Page 1

User Guide

Network control

AK-SM 720

ADAP-KOOL® Refrigeration control systems

www.danfoss.com

Page 2

User Guide | Network control AK-SM 720

Contents

1. Introduction

Application ................................................................................................. 3

Principles ..................................................................................................... 4

2. Design of a controller

Module survey .................................................................................................... 7

Common data for modules ............................................................................9

Dimensions ........................................................................................................10

System manager AK-SM.......................................................................11

Extension module AK-XM 101A ........................................................13

Extension module AK-XM 102A / AK-XM 102B ............................15

Extension module AK-XM 204A / AK-XM 204B ............................17

Extension module AK-XM 205A / AK-XM 205B ............................19

Extension module AK-XM 107A .......................................................21

Extension module AK-OB 110 ............................................................23

Power supply module AK-PS 075 / 150 ..........................................24

Preface to design .............................................................................................25

Functions ...................................................................................................25

Connections .............................................................................................26

Limitations ................................................................................................26

Design of a System manager ......................................................................27

Ordering .............................................................................................................35

3. Mounting and wiring

Mounting............................................................................................................36

Wiring ..................................................................................................................37

4. Configuration and operation

Installation in network...................................................................................39

Configuration ....................................................................................................41

Connect PC ...............................................................................................41

Unlock the configuration of the controllers .................................43

Clock function .........................................................................................44

Quick setup...............................................................................................45

Plants main data .....................................................................................46

Alarm relay on plant ..............................................................................47

Destinations to be communicated with ........................................48

Routing of alarms ...................................................................................49

Alarms from controllers .......................................................................51

Modem and IP settings ........................................................................52

Design some functions yourself .......................................................53

Alarms for boolean functions ............................................................54

AKC controllers on DANBUSS.............................................................55

Configuration of inputs and outputs ..............................................57

Set alarm priorities .................................................................................58

Lock configuration .................................................................................59

Check configuration ..............................................................................60

Check of connections ....................................................................................61

Find the controllers on the network .........................................................62

Setup of controllers ........................................................................................63

Setup functions ................................................................................................64

Logs ......................................................................................................................65

Plant operations ...............................................................................................67

First start of system manager ......................................................................81

Check alarms ............................................................................................81

Lock configuration of connections ..................................................82

Check level for safety ............................................................................83

Conclusion ................................................................................................83

5. Regulating function

Local data communication ..........................................................................85

Extern data communication ........................................................................86

Alarm handling ................................................................................................88

Plant controls ....................................................................................................90

Logs ......................................................................................................................94

Operation ...........................................................................................................96

Clock.....................................................................................................................97

2 | BC041586425769en-000602 © Danfoss | DCS (vt) | 2020.01

Page 3

User Guide | Network control AK-SM 720

1. Introduction

Application

AK-SM 720 is a complete system manager to control data communication to ADAP-KOOL® Refrigeration Control Systems.

The system unit makes it possible to transmit alarms and system

functions to external receivers.

The main function of the system manager is to transmit alarms.

It also contains the primary functions that the refrigeration system’s controllers can use to sub-optimise the individual refrigeration sites.

To mention some of the various functions briefly:

• Alarm receiver

• Forward alarms

• Collect logs

• Schedules

• Defrost groups

• Light functions

• Energy-saving functions

• Design of Boolean functions

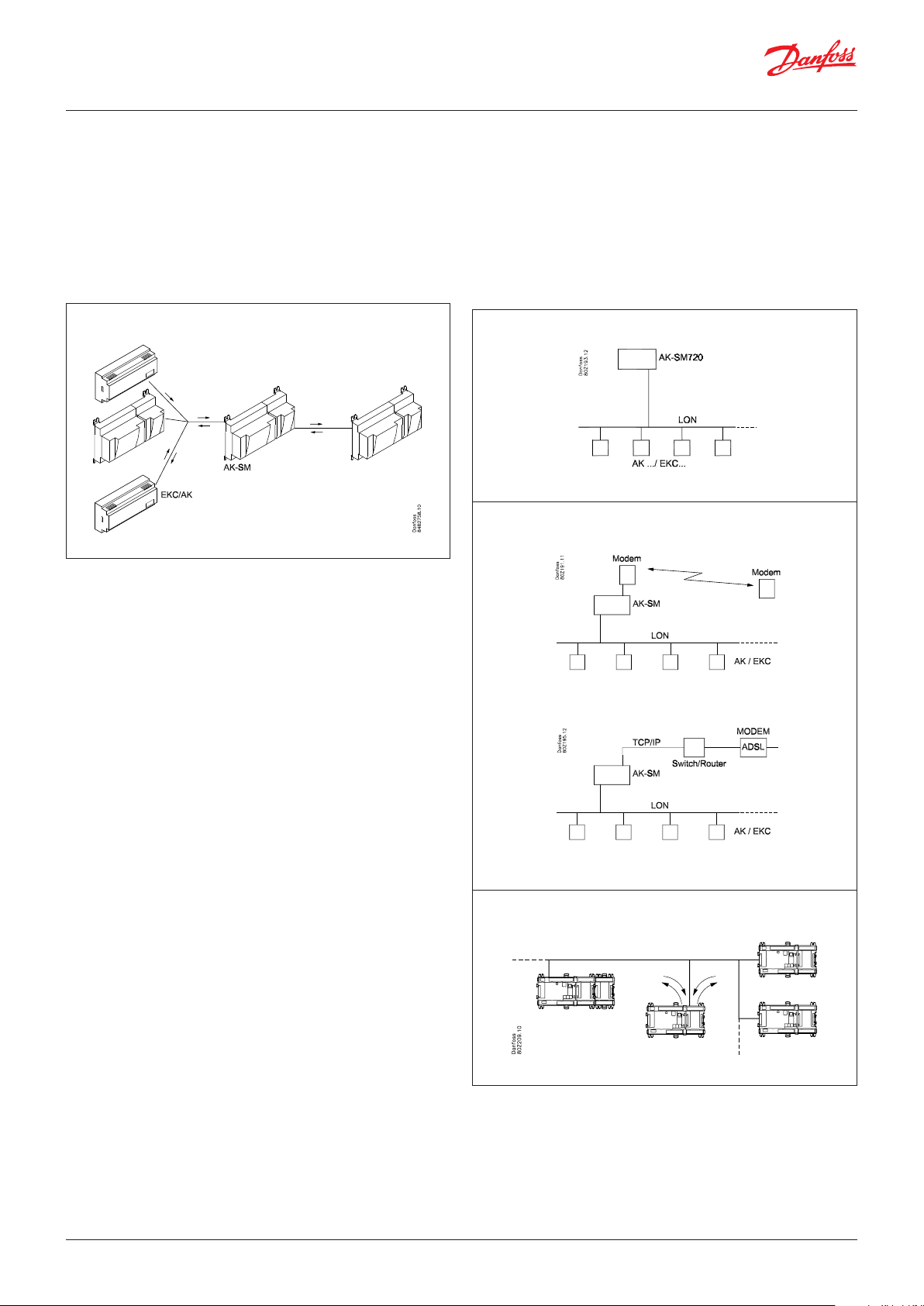

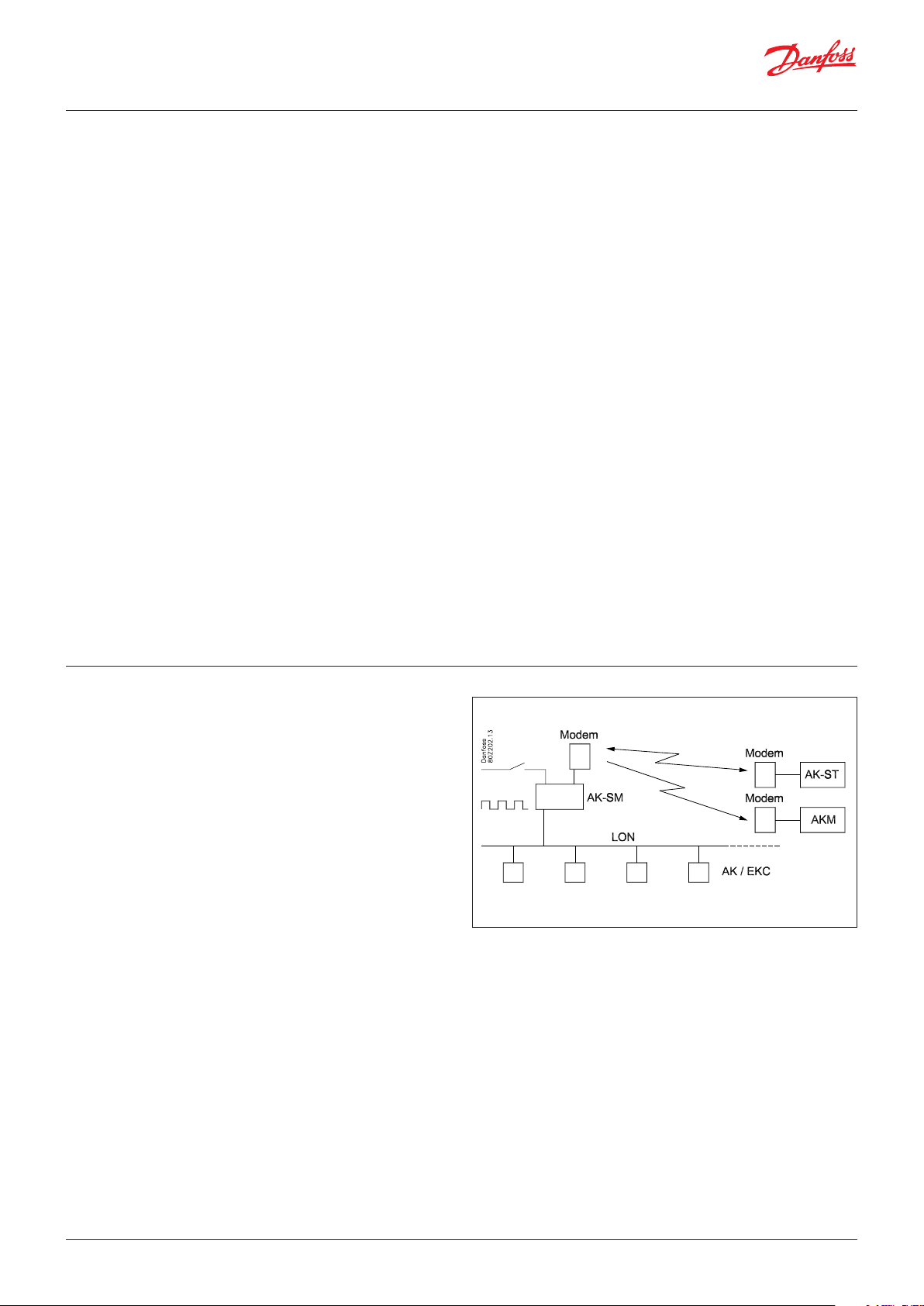

Examples

Here are a couple of examples where the system manager takes

care of communication to other units.

Receive alarms and logs from the controllers in the application

Modem connection to the service company

Local data communication can be:

• LON RS 485

• MODBUS

• DANBUSS (this does, however, also require a protocol interface

type AK-PI 200. Literature no. RS8EX)

• There is a maximum of 200 controllers on the data communication.

A maximum of 120 units of the EKC incl. SLV, where there must

be a maximum of 15 different types and software versions.

• TCP/IP

External data communication can be:

• TCP/IP

• Modem

Operation must take place using:

• Service tool type AK-ST

The system unit can transmit alarms and logs to:

• System software type AKM

© Danfoss | DCS (vt) | 2020.01 BC041586425769en-000602 | 3

Retrieve functions from some controllers and forward them to others

Page 4

User Guide | Network control AK-SM 720

Principles

The great advantage of this series of controllers is that it can

be extended as the size of the plant is increased. It has been

developed for refrigeration control systems, but not for any

specific application – variation is created through the read-in

software and the way you choose to define the connections.

It is the same modules that are used for each regulation and the

composition can be changed, as required. With these modules

(building blocks) it is possible to create a multitude of various

kinds of regulations. But it is you who must help adjusting the

regulation to the actual needs – these instructions will assist you

to find your way through all the questions so that the regulation

can be defined and the connections made.

Controller

Top part

Bottom part

The controller is the cornerstone of the regulation. The module has inputs and

outputs capable of handling small systems.

• The bottom part – and hence the terminals – are the same for all controller types.

• The top part contains the intelligence with software. This unit will vary according

to controller type. But it will always be supplied together with the bottom part.

• In addition to the software the top part is provided with connections for data

communication and address setting.

Advantages

• The controller’s size can “grow” as systems grow

• The software can be set for one or more regulations

• Several regulations with the same components

• Extension-friendly when systems requirements are changed

• Flexible concept:

- Controller series with common construction

- One principle – many regulation uses

- modules are selected for the actual connection requirements

- The same modules are used from regulation to regulation

Extension modules

If the system grows and more functions have to be controlled, the regulation can be

extended.

With extra modules more signals can be received and more relays cut in and out

– how many of them – and which – is determined by the relevant application.

Examples

A regulation with few connections can

be performed with the controller module

alone

If there are many connections one or more

extension modules have to be mounted

4 | BC041586425769en-000602 © Danfoss | DCS (vt) | 2020.01

Page 5

User Guide | Network control AK-SM 720

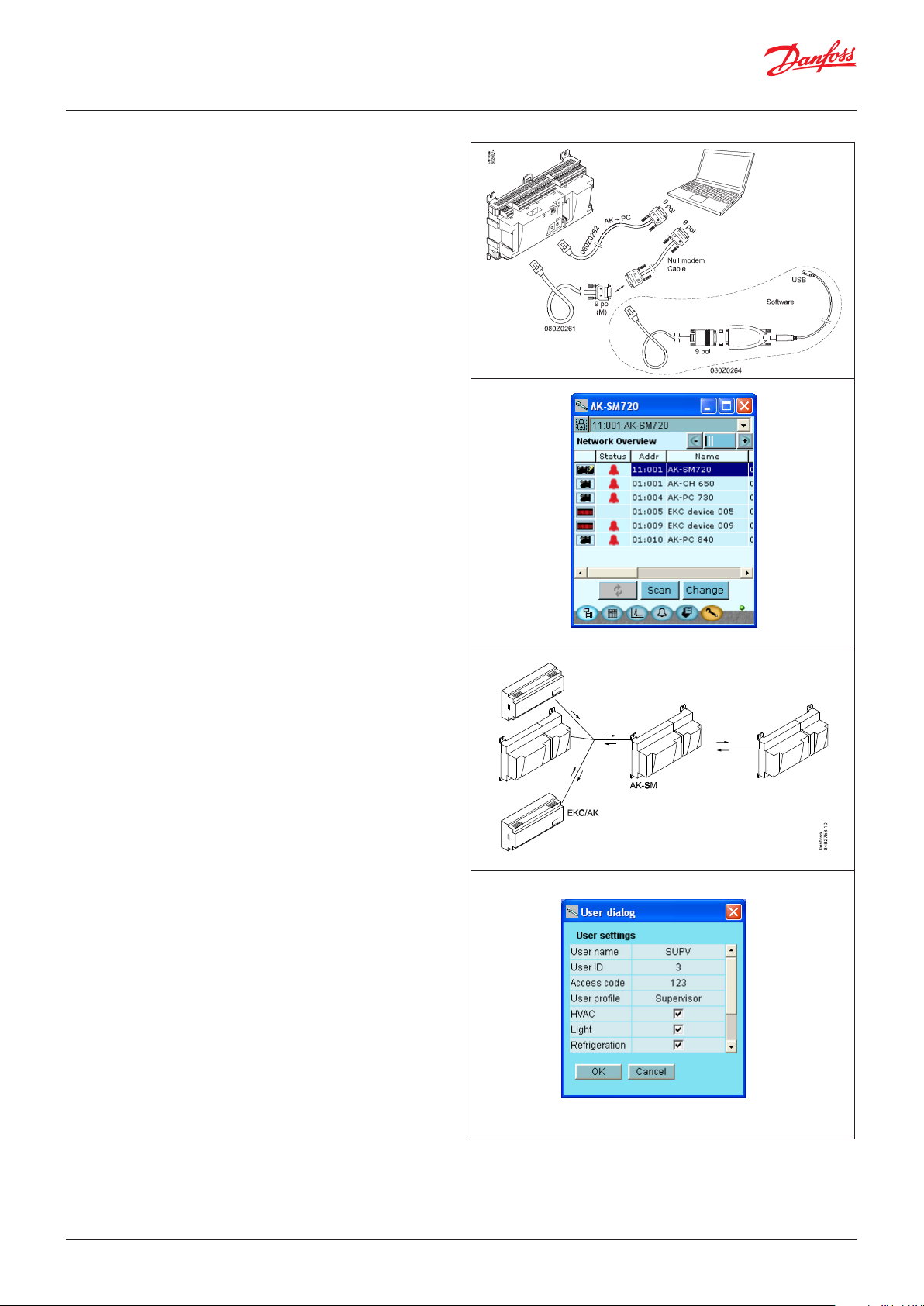

Direct connection

Setup and operation of an AK controller must be accomplished via

the “AK-Service Tool” software program.

The programme is installed on a PC, and setup and operation of

the various functions are carried out via the controller’s menu

displays.

Displays

The menu displays are dynamic, so that different settings in one

menu will result in different setting possibilities in other menus.

A simple application with few connections will give a setup with

few settings.

A corresponding application with many connections will give a

setup with many settings.

From the overview display there is access to further displays for

the compressor regulation and the condenser regulation.

At the bottom of the display there is access to a number of general

functions, such as "network overview", “time table”, “log function”,

“alarms”, "plant control" and “service” (configuration).

Data communication

The controller forwards the data communication to all of the

connected controllers. It receives measurements from selected

functions. The measurements are sent to other controllers, which

use the value in the control function.

The controller receives alarms from all connected controllers and

forwards them to the defined receivers.

Users

All users must be assigned a user profile which either gives access

to full operation or gradually limits the operation to the lowest

level that only allows you “to see”.

Users are added and defined in the menu item “Configuration”/

”Authorisation”.

© Danfoss | DCS (vt) | 2020.01 BC041586425769en-000602 | 5

Page 6

User Guide | Network control AK-SM 720

Light-emitting diodes

A number of light-emitting diodes makes it possible to follow the

signals that are received and transmitted by the controller.

Log

From the log function you can define the measurements you wish

to be shown.

The collected values can be printed, or you may export them to a

file. You can open the file in Excel.

If you are in a service situation you can show measurements in a

trend function. The measurements are then made realtime and

displayed instantly.

n Power

n Comm

n DO1 n Status

n DO2 n Alarm

n DO3 n Service Tool

n DO4 n LON

n DO5 n RS485

n DO6 n LAN

n DO7

n DO8 n Service Pin

Slow flash = OK

Quick flash = answer from master in 10 min.

after network installation

Constantly ON = error

Constantly OFF = error

Flash = Active alarm / not cancelled

Constant On = Aktive alarm / cancelled

External communication

Network installation

Alarm

The display gives you an overview of all active alarms. If you wish

to confirm that you have seen the alarm you can cross it off in the

acknowledge field.

If you want to know more about a current alarm you can click on it

and obtain an information display on the screen.

A corresponding display exists for all earlier alarms. Here you can

upload information if you need further details about the alarm

history.

6 | BC041586425769en-000602 © Danfoss | DCS (vt) | 2020.01

Page 7

User Guide | Network control AK-SM 720

2. Design of a controller

This section describes how the controller is designed.

The controller in the system is based on a uniform connection

platform where any deviations from regulation to regulation is

determined by the used top part with a specific software and

by which input and output signals the relevant application will

Module survey

• Controller module – capable of handling minor plant requirements.

• Extension modules. When the complexity becomes greater and

additional inputs or outputs are required, modules can be attached to the controller. A plug on the side of the module will

transmit the supply voltage and data communication between

the modules.

• Top part

The upper part of the controller module contains the intelligence.

This is the unit where the regulation is defined and where data

communication is connected to other controllers in a bigger

network.

• Connection types

There are various types of inputs and outputs. One type may, for

example, receive signals from sensors and switches, another may

receive a voltage signal, and a third type may be outputs with

relays etc. The individual types are shown in the table below.

require. If it is an application with few connections, the controller

module (top part with belonging bottom part) may be sufficient.

If it is an application with many connections it will be necessary to

use the controller module plus one or more extension modules.

This section will give you a survey of possible connections plus

assistance in selecting the modules required by your actual

application.

• Optional connection

When a regulation is planned (set up) it will generate a need for

a number of connections distributed on the mentioned types.

This connection must then be made on either the controller

module or an extension module. The only thing to be observed

is that the types must not be mixed (an analog input signal must

for instance not be connected to a digital input).

• Programming of connections

The controller must know where you connect the individual

input and output signals. This takes place in a later configuration where each individual connection is defined based on the

following principle:

- to which module

- at which point (”terminals”)

- what is connected (e.g. pressure transmitter/type/

pressure range)

Extension module with

additional analog inputs

Controller with analog inputs and

relay outputs.

Top part

Extension module with additional

relay outputs and additional

analog inputs.

The module with additional relay outputs is

also available in a version where the top part

is provided with change-over switches so

that the relays can be overridden.

Extension module with

analog output signals

© Danfoss | DCS (vt) | 2020.01 BC041586425769en-000602 | 7

Page 8

User Guide | Network control AK-SM 720

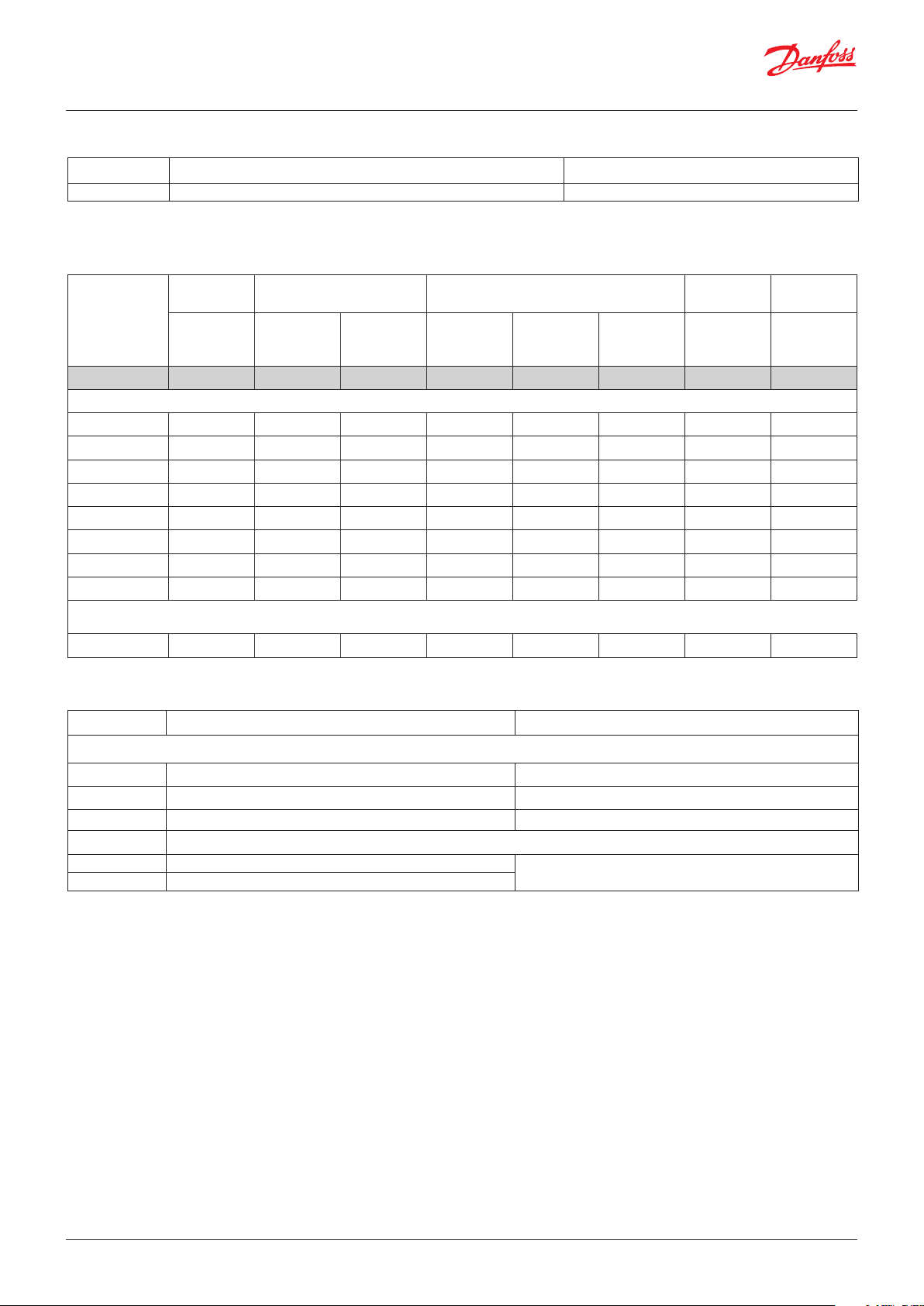

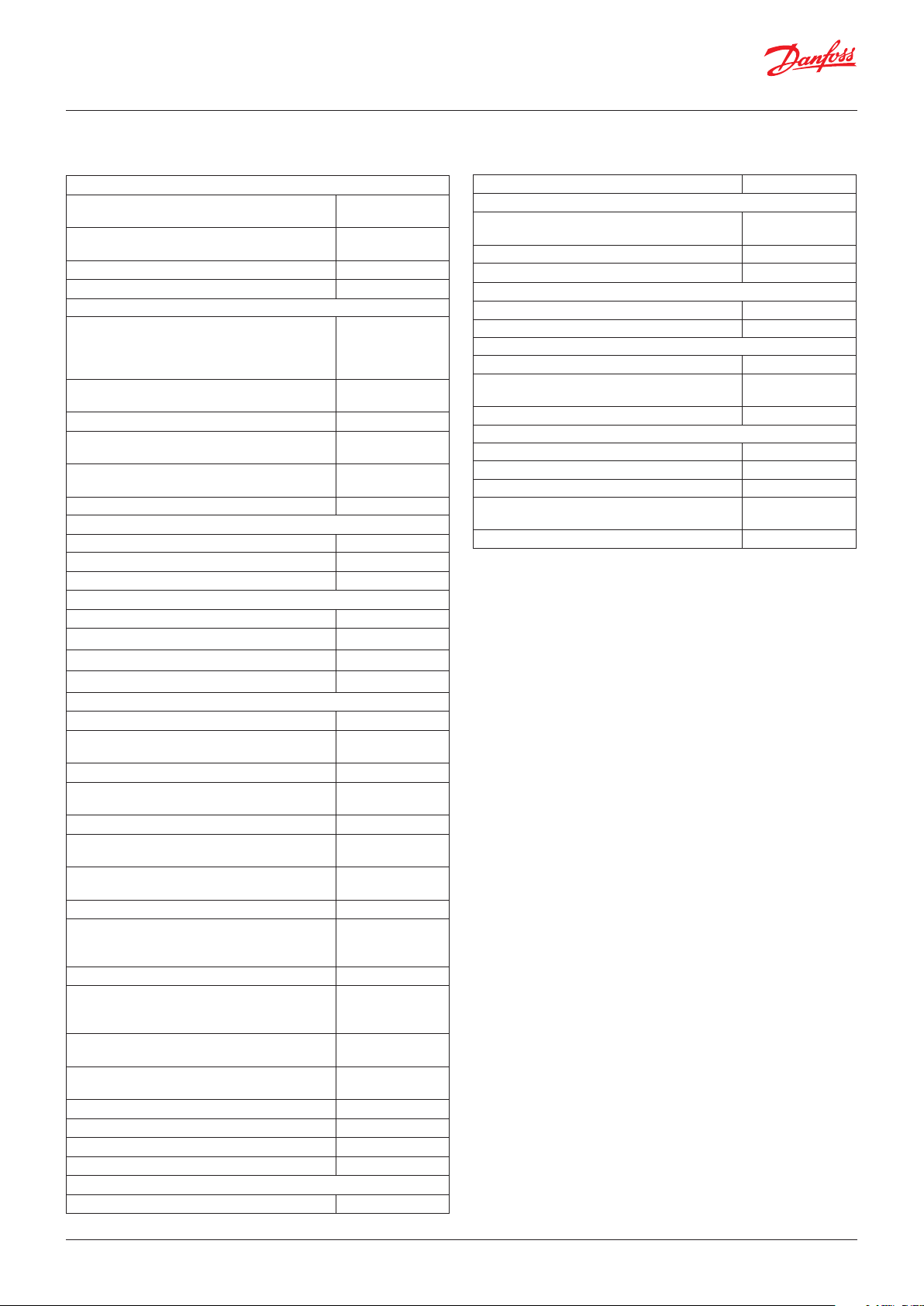

1. Controller

Type Function Application

AK-SM 720 System manager Control data communication

2. Extension modules and survey of inputs and outputs

Type Analog

inputs

For sensors,

pressure transmitters etc.

System manager 11 4 4 - - - - -

Extension modules

AK-XM 101A 8

AK-XM 102A 8

AK-XM 102B 8

AK-XM 204A 8

AK-XM 204B 8 x

AK-XM 205A 8 8

AK-XM 205B 8 8 x

AK-XM 107A 8

The following extension module can be placed on the PC board in the controller module.

There is only room for one module.

AK-OB 110 2

On/Off outputs On/off supply voltage

Relay

(SPDT)

Solid state Low voltage

(DI signal)

(max. 80 V)

High voltage

(max. 260 V)

Pulse counter

Low voltage

(max 30 V)

Analog

outputs

0 – 10 V DC For override of

Module with

switches

relay outputs

3. AK operation and accessories

Type Function Application

Operation

AK-ST 500 Software for operation of AK controllers AK-operation

- Cable between PC and AK controller AK - Com port

- Cable between zero modem cable and AK controller AK - RS 232

Accessories Power supply modul 230 V / 115 V to 24 V DC

AK-PS 075 18 VA DC

AK-PS 150 36 VA DC

Supply for controller

On the following pages there is data specific to each module.

8 | BC041586425769en-000602 © Danfoss | DCS (vt) | 2020.01

Page 9

User Guide | Network control AK-SM 720

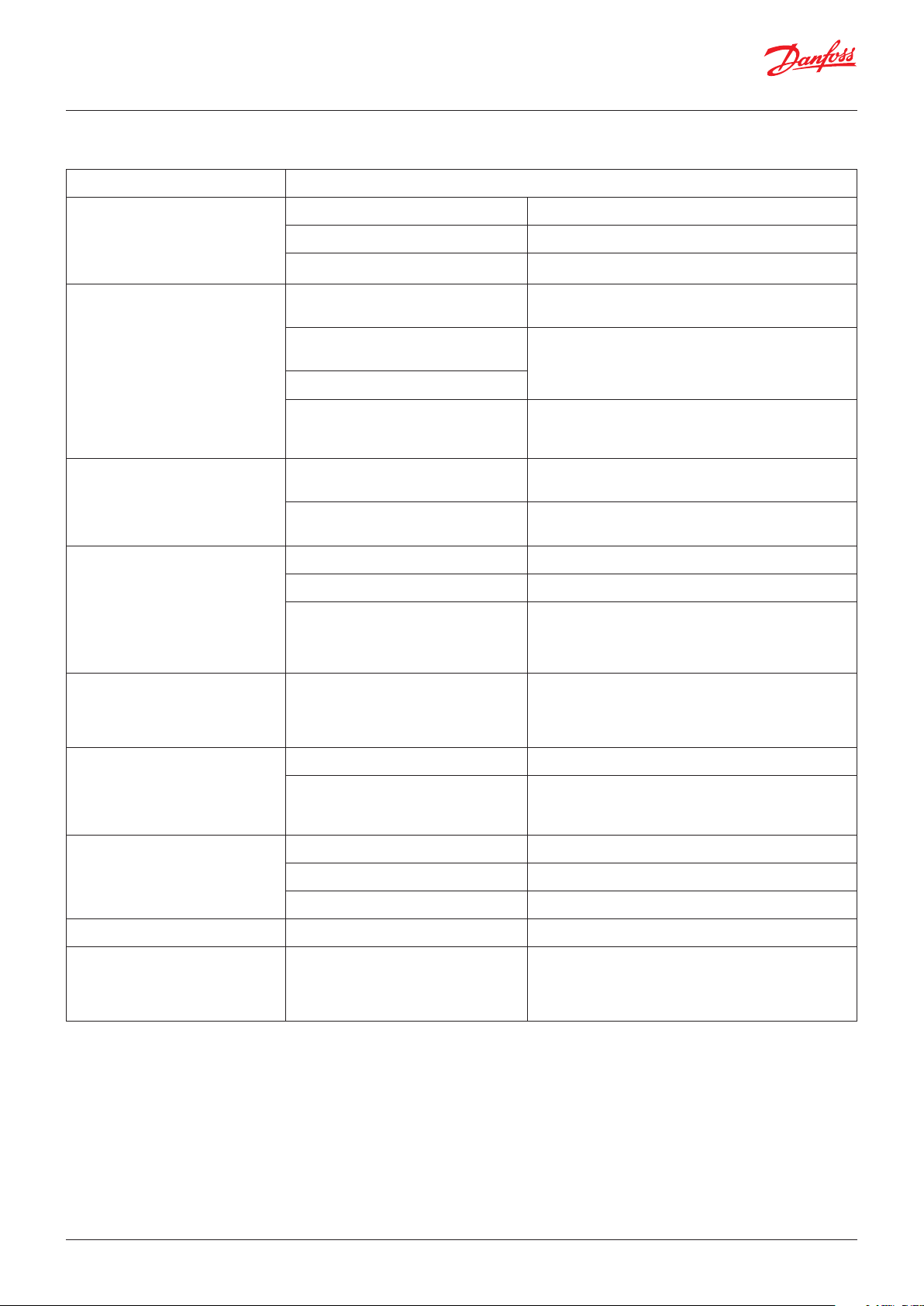

Common data for modules

Supply voltage 24 V DC/AC +/- 20%

Power consumption AK-SM 720 8 VA

AK-XM 101, 102, 107 2 VA

AK-XM 204, 205 5 VA

Analog inputs Pt 1000 ohm /0 °C Resolution: 0.1 °C

Pressure transmitter type AKS 32R /

AKS 32 (1 – 5 V)

Voltage signal 0 – 10 V

Contact function (On/Off) On at R < 20 ohm

On/off supply voltage inputs Low voltage

Relay outputs

SPDT

Solid state outputs Can be used for loads that are cut in and

0 / 80 V AC/DC

High voltage

0 / 260 V AC

AC-1 (ohmic) 4 A

AC-15 (inductive) 3 A

U Min. 24 V

out frequently, e.g. :

rail heat, fans and AKV valve

Accuracy: +/- 0.5 °C

Resolution: 1 mV

Accuracy +/- 10 mV

Max. connection of 5 pressure transmitters on one module

Off at R > 2K ohm

(Gold -plated contacts not necessary)

Off: U < 2 V

On: U > 10 V

Off: U < 24 V

On: U > 80 V

Max. 230 V

Low and high voltage must not be connected to the same

output group

Max. 240 V AC , Min. 48 V AC

Max. 0.5 A,

Leak < 1 mA

Max. 1 AKV

Ambient temperature During transport -40 – 70 °C

During operation -20 – 55 °C ,

0 – 95% RH (non condensing)

No shock influences / vibrations

Enclosure Material PC / ABS

Density IP10 , VBG 4

Mounting For mounting on panel wall or DIN rail

Weight with screw terminals Modules in100- / 200- / controller-series Ca. 200 g / 500 g / 600 g

Approvals EU low voltage directive and EMC require-

ments are complied with

The mentioned data applies to all modules.

If data is specific, this is mentioned together with the module in question.

LVD tested according to EN 60730

EMC tested

Immunity according to EN 61000-6-2

Emission according to EN 61000-6-3

© Danfoss | DCS (vt) | 2020.01 BC041586425769en-000602 | 9

Page 10

User Guide | Network control AK-SM 720

Dimensions

The module dimension is 72 mm.

Modules in the 100-series consist of one module

Modules in the 200-series consist of two

modules

Controllers consist of three modules

The length of an aggregate unit = n x 72 + 8

A power supply module is either 36 mm or 54

mm

If there is space on the DIN rail, the power supply module can be positioned to the left of the

system manager.

10 | BC041586425769en-000602 © Danfoss | DCS (vt) | 2020.01

Page 11

User Guide | Network control AK-SM 720

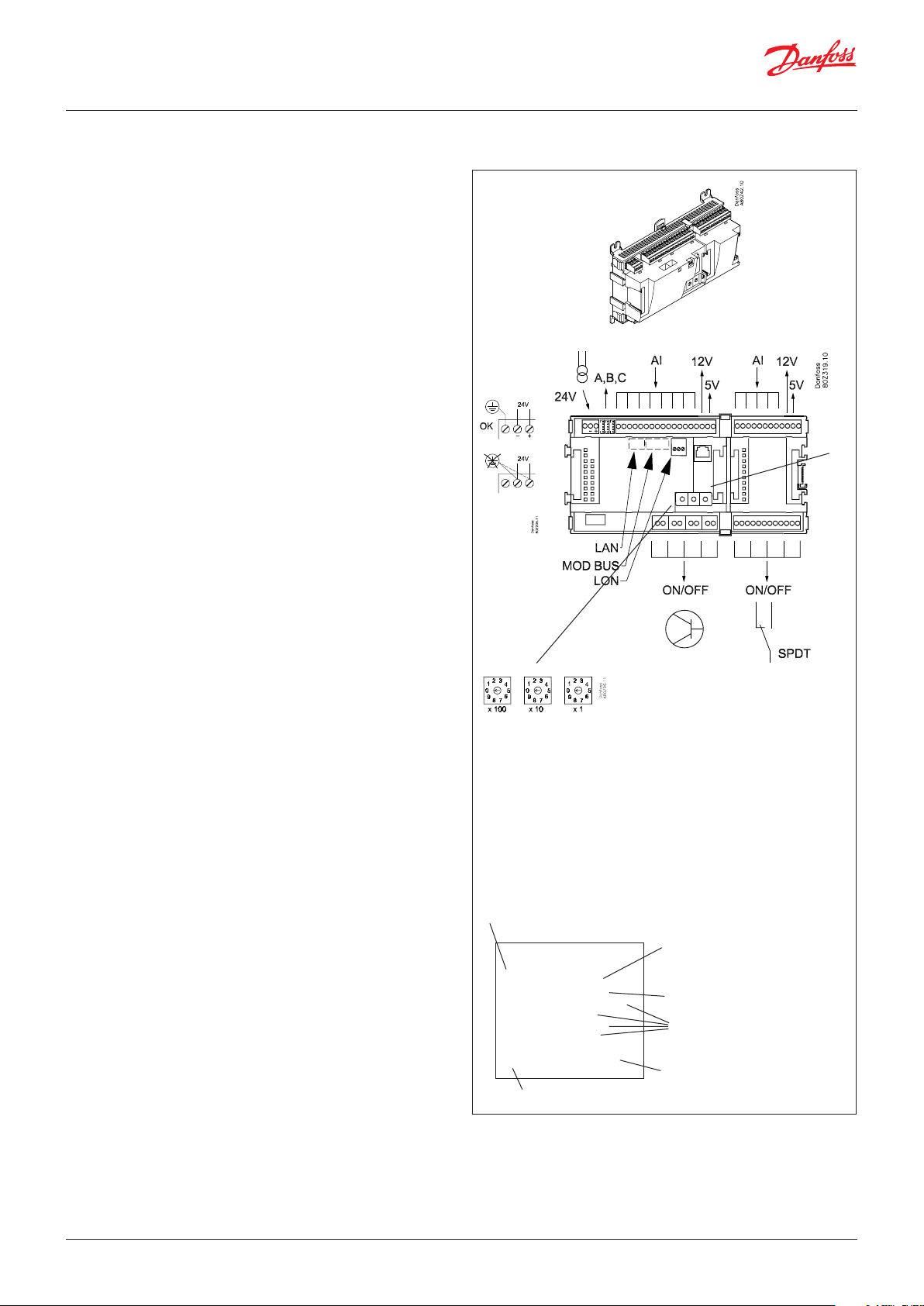

System manager AK-SM

Function

There are several controllers in the series. The function is

determined by the programmed software, but outwardly the

controllers are identical – they all have the same connection

possibilities:

11 analog inputs for sensors, pressure transmitters, voltage signals

and contact signals.

8 digital outputs, with 4 Solid state outputs and 4 relay outputs

Supply voltage

24 V AC or DC to be connected to the controller.

The 24 V must not be retransmitted and used by other controllers

as it is not galvanically separated from inputs and outputs. In

other words, you must use a transformer for each controller. Class

II is required. The terminals must not be earthed.

The supply voltage to any extension modules is transmitted via

the plug on the right-hand side.

The size of the transformer is determined by the power

requirement of the total number of modules.

The supply voltage to a pressure transmitter can be taken either

from the 5 V output or from the 12 V output depending on

transmitter type.

PIN

Data communication

The installation has to be made as mentioned in the separate

instructions.

Address setting

When the system manager is configured, the address must be set

in the range 1 to 10. 1 must always be used. If there are more than

one, the rest must be set with addresses 2 to 10.

Service PIN

When the address has been set, the software must know the setting. This is done by pressing the Service PIN button. The “Status”

LED will flash when acceptance is received.

Operation

The configuration operation of the controller must take place from

the software programme “Service Tool”. The program must be

installed on a PC, and the PC must be connected to the controller

via the network plug on the front of the unit.

Light-emitting diodes

There are two rows with LED’s. They mean:

Left row:

• Voltage supply to the controller

• Communication active with the bottom PC board (red = error)

• Status of outputs DO1 to DO8

Right row:

• Software status

• Alarm when LED flashes. Alarm acknowledged = constant light

• Communication with Service Tool

• Communication on LON

• Communication on MODBUS

• Communication on TCP/IP

• “Service Pin” switch has been activated

Address

Internal communication

between the moduls:

Quick flash = error

Constantly On = error

n Power

n Comm

n DO1 n Status

n DO2 n Alarm

n DO3 n Service Tool

n DO4 n LON

n DO5 n MODBUS

n DO6 n LAN

n DO7

n DO8 n Service Pin

Status on output 1-8

Slow flash = OK

Quick flash = answer from master in 10 min.

after network installation

Constantly ON = error

Constantly OFF = error

Flash = Active alarm / not cancelled

Constant On = Active alarm / cancelled

External communication

Network installation

Keep the safety

distance!

Low and high

voltage must not

be connected to

the same output

group

A small module (option board) can be placed on the bottom part

of the controller. The module is described later in the document.

© Danfoss | DCS (vt) | 2020.01 BC041586425769en-000602 | 11

Page 12

User Guide | Network control AK-SM 720

Point

Analog

inputs

on 1 - 11

Solid state outputs

on 12 - 15

Relay or AKV coil

fx 230 V AC

S

Pt 1000 ohm/0°C

Point 1 2 3 4 5 6 7 8 9 10 11

Type AI1 AI2 AI3 AI4 AI5 AI6 AI7 AI8 AI9 AI10 AI11

Signal Signal

type

S1

S2

Saux1

Pt 1000

Saux2

SSA

SdA

24 and 25 used

only when "Option board fitted"

Terminal 15 & 27: 12 V

max. 100 mA in total.

Terminal 16 & 28: 5 V

max 100 mA in total.

Terminal

17, 18, 29, 30:

(Cable screen)

Relay outputs on

16 - 19

Point 12 13 14 15 16 17 18 19

Type DO1 DO2 DO3 DO4 DO5 DO6 DO7 DO8

P

AKS 32R

3: Brown

2: Blue

1: Black

P0A

P0B

PcA

PcB

AKS 32

3: Brown

2: Black

1: Red

U

...

On/Off Ext.

Main

switch

Day/

Night

Door

DO

AKV

AKV

Comp 1

Comp 2

Fan 1

Alarm

Light

Rail heat

Defrost

Option Board

Please see the signal

on the page with the

module.

AKS 32R

-1 - xx bar

AKS 32

-1 - zz bar

0 – 5 V

0 – 10 V

Active at:

Closed

/

Open

Active at:

On

/

Off

Signal Module Point Terminal Signal type / Active at

1 (AI 1) 1 - 2

2 (AI 2) 3 - 4

3 (AI 3) 5 - 6

4 (AI 4) 7 - 8

5 (AI 5) 9 - 10

6 (AI 6) 11 - 12

7 (AI 7) 13 - 14

8 (AI 8) 19 - 20

9 (AI 9) 21 - 22

10 (AI 10) 23 - 24

11 (AI 11) 25 - 26

1

12 (DO 1) 31 - 32

13 (DO 2) 33 - 34

14 (DO 3) 35 - 36

15 (DO 4) 37 - 38

16 (DO 5) 39 - 41

17 (DO6) 42 - 44

18 (DO7) 45 - 47

19 (DO8) 48 - 50

24 -

25 -

12 | BC041586425769en-000602 © Danfoss | DCS (vt) | 2020.01

Page 13

User Guide | Network control AK-SM 720

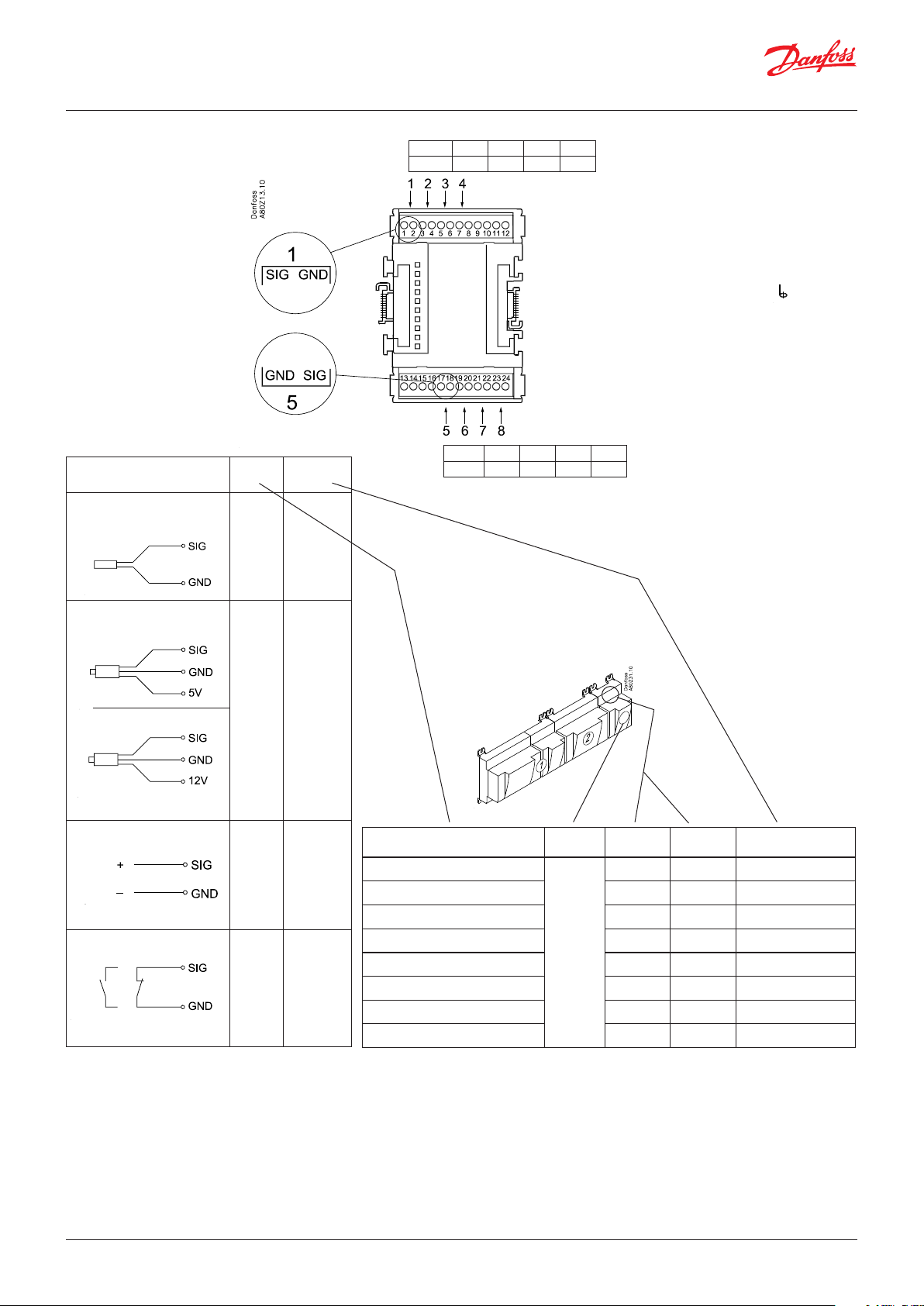

Extension module AK-XM 101A

Function

The module contains 8 analog inputs for sensors, pressure

transmitters, voltage signals and contact signals.

Supply voltage

The supply voltage to the module comes from the previous

module in the row.

Supply voltage to a pressure transmitter can be taken from either

the 5 V output or the 12 V output depending on transmitter type.

Light-emitting diodes

Only the two top LED’s are used. They indicate the following:

• Voltage supply to the module

• Communication with the controller is active (red = error)

© Danfoss | DCS (vt) | 2020.01 BC041586425769en-000602 | 13

Page 14

User Guide | Network control AK-SM 720

Point

S

Pt 1000 ohm/0°C

At the top the

signal input is

the left of the

two terminals.

At the bottom

the signal input

is the right of the

two terminals.

Signal Signal

S1

S2

Saux1

Saux2

SSA

SdA

type

Pt 1000

Point 1 2 3 4

Type AI1 AI2 AI3 AI4

Point 5 6 7 8

Type AI5 AI6 AI7 AI8

Terminal 9 & 16: 12 V max.

100 mA in total.

Terminal 10 & 15: 5 V max

100 mA in total.

Terminal

11, 12, 13, 14:

(Cable screen)

P

AKS 32R

AKS 32

3: Brown

2: Blue

1: Black

3: Brown

2: Black

1: Red

P0A

P0B

PcA

PcB

U

...

On/Off Ext.

Main

switch

Day/

Night

Door

AKS 32R

-1 - xx bar

AKS 32

-1 - zz bar

0 – 5 V

0 – 10 V

Active at:

Closed

/

Open

Signal Module Point

1 (AI 1) 1 - 2

2 (AI 2) 3 - 4

3 (AI 3) 5 - 6

4 (AI 4) 7 - 8

5 (AI 5) 17 - 18

6 (AI 6) 19 - 20

7 (AI 7) 21 - 22

8 (AI 8) 23 - 24

Terminal

Signal type /

Active at

14 | BC041586425769en-000602 © Danfoss | DCS (vt) | 2020.01

Page 15

User Guide | Network control AK-SM 720

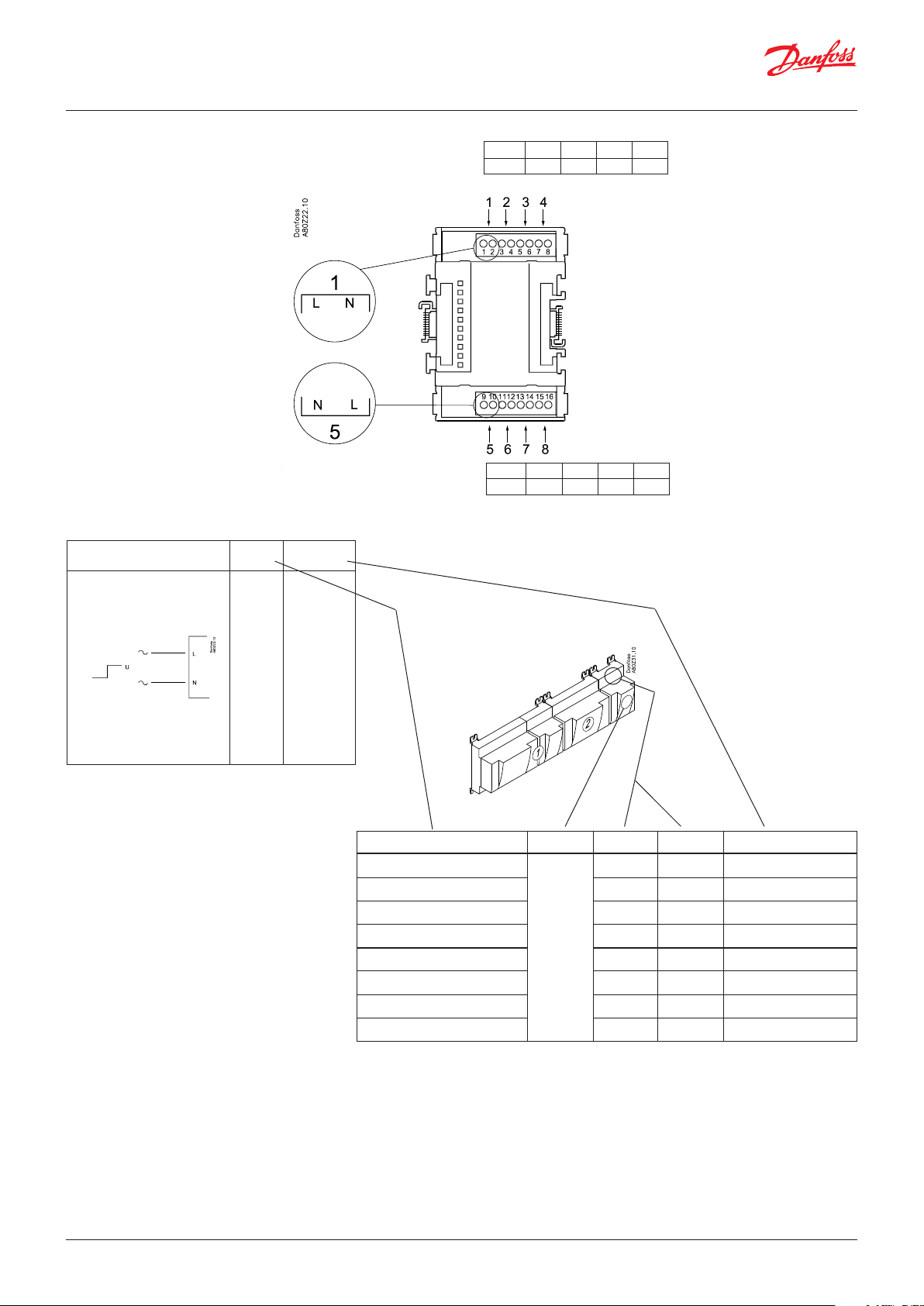

Extension module AK-XM 102A / AK-XM 102B

Function

The module contains 8 inputs for on/off voltage signals.

Signal

AK-XM 102A is for low voltage signals.

AK-XM 102B is for high voltage signals.

Supply voltage

The supply voltage to the module comes from the previous

module in the row.

Light-emitting diodes

They indicate:

• Voltage supply to the module

• Communication with the controller is active (red = error)

• Status of the individual inputs 1 to 8 (when lit = voltage)

AK-XM 102A

Max. 24 V

On/Off:

On: DI > 10 V AC

Off: DI < 2 V AC

AK-XM 102B

Max. 230 V

On/Off:

On: DI > 80 V AC

Off: DI < 24 V AC

© Danfoss | DCS (vt) | 2020.01 BC041586425769en-000602 | 15

Page 16

User Guide | Network control AK-SM 720

Point

DI

AK-XM 102A: Max. 24 V

AK-XM 102B: Max. 230 V

Signal Active at

Ext.

Main

switch

Day/

Night

Comp.

safety 1

Comp.

safety 2

Closed

(voltage on)

/

Open

(voltage off)

Point 1 2 3 4

Type DI1 DI2 DI3 DI4

Point 5 6 7 8

Type DI5 DI6 DI7 DI8

Signal Module Point Terminal Active at

1 (DI 1) 1 - 2

2 (DI 2) 3 - 4

3 (DI 3) 5 - 6

4 (DI 4) 7 - 8

5 (DI 5) 9 - 10

6 (DI 6) 11 - 12

7 (DI 7) 13 - 14

8 (DI 8) 15 - 16

16 | BC041586425769en-000602 © Danfoss | DCS (vt) | 2020.01

Page 17

User Guide | Network control AK-SM 720

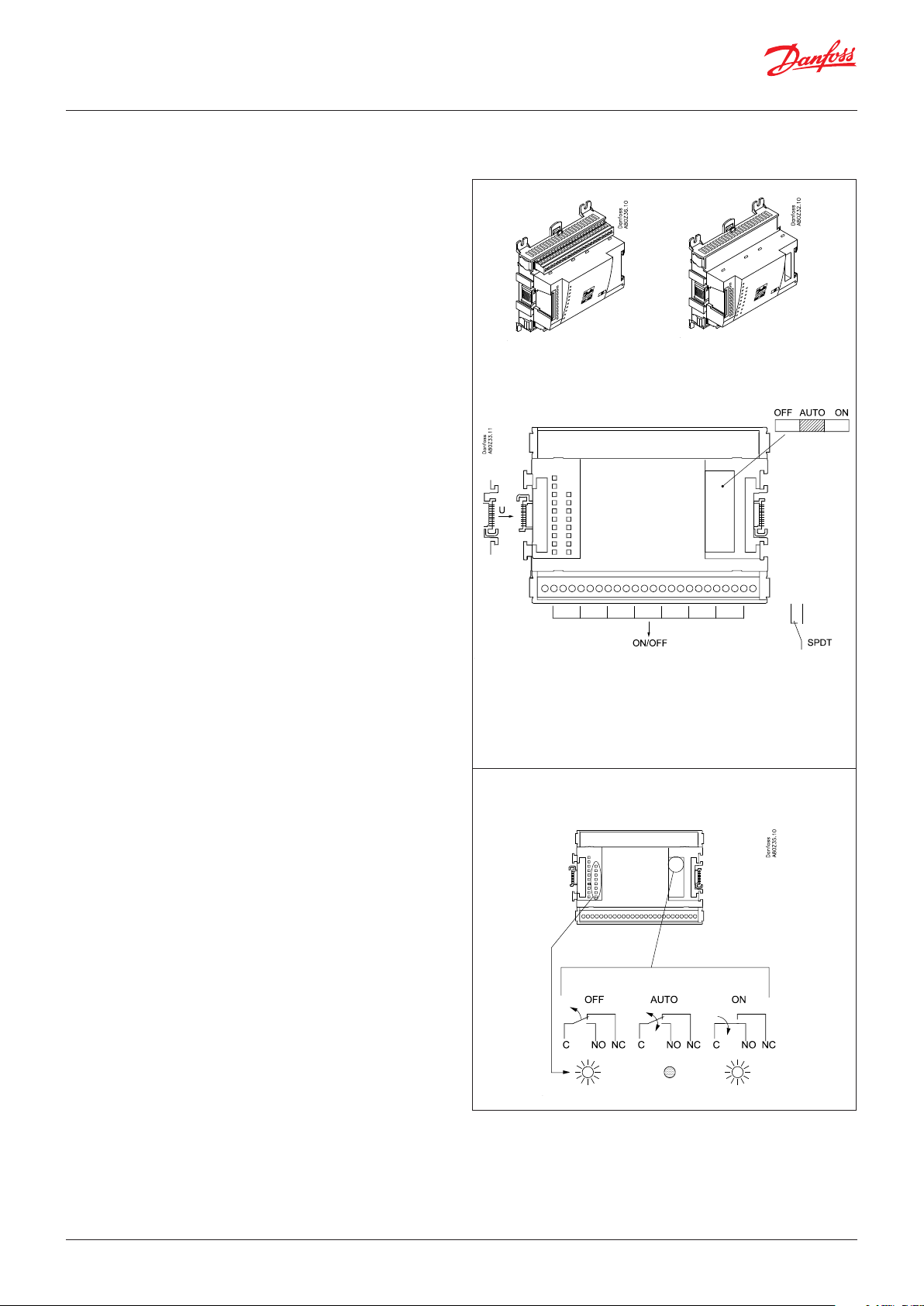

Extension module AK-XM 204A / AK-XM 204B

Function

The module contains 8 relay outputs.

Supply voltage

The supply voltage to the module comes from the previous

module in the row.

AK-XM 204B only

Override of relay

Eight change-over switches at the front make it possible to

override the relay’s function.

Either to position OFF or ON.

In position Auto the controller carries out the control.

Light-emitting diodes

There are two rows with LED’s. They indicate the following:

Left row:

• Voltage supply to the controller

• Communication active with the bottom PC board (red = error)

• Status of outputs DO1 to DO8

Right row: (AK-XM 204B only):

• Override of relays

Light ON = override

Light OFF = no override

AK-XM 204A AK-XM 204B

Fuses

Behind the upper part there is a fuse for each output.

Max. 230 V

AC-1: max. 4 A (ohmic)

AC-15: max. 3 A (Inductive)

AK-XM 204B

Override of relay

Keep the safety distance!

Low and high voltage

must not be connected to

the same output group

© Danfoss | DCS (vt) | 2020.01 BC041586425769en-000602 | 17

Page 18

User Guide | Network control AK-SM 720

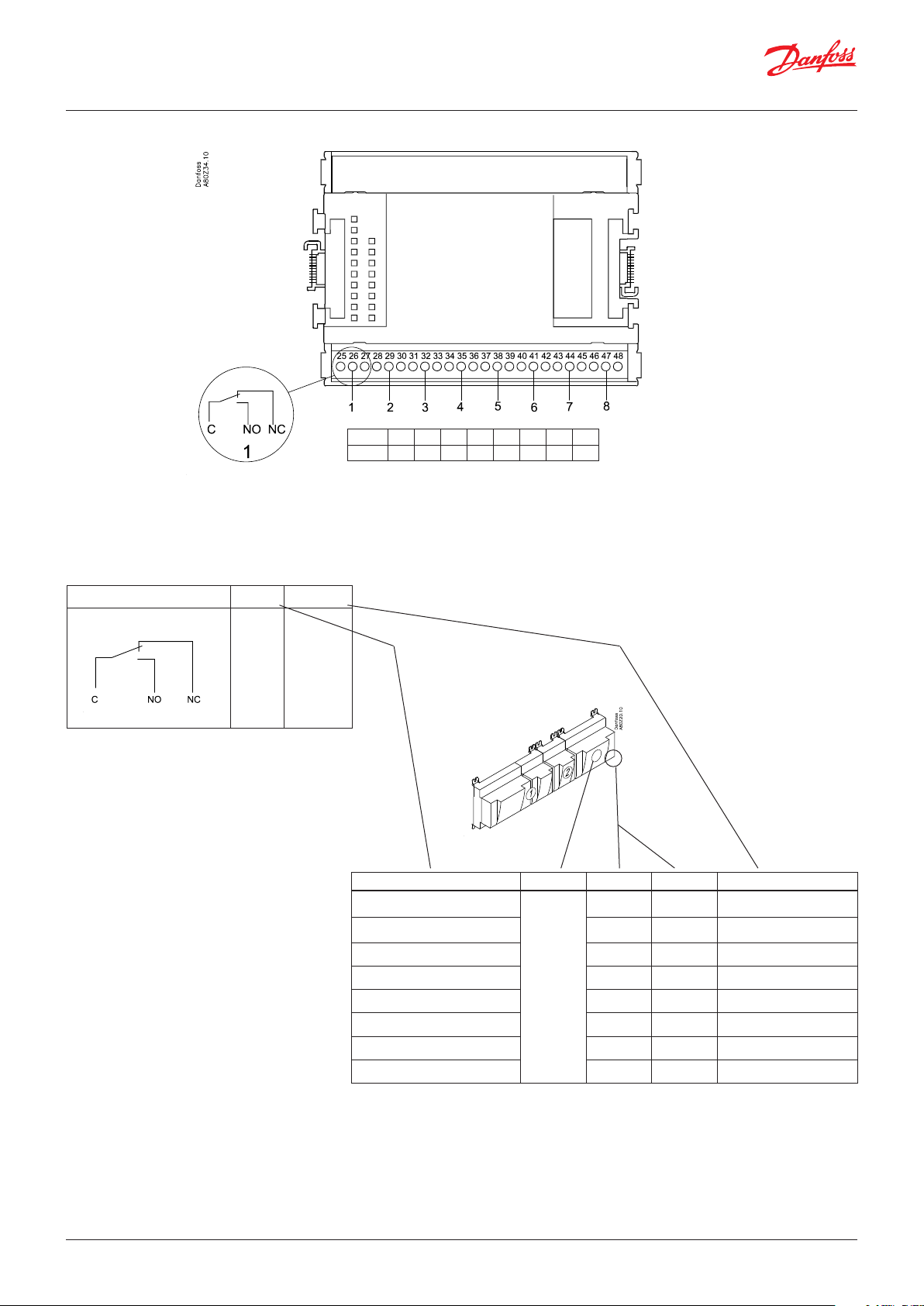

Point

Punkt 1 2 3 4 5 6 7 8

Type DO1 DO2 DO3 DO4 DO5 DO6 DO7 DO8

DO

Signal Active at

Comp. 1

Comp. 2

Fan 1

Alarm

On

/

Off

Signal Module Point Terminal Active at

1 (DO 1) 25 - 27

2 (DO 2) 28 - 30

3 (DO 3) 31 - 33

4 (DO 4) 34 -36

5 (DO 5) 37 - 39

6 (DO 6) 40 - 42

7 (DO 7) 43 - 45

8 (DO 8) 46 - 48

18 | BC041586425769en-000602 © Danfoss | DCS (vt) | 2020.01

Page 19

User Guide | Network control AK-SM 720

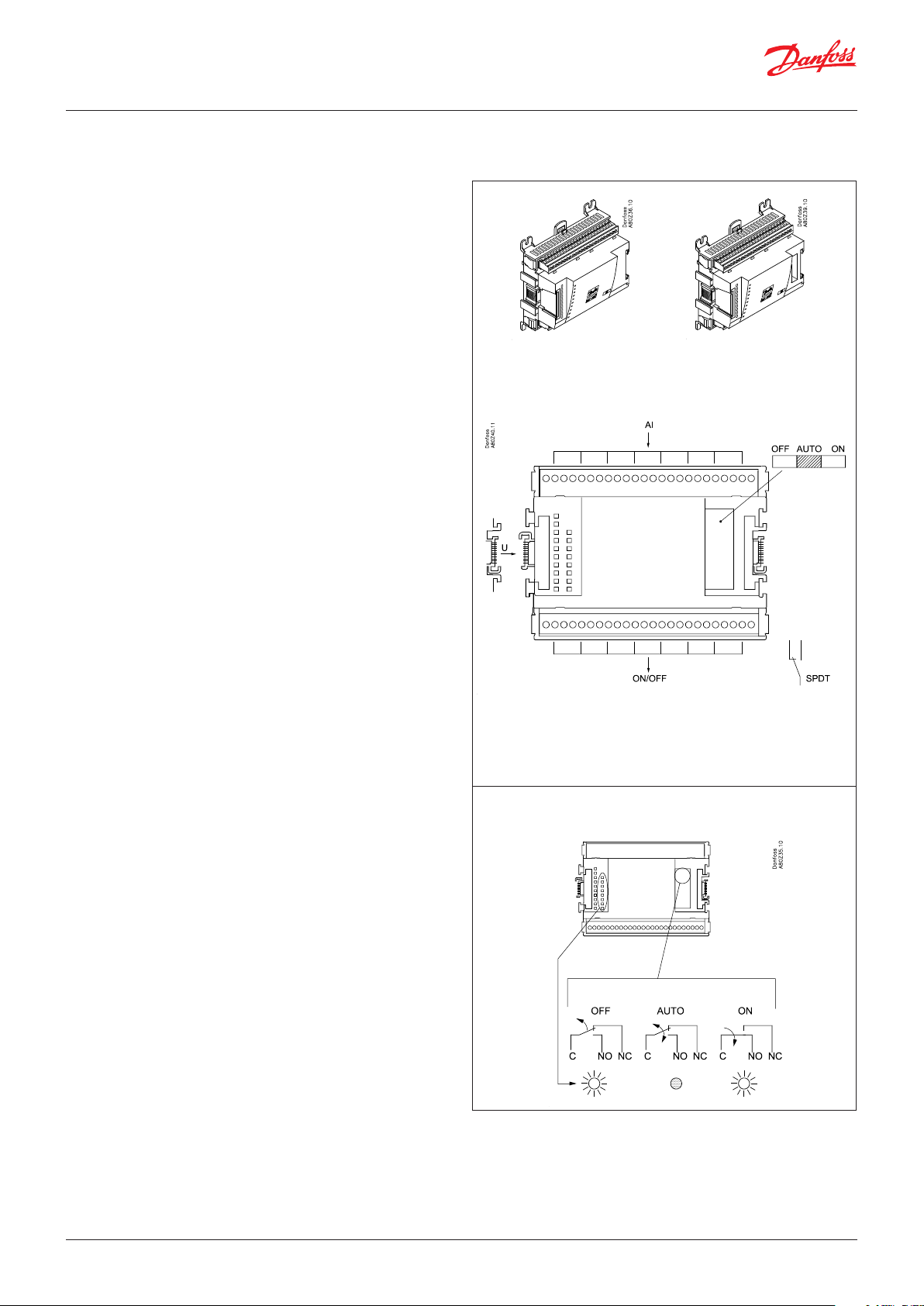

Extension module AK-XM 205A / AK-XM 205B

Function

The module contains:

8 analog inputs for sensors, pressure transmitters, voltage signals

and contact signals.

8 relay outputs.

Supply voltage

The supply voltage to the module comes from the previous

module in the row.

AK-XM 205B only

Override of relay

Eight change-over switches at the front make it possible to

override the relay’s function.

Either to position OFF or ON.

In position Auto the controller carries out the control.

Light-emitting diodes

There are two rows with LED’s. They mean:

Left row:

• Voltage supply to the controller

• Communication active with the bottom PC board (red = error)

• Status of outputs DO1 to DO8

Right row: (AK-XM 205B only):

• Override of relays

ON = override

OFF = no override

AK-XM 205A AK-XM 205B

max. 10 V

Fuses

Behind the upper part there is a fuse for each output.

Max. 230 V

AC-1: max. 4 A (ohmic)

AC-15: max. 3 A (Inductive)

AK-XM 205B

Override of relay

Keep the safety distance!

Low and high voltage

must not be connected to

the same output group

© Danfoss | DCS (vt) | 2020.01 BC041586425769en-000602 | 19

Page 20

User Guide | Network control AK-SM 720

Point

S

Pt 1000 ohm/0°C

Signal Signal

type

S1

S2

Saux1

Pt 1000

Saux2

SSA

SdA

Point 1 2 3 4 5 6 7 8

Type AI1 AI2 AI3 AI4 AI5 AI6 AI7 AI8

Terminal 9 & 21: 12 V max.

100 mA in total.

Terminal 10 & 22: 5 V max

100 mA in total.

Terminal 11, 12, 23, 24 :

(Cable screen)

Point 9 10 11 12 13 14 15 16

Type DO1 DO2 DO3 DO4 DO5 DO6 DO7 DO8

P

AKS 32R

AKS 32

U

On/Off

DO

3: Brown

2: Blue

1: Black

3: Brown

2: Black

1: Red

P0A

P0B

PcA

PcB

...

Ext.

Main

switch

Day/

Night

Door

Comp 1

Comp 2

Fan 1

Alarm

Light

Rail

heat

Defrost

AKS 32R

-1 - xx bar

AKS 32

-1 - zz bar

0 – 5 V

0 – 10 V

Active at:

Closed

/

Open

Active at:

on

/

Off

Signal Module Point

1 (AI 1) 1 - 2

2 (AI 2) 3 - 4

3 (AI 3) 5 - 6

4 (AI 4) 7 - 8

5 (AI 5) 13 - 14

6 (AI 6) 15 - 16

7 (AI 7) 17 - 18

8 (AI 8) 19 -20

9 (DO 1) 25 - 27

10 (DO 2) 28 - 30

11 (DO 3) 31 - 33

12 (DO 4) 34 - 36

13 (DO 5) 37 - 39

14 (DO6) 40 - 42

15 (DO7) 43 - 45

16 (DO8) 46 - 48

Terminal

Signal type /

Active at

20 | BC041586425769en-000602 © Danfoss | DCS (vt) | 2020.01

Page 21

User Guide | Network control AK-SM 720

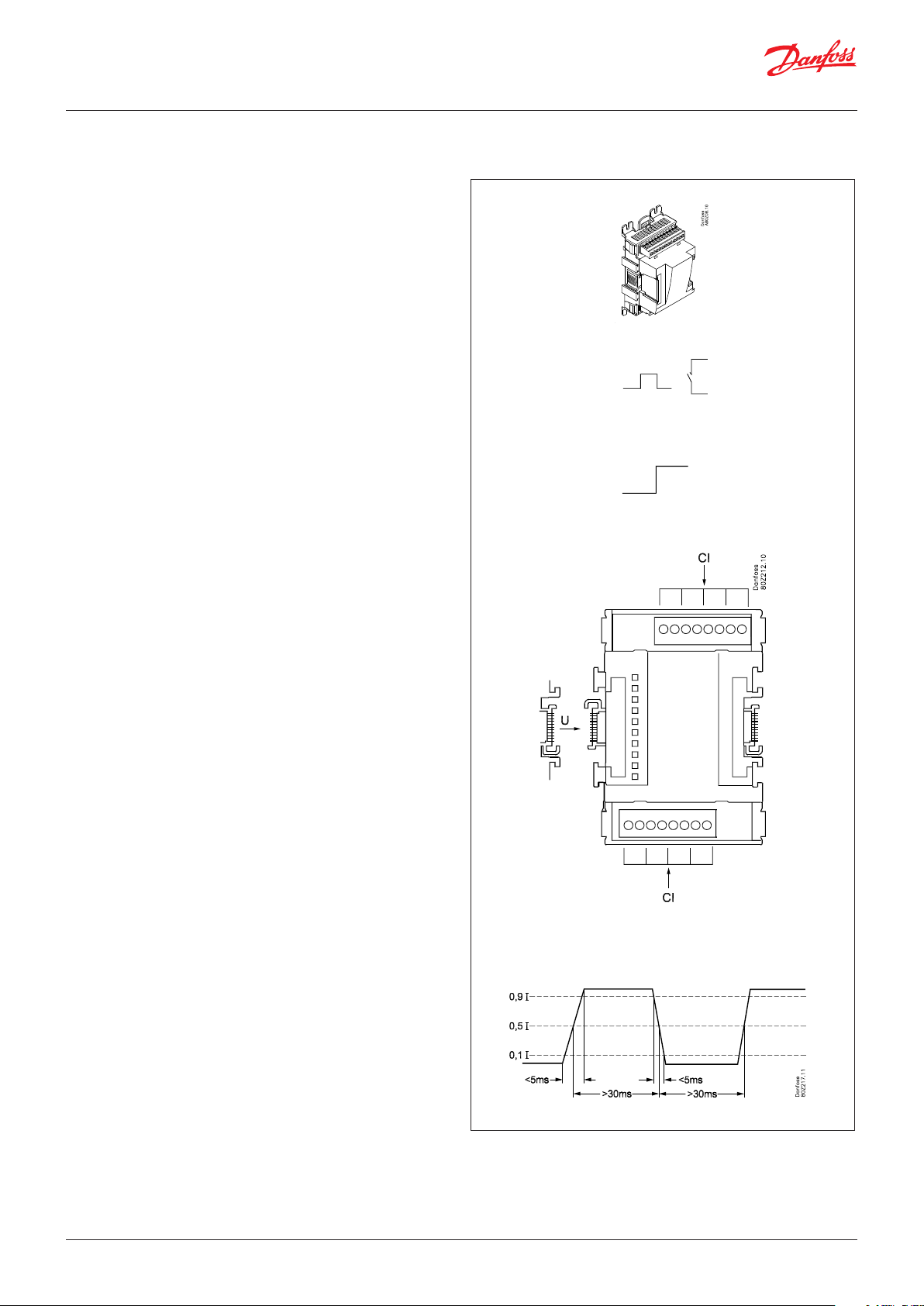

Extension module AK-XM 107A

Function

The module contains eight inputs for pulse counting. As an

alternative, the input can be used to register an On/Off signal. (DI

function).

Supply voltage

The supply voltage for the module comes from the previous module in the sequence.

LEDs

These indicate the following:

• Voltage of the module

• Communication with the controller is active (red = error)

(There is no LED indication for the individual signal inputs)

Signal

The signal is registered in accordance with DIN 43864.

Rise times and fall times must be less than 5 ms.

On and off times must be greater than 30 ms.

© Danfoss | DCS (vt) | 2020.01 BC041586425769en-000602 | 21

Page 22

User Guide | Network control AK-SM 720

Point

CI

Point 1 2 3 4

Type CI1 CI2 CI3 CI4

Point 5 6 7 8

Type CI5 CI6 CI7 CI8

Signal Active at

Puls - - -

Signal Module Point Terminal Active at

1 (CI 1) 1 - 2 - - 2 (CI 2) 3 - 4 - - 3 (CI 3) 5 - 6 - - 4 (CI 4) 7 - 8 - - 5 (CI 5) 9 - 10 - - 6 (CI 6) 11 - 12 - - 7 (CI 7) 13 - 14 - - 8 (CI 8) 15 - 16 - - -

22 | BC041586425769en-000602 © Danfoss | DCS (vt) | 2020.01

Page 23

User Guide | Network control AK-SM 720

Extension module AK-OB 110

Function

The module contains two analog voltage outputs of 0 – 10 V.

Supply voltage

The supply voltage to the module comes from the controller

module.

Placing

The module is placed on the PC board in the controller module.

Point

The two outputs have points 24 and 25. They are shown on the

earlier page where the controller is also mentioned.

Max. load

I < 2.5 mA

R > 4 kohm

AO

AO 0 – 10 V

Module

Point 24 25

Type AO1 AO2

1

AO2

AO1

© Danfoss | DCS (vt) | 2020.01 BC041586425769en-000602 | 23

Page 24

User Guide | Network control AK-SM 720

Power supply module AK-PS 075 / 150

Function

24 V supply for controller.

Supply voltage

100 V AC to 240 V AC 50/60Hz

Placing

On wall or DIN-rail

Effect

Type Output tension Output current Power

AK-PS 075 24 V DC 0.75 A 18 VA

AK-PS 150 24 V DC

(adjustable)

Dimension

Type High Width

AK-PS 075 90 mm 36 mm

AK-PS 150 90 mm 54 mm

1.5 A 36 VA

Connections

Supply to a System manager

AK-PS 075

AK-PS 150

24 | BC041586425769en-000602 © Danfoss | DCS (vt) | 2020.01

Page 25

User Guide | Network control AK-SM 720

Preface to design

In most cases the system manager may be able to manage the

control process without any kind of supplementary modules. Expansion modules will only be needed when measuring consumption, when using a large number of relays or when using Boolean

functions.

Be aware of the following when the number of extension modules

is being planned. A signal may have to be changed, so that an

additional module may be avoided.

• An ON/OFF signal can be received in two ways. Either as a contact

signal on an analog input or as voltage on a low or high-voltage

module.

Functions

Clock function

Clock function and change-over between summer time and winter time are contained in the system manager.

The clock’s setting is retained if there is a power failure.

Start/stop of regulation

Regulation can be started and stopped via the software. It cannot

be stopped with a switch function.

Alarm function

If the alarm is to be sent to a signal transmitter, a relay output will

have to be used.

System controls

Some of the possible system controls will require input signals or

output signals.

• Weekly schedule with the store’s hours of business

If there has to be an override to “day”, a switch function will be

required.

If there has to be an override to “night”, a switch function will be

required.

• An ON/OFF output signal can be given in two ways. Either with a

relay switch or with solid state. The primary difference is the permitted load and that the relay switch contains a cutout switch.

Mentioned below is a number of functions and connections

that may have to be considered when a regulation has to be

planned. There are more functions in the controller than the ones

mentioned here, but those mentioned have been included in

order that the need for connections can be established.

• Light control

A signal can be received from two light sensors. Each sensor

requires an analogue input.

Up to eight zones can be controlled. Each zone will require a

relay output or a triac output.

• Adaptive rail heat

A signal can be received from three dew point sensors. Each sensor requires two analogue inputs.

• Consumption measurement

When measuring consumption an expansion module must be

used for pulse counting.

A synchronisation signal will require an analogue or a digital

input.

A tariff signal will require an analogue or a digital input. Two

tariff signals can be received.

• Peak load limitation

This function requires a signal from a consumption measurement.

Up to ten relays can be connected.

• Weekly schedule for day/night operation

A switch signal will be required to override a schedule

• Weekly schedule for defrost

A switch signal will be required to override a schedule

• Weekly schedule for light

A switch signal will be required to override a schedule

• Inject ON function (closes the evaporator controls’ expansion valves

in the event of operational problems with the compressors)

The function can be enabled via data communication or it can

be wired outside the system manager

© Danfoss | DCS (vt) | 2020.01 BC041586425769en-000602 | 25

Data communication

The controller module has terminals for LON data communication.

The requirements to the installation are described in a separate

document.

Page 26

User Guide | Network control AK-SM 720

Connections

In principle there are the following types of connections:

Analog inputs ”AI”

This signal must be connected to two

terminals.

Signals can be received from the following

sources:

• Temperature signal from Pt 1000 ohm

temperature sensor

• Contact signal where the input is short-

circuited or ”opened”, respectively

• Voltage signal from 0 to 10 V

• Signal from pressure transmitter AKS 32

or AKS 32R

The supply voltage is supplied from the

module’s terminal board where there is

both a 5 V supply and a 12 V supply.

When programming the pressure

transmitter’s pressure range must be set.

ON/OFF voltage inputs ”DI”

This signal must be connected to two

terminals.

• The signal must have two levels, either 0 V

or ”voltage” on the input.

There are two different extension

modules for this signal type:

- low-voltage signals, e.g. 24 V

- high-voltage signals, e.g. 230 V

When programming the function must be set:

• Active when the input is without voltage

• Active when voltage is applied to the

input.

ON/OFF output signals ”DO”

There are two types, as follows:

• Relay outputs

All relay outputs are with change-over

relay so that the required function can be

obtained when the controller is without

voltage.

• Solid state outputs

Reserved for AKV valves, but output can

cut an external relay in and out, as with a

relay output.

The output is only found on the

controller module.

When programming the function must be set:

• Active when the output is activated

• Active when the output is not activated.

Analog output signal ”AO”

This signal is to be used if a control signal is

to be transmitted to an external unit, e.g. a

frequency converter.

When programming the signal range must

be defined: 0 – 5 V, 1 – 5 V, 0 – 10 V

or 2 – 10 V.

Pulse counter inputs

This signal must be used if consumption

measurement is to take place.

Limitations

As the system is very flexible regarding the number of connected

units you must check whether your selection complies with the

few limitations there are.

The complexity of the controller is determined by the software,

the size of the processor, and the size of the memory. It provides

the controller with a certain number of connections from which

data can be downloaded, and others where coupling with relays

can be performed.

There must a maximum of 200 controllers on the data communication.

A maximum of 120 units of the EKC type, where there must be a

maximum of 15 different types and software versions.

26 | BC041586425769en-000602 © Danfoss | DCS (vt) | 2020.01

• The sum of connections cannot exceed 80.

• The number of extension modules must be limited so that the

total power will not exceed 32 VA (including controller).

• No more than five pressure transmitters may be connected to

one controller module.

• No more than five pressure transmitters may be connected to

one extension module.

Page 27

User Guide | Network control AK-SM 720

Design of a System manager

Procedure:

1. Make a sketch of the system in question

2. Check that the controller’s functions cover the required

application

3. Consider the connections to be made

4. Use the planning table. / Note down the number of

connections. / add up

5. Are there enough connections on the controller module? – If

not, can they be obtained by changing an ON/OFF input signal

from voltage signal to contact signal, or will an extension

module be required?

6. Decide which extension modules are to be used

7. Check that the limitations are observed

8. Calculate the total length of modules

9. The modules are linked together

10. The connection sites are established

11. Draw a connection diagram or a key diagram

12. Size of supply voltage/power supply

1. Sketch

Make a sketch of the system in question

© Danfoss | DCS (vt) | 2020.01 BC041586425769en-000602 | 27

Page 28

User Guide | Network control AK-SM 720

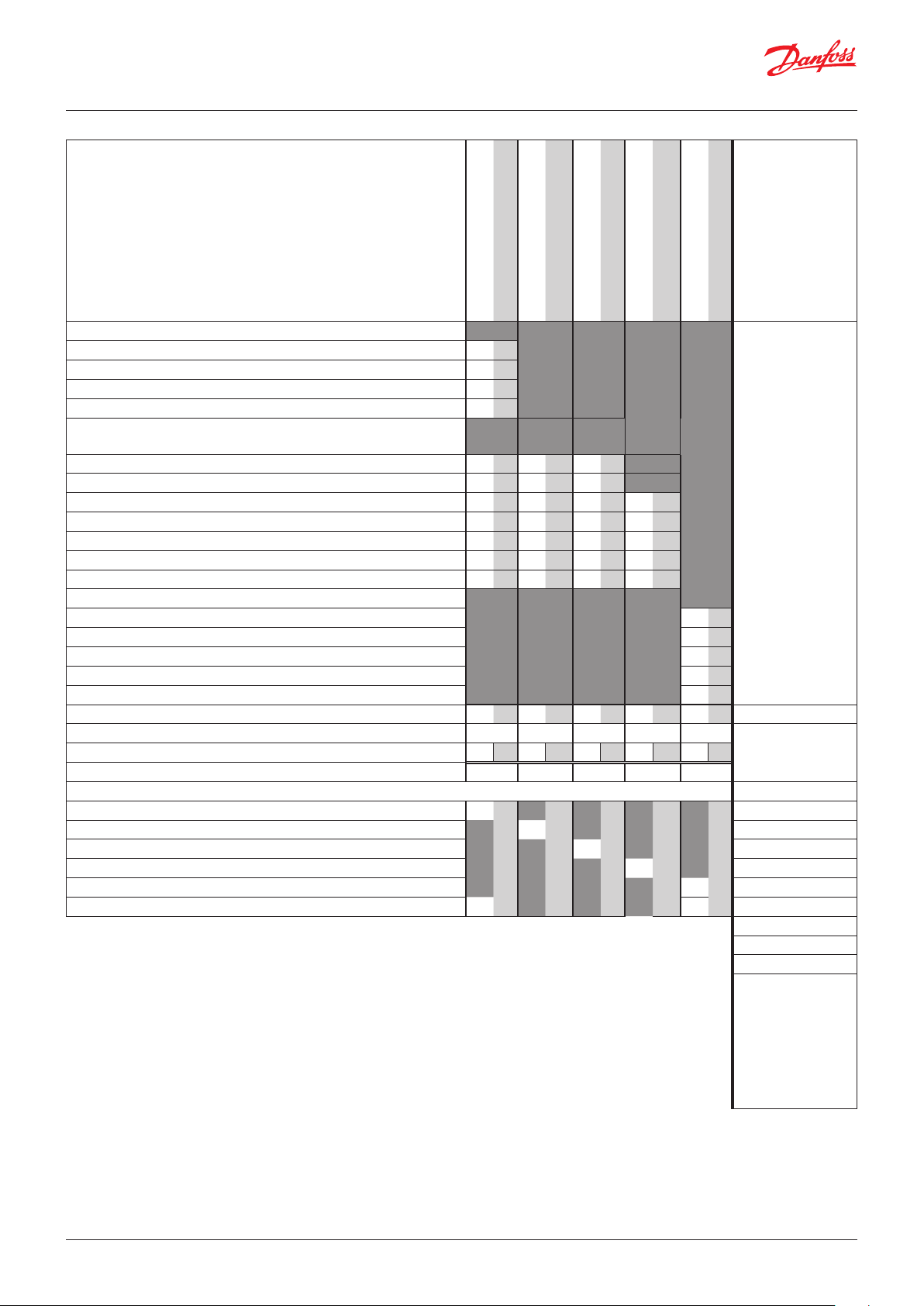

2. System functions

Application

Control of data communication on the refrigeration system

Control of data communication for external operation

Forward alarms and data collected x

Local data communication

LON RS485 together with

- Controllers type EKC

- Controllers type AK

- Frequency converter type AKD

MODBUS together with similar controllers that

have MODBUS communication

TCP/IP together with other AK-SM x

TCP/IP to AK-PI 200 and onwards to controllers

with DANBUSS

Max. number of controllers (addresses) in a

network

External data communication

Via modem and phone net x

Via TCP/IP and Internet x

200, although max.

120 EKC incl. SLV

x

x

x

x

x

User registration

User interface with Password and authorisation

levels

History Event x

Operation

Via PC and software type AK-ST x

Clock

Clock function with battery backup x

Resets the clock in the controllers after a power

failure

Safety

Communication control x

Watchdog function with adjustable interval time x

Data communication with "I'm a live" information x

High level of security against undesired user

access

x

x

x

A bit more about the functions ("2" continued)

Alarm management

LOG of alarms x

Routing of alarms to Systemsoftware x

A relay can be defined to an alarm relay x

System controls

Weekly schedule with the store’s hours of business x

Weekly schedules with time specified in relation to

hours of business

On/off control 5

Weekly schedules for use together with day/night

operation and start of defrost

Override weekly schedules with a switch function 10

Switch between day operation and night opera-

tion

Defrost start

Coordinated defrost (common start after defrost) x

Inject ON function (closes the evaporator controls’

expansion valves in the event of operational problems with the compressors)

P0-control 5 / 120 sections

Light control

Adaptive rail heat

Adaptive defrost

Consumption measurement 8

Load sheeding x

Synchronising signal x

max. 30 controllers

max. 30 controllers

x

10

Max. 20 groups of

Max. 20 groups of

5 / 120 sections

2 light sensors,

8 relais,

8 zones

3 groups /

30 sections

10 groups /

30 sections

Here is a little more about some of the functions that must use

an input or an output.

Modem connection

It is recommended that the supply voltage to the modem be

provided through a relay, so that the system manager can start the

modem in a controlled way.

The “Inject On” override function

This function closes expansion valves on evaporator controls when

all compressors have stopped.

The function can take place via data communication, or it can be

wired via a relay output on the compressor control.

Boolean functions

A function in the system unit makes it possible to set up some

logical functions. The functions can have both inputs and outputs.

The function is described in a separate document. Please refer to

literature sheet number RC8CA.

This setup of Boolean functions should only be undertaken by

trained personnel.

If you want to know more about the functions, go to chapter 5.

LOG

Stores LOG data from the connected controllers x

28 | BC041586425769en-000602 © Danfoss | DCS (vt) | 2020.01

Page 29

User Guide | Network control AK-SM 720

3. Connections

Here is a survey of the possible connections. The texts can be read

in context with the table on the next page.

Analog inputs

Temperature sensors

Up to 3 sensors for dew point measurement and 4 sensors for

boolean logic can be connected.

Pressure transmitter

A pressure transmitter type AKS 32 or AKS 32R can supply signals

to a maximum of five controllers.

Voltage signal

• 0 – 10 V

Used when signal is received from another control.

E.g. signal from dew point sensor. (A dew point sensor delivers

two signals – a temperature sensor signal and a voltage signal)

On/Off-inputs

Contact function (on an analog input)

or

Voltage signal (on an extension module)

• Switches to override a weekly schedule

• Switches to override light control

• Signal to register tariff levels

Pulse counter input (on an expansion module)

• E.g. for energy registration

On/off-outputs

Relay outputs

• Voltage supply to modem

• Watch dog function

• Injection On function (signal to evaporator control. One each

suction group)

• Alarm relay

• Light control

• Load sheeding

Solid state outputs

The solid state outputs on the controller module may be used

for the same functions as those mentioned under “relay outputs”.

(The output will always be “OFF” when the controller has a power

failure).

Example

• AK-SM 720 is with data communication for EKC controllers

• Modem connection for alarm routing (for System software AKM)

• Modem connection for external operation (for Service tool)

• Alarm output

• Contact to reset alarms

• Energy measurement, which receives puls signal from extern

unit.

Data from this example is used on the next page.

The result is that the following modules should be used:

• AK-SM 720 controller

• AK-XM 107A pulse module

© Danfoss | DCS (vt) | 2020.01 BC041586425769en-000602 | 29

Page 30

User Guide | Network control AK-SM 720

4. Planning table

The table helps you establish whether there are enough inputs

and outputs on the system manager.

If there are not enough of them, it must be extended by one or

more of the mentioned extension modules.

Note down the connections you will require and add them up

Analog inputs

Temperature signal from dew point sensor (max. 3)

Voltage signal from dew point sensor (max. 3)

Voltage signal from a light sensor (max. 2)

Analog input signal

Example

On/off voltage signal

Example

On/off voltage signal

Example

Pulse module

Example

On/Off output signal

Example

7

Limitations

On/off inputs Con-

tact

Contact for overriding of week schedule for day/night operation

Contact to overriding of weekly schedule for light

Pulse signal from meter for electr., gas, water etc. 1

On/Off signal about tariff change

Pulse pressure for stop of alarm 1

On/off outputs

Voltage supply for modem (reset function) 1

Alarm relay 1

Light zones (up to 8 relays)

5. Load sheeding limit (up to 10 relays)

6. Sum of connections 1 1 2 Sum = max. 80

Number of connections on a System manager 11 11 0 0 0 0 0 0 8 8

Missing connections, if applicable 0 - - 1 0

The missing connections to be supplied by one or more extension modules: Sum of power

AK-XM 101A (8 analog inputs) ___ pcs. á 2 VA = __

AK-XM 102A (8 digital low voltage inputs) ___ pcs. á 2 VA = __

AK-XM 102B (8 digital high voltage inputs) ___ pcs. á 2 VA = __

AK-XM 107A (8 pulse inputs) 1 ___ pcs. á 2 VA = __

AK-XM 204A / B (8 relay outputs) ___ pcs. á 5 VA = __

AK-XM 205A / B (8 analog inputs + 8 relay outputs) ___ pcs. á 5 VA = __

24 V 230 V

Pressure transmitters: Max. 5 each/

module

Boolean logic:

There are limitations to the number of functions.

Refer to separate

document RC8CA.

1 pcs. á 8 VA = 8

Sum =

Sum = max. 32 VA

Example:

None of the 3 limitations are exceeded

=> OK

30 | BC041586425769en-000602 © Danfoss | DCS (vt) | 2020.01

Page 31

User Guide | Network control AK-SM 720

8. Length

If you use many extension modules the controller’s length will

grow accordingly. The row of modules is a complete unit which

cannot be broken.

The module dimension is 72 mm.

Modules in the 100-series consist of one module

Modules in the 200-series consist of two modules

The controller consist of three modules

The length of an aggregate unit = n x 72 + 8

or in an other way:

Module Type Number at Length

Controller module 1 x 224 = 224 mm

Extension module 200-series _ x 144 = ___ mm

Extension module 100-series _ x 72 = ___ mm

Total length = ___ mm

9. Linking of modules

Example continued:

Controller module + Pulse module = 224 mm + 72 mm = 296 mm.

Start with the controller module and then mount the selected

extension modules. The sequence is of no importance.

However, you must not change the sequence, i.e. rearrange the

modules, after you have made the setup where the controller

is told which connections are found on which modules and on

which terminals.

The modules are attached to one another and kept together by a

connection which at the same time transmits the supply voltage

and the internal data communication to the next module.

Mounting and removal must always be performed when there is

no voltage.

The protective cap mounted on the controller’s plug connection

must be moved to the last vacant plug connection so that the

plug will be protected against short-circuit and dirt.

When the regulation has started the controller will all the time

check whether there is connection to the connected modules. This

status can be followed by the light-emitting diode.

When the two catches for the DIN rail mounting are in open

position the module can be pushed into place on the DIN rail – no

matter where in the row the module is found.

Removal is likewise carried out with the two catches in the open

position.

© Danfoss | DCS (vt) | 2020.01 BC041586425769en-000602 | 31

Page 32

User Guide | Network control AK-SM 720

10. Determine the connection points

All connections must be programmed with module and point, so

in principle it does not matter where the connections are made, as

long as it takes place on a correct type of input or output.

• The controller is the first module, the next one is 2, etc.

• A point is the two or three terminals belonging to an input or

output (e.g. two terminals for a sensor and three terminals for a

relay).

The preparation of the connection diagram and the subsequent

programming (configuration) should take place at the present

time. It is most easily accomplished by filling in the connection

survey for the relevant modules.

Principle:

Name On module On Point Function

fx Light 1 x x Close

fx Light 2 x x Close

fx Alarm relay x x NC

fx Modem x x Close

fx P0 x x AKS 32R 1-6 bar

The connection survey from the controller and any extension

modules are uploaded from the paragraph "Modules". See later in

the manual E.g. controller module:

Signal Module Point Terminal

1 (AI 1) 1 - 2

2 (AI 2) 3 - 4

3 (AI 3) 5 - 6

4 (AI 4) 7 - 8

Signal type /

Active at

Module Point

Mind the numbering.

The right-hand part of the

controller module may look like

a separate module. But it isn’t.

- Columns 1, 2, 3 and 5 are used for the programming.

- Columns 2 and 4 are used for the connection diagram.

Example continued:

Signal

Pulse pressure to set off the

alarm relay

Supply voltage to modem

Alarm relay for high priority

alarms

Mod-

ule

10 (AI 10) 23 - 24

11 (AI 11) 25 - 26

1

12 (DO 1) 31 - 32

13 (DO 2) 33 - 34

14 (DO 3) 35 - 36

15 (DO 4) 37 - 38

16 (DO 5) 39 - 41

17 (DO6) 42 - 44

18 (DO7) 45 - 47

19 (DO8) 48 - 50

Point Terminal

1 (AI 1) 1 - 2

2 (AI 2) 3 - 4

3 (AI 3) 5 - 6

4 (AI 4) 7 - 8

5 (AI 5) 9 - 10

6 (AI 6) 11 - 12

7 (AI 7) 13 - 14

8 (AI 8) 19 - 20

9 (AI 9) 21 - 22

24 -

25 -

Signal

type /

Active at

-

ON

OFF

Pulse signal

Signal

Mod-

ule

2

Point Terminal Active at

1 (CI 1) 1 - 2

2 (CI 2) 3 - 4

3 (CI 3) 5 - 6

4 (CI 4) 7 -8

5 (CI 5) 9 - 10

6 (CI 6) 11 - 12

7 (CI 7) 13 - 14

8 (CI 8) 15 - 16

- - -

- - -

- - -

- - -

- - -

- - -

- - -

- - -

32 | BC041586425769en-000602 © Danfoss | DCS (vt) | 2020.01

Page 33

User Guide | Network control AK-SM 720

11. Connection diagram

Drawings of the individual modules may be

ordered from Danfoss.

Format = dwg and dxf.

You may then yourself write the module

number in the circle and draw the individual

connections.

Example continued:

The modem connection is made

to this plug, but the plug is also

used by AK-ST 500.

So the modem plug can only be

positioned when all settings in

the system manager have been

completed.

© Danfoss | DCS (vt) | 2020.01 BC041586425769en-000602 | 33

Page 34

User Guide | Network control AK-SM 720

12. Supply voltage

Supply voltage is only connected to the controller module. The

supply to the other modules is transmitted via the plug between

the modules. The supply must be 24 V +/-20%. One power supply

must be used for each controller. The transformer must be a class

II. The 24 V must not be shared by other controllers or units. The

analog inputs and outputs are not galvanically separated from the

supply.

The + and – 24V input must not be earthed.

Example continued:

Controller module 8 VA

Pulse counter module 2 VA

------

Size of power supply 10 VA

Power supply size

The power consumption grows with the number of modules used:

Module Type Number á Effect

Controller 1 x 8 = 8 VA

Extension module 200-series _ x 5 = __ VA

Extension module 100-series _ x 2 = __ VA

Total ___ VA

34 | BC041586425769en-000602 © Danfoss | DCS (vt) | 2020.01

Page 35

User Guide | Network control AK-SM 720

Ordering

1. Controller

Type Function Application Language Code no.

AK-SM 720 System manager Control data communication

2. Extension modules and survey for inputs and outputs

Type Analog

inputs

On/Off outputs On/off supply voltage

(DI signal)

English, German, French,

Dutch, Italian

English (UK), Spanish, Portuguese, English (US)

English, Danish, Swedish,

Finnish

Analog

outputs

Module

with

switches

080Z8511 x

080Z8512

080Z8513

Code no.

Example

continued

Example

continued

For sensors,

pressure

transmitters

Relay

(SPDT)

Solid state Low voltage

(max. 80 V)

High voltage

(max. 260 V)

Pulse

counter

0 – 10 V DC For override

of relay

outputs

With screw

terminals

etc.

Controller 11 4 4 - - - - -

Extension modules

AK-XM 101A 8 080Z0007

AK-XM 102A 8 080Z0008

AK-XM 102B 8 080Z0013

AK-XM 204A 8 080Z0011

AK-XM 204B 8 x 080Z0018

AK-XM 205A 8 8 080Z0010

AK-XM 205B 8 8 x 080Z0017

AK-XM 107A 8 080Z0020 x

The following extension module can be placed on the PC board in the controller module.

There is only room for one module.

AK-OB 110 2 080Z0251

3. AK operation and accessories

Type Function Application Code no.

Operation

AK-ST 500 Software for operation of AK controllers AK-operation 080Z0161 x

- Cable between PC and AK controller AK - Com port 080Z0262 x

- Cable between zero modem cable and AK controller AK - RS 232 080Z0261

Example

continued

Accessories Power supply module 230 V / 115 V to 24 V DC

AK-PS 075 18 VA, 24 V DC

AK-PS 150

36 VA, 24 V DC 080Z0054

Supply for controller

080Z0053 x

Modem Please use a modem from Danfoss’s approved suppliers list. x

© Danfoss | DCS (vt) | 2020.01 BC041586425769en-000602 | 35

Page 36

User Guide | Network control AK-SM 720

3. Mounting and wiring

This section describes how the controller:

• Is fitted

• Is connected

Mounting

Mounting of extension module on the basic module

1. Move the protective cap

Remove the protective cap from the connection plug on the righthand side of the basic module.

Place the cap on the connection plug to the right of the I/O

module that is to be mounted on the extreme right-hand side of

the AK assembly.

We have decided to work on the basis of the example we went

through previously, i.e. the following modules:

• AK-SM 720 controller module

• AK-XM 107A pulse counter module

In our example one extension module is to be fitted to the basic

module.

All of the subsequent setting are determined by the module positions.

Here 1 and 2.

2. Assemble the I/O module and the basic module

The basic module must not be connected to voltage.

When the two snap catches for the DIN rail mounting are in the open

position, the module can be pushed into place on the DIN rail –

regardless of where the module is on the row.

Disassembly is thus done with the two snap catches in the open

position.

36 | BC041586425769en-000602 © Danfoss | DCS (vt) | 2020.01

Page 37

User Guide | Network control AK-SM 720

Wiring

Decide during planning which function is to be connected

and where this will be.

Here are the tables for the example:

1. Connect input and outputs

Signal Module Point

Pulse pressure for stopping

the alarm relay

Supply voltage to modem 16 (DO 5) 39 - 41 ON

Alarm relay for high priority

alarms

1 (AI 1) 1 - 2

1

17 (DO6) 42 - 44 OFF

Terminal

Signal type/

-

Active at

Important

Keep signal cables away from cables with high voltages.

Signal Module Point Terminal Active at

Pulse signal

2 1 (CI 1) 1 - 2

- - -

2. Connect LON and MODBUS communication network

Check that data communication is terminated at either end

3. Connect supply voltage

Is 24 V, and the supply must not be used by other controllers or

devices.

The two terminals must not be earthed.

4. Follow light-emitting diodes

When the supply voltage is connected the system manager will

go through an internal check. The controller will be ready in

just under one minute when the light-emitting diode ”Status”

starts flashing slowly.

5. When there is a network

Set the address and activate the Service Pin. See next

paragraph

6. The system manager is now ready for configuration.

The installation of the data communication must comply

with the requirements set out in document RC8AC.

Internal communication between the

modules:

Quick flash = error

Constantly On = error

n Power

n Comm

n DO1 n Status

n DO2 n Alarm

n DO3 n Service Tool

n DO4 n LON

n DO5 n MODBUS

n DO6 n LAN

n DO7

n DO8 n Service Pin

Status on output 1-8

Slow flash = OK

Quick flash = answer from gateway

in 10 min. after network installation

Constantly ON = error

Constantly OFF = error

Flash = active alarm/not cancelled

Constant ON = Active alarm/cancelled

External communication

Network installation

© Danfoss | DCS (vt) | 2020.01 BC041586425769en-000602 | 37

Page 38

User Guide | Network control AK-SM 720

4. Configuration and operation

This section describes how the controller:

• Is configured

• Is operated

Plant example

We have decided to describe the setup by means of an example

comprising a system manager and a number of controllers.

The example is the same as the one given in the "Design" section,

i.e. the system manager and one extension module.

Controllers:

• The controllers are of types AK- and EKC

• They are connected in a LON network

• They transmit alarms to the system manager

We have decided to work on the basis of the example we went

through previously.

The example is shown overleaf.

Modem:

• The modem is a type from the positive list

• It is connected to the system manager (it cannot be connected

until the setup has been completed as it is the same plug that is

used)

Operation:

• The setup is performed on the plant with PC and software

programme AK-ST

• After the setup operation can also take place via the modem and

AK-ST

Alarms:

• The alarm destination is System software type AKM at the

external modem

Alarm routing:

• To System software type AKM at the external modem

Controls:

• A table is set up for the shop’s opening hour

• Logs are collected in the system manager

• Logs are downloaded from the system manager with AKM

• Day/night hours for the refrigeration appliances are managed by

the system manager

• Defrost start is carried out by the system manager

• Consumption measurement (pulse signal is received from an

external unit)

• Switch to override the day/night schedule

• Switch (pulse pressure) to reset alarm

In the example the same modem will be used by both system software

type AKM and by Service tool type AK-ST.

This can only be achieved when it is possible to switch between the

two operating interfaces,

i.e. only one single destination is created.

If, however, it is not possible to switch, two destinations must be created, one for each modem.

38 | BC041586425769en-000602 © Danfoss | DCS (vt) | 2020.01

Page 39

User Guide | Network control AK-SM 720

Installation in network

1. Set net number

In our example the system manager must have address 1.

Turn the right-hand address switch so that the arrow will point at 1.

The arrow of the two other switches must point at 0.

2. Push the Service Pin

The system manager will be the master of a number of controllers in a

network. The number of this network can be set between 1 and 10. In

any network there must always be a number 1 as number 1 will appear

as master and coordinate the communication if there are several system

managers on the same network.

Press down the service pin and keep it down until the Service Pin

LED lights up.

3. Wait for answer

4. Carry out new login via Service Tool

A change of the setting of the switch will only take place after activation of the service pin button.

When the ”Status” light emitting diode starts flashing faster than normal

the network number has been installed. There will be a flash every half

second and change-back to slow flashing again after some 10 minutes.

If the Service Tool was connected to the System manager while you

installed it in the network, you must carry out a new login to the system

manager via the Service Tool.

© Danfoss | DCS (vt) | 2020.01 BC041586425769en-000602 | 39

Page 40

User Guide | Network control AK-SM 720

(If there are several network and with that several system managers)

If several system managers are linked up, the subsequent units

must have network numbers 2 and up, but max. 10.

Communication between the system managers takes place via the

TCP/IP network.

40 | BC041586425769en-000602 © Danfoss | DCS (vt) | 2020.01

Page 41

User Guide | Network control AK-SM 720

Configuration

Connect PC

PC with the program “Service Tool” is connected to the system

manager.

The controller must be switched on first and the LED “Status” must

flash before the Service Tool programme is started.

Start Service Tool programme

Login with user name SUPV

The AK Service Tool is mentioned at the beginning of the manual.

For connection: please see AK-ST.

The first time the Service Tool is connected to a new version of a controller the start-up of the Service Tool will take longer than usual while

information is retrieved from the controller.

Time can be followed on the bar at the bottom of the display.

Select the name SUPV and key in the passcode.

When the controller is supplied the SUPV access code is 123.

When you are logged into the controller an overview of it will always

appear.

When you are logged in on the system manager an overview of the

connected controllers will always appear.

In this case the overview is empty. This is because the system manager

and the controllers have not yet been set up.

The red alarm bell at the bottom right tells you that there is an active

alarm in the system manager. In our case the alarm is due to the fact

that the time has not yet been set.

The address is shown as 11:001.

This means that the master network is 11 and that this network is 1 (the

master network will always be 11, and this cannot be changed).

Subsequently the overview will also show the connected controllers

with their respective addresses. The illustration here has only been

included for your information so that you can see that the network

number is 1.

© Danfoss | DCS (vt) | 2020.01 BC041586425769en-000602 | 41

Page 42

User Guide | Network control AK-SM 720

Authorization

1. Go to Configuration menu

Press the orange setup button with the spanner at the bottom of

the display.

2. Select Authorization

When the controller is supplied it has been set with a standard authorization for different user interfaces. This setting should be changed so it is

adapted to the plant. You can change this now or later.

You will use this button again and again whenever you want to get to

this display.

On the left-hand side are all the functions not shown yet. There will be

more here the further into the setup we go.

Press the line Authorization to get to the user setup display.

3. Change setting for the user ‘SUPV‘

4. Select user name and access code

Mark the line with the user name SUPV.

Press the button Change

This is where you can select the supervisor for the specific system and a

corresponding access code for this person.

In earlier versions of the service tool AK-ST 500 it was possible to select

the language in this menu.

An updated version of the service tool will be released in the spring of

2009. If the controller is operated with the new version, language selection will happen automatically in connection with the configuration of

the service tool.

The controller will utilize the same language that is selected in the

service tool but only if the controller contains this language. If the

language is not contained in the controller, the settings and readings

will be shown in English.

5. Carry out a new login with the new user name and the new

access code

To activate the new settings you must carry out a new login to the controller with the new user name and the relevant access code.

You will access the login display by pressing the padlock at the top left

corner of the display.

42 | BC041586425769en-000602 © Danfoss | DCS (vt) | 2020.01

Page 43

User Guide | Network control AK-SM 720

Unlock the configuration of the controllers

1. Go to Configuration menu

2. Select Lock/Unlock configuration

3. Select Configuration lock

Press the blue field with the text Locked

The controller can only be configured when it is unlocked.

It can only be adjusted when it is locked.

The values can be changed when it is locked, but only for those settings

that do not affect the configuration.

(The configuration lock blocks for all settings concerning the setup of

inputs and outputs as well as the setting of the IP address).

4. Select Unlocked

Select Unlocked and press OK.

© Danfoss | DCS (vt) | 2020.01 BC041586425769en-000602 | 43

Page 44

User Guide | Network control AK-SM 720

Clock function

1. Go to Configuration menu

2. Select Setup time and date

3. Time setting

Press in the blue field with a setting.

An auxiliary setting will now be shown. Press the ”PC” button and then

”OK” to transfer the PC’s times to the system manager.

The system manager’s times will automatically be retransmitted to the

individual controllers on the network.

A battery will protect the clock function if there is power failure. The

working life of the battery is several years. The battery is checked

continuously and an alarm will be given when it is time for a replacement. After a replacement the clock has to be reset.

44 | BC041586425769en-000602 © Danfoss | DCS (vt) | 2020.01

Page 45

User Guide | Network control AK-SM 720

Quick setup

1. Go to Configuration menu

2. Select Quick setup

3. Write neccessary data

4. Set data for the external recipient

In this menu the necessary settings have been gathered so that

a simple alarm routing can be established. All settings will be

transferred to other respective displays.

- Site name

- Receive alarms from controllers on network

- The language in which the alarms are to be received

- Select the alarms to be retransmitted to an external recipient

Press the OK button to gain access to the settings for the external recipient.

- Give the destination a name

- The connection to take place via a modem

- Write the phone number

- Write passcode

- Define that alarms are to be sent (next line a little further down

on the screen)

- Define the alarm priorities that are to be sent (the next line a

little further down in the display).

Setting Log Alarm relay selection Net-

Non High Low - High

High X X X X 1

Middle X X X 2

Low X X X 3

Log only X

Disabled

work

AKM dest.

© Danfoss | DCS (vt) | 2020.01 BC041586425769en-000602 | 45

Page 46

User Guide | Network control AK-SM 720

Plants main data

1. Go to Configuration menu

2. Select Local site setup

3. State main data

- Write the name (it will already be there if you entered it under

”Quick setup”).

- The name of the system manager will also be the same if you

entered it under ”Quick setup”. You may overwrite the name if

it is to be changed. (This is the name that will be shown in the

general view of the plant).