Page 1

User Guide

Monitoring unit with alarm

function and data collection

AK-SM 350

ADAP-KOOL® Refrigeration control systems

Page 2

Introduction

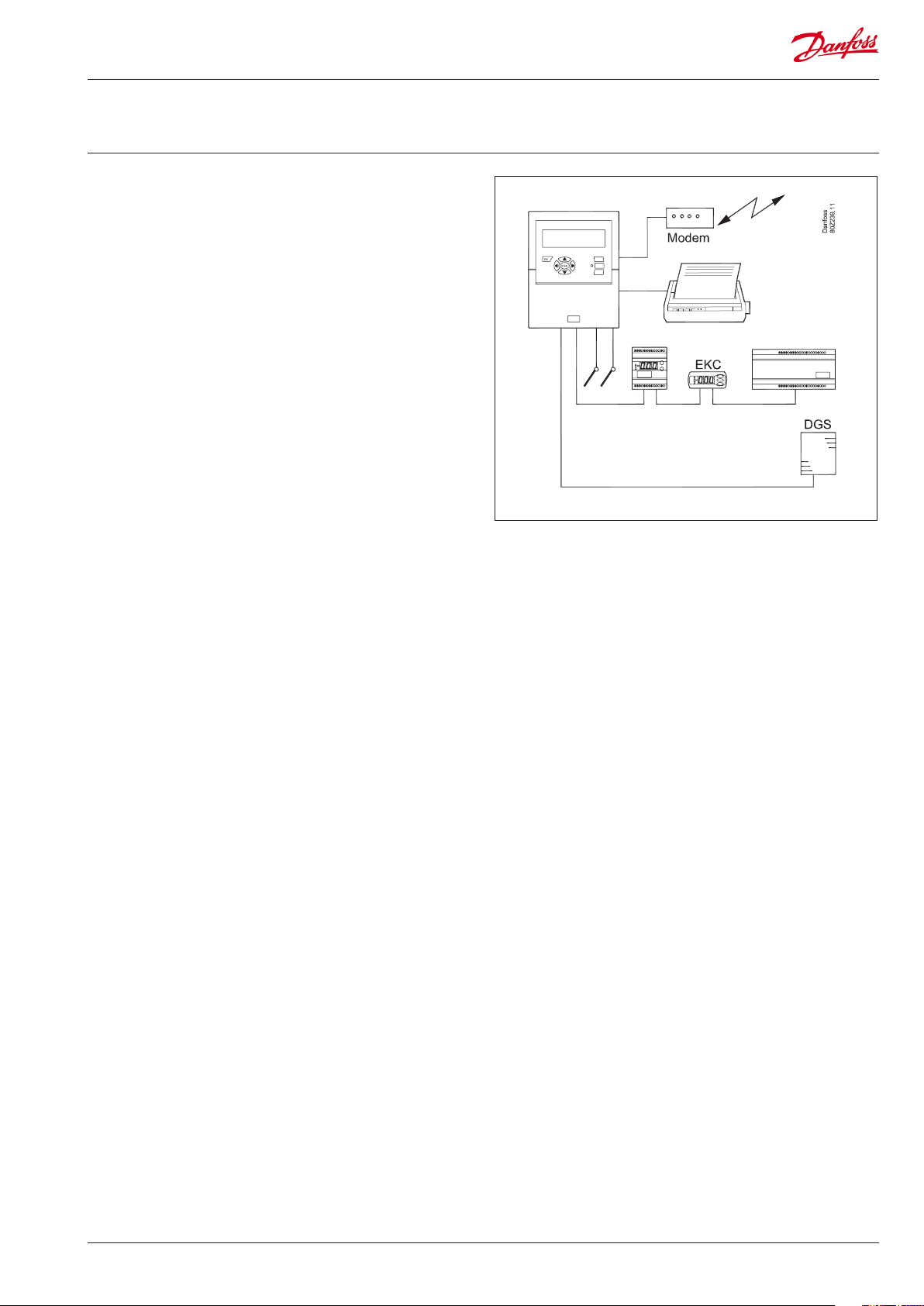

The AK-SM 350 is a combined data collection and monitoring unit

for use in refrigeration plant in small supermarkets.

It is used to record the temperature in the various refrigeration

applications, store this data and then present it as documentation

in compliance with regulatory requirements.

Along with recording temperatures, there are alarm limit settings

and the unit will emit an alarm if a threshold value is exceeded.

The alarm is presented on the display and it can be sent to an

external alarm destination such as a mobile phone or a service

company.

The unit is positioned centrally in the supermarket, and the userfriendly interface makes it easy to follow the dierent temperature

readings.

With just a few pushes of the buttons, graphs of the dierent

temperature sequences can be brought up, and in the event of an

alarm, the cause can be read from the display.

All store employees will be able to operate the monitoring unit

and authorised personnel will have access to important settings

with a password.

Setups and settings can be entered via the front panel, but if there

are a lot of names and settings, they can be entered using the AKST type software. This software must be loaded on to a PC.

If there is more than one AK-SM 350 that is to be programmed

with the same settings, the back-up and restore function in the

AK-ST software may prove useful.

Advantages

• Compact unit for registration of temperatures

• Collects temperature data to present to authorities

• System unit with

- Optimisation of suction pressure (P0 optimisation)

- Day/night override

- Alarm function

Contents

Overview .......................................................................... 3

Data .................................................................................. 6

AK-SM 350 ................................................................................................6

Installation ....................................................................... 8

Assembly ................................................................................................... 8

Connections .............................................................................................9

External communication ...................................................................12

Conguration ................................................................13

The functions' mode of operation ........................14

The display .............................................................................................14

The overview display ...................................................................14

Display screens for daily use .....................................................15

Main menu ......................................................................................15

Functions for daily use - Setups/adjustments ...........................16

Day / Night setup ..........................................................................16

Injection ON Signal ......................................................................17

Starting defrosts ............................................................................18

Adaptive defrost ............................................................................19

P0 optimization .............................................................................19

Adaptive Rail heat.........................................................................20

Conguration settings .......................................................................21

Basic setup ......................................................................................21

Setup of points ..............................................................................24

Alarm settings ................................................................................33

Alarm routes ...................................................................................34

Alarm destinations .......................................................................36

Print setup .......................................................................................40

IP conguration .............................................................................41

Relay conguration ......................................................................41

Setup for other networks via protocol interface ...............43

Alarm priorities ..............................................................................43

Daily use .........................................................................44

When there is an alarm ......................................................................44

When you want to print out a data collection ..........................45

When you want to see a graph of the collected temperatures

.............................................................................................................46

When you want to change the store's opening times ...........47

When you want to change the defrost times ............................48

Appendix - Template compiler ............................... 49

Menu survey ..................................................................53

2 Manual RS8EF602 © Danfoss 01-2016 AK-SM 350 Version 2.5x

Page 3

Overview

Number of connections

The AK-SM 350 is a central monitoring unit that can monitor up to

65 readings. They can originate from:

- up to 16 direct connections from sensors or switch functions

- signals from separate refrigeration controllers, EKC and AK types,

via data communication and AKC via interface AK-PI 200.

- signals from gas detectors. These readings are also transferred

via data communication.

Alarms

The unit advises you of an alarm in several ways:

• With an audio signal

• By ashing the LED on the front

• By showing an alarm symbol on the display

• In addition to this, the unit can route alarms to external alarm

destinations. This alarm routing can be categorised into priorities

and times for dierent alarm destinations at dierent times of

the day.

Alarms from freestanding refrigeration controllers received via

data communication are forwarded to the monitoring unit. The

warnings are then generated as described above.

Data collection

All dened points can be recorded and saved with the set time

intervals.

The values can be viewed on the display and retrieved by connecting a printer or connecting a PC or modem.

Signals

The following types of signals can be received:

• Temperature readings

• Switch functions

• Pulse signal for output reading

• Voltage signal

• Current signal

• Signals from refrigeration controllers types EKC and AK.

• Signals for P0 optimization

• Day/night override.

Gas detector

One or more of the measuring points can be a gas detector. The

gas detector is connected to the data communication, after which

it will send the measured value to the monitoring unit. If the

threshold value set in the monitoring unit is exceeded an alarm is

generated.

For further information on the gas detector, please see document

RD7HA or USCO.EN.S00.A.

Printer

The connection of a printer means that the data collected can be

printed out. The printer must be an HP PCL-3 compatible printer.

The print-out may contain:

• The measuring points’ actual values

• Graphic readout of temperature sequences

• Alarm history

External connections

• Modem

A modem can be connected so that the unit can be in contact

with external alarm destinations or service companies.

The modem can be a standard telephone modem or a GSM

modem for mobile telephony.

• Ethernet

The link to external alarm destinations and service companies

can take place via a TCP/IP network.

• PC

A PC can be connected to the unit. The PC may be stationary,

portable or handheld. Setups and/or alarm receipt can be performed via an operating program.

• Service companies

Users of the following programs can receive alarm calls from the

unit.

AK series software (operating and setting)

AKM type software (only receiving alarms and logging data)

Security

Important settings are password-protected.

When logging on or out from external links, an additional security

check is required to verify the connection. This will be carried out

during the setup.

Battery Backup

The unit contains a battery, so that the clock function is still maintained if there is a power failure.

The recording of temperatures will resume when the power

comes back on.

All setups will be retained during a power failure.

AK-SM 350 Version 2.5x Manual RS8EF602 © Danfoss 01-2016 3

Page 4

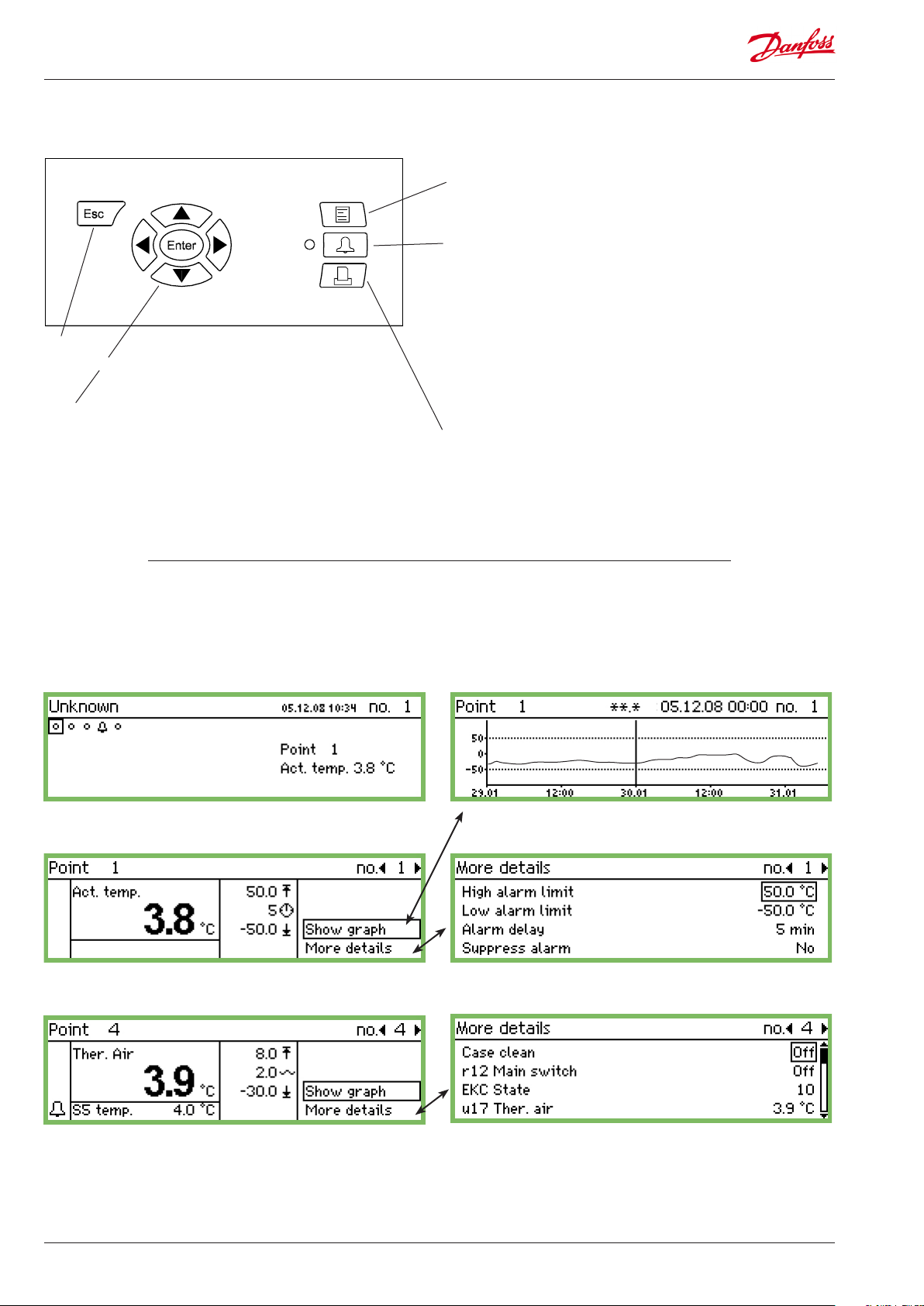

Operation

The following operation options are found on the front of the

monitoring unit:

Escape

• Goes back to the display readout

Navigation

• The arrow keys change what is highlighted in the display. Values

can be changed.

• "Enter" executes a selection.

When an "arrow" is shown on the top right-hand side of the

display, this means there are several menus for this level. Press an

arrow key to move to the menu.

Menu

Provides access to the menu system and consequently the setups.

See page 15 for more information.

Alarm signal and operating the alarms

• The LED ashes when there is a new alarm

• The LED lights up when the alarm is acknowledged and the

"error" has not been dealt with.

• The LED does not go out until the error has both been rectied

and acknowledged.

• The button shows the alarm text and stops the alarm signal

when it is pressed twice.

See overleaf for more information.

Print

• Starts the print-out function. Only used if a printer is connected

to the unit.

See page 40 for more information.

The display

There are several display screens used in daily operation. Here is a

short presentation:

• Overview display, with all measuring point

• Point detail display, showing the point’s actual values

• Point detail display from a controller

• Graph display, showing the point’s previous readings

• "More details" from a point

• "More details" from a controller

Descriptions of the display screens can be found on page 14

onwards.

4 Manual RS8EF602 © Danfoss 01-2016 AK-SM 350 Version 2.5x

Page 5

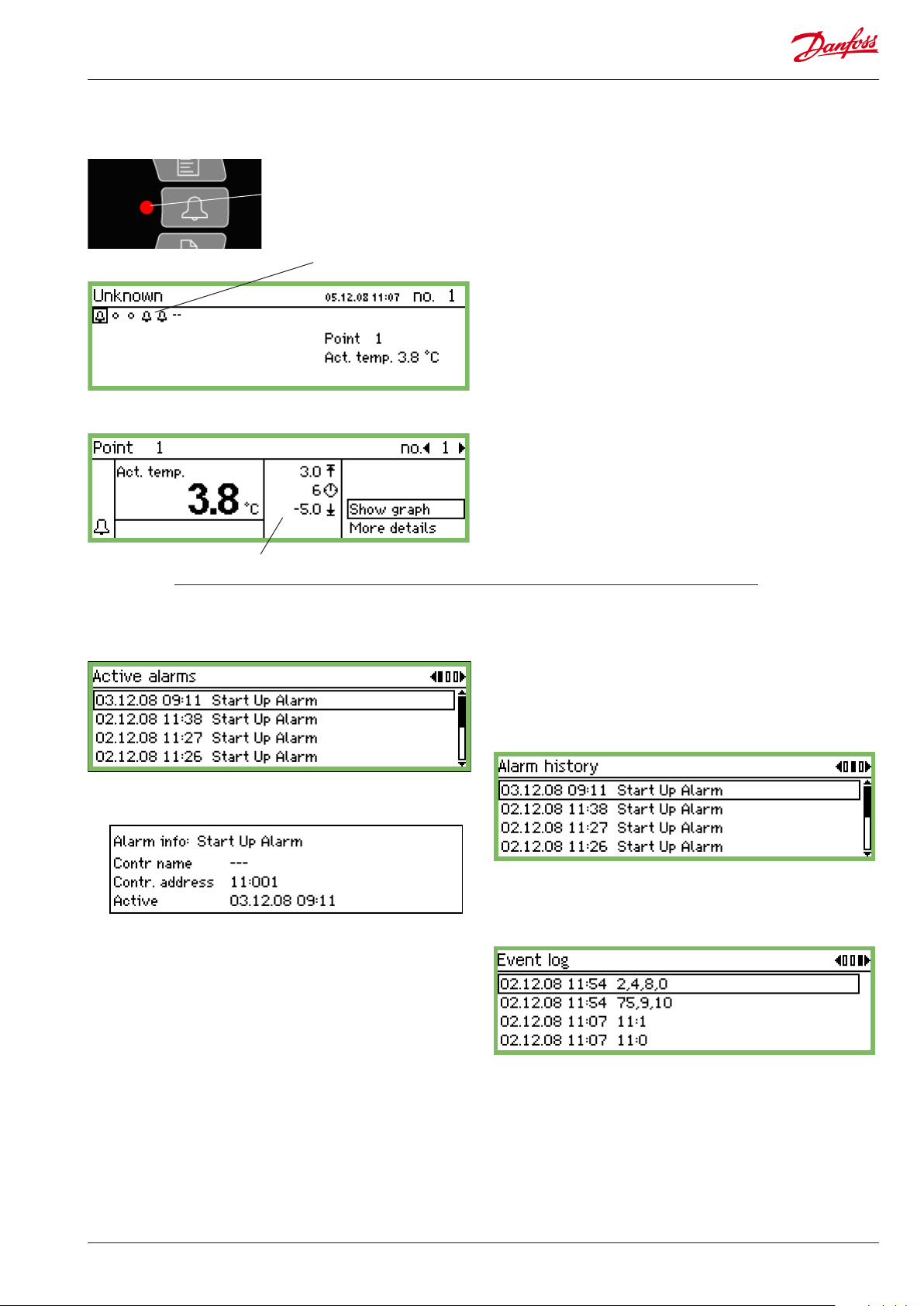

Alarm situations

If there is an alarm, the following will happen:

Flashes

Shows alarm symbol

This area shows the alarm limits and delay time

- An alarm symbol will appear in the overview display for the point

in question

- The LED by the alarm button will ash

- The built-in siren will be activated for a set period (but only if it

has been dened)

- If a relay to the alarm function has been dened, the relay will be

enabled

- When you move to the point in question, the alarm symbol will

also be visible at the bottom left-hand side

- The alarm text is entered into the alarm list of active alarms

- If external alarm destinations have been dened, the alarm and

alarm text will be forwarded to the destination.

If you press the alarm button:

- The alarm list is shown in the display

When you select an alarm from the alarm list of active alarms

and then press "Enter", you will see several pieces of information

about the alarm.

When you press the alarm button again:

- All the alarms are acknowledged (conrmation that they have

been seen)

- The built-in siren stops

- If a relay to the alarm function has been dened, it will return to

the state "no alarm" (relay conguration page 41).

- The LED by the alarm button stops ashing and changes over to

being lit constantly if the error is still there. It will go out if the

error has disappeared.

- The alarm text is transferred to the "Alarm history" list

- Active alarms will continue to be shown in the display.

(This second press (acknowledgement) can be blocked with a

password.)

When the alarm disappears:

- The alarm symbol in the overview display disappears

- A "cancelled alarm" is sent to alarm destinations (only IP, SMS

and modem connections).

If you want to see the Alarm history, you need to press the alarm

button and then the "right arrow" button

The Alarm history can store up to 200 alarms. Once it reaches 200 the

new alarms will overwrite the oldest ones.

If you want to see the Event log you need to press the alarm button

and then press the "right arrow" twice

AK-SM 350 Version 2.5x Manual RS8EF602 © Danfoss 01-2016 5

Page 6

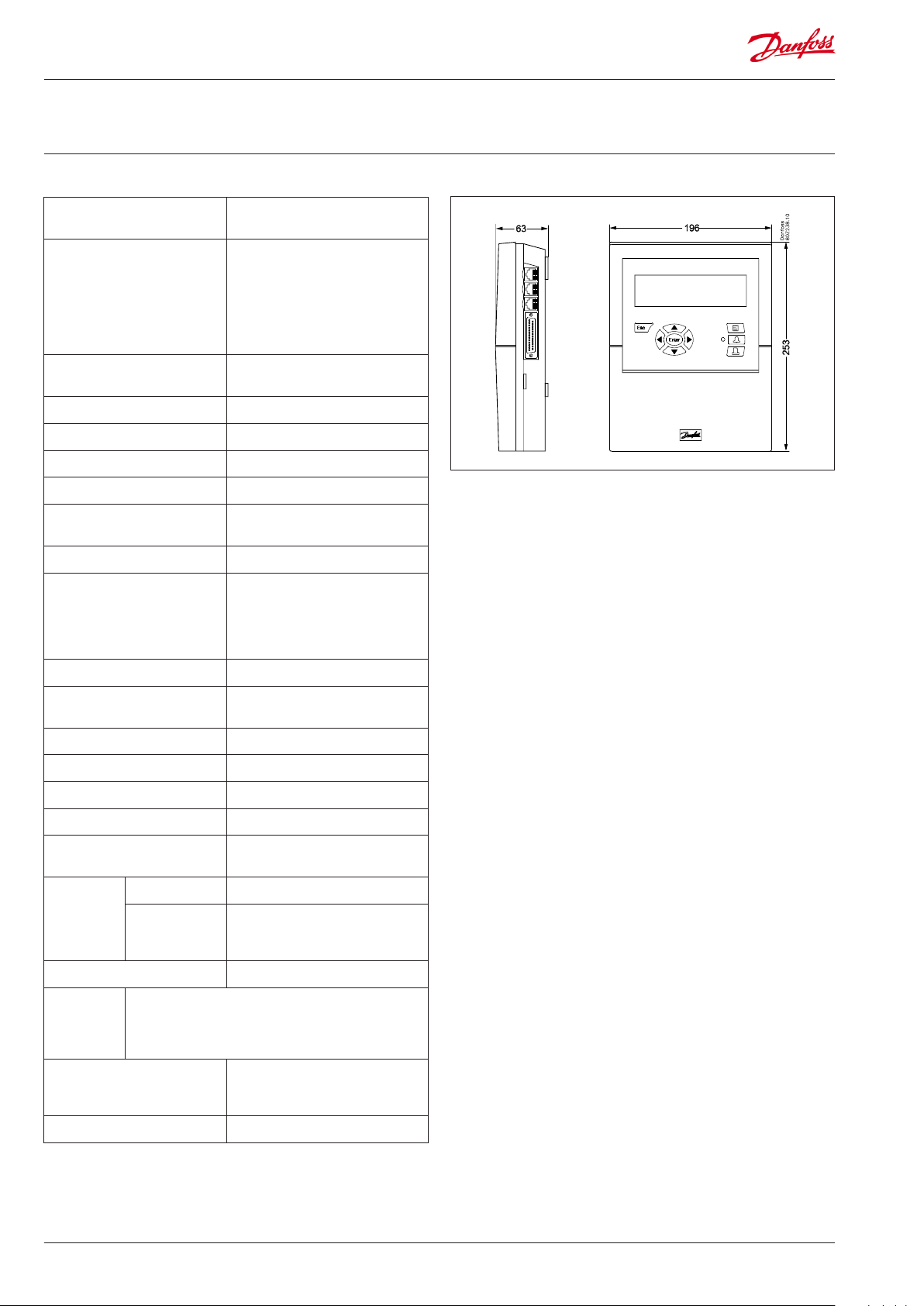

AK-SM 350

Supply 115 V / 230 V

+10/-15%, 50/60 Hz, 10 VA

Data

Connection PT 1000 ohm at 0°C or

Pulse counter inputs for output

reading

Display Graphic LCD, 240 x 64

Direct measuring points 16

Total number of points 65

Measuring range, general -100 to +150°C

Measuring accuracy at Pt 1000 Resolution 0.1 K

Measuring interval 15, 30, 60, 120 or 240 minutes

Data capacity 12 MB ash

Battery backup Button cell for clock function (2032)

Power supply for e.g. pressure

transmitter

PTC 1000 ohm at 25°C or

NTC 5000 ohm at 25°C or

Termistor (-80 to 0, -40 to 40 or 0

to 100°C)

Digital On/O signal or

Standard 0 - 10 V / 4 - 20 mA signal

Acc. to DIN 43864.

(Only for inputs 1 and 2)

Accuracy: +/- 0.5 K

Recording of all data from all

measuring points for one year at

30-minute intervals.

Last 200 alarm warnings

5 V max. 50 mA

12 V max. 50 mA

Printer connection HP PCL-3, Parallel

Modem connection RJ 45

TCP/IP connection RJ 45

PC connection RJ 45 (RS 323)

Data communication RS232, RS485 (LON), RS485 (MOD-

Relays Quantity 2

Max. load 24 V a.c. or 230 V a.c.

Enclosure IP 20

Ambient

environment

Approvals EN 60730-1 and EN 60730-2-9

Weight 1.6 Kg

Capacitive load

The relays cannot be used for the direct connection of capacitive loads such as LEDs

and on/o control of EC motors.

All loads with a switch mode power supply must be connected with a suitable contactor or similar.

0 to 50°C, during operation

-20 to +70°C, during transport

20-80% RH, Non-condensed

No shock loads/vibrations

bus), RS485 (TP) (TP= Third Party)

Imax (AC-1) = 5 A

Imax (AC-15) = 3 A

EN 61000-6-3 and EN 61000-6-2

EN 12830 and EN 13485

6 Manual RS8EF602 © Danfoss 01-2016 AK-SM 350 Version 2.5x

Page 7

Ordering

Type Measuring points Description Language Code no.

English, German, French,

Dutch, Italian

AK-SM 350 16

Cable for PC

(see also AK-ST 500 literature)

Modem cable 080Z0261

With inputs for PT 1000 ohm,

PTC 1000 ohm , NTC 5000 ohm

RJ 45 - Com port 080Z0262

English (UK), Spanish,

Portuguese, English (US)

English, Polish, Czech 080Z8504

080Z8500

080Z8502

AK-SM 350 Version 2.5x Manual RS8EF602 © Danfoss 01-2016 7

Page 8

Installation

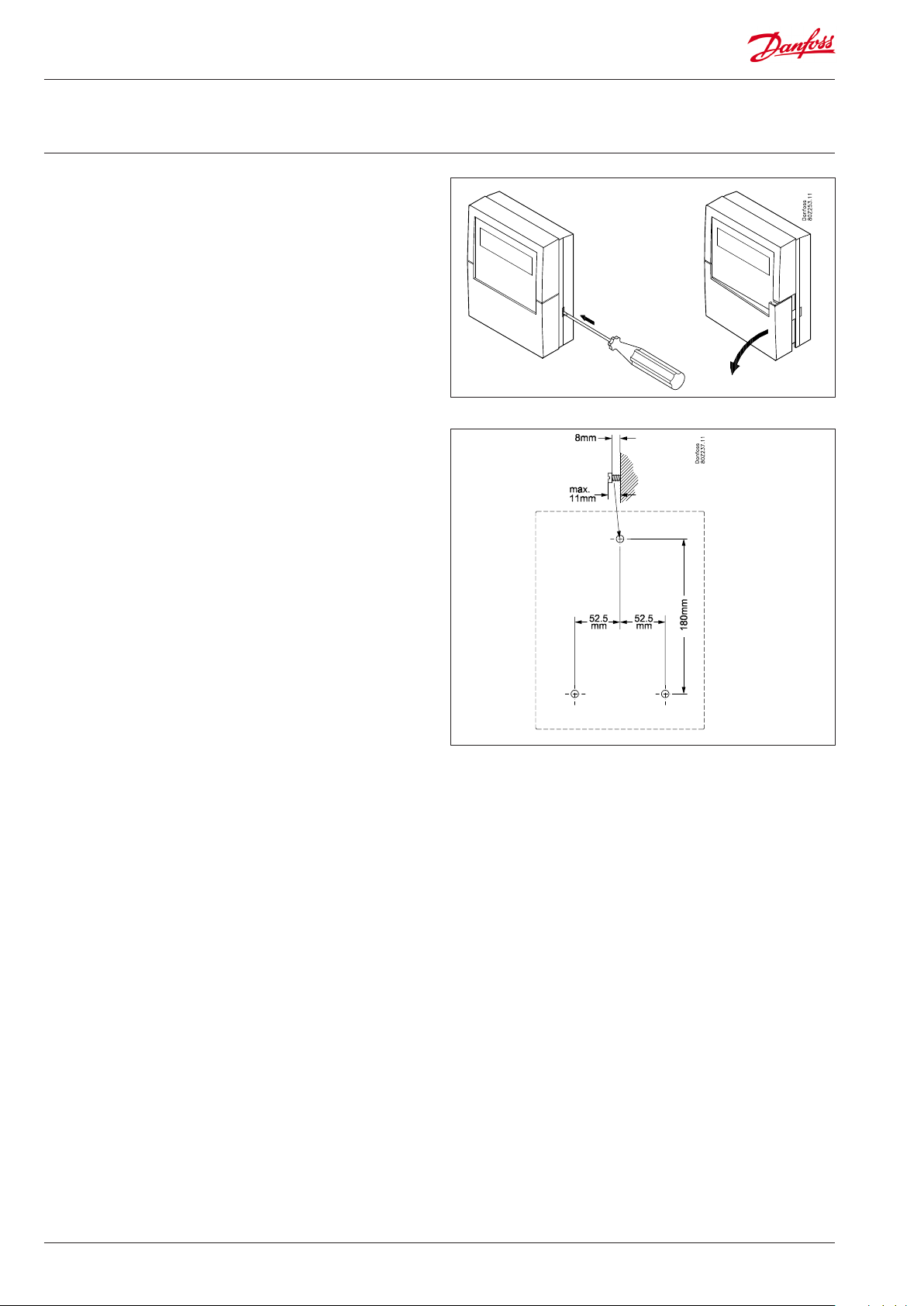

Assembly

Opening

1. Release one of the two snap catches on the side of the unit.

2. Pull o the cover.

Closing

Push the cover into place so that the two snap catches click shut.

Position

The unit should be positioned as follows:

• At eye level

• Not in direct sunlight

• Nowhere strong light can cause reections on the display

• Not in extreme temperatures or anywhere damp

• Not close to sources of electrical interference

The unit is secured with 3 screws.

The top one is positioned at eye level. Make sure that the head of

the screw is not sticking out so much that it is touching the PCB.

Then hook the unit on the screw and t the two remaining screws.

8 Manual RS8EF602 © Danfoss 01-2016 AK-SM 350 Version 2.5x

Page 9

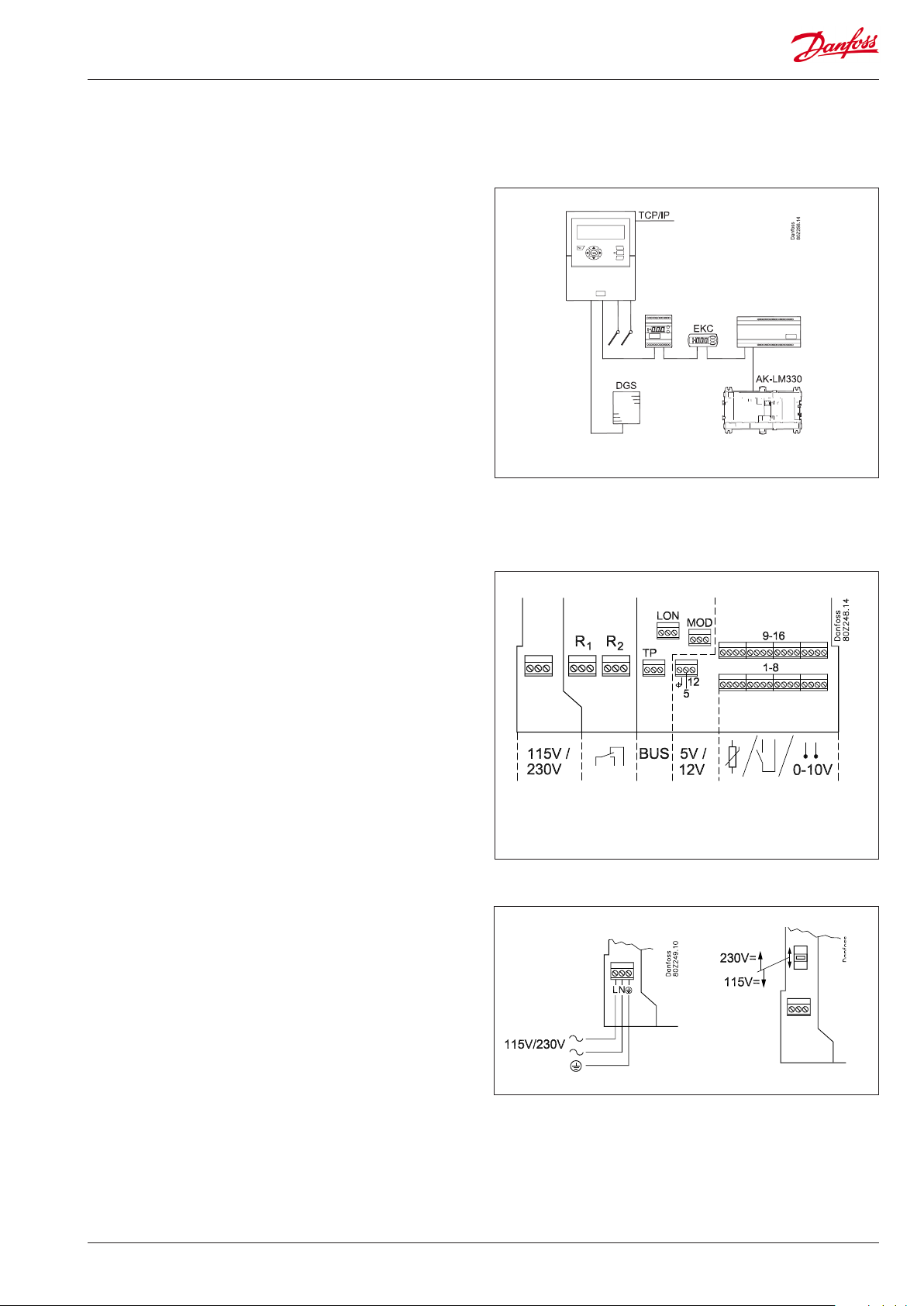

Connections

Principle

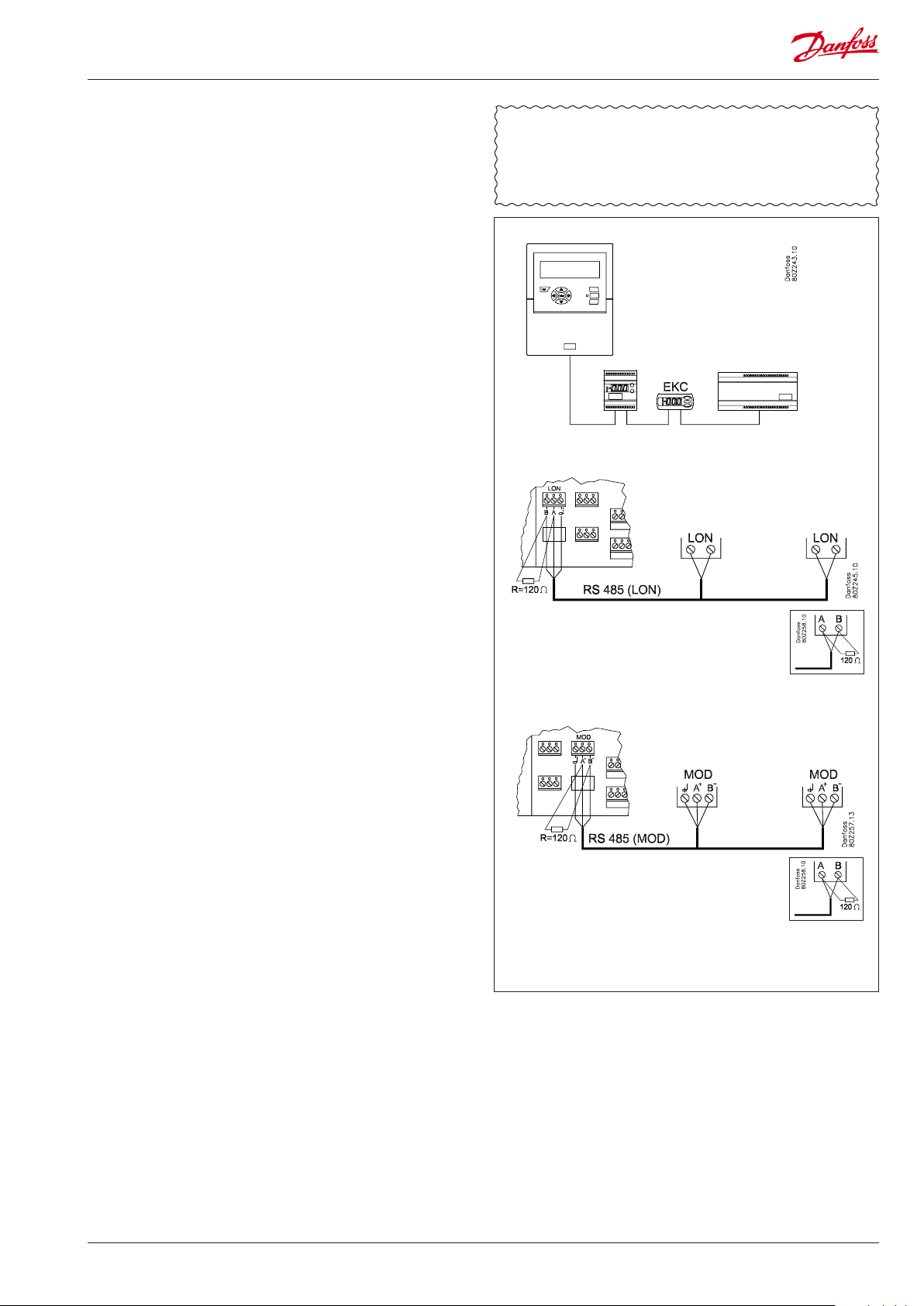

Up to 16 direct readings can be connected to the AK-SM 350.

If the number of direct measuring points is not sucient, readings

can be retrieved from an AK-LM 330. The readings are retrieved via

the RS485 - LON data communication.

Readings from a gas detector are also retrieved from this data

communication.

If separate refrigeration controllers (type EKC or AK) are used,

temperature readings can be retrieved from these controllers.

The readings are retrieved via the RS485 - LON or MOD-bus data

communication.

Controllers type AKC (DANBUSS data communication) can be connected via AK-PI 200 connected to the TCP/IP input.

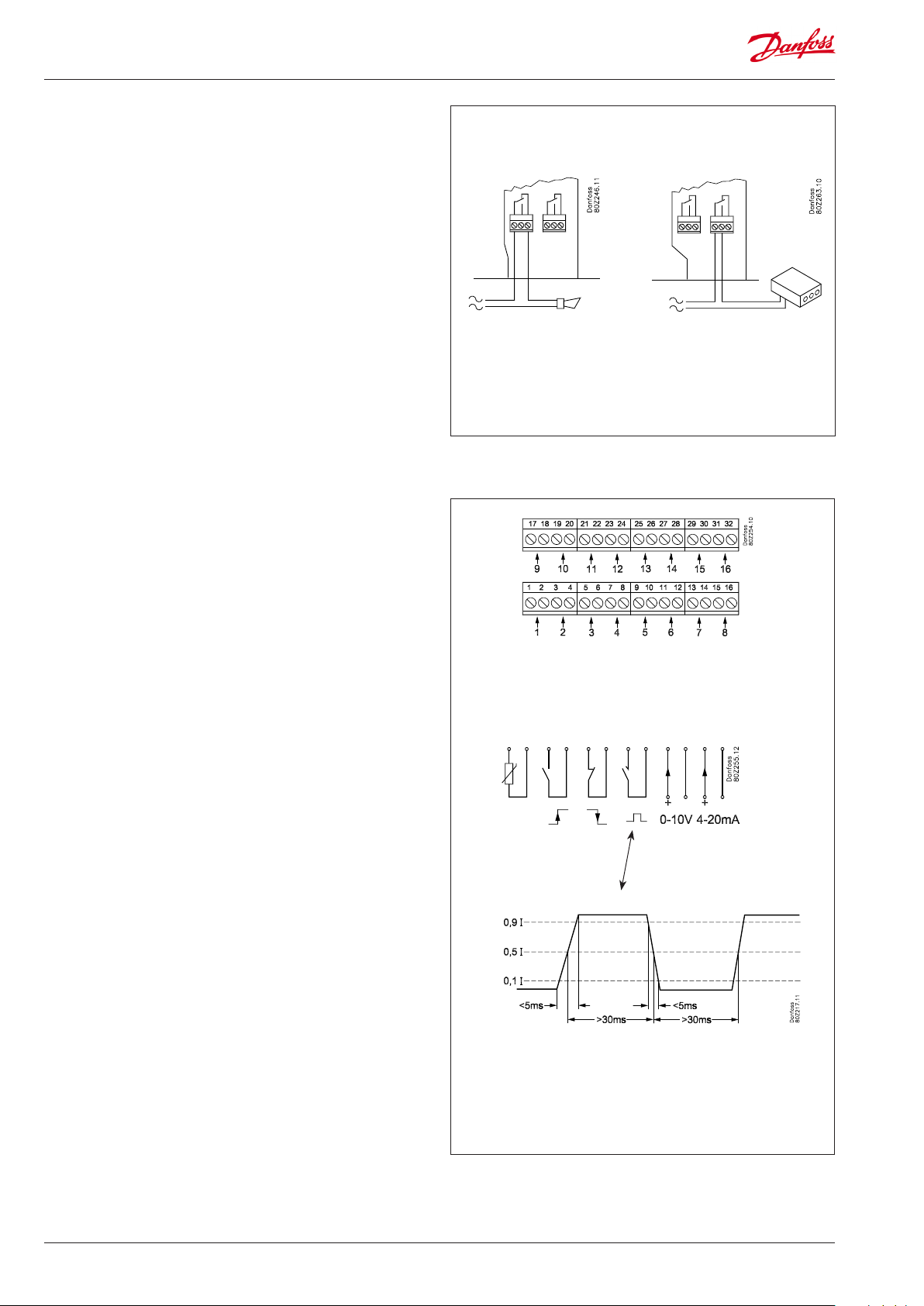

Connections overview

The supply voltage is connected on the left-hand side. Next to this

connection are two relays which can, for example, be used for the

modem reset, watchdog or alarm relay. For safety reasons both

relays must be used at the same voltage – 24 V on one relay and

230 V on the other is not permitted.

On the right-hand side all the connections are low voltage.

There are three types of data communication which can be connected to other Danfoss cooling controllers equipped for the

same type of data communication.

Then there is a 5 V and a 12 V supply. They can be used for supply

voltage to a pressure transmitter that is to provide a signal to one

of the measuring points.

There are 16 connections on the far right-hand side. They can be

linked up however you like to signals from sensors, switch functions and voltage signals of up to 10 V. However, if there are pulse

readings, they must be linked up to nos. 1 or 2.

1. Supply voltage

The supply voltage must be 230 V AC or 115 V AC. At

connection, the changeover switch must be set to the actual

voltage.

The permitted tolerances mean that the supply of 115 V also

includes supply voltages of 110 V and 120 V.

1. 2. 4. 3.

AK-SM 350 Version 2.5x Manual RS8EF602 © Danfoss 01-2016 9

Page 10

2. Relays

The two relays can be used for:

• External alarm function

When connected as shown, an alarm will be emitted in alarm

situations and when the power to the AK-SM 350 disappears.

• Resetting the supply voltage for a modem

After a power outage, the AK-SM 350 will control the supply

voltage for the modem, ensuring the modem restarts in a

controlled manner.

• Watchdog

Here the relay is enabled in time intervals. For example, once

an hour. If there is no relay change, an external unit will sound

an alarm.

The two relays must be connected to either low or high voltage

(115/230 V), but not low voltage on one and high voltage (115/230

V) on the other.

3. Direct measuring points

There are 16 direct measuring points.

All the odd numbers are signal inputs. All the even numbers

are earth. All the even numbers on the PCB behind the terminal

block are linked to a common earth.

If you use a common earth wire to several measuring points you

should delimit it into groups. Do not put temperature signals,

switch signals and voltage signals in the same group.

Keep your distance from sources of electrical interference and

power lines.

Relay 1

Relay 2

Sensor connections

One of the conductors is wired to an odd terminal block

number. The other is wired to earth (even number).

On/o signals from a switch function

One of the conductors is wired to an odd terminal block

number. The other is linked to earth (even number).

The switch can either be a make contact or a circuit breaker. The

function is dened under setup.

Output reading (pulse recording)

Only measuring points 1 and 2 can be used for output readings.

These inputs are designed for fast on/o changes.

Pulses are measured in accordance with DIN 43864.

The signal is wired as an on/o signal.

Voltage signal

The voltage can vary between 0 and 10 V DC.

Minus is wired to earth (even number).

Current signal

The current signal can vary between 4 and 20 mA.

Minus is wired to earth (even number).

Gas detector, type DGS

This gas detector can give a voltage signal or a current signal for

AK-SM 350.

DIN 43864

S01 interface

10 Manual RS8EF602 © Danfoss 01-2016 AK-SM 350 Version 2.5x

Page 11

4. Data communication

If readings are to be retrieved via data communication, this

must be done as follows:

Controllers

The AK-SM 350 can receive signals from a number of controllers.

The controllers are connected to the RS485-LON communication

or RS485-MOD-bus communication. These two types cannot be

mixed.

Cable

There are no requirements concerning the positioning of the

AK-SM 350 for data communication. It can be at one end of the

cable or it can be anywhere along the cable.

Wiring

• LON-bus

There are no requirements concerning the polarisation of the

A and B connections. The screen connection must be looped

onwards for each controller.

• MOD-bus

A+ must be wired to A+.

B- must be wired to B-.

The screen connection must be fed onwards and tted into all

controllers.

Termination

Each end of the data communication cable must be terminated

with a resistance of 120 Ω. In some EKC controllers a termination jumper is tted. Termination takes place here by closing the

jumper.

The actual installation of the data communication cable must

comply with the requirements mentioned in the document

"Data communication between ADAP-KOOL® Refrigeration

controls". Literature sheet number = RC8AC.

Addressing

Every controller must have an address set. This address will then

be recognised by the AK-SM 350.

BUT this is provided that the address has not already been dened

for the other side (another controller on the same or dierent data

communication). If it has already been used, the existing setting

will be kept and the last one entered will not be used. Nor should

you use an address taken by a gas detector. Duplicated addresses

are not permitted.

• Each EKC controller must have "o03" entered with every address.

• The AK-SM 350 is then able to receive these addresses. There

are two possible ways for this to happen:

- Either by activating "o04" in every EKC controller, but this will

require a voltage on the AK-SM 350. (Controllers with MODbus communication do not have an "o04".)

- Or by enabling the "scan function" in the AK-SM 350. This

requires all the EKC controllers to have an address set. A

controller with MOD-bus communication can only be found

via this scan function.

In the later setup, we want to activate the "scan function", after

which all addresses can be viewed in the network list.

Gas detector, type GD

If a type GD gas detector is used, it must be connected to the

"TP" data communication.

For assembly and connection, please see literature sheet

RD7HA.

Set the address in the gas detector (max. no. of addresses is 65).

An address used by an EKC controller must not be duplicated.

Make a note of the address. It will be used later on, when the

AK-SM 350 has to be set up.

AK-SM 350 Version 2.5x Manual RS8EF602 © Danfoss 01-2016 11

Page 12

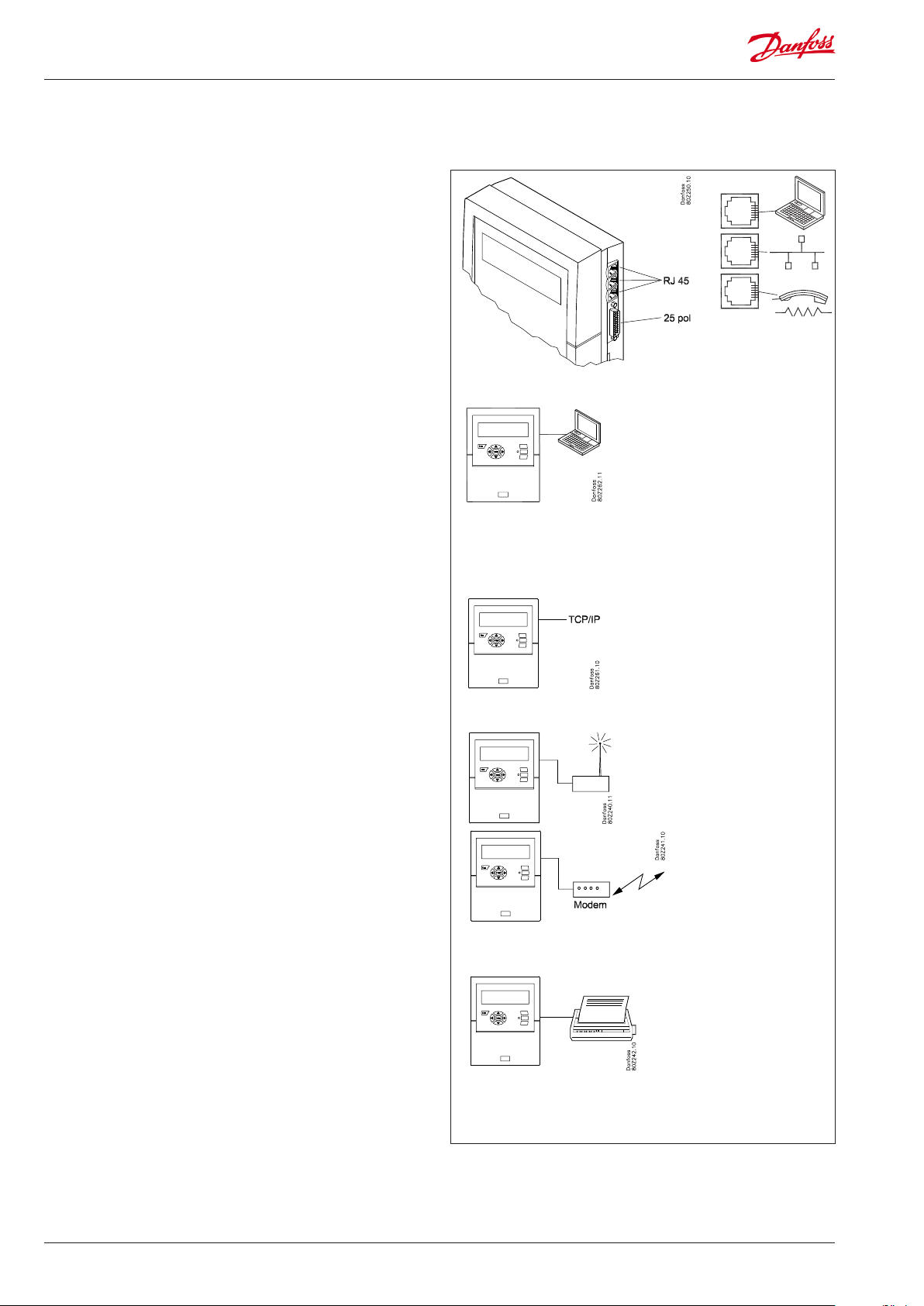

External communication

Danfoss

80Z260.11

At the side of the unit there are connectors for external communication.

They can be used for the following:

• Setting up the unit

• Receiving alarms at a service company

• Receiving alarms on a mobile phone

• Service

• Printer connection. Printing out logs and alarms

PC connection

This connection can be used when setting up the unit or when

carrying out service.

The PC must have the AK service tool program uploaded.

If text for individual points needs to be entered, it would be a

good idea to use a PC connection.

If several units are to be installed with the same setup, it would be

very helpful to use the copy function in the AK service tool.

If logs are to be retrieved from the unit, this can also be done in

this way.

See also the literature sheet for the AK service tool.

TCP/IP connection

Here the unit can be linked to an Ethernet or a unit can be connected for setup and service.

Fx AK-PI 200 and controllers with DANBUSS data

communication

Modem connection

Here a modem can be connected to a xed network or mobile

network.

Printer connection

The printer can be connected when there is a need for print-outs

of e.g. logs, alarms or curves of a temperature sequence.

GSM / SMS

Cable = Modem cable

GSM Box: Siemens TC35I

(Danfoss' approved suppliers list)

Fixed network

Cable = Modem cable

Modem: Ask for a copy of

Danfoss' approved suppliers list.

Cable = Standard parallel

Printer: HP PCL-3 compatible.

Ask for a copy of Danfoss' approved suppliers list.

12 Manual RS8EF602 © Danfoss 01-2016 AK-SM 350 Version 2.5x

Page 13

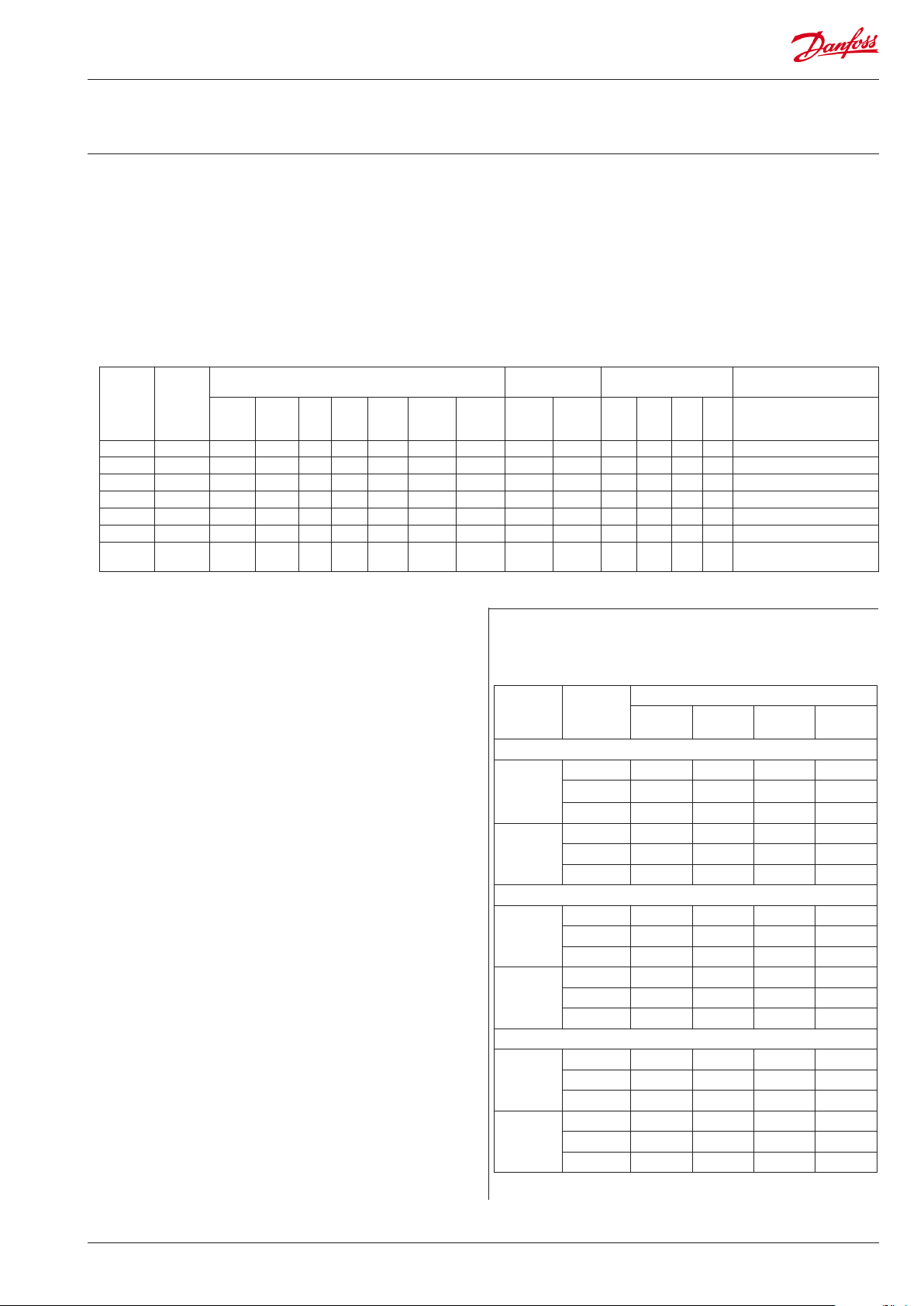

Conguration

Principle

This page describes the setups that are to be installed in the

monitoring unit.

The points are detailed briey so that the list can be used as a

checklist.

The monitoring unit is set up once each point has been reviewed.

Procedure

1. Create an overview of all the connections.

Decide where they will be connected.

Decide the alarm priority for the reading.

The table below shows some examples of the various possibilities.

Point no.

in display

Name Type of connection Place of

Tempe-

Di

Ai

Pow-

Power

rature

(on/

(analog)

er

meter

o)

1 xxxx A x 1-16 x

2 xxxx B x 1-16 x

3 xxxx C x 1-16 x

4 xxxx D x 1-2 x 1 or 2 only

5 xxxx E x 1-65 x

6 xxxx F x 1-xxx x

7 xxxx G x Load/store data from Power

meter

log

Gasdetector

If you require help setting up individual points, you will nd a

more detailed explanation in the next section – The functions’

mode of operation.

connection

Controller Terminal Address High Me-

Priority of alarm Note

Low Log

dium

only

meter

Then continue by:

2. Pressing the button for the main menu

3. Selecting "Service Setup" at the bottom of the display

4. Go through all the functions in "Basic setup". In one of the functions, the network will be scanned, which allows the monitoring

unit to recognise all the connected units on the data communication. Do not forget that the controllers must have an address

set, or to check that the power is turned on before the scan

function is enabled.

5. Select Point setup

6. Set all points. Use data from a table like the one above. Some of

the readings will have two alarm limits. Dierent alarm priorities

can be set for each one.

7. Create a table of the alarm activities. See the table on the right.

8. Set up the alarm function

a. Set the general functions rst

b. Then set how an alarm should be handled/routed (i.e. what

will be enabled)

c. And nally, set up the activities chosen (e.g. addresses of the

alarm destinations)

9. Check that the alarms can be sent properly

a. Set the function "Test alarm priority" to "high"

b. Enable the function "Test alarm"

c. Check that the alarm is received

d. Repeat this check for the other alarm priorities

e. Repeat this check until all the destinations have been tested

to see if they can receive alarms.

Table of alarm activities (example)

(Referred to in point 7 and utilised in point 8b)

Route 1

Time Alarm

Day High 1 x

Night High 2

Day High

Night High

Day High

Night High

priority

Medium 1

Low 1

Medium 2

Low -

Alternate destination (if the link to the primary destination fails)

Medium

Low

Medium

Low

Medium

Low

Medium

Low

Remote

no.

Primary alarm destination

Copy destination

Alarm activity

Relay Buzzer SMS

AK-SM 350 Version 2.5x Manual RS8EF602 © Danfoss 01-2016 13

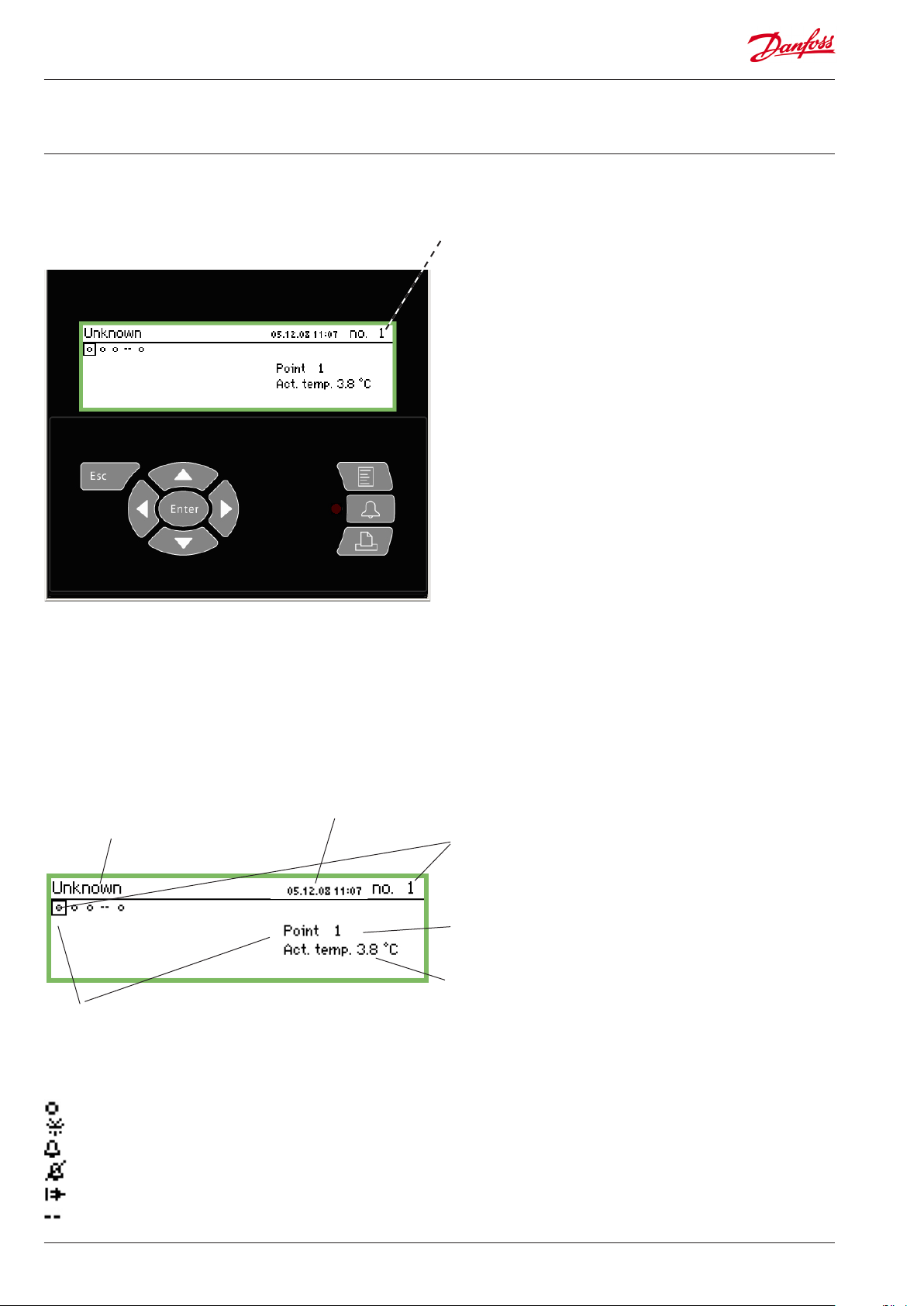

Page 14

The functions' mode of operation

The display

This section will explain all the dierent functions in the dierent

display screens.

In the overview display you can use the buttons to get to the

dierent points, or the monitoring unit can be set up to "scroll"

through the points. The view is reset once the last point has been

shown.

When an arrow is shown in this position, you can move to the next

or previous point (or display) by pressing the "right arrow" or "left

arrow".

This is the overview display that shows all the dened readings.

Here each point is represented by a symbol.

Point 1 is at the top left. 2 comes next and so on. A total of 65

points, and thus 65 readings, can be shown.

A reading can be a :

• Temperature reading

• Voltage signal or current signal

• On/o signal from e.g. a door switch

• Pulse signal from an output reading

• Signal indicating that a defrost cycle is in progress

• Signal from a gas detector

• Signal from a refrigeration controller. In this case the reading

could be a temperature etc.

If you want to see the reading for point 3 for example, you need

to press the "right arrow" or "left arrow" a number of times until

point 3 is highlighted. Then you need to press "Enter" in order to

see the next display.

Changing the light strength

Hold the ESC button down and press the up/down arrow.

The overview display

The readout always returns to the overview display if it is inactive

for two minutes.

Name

The name of the plant will be entered here.

Symbol for each point

When a point is marked with a square, the text and reading for this

point will be shown at the right of the display.

A symbol for the point is shown inside the square.

The symbol could be one of the following:

Circle = Point

Drops = Defrost

Alarm

The alarm has been suppressed (via the "More details" screen)

Connector = No link to controller

Dashes = Conguration error. See page 26 for information.

Date and time

Changing the contrast

Hold the ESC button down and press the left/right arrow.

Point number

Here it is no. 1 of the 5 dened points.

This text will be replaced with a text that tells you more about the

point, e.g. "Fruit and vegetables".

Reading

Scanning of all points

This function can be chosen as an option. The point's value is

shown here for about 3 seconds. Then it moves on to the next

point. When all the points have been scanned, the process starts

again from the beginning.

14 Manual RS8EF602 © Danfoss 01-2016 AK-SM 350 Version 2.5x

Page 15

Display screens for daily use

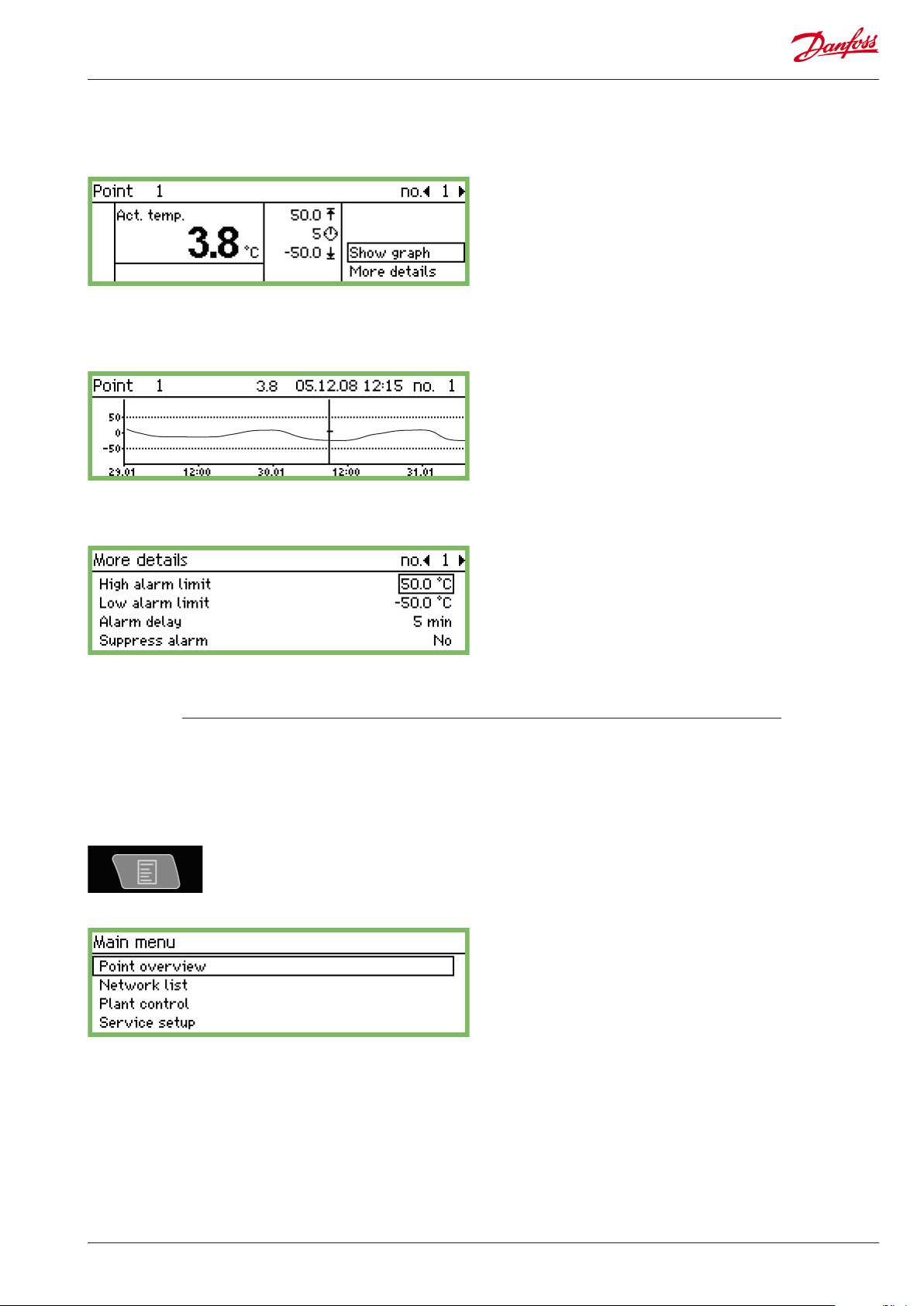

• Point detail display, showing the point’s actual values

• Graph display, showing the point’s previous readings

Name and point number

• Symbol illustrating the operating situation of the point

• Temperature values

• Value for the high temperature alarm

• The delay time for the alarm

• Value for the low temperature alarm

• Access to the graph screen etc.

Temperature sequence for the point

If you want to examine the values from the graph more closely,

press "Enter". A vertical line will then be shown on the graph. This

line indicates the time of the graph.

The temperature value for this time is shown on the top line.

The vertical line can be moved using the arrow keys.

If you want to zoom in or out on a time, use the up/down arrow

keys. These are indicated on the top line with an up arrow and

down arrow.

The values in the "More details" screen can be changed from the

monitoring unit. The new setting will be sent to the controller.

The values in "More details" are written to the controller if they are

changed.

Main menu

The main menu comes up if you press the top right-hand button

on the front panel.

You can access the following four functions from this menu:

Point overview

From here you can go back to the overview display. Please see the

previous page.

(The monitoring unit will automatically return to the overview

display if the buttons are not activated for 2 minutes.)

Network list

The units that are connected via data communication are shown

here.

The readout is only available during setup and service (e.g. in an

alarm situation in which no signal is received from a controller).

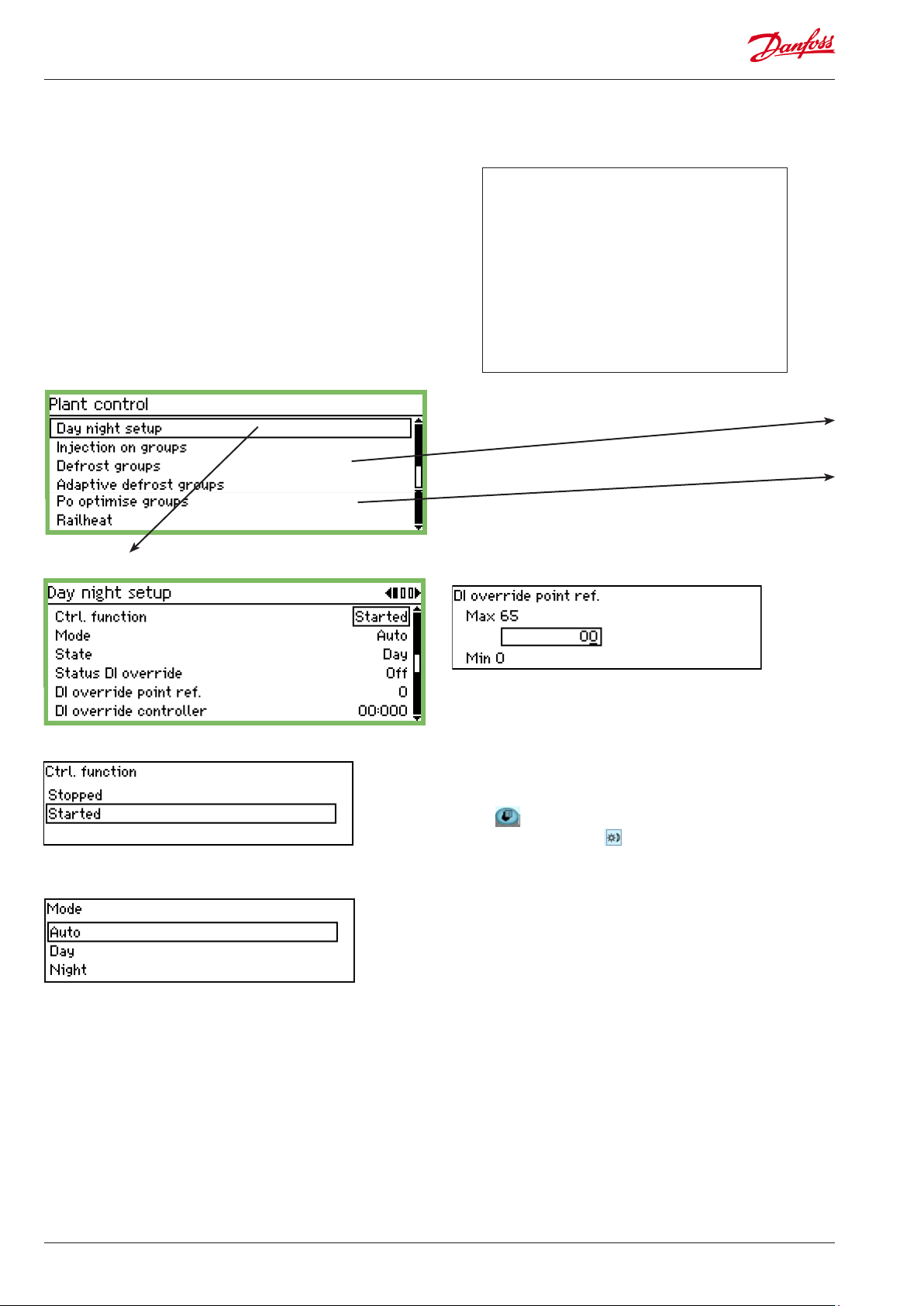

Plant control

Here you will nd the functions that are used in daily operation,

i.e.

• Defrost and lighting schedules

• Defrost setups

• P0-optimization

This screen is described overleaf.

Service setup

This is where the basic setups for the individual points and functions are carried out.

This screen is described from page 21 onwards.

AK-SM 350 Version 2.5x Manual RS8EF602 © Danfoss 01-2016 15

Page 16

Functions for daily use – Setups/adjustments

This is where you set the functions used for daily operation.

• Time schedule for specifying the store’s opening time

This schedule is for sending a signal to selected controllers in

order to tell them that the temperature needs to be adjusted

because covers have been placed over the refrigeration applications.

The schedule is also used to route alarms. However, this is only

if dierent alarm destinations have been dened for the day

period and the night period.

• Time schedule for specifying defrost points

The schedule is used to send signals to selected controllers telling them to start a defrost cycle.

To the end user

These functions are an option, but they are only applicable if controllers have been installed that can

receive the signals in question.

To the installer

Please put a cross in the box if the functions have

been installed in such a way that they can be operated from the monitoring unit.

Yes

No

Defrosts, see 2 pages further

P0 optimisation, see 3 pages further

Day / night setup

Control:

If "Started" the signal status will be sent to the EKCs.

Mode:

• If "Auto" is selected, day and night will change automatically.

The signal follows the on/o value on the reference point. See

next setting.

• If "Day" is selected, the controller will always be in daytime

operation.

• If "Night" is selected, the controller will always be in night-time

operation.

DI override from a Reference point (see “Mode” = auto)

The point which the override signal is to follow is selected here.

If the point is On, the signal status “Day” will be sent to the EKCs.

DI override from a controller parameter

The address and parameter can be set via service tool type AK-ST

500. This is performed as follows:

1. Connect the AK-ST 500 to the monitoring unit

2. When the network overview is shown, press the plant control

button

3. Select day/night group

4. Select the location from which the signal will come:

a. Press 'New'

b. Select controller address (e.g. 001:005)

c. Select the group from which the signal will come

d. Select which parameter will send the signal

State:

This display shows whether the controller is in Day or Night mode.

Status DI override:

This display shows the status of the override signal, which is received from one of the two following settings.

16 Manual RS8EF602 © Danfoss 01-2016 AK-SM 350 Version 2.5x

Page 17

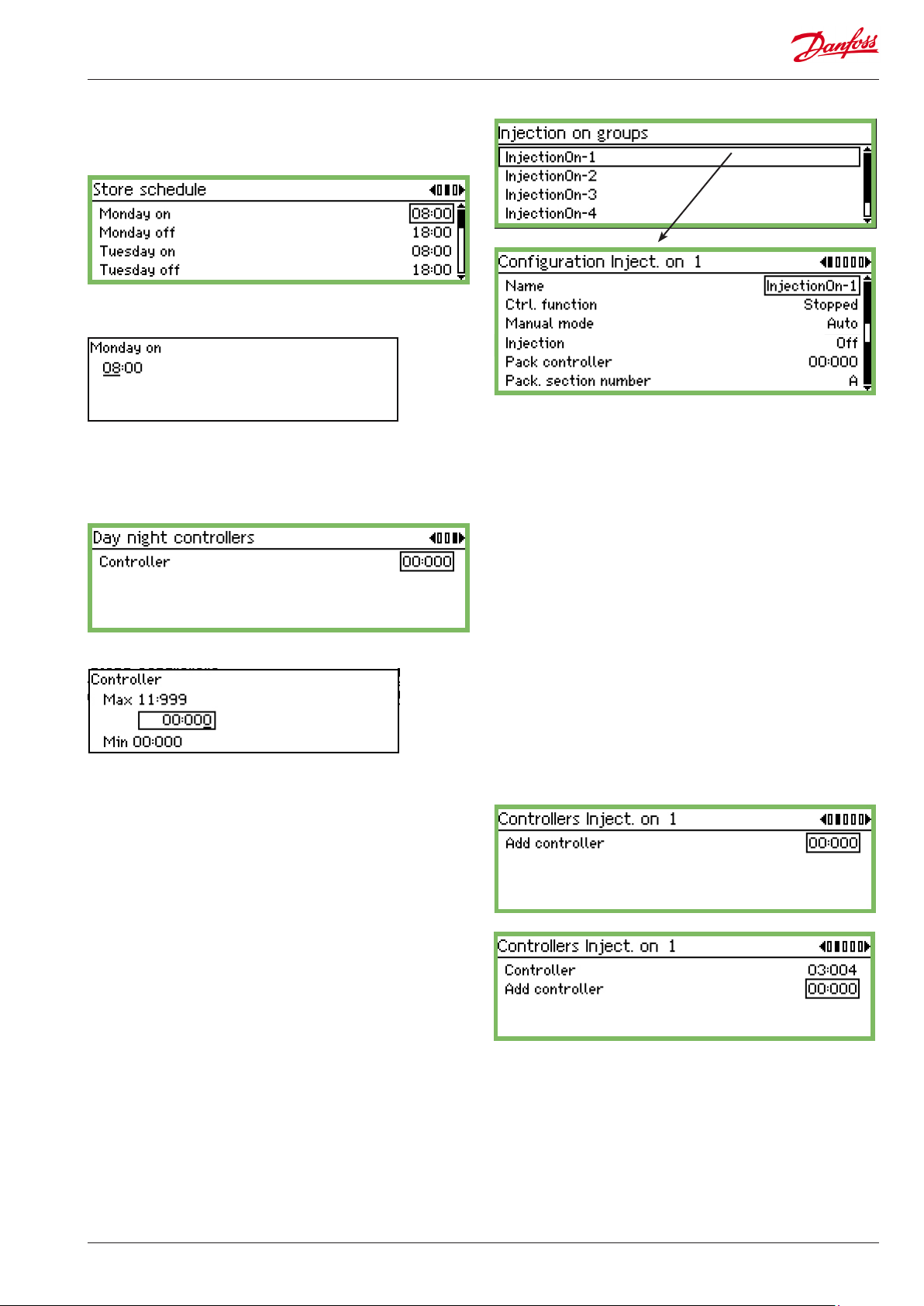

Time schedule

(The schedule is found "one arrow to the right" of "Day/night

setup")

This is where you set the store’s opening and closing times. The

times can be used for alarm routing and day/night signals to the

controllers.

The hour setting and minute setting is entered using the arrow

keys.

Day/night signal controllers

(The schedule is found "one arrow to the right" of "Store schedule")

Inject ON signal

Name

Enter the name of the group here.

Ctrl. function

Here the user can see if the compressor regulation is in operation

or stopped.

Manual

Here the Injection On regulation can be overridden

This is where you set the addresses for all the controllers that are

to receive day/night signals

Set address.

(00:000 means no address).

Injection

Here the status of the Injection On function is shown

Pack controller

The address of the controller regulating the compressors is set

here.

Pack section number

If the controller can control more than one compressor group, the

current group must be set.

Press 'right arrow' to dene the controllers that will receive the

signal.

Set the controller's address and press 'Enter'.

Continue with the addresses of the other controllers.

AK-SM 350 Version 2.5x Manual RS8EF602 © Danfoss 01-2016 17

Page 18

Starting defrosts

This is where you select a group of controllers which are to have a

defrost signal.

There are two ways in which the controllers can be grouped:

1. Individually. Once the defrost has started, each controller will

carry out the defrost and then restart refrigeration as soon as

possible afterwards.

2. Coordinated. In this case, refrigeration will not resume until the

whole group has nished defrosting.

It is possible to create 10 defrost groups, with each group containing a max. of 30 controllers.

The way to access the groups is shown on the previous page.

Group 1

Defrost schedule

(You will nd the setting "one arrow to the right" of the group.)

Up to 8 defrosts per day can be started.

A defrost time point is dened by setting a time. The time point

00.00 will not start a defrost.

Controllers group

This is where you dene which controllers are to be in the group.

(You will nd the setting "one arrow to the right" of the schedule.)

Name

Enter the name of the group here.

Defrost function

By using the setting “Started” the function is active. The schedule

determines when the signal is to be sent to the individual controllers.

Starting a defrost manually

By pressing “Enter” you start a defrost in all the controllers in the

group.

Coordination

(There can be up to 30 controllers in a group.)

Controller address

State the address of the controller that is to be part of the group.

Once the address has been set, you will automatically be able to

enter one more.

Group 2.

If there is a second or third group, or more, settings must also be

entered for these.

Select "Yes" if the whole group can only start cooling once the last

controller has completed a defrost cycle.

(The group of controllers must support the function.)

18 Manual RS8EF602 © Danfoss 01-2016 AK-SM 350 Version 2.5x

Page 19

Adaptiv Defrost

Other defrost groups can be created in which the controllers have

an adaptive defrost function. The controllers receive signals for the

current condensing temperature from the condensation control.

Only controllers with the adaptive function can be selected for the

group.

Name

Enter the name of the group here.

Ctrl. function

This display shows whether the defrosting is in operation or has

been stopped.

Group 1

Name

Enter the name of the group here.

Starting and stopping the function

Actual P0

The condensing temperature received from the compressor

control can be read here.

Pack controller

The address of the controller regulating the compressors is set

here.

Pack section number

If the controller can control more than one compressor group, the

current group must be set.

Press 'right arrow' to dene the controllers that will receive the

signal.

Set the controller's address and press 'Enter'.

Continue with the addresses of the other controllers.

P0 optimisation

Here you are able to select a group of controllers from which AKSM 350 will be receiving signals. The received signals are processed and then a signal is sent to the pack control which adjusts

the operation of the compressor so that it works optimally.

Max. 120 refrigeration sections can be selected in one group.

A section that has just completed a defrost will not be included in

this function. Data will only be collected again from the controller

after 30 minutes. The time can be adjusted.

The P0 optimisation can be started and stopped here.

Oset

Here you allow the suction pressure to be oset.

Overriding the function

If you need to interrupt the P0 optimisation for a period during

regulating, this can be done with a contact function on an input.

Set the point number that follows the switch signal.

Pack control

Set the address belonging to the group of controllers on the pack

control.

Pack section number

If the controller can control more than one compressor group, the

current group must be set.

P0 oset

The P0 displacement can be read here.

Most loaded case

This displays the address of the appliance bearing the greatest

load.

Most loaded section

This shows which section of the appliance is bearing the greatest

load.

AK-SM 350 Version 2.5x Manual RS8EF602 © Danfoss 01-2016 19

Page 20

Advanced settings

The setting can be found by pressing the right arrow once.

Avoid making changes – the settings should only be carried

out by trained personnel.

Time period

Dene how often data are to be collected from the dierent controllers and the ‘section with the highest load’.

Filter, Kp, Tn, S

Regulating parameters

Scan time

How often data is collected from the ‘section with the highest

load’.

Alarm and Alarm delay

A function that can trigger an alarm if the optimisation function

displaces (lowers) the suction pressure down to 90% of the pack

control’s minimal P0 setting.

Name

Enter the name of the sensor.

Temperature reading reference

Set the point established to register the temperature.

Moisture reference

Set the point established to register the moisture.

The point must also be set to analogue input and the signal to e.g.

0-10 V. The moisture sensor must be set to deliver the same signal

type.

Reading

In the next three lines you can read the actual values for 'calculated dew point', 'measured temperature' and 'measured relative

humidity'.

Press the 'right arrow' if there are several groups and thereby

several sensors that must be set.

Groups

Dene the controllers that are to be included in the group.

Selecting controllers for the group

The setting can be found by pressing the right arrow once.

Set the address of a controller to be included in the group.

Set the section.

Continue to the next controller address, etc.

Adaptive Railheat

Sensor 1

Group 1

Name

Enter the name of the group

Ctrl. function

The function is started and stopped here.

Dew point sensor

Select one of the dened sensors here.

Dew point

The actual dew point can be read here. The address is sent to the

respective controllers.

Press the 'right arrow' to dene which controllers will receive the

signal and initiate the rail heating function.

Set the controller's address and press 'Enter'.

Continue with the addresses of the other controllers.

20 Manual RS8EF602 © Danfoss 01-2016 AK-SM 350 Version 2.5x

Page 21

Conguration settings

• The rst three pages contain the basic settings.

• Then there are seven pages containing settings for measuring

points.

• After this come alarm settings and print setups.

Basic setup

The basic settings are as follows:

Conguration lock

This is where the conguration is locked once all the settings are

in place. Setups can only be performed when the setting is "O".

Scan network

This function is used when installing controllers.

All EKC controllers and gas detectors must be connected to the

appropriate data communications before the function is activated.

When the function is started, the monitoring unit will scan the

data communication and register which controllers are at which

addresses.

The results can be viewed in the network list.

Language

This is where you select the language used in the monitoring unit.

Name

The name of the store is entered here.

The name is used in external communication and can be seen at

the external operating interface. Use the four arrow keys to enter

the name.

AK-SM 350 Version 2.5x Manual RS8EF602 © Danfoss 01-2016 21

Page 22

Device name

The factory enters the type designation in this position. The name

can be changed as required. Use the four arrow keys to change

the text.

Daylight saving

This is where you set whether the monitoring unit’s clock function

is to switch to summer/winter time at the appropriate date and

time.

If a change to summer/winter time is required, you must select the

relevant European or US times.

The monitoring unit will change time itself when the day arrives to

put the clocks forward/back.

Time zone

Service password

A password can be entered if you need to limit access to the

important settings. Once access has been achieved with this password, it will be possible to carry out service and install new setups.

Password for daily access

A password can be entered if you need to limit access to the daily

settings. Once access has been achieved with this password, it will

be possible to make settings.

Access without using a password

If a password is used for daily use and/or for service, access without the use of codes will be limited to read-only parameters.

Timeout of network

0 is UK (GMT) time.

1 represents the time zone Germany, France, Spain, Italy, etc.

Date and time

This is where you set the date and time.

A battery in the monitoring unit will maintain the clock function

in the event of a power failure. The battery will normally last for

several years and an alarm will be generated when the battery is

due to be replaced.

Names of measuring units

This is where you set which units the various readings will be

shown in:

SI: Bar and Kelvin K, (°C)

US: Psi and °F

Danfoss SI: Bar and °C (pt is no dierent to the SI setting).

If the monitoring unit cannot contact a controller on the network,

it will try again. This will happen repeatedly, and if it does not succeed in contacting the controller within the set time, an alarm will

be generated.

Delete a controller from the network

This function must be used if a controller is deleted from the data

communication. The function updates the network list so that "ofine controllers" are deleted from the network list.

22 Manual RS8EF602 © Danfoss 01-2016 AK-SM 350 Version 2.5x

Page 23

Readout of the point in the overview display

This function only applies to the readout in the overview display.

With the setting = On, a point will be shown for a few seconds, after which the display moves on to the next point. When all points

have been displayed, the readout starts again from the beginning.

With the setting = O, the point required will be displayed continuously in the overview display.

Mains frequency

This is where you set the frequency for the supply voltage.

Reset to factory

This function must be used if you want to reset to factory settings.

AK-SM 350 Version 2.5x Manual RS8EF602 © Danfoss 01-2016 23

Page 24

Setup of points

The next 9 pages contain settings for measuring points. The rst

three pages cover the settings for a temperature reading. If the

reading is not a temperature reading, the settings can be viewed

on the following 6 pages.

1. Select a point

A point which is highlighted is shown on the top line. Here it is

number 1. If you would like another number, scroll up or down

using the "left arrow" or "right arrow". Stop at the number you

require.

2. Name

The name of the start text will always be "Point no.".

Press "Enter" to edit the text

Enter the name of the reading.

3. Type

This is where you dene the type of reading received for the point.

When the denition has been entered, further settings for the

reading are enabled. Here, "Temperature" has been selected.

This screenshot shows

the various type options

Settings if you choose

temperature are shown on

the next two pages.

Settings for the other types

can be found immediately

afterwards.

(Some of the settings are

the same, regardless of

type.)

24 Manual RS8EF602 © Danfoss 01-2016 AK-SM 350 Version 2.5x

Page 25

4. Alarm from point (also for service)

8. Input no.

With this setting the alarm from a point can be suppressed.

The default setting will be "No" – which means that alarms are

received from the point.

Select the "Yes" setting if an irritating alarm needs to be stopped

during servicing. After 12 hours, the setting will automatically

return to "No".

5. Log

This is where you dene whether the point’s readings should be

saved.

O: No collection

On: This is where the actual value for each interval is saved. ( The

interval times can be: "15", "30", "60", "120" or "240" minutes. The

times are xed and cannot be changed.)

"Selected for print": This is where the actual values are saved so

that they can also be printed out.

If not all 65 points are set up with log collection a number of different service logs can be dened. The capacity determines how

many. Follow the remaining capacity when the setup is done from

the "Service tool".

Should only be set if the reading is directly connected to the

monitoring unit’s terminals.

This is where you specify which set of terminals is to be used. The

following settings only apply if "Temperature" was selected in point 3.

9. Type = TEMPERATURE

Only with sensors that are directly connected to the monitoring.

The sensors can be:

Pt, 1000 ohm at 0°C

PTC, 1000 ohm at 25°C

NTC, 5000 ohm at 25°C

PT1: Thermistor -80 at 0°C

PT2 : Thermistor -40 at 40°C

PT3 : Thermistor 0 at 100°C

10. Alarm limit for too high temperature

6. Log sample rate

This is where you set how often the measured value is to be saved.

A reading is stored for one year. It is overwritten once a year

has passed.

Choose between 15 mins., 30 mins., 1 hour, 2 hours or 24 hours.

Examples of the capacity:

approx. 57 measuring points @ 15 mins. corresponds to one year.

approx. 50 measuring points @ 15 mins. + 15 measuring points @

30 mins. correspond to one year.

Fewer measuring points and/or longer interval times will not create problems, but if you exceed the guidelines and thus the capacity, you will get a conguration error. See overleaf.

7. The measuring point’s address on the data communication

There should only be one setting here if the reading is produced

with one of the three data communications: LON, MOD or TP. E.g.

from an EKC controller or a gas unit.

Set the temperature value at which the alarm will occur.

(The setting will also be used for scaling the graph display.)

11: Alarm limit for too low temperature

Set the temperature value at which the alarm will occur.

(The setting will also be used for scaling the graph display.)

12. The delay time for the alarm

The alarm will not occur until the temperature value has been

exceeded for the number of minutes specied. Set the number of

minutes required.

Set the address.

The setting 00:000 is a reading connected directly to the AK-SM

350 unit. All other settings mean that the reading is retrieved from

the address given in the setting. (When an address is set, the digit

"00:" is automatically set to "01" or "11". This setting cannot be

changed.)

AK-SM 350 Version 2.5x Manual RS8EF602 © Danfoss 01-2016 25

Page 26

13. Text for the high temperature alarm

This is where you can enter the alarm text that is to follow a high

temperature alarm from this reading. If you do not enter a text, a

factory-set text will appear.

Fx "Max temp Point _".

14. Text for the low temperature alarm

This is where you can enter the alarm text that is to follow a low

temperature alarm from this reading. If you do not enter a text, a

factory-set text will appear. Fx "Min temp Point _".

15. Priority of high temperature alarms

Set the priority

The setting determines the sort/action which must be carried out

when an alarm occurs.

• "High" is the top priority

• "Log only" is the lowest priority

• "Disabled" does not initiate any action

The relationships between the setting and action are as follows:

Setting Log Alarm relay Network AKM

Non High Low - High

High X X X X 1

Medium X X X 2

Low X X X 3

Log only X

Disabled

destination

(priority)

18. Temperature reading oset

Corrections to the sensor signal can be made here.

The correction is used when the sensor wires are long.

19. Is there a conguration error?

The value on this line is normally = 0.

Any other value indicates that an error has occurred. The explana-

tions are as follows:

0: No error.

1: Incorrect address entered – it cannot be found in the network

list or it cannot be used for this point type.

2: Incorrect point entered – the number is outside those permitted

for this unit.

3: The unit does not support this point type.

4: The transmitter type is not supported.

5: The input signal specied is already in use as a signal for an-

other point, and this signal has been dened dierently.

6: Incorrect setting for defrost signal. The point cannot be found or

has not been dened for the type "Defrost".

7: Internal system error. Try turning the unit o and on again.

8: The controller or software version is newer, which means the

monitoring unit does not recognise its data. See Appendix 1 for

instructions on how to generate a template that can be used in

the AK-SM 350.

9: The data is not presented correctly. Try selecting another setting

in the function "Template view".

10: The log capacity has been exceeded. Log data cannot be

stored for one year. Extend the interval time for one or more

readings.

11: Too many ‘Template views’ have been created.

12: The selected reference point for power meter reading is invalid.

16. Priority of low temperature alarms

Same setting as for high temperature.

17. Cancelling alarms during defrost

If a defrost signal is registered at a given point, an alarm will not

be triggered. When the signal disappears again, alarms will be

permitted.

Set the point, which follows the defrost signal.

26 Manual RS8EF602 © Danfoss 01-2016 AK-SM 350 Version 2.5x

Page 27

The following settings only apply if "Analogue input" was selected in

point 3.

Analogue input - AI

This list of settings was

previously covered under

temperature. Please see the

explanation on pages 25-26.

Signal type

This is where you set whether it is a voltage signal or a current

signal.

Unit

This is where you set the name of the signal.

Readout at max. signal

This is where you set the value that will be presented when the

input signal is at its highest (max. 10 V or 20 mA).

Readout at min. signal

This is where you set the value that will be presented when the

input signal is at its lowest (min. 0 V or 4 mA).

AK-SM 350 Version 2.5x Manual RS8EF602 © Danfoss 01-2016 27

Page 28

The following settings only apply if "Digital input" was selected in

point 3.

Digital (contact function)

This list of settings was

previously covered under

temperature. Please see the

explanation on pages 25-26.

Denation of contact

This is where you set whether the function should be active when

the input signal is recorded as closed or open.

28 Manual RS8EF602 © Danfoss 01-2016 AK-SM 350 Version 2.5x

Page 29

The following settings only apply if "Power meter" was selected in

point 3.

Pulse input

This list of settings was

previously covered under

temperature. Please see the

explanation on pages 25-26.

Pulse setting

This is where you set the number of pulses that can be received

before one unit is counted out. The unit is given in kW.

NB. Only inputs 1 and 2 can be used for pulse counting.

Scaling factor

The reading from the unit can be corrected with a factor so that

the readout becomes more comprehensible.

KWh = scaling factor/pulses per KWh

Start value/Reset reading

The previous day’s power consumption

This is where you can read the power consumption for the previous 24 hours.

Consumption from 0:00 to 24:00.

Power consumption for the past week

This is where you can read the power consumption for the past

week.

Power consumption from Monday at 0:00 to Sunday at 24:00.

This is where you select a start value or reset the accumulated

value of the power meter.

On the next line you can see the date and time of the setting.

AK-SM 350 Version 2.5x Manual RS8EF602 © Danfoss 01-2016 29

Page 30

The following settings only apply if "Defrost" was selected in point 3.

Defrost

This list of settings was

previously covered under

temperature. Please see the

explanation on pages 25-26.

Defrost

With this function the point can receive information about when a

defrost is in progress.

This information can be used by other points to ensure they do

not send temperature alarms during this period.

The alarm function will be enabled if the defrost signal remains on

the input.

The following settings only apply if "Gas detector" was selected in

point 3.

Gas detector

This list of settings was

previously covered under

temperature. Please see the

explanation on pages 25-26.

Gas detector

This function monitors the concentration of refrigerant in the

room air. An alarm is generated if the set value is exceeded.

Two alarm limits can be set.

A "high" is when the critical limit is reached. This is when the alarm

is transmitted.

A slightly lower threshold will also generate an alarm, but this

alarm can be read as a "Leakage check".

This setting only applies to gas detectors connected to AK-SM 350

via data communication.

If the gas detector is of type DGS, it can be installed on an

analogue input.

Scaling factor

The measurement from the gas detector is recorded as a %, i.e.

0-100.

A factor can be set here so that the display is shown in ppm.

Setting = full reading from the gas detector divided by 100.

For example, 30000ppm/100=300.

30 Manual RS8EF602 © Danfoss 01-2016 AK-SM 350 Version 2.5x

Page 31

The following settings only apply if "Controller" was selected in point

3.

Controller

This list of settings was

previously covered under

temperature. Please see the

explanation on pages 25-26.

Select a predened set of readouts

There are several sets to choose from. Select the set that represents the temperature controller in question:

1 When it is a temperature controller or a refrigeration ap-

plication control for one section.

2 When it is a refrigeration application control for two sec-

tions and a readout for Section 2 is required.

Or it is a compressor or condenser control and a readout of

the condenser control is required.

3 When it is a refrigeration application control for three sec-

tions

4 When it is a refrigeration application control for four sec-

tions.

Controller address.

(1 or 11 is the network

number and cannot be

changed.)

Alarm limits

The alarm limits must be set for the dierent controllers.

It is the individual controllers that emit alarms.

The alarms are received by the AK-SM 350, which then presents

them.

If an alarm limit has to be changed in a controller, this can be

done from the AK-SM 350 via the "More details" screen.

AK-SM 350 Version 2.5x Manual RS8EF602 © Danfoss 01-2016 31

Page 32

The following settings only apply if “Power meter log” has been

selected in Point 3:

Log of power meter

This list of settings was

previously covered under

temperature. Please see the

explanation on pages 25-26.

Function

This function collects readings from the “Power meter” function.

The readings that are collected can either be the daily or the

weekly power meter reading.

The collected reading is summarised in the log (point).

Start/Stop

Logging can be started and stopped with the On/O setting.

Sample rate

This is where you set how often the log value is to be plotted in

the graph.

Type

Select which reading is to be collected.

From point number

Select the point number from which the reading is to be collected.

(See pulse input.)

32 Manual RS8EF602 © Danfoss 01-2016 AK-SM 350 Version 2.5x

Page 33

Alarm setup

Alarm common settings

This is where you enter the general settings for:

• Alarm routes

• Modem

• "i'm alive alarm"

Alarm routes

This is where you set the number of alarm routes to be created.

An alarm route describes what will be done when an alarm is

generated with a given priority at a given time.

(The route is set later on.)

Modem baudrate

Once one or more alarm routes have been

created, this enables settings for them to be

set. The settings can be seen on the next page.

Modem initialising string

The factory-set initialising string should only be changed in special circumstances.

Automatic cancellation of alarms

The baudrate setting can be changed if this is necessary.

The settings "9600" and "19200" are available in addition to the

settings shown.

Default = "38400".

AK-SM 350 Version 2.5x Manual RS8EF602 © Danfoss 01-2016 33

Select which alarms are to be auto-acknowledged. (These will be

shown in the list of active alarms and they will also be entered

under alarm history.)

Page 34

Tidy up the alarms

This function deletes all the active alarms. You use this function

at the start-up of a new plant for which you want to update the

alarms that are always active (after activation all the active alarms

will be regenerated).

Alarm routes

Clearing the alarm history

Only use this function when no alarms are active.

This function deletes all alarms that were previously triggered.

Also those are currently active.

Reset the list by pressing Enter.

Test of alarm function

This function is used to check whether an alarm route and an

alarm destination are correctly congured.

When "On" is activated, a test alarm will be generated with the

alarm priority set for the next function.

Repeat the test with the other alarm priorities.

When the test is complete, the function should be set to "O".

Alarm priority to be tested

This is where you set how the alarms are to be routed.

The description selects an alarm route. This route sends alarms to

"Destination 1" at the store’s opening time and to "Destination 2"

at the store’s closing time.

This setup is displayed so that all alarms are handled at the same

time. If you want to distinguish important alarms from each other,

you must create several alarm routes. This means each alarm route

can handle its own alarm priority.

In addition to the settings shown, "Log only" and "Disabled" are

also available.

"I'm alive alarm"

This function will send an "I’m alive alarm" to the alarm destination. The alarm is sent at xed intervals, and if it fails to arrive at

the alarm destination the monitoring unit will indicate that there

is a problem.

Interval for "I'm alive alarm"

Set time interval.

Mode

Select "Enabled"

Alarm priority

This is where you set which alarms are to be sent along this route.

In this example, "All" is selected.

34 Manual RS8EF602 © Danfoss 01-2016 AK-SM 350 Version 2.5x

Page 35

Day night mode

This is where alarms are divided up so they are sent to one place

at the store’s opening time and somewhere else at the closing

time.

In this example, "Yes" is selected. (With the setting = "Yes", the

bottom ve lines are visible in "Route display". The lines contain

"Night functions".)

Primary destination

Night alternate destination

If the alarm cannot be transmitted to the primary destination, it will be sent to the alternate destination.

This destination can be, for example, a service company, which

will acknowledge night-time alarms, but only if there is no contact

with destination 1.

Night copy xx

This destination will receive a copy of all the alarms sent.

Here an SMS destination has been selected.

In this example, "Buzzer" is chosen, i.e. the internal buzzer is activated if alarms go o at the opening time.

Alternate destination

(In this example no alternate destination is selected for the opening time.)

Copy 1

In this example we are choosing to send a copy of the alarm to a

service company (Remote destination no. xx).

In the store’s closing period:

Another set of destinations are set for the closing period. They are

as follows:

Night — PrImary dest.

This destination can be a monitoring centre which acknowledges

night-time alarms. (The choice of settings is greater than shown

here. The complete list can be viewed above in the "Primary destination" display.)

AK-SM 350 Version 2.5x Manual RS8EF602 © Danfoss 01-2016 35

Page 36

Alarm destinations

This is where you set who or what can be enabled in the event of

an alarm. Below you will see an overview of the destinations. The

settings are shown on the next few pages.

Overview

Remote

destination

Buzzer in monitoring unit

Remote destination

via SMS

Data can be set on up to four destinations, that are to be connected via

a modem or TCP/IP. The settings are described overleaf.

Will only be set if the buzzer is to

be used in an alarm situation. The

settings are described three pages

on from here.

Data can be set on up to

three destinations.

The settings are described

three pages on from here.

36 Manual RS8EF602 © Danfoss 01-2016 AK-SM 350 Version 2.5x

Page 37

Remote destination

There are three options for this setting:

Enabled. Which is the default setting.

Disabled. Where alarms are not sent to the destination. This set-

ting is necessary during setup.

Suspend. Where the destination will not receive alarms within

the next number of hours. The time is also set with this

function.

When the time has run out, the setting will automati-

cally change to "Enabled".

This is where you select how the connection is to be established:

Settings can only be made in "Disabled" mode.

Host name or IP addr.

Type in the name or IP address.

Example of number structure = 192.186.0.100

Do not forget the full stops between the groups of numbers.

Modem

When the connection is to be via Modem, the following settings

apply:

Ethernet

When the connection is to be via Ethernet, the following settings

apply:

Name

Type in the desired name. The name is also the ID for calls to the

monitoring unit via the IP network.

Type the name. The name is also the ID for the call to the monitoring unit via modem.

Enter the password.

Type in the phone number for the alarm destination.

Enter the password.

AK-SM 350 Version 2.5x Manual RS8EF602 © Danfoss 01-2016 37

Page 38

Dial back

This function is used during modem connection and when transferring logs to a service company. This is what happens:

- The service company calls the monitoring unit.

- The dial back function is enabled.

- The connection is broken.

- After a short while the monitoring unit itself rings the set destination. The destination can then retrieve logs and alarms.

The following settings are available:

Type the name.

Enter the password.

Type in the phone number.

If there are more Remote destinations (Destinations 2, 3 and 4), they

must be set up in the same way.

38 Manual RS8EF602 © Danfoss 01-2016 AK-SM 350 Version 2.5x

Page 39

The buzzer in the monitoring unit

This function is used if the buzzer in the monitoring unit will be

enabled in an alarm situation. Select the "Buzzer" setting.

Remote alarm destinations via SMS

This function is used if an SMS is to be sent to a destination when

an alarm occurs. Select the setting "SMS 1".

There are three options for this setting:

Enabled. When the buzzer will be enabled for alarms.

Disabled. When the buzzer will not be enabled for alarms. This

setting is necessary during setup.

Timed. Where the buzzer will not sound alarms within the next

number of hours. The time is also set with this function.

When the time has run out, the setting will automati-

cally change to "Enabled".

This is where you select how long the buzzer must be enabled for

if there is an alarm.

With the setting = 0, the buzzer will be continuously enabled at

alarms. The buzzer is not disabled until the alarm button on the

front panel is enabled and "set alarm" is acknowledged. (2)

With a setting greater than 0, the buzzer will be active for the set

amount of time.

There are three options for this setting:

Enabled. When the destination can expect to receive alarms.

Disabled. When the destination will not receive any alarms. This

setting is necessary during setup.

Timed. Where the destination will not receive alarms within

the next number of hours. The time is also set with this

function.

When the time has run out, the setting will automati-

cally change to "Enabled".

This is where you set the phone number of the SMS destination.

If there are more SMS message destinations (SMS 2 and SMS 3), they

must be set up in the same way.

AK-SM 350 Version 2.5x Manual RS8EF602 © Danfoss 01-2016 39

Page 40

Print setup

Graph or table

Select how the readings will be presented

Choose between Graph or Table. In the following screenshot you

can see the settings that appear if Table has been chosen.

The frequency of the print-outs

Select one of the possible periods. In the following screenshot you

can see the settings that appear if weekly has been chosen.

The time of day of the print-outs

Data concentration

With this function the measured values recorded can be presented in concentrated form. A series of readings is averaged here, so

only the points' mean temperatures are shown.

Example

A reading is taken every 15 mins. The setting is set to 1 hour.

The values shown are the average for the 4 readings.

Set the length of time over which the averaging should take place.

Set the time.

The day of the week of the print-outs

Set the day.

40 Manual RS8EF602 © Danfoss 01-2016 AK-SM 350 Version 2.5x

Page 41

IP setup

Relay setup

If AK-SM 350 is using IP, the settings should be done as follows.

Select whether the address should be Dynamic or Static.

If the system is to be called up from the AKM or from the Service tool, “Static address” should be used.

When using Static, the address should be obtained from the local

IT department.

There are 2 relays in the unit. They can be used for 2 of the following:

• Modem relay

• Watchdog relay

• Alarm relay

Modem

This function turns the modem o and on every six hours.

If the function is used, one of the relays must be selected. Set

which one.

Watchdog function

This function will enable one of the two relays at xed intervals.

An external unit will monitor whether the relay is activated. If it is

not enabled, the external unit will generate an alarm.

If the function is used, it must be enabled.

Relay for watchdog function

If the function is used, one of the relays must be selected. Set

which one.

AK-SM 350 Version 2.5x Manual RS8EF602 © Danfoss 01-2016 41

Page 42

Time interval for watchdog function

Relay function

Set the interval between the relays being enabled.

Watch alarm routes

This function belongs with the Watchdog function and will stop

the interval activation of the relay if the following is in evidence:

• The modem cannot forward an alarm

• The modem cannot forward an SMS

• There is no contact via ethernet

Alarm relay in the monitoring unit

This function is used if one of the two relays in the monitoring unit

is to be enabled in an alarm situation. Select either the setting for

"Relay A" or the setting for "Relay B". (The relays can be used for

a modem connection or watchdog connection. If this is the case,

the setting will not work as an alarm relay.)

Select how the relay is to be active during an alarm:

• Active until the alarm button is pressed (see and acknowledge)

• Active as long as the fault is present

• Active until alarm reset is enabled

(The time can be limited. See “Automatic reset alarm”.)

Alarm priority range

Select the alarm priority range for which this function is to be

active.

Automatic relay reset

This is where you select how long the relay must be enabled for if

there is an alarm.

With the setting = 0, the relay will be continuously enabled at

alarms. The relay is not disabled until the alarm button on the

front is enabled and "set alarm" is acknowledged.

This function has to be activated.

Select relay

Select which of the two relays is to be used.

Alarm schedule

This is where you select when the alarm relay is to be activated.

• Allways (even day and night)

• Day only

• Night only

Relay status

This display shows the status of the relay.

42 Manual RS8EF602 © Danfoss 01-2016 AK-SM 350 Version 2.5x

Page 43

Setup for other networks via protocol

interface