function

works when copying settings to and from same controller version

/ type devices. The procedure described below is one example of

the copy /paste function.

Use the Copy tab to open the copy page, where any same

controller type devices can be copied to. The actual device page

will act as the copy base, so ensure the correct circuit is selected

(in the drop down list). Select all or individual controllers that

will be copied to, then press the copy to line.

The copy function copies controller parameters etc from

once device to the AK-SM database, to complete the

operation the (copied) settings need to be downloaded to

the required controllers.

The Global download function can be seen under the

Network Nodes -> Download section

Import SI | OI function

Use the Import SI (Sensor Input) and Import OI (On/Iff ) function

to gain access to ‘generic’ controller (Evap & Pack) parameters

that are normally not accessible for alarm / logging / Boolean use.

This function can be used to alarm on specic parameters not in

the factory alarm list and / or can be used to import controller

parameters in the Boolean logic calculator. Up to sixteen points

can be selected per controller. This function extends the exibility

of controller support in the AK-SM and opens up the generic

controllers parameter list for more customer specic needs. The

following steps highlight the procedure in ‘Importing’

From the import page(s) double click an import line to present

a pop up box that shows all available parameters. Select the

parameter that you wish to ‘import’ from the controller (you may

give it a custom name).

In the example below, the parameter Po Set point has been

selected. This parameter can now be seen in the miscellaneous

calculator.

Extended Cong function

Extended conguration (changing what parameter is seen in the

System View, Dashboard & Device detail status)

Using the extended conguration tab the factory standard

parameter that is used for ‘System View’ status can be changed.

This feature is useful in giving the end user more exibility in

showing the relevant sensor at the system and device detail views.

By changing the overview value the AK-SM will then display the

new selected parameter or status in the system view, Dashboard

and device detail pages.

© Danfoss | ADAP-KOOL® | 2015.10

USCO.PI.R1.H2.02 | 31

Page 32

Quick Setup Guide | System Manager, AK-SM 800

Alarms and Alarm Select

Use the Alarm tab to dene the alarm actions associated with this

device. Use the Alarm select tab to select up to 300 alarm points

(max 300 per AK-PC controller)

Conguration -> HISTORY

The AK-SM history section allows the collection and recording of

control parameters, values and status. The central history

function allows up to 600 ‘points’ to be congured, a point being

a temperature, pressure, status, relay, etc. The collection of

history allows further analysis using the AK-SM or remote web

browser, where a graphical representation of this data can be

made.

To congure history, navigate to the Setup tab (Conguration>History). The following setup lines are visible;

Auto Congure History: Use this function to auto select typical

points needed for logging (the AK-SM will select key points in the

Refrigeration, HVAC, Lighting and Misc control areas. Manual

conguration can be done to override these selections or add

more as required.

Clear History Conguration: Use this function to clear history

conguration (points selected for history & the frequency of

samples)

Clear History log: Use this function to clear stored history in the

AK-SM

Start / Suspend History: Once the relevant points have been

selected for history collection (using either the Auto history,

manual or a combination of both) press this line to Start the

collection. Press again to Stop collection

Status: Displays the current status of history collection (Collecting or Suspended)

No of Congured datapoints: Displays the number of congured history points (max 600)

Note: Ensure the correct time & date are set in

the AK-SM. Make sure the history collection

function is running to ensure the collection of

datapoints. Use the ‘Start History’ line and

check that the status reects ‘Collecting’

32 | USCO.PI.R1.H2.02 |

Auto Congure History

When selecting the auto congure history function

the AK-SM presents the option to select the history

collection sample rate.

These can be later changed & modied under the

relevant history device type (Controllers/Relays/

Sensors/On/O/Variable/Other)

© Danfoss | ADAP-KOOL® | 2015.10

Page 33

Quick Setup Guide | System Manager, AK-SM 800

Conguration -> HISTORY

Controllers

If any controllers are congured for history collection, these can

be seen in the ‘Controllers’ tab. The example below shows a

evaporator controller with the various control groups accessible

via a drop down menu. Any auto history settings will be seen in

these controller group lists, manual conguration of any parameter can be done in this page.

Navigate and select appropriate points for

history collection, via the drop down menu

selector. Double click a required line, a pop up

selection box allows the choice of sample rates;

1,2,10,30 mins

1 Hr

Relays, Sensors, On/O Inputs, Variable Outputs & Other

Depending on the dened control criteria, other points may be

viewed and modied under the respective tabs.

© Danfoss | ADAP-KOOL® | 2015.10

USCO.PI.R1.H2.02 | 33

Page 34

Quick Setup Guide | System Manager, AK-SM 800

Service Tool Support

Your AK-SM supports the Danfoss Service Tool (version 3.23 and

above). The Service Tool (CT) must be connected via an IP

interface. Once an connection is established the ST will show the

AK-SM and all AK2 platform devices. Note that non AK2 platform

based devices will not show up in the ST device list.

When creating a new connection in your ST make sure you select

TCP/IP channel.

Assuming the factory default user name and password, enter

Supervisor for the Destination name

123 45 for the Pass code

Once connected, navigate to your required controller in the

available list. Access to all AK2 parameters is available via this

connection.

34 | USCO.PI.R1.H2.02 |

© Danfoss | ADAP-KOOL® | 2015.10

Page 35

Quick Setup Guide | System Manager, AK-SM 800

General navigation, operation and use (via web)

Once your AK-SM has been congured, general navigation and

daily use is done via the Dashboard screen. The Dashboard

screen acts as the central system home page, where further

system details can be reached. The Dashboard and subsequent

device screens have been developed to provide an easy to use

navigation environment for the user, where typical status and

setting can be found.

Connecting to your AK-SM:

Using a standard web browser or your StoreView Desktop

application, enter your AK-SM IP address

The factory default User name

& password:

User Name: Supervisor

Password: 12345

Translation Tool (used for local language translation)

Download Report (system report of conguration)

Log O

Dashboard screen System View screen Schedule screen Histroy (logs)

Dashboard view:

Once the correct user name and password has been entered the

Dashboard screen will load. The Dashboard screen will only

reect what your application conguration has been set to. For

example, if your application does not have any HVAC congured

the Dashboard will not show the HVAC panel. Dashboard panels

are automatically generated depending on the conguration, no

user action is required to build the panels.

To guarantee the best experience when

connecting to your AK-SM, ensure you PC

has the latest version of Adobe® Flash®

On board quick setup

guide

Use the simulator tool to

simulate congured Misc

points

Data poll refresh info

Active alarm panel

Lighting panel Misc panel

Global alarms (all

connected AK-SM units)

Expand panel button

Device detail screen

Refrigeration panel

Info screen (software version, etc)

HVAC panel

Energy panel

Central AK-SM conguration

screens

data communication status

Once the correct user name and password has been entered the

Dashboard screen will load. The Dashboard screen will only

reect what your application conguration has been set to. For

example, if your application does not have any HVAC congured

the Dashboard will not show the HVAC panel. Dashboard panels

are automatically generated depending on the conguration, no

user action is required to build the panels.

© Danfoss | ADAP-KOOL® | 2015.10

Upon the Dashboard loading, if any active alarms are

present the built in alarm buzzer can be heard. To silence the

alarm press the silence button. This does not acknowledge or

clear any alarms.

USCO.PI.R1.H2.02 | 35

Page 36

Quick Setup Guide | System Manager, AK-SM 800

Managing alarms:

Any active alarms will be shown in the Dashboard alarm panel.

To view more details regarding the alarm double click the

relevant alarm line. A alarm info box will appear with further

details regarding the alarm.

In addition to more information, the info box also allows the

authorized user to Mute/Acknowledge the alarm and to jump

to the device detail screen.

Use the Mute/Ack button to

acknowledge the alarm. When

pressed the alarm will ‘move’ to

the Acknowledge list

To view all system alarms (known as global alarms) use the

Alarms tab (found on the main menu)

Alarm info pop up

Click the detail button to jump to the device

detail screen

Global alarm screen

Global acknowledge list

Global active alarm list

Service screen

Under the service screen tab, test alarms can be congured and

set.

Global cleared alarm list

Status and Service screens

Export Alarms

Export to CSV le

36 | USCO.PI.R1.H2.02 |

© Danfoss | ADAP-KOOL® | 2015.10

Page 37

Quick Setup Guide | System Manager, AK-SM 800

Device detail:

Whilst the Dashboard screen will show basic asset information

(AK-SM unit address, Asset Name, Value, Status and alarm), more

detailed information can be found by double clicking an asset

line in the Dashboard. The resulting device detail screen will

reect more details and settings. The device detail screen is

designed to provide key status and operational settings for the

selected device. Easy navigation to other assets is done via the

navigation tree. The screen image below highlights some of the

main areas of the device detail screen.

Navigation Tree

Status | Settings | Manual Operation tabs

Status

Under the status tab, common read only datapoints are shown

Settings

Under the settings tab, read and write values can be shown.

Double click a line to make changes (if authorized)

Manual Operation

Under the Manual Operation tab, key user override functions are

available

Device alarms/History/Schedules

and Advanced View

Controller group menu (based on the controller type)

‘Snap shot’ history

Full screen button

Use the ‘Advanced view’ screen to access Measurements and

Settings side by side. This screen is useful to access all read/write

parameters for the particular controller

Advanced screen

© Danfoss | ADAP-KOOL® | 2015.10

USCO.PI.R1.H2.02 | 37

Page 38

Quick Setup Guide | System Manager, AK-SM 800

System view:

The system view provides a generic yet graphical view of your

congured controls.

The same principle of the navigation tree can be seen in the left

side of the screen. The system view screen shows any congured

Rack or Pack, with associated evaporator circuits. To see additional information, hover your mouse pointer over an icon, a pop

up box will appear showing additional information. To view

additional information and gain access to settings click the ‘show

Detail’ button. A dashboard will slide across, where a Status,

Settings and Manual operation can be seen. Simply click an asset

to highlight and the detail table will update with reference to this

selected device. Once complete with the device settings, close

the dashboard by clicking the ‘Hide Detail’ button.

System View (Refrigeration)

Gain access to more details via the ‘Show Details’ button

38 | USCO.PI.R1.H2.02 |

© Danfoss | ADAP-KOOL® | 2015.10

Page 39

Quick Setup Guide | System Manager, AK-SM 800

Schedule view:

The schedule view provides a system wide view of schedules

(previously congured) in your AK-SM or host of controllers. The

following schedules are currently supported under the schedule

view;

Shutdown (Generic controllers - i.e. AK-CC)

Defrost (Generic controllers - i.e. AK-CC)

Case Lights (Generic controllers - i.e. AK-CC)

Night Setback (Generic controllers - i.e. AK-CC)

If a host network of AK-SM units are congured, a full system view

can be seen by selecting the folder icon, for a (AK-SM) unit display

click the relevant heading under the folder view. The schedule

screen includes a mouse hover over, that indicates (per circuit) the

schedule times.

Change the graphical view to text (table) form, Print, save as PDF

or save as CSV

© Danfoss | ADAP-KOOL® | 2015.10

USCO.PI.R1.H2.02 | 39

Page 40

Quick Setup Guide | System Manager, AK-SM 800

History (Logs)

To access your AK-SM history, select the history tab.

Upto 8 datapoints can be viewed at any given time on the history

screen.

History Tool bar

When viewing data in the history view the tool bar has a set of

functions to enable various actions to be performed.

Export history function

Export to .hst or csv le format. Saving the collected history

points (as .hst) will allow the user to re-load these at a later date

(via the ‘load history from le’ button

Load history from file

Load a saved .hst le to view

Convert history le to .CSV

Zoom

Page control

Print

Load history group

from le

Preferences

Save history group to le

(Creates a le that contains dened parameters.

This saves time locating the parameters when loading a graph)

40 | USCO.PI.R1.H2.02 |

© Danfoss | ADAP-KOOL® | 2015.10

Page 41

Quick Setup Guide | System Manager, AK-SM 800

Collecting and viewing history

1/ from the history page, press the collect button

2/ Select the required datapoints and time/date range. Multiple

points can be collected but only 8 can be later shown in the

history screen at any given time. After the datapoints have been

downloaded, a dialogue box will appear which provides two

options:

Select points to draw

Save to .hst le (for later view)

3/ The graph will be presented for view and analysis. Use the

zoom buttons or hold the left mouse button and hold for zoom

area. Moving the mouse pointer will show a tool tip with point

description, time/date and value.

Show curves (provides a computed rounding of the analog curve)

Show Symbols (each symbol represents a sample)

Save History Group to le (saving time for frequent datapoint

selections)

This feature allows the user to save a set of history datapoints.

Typically this feature would be used when a set of datapoints is

frequently needed to be loaded and viewed. Once the datapoints are saved, this history group can then be easily loaded thus saving time in selecting datapoints.

Load History Group from le

Use this feature to load any previously save datapoint groups.

When opening the history group le the system will prompt for

the le location. Once loaded a ‘select datapoint’ box will appear

with the datapoints already pre-selection

Export History data

This feature allows the user to export the previously collected

history data. A pop up window asks the user to select a le

format, the following formats are possible;

.hst (Danfoss history le format)

.csv (Excel compatible spreadsheet)

Saving any collected history as a le allows for future loading and

view, use the ‘Load history from le’ button to load any saved

history les.

© Danfoss | ADAP-KOOL® | 2015.10

USCO.PI.R1.H2.02 | 41

Page 42

Quick Setup Guide | System Manager, AK-SM 800

Updating Software (via USB Flash Drive)

The AK-SM can read & write to USB ash based drives. Upon

insertion (or via main menu option 7), the USB menu window will

be shown (for DIN units read following section). A typical

example of the resulting pop up screen can be seen below, with

descriptions for each option. The menu reects supported les

located on the USB memory stick, and may vary from the

example below. Ensure relevant software les are located in the

USB root directory. When updating your AK-SM it is recommended to rst update the ‘Bootloader’ (if specied), followed by

the Master Application Image (MAI). The MAI contains AK-SM

rmware, EDF and Web les needed.

Bootloader le- used for AK-SM system le management

AK-SM Application code (does not include EDF/HTML les)

Master Application Image (includes rmware, EDF and HTML les)

Save AK-SM database (does not include any graphic view les)

Load a SM-800 database

Save AK-SM system conguration as .txt le

File type / Description Method of loading

Boot.csi / Boot Loader le (required for system le management) USB Flash drive

CSI / Application code for AK-SM. Includes all system EDF les USB Flash drive or RMT tool

MAI / Master Application code for AK-SM. Includes all rmware, EDF and Web les USB Flash drive or RMT

Flash Drive options

Option 1: The Bootloader le can be updated via USB connection.

Option 2: The Application software can be updated via USB

connection.

Option 3: Master Application Image (MAI). This is the recommended le to update your AK-SM, it contains rmware, EDF and

Web les

Option 4: Save AK-SM database via USB

Option 5: Load AK-SM database via USB

Option 6: Save report (txt le format, containing main system

conguration details)

Option 7: Save Report (txt le format, containing congured

system status, not full conguration details)

FAI / Factory Application Image USB

Remotely Upgrading you AK-SM unit - what is the FAI le

Your AK-SM has the ability to be upgraded via a remote connection (RMT). Upgrading via remote oers several advantages, the

obvious one being time saving. However, this is increased risk

when preforming remote upgrades (i.e. quality of connectivity,

power..). Software version 03_051 (and above) comes with an

additional extension, FAI (Factory Application Image). The FAI

software le contains special code designed to support remote

software upgrades. The FAI le provides a ‘fall back’ state, if at

any time a later remote upgrade fails or gets corrupted. Rather

than leave a unit in a unstable state in the event of a corrupted

remote upgrade, the factory image ensures you can always make

contact to re-install code again. In addition, the FAI contains the

MAI, which also contains all relevant web and EDF les. Via the

Info screen, check if your AK-SM unit has a Factory Application

installed. For future remote upgrades it is recommended that the

FAI is installed if it is not already present in your system. The AKSM can run without the FAI, with rmware updates being done

via the MAI le.

Under the Info->Information tab, check to see if a Factory Application

is installed (FAI).

If you intend to perform remote software updates, Danfoss recommends the loading of the FAI le.

Recommended method for upgrading your AK-SM - Bootloader

The AK-SM bootloader le is a critical le that manages system