Page 1

User Guide

AK-System Manager

AK-SM 800 Series

ADAP-KOOL® Refrigeration Control System

www.danfoss.com

Page 2

User Guide | AK-System Manager, AK-SM 800 Series

Contents

Chapter 1: Product Introduction

Product Introduction ....................................................................................... 3

Specifications ..................................................................................................... 4

Chapter 2: Installation and start-up configuration

Installation ........................................................................................................... 5

Connections ........................................................................................................ 7

Network topology ............................................................................................ 7

Lon RS485 Topology .............................................................................. 8

MODBUS topology ................................................................................. 9

First time startup ............................................................................................. 10

AK-SM 800 Host Network Configuration ................................................ 10

Connecting to AK-SM 810 ............................................................................ 12

Initial Configuration - language.................................................................13

Remote Management Tool (RMT) ............................................................. 14

System Upload / Download ........................................................................ 15

Device Management

(Configuration/System/Device Management) ..................................... 16

IP Configuration and suggested security settings ............................. 17

Chapter 3: Navigation and use

General navigation, operation and use (via web) ............................... 19

Connecting to your AK-SM .......................................................................... 19

Dashboard view ...............................................................................................19

File.........................................................................................................................20

Auto History Log Collection ........................................................................23

Auto Alarm Log Collection .......................................................................... 24

Managing alarms .............................................................................................25

Device detail .....................................................................................................26

System view ......................................................................................................27

Schedule view .................................................................................................. 28

History (Logs) ....................................................................................................29

Collecting and viewing history .................................................................. 30

Chapter 4: Configuration

Initial Configuration - Web Wizard ........................................................... 32

Copy Wizard ......................................................................................................35

Network Nodes ................................................................................................36

System configuration (Time settings / preferences) ..........................37

Communication ...............................................................................................40

Alarms..................................................................................................................40

Control tab .........................................................................................................47

Chapter 5: Master Control Functions

Rail Heat ..............................................................................................................53

Schedules ........................................................................................................... 56

Customized control ........................................................................................ 59

Suction Pressure Optimization .................................................................. 60

Adaptive Liquid Management ...................................................................62

AKC ON (Evap shutdown when injection off) ......................................63

Coordinated Adaptive Defrost ..................................................................64

Chapter 6: Advanced features and configurations

Managers Override .........................................................................................65

Light .....................................................................................................................66

Lighting Configuration .................................................................................66

Dimming control via AK I/O ........................................................................69

HVAC Configuration .......................................................................................71

Miscellaneous Configuration ......................................................................74

Energy .................................................................................................................87

Energy Configuration ....................................................................................87

Energy Measurement / Load shed ............................................................ 91

Detail Energy ...............................................................................................93

Enterprise Load Shed (via Danfoss EDS Service) .................................94

Demand Limiting ............................................................................................95

Boolean Logic / Calculations ......................................................................96

Chapter 7: Device support

Danfoss AKC Support (Via AK-PI 200) ......................................................98

Service Tool Support....................................................................................102

CoreSense™ (MODBUS) Support ............................................................ 103

AK-SM 800 Device support guidelines ................................................. 104

Chapter 8: Miscellaneous

Recommended method for upgrading your

AK-SM 800 series front end ...................................................................... 105

Ordering .......................................................................................................... 108

Document History ....................................................................................... 108

Glossary of terms .......................................................................................... 109

2 | BC316842192932en-001001 © Danfoss | DCS (vt) | 2020.03

Page 3

User Guide | AK-System Manager, AK-SM 800 Series

Chapter 1: Product Introduction

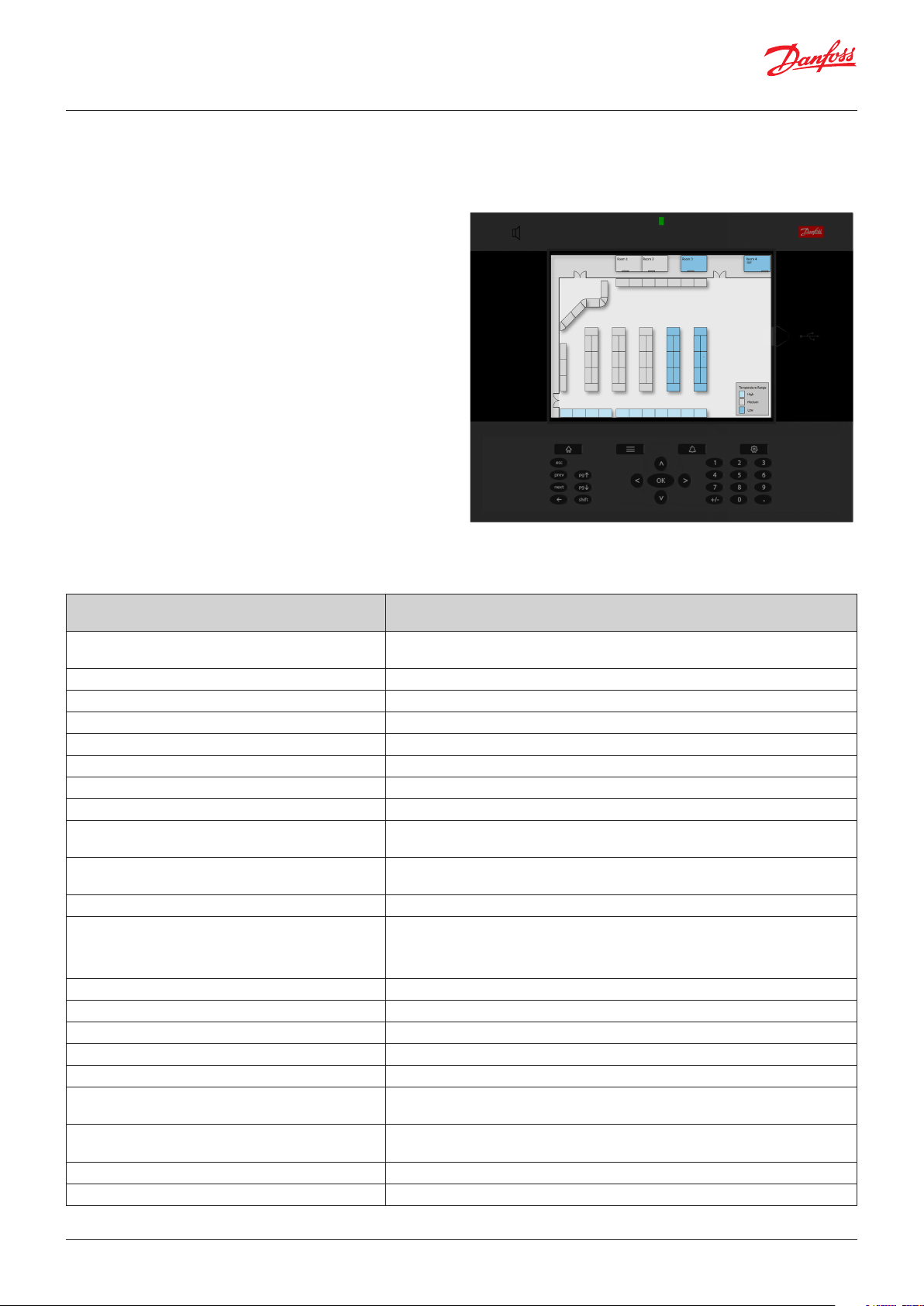

Product Introduction

Your Application

The Danfoss AK-System Manager (AK-SM) is a modern solution for

the food retail markets. The AK-SM uses the latest technology to

provide the maximum benefit to the end user, both in terms of

energy saving optimization, control options and user friendly

access. Designed specifically with the food retail applications in

mind, the AK-SM provides all the functionality and tools to

provide full application ‘coverage’, for the Refrigeration control

and monitoring application.

The Danfoss AK-SM represents the most flexible answer to today’s

demands & balances cost effective control, continuous energy

optimization and long term flexibility via miscellaneous inputs

and boolean logic commands, all built in to one easy to use front

end controller.

Modern Technology at work for you

Modern tools like the built-in USB flash drive port allows for easy

firmware updating & saving of the database. All part of the AK-SM

package is the Remote Management Tool, a simple yet powerful

application that allows remote updates, software management

and the saving of databases on the AK-SM. Full remote access is

powered by the AK-SM built in web server, providing you with an

advanced web browser environment in which to control, view &

monitor all your important assets.

AK-SM Headline Features

*License dependent

Refrigeration Control (centralized and de-centralized

methods)

Energy saving technology (built in) Master control, Suction optimization, scheduling, enterprise load shed

Schedules Groups Central Defrost, Case lighting, Store / Outside Lighting, Night setback, Shutdown

Flexible Alarm Routing / Output e-mail, IP address, relay

Built in MODBUS, LonWorks® network More scope for control solutions - Established protocols

Full color VGA Local screen view & access Access all areas of your system from easy to use local screen

Built in Buzzer & 2-tone LED Easy local level alarm notification

Support for Danfoss AK I/O modules I/O module support offering extended and flexible control, monitoring

Local screen custom graphics Create simple & clear graphic screen with only ‘key parameters’ shown - simply the

Consolidated store view Show a consolidated web view of your store, not just individual AK-SM controllers. View

600 History points Large history storage capacity to ensure HACCP compliance & service level detail

Web browser custom graphics Create custom web graphics that present in the AK-SM web screens. Map any datapoint

Multiple users / user levels Definable user list with clear authorization levels

Multiple language support Local & Browser language support

USB flash drive support (load,save and update software) Reduce commissioning time & Cost

Full web browser access Standard web browser connection provides access to all areas of the system

Built in Boolean Logic commands Create your own logic to control even the most obscure application

Remote Management Tool Remotely manage your system - Update software, save database, controller file

Service Tool support Gain access to Danfoss AK2 based controls via Service Tool tunneling

Control and monitor your Refrigeration application via centralized (Rack) or

de-centralized (Case/Pack) dependent on your control needs.

management of your services. Max.5 BMP’s max. 100 log points each

all data from all interconnected AK-SM devices in common web browser pages

from any AK-SM controller and vizualize in the web.

Max.5 JPG’s max. 200 log points each

management, load images, allowing custom image & mapping of parameters

Benefits

HVAC Control AK SM 820 and AK-SM 880 offer HVAC support

Lighting Control All systems support Lighting Control

© Danfoss | DCS (vt) | 2020.03 BC316842192932en-001001 | 3

Page 4

User Guide | AK-System Manager, AK-SM 800 Series

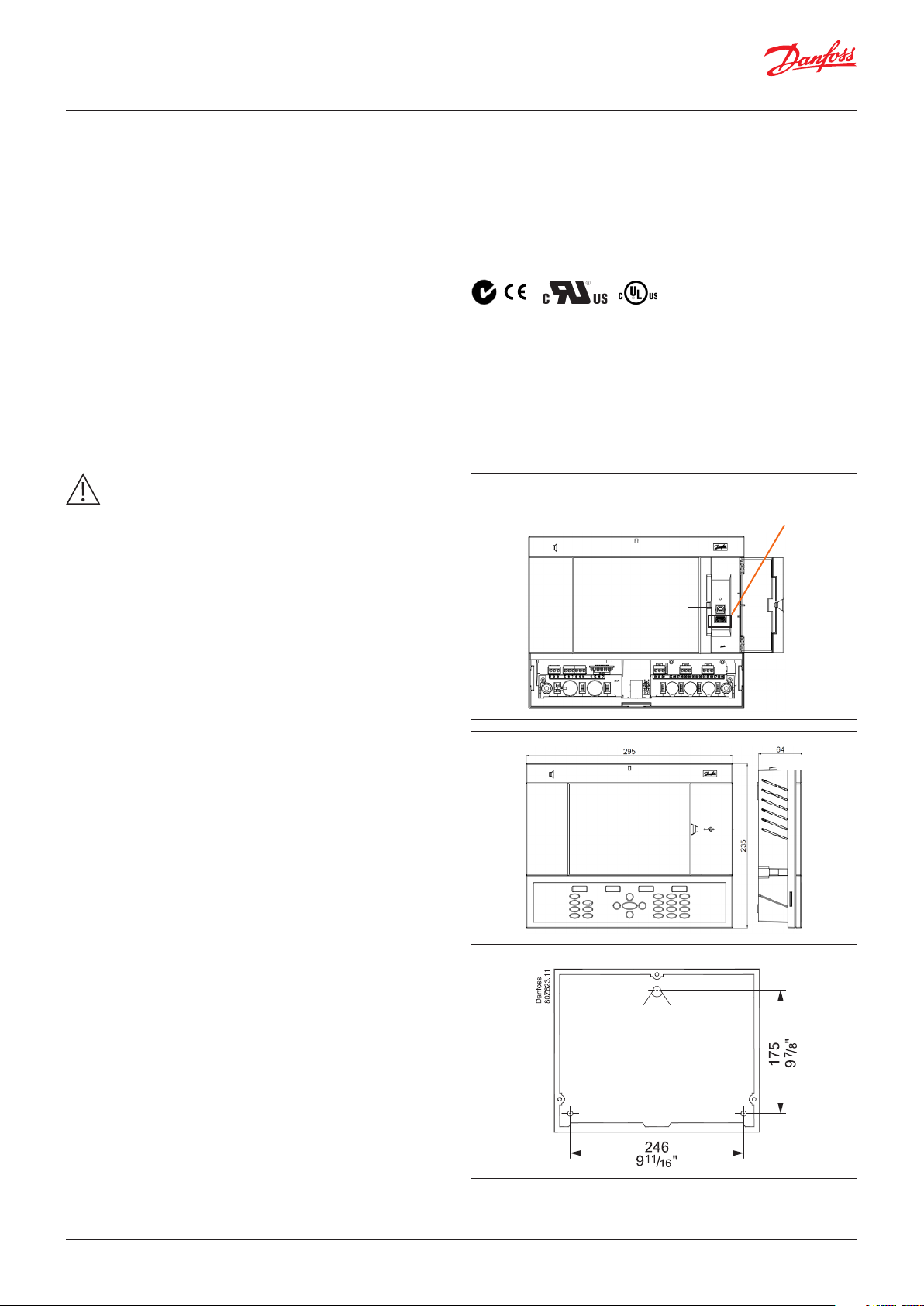

Specifications

The mounting location should be flat, dry and free of major

vibrations. The AK-SM 800 should be mounted at eye level.

Environmental Range:

Operating temperature:

-10 – 55˚C (14 – 131˚F)

@ 90% RH (non condensing)

IP20

Electrical range:

~ 100 – 240 V AC 50/60 Hz, 12 W

Built in alarm relay,

Contact voltage: Up to 240 V, Load: AC-1 (Ohmic) Current rating.

5 Amp AC-15(inductive) Current rating. 3 Amp

LCD

Active TFT colours (thin-film transistor), SVGA 800 x 600

Size

Unit Width 295 mm (11.6”), Unit Height 235 mm (9.3”),

Unit Depth 65 mm (2.5”)

Mounting holes 246 mm (9.7”) Width

Mounting holes 175 mm (6.9”) Height

Approvals:

Declaration of conformity info

- Regulation 2005/37/EC

- EN 12830, 07-1999

- EN 13485, 11-2001

- HACCP 080R1215

- CE 080R1213

- C-Tick 080R1214

- UL E31024

WARNING: To avoid risk of injury from electric shock,

ensure correct electrical isolation is made before

working within the enclosure.

USB Access door

Active USB Flash drive (use for load/save database and

AK-SM software) User Authorization required’

Not currently Used

65

4 | BC316842192932en-001001 © Danfoss | DCS (vt) | 2020.03

Page 5

User Guide | AK-System Manager, AK-SM 800 Series

Chapter 2: Installation and start-up configuration

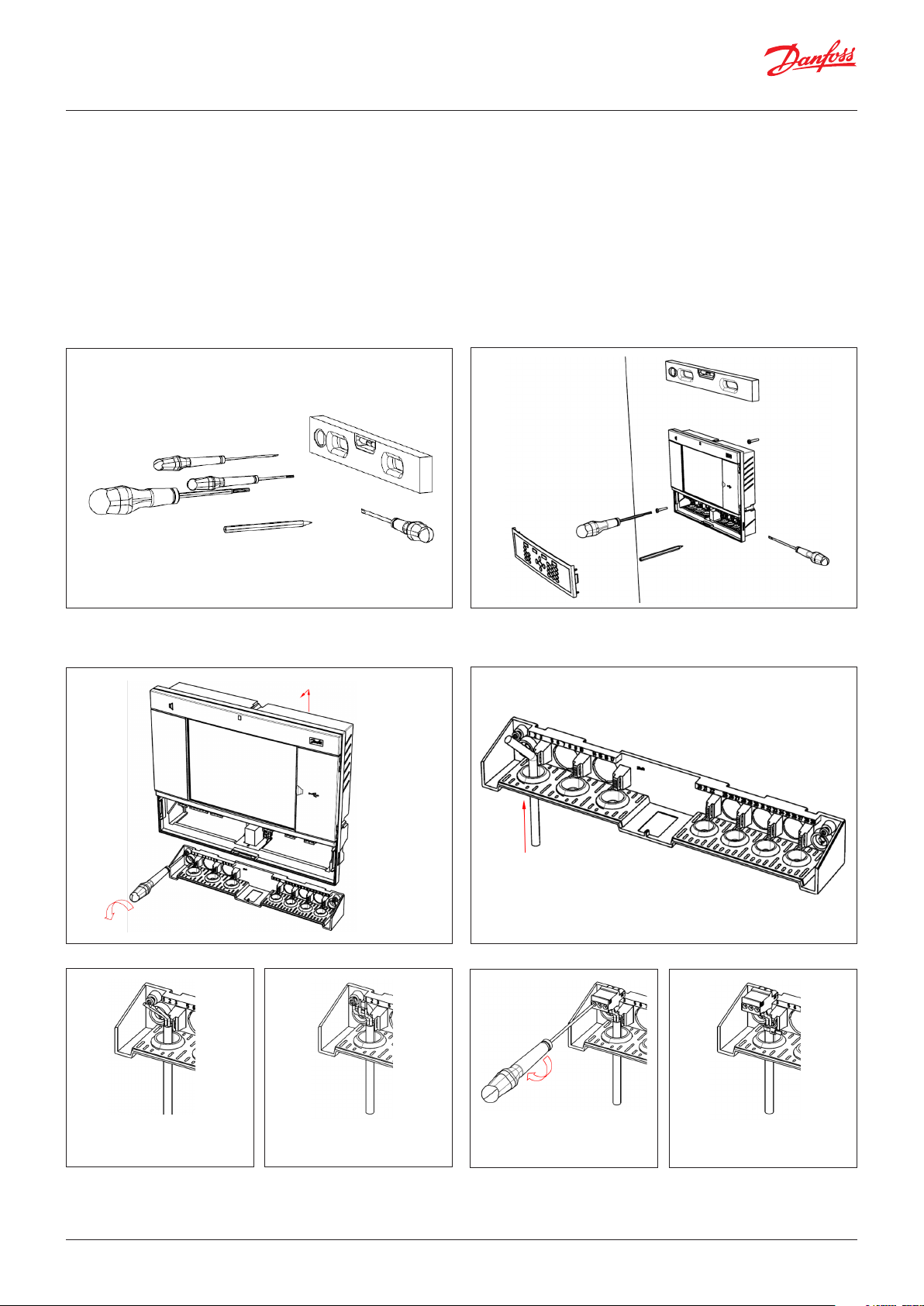

Installation

Tools needed

1. Bubble level

2. Small slotted screwdriver for connector screws

3. Torx 8 screwdriver for releasing the electronic unit and for

fastening the unit when recessed mounted

4. Screwdriver for fixating the AK-SM 800

5. Pen for marking the 2 lower fixation holes

6. Larger slotted screwdriver for releasing the Technician lid

Wall Mounting- box

1

1. Attach screw to the wall

2. Mount AK-SM 800 to the screw

3. Loosen Technician lid (three sides)

4. Remove Technician lid

5. Level the AK-SM 800

6. If drilling is necessary, mark up 2 screws in Connector part.

7. Attach the Connector part to the wall using another 2 screws

Wall Mounting- wiring

Insert cables through the rubber grommets

Strip the cables Strip the wires

Secure wires in

Strain relief the cables

connectors by screwdriver

1

For installation in countries where UL Listing is required, please refer to the installation instruction provided with the product.

© Danfoss | DCS (vt) | 2020.03 BC316842192932en-001001 | 5

Page 6

User Guide | AK-System Manager, AK-SM 800 Series

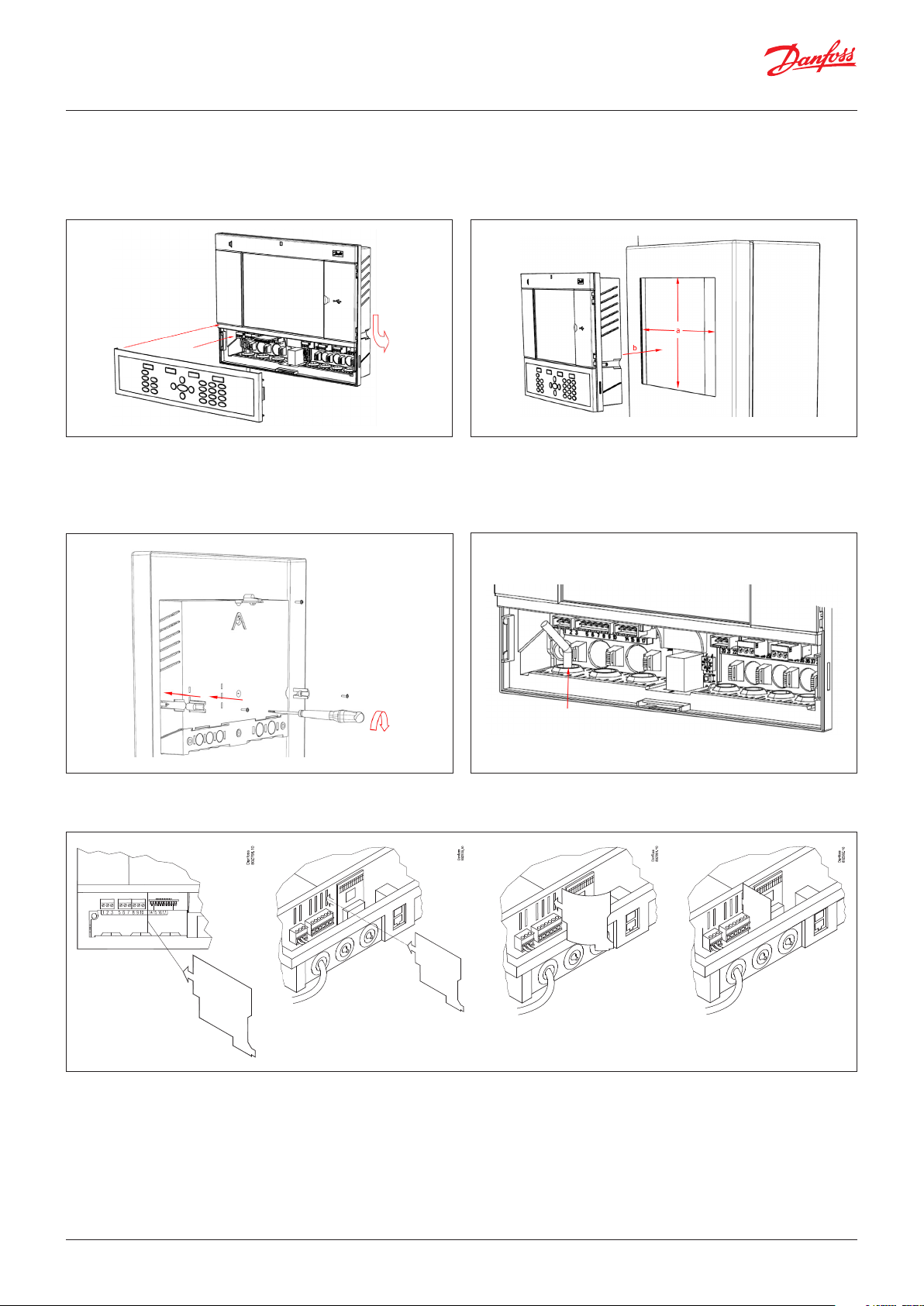

Carefully replace the keypad, ensure that it securely snaps into

place

From the backside:

Slide the 3 fastener into the housing part

The screws are inserted into the fasteners

Secure the unit by tightening the screws

Wall Mounting- Panel recessed

From the front:

A hole of the size 280 x 220mm is machined

The AK-SM 800 is inserted in the hole

Remove Technician lid

From the back, push cables inside the housing

Insert the plastic divider to separate and make sure firmly snaps into place.

The plastic insert is provided in the accessory bag and is required for panel mounting the unit where UL Listing is required.

6 | BC316842192932en-001001 © Danfoss | DCS (vt) | 2020.03

Page 7

User Guide | AK-System Manager, AK-SM 800 Series

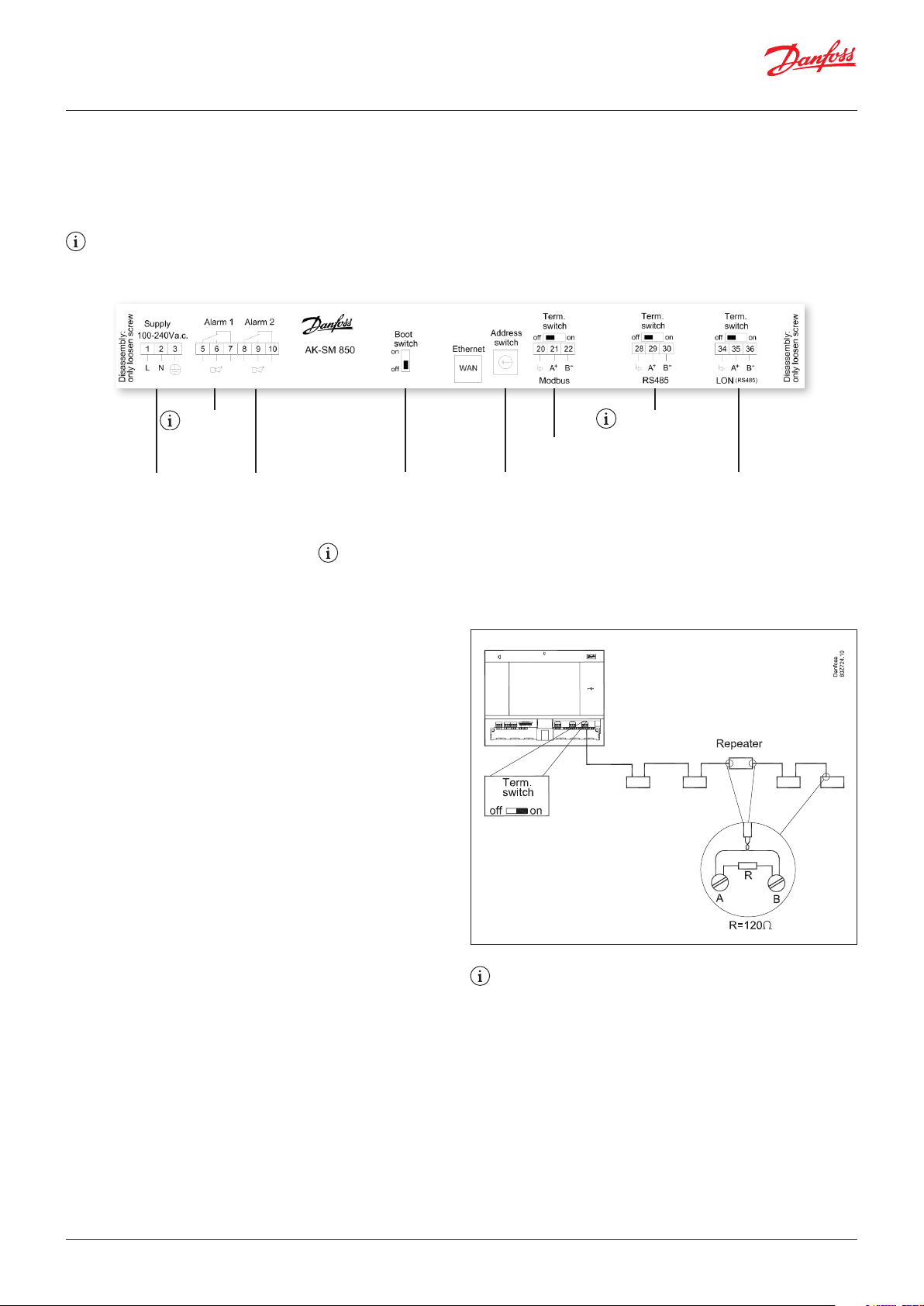

Connections

The following chapter describes the available connections on

your AK-SM 800.

Please note that not all connection points are currently

active, please refer to the drawing below for more details

not cu rrently

used

Power Supply Alarm relay

(used to place unit in

Boot switch

boot loader mode)

RJ 45 LAN, Use shielded Ethernet cable

Network topology

Your AK-SM supports both MODBUS and Lon RS485 local bus

connections. For further detailed description of network

connections please refer to document ‘Data Communication

between ADAP-KOOL® Refrigeration controllers_RC8AC802’

Lon RS485

Follow standard topology guidelines for Lon RS485, with

particular respect to maximum cable length, when to use a

repeater and ensuring suitable resistors are in place.

Cable type

Cables twisted in pairs must be used, and they may be provided

with a screen. Some types of communication require a cable with

a screen to be used.

Examples:

For Lon RS485, MODBUS, RS485 Third party - General ‘EIA 485’ recommendation:

- Belden 9841, 24 AWG, 1 pair with screen

- Belden 3107A, 22 AWG, 2 pairs with screen

- Smartwire 043006AL, 22 AWG, 1 pair with screen

- Alpha wire 6453, 22 AWG, 1 pair with screen

- Carol C4841A, 24 AWG, 1 pair with screen

- Dätwyler Uninet 3002 4P 4 pairs with screen(CAT5 cable)

For Lon TP78 communication - Level 4 cable general

recommendation:

- Belden 7703NH, 22 AWG, 1 pair with screen

- Belden 7704NH, 22 AWG, 2 pair with screen

- Smartwire 106500, 22 AWG, 1 pair with screen

Wires with larger cross-section than AWG 22 is not recommended.

( Eg. AWG 20 and 19).

not currently used

MODBUS field bus

Address switch

(used when configuring

multiple SM units

When using the Lon RS485 network, ensure the Term. Switch

on the AK-SM is in the ‘ON’ position (enable internal resistor).

Any repeaters must also have 120 Ohm resistor in place.

Finally, ensure that the last controller on the network run also

has its end of line on line resistor enabled.

Lon (RS485)

field bus

© Danfoss | DCS (vt) | 2020.03 BC316842192932en-001001 | 7

Page 8

User Guide | AK-System Manager, AK-SM 800 Series

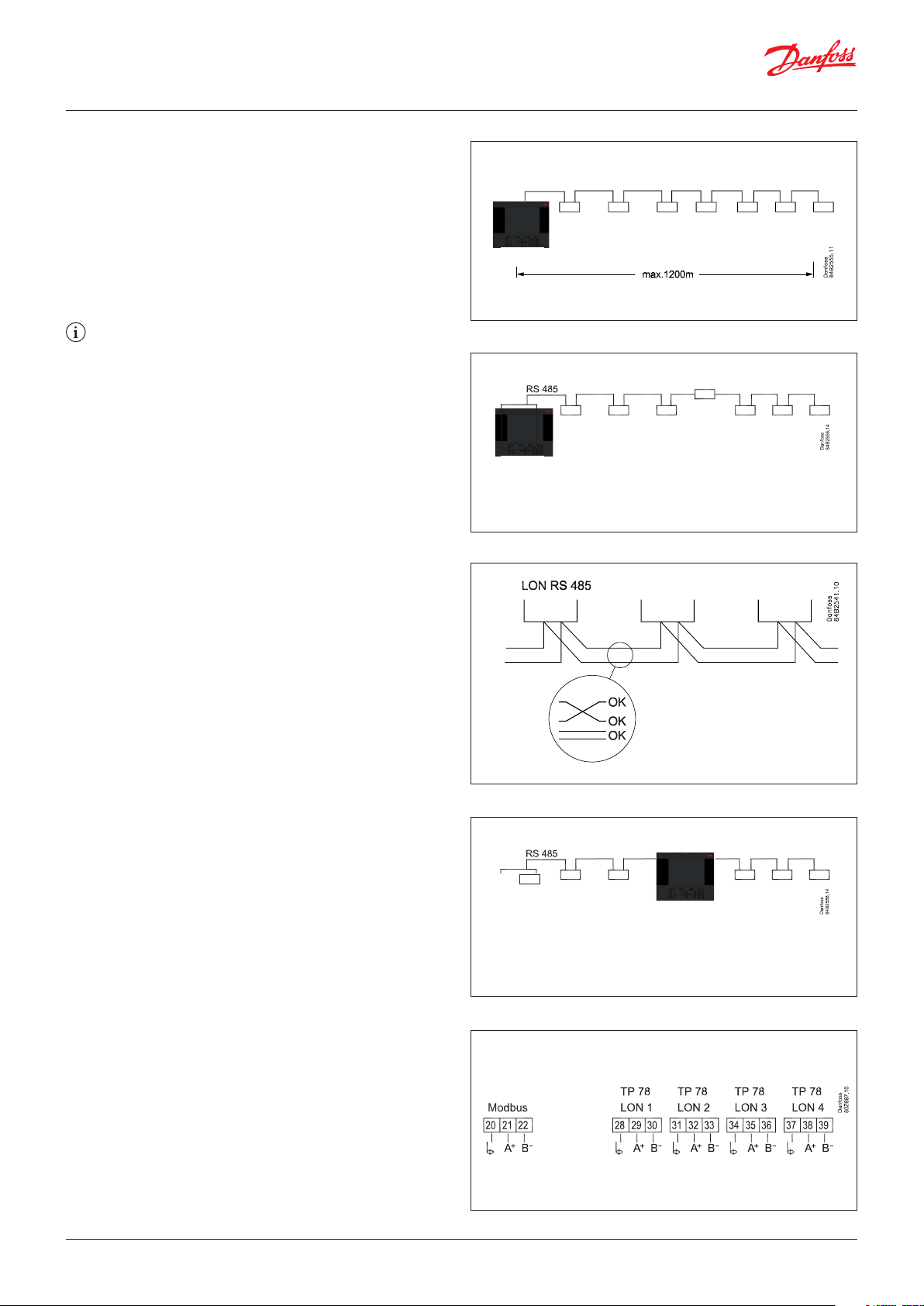

Cable length

A cable length must not exceed 1200 m (4000 foot). A repeater

(Part # 084B2241 ) must be used for longer lengths.

Lon RS485 Topology

The cable connection must be connected from controller to

controller, and no branches are allowed on the cable. If the

cable length exceeds 1200 m a repeater must be inserted. If the

data communication cable runs through an electrically noisy

environment which impairs the data signal, one or more repeaters

must be added to stabilise the signal.

When configuring Lon devices on the control bus, the

highest device address that can be can be used is 127 (max.

120 controller in total)

Remember to use 120 Ohm terminators on the last filed bus

controller device. Note also to enable (ON) the Term. Switch,

located above each network connection point on the AK-SM 800,

this will enable the built in terminator(s) for each network point

on the AK-SM 800.

Conductors

The two wires are looped from device to device. There are no

polarisation requirements. (On some controllers, the clamps are

designated A and B. On others there is no designation. Otherwise

the connections are identical.) If a screen is used, it must be

connected to the system device and any repeaters. A screen must

always be looped from device to device.

The screen must not be connected to anything else. (The screen is

earthed inside the screen and must not be earthed in any other

way.)

R=12 0 ohm

AK-SM

R=12 0 ohm

AK-SM

Mid network connection

This example shows the AK-SM 800 series RS485 version used in

the middle of a network run. In this example ensure that both

ends of the controller run are fitted with 120 Ohm terminators.

Over the past several years Danfoss has offered a version of the

AK-SC 255 and AK-SC 355 which has a LonWorks® option of TP78.

As a physical layer of the LonWorks® protocol these older systems

offered x5 network connection points. Due to the global phase

out of the TP78 option by the OEM, Danfoss has made available a

special order version of the AK-SM 880 (080Z4009), which will

come pre-installed with a LonWorks® TP78 options card. This

‘special’ version of the AK-SM 880 is designed to support

customers who wish to migrate from existing AK-SC 255 and

AK-SC 355 TP78 systems. Please note that this version of the

AK-SM 880 is not intended or available in Europe’ , and offers x4

TP 78 connection points.

R=12 0 ohm

TP 78-Version

RS 485

R=12 0 ohm

AK-SM

8 | BC316842192932en-001001 © Danfoss | DCS (vt) | 2020.03

Page 9

User Guide | AK-System Manager, AK-SM 800 Series

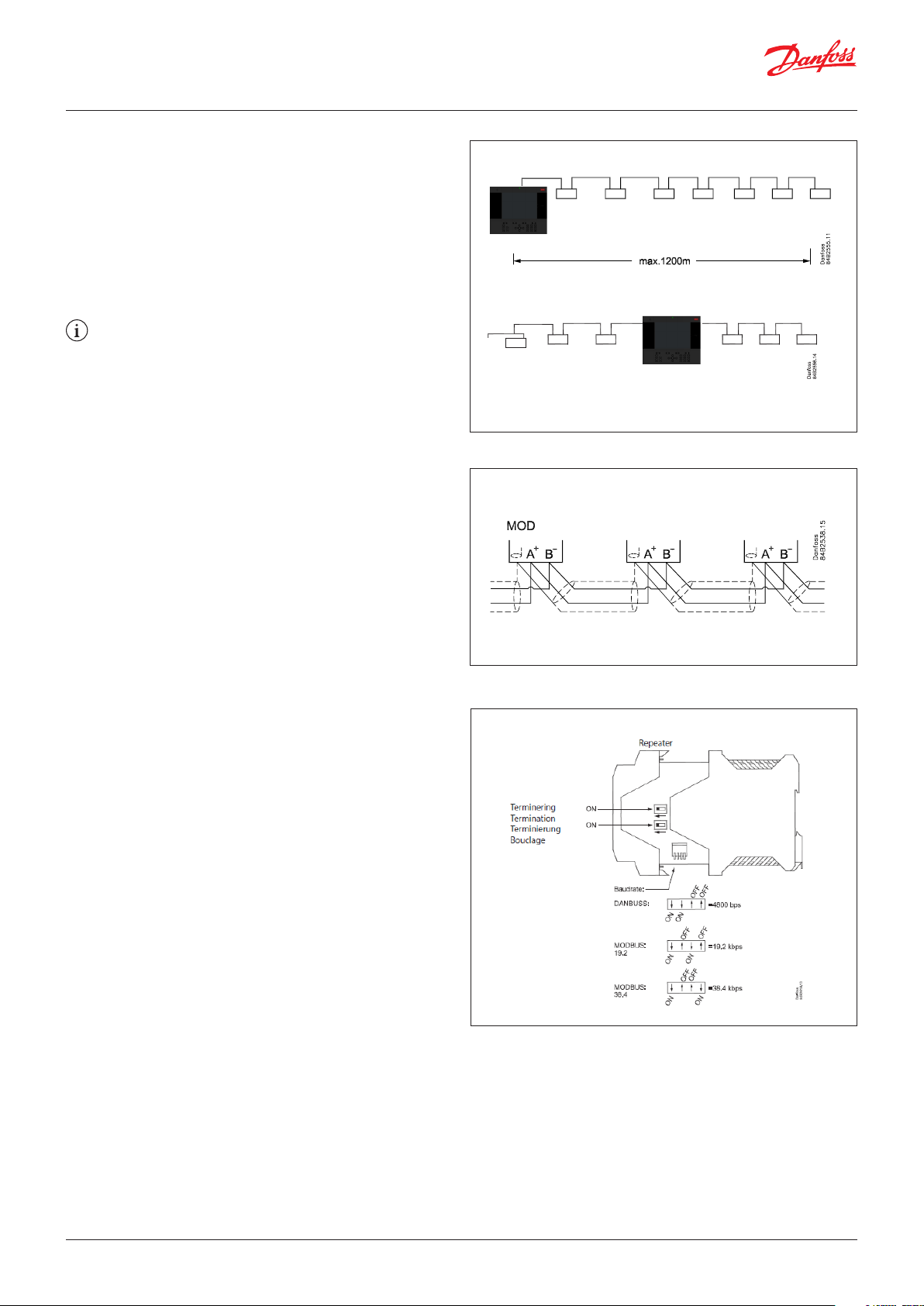

MODBUS topology

The cable must be with screen. The cable is connected from

controller to controller, and no branches are allowed on the cable.

If the cable length exceeds 1200 m a repeater must be inserted. If

the data communication cable runs through an electrically noisy

environment which impairs the data signal, one or more repeaters

must be added to stabilise the signal.

‘The System Manager can be inserted in middle of network,

ensure System Manager termination is OFF. Refer to Danfoss

document ‘RC8AC802 Data Communication’.

When configuring MODBUS devices on the control bus, the

highest device address that can be used is 199 (max. 120

controller in total)

The wires are looped from device to device.

A is connected to A

B is connected to B.

The screen must be connected to the system device, all controller

and any repeaters.

A screen must always be looped from device to device.

The screen must not be connected to anything else.

AK-SM

MODBUS

R=12 0 ohm

MODBUS

R=12 0 ohm

AK-SM

Be sure to configure the MODBUS repeater AKA 222

(code#084B2240) to the correct baud rate.

See notes section at the back of this guide for MODBUS device

baud rate properties.

Refer to Danfoss Instructions RI8KN402 for further details on the

AKA 222 repeater’

© Danfoss | DCS (vt) | 2020.03 BC316842192932en-001001 | 9

Page 10

User Guide | AK-System Manager, AK-SM 800 Series

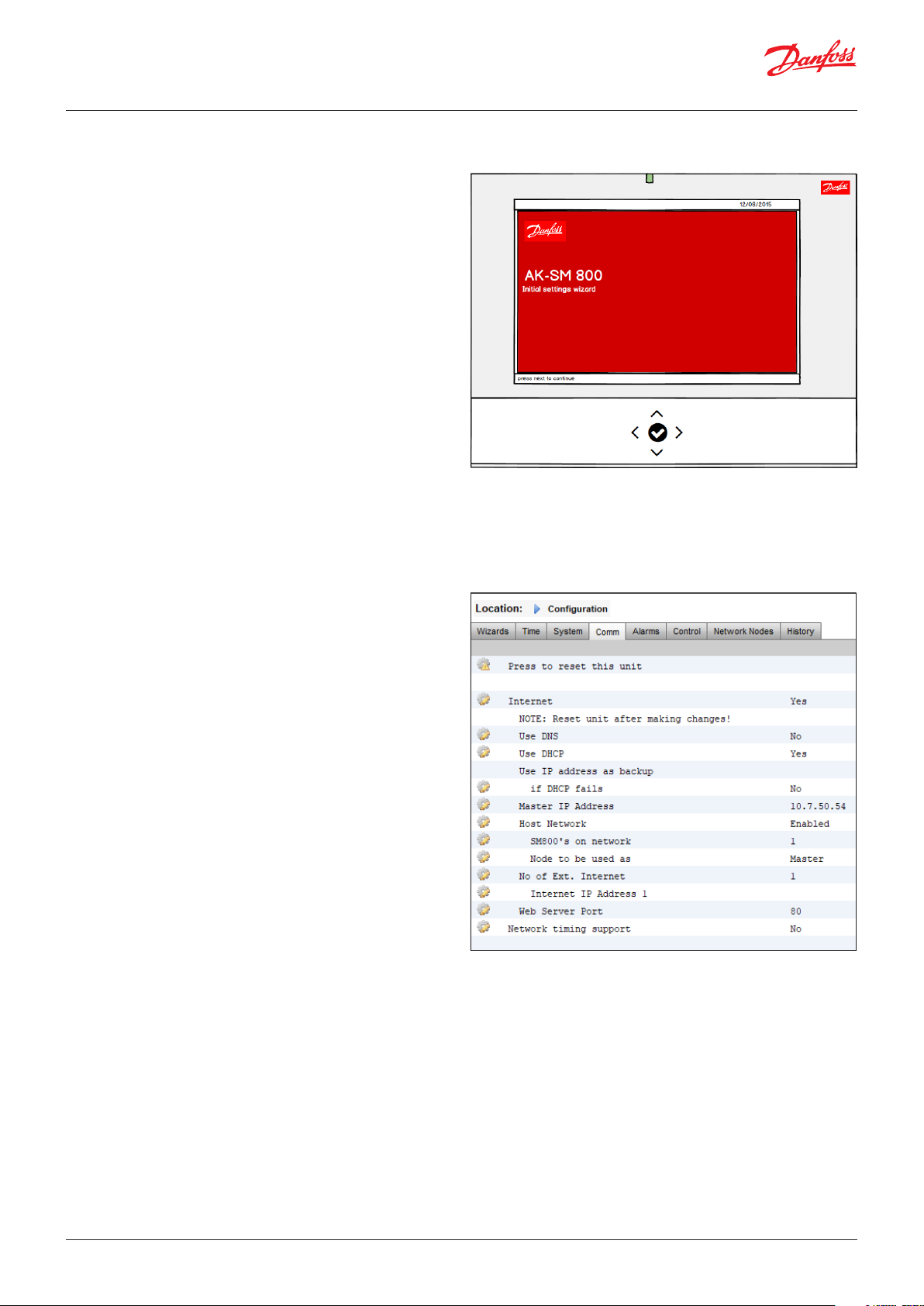

First time startup

A new feature in 08.045 is initiated when installing and powering

up your AK-SM 800 series for the first time, a wizard style guide

will appear on the local screen. The idea of this initial settings

wizard is to allow the Commissioning user to configure the basic

parameters required for setup. Note that once a AK-SM 800 series

database field has been set, the initial settings wizard will no

longer be displayed, the work-flow is only designed to run once

on new systems.

The following screens will be presented in the initial settings

wizard;

LANGUAGE (this selection will also set the system units of

measurement)

DATE/TIME

PREFERENCES

USERS/PASSWORDS

COMM

After completion of the settings wizard the AK-SM 800 Series will

request a reset, where settings will saved. Commissioning

activities can now continue using Web wizards and control

screens

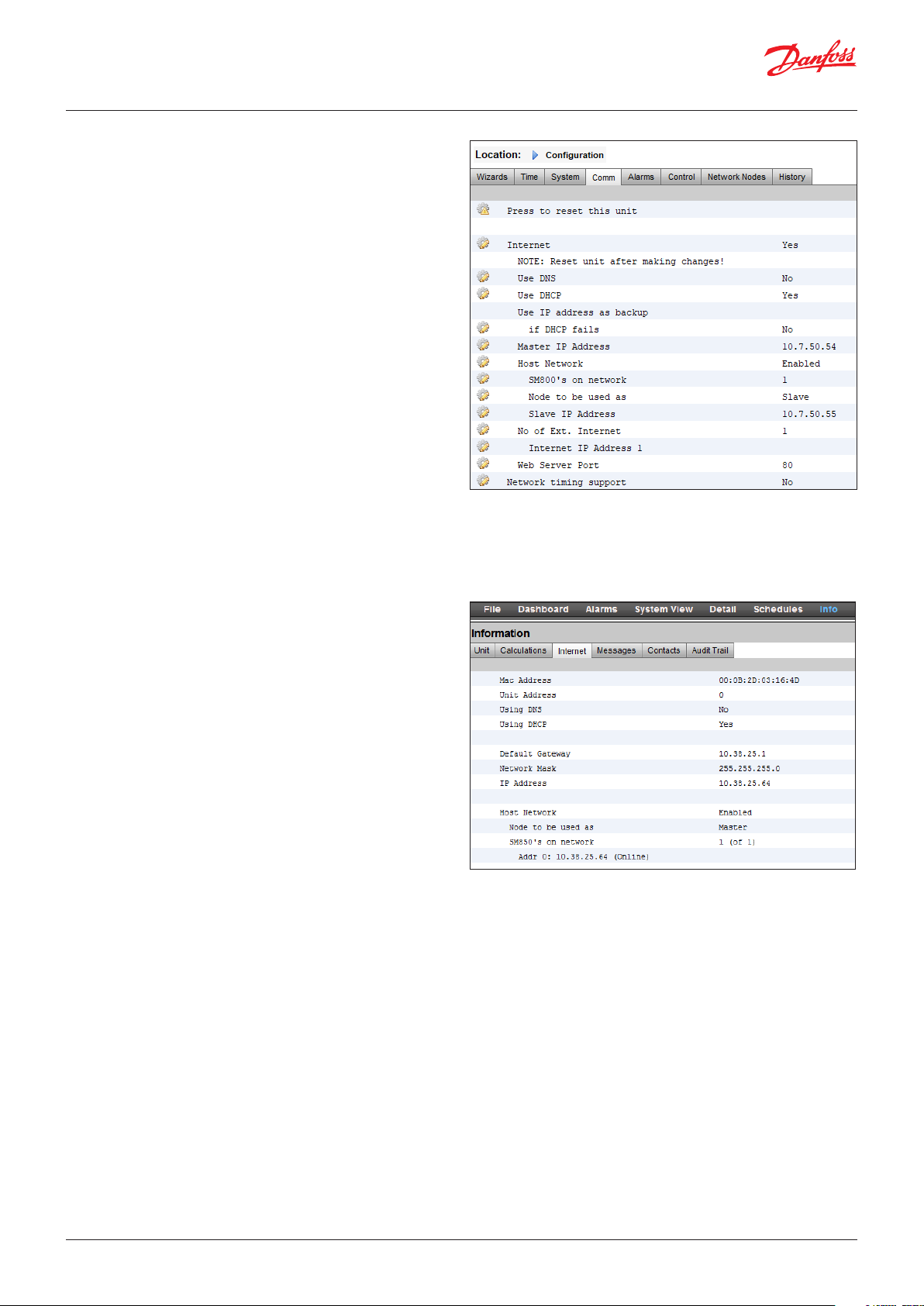

AK-SM 800 Host Network Configuration

The following section describes how to configure your AK-SM 800

to facilitate a host network. The AK-SM 800 host network can

support up to a max of 10 interconnected AK-SM800 units. The

practice of interconnecting on a host network allows for support

of larger applications or to separate discrete control applications

onto dedicated AK-SM 800 units. For example HVAC and

Refrigeration control could be done via dedicated AK-SM 800

units. The host network requires an IP Ethernet connection to

each AK-SM 800 unit. Once configured all AK-SM 800 units can be

viewed in a consolidated format via a web browser of via the

StoreView Desktop. Note that the consolidation view is only

available via the browser or StoreView desktop, not local screens.

Master device configuration

Make sure you have suitable fixed IP or DHCP addresses for each

of your AK-SM 800 units you wish to deploy on the host network.

Also ensure all Ethernet cables are connected.

Make sure the rotary address switch (located behind keypad) is

set to 0. Zero defines your AK-SM 800 as the master node on the

host network.

Navigate to the Configuration/Comm screen and check your unit

has a valid Master IP address. Set the ‘Host Network’ question to

Enabled. Enter the number of System Manager units you intend

to have on the host network.

After all changes are complete reset the master AK-SM 800 unit

10 | BC316842192932en-001001 © Danfoss | DCS (vt) | 2020.03

Page 11

User Guide | AK-System Manager, AK-SM 800 Series

Slave device configuration

Make sure the rotary address switch (located behind keypad) is

set to the appropriate number. For example, setting the switch to

1, will define the unit as a slave device address 1. All units in the

host network must have unique host network addresses (address

0 is always master).

Once you have set the rotary address switch, reset the unit and

allow the AK-SM 800 to boot up. Navigate to the Configuration/

Comm screen and check your unit shows the Master IP address.

Set the ‘Host Network’ question to Enabled. Enter the number of

System Manager units you intend to have on the host network

(matching what you have already set in the master unit)

Make sure the slave unit has a valid IP address.

To validate the host network has been correctly configured and

all System Managers can see each other refer to the Master unit

‘info’ screen. Here you should see all AK-SM 800 on the host

network

© Danfoss | DCS (vt) | 2020.03 BC316842192932en-001001 | 11

Page 12

User Guide | AK-System Manager, AK-SM 800 Series

Connecting to AK-SM 810

This section describes the steps in making an initial connection to

the (screen-less) AK-SM 810 product. Once initial connectivity has

been established, the system can be configured using standard

workflows, as all menus, features and functions are identical to

the AK-SM 820.

1. Set the rotary address switch to position 9 and power up unit.

By setting address 9 the SM810 will be set to a fixed IP address

of 192 .168.1.161

2. Connect to the AK-SM810 via a suitable Ethernet cable to your

PC, which should be running either RMT or StoreView Desktop

3. Using the address 192.168.1.161 connect to the AK-SM 810, log

in using either factory set User Name and Password (Supervisor

\ 12345) or what has previously been defined

4. After system configuration has been completed, it is

recommended to apply a known fixed IP address in the

Configuration > Comm screen. By adding a fixed IP address it

will ensure subsequent connections can repeatedly be

performed without issue.

5. Power Off the AK-SM 810

6. Set rotary switch to 0 (is used as Master), else set to desired

slave address

7. Power unit up and validate connection by using static IP

address used in the Comm screen

8. Make sure that the web port is not changed to port 1041.

Doing so will render the unit unaccessible!

Port 1041 is reserved for AK-ST 500 service tunnelling and does

not provide access to the web interface.

12 | BC316842192932en-001001 © Danfoss | DCS (vt) | 2020.03

Page 13

User Guide | AK-System Manager, AK-SM 800 Series

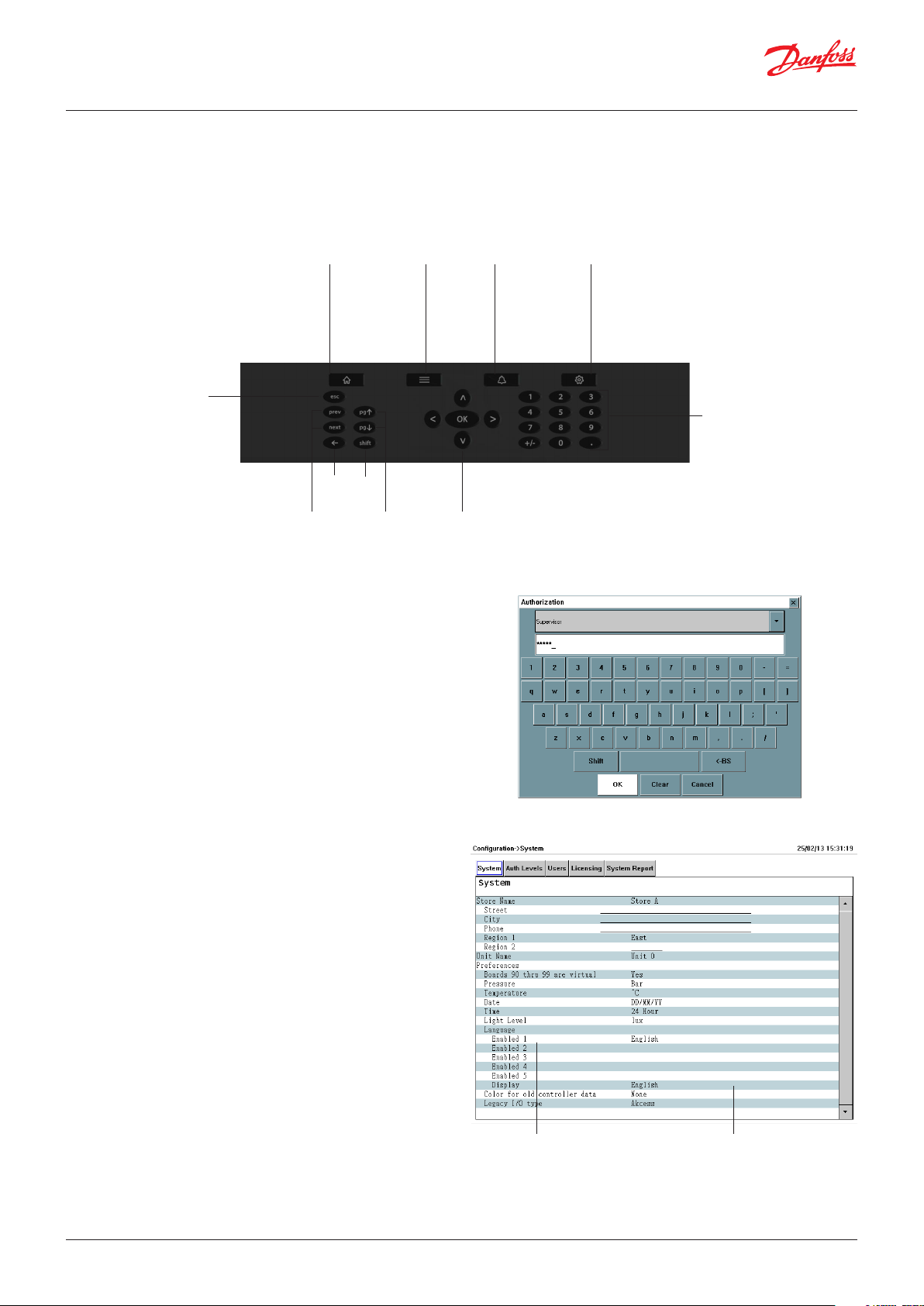

Initial Configuration - language

The following section describes the recommended actions to get

your AK-SM up and running.

Escape

Home

(System View)

Back Shift

Previous

Next

Page Up

Page Down

Menu

Menu Navigation

The following section describes the recommended actions to get

your AK-SM up and running.

Local keypad - button layout

Setting language for local SM display

Your AK-SM can display several different languages. The

factory default the unit will display English, in addition your

required language can also be enabled. Follow the simple

Alarms Configuration

Numeric keypad

Note: The AK-SM 800 supports standard USB keyboards. This may

offer a more convenient method of text input whilst in the

commissioning phase. Use the USB socket (located behind the

front panel lid).

Steps below to display your preferred language in the local

screen;

1. Press the Configuration button, and if required enter the

factory default user name and password (Supervisor, 12345)

2. It is strongly recommended to always change the default

password. Failing to do so poses a sever security risk also on

protected networks

3. Using the arrow keys, navigate to the ‘System’ menu.

4. Using the down arrow, navigate to the Language line and

select your required language

5. Select your language for ‘Display’. The unit will then request

a reset.

Select language Display language

© Danfoss | DCS (vt) | 2020.03 BC316842192932en-001001 | 13

Page 14

User Guide | AK-System Manager, AK-SM 800 Series

Remote Management Tool (RMT)

The Remote Management Tool (RMT) is a PC software application

tool that is designed to support the AK-SM, both in

commissioning and service. The RMT is a powerful tool that

allows full offline programming and simulation of AK-SM

databases, providing the opportunity to save considerable on site

commissioning times. In addition, the RMT tool has various

remote management features, facilitating complete system

management. Creating custom images for the AK-SM web

browser is also another function of the RMT tool. The following

features can be seen in the RMT;

• Offline web Programming

Launch offline web simulator(s) to allow full offline AK-SM

database programming, with controller simulation you can

fully pre-program your application and save the resulting

database to USB for on site install.

• Program simulation

From within the web browser session simulate board and point

variables to test calculations and system behaviour

• Custom Graphics

Use your own Jpeg or bitmp file to create custom images,

mapped with any configured system datapoint

• File Transfer

FTP is not available from firmware v08.080 and later.

Remotely connect, load and access system files (html web &

EDF device files) Retrieve datapoints

• Address Book

Save your most commonly connected site details to allow for

one click connection

• Tools

Download System software, backup (save) & load database

files.

• Language

Compatible in multi- languages

The RMT tool is available from your Danfoss sales office with

associated supporting documentation.

14 | BC316842192932en-001001 © Danfoss | DCS (vt) | 2020.03

Page 15

User Guide | AK-System Manager, AK-SM 800 Series

System Upload / Download

When to use Upload / Download function.

Your AK-SM 800 offers both Online and Offline configuration

methods. Understanding the concept of these difference

methods will help in determining the use of the Upload or

Download feature.

Upload = Retrieve field bus controller device settings and sync

with AK-SM 800 database

Download= Send controller device settings held in the SM800 to

the field bus controller

Online Configuration:

Online configuration is where the site application has live control

devices (i.e. Danfoss AK-CC 550) connected to a field bus and the

SM800 will be used to configure the settings and configuration of

these control devices. Since the AK-SM 800 has the ability to offer

online and offline programming it is important to sync the AK-SM

800 database BEFORE attempting any online configuration or

setpoint changes. The UPLOAD function is used to ‘retrieve’ the

control device settings and update the SM800 database. Once

the upload is performed and completed any subsequent device

setpoint changes done via the SM800 will get immediately sent to

the field device (no need to perform upload/download)

Upload Example: A contractor arrives on site and connects the

control devices to the field bus. The contractor performs a

network scan to ensure all nodes on the network are present.

After the network scan the contractor performs an upload

function, which will sync the AK-SM 800 database with the

settings that exist in the field bus control devices. The upload will

take the settings from the control devices and sync to the SM800

database. Once the upload is complete the contractor can

continue to configure via the AK-SM 800 and change settings in

the control devices.

Offline Configuration: With the use of the RMT tool, a

comprehensive AK-SM 800 offline configuration can be

accomplished without even being connected to any control

device or AK-SM 800. For many customers and users this

represents a considerable time saving in the configuration phase

(assuming the site definition is known).

By selecting the appropriate AK-SM 800 simulator in the RMT tool

you can simulate (in an offline state) a AK-SM 800 installation,

complete with control device selections (known as EDF

selections). The EDF device selections come pre-set with factory

parameter settings. Once your application has been defined and

any EDF setting changes made, the simulator (including all EDF’s)

can be saved in a AK-SM 800 database format. This saved AK-SM

800 database file can then be later loaded to a live AK-SM 800 on

site and all the control device settings (contained in the EDF files)

can be ‘pushed down’ to the relevant connected live control

devices to configure them. [Note that for some Danfoss controls

the Main Switch is required to be in the off mode before settings

can be written].

To ensure the original ‘offline’ AK-SM 800 database (which holds

all the control EDF device settings) is in sync with the live control

devices the ‘DOWNLOAD’ function is required. It is critical that

the AK-SM 800 is in sync with the live control devices since the

parameters in the SM800 database could be different to the

parameters residing in the live control device(s). Use the

Download function when you have performed an offline

configuration of your application.

Download Example: A contractor opens the RMT tool and decides

to fully configure the AK-SM 800 which will be used in a

supermarket in the following week. He knows how many and

what type of devices will be on site and decides to deploy the

RMT tool to offline program the AK-SM 800 database. After

selecting the device type(s), via the EDF selections the contractor

decides to configure some key parameters per the customer

application. Finally the AK-SM 800 database is saved to USB and

the following week the contractor arrives on site. The AK-SM 800

on site is connected to all the control devices via the filed bus and

a network scan is performed to check field communications is

valid. The contractor loads the AK-SM 800 database and performs

a DOWNLOAD function to ensure that the settings made offline

now get sent to the devices on the field bus.

The Upload and Download function can be found under

Configuration>Network Nodes.

Note: Due to field bus speeds, quantity of data sets and devices

the Upload or Download function can take several minutes. On

sites with a large number of devices Danfoss recommends

selecting 30 to 40 devices at a time and repeating the procedure.

© Danfoss | DCS (vt) | 2020.03 BC316842192932en-001001 | 15

Page 16

User Guide | AK-System Manager, AK-SM 800 Series

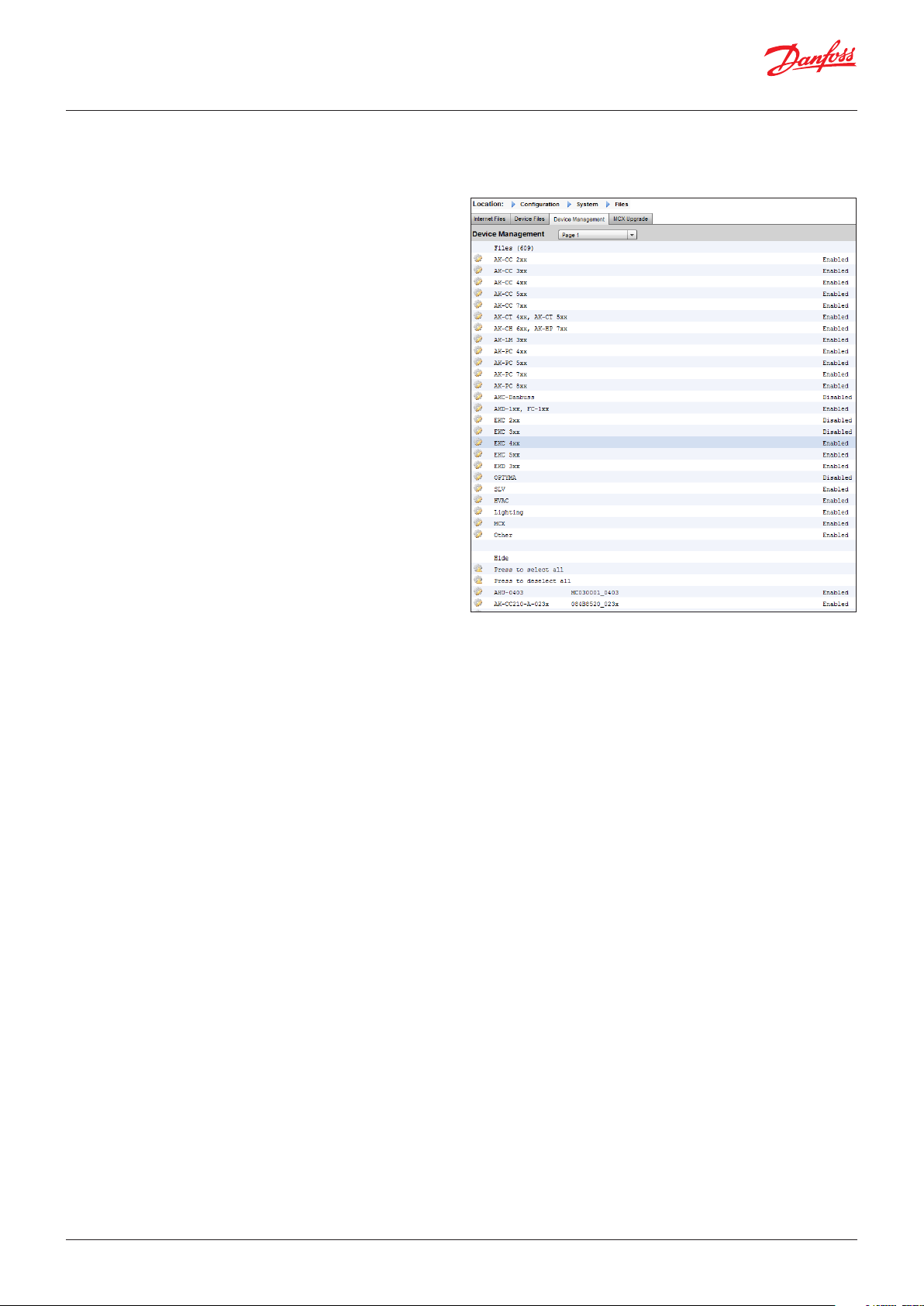

Device Management

(Configuration/System/Device Management)

The purpose of the Device Management feature is to control the

amount of active device files at any given time (max 1000), thus

saving system RAM and improving system performance.

The updated file management screen are effective with AK-SM

800 software version 8.021.

By default the most common controller types are set to ‘Enabled’.

Groups which are not enabled (Disabled) are not actively loaded

into system RAM. To enable any controller group simply double

click the group and from the action menu select ‘Enabled’.

As device files are Enabled / Disabled the file counter will reflect

the total number of active device files. The term ‘Files’ in this case,

is actually the total number of device selections available. For

example, a controller such as an AK-CC 550 has 10 different

applications. Therefore each application is a ‘selection’. Then the

number of selections is multiplied over several software versions

that may be available for that device.

The maximum number of active selections per front end will

now be 1000

This means that once the controller selection reaches 1000, you

will need to disable groups of those devices not being used, in

order to keep this number at, or below 1000. A message will be

presented to alert if the capacity has been reached.

Using the network scan or Refrigeration layout/scan wizard will

automatically enable any group is detected on a scan (even if the

device file was previously set to ‘disabled’).

EDF’s not packaged within the ‘MAI’ file for the AK-SM 800 will be

available via the Danfoss Support web site http://www.ak-sm800.

danfoss.com. When installing the latest AK-SM 800 firmware

package, recently released / new EDF device files may not be

included.

The ‘Interim ED3’ collection of files are the ones which were not

included in the MAI (master application install), and can also

include either new files or updates of existing files after the

software release date.

In this situation, there are two recommended methods to update

your AK-SM 800 system.

Note: Only version 08.07x and above supports device files that

have an extension of .ed4

Option 1 – Local screen - USB flash drive

a) Download latest EDF zip file from the AK-SM 800 support site

b) Review the enclosed ‘ReadMe’ document to see what’s

included in this file collection

c) Copy the relevant file into the root directory of a USB flash drive.

Note, only 1 file can be loaded at a time

d) Log in as Supervisor at the AK-SM 800

e) Insert USB flash drive and follow menu prompt to install the

required ‘ED3/4’ and Device.ls3 files (only one at a time). Note

that the Ephrases.tbl file is not currently set up to be loaded via

USB. – see the RMT section below.

Make sure to always disable all device groups that are not in use.

When performing a re-scan, device groups are activated

automatically if any devices within the groups are detected.

Exceeding the max number of active devices may result in

unexpected list behavior.

16 | BC316842192932en-001001 © Danfoss | DCS (vt) | 2020.03

Page 17

User Guide | AK-System Manager, AK-SM 800 Series

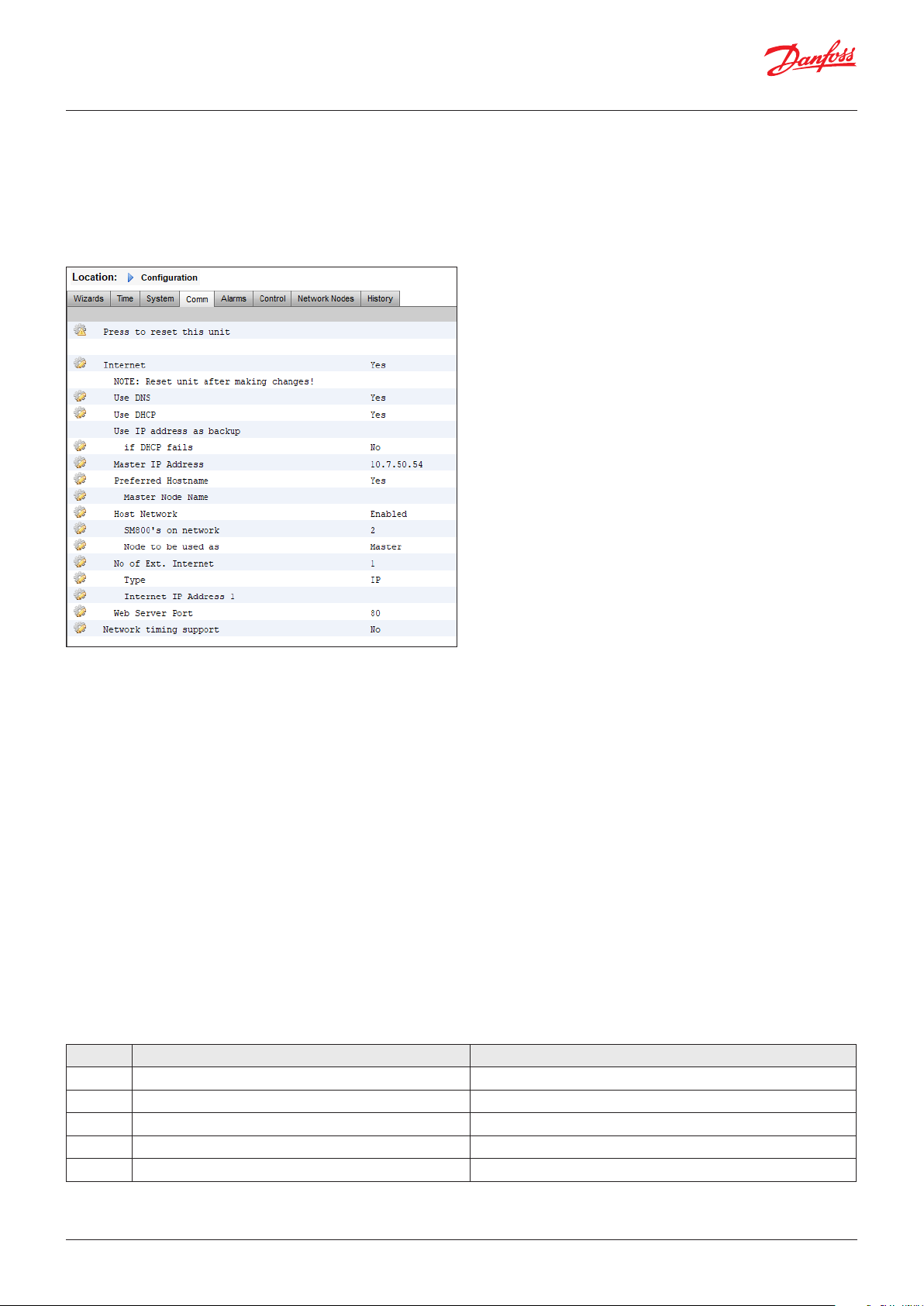

IP Configuration and suggested security settings

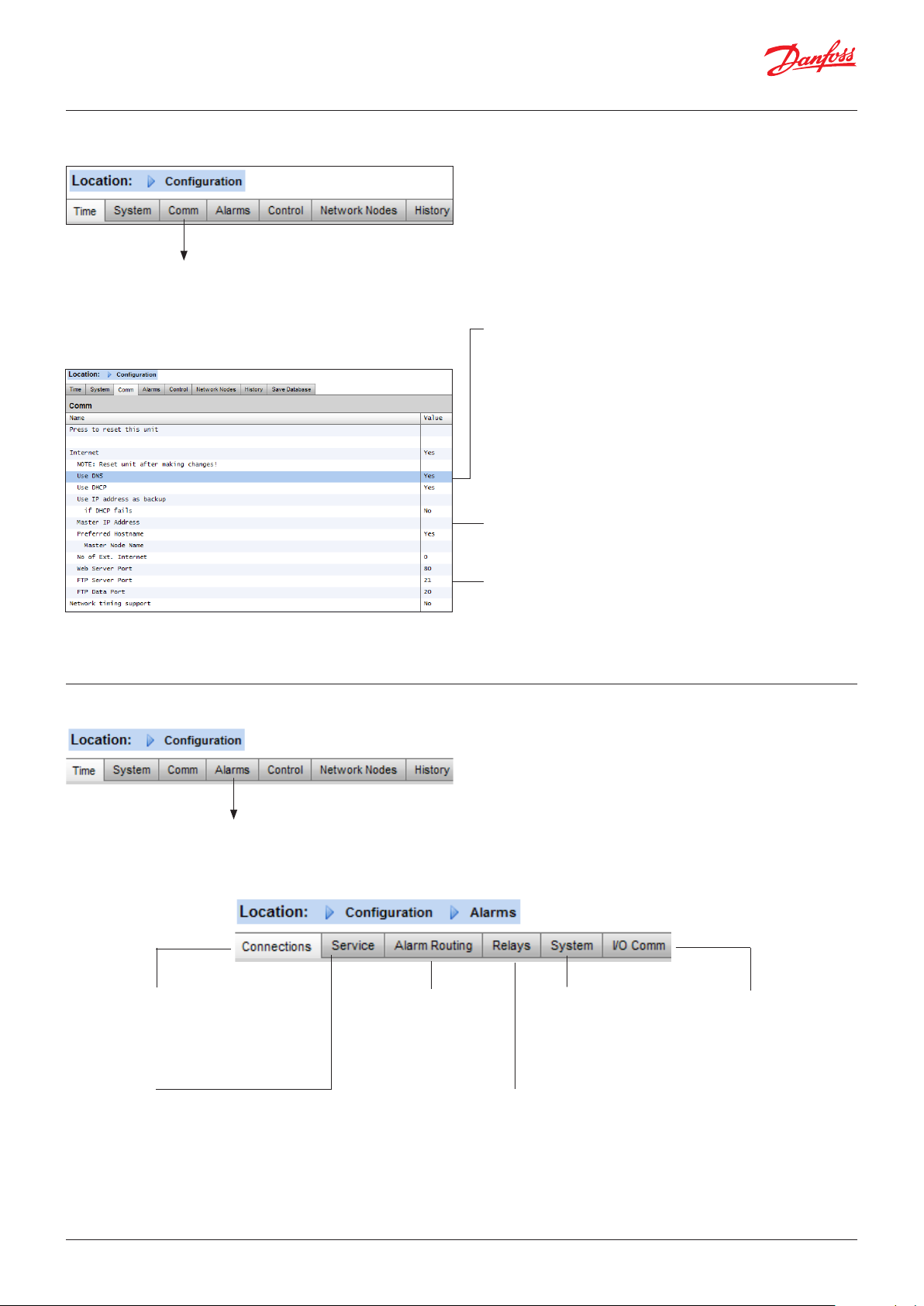

The ConfigurationComm screen allows important routing and

IP configuration to be set. With correct settings you will be able

to remotely connect to your AK-SM 800 series controller. Note

that after making any changes in this screen a system re-set is

required to save settings.

Use DNS (Yes/No)

Domain Name System- select to YES to enable this feature and

take advantage of your networks naming service. When

answering YES (and with DHCP set to NO), the preferred host

name line appears together with Domain Server IP address. There

are two lines for the domain server IP or DNS name. Note that if

DHCP is set to yes, the domain server IP address lines are not

visible.

Use DHCP (Yes/No)

Dynamic Host Configuration Protocol (DHCP) is a standard

network protocol that dynamically distributes network

configuration parameters, such as IP addresses. If you connect

the AK-SM 800 controller to a valid DHCP server the controller will

obtain an address automatically. The management (renewal,

binding and lease) of the IP address is fully automatic. It is

strongly recommended that DNS is used in conjunction with

DHCP so to keep track of dynamic addressing.

Use IP address as backup if DHCP fails (Yes/No)

If a non-reliable DHCP service is suspected, you can insert a fixed

IP address that will be used in the event of a DHCP failure. Under

normal network conditions this feature would not normally be

required.

Master IP address

Your AK-SM 800 series controller is a so called ‘master’ when the

rotary address switch (located behind keyboard cover) is set to 0.

This automatically assigns the unit as a master and is used when

operating with multiple AK-SM 800 units (host network)

Preferred Hostname

If DNS is set to YES then a preferred hostname line appears.

Selecting YES to the preferred hostname will enable Master node

name line (see below). If DNS is set to No, the site name and unit

name (site name-unit name) will be used by default.

Note: Site Name and Unit name should be configured under the

ConfigurationSystem screen.

Master node name

Enter a name here, used to identify the AK-SM 800 controller on

the router.

Host Network (Enabled / Disabled)

If your AK-SM 800 will be part of an interconnected host network

of AK-SM 800 units, select ‘Enabled’ to this question. If there is

only 1 AK-SM 800 controller then leave set as Disabled.

SM800 on network (1-10) – enter how many units will be

on host network

Node to be used as (Master / Slave) – Select ‘Slave’ for all

units with rotary address switch set to 1 or above

No of external Internet (1-3)

If your AK-SM 800 series controller will be made accessible from

an external location (outside of LAN/Internet), then this feature

needs to be enabled with at least 1 external internet ID. Once at

least 1 external internet line is added the type (see below) can be

entered. The use of the external internet configuration is to

ensure remote web browsers or Store View Desktop can access

your AK-SM 800 from outside of the local area network.

Type (IP/ Name) – This is a new feature added in software

version V08_027 and higher. Select IP for static addressing

or Name if using DHCP

Internet IP / Name address – Enter IP or Name (based on

above selection)

Web server port (user configurable)

Used to allow HTTP traffic / support browser access to your AK-SM

800 controller. Danfoss strongly recommends changing the

factory default to something other than port 80 if used outside of

LAN network or exposing to the Internet. For example, change

web server port to 5080.

From firmware G08.080 FTP access is removed and not available

for security reasons.

IP Port Use Notes

80 web browser This port is user configurable but factory set to 80

20 & 21 RMT tool (from version 4.15 HTTP transfer is supported) This port is user configurable only in firmware prior to G08.080

25 E-mail E-mail output

3001 XML Used for XML communications

1041 Service tool (ST500 ver. 3.29d and higher) used for tunneling through SM800 series to AK2 controller

© Danfoss | DCS (vt) | 2020.03 BC316842192932en-001001 | 17

Page 18

User Guide | AK-System Manager, AK-SM 800 Series

FTP Server port (user configurable)

The AK-SM 800 series controller uses ‘Active’ FTP. Used to transfer

database and EDF files. Danfoss strongly recommends changing

the factory default to something other than port 21

FTP Data port (user configurable)

The port used to support file transfer

Network timing support (NTP)

Use this function (if supported by your network) to sync the

AK-SM 800 real time clock over the network, known as NTP.

Requires NTP sever address and Time Zone offset to be

programed.

Note: Time Zone offset can be configured under the

ConfigurationTime screen

General IT security / Recommendations

The AK-SM 800 series device is an embedded controller designed

to be installed behind an appropriate router and firewall. The

AK-SM 800 itself does not offer routing or firewall options,

additional security steps must be taken to secure appropriate

levels of security dependent on the application needs.

Danfoss recommends changing the default user name and

password, used to log into the AK-SM 800 series controller.

Danfoss recommends changing the default web server port if

used outside of secure LAN network.

Ensure the AK-SM 800 is behind a well configured firewall(i.e. port

forwarding rules, FTP access (FTP is disabled from firmware

version G08.080.054), HTTP access). A well configured router/

firewall will help in;

Firewall between our controllers and the Internet

The ability to designate the ports/protocols allowed to our

controllers

The ability to limit and monitor in-store IP connections to our

controllers.

The AK-SM 800 controller supports auto negotiated 10/100

Ethernet speeds.

The AK-SM 800 controller supports auto negotiated full / half

duplex Ethernet communications.

From firmware G08.080 FTP access is removed and not available

for security reasons.

18 | BC316842192932en-001001 © Danfoss | DCS (vt) | 2020.03

Page 19

User Guide | AK-System Manager, AK-SM 800 Series

Chapter 3: Navigation and use

General navigation, operation and use (via web)

Once your AK-SM has been configured, general navigation and

daily use is done via the Dashboard screen. The Dashboard

screen acts as the central system home page, where further

system details can be reached. The Dashboard and subsequent

device screens have been developed to provide an easy to use

navigation environment for the user, where typical status and

setting can be found.

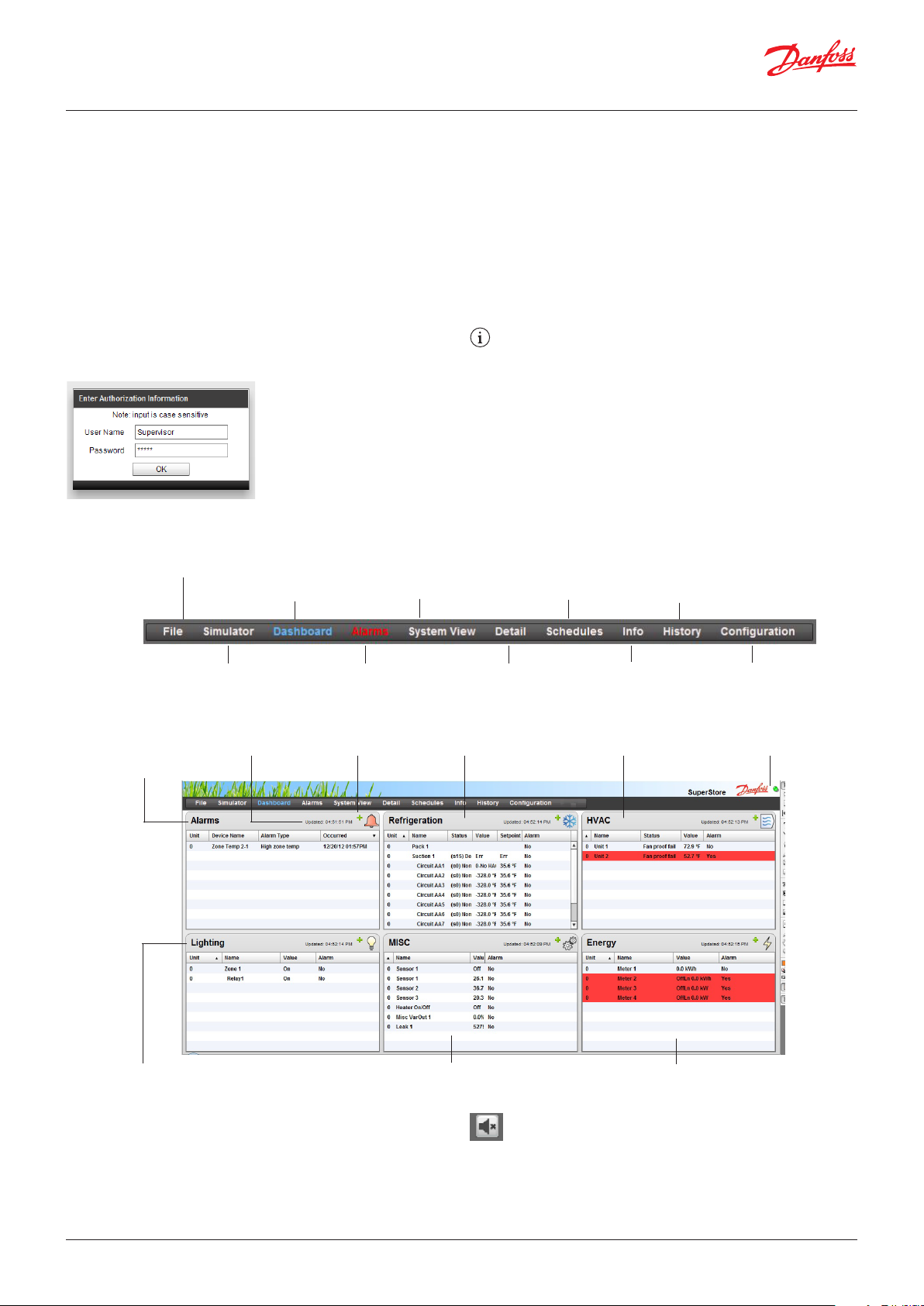

Connecting to your AK-SM

Using a standard web browser or your StoreView Desktop

application, enter your AK-SM IP address

The factory default User name &

password:

User Name: Supervisor

Password: 12345

Preferences

Refrigeration Report

Download Report

History Log Collection

Alarm Log Collection

Log Off

Dashboard screen

System View screen

Dashboard view

Once the correct user name and password has been entered the

Dashboard screen will load. The Dashboard screen will only

reflect what your application configuration has been set to. For

example, if your application does not have any HVAC configured

the Dashboard will not show the HVAC panel. Dashboard panels

are automatically generated depending on the configuration, no

user action is required to build the panels.

To guarantee the best experience when connecting to your

AK-SM, ensure you PC has the latest version of Adobe® Flash®

Schedule screen

History (logs)

Use the simulator tool to

simulate configured Misc

points (only available through

RMT off line tool)

Active alarm panel

Lighting panel Misc panel Energy panel

Global alarms (all

connected

AK-SM units)

Expand panel buttonData poll refresh info Refrigeration panel HVAC panel data communication status

Once the correct user name and password has been entered the

Dashboard screen will load. The Dashboard screen will only

reflect what your application configuration has been set to. For

example, if your application does not have any HVAC configured

the Dashboard will not show the HVAC panel. Dashboard panels

are automatically generated depending on the configuration, no

user action is required to build the panels.

Device detail screen Info screen (software

version, etc)

Central AK-SM

configuration screens

Upon the Dashboard loading, if any active alarms are

present the built in alarm buzzer can be heard. To silence

the alarm press the silence button. This does not

acknowledge or clear any alarms.

© Danfoss | DCS (vt) | 2020.03 BC316842192932en-001001 | 19

Page 20

User Guide | AK-System Manager, AK-SM 800 Series

File

Preferences

Setup the preferred start screen

Visualize the Misc section on the dashboard

Enable or disable sound if an alarm occurs

Enable or disable the possibility to minimize or close Storeview

Desktop

Enable or disable the possibility to resize or minimize Storeview

Desktop

Logs the user off after a time of inactivity

Enable or disable the possibility to logon automatically if Storeview

Desktop starts. If the function is enabled, credentials are needed.

Section to customize graph colors for analog and digital lines. Used

in displaying history.

20 | BC316842192932en-001001 © Danfoss | DCS (vt) | 2020.03

Page 21

User Guide | AK-System Manager, AK-SM 800 Series

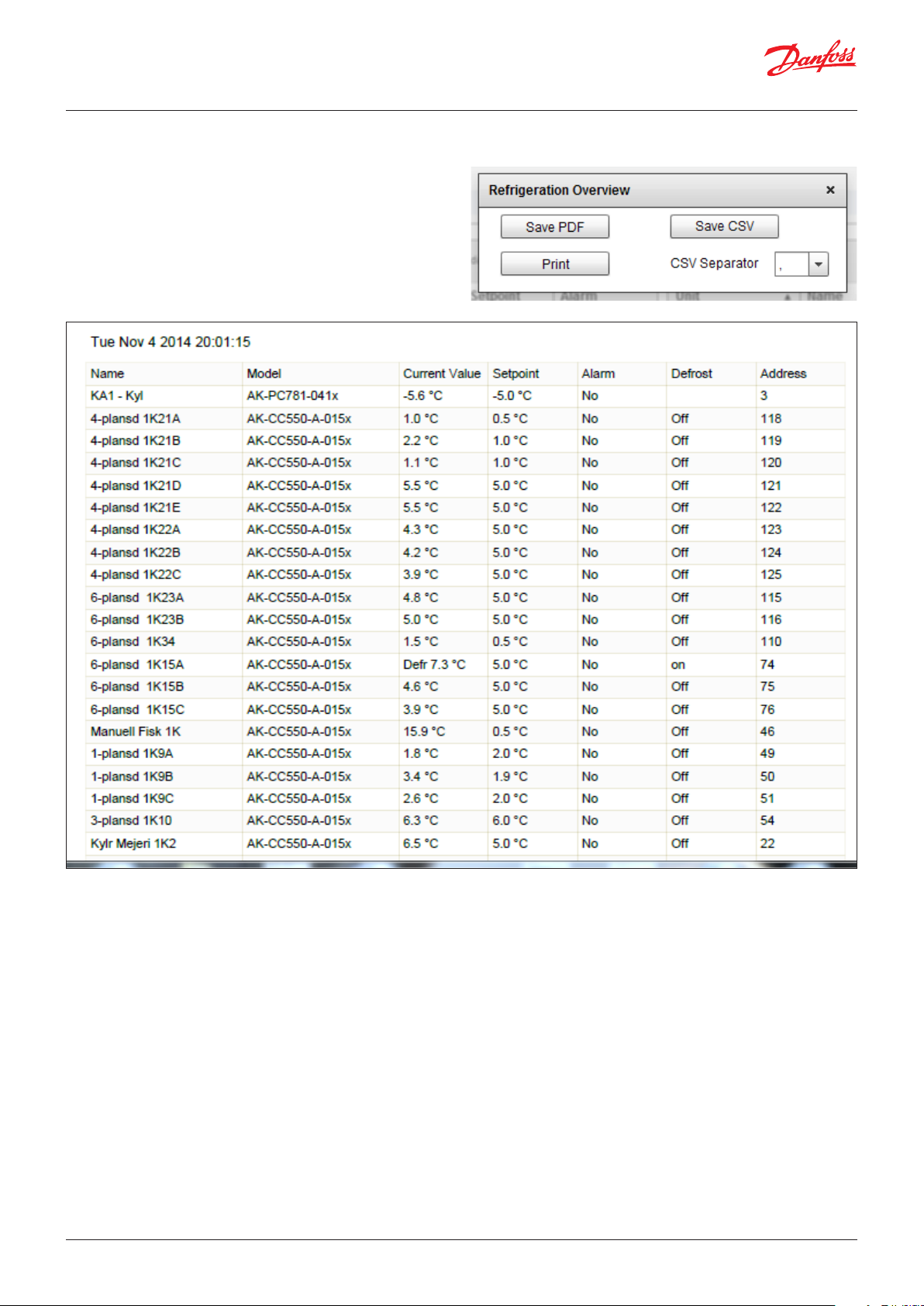

Refrigeration Report

When selecting the Refrigeration Overview report it is possible to

output a current status report of configured refrigeration. The

report will display current value, setpoint, alarm, defrost and

device address. The report can be exported to PDF, CSV and Print.

It is also possible to export the Refrigeration report to a USB flash

drive in simple text format, which is mounted in the AK-SM 800

USB port (user must be authorized).

© Danfoss | DCS (vt) | 2020.03 BC316842192932en-001001 | 21

Page 22

User Guide | AK-System Manager, AK-SM 800 Series

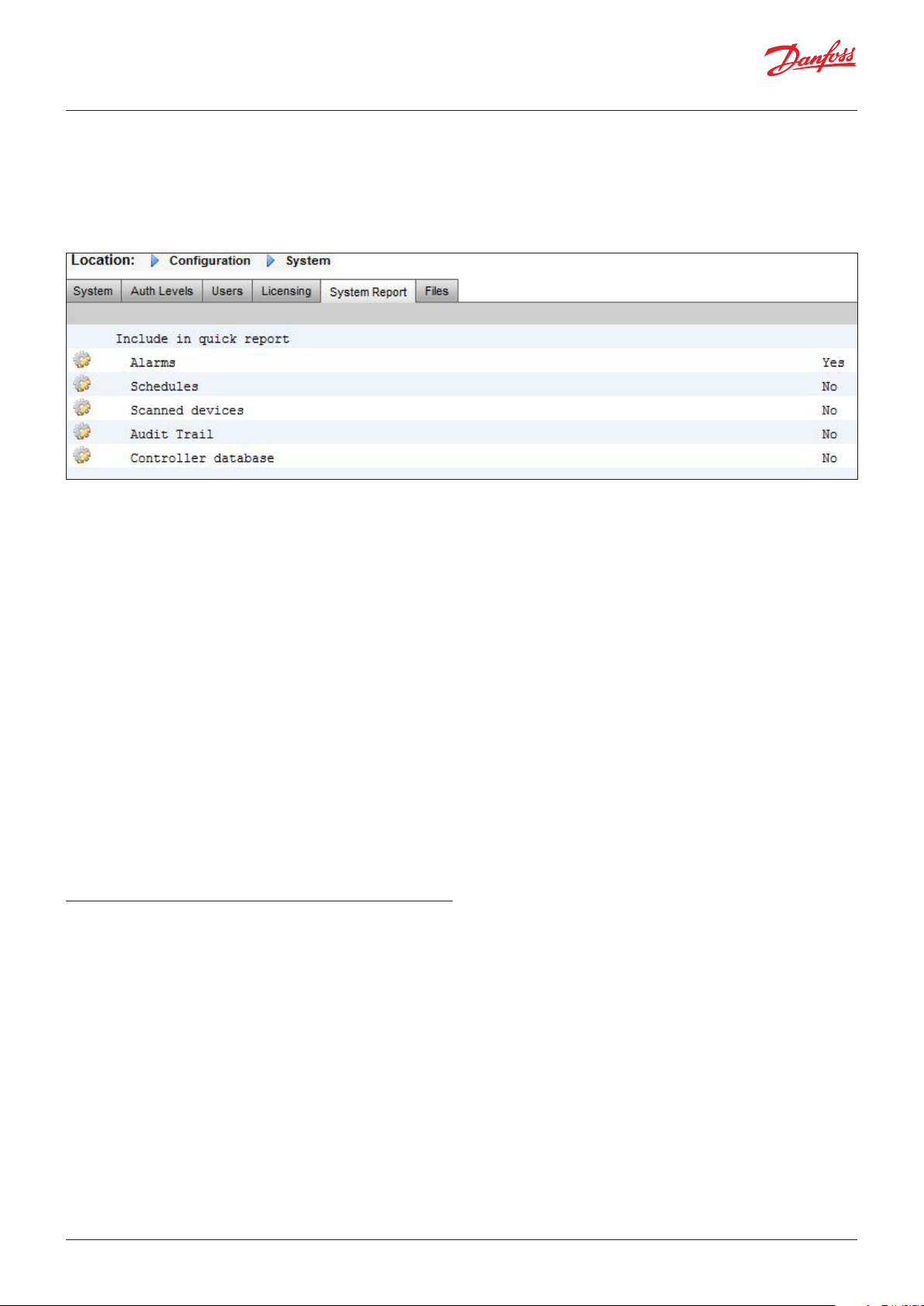

Download report

It is possible to download a text file which contains all

information’s of the unit. It is information’s about the whole unit

setup, alarms, schedules, scanned devices, audit trail and the

controller database. If some of the information’s is not needed, a

setup can be made under Configuration/System/System Report

System Report :

Store Name : Super Store

Store Id1 :

Store Id2 :

Street : Millerstreet 63

City : 46569 Baltimore

Phone :

Mac Address : 00:0B:2D:08:00:17

Unit Address : 0

Unit Name : Superstore Unit 1

Created on : 03/07/14 09:02

Software Version : G08.020

Software Created : 14/02/14 10:55

Factory Application : G08F011

Boot-loader : 9.3

CPU Base Board : 2

CPU Version : MPC5125 V1.0

CPLD Version : 2

Dynamic RAM : 256 Mbyte

MRAM : 512 Kbyte

Serial Flash : 64 Mbyte ST Device ID 0x76

Parallel Flash : 64 Mbyte Unknown Device ID 0x7e2301

RAM Disk : 40 Mbyte 24% Full

IP Address : 192.168.178.24

Licensed features:

Refrigeration

HVAC

Lighting

Com-Trol

22 | BC316842192932en-001001 © Danfoss | DCS (vt) | 2020.03

Page 23

User Guide | AK-System Manager, AK-SM 800 Series

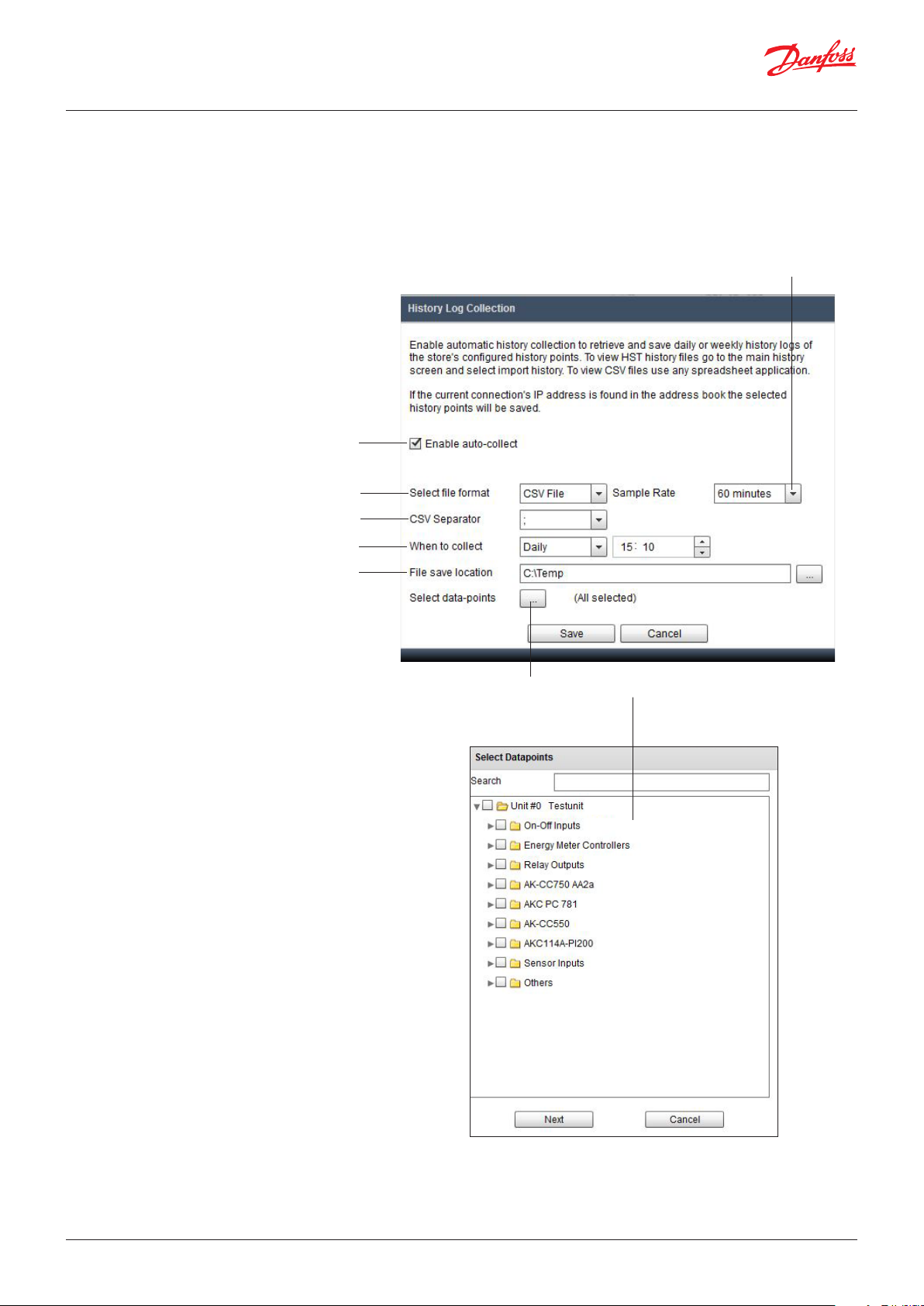

Auto History Log Collection

The user can create with Store view Desktop a daily or weekly

export of Log data. The computer running Store View must be

permanently connected to the AK-SM 800 network and remain

running in order to auto collect log data.

The file format can be CSV for further use in Excel or other tools or

HST to reread the data with Store view Desktop. To export Store

view Desktop must be connected to the AK-SM 800.

Enable/Disable the auto collection

Selection of the file format

Separator for CSV (, or ;)

Collection rate daily or weekly

Select the destination folder for the

exported files

Select the sample rate for

the exported file

Conditions, if the frequently export is always used:

1. Add Store view Desktop to the PC auto start section

2. Disable in “Preferences” the log off after inactivity period

3. Enable the auto logon feature and set the credentials

Selection of data points

© Danfoss | DCS (vt) | 2020.03 BC316842192932en-001001 | 23

Page 24

User Guide | AK-System Manager, AK-SM 800 Series

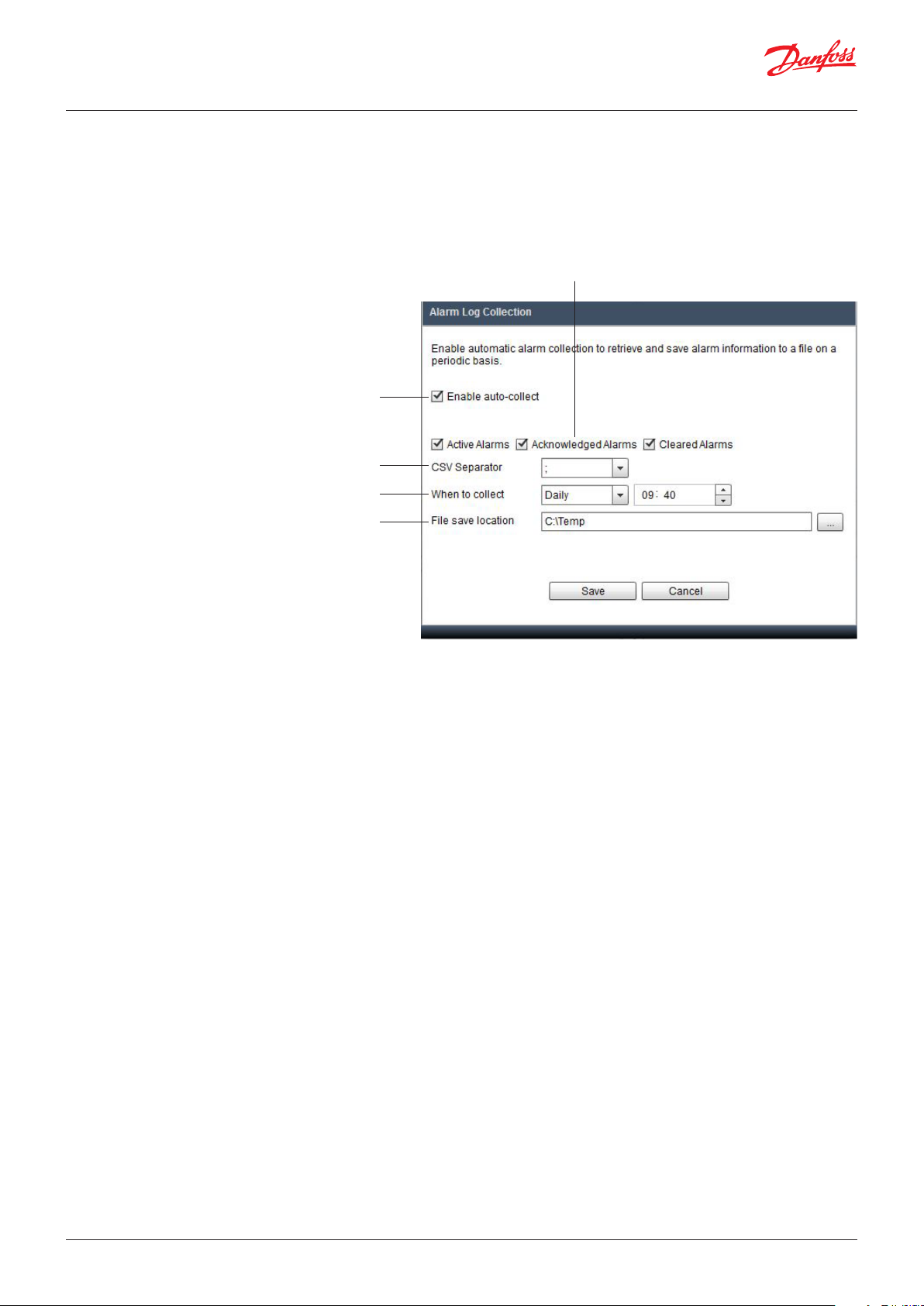

Auto Alarm Log Collection

The user can create with Store view Desktop a daily or weekly

export of alarms.

The computer running Store View must be permanently

connected to the AK-SM 800 network and remain running in order

to auto collect alarm data.

Enable/Disable the auto collection

Separator for CSV (, or ;)

Collection rate hourly,daily, weekly, monthly

Export of all alarms or only active, acknowledged or cleared alarms

Select the destination folder for the

exported files

Collection rates:

Hourly – no additional setup is needed

Daily – Time stamp is needed

Weekly – Time stamp and day of the week is needed

Monthly – Time stamp and day of the month is needed

Conditions, if the frequently export is used:

1. Add Store view Desktop to the PC auto start section

2. Disable in “Preferences” the log off after inactivity period

3. Enable the auto logon feature and set the credentials

24 | BC316842192932en-001001 © Danfoss | DCS (vt) | 2020.03

Page 25

User Guide | AK-System Manager, AK-SM 800 Series

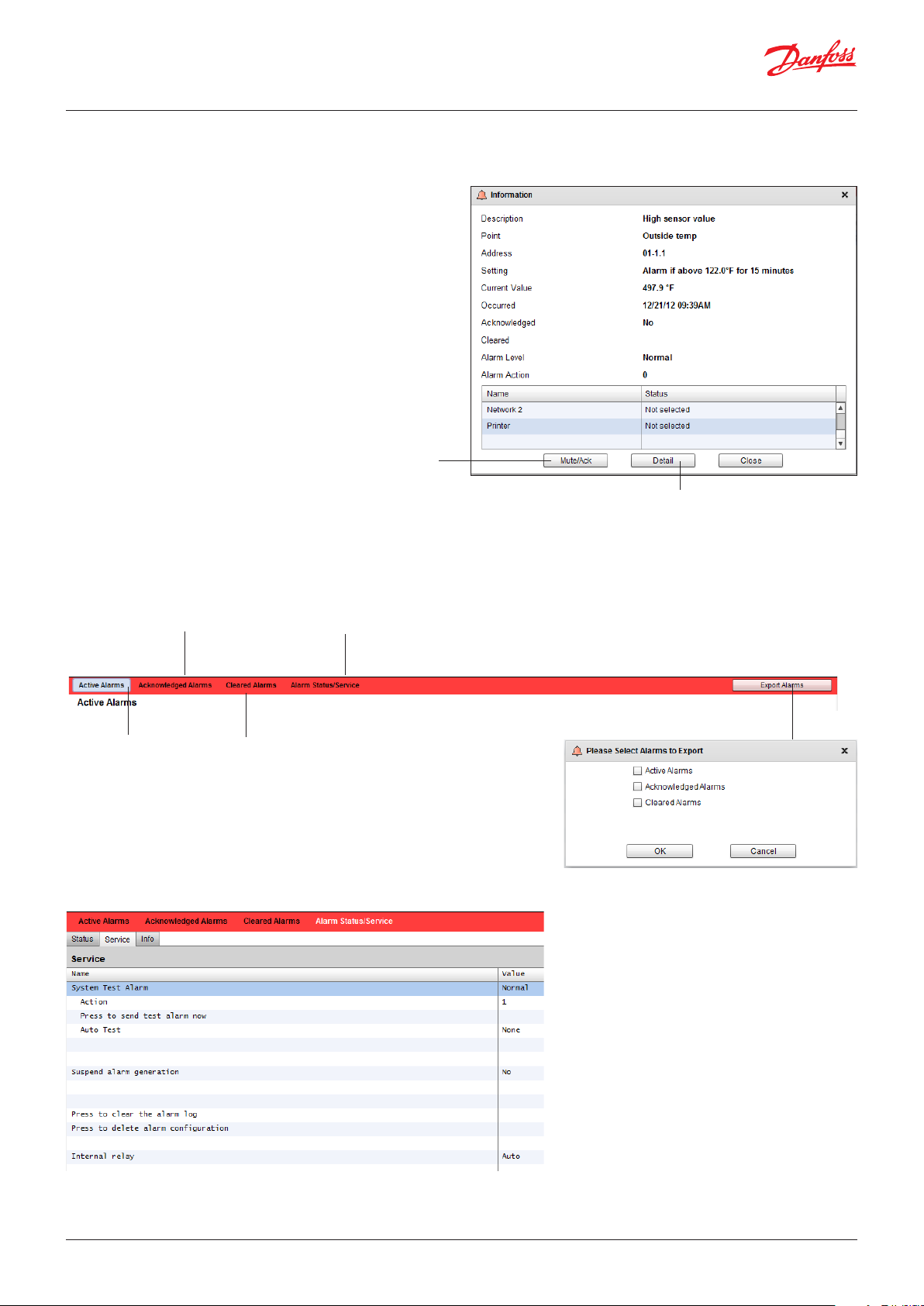

Managing alarms

Any active alarms will be shown in the Dashboard alarm panel. To

view more details regarding the alarm double click the relevant

alarm line. A alarm info box will appear with further details

regarding the alarm.

In addition to more information, the info box also allows the

authorized user to Mute/Acknowledge the alarm and to jump to

the device detail screen.

Use the Mute/Ack button to

acknowledge the alarm. When

pressed the alarm will ‘move’ to the

Acknowledge list

Alarm info pop up

Click the detail button to jump to the device detail

screen

To view all system alarms (known as global alarms) use the Alarms

tab (found on the main menu)

Global alarm screen

Global acknowledge list

Global active alarm list

Status and Service screens

Global cleared alarm list

Service screen

Under the service screen tab, test alarms can be configured and set.

Export Alarms

Export to CSV file

© Danfoss | DCS (vt) | 2020.03 BC316842192932en-001001 | 25

Page 26

User Guide | AK-System Manager, AK-SM 800 Series

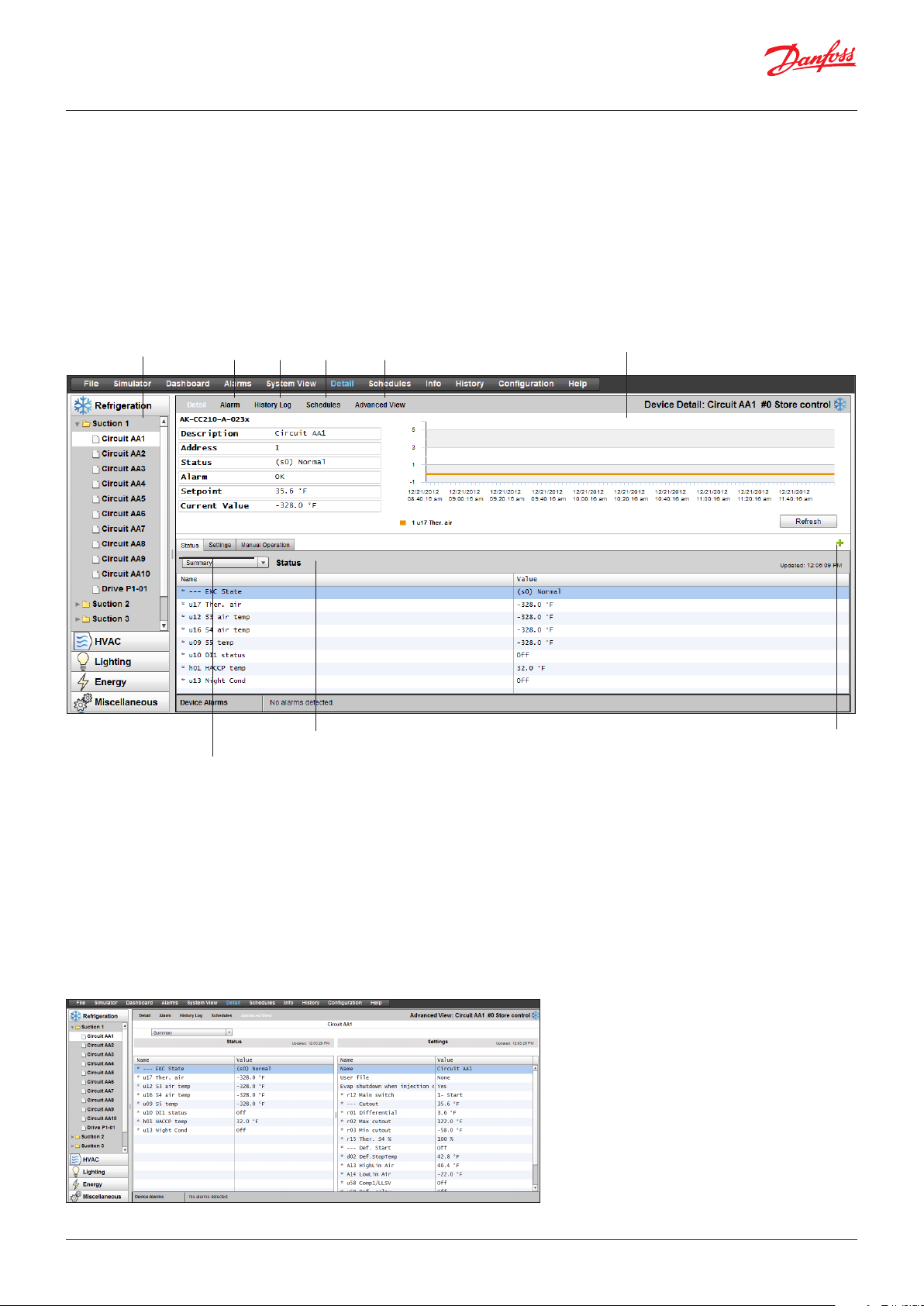

Device detail

Whilst the Dashboard screen will show basic asset information

(AK-SM unit address, Asset Name, Value, Status and alarm), more

detailed information can be found by double clicking an asset line

in the Dashboard. The resulting device detail screen will reflect

more details and settings. The device detail screen is designed to

provide key status and operational settings for the selected

device. Easy navigation to other assets is done via the navigation

tree. The screen image below highlights some of the main areas

of the device detail screen.

Navigation Tree

Status | Settings | Manual Operation tabs

Device alarms/History/Schedules

and Advanced View

Controller group menu (based on the controller type)

‘Snap shot’ history

Full screen button

Status

Under the status tab, common read only datapoints are shown

Settings

Under the settings tab, read and write values can be shown. Double click

a line to make changes (if authorized)

Manual Operation

Under the Manual Operation tab, key user override functions are available

Use the ‘Advanced view’ screen to access Measurements and

Settings side by side. This screen is useful to access all read/write

parameters for the particular controller

Advanced screen

26 | BC316842192932en-001001 © Danfoss | DCS (vt) | 2020.03

Page 27

User Guide | AK-System Manager, AK-SM 800 Series

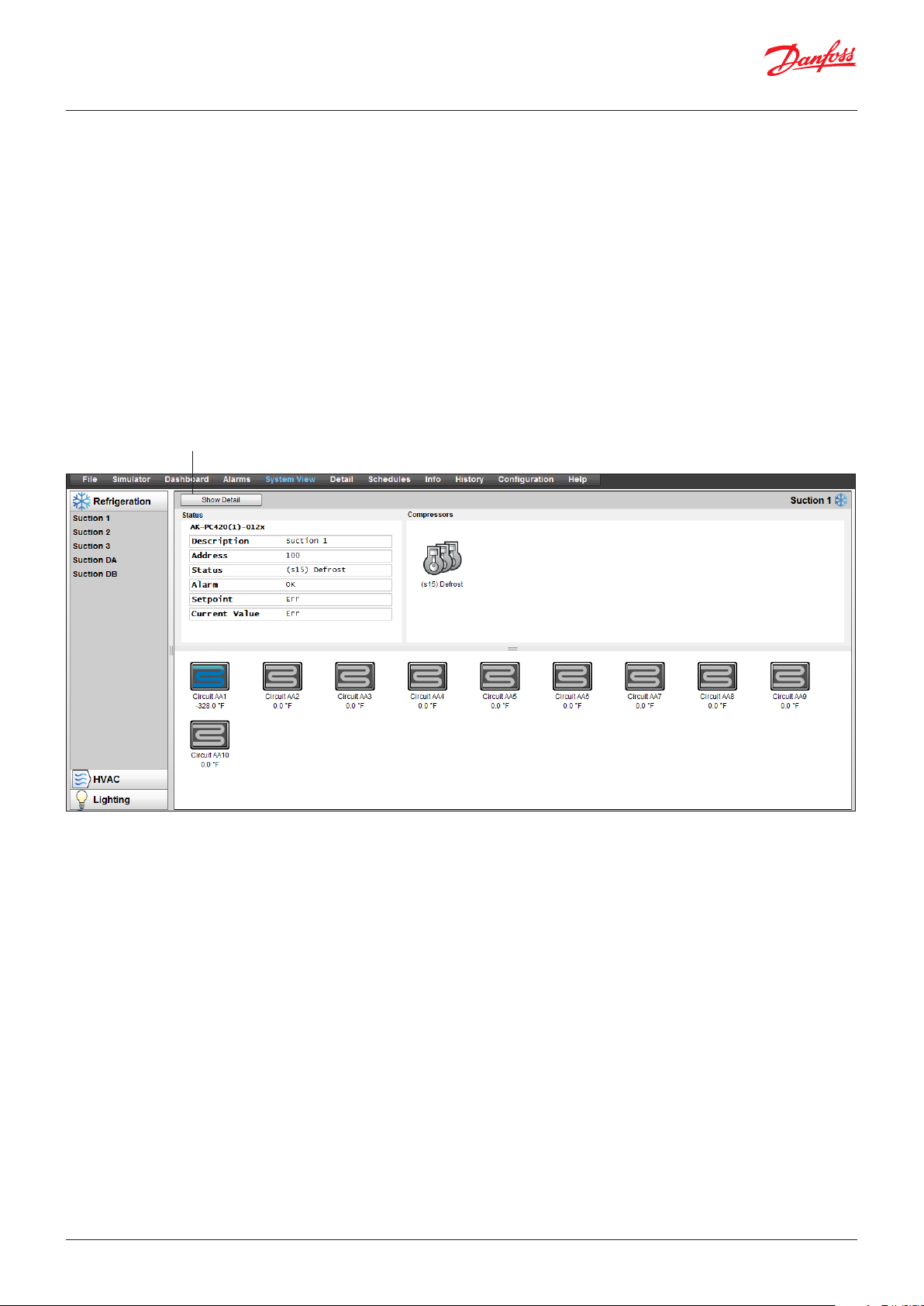

System view

The system view provides a generic yet graphical view of your

configured controls.

The same principle of the navigation tree can be seen in the left

side of the screen. The system view screen shows any configured

Rack or Pack, with associated evaporator circuits. To see

additional information, hover your mouse pointer over an icon, a

pop up box will appear showing additional information. To view

additional information and gain access to settings click the ‘show

Detail’ button. A dashboard will slide across, where a Status,

Settings and Manual operation can be seen. Simply click an asset

to highlight and the detail table will update with reference to this

selected device. Once complete with the device settings, close

the dashboard by clicking the ‘Hide Detail’ button.

System View (Refrigeration)

Gain access to more details via the ‘Show Details’ button

© Danfoss | DCS (vt) | 2020.03 BC316842192932en-001001 | 27

Page 28

User Guide | AK-System Manager, AK-SM 800 Series

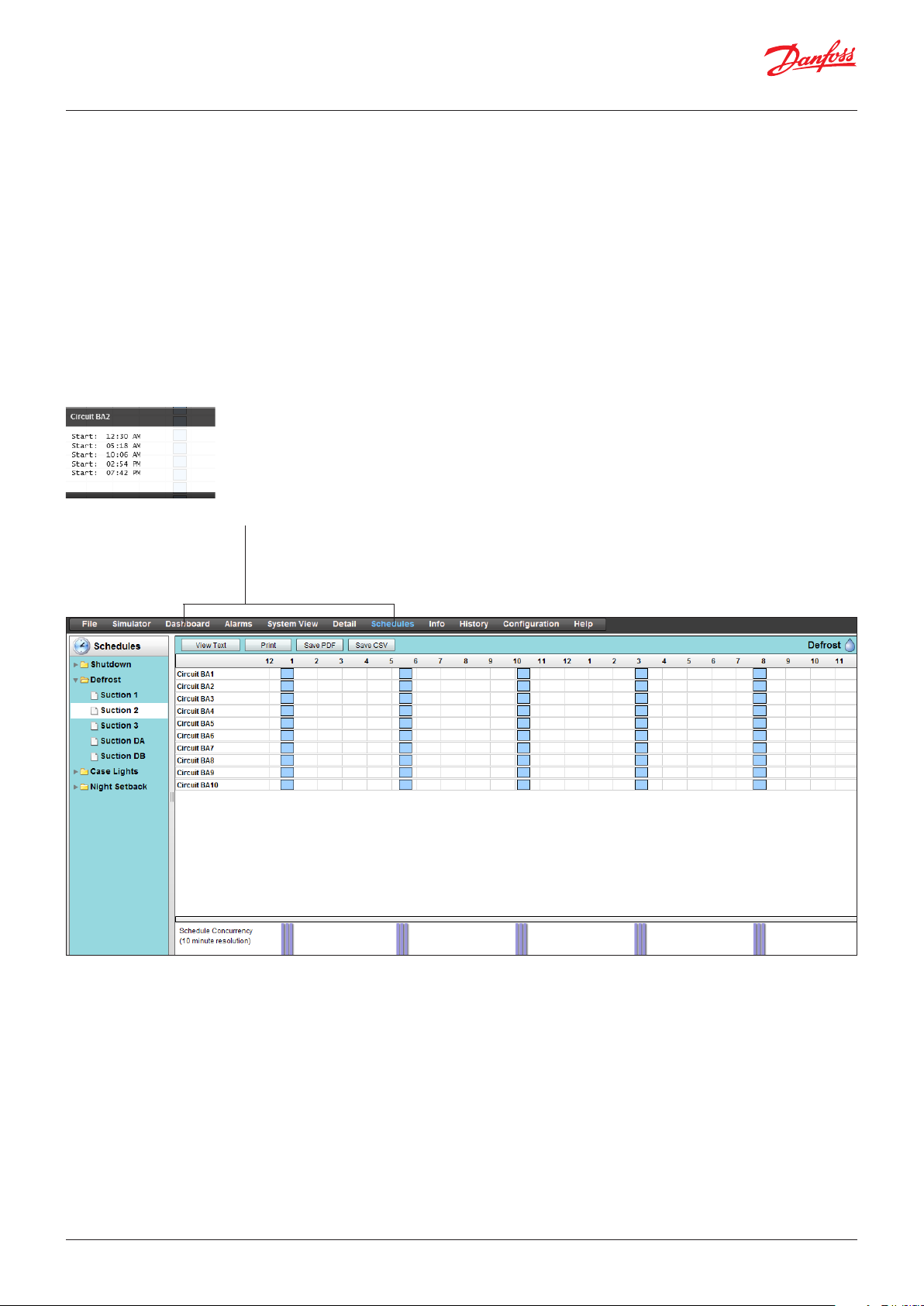

Schedule view

The schedule view provides a system wide view of schedules

(previously configured) in your AK-SM or host of controllers. The

following schedules are currently supported under the schedule

view;

Shutdown (Generic controllers - i.e. AK-CC)

Defrost (Generic controllers - i.e. AK-CC)

Case Lights (Generic controllers - i.e. AK-CC)

Night Setback (Generic controllers - i.e. AK-CC)

If a host network of AK-SM units are configured, a full system view

can be seen by selecting the folder icon, for a (AK-SM) unit display

click the relevant heading under the folder view. The schedule

screen includes a mouse hover over, that indicates (per circuit) the

schedule times.

Change the graphical view to text (table) form, Print, save as PDF

or save as CSV

28 | BC316842192932en-001001 © Danfoss | DCS (vt) | 2020.03

Page 29

User Guide | AK-System Manager, AK-SM 800 Series

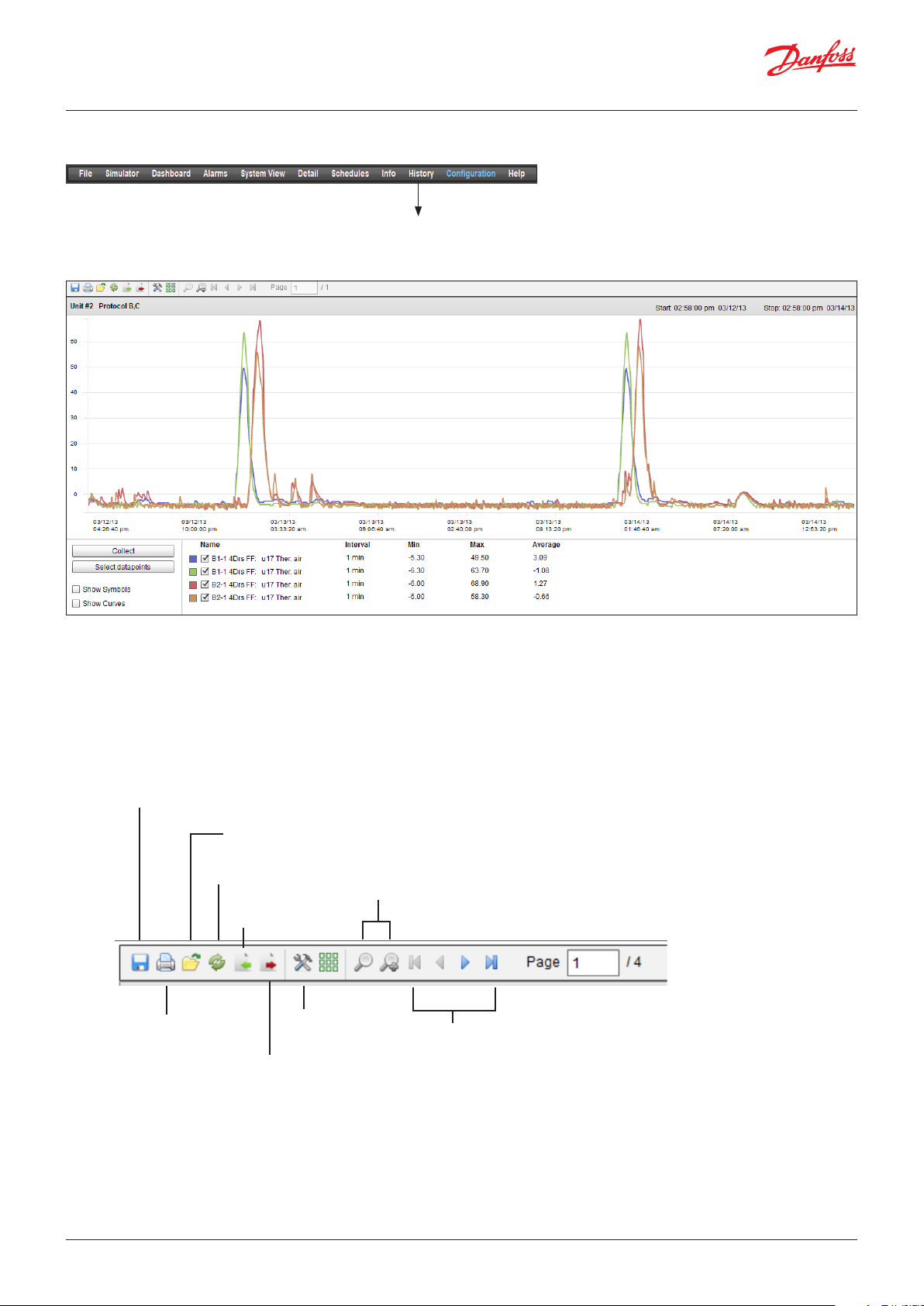

History (Logs)

To access your AK-SM history, select the history tab.

Upto 8 datapoints can be viewed at any given time on the history

screen.

History Tool bar

When viewing data in the history view the tool bar has a set of

functions to enable various actions to be performed.

Export history function

Export to .hst or csv file format. Saving the collected history

points (as .hst) will allow the user to re-load these at a later date

(via the ‘load history from file’ button

Load history from file

Load a saved .hst file to view

Convert history file to .CSV

Zoom

Page control

Print

Load history group from

file

Preferences

Save history group to file

(Creates a file that contains defined parameters.

This saves time locating the parameters when loading a graph)

© Danfoss | DCS (vt) | 2020.03 BC316842192932en-001001 | 29

Page 30

User Guide | AK-System Manager, AK-SM 800 Series

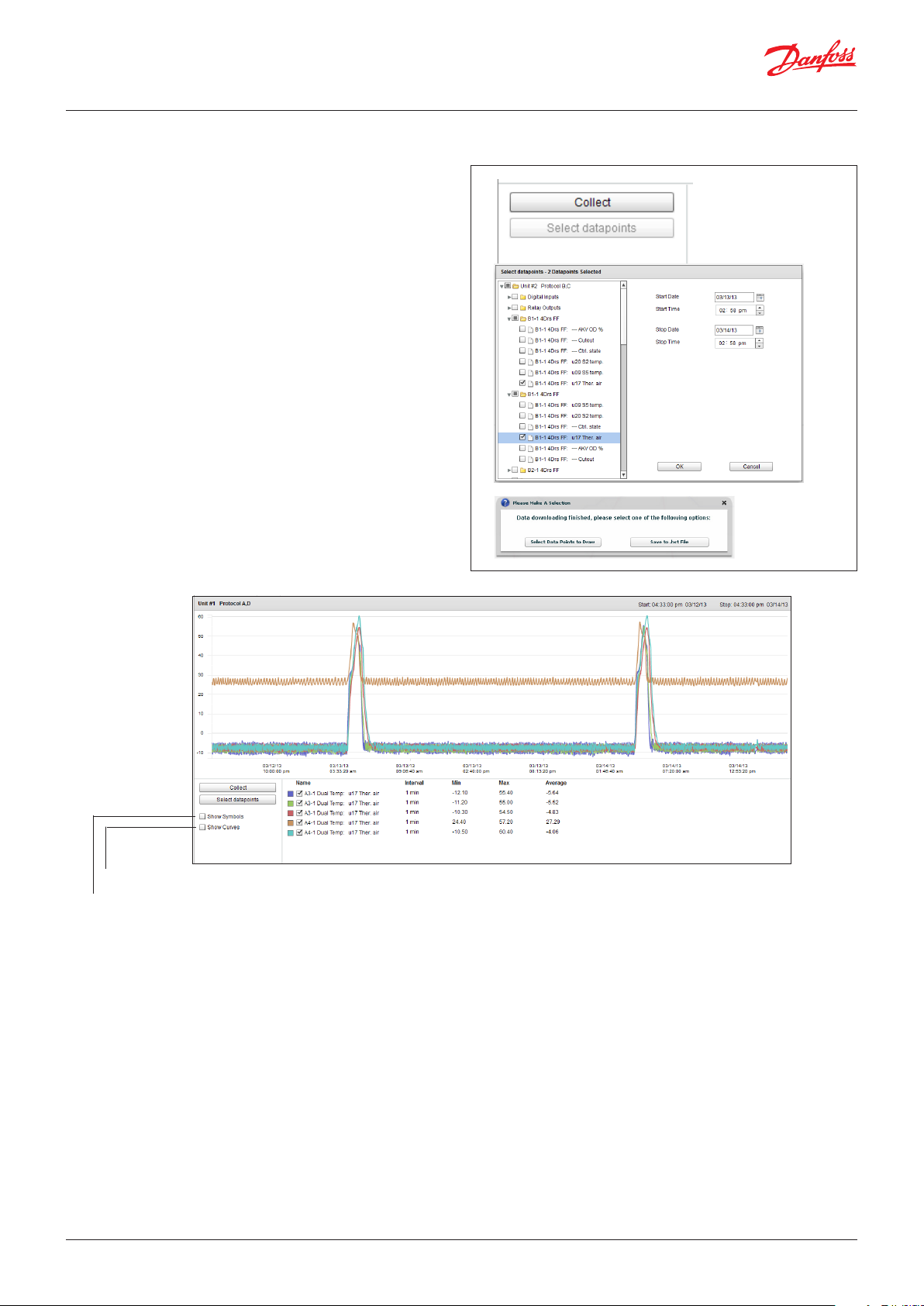

Collecting and viewing history

1. From the history page, press the collect button

2. Select the required datapoints and time/date range. Multiple

points can be collected but only 8 can be later shown in the

history screen at any given time. After the datapoints have

been downloaded, a dialogue box will appear which provides

two options:

- Select points to draw

- Save to .hst file (for later view)

3. The graph will be presented for view and analysis. Use the

zoom buttons or hold the left mouse button and hold for

zoom area. Moving the mouse pointer will show a tool tip with

point description, time/date and value.

Show curves (provides a computed rounding of the analog curve)

Show Symbols (each symbol represents a sample)

Save History Group to file (saving time for frequent datapoint

selections)

This feature allows the user to save a set of history datapoints.

Typically this feature would be used when a set of datapoints is

frequently needed to be loaded and viewed. Once the datapoints

are saved, this history group can then be easily loaded - thus

saving time in selecting datapoints.

Load History Group from file

Use this feature to load any previously save datapoint groups.

When opening the history group file the system will prompt for

the file location. Once loaded a ‘select datapoint’ box will appear

with the datapoints already pre-selection

30 | BC316842192932en-001001 © Danfoss | DCS (vt) | 2020.03

Export History data

This feature allows the user to export the previously collected

history data. A pop up window asks the user to select a file

format, the following formats are possible;

.hst (Danfoss history file format)

.csv (Excel compatible spreadsheet)

Saving any collected history as a file allows for future loading and

view, use the ‘Load history from file’ button to load any saved

history files.

Page 31

User Guide | AK-System Manager, AK-SM 800 Series

Chapter 4: Configuration

The following section describes the typical steps required for

commissioning and configuration of your AK-SM. Although site

applications can differ from one site to another, many setup

procedures are common. This setup section assumes the AK-SM is

mounted and all necessary power, network cabling and

controllers are in place. The described work flow is based around

the AK-SM web browser interface, but would equally apply if

being done via the local screen. Further detailed commissioning

instructions are found throughout this user guide.

The AK-SM offers unique control flexibility in that both centralized

and de-centralized control methods are supported. The term

‘centralized’ is used to describe the control of refrigeration Racks

via I/O (Danfoss Input / Output modules). Under this method of

control the refrigeration control is managed directly from the

front end (AK-SM), with field bus I/O. De-centralized control is the

term used to describe the full support of Danfoss Pack and Case

controllers. Under this method, each Pack or Case controller on

the network can be seen as self contained, with control logic built

in. The front end (AK-SM) under this type of application is more of

a network manager, providing full read / write access and energy

saving functions.

When starting your system configuration you will have the

opportunity to select either Centralized or De-centralized (or a

mix of both) control methods.

The following areas of system configuration will be covered in this

section:

1. Initial configuration - web wizard and copy wizard

2. Network Nodes (Network scan/ Node overview, Points, scan /

config status, duplicates, upload/download)

3. Time (Set time/date, time zone, operating Hours, Daylight

savings, Holidays)

4. System (Store / Region Names, Units preferences,

Authorization levels and users)

5. Communication (DNS, DHCP, IP Ports)

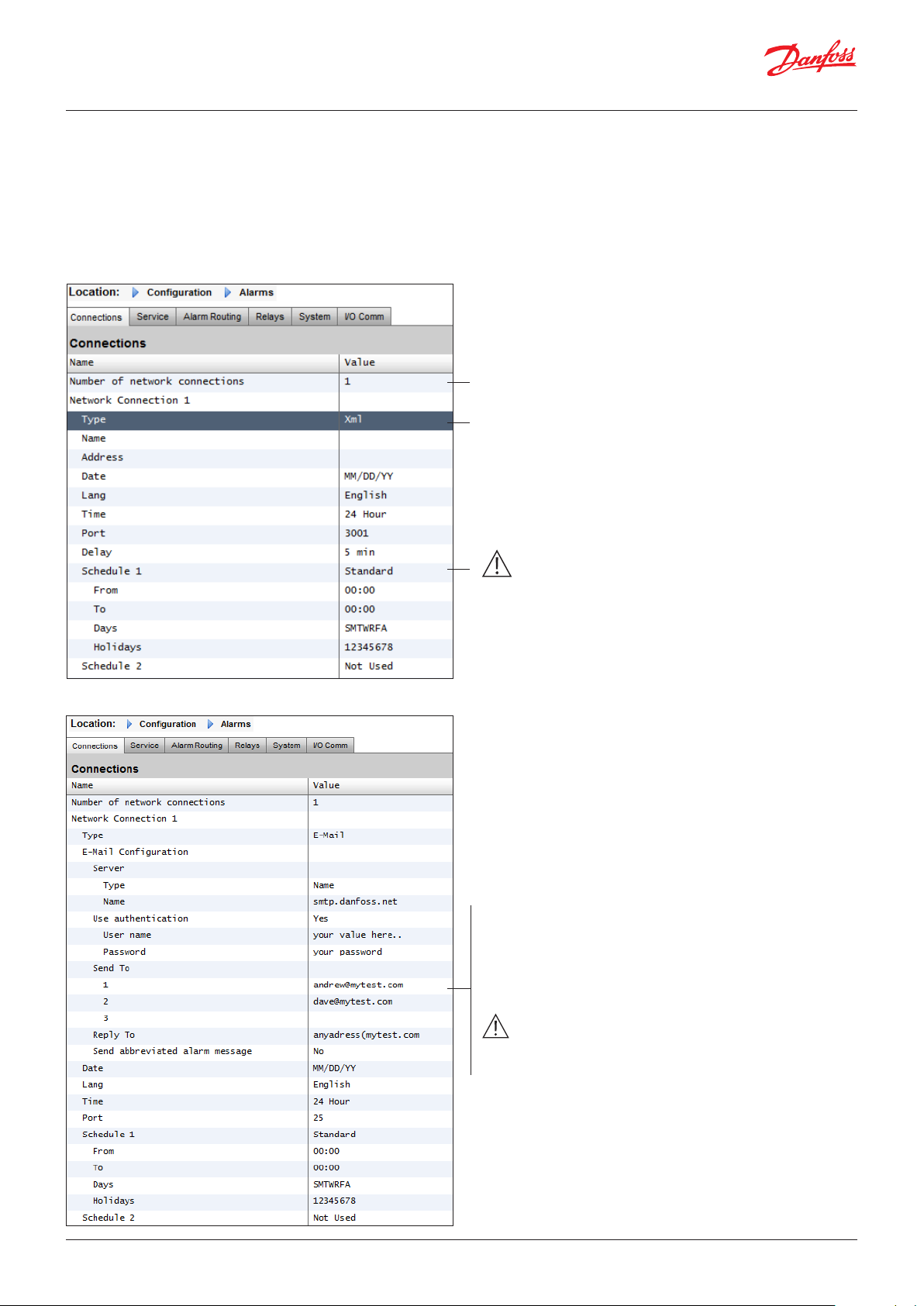

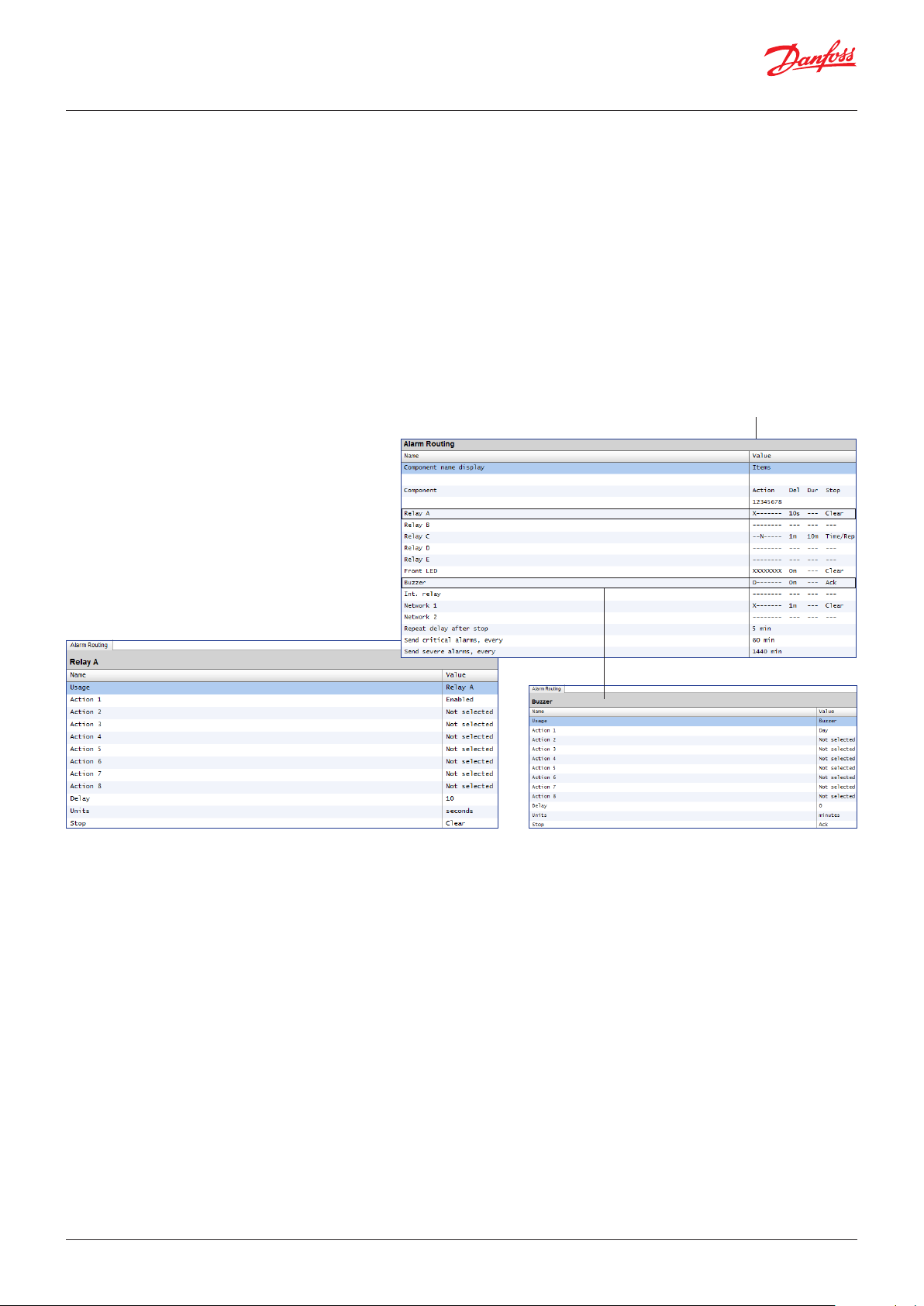

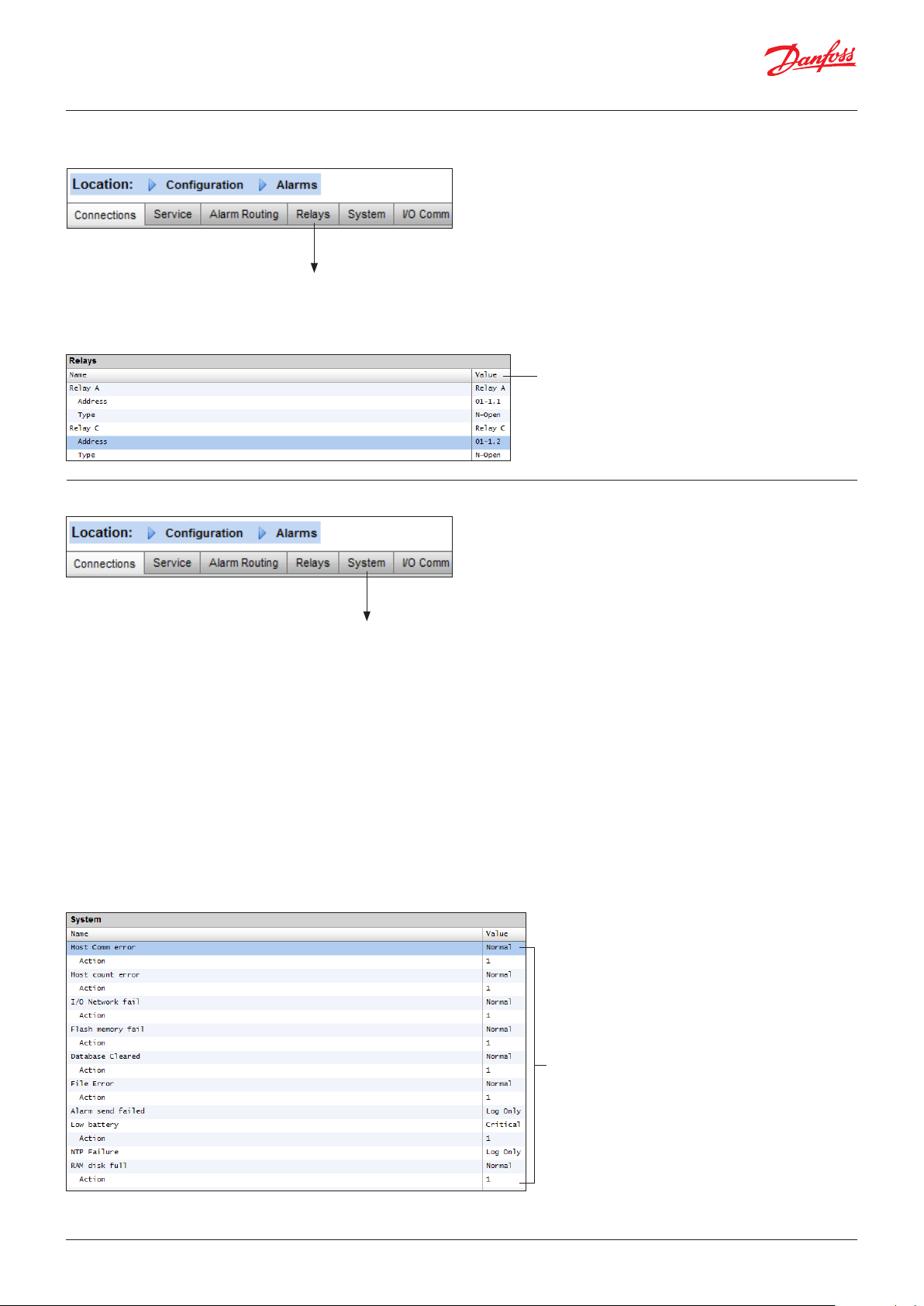

6. Alarms (XML, e-mail, Routing)

7. Control (Configure Refrigeration, Lighting, Miscellaneous,

Energy meters and Gas detection)

Once successfully logged into the AK-SM (web) and assuming you

have the required authorization, system configuration is done via

the central ‘Configuration tab’. Clicking this tab reveals the

configuration ‘sub tabs’. Depending on your selection, these sub

tabs will change dependent on content.

Using the menu structure seen in the ‘Configuration’ page, a step

by step process can be applied when setting up your AK-SM.

De-Centralized

Pack & Case

When configuring your

application, have in mind

which control strategy you

wish to utilise.

Centralized

Rack I/O

Navigation ‘bread-crumb’

Central configuration menu

© Danfoss | DCS (vt) | 2020.03 BC316842192932en-001001 | 31

Page 32

User Guide | AK-System Manager, AK-SM 800 Series

Initial Configuration - Web Wizard

The following section describes the current Web Wizards, used for

simplifying initial settings and Refrigeration layout. The Web

Wizards can be used in an offline or online configuration. Danfoss

recommends using the AK-SM web environment for commission

tasks.

Establish a web connection to your AK-SM (if working online,

enter the valid IP address of the AK-SM and apply the factory user

name and password). Navigate to the Configuration menu

Preferences Wizard (Language, store names, units, preferences,

time, date, daylight savings)

1. To easily configure your units preferences, launch the

Preferences wizard. Use the Wizard navigation controls to

move thought the Wizard screens.

2. To make changes, double click on the relevant line and continue

until the final screen.

3. Press the finish button to complete and close the wizard (return

to main wizard screen)

Users Wizard (Create, modify users, user groups, authorization

levels)

1. Enter number of users required (max 22), set password and

browser language for each user

2. Enter the number of authorization types (max 7), against the

settings line double click to modify the scope of system access

3. Press the Finish button to complete the Web Wizard

Licensing Wizard (Enter new license functionality)

Not currently used

Refrigeration layout Wizard

The layout wizard is designed to be used as multi use database

layout tool, allowing the scan and mapping of refrigeration

devices.

Make sure that the vast majority of your refrigeration devices are

available and ready for layout prior to using the layout wizard.

The wizard allows to scan organize and reorganize the complete

layout.

Web Wizard Navigation

Back Close Progress Forward

Limitations: Whilst the wizard will layout the Pack and Case

relationships, further controller configuration may be required.

Refer to section 6 under ‘ Configuration’ for guidance on any

remaining configuration areas required. Currently the wizard is

intended for Pack and Case devices and HVAC devices, any

controls not designated as such will have to be configured using

traditional config methods (see Configuration section).

Important Notes: If subsequent configuration is required after

an initial use of the Layout Wizard or an offline database has

been loaded, go to the Configuration Control section to add

/ modify your device(s).

Only use StoreView version 1.19.07 and above or a live SM800

Web Browser connection when utilizing the Refrigeration

configuration wizards.

To re-use the Layout wizard more than once the Refrigeration

database layout needs to be reset- do this by going to the

Configuration Control page and set # of Racks/Packs to 0.

Warning- this will delete any previous Refrigeration configuration

(all other configuration remains unchanged)

32 | BC316842192932en-001001 © Danfoss | DCS (vt) | 2020.03

Page 33

User Guide | AK-System Manager, AK-SM 800 Series

Open the Refrigeration layout wizard and follow the described

steps, each step has some description for the available actions.

The following wizard screens are available in sequential order;

Network (select and perform network scan)

Discovery (list scanned devices)

Compressors (Input Pack controller name, view address, model,

add, copy, remove)

Circuits (Input Evaporator controller name, view address, model,

add, copy, remove)

Suction Group mapping (Drag and drop your evap controllers

under each pack)

Summary (view your groupings before finishing wizard and thus

processing your selections to the AK-SM)

Note: For ModBus networks with >40 devices, set number of polls

to 2 in the network selection screen.

Please note that the Danfoss Refrigeration gas sensors will not

show up via a layout wizard scan. A manual scan is currently

required to detect and configure these sensors.

After the relevant networks have been selected an scanned the

‘Discovery’ screen will show all detected devices. Once satisfied

with the correct content press the forward button to continue the

wizard.

Double click the ‘Name’ line to enter a custom description for the device.

Pressing return will automatically focus on the next device name in the

list.

Use the Add button when creating offline nodes. Double click

the ‘model’ line to bring up a selection of nodes

If your scanned list has known devices that are standalone

(not associated with a Pack) these must be mapped under

‘No Compressor’. Manually add a new compressor and

double click the model line and select ‘No Compressor’.

When the final wizard screen is presented any standalone

controls can be mapped under this ‘No Compressor’ group.

The ‘Compressors’ screen allows for custom text input. If working

offline (programming a database not being connected to a

AK-SM) the Add, Copy and Remove buttons can be used.

The ‘Circuits’ screen follows the same principle as the

Compressors screen.

© Danfoss | DCS (vt) | 2020.03 BC316842192932en-001001 | 33

Page 34

User Guide | AK-System Manager, AK-SM 800 Series

The ‘Suction group mapping’ screen allows for the defined

evaporator devices to be ‘mapped’ under the required Pack

controller. This mapping forms a relationship or grouping

between the pack and the evaporator devices. This grouping

association will then be seen in the AK-SM configuration and

dashboard screens (and can be used to easily set up master

control functions like Suction optimization).

As the user description indicates, use a drag and drop action to

group your controls. Use the CTRL key and multi-select cases to

save time when making bulk actions. You can remove any case

devices by simply dragging back to the available case list.

The check box labelled ‘Allow multi-case circuit creation’ is to

support Centralized refrigeration control configuration, where

multiple case circuits are available’. Leave this check box empty if

you are using a de-centralized control strategy (i.e. Case and pack

controllers).

Once satisfied with the mapping, press the forward button and

the summary screen will be shown. Pressing the finish button will

then send your configuration layout to the AK-SM. During this

time a progress bar will be shown and finally a status dialogue

box.

This completed wizard process will layout your refrigeration

application. Typically some additional configuration tasks will

then need to be completed (i.e. define alarms, setpoint changes,

configure history), please refer to the following section for further

details on detailed configuration.

34 | BC316842192932en-001001 © Danfoss | DCS (vt) | 2020.03

Page 35

User Guide | AK-System Manager, AK-SM 800 Series

Copy Wizard

Before performing the copy function ensure your SM 800

database is in sync with any control devices on line – refer to

previous section ‘System Upload / Download’ before starting

copy wizard’

The copy wizard is designed to speed up the commissioning

workflow by providing the ability to define a ‘source’ device and

then copy the settings to like type devices. In addition to

controller settings, the copy wizard also provides the ability to

define and copy alarm controller configuration and history point

configuration. A new feature added under the copy wizard for

version G08_031 is the ability to save / load controller settings to

and from a file.

During normal operations, your AK-SM 800 auto polls certain

online controller parameters to sustain communications and to

refresh key parameters at regular intervals. Please note that

during the copy wizard process auto polling is temporarily

suspended. Polling is stopped when you reach the parameter

configuration screen. Auto polling will resume after a max 2Hr

timeout or completion of wizard task or if wizard is cancelled,

whichever is first. To cancel the wizard at any time only use the

top left close ‘X’ button.

Some Danfoss controllers require that the ‘Main switch’ is OFF

before allowing any parameter changes. To accommodate this

fact, the copy wizard will automatically turn off the main switch

for the source and destination controller(s). The main switch will

be reverted to original position after the copy or copy/download

is completed. Since the copy wizard changes the state of the

device main switch, please pay special attention to operational

conditions (i.e. food temperature) during this operation and

validate all devices are correctly running after copy completion or

cancellation of copy wizard. Failure to review device status may

result in devices being left with main switch off (i.e. no

refrigeration).

Important limitations

The copy wizard is currently not designed to fully support the

Danfoss AK2 platform of devices (i.e. AK-PC 781, AK-CC 750..) since

these devices have a different framework than other Danfoss

controllers. When using the copy wizard in an on-line

environment (connect to active controller network) the copy

wizard will only allow ‘Alarms and History’ points to be set and

copied. For full configuration of AK2 device parameters Danfoss

recommends using the available Service Tool to facilitate

commissioning on these device types.

Please note that the copy function will only work against same

device, application/code type and is not designed to fully support

Danfoss AK2 style controllers.

Preparation

Online Configuration

For onsite (online) commissioning, the copy wizard assumes all

relevant controller devices are installed on the network, have

correct addressing, and if relevant application type set. Naming

of the asset will also help in the copy wizard due to easy

recognition of your devices. The ‘Layout wizard’ can assist in this

preliminary task.

During the final copy/download phase, the main switch of the

target device(s) will be switched off then on after the copy/

download is complete.

Offline Configuration

The copy wizard can be used in an online or offline (via RMT

simulator) environment.

Before using the copy wizard make sure the source device

is fully configured (settings, history, alarms). Whilst it is

possible to use the copy wizard to set up the source

device, it is not recommended and has been seen that

potential errors can occur with this workflow – please

configure the source device first (outside of the copy

wizard). Once source device is configured the copy wizard

can be used, do not make any changes (settings, alarms,

history) to the source device whilst in the copy wizard.

When copying history. Be aware, that the copy process always

keeps existing logs in the destination and new logs will be added.

BE SURE TO VALIDATE MAIN SWITCH STATUS AFTER COPY WIZARD

Note: When assigning history points to a controller device a

recommended max of 100 points per device is allowed. Assigning

more than 100 points per device will cause points not to record

log history.

© Danfoss | DCS (vt) | 2020.03 BC316842192932en-001001 | 35

Page 36

User Guide | AK-System Manager, AK-SM 800 Series

Network Nodes

If your application already has controllers and/or I/O modules set

and powered you may wish to perform a network scan to validate

their connection to the AK-SM. Follow this section to perform a

network scan

From the Configuration tab select the ‘Network Nodes’ sub-tab.

When your field network is complete and all controllers are on line

Use this screens to

perform network scan

Relays | Sensors | On/Off | Variable Output

This tab relates to any AK I/O configured points,

the term points relates to AK I/O relay, sensors,

On/Off Inputs and variable outputs. Any control

questions that have required AK I/O control will

be seen in these tabs. The purpose of these tabs

is to allow the viewing of the I/O point status.

All nodes | Controllers | I/O boards | Other nodes

The scan status menu/tabs allows the user to view any scanned nodes

found on the network.

All Nodes: Central list will display configured devices and points. Only

configured controllers will be visible in this list.

Controllers: view any scanned generic controllers. This screen will also

reflect address and controller type

I/O Boards: Display AK Board & Point status.

Other Nodes: List of other nodes

‘Use this screens to

view status of your

assets (Online)

a network scan can be initiated. The operation of a network scan

allows the AK-SM to be aware of any controller devices on the

network, allowing the AK-SM to communicate and function with

the controllers on the field bus.

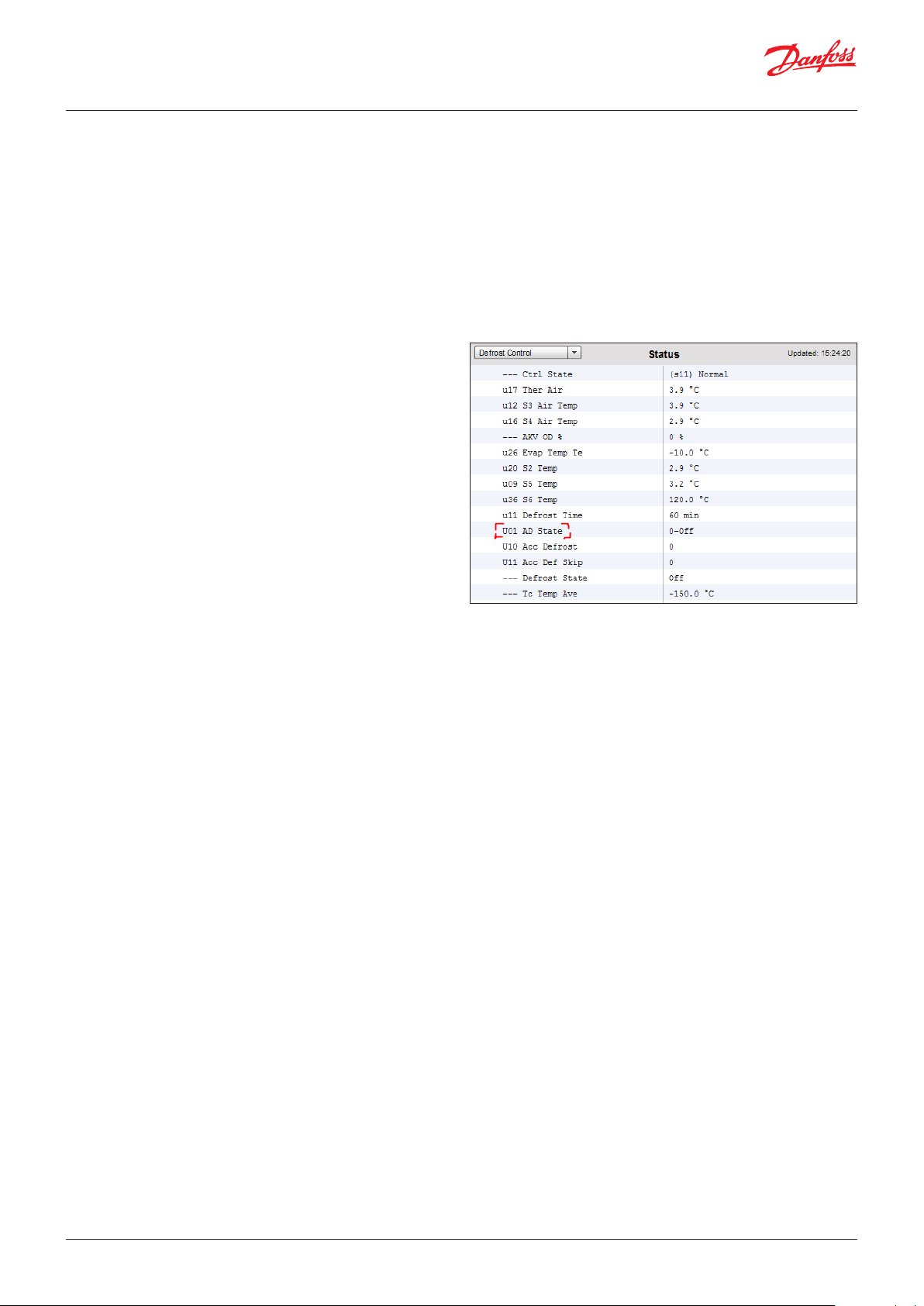

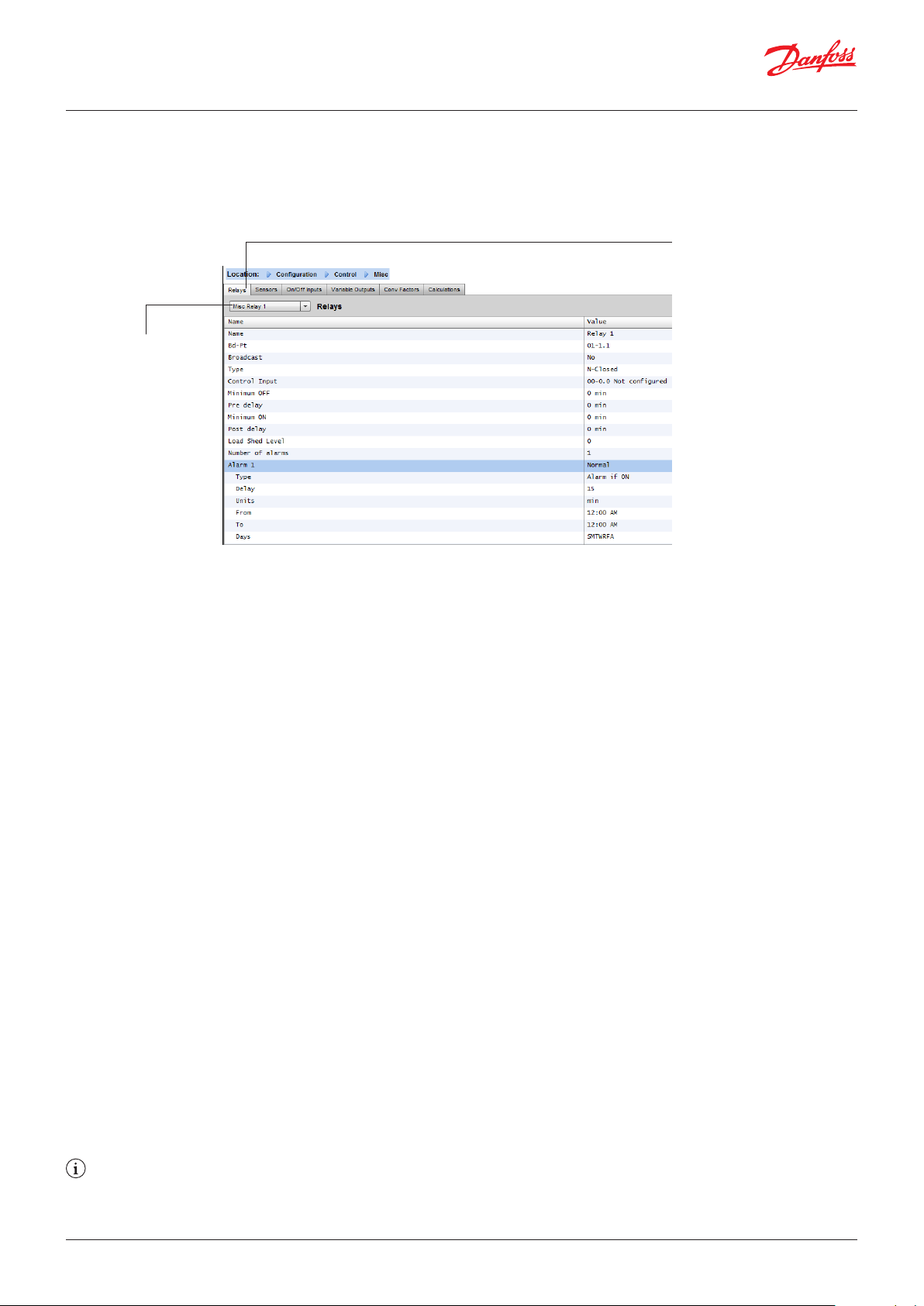

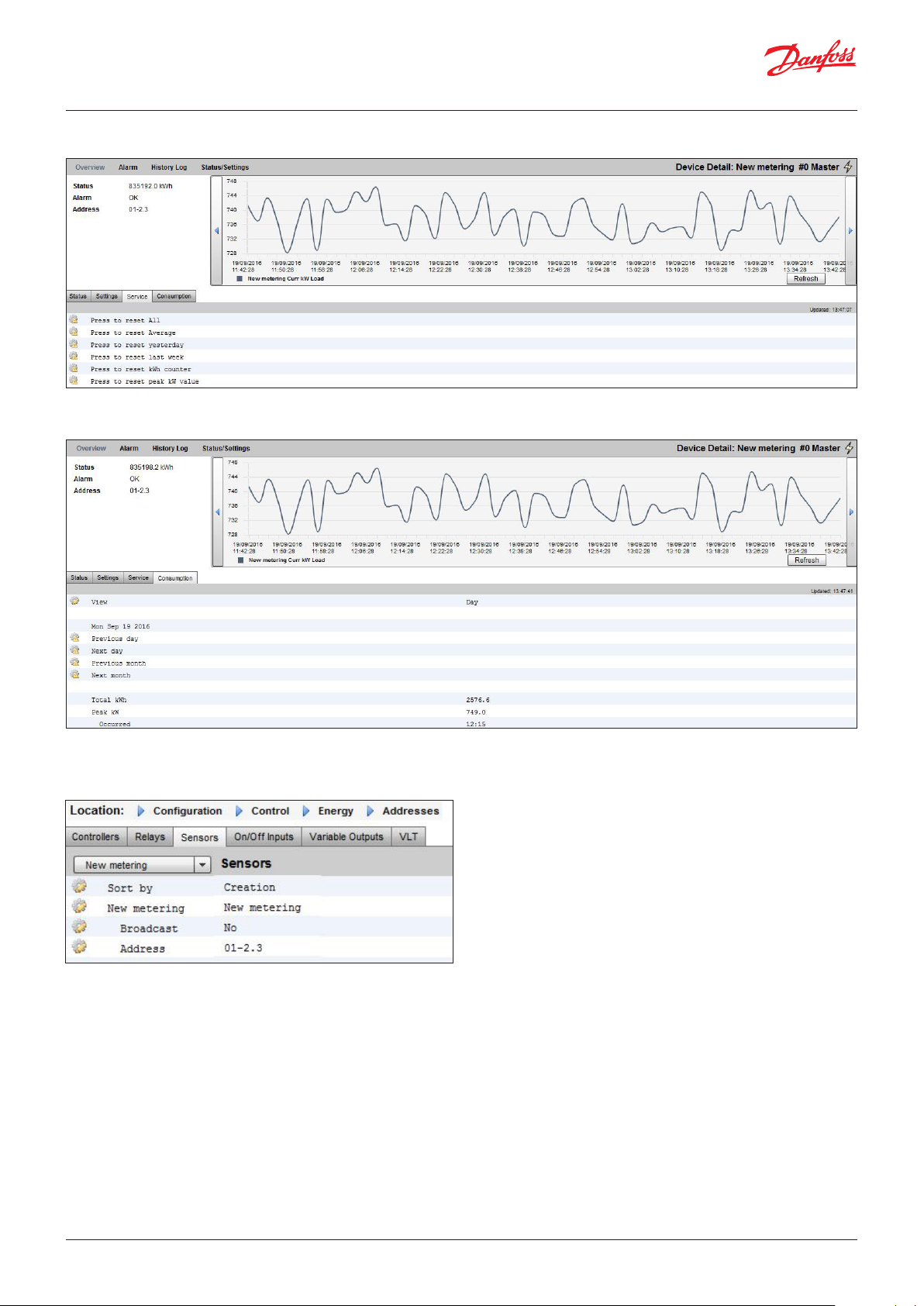

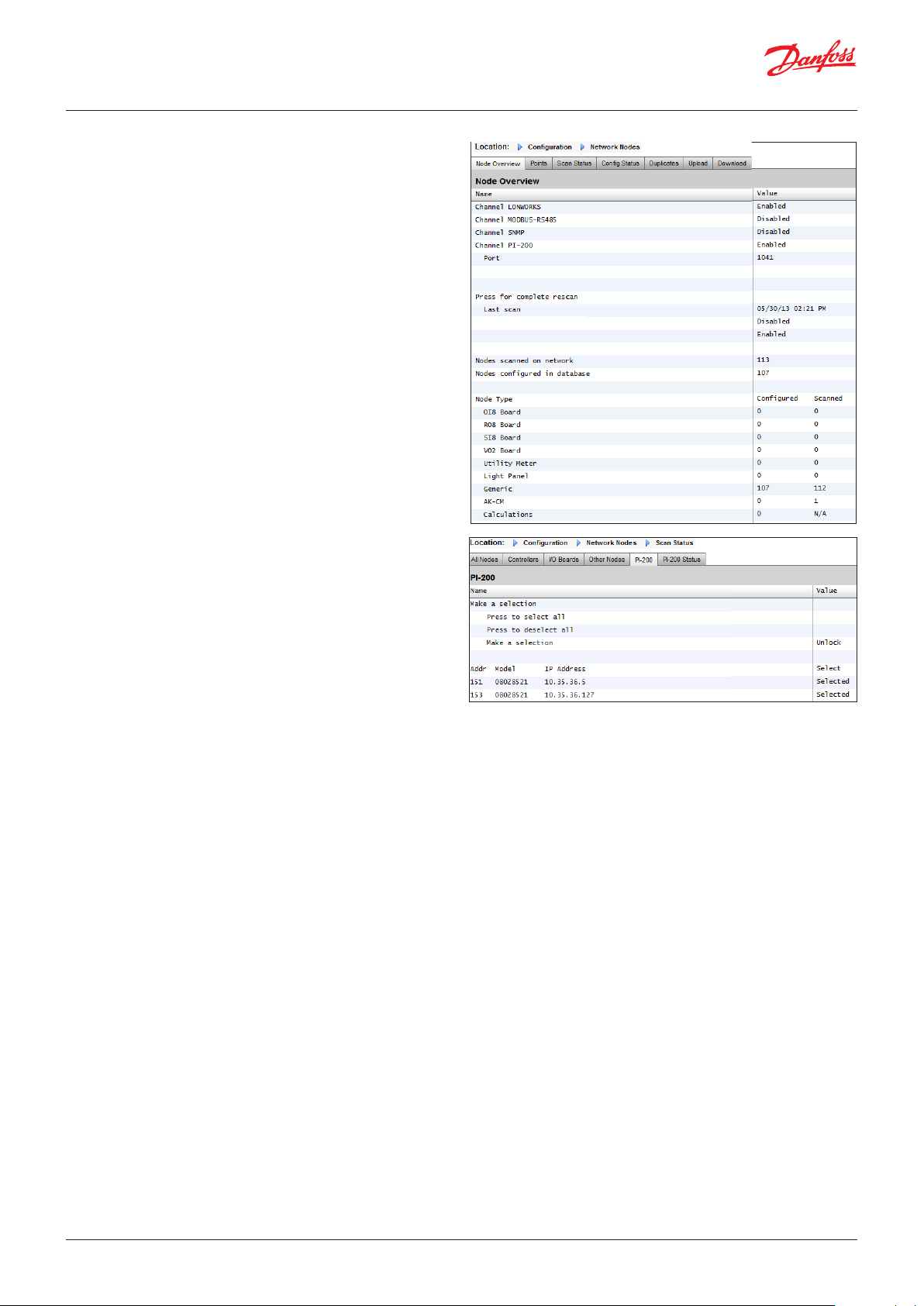

Note: For ModBus networks with >40 devices, set number of polls