User Guide

Temperature controller

for walk-in coolers and freezers

Type AK-RC 251

User Guide | Temperature controller for walk-in coolers and freezers, Type AK-RC 251

Contents 1. Versions and references .............................................................................................................................................. 3

2. Warnings ............................................................................................................................................................................. 3

3. Maintenance ..................................................................................................................................................................... 3

4. Description ........................................................................................................................................................................ 3

5. Installation ........................................................................................................................................................................4

6. Wiring ................................................................................................................................................................................... 5

7. Initial configuration ...................................................................................................................................................... 5

8. Operation ........................................................................................................................................................................... 6

8.1 Cold regulation ........................................................................................................................................................ 7

8.2 Door management ................................................................................................................................................ 9

8.3 Defrost ......................................................................................................................................................................10

8.4 Defrost control .......................................................................................................................................................10

8.5 Fan control ..............................................................................................................................................................11

8.6 Alarms .......................................................................................................................................................................12

8.7 Alerts .........................................................................................................................................................................13

8.8 Light control ...........................................................................................................................................................13

8.9 Password ..................................................................................................................................................................13

8.10 Remote Stand-by mode .....................................................................................................................................13

8.11 Operation of the auxiliary relays .....................................................................................................................13

9. Configuration .................................................................................................................................................................14

10. Technical specifications.............................................................................................................................................19

11. Ordering ...........................................................................................................................................................................20

2 | BC364433930186en-000101 © Danfoss | DCS (vt) | 2021.02

User Guide | Temperature controller for walk-in coolers and freezers, Type AK-RC 251

1. Versions and references

Model Description Power supply Circuit Breaker Protection Contactor

AK-RC 251 5 relay temperature controller

100 – 240 V~

50 – 240 Hz

No No

2. Warnings

• Using the unit without observing the manufacturer's

instructions may alter the appliance's safety requirements. Only

NTC probes supplied by Danfoss should be used for the unit to

operate correctly.

• From -40 – +68 °F, if the NTC probe is extended to 3,280 ft with

at least 20AWG cable, the maximum deviation will be 0.45 °F.

• IP65 protection degree is only valid if the cables enter the device

using electrical conduit + gland with IP65 or above. The size of

the glands should be suitable for the diameter of the conduit

used.

• Do not spray the unit directly with high-pressure hoses, as this

could cause damage.

• It should be installed in a place protected from vibrations, water

and corrosive gases, where the ambient temperature does not

exceed the value indicated in the technical data.

• For the reading to be correct, the probe should be used in a

place without heat influences apart from the temperature you

want to measure or control.

• IP65 protection degree is only valid with the protection cover

closed.

Important:

• Before starting the installation, you must take the advice of

local regulations in force.

• The AUXILIARY relays are programmable, and their operation

depends on the configuration.

• The function of the digital inputs depends on the configuration.

• The recommended currents and powers are the maximum

working currents and powers.

3.0 Maintenance

• Clean the surface of the unit with a soft cloth, water and soap.

• Do not use abrasive detergents, gasoline, alcohol or solvents, as this might damage the unit.

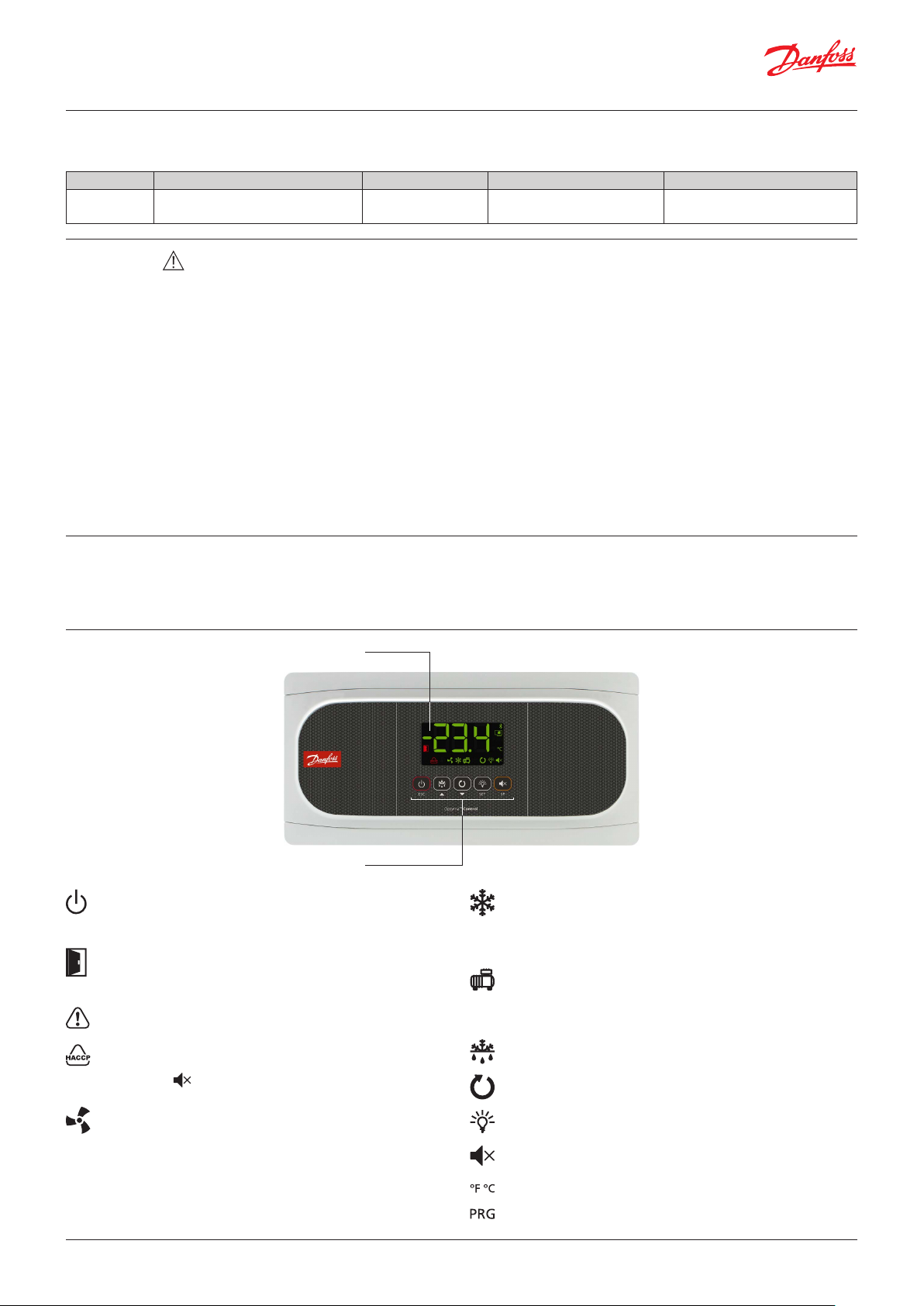

4.0 Description

Display

Keypad

Fixed: Stand-By Mode activated. Regulation is paused.

Flashing: Controlled shutdown process for the regulation

underway.

Fixed: The cold solenoid is active.

Flashing: The solenoid should be active but a delay or

protection is preventing this.

(Refer to the Fan start-up section).

Fixed: Cold room door open.

Flashing: The door has been open for a greater time than

has been defined in parameter A12.

Fixed: Compressor active.

Flashing: The compressor should be active but a delay

or protection is preventing this.

There is an active alarm, but not an active HACCP alarm.

Fixed: HACCP alarm active.

(Refer to the Compressor Protection timing section).

Defrost relay active.

Flashing: HACCP alarm registered and unconfirmed.

Press the key to confirm an HACCP alarm.

Fixed: Evaporator fans active.

Flashing: The evaporator fans should be active but a

Continuous cycle mode active.

Cold room light active.

delay is preventing this.

(Refer to the Drip time section).

Alarm in progress muted.

Temperature displayed in ° Fahrenheit / ° Centigrade.

Programming mode active.

© Danfoss | DCS (vt) | 2021.02 BC364433930186en-000101 | 3

User Guide | Temperature controller for walk-in coolers and freezers, Type AK-RC 251

80Z8117

4.1 Keypad

Pressing it for 3 seconds activates/deactivates Stand-By

mode. In this mode, regulation is paused and the power

icon is displayed.

In the programming menu, this exits the parameter

without saving changes, returns to previous level or exits

programming.

Pressing once activates/deactivates the cold room light.

Pressing it for 3 seconds accesses the condensed

programming menu.

Pressing it for 6 seconds accesses the expanded

programming menu.

In the programming menu, this accesses the level shown

on the display or, during the setting of a parameter,

accepts the new value.

Pressing once displays the temperature of probe S2 for 10

seconds (If it is enabled).

Pressing it for 3 seconds starts/stops the defrost.

In the programming menu, this allows scrolling around

the different levels, or, during the setting of a parameter,

changing its value.

Pressing once displays the current effective value of

the Set Point, taking into consideration temporary

modifications by other parameters (C10 or C12).

When an alarm is underway, pressing once mutes the

acoustic alarm. Pressing for 3 seconds accesses the Set

Point setting.

Pressing it for 3 seconds activates/deactivates continuous

cycle mode.

In the programming menu, this allows scrolling around

the different levels, or, during the setting of a parameter,

changing its value.

STAND-BY

If the temperature regulation cannot be instantly stopped due to its configuration, a controlled stop process starts and the

icon flashes. To stop the controlled stop process and force the step to Stand-by, press the Stand-by key again for 3 seconds.

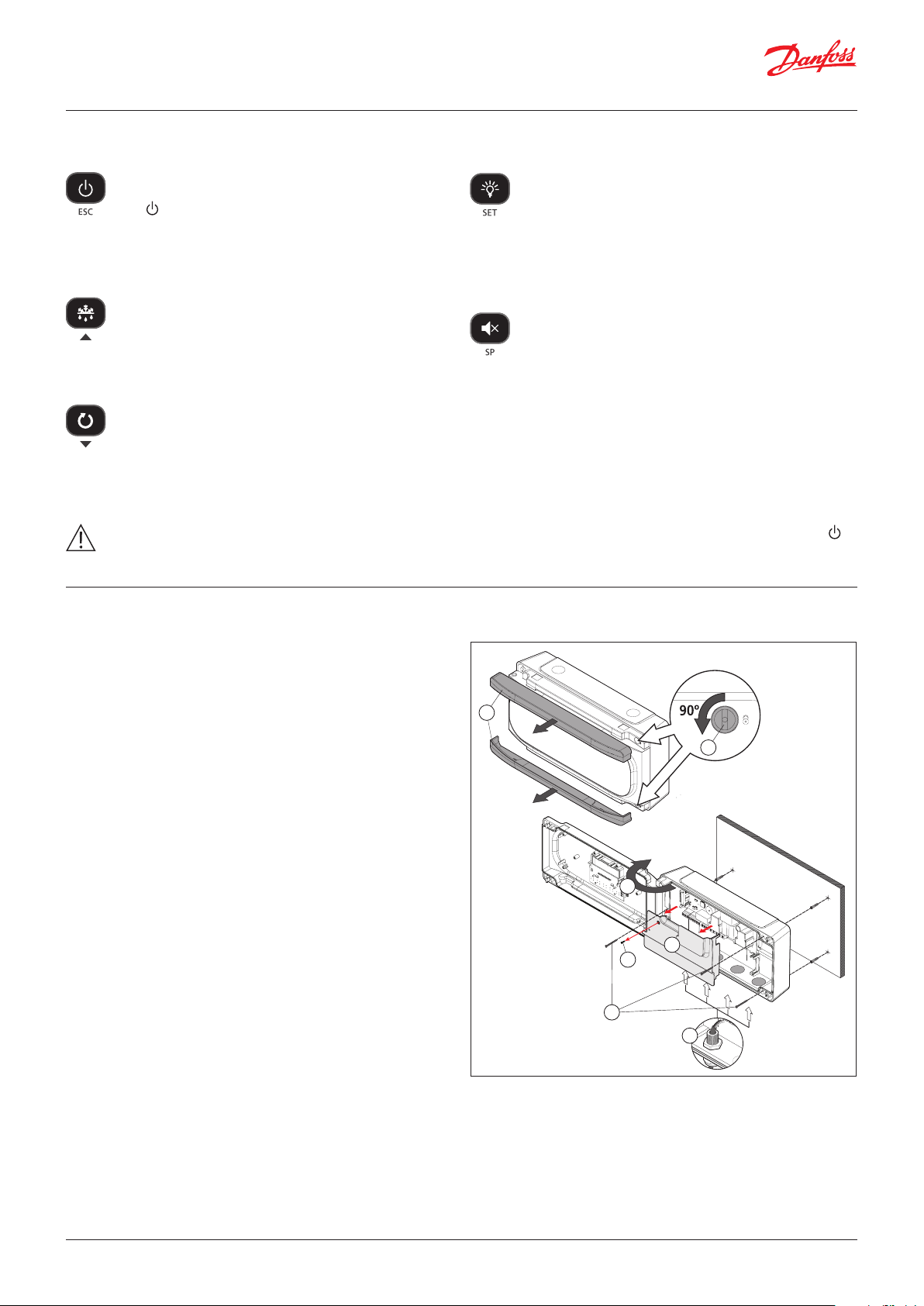

5. Installation

• Remove the bezels (1) by pulling out on one side first and then

the other side.

• Make a 1/4 turn of the screws (2) counter-clockwise and open

the door (3).

• Install the necessary glands (4) removing the provided caps.

• Mark and make the holes in the wall with the aid of the template

included.

• Fix the device to the wall. If it is a brick wall, use the screws and

anchors supplied; if the wall is made of sheet metal (cold room

store), use the screws provided without anchors (5).

• Remove the plastic cover (7) loosening the screw (6) and wire

the device by following the recommendations indicated on p. 7.

• Once the wiring is done, reinstall the plastic cover (7), close the

cover (3), tighten the screws (2) and reinstall the bezels (1)

1

2

3

Danfoss

7

6

5

4

Ø Max.25 mm

4 | BC364433930186en-000101 © Danfoss | DCS (vt) | 2021.02

User Guide | Temperature controller for walk-in coolers and freezers, Type AK-RC 251

CORECORE

1

Danfoss

CORECORE

2

Danfoss

80Z8119

6. Wiring

Always disconnect the power supply to do the wiring.

The probes and their cables should NEVER be installed in

a conduit together with power, control or power supply

cables.

For disconnection, the power supply circuit must be equipped

• The specific wiring to be performed depends on the option

selected in the initial configuration wizard.

• Use the appropriate diagram based on the option selected.

• Check the available options on the diagram sheet included

with your device.

with a switch of at least 2 A, 230 V, located near the device. The

power supply cable will be H05VV-F or NYM 1x16/3. The section to

be used will depend on the local standard in force but must never

be less than 14AWG.

Cables for relay or contactor outputs should have a section of

14AWG, allow working temperatures equal to or over 158 °F and

be installed with as few bends as possible.

The 120/230 V~ wiring must be kept clear of any other external

element.

Important:

• Before starting the installation, you must take the advice of

local regulations in force.

• The AUXILIARY relays are programmable, and their operation

depends on the configuration.

• The function of the digital inputs depends on the configuration.

• The recommended currents and powers are the maximum

working currents and powers.

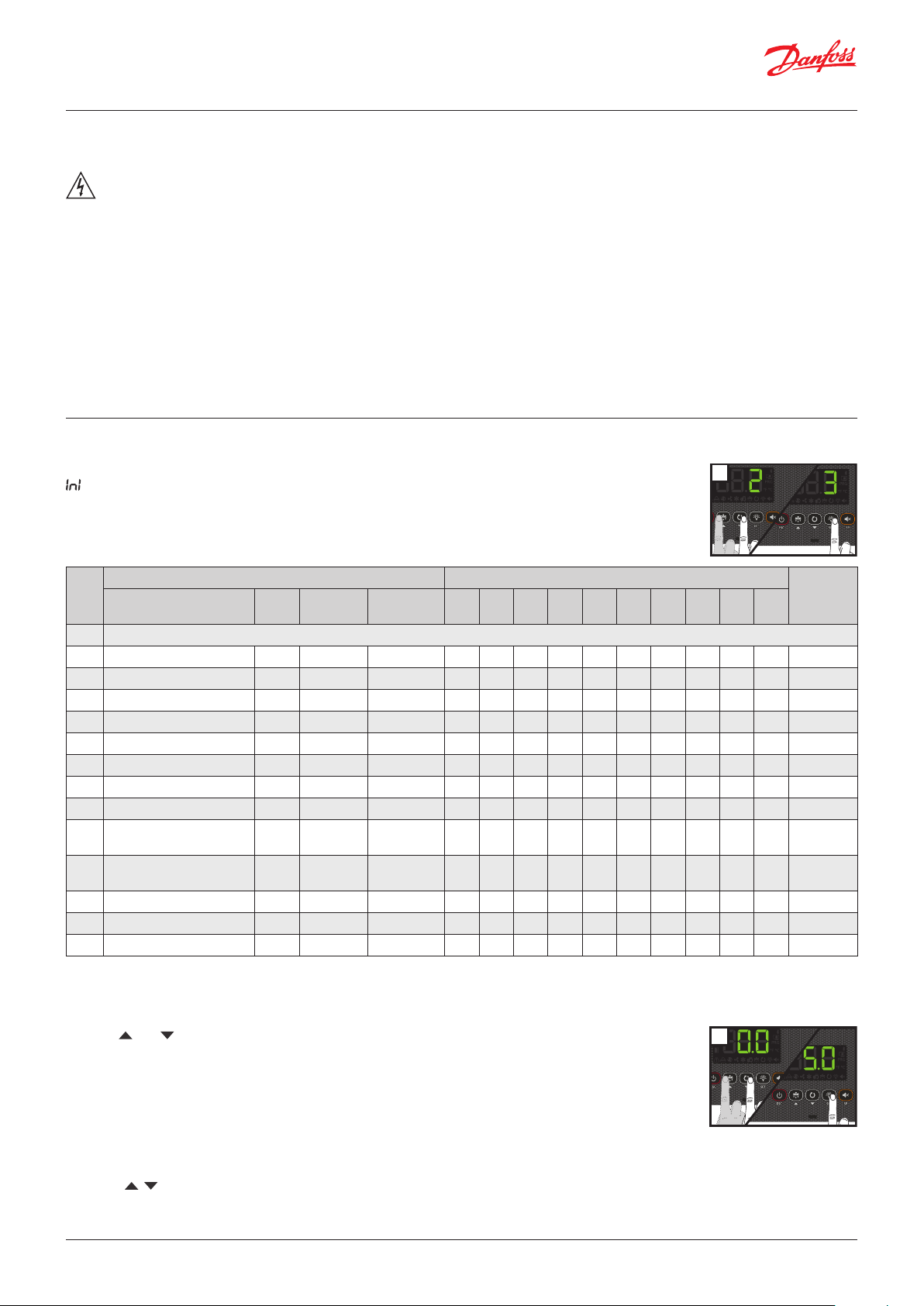

7. Initial configuration

The first time the unit is powered up, it will enter into the Wizard mode. The display will show the message

flashing with 0.

Step 1:

Select the most suitable InI option based on the type of installation to be carried out and press SET. The

available options will be shown in the following table:

Type of installation Parameters

InI

Cold regulation

0 Demo Mode: it displays the temp. but does not regulate or activate relays

1 Solenoid No Electric Yes 0 0 2 0 0 0 0 20 0 0 A

2 Solenoid + compressor Yes Electric Yes 1 1 2 7 1 0 0 20 0 0 B

3 Solenoid + compressor No Electric Yes 0 1 2 0 0 0 0 20 0 0 B

4 Solenoid No Air Yes 0 0 1 0 0 0 0 20 1 1 A

5 Solenoid + compressor Yes Air Ye s 1 1 1 7 1 0 0 20 1 1 B

6 Solenoid + compressor No Air Yes 0 1 1 0 0 0 0 20 1 1 B

7 Solenoid + compressor Yes Hot gas Yes 1 1 2 7 1 9 1 5 2 0 C

8 Solenoid + compressor No Hot gas Yes 0 1 2 0 0 9 1 5 2 0 C

9 Solenoid + compressor Ye s

10 Solenoid + compressor No

11 Solenoid No Static No 0 0 1 0 0 0 0 20 1 - A

12 Solenoid + compressor Yes Static No 1 1 1 7 1 0 0 20 1 - B

13 Solenoid + compressor No Static No 0 1 1 0 0 0 0 20 1 - B

Pump

Down

Defrost

Reversed

cycle

Reversed

cycle

Evaporator

fans

Yes 1 1 2 7 1 0 0 5 3 0 D

Yes 0 1 2 0 0 0 0 5 3 0 D

Pd

o00 I00 I10 I11 I20 I21 d1 d7 F3

80Z8118

CORECORE

Diagram

to be

used

Note: If options 2, 5, 7, 9 or 12 are chosen, check the configuration of parameter I11 according to the pressure switch type used. (See

diagram included with the device).

Step 2:

Use keys and to enter the desired Temperature Set Point value and press SET. The wizard has finished.

The unit will begin to regulate the temperature.

IIf this is not the first time you run the wizard, after completing the last step the display will show the

message dFp (default parameters). You may choose between two options:

0: Only change the parameters which affect the wizard. The other parameters will remain the same.

1: All parameters return to their factory setting except those which have been modified by the wizard.

CORECORE

Important: The wizard will not start automatically once the unit has been powered up at least once. To start the Wizard at any time turn

off the controller by pressing the power button for 3 seconds and wait until the power symbol is ON. The press the buttons listed here in

sequence , and SET.

If the pump down function is active, a certain amount of time may elapse between starting the stand-by function and the controller

stopping (see page 8).

© Danfoss | DCS (vt) | 2021.02 BC364433930186en-000101 | 5

User Guide | Temperature controller for walk-in coolers and freezers, Type AK-RC 251

Wizard parameters list

Pd Pump down active? 0=No 1=Yes

o00 Configuration of relay AUX1

I00 Connected probes 1=Probe 1 (Cold room) 2=Probe 1 (Cold room) + Probe 2 (Evaporator)

I10 Configuration of digital input 1

I11 Polarity of the digital input 1 0=Activates on closing contact 1=Activates on opening contact

I20 Configuration of digital input 2

I21 Polarity of the digital input 2 0=Activates on closing contact 1=Activates on opening contact

d1 Maximum defrost duration (0=defrost deactivated)

d7 Type of defrost

F3 Status of the fans during the defrost 0=Shut down 1=Running

0=Deactivated 1=Compressor/Crankcase heater

2=Light 3=Virtual control

0= Deactivated 1=Door contact 2=External alarm

3=Severe external alarm 4=Change of SP 5=Remote defrost

6=Defrost block 7= Low pressure switch 8=Remote Stand-by

0= Deactivated 1=Door contact 2=External alarm

3=Severe external alarm 4=Change of SP 5=Remote defrost

6=Defrost block 7=Register probe 8=Probe 2° evaporator

9=High pressure switch for Hot Gas 10=Remote Stand-by

0=Resistors 1=Air/fans 2=Hot gas

3=Reversal of cycle

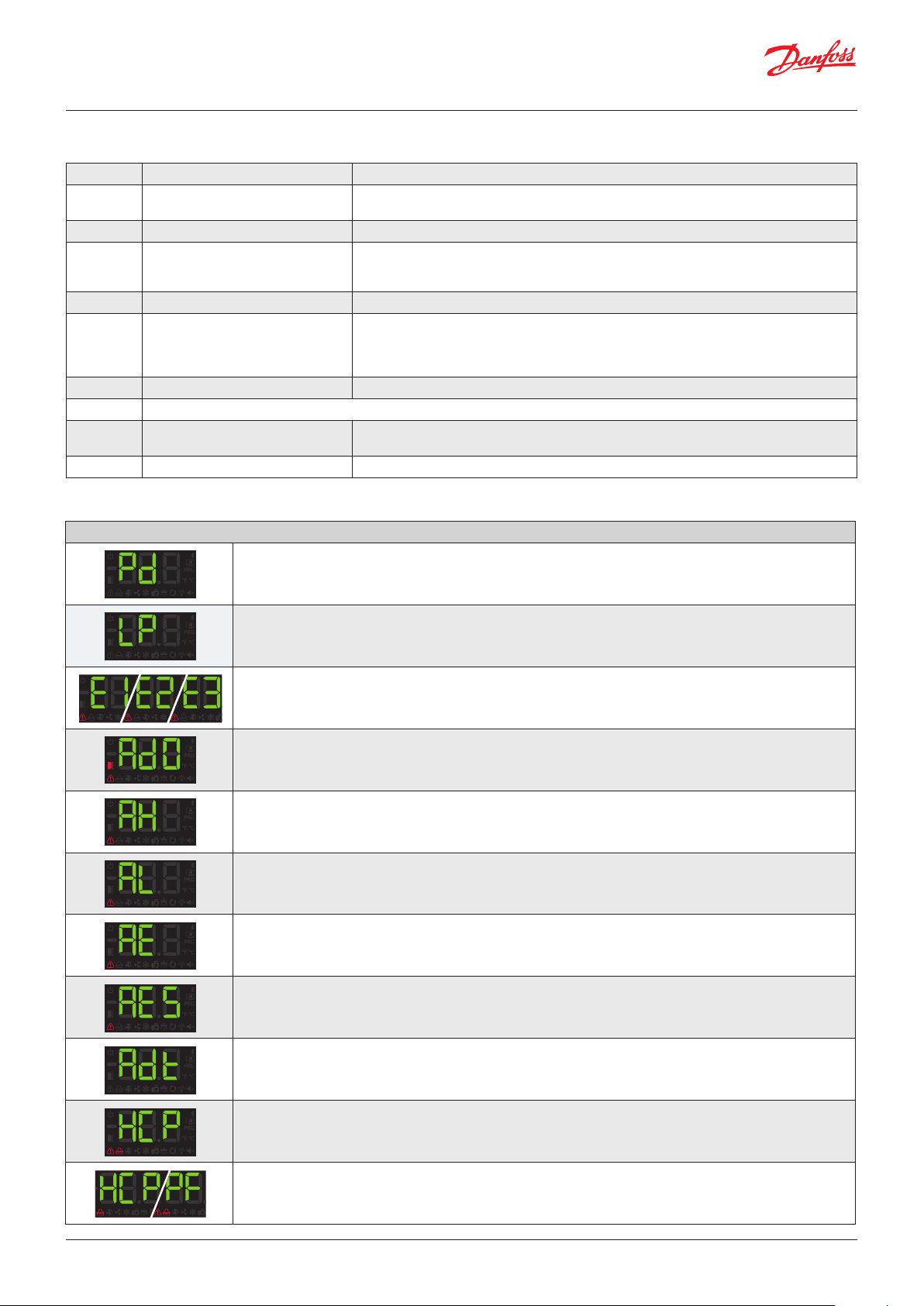

8. Operation

Display messages

Pump down malfunction error (stop), the time configured in parameter C20 has been exceeded (see page 8).

Only displayed on screen.

Pump down malfunction error (start-up), the time configured in parameter C19 has been exceeded (see page 8).

Only displayed on screen.

Probe 1/2/3 failure (open circuit, crossed circuit or temperature outside the limits of the probe)

Only E2 and E3: Damp evaporator probe (see page 12).

Activates the alarm relay and the audible alarm.

Open door alarm.

Only if the door remains open for a longer time than defined in parameter A12 (see page 12).

Activates the alarm relay and the audible alarm.

Maximum temperature in control probe alarm.

The temperature value programmed in A1 has been reached (see page 12).

Activates the alarm relay and the audible alarm.

Minimum temperature in control probe alarm.

The temperature value programmed in A2 has been reached (see page 12).

Activates the alarm relay and the audible alarm.

External alarm activated (by digital input) (see page 12).

Activates the alarm relay and the audible alarm.

Severe external alarm activated (by digital input) (see page 12).

Activates the alarm relay and the audible alarm.

Alarm for defrost completed due to time-out.

The time set in d1 has been exceeded (see page 13).

Activates the alarm relay and the audible alarm.

HACCP alarm.

The temperature has reached the value of parameter h1 during a longer period than established in h2 (see page 12).

Activates the alarm relay and the audible alarm.

HACCP alarm due to a power supply failure.

The temperature established in h1 has been reached, following a power supply failure (see page 12).

Activates the alarm relay and the audible alarm.

6 | BC364433930186en-000101 © Danfoss | DCS (vt) | 2021.02

User Guide | Temperature controller for walk-in coolers and freezers, Type AK-RC 251

Solenoid

S1

Compressor

S1

80Z8121

Compressor

C7 C7C8

oss

80Z8122

Indicates that a defrost is being performed (see page 10).

Only displayed on screen.

Password request. See parameters b10 and PAS (see page 13).

Only displayed on screen.

Shown sequentially with the temperature: The controller is in demo mode, the configuration has not been made.

8.1 Cold regulation

Solenoid control (COOL Relay)

The cooling process is regulated by means of opening / closing the

solenoid valve.

When the temperature in probe S1 reaches the set point (SP) value

plus the probe's differential (C1), the solenoid opens and causes

the temperature to drop. Once the set point (SP) value is reached,

the solenoid closes.

Compressor control (Relay AUX 1)

With Pump Down (Inl: 2, 5, 7, 9, 12)

Requires the connection of a low pressure switch in digital

input 1.

When the temperature in probe S1 reaches the set point (SP) value

plus the probe’s differential (C1), the solenoid opens, causing the

pressure in the evaporator to increase and, therefore, the low

pressure switch deactivates and the compressor starts up.

Once the set point (SP) value is reached, the solenoid closes,

causing the pressure in the evaporator to decrease, triggering the

low pressure switch and stopping the compressor.

For further details of the process, see page 8.

SP+C1

SP

SP+C1

Solenoid

pressure

SP

Low

switch

ON

ON

ON

ON

Danfoss

80Z8120

Danfoss

Without Pump Down (Inl: 3, 6, 8, 10, 13)

The compressor operates simultaneously with the solenoid valve,

starting up when the latter opens and stopping when it closes.

Operation in the event of a fault in probe S1

If probe S1 fails (fault, disconnection, etc.), compressor behavior

will depend on parameter C6, with one of 3 options available:

C6=0: The compressor is stopped until probe S1 begins to

operate again.

C6=1: The compressor is started-up until probe S1 begins to

operate again

C6=2: The compressor operates in line with the average operation

during the 24 hours prior to the error, taking into account

the number of start-ups and stops and the average time in

each state (stop-start). If 24 hours have not elapsed without

a probe error, the device moves to C6=3 mode.

ON ON

Danf

C6=3: The compressor operates in line with the times

programmed in C7 (ON) and C8 (OFF).

© Danfoss | DCS (vt) | 2021.02 BC364433930186en-000101 | 7

User Guide | Temperature controller for walk-in coolers and freezers, Type AK-RC 251

ON

Liquid solenoid

1S

80Z8123

Solenoid

S1

80Z8124

Pump down function

This function provides direct control of the solenoid and the

compressor and requires the use of a low pressure switch

connected to the digital input 1. It prevents pressure problems in

the system by ensuring that the compressor operates only when

the pressure is within the correct range. Use only if controlling

both, the solenoid valve and the compressor. If controlling only

the solenoid valve, DO NOT USE THIS SETTING and use any other

of the options as it will trigger an error if the low pressure switch is

not connected.

This function is only available for Inl options 2, 5, 7, 9 and 12

STOP

When the temperature in probe S1 reaches the set point (SP)

value, the COOL relay deactivates, closing the liquid solenoid.

Because the compressor continues to operate, pressure in the

evaporator quickly drops. Upon reaching a given value, the low

pressure switch activates, changing the status of digital input 1,

which stops the compressor (relay AUX 1).

This action isolates all of the refrigerant in the high-pressure line,

far from the compressor crankcase, preventing serious faults upon

start-up.

Should the low pressure switch fail, the controller stops the

compressor once the safety interval defined in C20 has elapsed,

displaying the message “Pd” (an informative message that does

not affect the unit's operation).

If C20 time is 0 (default value), the compressor will not stop until

the low pressure switch is activated, but it will display the “Pd”

message after 15 minutes.

START

When the temperature in probe S1 reaches the set point value plus

the differential (SP+C1), the COOL relay activates, opening the liquid

solenoid. This increases the pressure in the evaporator, deactivating

the low pressure switch, which turns the compressor on.

If, some time (determined by C19) after the liquid solenoid is

opened (COOL relay set to ON), the low pressure switch does

not deactivate, the controller will once again close the solenoid

(COOL relay set to OFF) and the “LP” message will be displayed.

This action will be repeated every 2 minutes, indefinitely, until the

pressure switch is deactivated and the installation reverts to its

normal operation.

If C19 time is 0 (default value), the solenoid will remain open until

the low pressure switch deactivates, but it will display the “LP”

message after 5 minutes.

STAND-BY

If the pump down function is active, a certain amount of

time may elapse between starting the stand- by function

and the controller stopping; this is because certain

installation control phases cannot be interrupted.

To force the stop of the controller, press the Stand-by key

again for 3 seconds.

Continuous cycle mode

This is used to quickly cool the cold room stores before products

are loaded and is activated by pressing the key for 3 seconds.

Upon activating this mode, the compressor begins to operate until

the temperature in probe S1 reaches the set point value, minus the

variation indicated in parameter C10. The value of C10 is always

negative, unless it is 0.

The unit will immediately return to normal operation. Should it

not be possible to reach this point, the device will return to normal

operation once the time configured in C9 has elapsed, or by

pressing the key again for 5 seconds.

Low pressure

switch

Compressor

Pressure in

evaporator

COOL

D1

AUX 1

OFF

ON

OFF

ON

OFF

+

SP SPSP+C

SP+C1

SP

SP+C10

Pressure

switch fault

C20

Danfoss

Pressure

switch fault

C19

P+C1

Danfoss

ON ON

8 | BC364433930186en-000101 © Danfoss | DCS (vt) | 2021.02

User Guide | Temperature controller for walk-in coolers and freezers, Type AK-RC 251

Set Poin

S1

80Z8125

OFF-ON (C4=0)

80Z8126

C23

SP+C1

Set Point change mode

This allows for quick alternation between two working

temperatures in the cold room store, modifying the Set

Point in line with the value indicated in parameter C12. The

aforementioned value may be negative or positive, which allows

for the Set Point to be reduced or increased. If it is configured in 0,

the mode is disabled.

It can be activated as follows:

• By means of an external switch connected to one of the digital

inputs. The digital input should be configured as “Set Point

change (I10 or I20=4). Activation through this method cancels

any other activation and can only be deactivated using the same

method.

Parameter C0 allows for correction of the temperature detected

by probe 1; this is particularly useful when the probe cannot be

located in the ideal place.

Set Point locking

Parameters C2 and C3 allow for an upper and lower limit to

be established for the set point (SP), to protect the product or

installation from Set Point manipulation.

Compressor protection timing

Parameter C4 allows for selection of the type of timing to

be applied to protect the compressor. These delays prevent

continuous compressor starts and stops.

These timings affect the COOL and AUX 1 relays (if o00=1)

OFF-ON (C4=0): Minimum time in OFF mode before each start-up.

OFF-ON / ON-OFF (C4=1): Minimum time in ON and OFF mode for

each cycle. The delay time is defined by means of parameter C5; if

C5=0, timing is disabled.

EXAMPLE 1:

Calibration of probe 1

Configuration

I10: 4

0I11:

t

change

DIG.IN

D1

Gnd

(SP+C12)+C1

D2 / S3

ON

COOL

OFF

SP+C1

SP+C12

Solenoid

SP

Danfoss

SP

ON ON

D1

D1= OND1= OFF

Danfoss

SP+C1

C5

8.2 Door management

Door management allows for the installation's behavior to be

controlled, should the cold room door open through parameters

C22 and C23.

Parameter C22 defines whether cooling should be stopped if the

door opens. If C22=1, when the door opens, the fans stop and, 15

seconds later, the solenoid closes (COOL relay).

Parameter C23 defines the maximum time, in minutes, that the

installation can remain without cooling whilst the door is open. If

C23=0, cooling does not occur with the door open.

Management of door frame resistor

If the Set Point is equal to or below 25 °F and the relay AUX 2 has

been configured as “door frame resistor” (o10=4), the resistor is

activated (relay ON) when the temperature of the cold room drops

below 26 °F, and is deactivated (relay OFF) when 32 °F is reached.

COOL

S1

SP

Door

COOL

OFF-ON / ON-OFF (C4=1)

ON

OFF

Configuration:

C22: 1

5C23:

ON ON

SP

SP+C1

C5C5

Open

Danfoss

80Z8127

© Danfoss | DCS (vt) | 2021.02 BC364433930186en-000101 | 9

User Guide | Temperature controller for walk-in coolers and freezers, Type AK-RC 251

F4

Máx.d1 d3d9

80Z8129

8.3 Defrost

Types of defrost

There are 5 possible defrost types, depending on the option

selected in the wizard (Inl):

Electric (InI=1, 2 and 3) (d7=0)

Defrost is performed through electrical resistors, supplying the

evaporator with heat. The operation of fans in this mode depends

on parameter F3; the compressor and solenoid are stopped.

By air (InI=4, 5 and 6) (d7=1)

Usually used in positive cold rooms (> 37 °F), since the inside

temperature of the cold room is sufficient to melt evaporator ice.

By default, the fans are activated so that air may circulate through

the evaporator; to stop them, change parameter F3 to 0. The

compressor and solenoid are stopped.

Static (InI=11, 12 and 13)

In this type of installation, there are no evaporator fans and defrost

is performed by stop cooling.

Hot gas (InI=7 and 8) (d7=2)

The hot gas from compressor discharge is used to melt evaporator

ice and, to this end, two valves are necessary: one at the condenser

input (A) (SSV relay) and another between the compressor output

and the evaporator input (B) (DEF relay).

DIG.IN

D1

Gnd

D2 / S3

D

A

B

EVAP.

During the process, the liquid solenoid valve (C) and the

condenser input valve are closed and the evaporator input valve

is opened, forcing hot gas to pass through the latter and melting

the ice.

Optionally, a high pressure switch (D) can be added to control the

solenoid valve (digital input D2, l20=9) during the defrost process

using hot gas. If the pressure decreases, the solenoid opens to

allow liquid into the tank; when the pressure rises again, the

solenoid closes.

COND.

SSV

.

N

N

FA

N

DEF

N

C

UX 1

H. CRANK

N

N

COOL

A

Danfoss

N

80Z8128

Reversed cycle (InI=9 and 10) (d7=3)

A 4-way valve is used to invert the refrigeration cycle, using the

evaporator as a condenser to melt the ice formed. The process

begins by stopping the cooling process (if it is active). If Pump

Down is active, defrost begins once the action is complete.

Next, the 4-way valve is activated (DEF relay ON), alongside the

solenoid (COOL relay ON) and the compressor (AUX 1 ON), and

the defrost process begins. D1 time begins to be counted after the

COOL relay is activated.

8.4 Defrost control

Defrost start

Defrost will start if:

• The time programmed in parameter d0 has elapsed since the

start of the last defrost.

• We press the key for 3 seconds.

• By means of an external push-button (I10 / I11=5).

Defrost completion

Defrost will complete if:

• The temperature programmed in parameter d4 has been

reached in probe 2. This requires a 2nd probe (l00=2) to be

available, located in the evaporator.

• The time configured in parameter d1 has elapsed (maximum

defrost duration).

• We press the key for 5 seconds.

• By means of an external push-button (I10 / I11=5).

When defrost is complete, the action can be stopped in two

possible ways:

• Pump down active (Inl=9): The solenoid closes (COOL relay OFF)

and the 4-way valve returns to its initial position (DEF relay OFF)

while the compressor continues to operate (AUX 1 relay ON),

until the low pressure switch activates, stopping the compressor

(AUX 1 relay OFF), starting the drip time.

• Without Pump Down (Inl=10): The solenoid closes (COOL relay

OFF) and the 4-way valve returns to its initial position (DEF relay

OFF) and the compressor stops (AUX 1 relay OFF), starting the

drip time.

COLD REGULATION

S1

DEFROST

DRIPTIME

"DEF” MESSAGE

COLD REGULATION

FAN START-UP

DELAY

d0

DEFROST

d4

SP+C1

SP

Danfoss

Drip time

This is established through parameter d9 and sets the time added

at the end of defrost to allow for the removal of surplus water from

melted evaporator ice, during which there is no cooling.

10 | BC364433930186en-000101 © Danfoss | DCS (vt) | 2021.02

User Guide | Temperature controller for walk-in coolers and freezers, Type AK-RC 251

S2

F

80Z8130

Fan start-up delay

This is established through parameter F4 and allows for the

possible drops left in the evaporator to freeze before the fans

activate, preventing them from being projected into the cold

room. It also prevents heat being supplied to the cold room due to

defrost in the evaporator.

Note: If defrost is cancelled before 1 minute has elapsed, the drip

time (d9) is not applied and the fans are activated without taking

into account the start-up delay (F4).

If defrost is by air or is static, the drip time (d9) and fan start-up

delay (F4) are deactivated.

Message displayed during defrost

This is established using parameter d2, and you can choose

between displaying the real temperature captured by probe 1

(d2=0), showing the temperature captured by probe 1 at the

start of the defrost (d2=1), or displaying the dEF (d2=2) message.

Parameter d3 defines the time during which the aforementioned

message will be displayed once the drip time (d9) and fan stop

time (F4) are complete.

Remote defrost

This function allows defrost of the unit to be activated using an

external button, connecting it to one of the digital inputs that

must be configured as remote defrost (I10 or I20=5) .

Defrost locking

This prevents defrost starting at unusual points by means of

an external switch, which may be useful for ensuring that the

installation's load does not excessively increase, exceeding the

permitted limits.

The external switch must be connected to one of the digital

inputs, which should be configured as “Defrost locking” (I10 or

I20=6).

Defrost of a second evaporator

This function allows for defrost to be controlled in a second

evaporator, provided that defrost is by electric heat, by air or is

static. The same type of defrost should be used for the first and

second evaporators.

This requires configuration of input 2 as a 2nd evaporator probe

(l20=8). In the event of an error in the 2nd evaporator probe,

defrost completes once the time defined in d1 has elapsed.

Electric defrosting

This requires configuration of relay AUX 2 as 2nd evaporator

defrost (o10=5).

Defrost begins simultaneously in both evaporators. When the

probe of evaporator 1 reaches the temperature defined in d4,

the DEF relay deactivates, completing defrost of evaporator 1.

Defrost of evaporator 2 is completed when the evaporator 2 probe

reaches the temperature defined in d4. Drip time begins when

both defrosts are complete.

Defrost by air

The fans of both evaporators are connected in parallel to the FAN

relay.

Defrost begins simultaneously in both evaporators and does not

complete until both probes reach the temperature defined in d4.

Drip time subsequently begins.

Static defrost

Defrost begins simultaneously in both evaporators and does not

complete until both probes reach the temperature defined in d4.

Drip time subsequently begins.

Other parameters

Using parameter d5, you can configure whether the unit performs

a defrost (d5=1) or not (d5=0) when it receives power (first startup or after a power supply failure). Should the option YES (d5=1)

be selected, defrost will begin once the delay time defined in d6

has elapsed.

Using parameter d8, we define the time tally established in

d0, choosing between total time elapsed (d8=0) or the sum of

compressor operation time (d8=1).

Remark: If parameter d1 is configured to 0, no defrosts are

performed.

8.5 Fan control

Fans are controlled through probe 2 (evaporator) and parameters

F0 (stop temperature) and F1 (probe differential). If probe 2 is

not connected or an error in the probe (E2) is detected, the fans

continuously operate without taking into account parameters

F0 and F1, but taking the remaining parameters (F2 to F4) into

account.

Using parameter F2, the status of the fans during compressor

stops is defined. Using parameter F3, the status of the fans during

defrost is defined.

Parameter F4 defines the fan start-up delay time after defrost.

Parameter C22 defines whether fans stop when the door is

opened.

© Danfoss | DCS (vt) | 2021.02 BC364433930186en-000101 | 11

ans

F0

F0-F1

COOL

F2=0

F2=1

SP SP

SP+C1

ON ON

ON

ON ON

Danfoss

User Guide | Temperature controller for walk-in coolers and freezers, Type AK-RC 251

8.6 Alarms

The device warns the user through an on-screen message,

activation of a relay (only if o10=1) and a sound alarm when the

criteria programmed in the parameters are met.

Maximum / minimum temperature alarm

It shows the message “AH” or “AL” when the temperature in probe

1 reaches the value configured in parameters A1 (maximum

temperature) and A2 (minimum temperature).

This value may be:

• Absolute (A0=1): The temperature at which the alarm should

activate must be indicated in A1/A2.

• Relative to the SP (A0=0): The increase or decrease in the

number of degrees necessary for the alarm to activate, in

relation to the set point, must be indicated in A1/A2. This option

enables us to change the set point without having to reset the

maximum and minimum alarms.

Parameter A10 establishes the differential of both parameters

(Hysteresis).

Note: We configure the following parameters in a controller: SP=2,

A1=10, A10=2

• If A0=0 (Relative to the SP), the maximum temperature alarm

will activate when 12 degrees are reached in probe 1, and will

deactivate when 10 degrees are reached.

• If A0=1 (Absolute), the maximum temperature alarm will

activate when 10 degrees are reached in probe 1, and will

deactivate when 8 degrees are reached.

External alarm / severe external alarm

The message AE (External alarm) or AES (Severe external alarm) is

displayed when the digital input configured as external alarm or

severe external alarm is activated.

The severe external alarm also deactivates all the loads and,

therefore, temperature regulation stops. When this alarm

disappears, the device returns to its normal operation.

At least one of the digital inputs must be configured as an external

alarm (I10 or I20=2) or as a severe external alarm (I10 or I20=3).

Probe error alarm

If one of the enabled probes is crossed, in open circuit or out of

range, the message

E1, E2 or E3 will be shown, depending on whether probe S1, S2 or

S3 is involved.

Evaporator probe error alarm due to moisture ingress

If, at the start of defrost, the temperature in probe S2 is 40 °F

higher than the temperature in probe S1, the controller ignores

probe S2 and defrost is instead completed based on defrost time.

The display shows the message E2, activates the alarm relay and

sound alarm.

The alarm can be silenced, but the B alarm icon will not disappear

until:

• The controller is switched off and then on again.

• Defrost without error is started in probe S2.

If the 2nd evaporator probe (l20=8) has been enabled, it will

behave in the same way, but displaying the message E3.

Open door alarm

The door has been open for a longer time than defined in

parameter A12, the open door alarm is activated.

In order to detect the open door, configuration is required of one

of the digital inputs as “door contact” (I10 or I20=1).

Activates alarm relay and sound alarm.

HACCP alarm

The alarm is activated should situations be detected which could

endanger the integrity of the products stored in the cold room.

If the temperature of the cold room is higher than that defined

in parameter h1 for a length of time exceeding that defined in

parameter h2, the alarm activates, displaying the message HCP. on

screen.

Upon pressing the mute key, the sound alarm switches off, but the

alarm remains.

Once the temperature drops below parameter h1, if the mute

key has been pressed, the alarm disappears. If the mute key has

not been pressed, the audible alarm deactivates but the HACCP

indicator remains in flashing mode, indicating than a nonconfirmed HACCP alarm has occurred.

Press the mute key to confirm an HACCP alarm.

If, during a power failure, a HACCP alarm occurs, when the power

supply returns, the HACCP alarm is activated and the display

shows the messages HCP and PF (power failure) alternately.

Alarm delays

These delays prevent certain alarms from being shown, to allow

the installation to recover its normal operation after certain events.

• Delays in start-up (A3): This delays the activation of the

temperature alarms upon receiving power (at start-up or after

a power supply failure) or when exiting Stand-by mode. This

allows for the installation to start up avoiding alarms.

• Delay after a defrost (A4): This delays the activation of the

temperature alarms when a defrost completes.

• Delay to minimum and maximum temperature alarm (A5): This

delays the activation of the maximum (A1) and minimum (A2)

temperature alarms, from when the temperature in probe 1

reaches the programmed value.

• Delay to activation of external alarm (A6): This delays the

activation of the external alarm, from when the digital input

becomes active.

• Delay to deactivation of external alarm (A7): This delays the

deactivation of the external alarm, from when the digital input

becomes active.

• Delay to open door alarm (A12): This delays the activation of the

alarm upon detecting that the door is open.

12 | BC364433930186en-000101 © Danfoss | DCS (vt) | 2021.02

User Guide | Temperature controller for walk-in coolers and freezers, Type AK-RC 251

(I10 =8)

DIG. IN

Configuration of alarm relay

Should any relay have been configured as an alarm relay,

parameter A9 allows for the relay status to be defined when an

alarm is triggered:

• A9=0 Relay active (ON) in the event of an alarm (OFF without

alarm)

• A9=1 Relay inactive (OFF) in the event of an alarm (ON without

alarm)

8.7 Alerts

The device alerts the user through an on-screen message when

an event occurs which requires his/her attention. However, it does

not activate the sound alarm or the alarm relay (if active).

Defrost finished by time alarm

The message Adt is displayed when a defrost has completed due

to time-out, if parameter A8=1.

Pump down malfunction error (stop)

The message Pd is displayed if a malfunction is detected when the

refrigeration system is stopped using the pump down action. (See

page 8).

Pump down malfunction error (start-up)

Displays the LP message if a malfunction is detected when the

refrigeration cycle is started up using the pump down action. (See

page 8).

8.8 Light control

Relay AUX 1 or AUX 2 must be configured as “Light” (o00 or

o10=2).

Switching the lights on or off is controlled using:

The push-button: One press switches the lights on or off.

The cold room door: When the door is opened, the lights remain

on for the time defined by parameter b01. If the value is 0, when

the door closes the lights go out. (One of the digital inputs must

be configured as door contact (I10 or I20=1).

The control even occurs with the equipment in Stand-by.

8.9 Password

It allows protecting the configuration of the unit using a 2 digit

code (from 01 to 99). If it is active a code is requested when you try

to access the programming menu. This menu cannot be accessed

if a wrong value is entered. The code is set via the PAS parameter.

Parameter b10 defines the operation of this code.

8.10 Remote Stand-by mode

Danfoss

80Z8131

D1

Gnd

D2 / S3

Remote

Stand-by

This allows activating Stand-by mode using a switch connected to

one of the digital inputs. Said digital input must be set to Stand-by

remote activation (I10=8 or I20=12).

8.11 Operation of the auxiliary relays

Depending on the controller model, it may have 1 or 2 auxiliary

relays. The function of these relays is configurable through the

parameters menu.

AUX 1 relay

• Deactivated (o00=0): It does not carry out any function.

• Compressors / crankcase resistor (o00=1): Controls

compressor operation. When the compressor is not in operation,

it powers the crankcase resistor. This function can only be

selected via the initial wizard (Inl).

• Light (o00=2): This regulates the operation of cold room light.

AUX 2 relay

• Deactivated (o10=0): It does not carry out any function.

• Alarm (o10=1): This activates the relay every time that an alarm

occurs

• Light (o10=2): This regulates the operation of cold room light

• Door frame resistor (o10=4): This controls the operation of the

cold room’s door frame resistor.

• Defrost 2º evaporator (o10=5): This controls the defrost

resistors of a second evaporator.

• Same as solenoid status (o10=6): Imitates solenoid status:

active if the solenoid is in ON mode, inactive if the solenoid is in

OFF mode.

• Same as unit status (o10=7): Indicates the unit’s status: active if

the unit is in ON mode, inactive if the unit is in Stand-by mode.

© Danfoss | DCS (vt) | 2021.02 BC364433930186en-000101 | 13

User Guide | Temperature controller for walk-in coolers and freezers, Type AK-RC 251

T

9. Configuration

Condensed programming menu

This allows for the most-used parameters to be quickly configured.

Press the SET key for 3 seconds to access it.

OUT OF

PROGRAMMING

emperature control

3 seg.

20 sec.

Parameters

Change

parameter

IN PROGRAMMING

OK

Values

Change

value

OK

20 sec.

OK

Parameters

Level 2 Description Values Min. Def. Max.

SP Temperature setting (Set Point) ºF -58 0.0 210

C1 Probe 1 differential (Hysteresis) ºF 0.2 3.6 36

d0 Defrost frequency (Time between 2 starts) H. 0 6 96

d1 Maximum defrost duration (0=defrost deactivated) Min. 0 * 255

d4 Final defrost temperature (by probe) (If I00 ≠1) ºF -58 46.4 122

F3 Status of the fans during the defrost 0=Shut down; 1=Running 0 0 1

A1 Alarm for maximum in probe 1 (It should be higher than the SP) ºF A2 210 210

A2 Alarm for minimum in probe 1 (It should be lower than the SP) ºF -58 -58 A1

Save changes

Do not save changes

Danfoss

80Z8132

Extended programming menu

Use the extended programming menu to configure all of the unit’s

parameters in order to adapt it to your installation requirements.

Press the SET key for 6 seconds to access it.

Important:

• If the password function has been configured as a keypad lock

(b10=2), or as an access to parameters block (b10=1), you will

OUT OF

PROGRAMMING

Temperature

indication

6 sec.

Level 1

Menus

Change

menu

20 sec.20 sec.

IN PROGRAMMING

Level 2

Parameters

Change

parameter

OKOK

Level 3

Values

Change

value

Save changes

Do not save changes

OK

be requested to enter the password programmed in PAS when

attempting to access either of the two functions. If the entered

password is not correct, the unit will go back to showing the

20 sec.

temperature.

• Certain parameters or menus may not be visible depending on

the configuration of the rest of the parameters.

OK

OK

Danfoss

80Z8133

14 | BC364433930186en-000101 © Danfoss | DCS (vt) | 2021.02

User Guide | Temperature controller for walk-in coolers and freezers, Type AK-RC 251

Regulation and control

Level 1 Level 2 Description Values Min. Def. Max.

SP Temperature setting (Set Point) ºF -58 32.0 210

C0 Probe 1 calibration (Offset) ºF -36.0 0.0 36.0

C1 Probe 1 differential (Hysteresis) ºF 0.1 3.6 36

C2 Set Point top locking (it cannot be set above this value) ºF -58 210 210

C3 Set Point bottom locking (it cannot be set below this value) ºF -58 -58 C2

Type of delay for the protection of the compressor:

C4

0=Minimum time of compressor in OFF

1=Minimum time of compressor in OFF and in ON in each cycle

C5 Protection delay time (Value of the option selected in parameter C4) Min. 0 0 120

COOL relay status with fault in probe 1:

C6

0=OFF; 1=ON; 2=Average according to last 24 h prior to probe error

3=ON-OFF according to prog. C7 and C8

Relay time in ON in the event of probe 1 failure

C7

(If C7=0 and C8≠0, the relay will always be disconnected in OFF)

Relay time in OFF in the event of probe 1 failure

C8

rE

C10

C12

C19

C20 Maximum time for pump down (0= deactivated) Min. 0 0 15

C21

C22 Stop fans and compressor on opening door 0=No, 1=Yes 0 0 1

C23 Start-up delay for fans and compressor with door open Min. 0 0 999

C27 Probe 3 calibration (Offset) ºF -36.0 0.0 36.0

(If C8=0 and C7≠0, the relay will always be connected in ON)

C9 Maximum duration of the continuous cycle mode. (0=deactivated) H. 0 0 48

Variation of the Set Point (SP) in continuous cycle mode. When it reaches this point

(SP+C10), it reverts to the normal mode. (SP+C10 ≥ C3).

The value of this parameter is always negative, unless it is 0. (0=OFF)

Variation of the Set Point (SP) when the change Set Point function is active. (SP+C12 ≤

C2) (0= deactivated)

Maximum start time from Pump Down

(Values between 1 and 9 seconds will not be accepted) (0=deactivated)

Probe to be displayed 0=All probes (sequential)

1=Probe 1 (Cold Room), 2=Probe 2 (Evaporator), 3=Probe 3 (According to I20)

EP Exit to level 1

Min. 0 10 120

Min. 0 5 120

ºF 0 -90 C3-SP

ºF C3-SP 0.0 C2-SP

Sec. 0 0 120

0 0 1

0 2 3

0 1 3

Defrost

Level 1 Level 2 Description Values Min. Def. Max.

d0 Defrost frequency (Time between 2 starts) H. 0 6 96

d1 Maximum defrost duration (0=defrost deactivated) Min. 0 * 255

Type of message during the defrost:

d2

0=Displays the real temperature; 1=Displays the temperature at the start of

the defrost; 2=Displays the dEF message

Maximum duration of the message

d3

(Time added at the end of the defrost process)

d4 Final defrost temperature (by probe) (If I00 ≠ 1) ºF -58 46.4 122

dEF

Defrost on connecting the unit:

d5

0=NO First defrost according to d0; 1=YES, First defrost according to d6

d6 Delay of the defrost start on connecting the unit Min. 0 0 255

d7**

Type of defrost:

0=Resistors; 1=Air/fans, 2=Hot gas; 3=Reversal of cycle

Count of time between defrost periods:

d8

0=Total real time, 1 =Sum of compressor connected time

d9 Drip time when completing defrost (Shutdown of compressor and fans) Min. 0 1 255

EP Exit to level 1

* According to wizard.

** It can only be modified using the configuration wizard (InI).

Min. 0 5 255

0 2 2

0 0 1

0 * 3

0 0 1

© Danfoss | DCS (vt) | 2021.02 BC364433930186en-000101 | 15

User Guide | Temperature controller for walk-in coolers and freezers, Type AK-RC 251

Evaporator fans

Level 1 Level 2 Description Values Min. Def. Max.

F0 Shutdown temperature of fans ºF -58 113 122

F1 Probe 2 differential if fans are shut down ºF 0.1 3.6 36

F2 Shut down fans when the compressor shuts down 0=No, 1=Yes 0 0 1

FAn

F3 Status of the fans during the defrost 0=Shut down; 1=Running 0 0 1

Delay of start-up after defrost (If F3=0)

F4

It will only actuate if it is higher than d9

EP Exit to level 1

Min. 0 2 99

Alarms

Level 1 Level 2 Description Values Min. Def. Max.

A0 Configuration of the temperature alarms 0=Relative to SP 1=Absolute 0 1 1

A1 Alarm for maximum in probe 1 (It should be higher than the SP) ºF A2 210 210

A2 Alarm for minimum in probe 1 (It should be lower than the SP) ºF -58 -58 A1

A3 Delay of temperature alarms in the start-up Min. 0 0 120

A4 Delay of temperature alarms from the end of a defrost Min. 0 0 99

A5 Delay of temperature alarms from when the A1 or A2 value is reached 0 30 99

Delay of the external alarm/Severe external alarm on receiving a signal in

AL

A6

digital input (I10 or I20 =2 or 3)

Delay of external alarm deactivation/Severe external alarm deactivation

A7

when the signal in digital input disappears (I10 or I20=2 or 3)

A8 Show warning if the defrost ends for maximum time, 0=No, 1=Yes 0 0 1

Relay alarm polarity

A9

0= Relay ON in alarm (OFF without alarm); 1= Relay OFF in alarm (ON

without alarm)

A10 Differential of temperature alarms (A1 and A2) ºF 0.1 1.8 36

A12 Delay of open door alarm (If I10 or I20=1) Min. 0 10 120

EP Exit to level 1

Min. 0 0 120

Min. 0 0 120

0 0 1

Basic configuration

Level 1 Level 2 Description Values Min. Def. Max.

b00 Delay of all functions on receiving power supply Min. 0 0 255

b01 Cold room light timing Min. 0 0 999

Function of password

0=Inactive, 1=Block access to parameters, 2=Block keypad

Communication speed:

0=9600 bps, 1=19200 bps, 2=38400 bps, 3=57600 bps

EP Exit to level 1

0 0 2

bps 0 0 3

bcn

b10

PAS Access code (Password) 0 0 99

b20 MODBUS address 1 1 247

b21

b22 Acoustic alarm enabled: 0= No, 1=Yes 0 1 1

Unt Work units: 0=ºC, 1=ºF 0 1 1

16 | BC364433930186en-000101 © Danfoss | DCS (vt) | 2021.02

User Guide | Temperature controller for walk-in coolers and freezers, Type AK-RC 251

Inputs and outputs

Level 1 Level 2 Description Values Min. Def. Max.

Connected probes

1=Probe 1 (Cold room), 2=Probe 1 (Cold room) + Probe 2 (Evaporator)

Configuration of digital input 1

0= Deactivated, 1=Door contact, 2=External alarm,

3=Severe external alarm, 4=Change of SP, 5=Remote defrost,

6=Defrost block, 7= Low pressure switch, 8=Remote Stand-by

Polarity of the digital input 1

0=Activates on closing contact; 1=Activates on opening contact

Configuration of digital input 2

0= Deactivated, 1=Door contact, 2=External alarm,

3=Severe external alarm, 4=Change of SP, 5=Remote defrost,

6=Defrost block, 7=Register probe, 8=Probe 2° evaporator,

9=High pressure switch for Hot Gas, 10=Remote Stand-by

Polarity of the digital input 2

0=Activates on closing contact; 1=Activates on opening contact

Configuration of relay AUX1

0=Deactivated, 1=Compressor/Resistor sump, 2=Light, 3=Virtual control

Configuration of relay AUX2

0=Deactivated, 1=Alarm, 2=Light, 3=Virtual control,

4=Door frame resistance, 5=Defrost 2° evaporator,

6=Same as solenoid status, 7=Same as unit status

EP Exit to level 1

1 2 2

0 * 8

0 * 1

0 0 10

0 0 1

0 * 3

0 2 7

In0

I00

I10**

I11

I20

I21

O00**

O10

* According to wizard.

** It can only be modified using the configuration wizard (InI).

HACCP alarm

Level 1 Level 2 Description Values Min. Def. Max.

h1 Maximum temperature of HACCP alarm ºF -58 210 210

HCP

h2 Maximum permitted time for activation of the HACCP alarm (0=Disabled) H. 0 0 255

EP Exit to level 1

Information (reading only)

Level 1 Level 2 Description Values Min. Def. Max.

InI Option chosen in the configuration wizard

Pd** Pump down active? 0=No, 1=Yes

PU Program version

tid

Pr Program revision

bU Bootloader version

br Bootloader revision

PAr Parameter map revision

EP Exit to level 1

** It can only be modified using the configuration wizard (InI).

© Danfoss | DCS (vt) | 2021.02 BC364433930186en-000101 | 17

User Guide | Temperature controller for walk-in coolers and freezers, Type AK-RC 251

Messages

Messages A R

Pd Pump down malfunction error (Shutdown)

LP Pump down malfunction error (Start-up)

E1/E2/E3 Probe 1/2/3 failure (Open circuit, crossed circuit or temperature outside the limits of the probe)

Ad0 Open door alarm. Only if the door stays open for a greater time than is indicated in parameter A12

AH Maximum temperature alarm in control probe. The temperature value programmed in A1 has been reached

AL Minimum temperature alarm in control probe. The temperature value programmed in A2 has been reached

AE External alarm activated (by digital input)

AES Severe external alarm activated (by digital input)

Adt Defrost alarm concluded due to time-out. The time established in d1 has been exceeded

HCP

hCP + PF

dEF Indicates that a defrost is being performed

PAS Access code (Password) request. See parameters b10 and PAS

S1 - S2

A: Activates the acoustic alarm

R: Activates the alarm relay

HACCP alarm. The temperature has reached the value of parameter h1 during a longer period than has been

established in h2

HACCP alarm due to a fault in the power supply. The temperature established in h1 has been reached following a

fault in the power supply

Shown sequentially with the temperature: The controller is in demo mode, the configuration has not been

made.

18 | BC364433930186en-000101 © Danfoss | DCS (vt) | 2021.02

User Guide | Temperature controller for walk-in coolers and freezers, Type AK-RC 251

10. Technical specifications

Features Specifications

Power supply 100 - 240 V~, 50 - 60 Hz

Maximum input power in the operation 8.1 VA

Maximum nominal current 15 A

NO

Relay DEFROST - SPDT - 20 A

NC

Relay FAN - SPST - 16 A

Relay COOL - SPST - 16 A

NO

Relay AUX 1 - SPDT - 20 A

NC

NO

Relay AUX 2 - SPDT - 16 A

NC

No. of relay operations EN60730-1:100.000 operations

Probe temperature range -58 – 211 ºF

Resolution, setting and differential 0.2 ºF

Thermometric precision ±1.8 ºF

Loading tolerance of the NTC probe at 25 °C ±0.7 ºF

Working ambient temperature 14 – 122 ºF

Storage ambient temperature -22 – +140 ºF

Protection degree IP 40 (IP 65 installing the proper glands)

Pollution degree II acc. UL 60730-1

Construction Independently mounted acc. UL 60730-1

Control device classification

Temperature during ball-pressure test

Current of radio jamming suppression tests 270 mA

Voltage and current as per EMC tests 207 V, 17 mA

Type of assembly Fixed internal

MODBUS address Shown on label

Dimensions 11.42 in (W) x 5.55 in (H) x 3.32 in (D)

Internal buzzer

EN60730-1: 15 (15) A 250 V~

UL-60730: 9 FLA 54 LRA, 240 V AC

UL-60730: RES 12 A, 240 V AC)

EN60730-1: 15 (13) A 250 V~

UL-60730: 6 FLA 36 LRA, 240 V AC

UL-60730: RES 6 A, 240 V AC

EN60730-1: 12 (9) A 250 V~

UL-60730: 5 FLA 30 LRA, 240 V AC

UL-60730: RES 10 A, 240 V AC

EN60730-1: 12 (9) A 250 V~

UL-60730: 5 FLA 30 LRA, 240 V AC

UL-60730: RES 10 A, 240 V AC)

EN60730-1: 15 (15) A 250 V~

UL-60730: 9 FLA 54 LRA, 240 V AC

UL-60730: RES 12 A, 240 V AC

EN60730-1: 15 (13) A 250 V~

UL-60730: 6 FLA 36 LRA, 240 V AC

UL-60730: RES 6A, 240 V AC

EN60730-1: 12 (9) A 250 V~

UL-60730: 5 FLA 30 LRA, 240 V AC

UL-60730: RES 10 A, 240 V AC

EN60730-1: 10 (8) A 250 V~

UL-60730: 5A, 240 V AC

Built-in assembly, with Type 1.B automatic operation action feature, for use in clean situations,

logical support (Software) class A and continuous operation.

Double isolation between power supply, secondary circuit and relay output.

Accessible parts: 167 ºF

Parts which position active elements: 257 ºF

© Danfoss | DCS (vt) | 2021.02 BC364433930186en-000101 | 19

Danf

already on order pro

All trademarks in this material are property of the respec

11. Ordering

Controller

Model Description Comments Code no.

Includes:

AK-RC 251 AK-RC 251 Gen. 2,5 O/P, Single phase

Accessories (for spares and replacement purposes):

Name Features Qty Code no.

3.5 m, NTC 10K Sensor Thermo plastic rubber probe 1 084N3210

8.5 m, NTC 10K sensor Thermo plastic rubber probe 50 084N3208

1.5 m, NTC 10K sensor Stainless steel probe 150 084N3200

• 1 x 1.5 m, NTC 10K sensor

• 1 x 3 m, NTC 10K sensor

• 2 x 2 caps to provide IP65 protection after installation

080Z5000

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

© Danfoss | DCS (vt) | 2021.02 BC364433930186en-000101 | 20

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

Loading...

Loading...