Page 1

Design Guide

Capacity controller with

cascade control

AK-PC 783A

ADAP-KOOL® Refrigeration control systems

Page 2

Contents

1. Introduction .............................................................................3

Application .................................................................................................. 3

Principles...................................................................................................... 4

2. Design of a controller ..............................................................7

Module survey ........................................................................................... 8

Common data for modules .................................................................10

Controller ...........................................................................................12

Extension module AK-XM 101A .................................................14

Extension module AK-XM 102A / AK-XM 102B .....................16

Extension module AK-XM 103A .................................................18

Extension module AK-XM 204A / AK-XM 204B .....................20

Extension module AK-XM 205A / AK-XM 205B .....................22

Extension module AK-XM 208C ................................................24

Extension module AK-OB 110 ....................................................26

Extension module EKA 163B / EKA 164B ............................... 27

Graphic display MMIGRS2 ............................................................27

Power supply module AK-PS 075 / 150 / 250 ........................28

Communication module AK-CM 102 .......................................29

Preface to design ....................................................................................30

Functions ............................................................................................30

Connections ...................................................................................... 31

Limitations ......................................................................................... 31

Design of a compressor and condenser control .........................32

Procedure: ..........................................................................................32

Sketch .................................................................................................. 32

Compressor and condenser functions ....................................32

Connections ...................................................................................... 33

Planning table .................................................................................. 35

Length .................................................................................................36

Linking of modules ......................................................................... 36

Determine the connection points ............................................37

Connection diagram ...................................................................... 38

Supply voltage ................................................................................ 40

Ordering ..................................................................................................... 41

3. Mounting and wiring .............................................................43

Mounting ................................................................................................... 44

Mounting of analog output module ........................................ 44

Mounting of extension module on the basic module ....... 45

Wiring .......................................................................................................... 46

4. Configuration and operation ................................................49

Configuration ...........................................................................................50

Connect PC ........................................................................................ 50

Authorization .................................................................................... 52

Unlock the configuration of the controllers ..........................53

System setup ....................................................................................54

Set plant type ................................................................................... 55

Set control of suction group MT ................................................56

Set control of suction group LT .................................................. 60

Set oil management ....................................................................... 63

Setup control of condenser fans ...............................................65

Set control of cascade heat exchanger ..................................67

Setup control of heat recovery.................................................. 68

Setup control of pump function ............................................... 68

Setup Display .................................................................................... 69

Setup Functions for General purpose ......................................70

Separate thermostats ............................................................. 71

Separate pressostats ..............................................................71

Separate voltage signals .......................................................72

Separate alarm inputs ............................................................ 72

Separate PI functions ............................................................. 73

Configuration of inputs and outputs .......................................74

Set alarm priorities..........................................................................76

Lock configuration ..........................................................................78

Check configuration .......................................................................79

Check of connections ............................................................................ 81

Check of settings.....................................................................................83

Schedule function .................................................................................. 85

Installation in network .......................................................................... 86

First start of control ................................................................................87

Start the control ...............................................................................88

Manual capacity control ............................................................... 89

5. Regulating functions .............................................................91

Suction group ..........................................................................................92

Controlling sensor selection .......................................................92

Reference ...........................................................................................93

Capacity control of compressors ...............................................94

Capacity distribution methods ........................................... 96

Power pack types – compressor combinations ............97

Compressor timers ................................................................101

The capacity from the digital scroll compressor ........102

Cascade control .....................................................................103

Load shedding ........................................................................104

Injection ON ............................................................................105

Liquid injection in suction line .........................................105

Safety functions .............................................................................106

Oil management............................................................................108

Pump control ..................................................................................110

Condenser ...............................................................................................112

Capacity control of condenser .................................................112

Reference for condensing pressure ........................................112

Capacity distribution ...................................................................114

EC motor ...........................................................................................114

Step regulation ......................................................................................114

Speed regulation ..................................................................................114

Condenser couplings ...................................................................115

Safety functions for condenser ................................................115

General monitoring functions .........................................................116

Miscellaneous ........................................................................................118

Appendix A – Compressor combinations and coupling pat-

terns ...........................................................................................................122

Appendix B - Alarm texts ...................................................................128

2 Capacity controller RS8HN102 © Danfoss 2017-11 AK-PC 783A

Page 3

1. Introduction

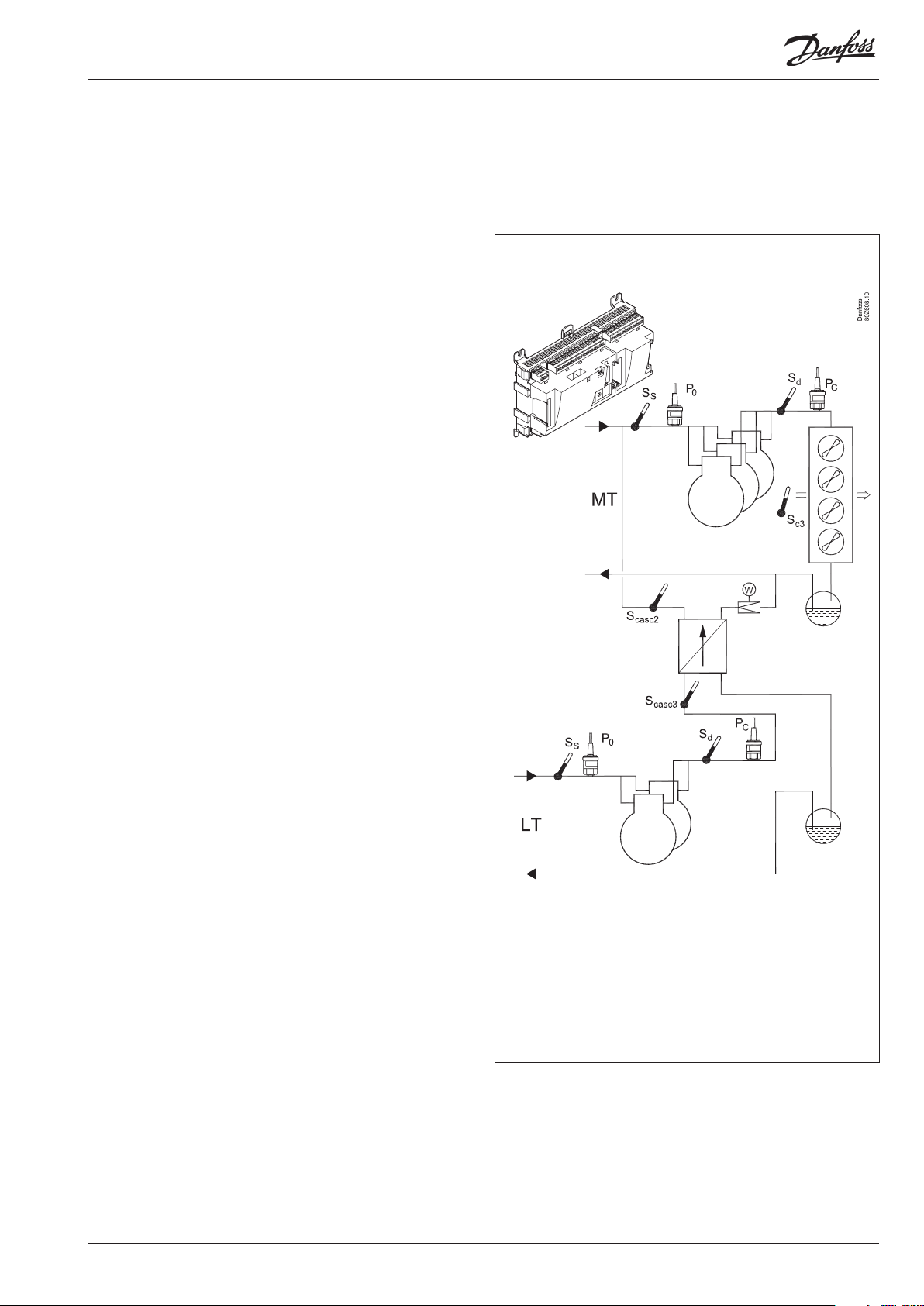

Application

AK-PC 783A is complete regulating units for capacity control of

compressors and condensers in refrigeration plants with cascade

function.

The controller controls the high-pressure circuit, low-pressure

circuit and cascade circuit.

The controller is with oil management, simple heat recovery function and coordination between the high-pressure control and

low-pressure control.

In addition to capacity control the controllers can give signals to

other controllers about the operating condition, e.g. forced closing of expansion valves, alarm signals and alarm messages.

The controller’s main function is to control compressors and

condensers so that operation all the time takes place at the

energy-optimum pressure conditions. Both suction pressure

and condensing pressure are controlled by signals from pressure

transmitters.

Capacity control is carried out by suction pressure P0 on the two

circuits.

Cascade control is performed in accordance with the two temperature sensors, Scasc2 and Scasc3.

Among the different functions are:

- Capacity control of up to 12 compressors

(Max. 6 on each circuits or 7 MT + 5 LT or 8 MT + 4 LT)

- Up to 3 unloaders for each compressor

- Up to 3 screw compressors

- Digital scroll compressor

- Oil equalisation function on MT circuit

- Oil management. Either shared or individual for all of the compressor's oil valves in the LT circuit. Receiver pressure control.

- Speed control of one or two compressors

- Up to 6 safety inputs for each compressor

- Option for capacity limitation to minimize consumption peaks

- When the compressor does not start, signals can be transmitted

to other controllers so that the electronic expansion valves will

be closed

- Control of liquid injection into suction line

- Control of liquid injection into screw compressor

- Control of liquid injection in heat exchanger (cascade)

- Control of two cascade circuits in parallel

- Safety monitoring of high pressure / low pressure / discharge

temperature

- Capacity control of up to 8 fans on the condenser

- Floating reference with regard to outside temperature

- Heat recovery function

- Step coupling, speed regulation or a combination

- Control of CO2 pump system

- Safety monitoring of fans

- Control of fans with EC motors

- The status of the outputs and inputs is shown by means of lightemitting diodes on the front panel

- Alarm signals can be generated via data communication

- Alarms are shown with texts so that the cause of the alarm is

easy to see.

- Plus some completely separate functions that are totally independent of the regulation – such as alarm, thermostat ,pressure

and PI-regulating functions.

SW = 1.1x

AK-PC 783A Capacity controller RS8HN102 © Danfoss 2017-11 3

Page 4

Principles

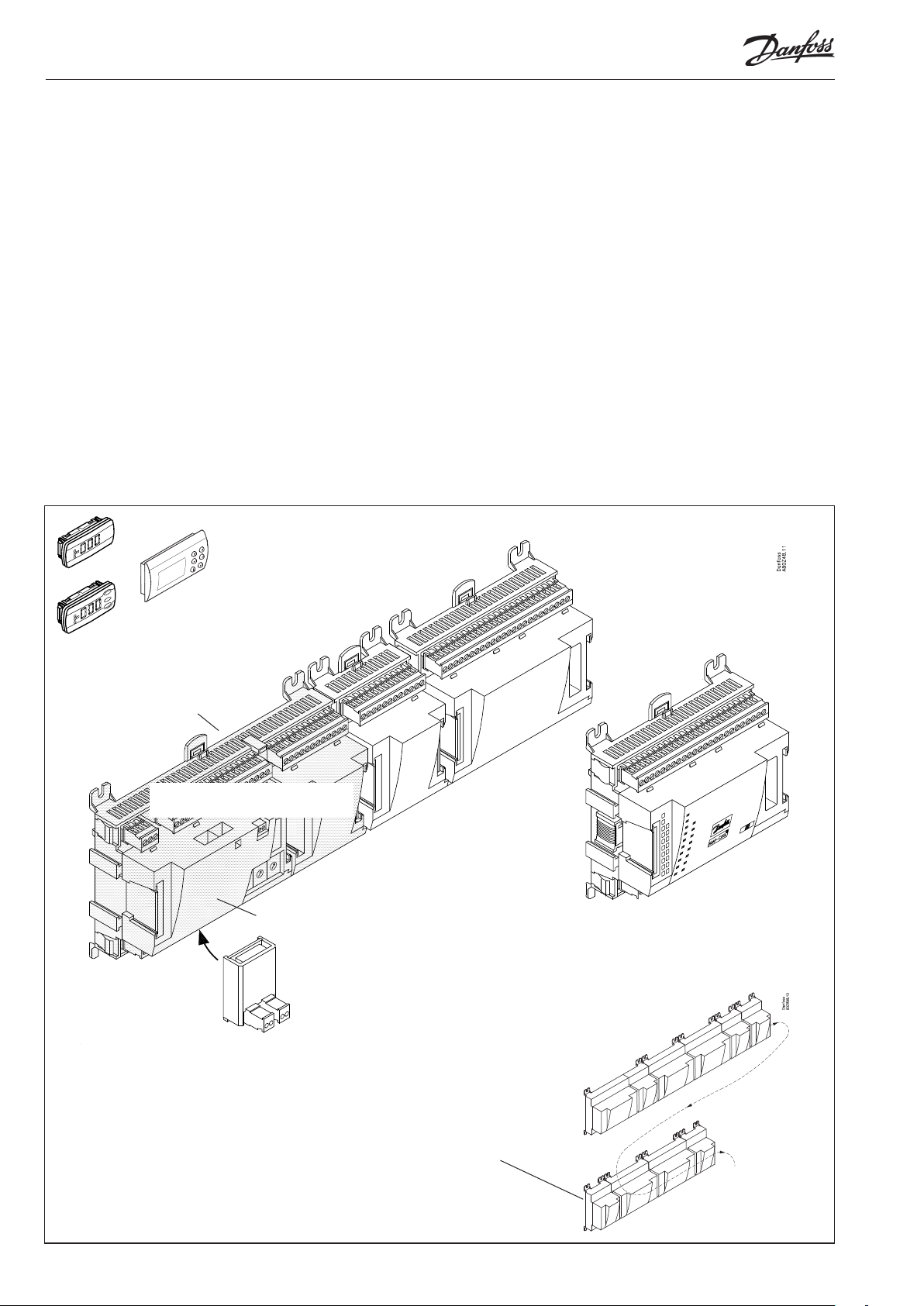

The great advantage of this series of controllers is that it can be

extended as the size of the plant is increased. It has been developed for refrigeration control systems, but not for any specific

application – variation is created through the read-in software and

the way you choose to define the connections.

It is the same modules that are used for each regulation and the

composition can be changed, as required. With these modules

(building blocks) it is possible to create a multitude of various

kinds of regulations. But it is you who must help adjusting the

regulation to the actual needs – these instructions will assist you

to find your way through all the questions so that the regulation

can be defined and the connections made.

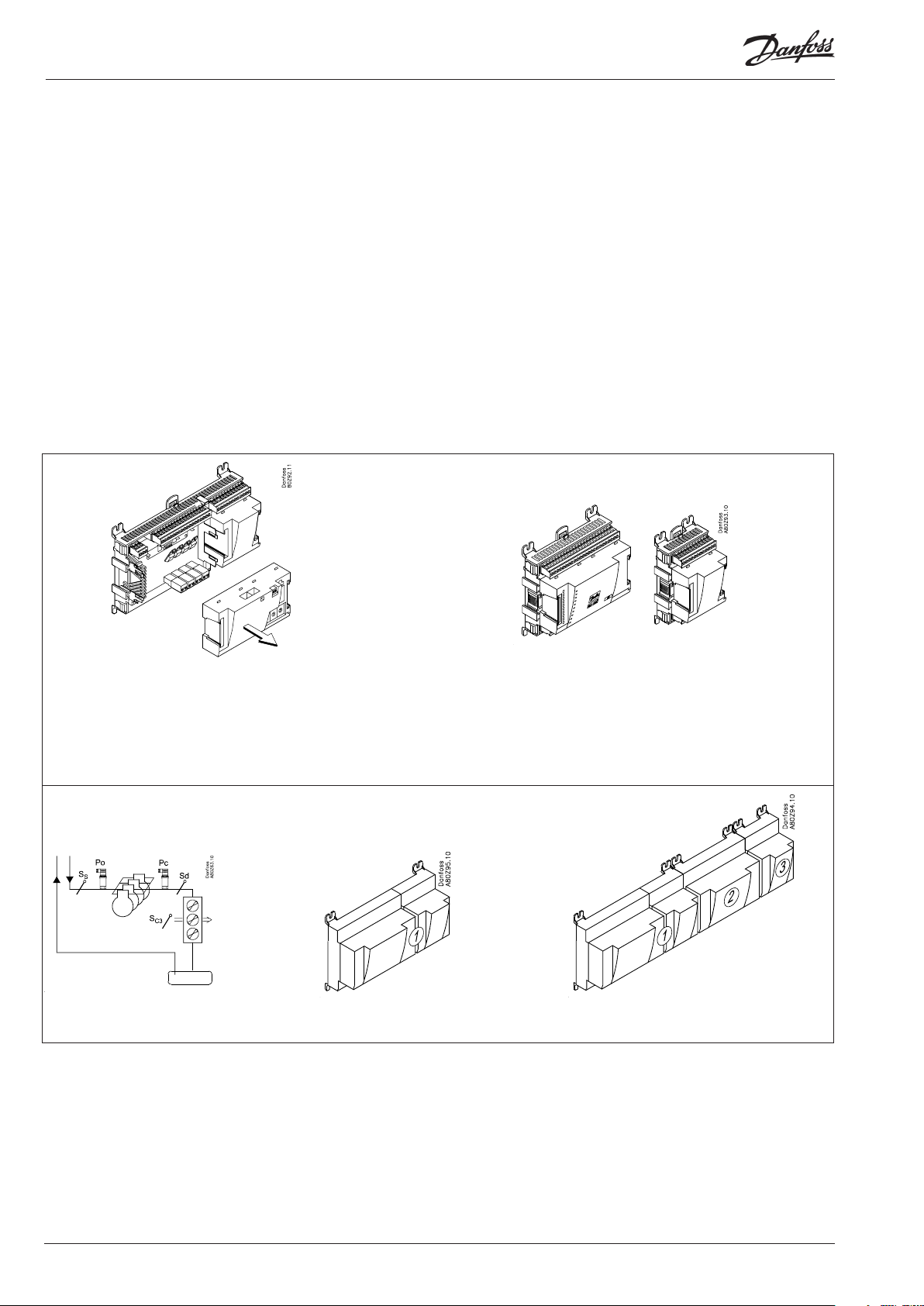

Controller

Top part

Advantages

• The controller’s size can “grow” as systems grow

• The software can be set for one or more regulations

• Several regulations with the same components

• Extension-friendly when systems requirements are changed

• Flexible concept:

- Controller series with common construction

- One principle – many regulation uses

- modules are selected for the actual connection requirements

- The same modules are used from regulation to regulation

Extension modules

Bottom part

The controller is the cornerstone of the regulation. The module has inputs and

outputs capable of handling small systems.

• The bottom part – and hence the terminals – are the same for all controller types.

• The top part contains the intelligence with software. This unit will vary according

to controller type. But it will always be supplied together with the bottom part.

• In addition to the software the top part is provided with connections for data

communication and address setting.

Examples

A regulation with few connections can

be performed with the controller module

alone

If the system grows and more functions have to be controlled, the regulation can be

extended.

With extra modules more signals can be received and more relays cut in and out –

how many of them – and which – is determined by the relevant application.

If there are many connections one or more extension modules have to be mounted

4 Capacity controller RS8HN102 © Danfoss 2017-11 AK-PC 783A

Page 5

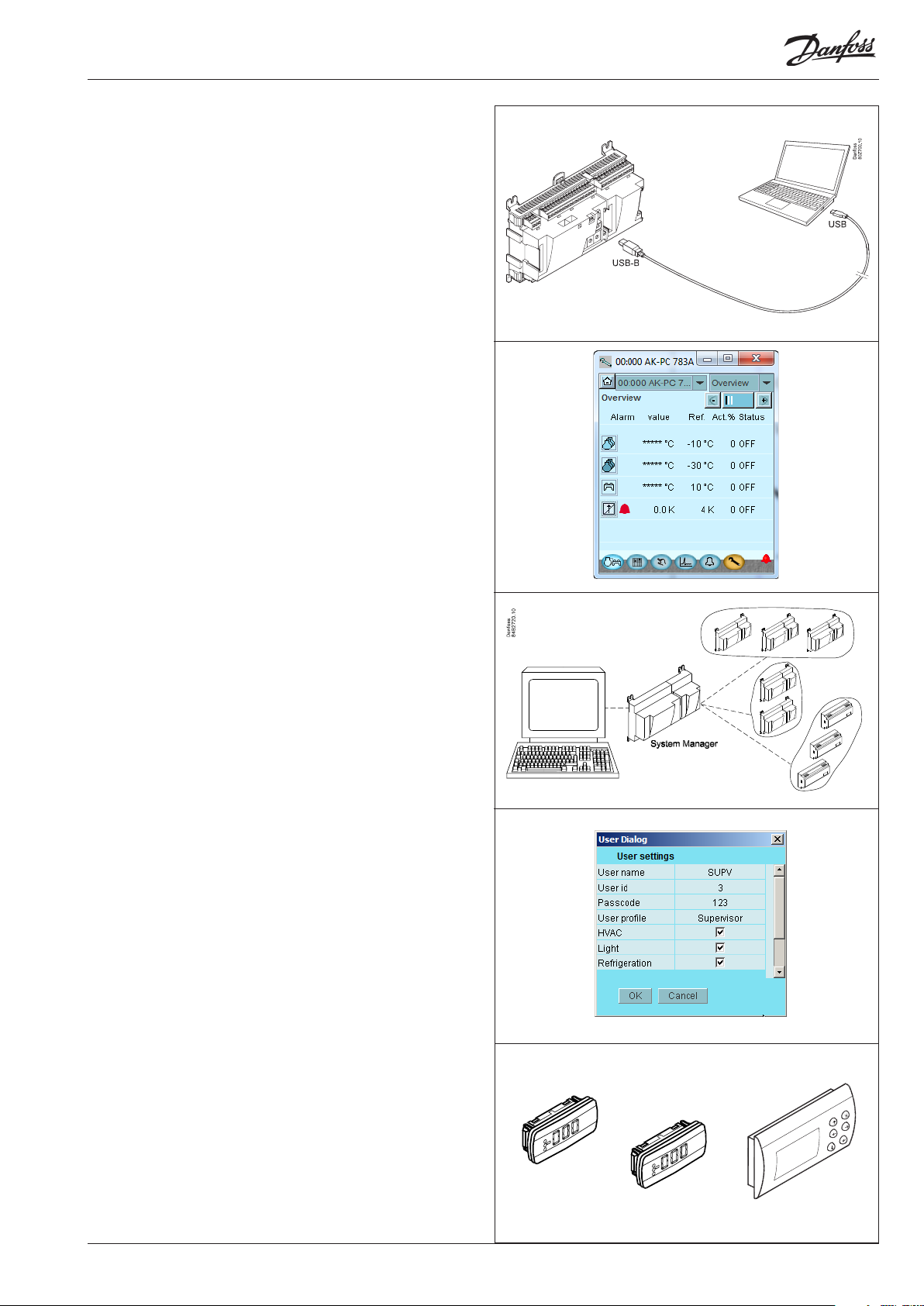

Direct connection

Setup and operation of an AK controller must be accomplished via

the “AK-Service Tool” software program.

The program is installed on a PC, and setup and operation of

the various functions are carried out via the controller’s menu

displays.

Displays

The menu displays are dynamic, so that different settings in one

menu will result in different setting possibilities in other menus.

A simple application with few connections will give a setup with

few settings.

A corresponding application with many connections will give a

setup with many settings.

From the overview display there is access to further displays for

the compressor regulation and the condenser regulation.

At the bottom of the display there is access to a number of general

functions, such as “time table”, “manual operation”, “log function”,

“alarms”, and “service” (configuration).

Network linking

The controller can be linked up into a network together with other

controllers in an ADAP-KOOL® refrigeration control system. After

the setup operation can be performed at a distance with, say, our

software program type AKM.

Users

The controller comes supplied with several languages, one of

which can be selected and employed by the user. If there are several users, they may each have their choice of language. All users

must be assigned a user profile which either gives access to full

operation or gradually limits the operation to the lowest level that

only allows you “to see”.

Language selection is part of the service tool settings.

If the language selection is not available in the service tool for the

current regulator, English texts will be displayed.

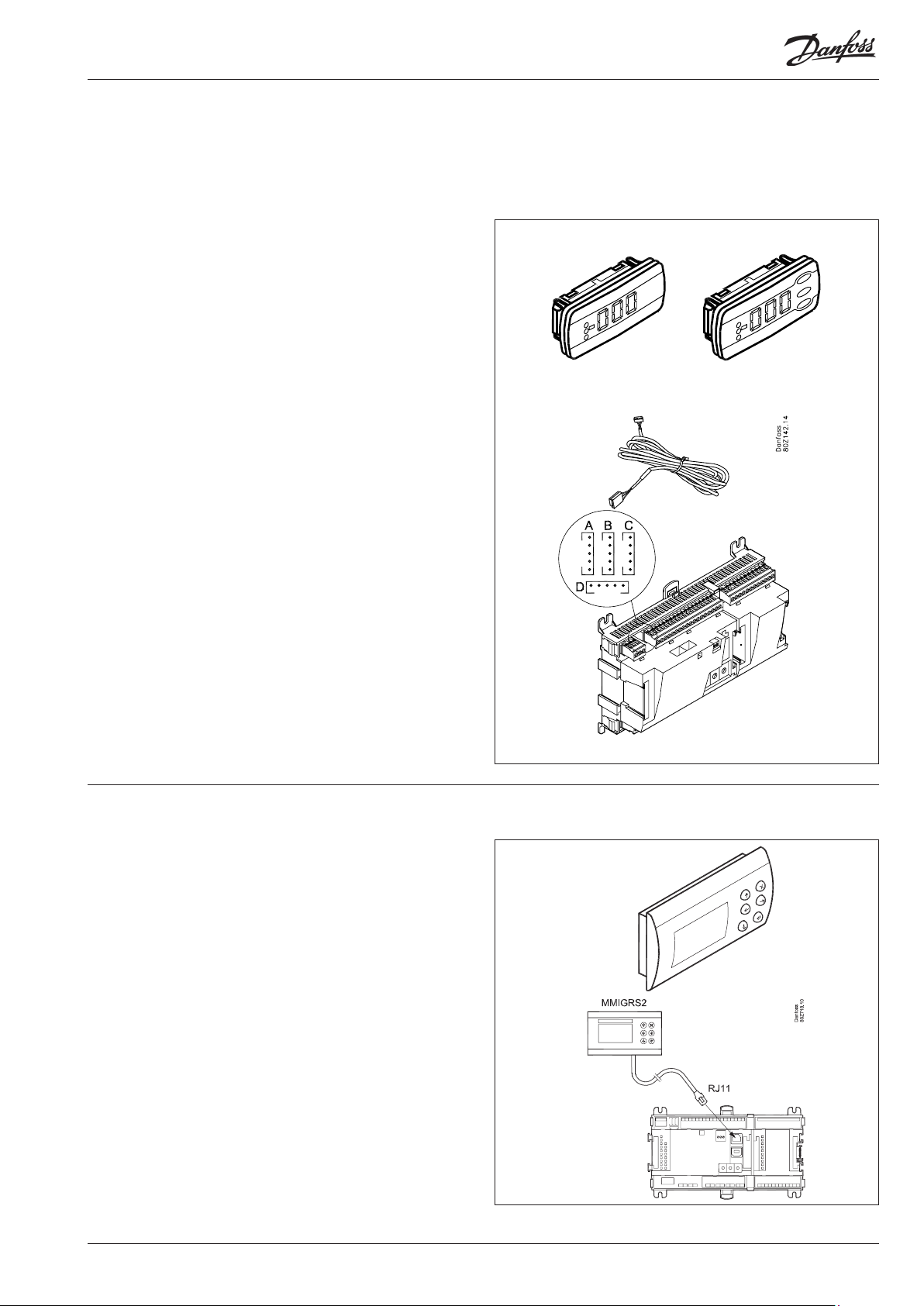

External display

An external display can be fitted in order for P0 (Suction) and Pc

(Condensing) readings to be displayed.

A total of 4 displays can be fitted and with one setting it is possible to choose between the following readings: suction pressure,

suction pressure in temperature, S4, Ss, Sd, condenser pressure,

condenser pressure in temperature, S7 media temperature etc.

A graphical display with control buttons can also be fitted.

AK-PC 783A Capacity controller RS8HN102 © Danfoss 2017-11 5

Page 6

Light-emitting diodes

A number of light-emitting diodes makes it possible to follow the

signals that are received and transmitted by the controller.

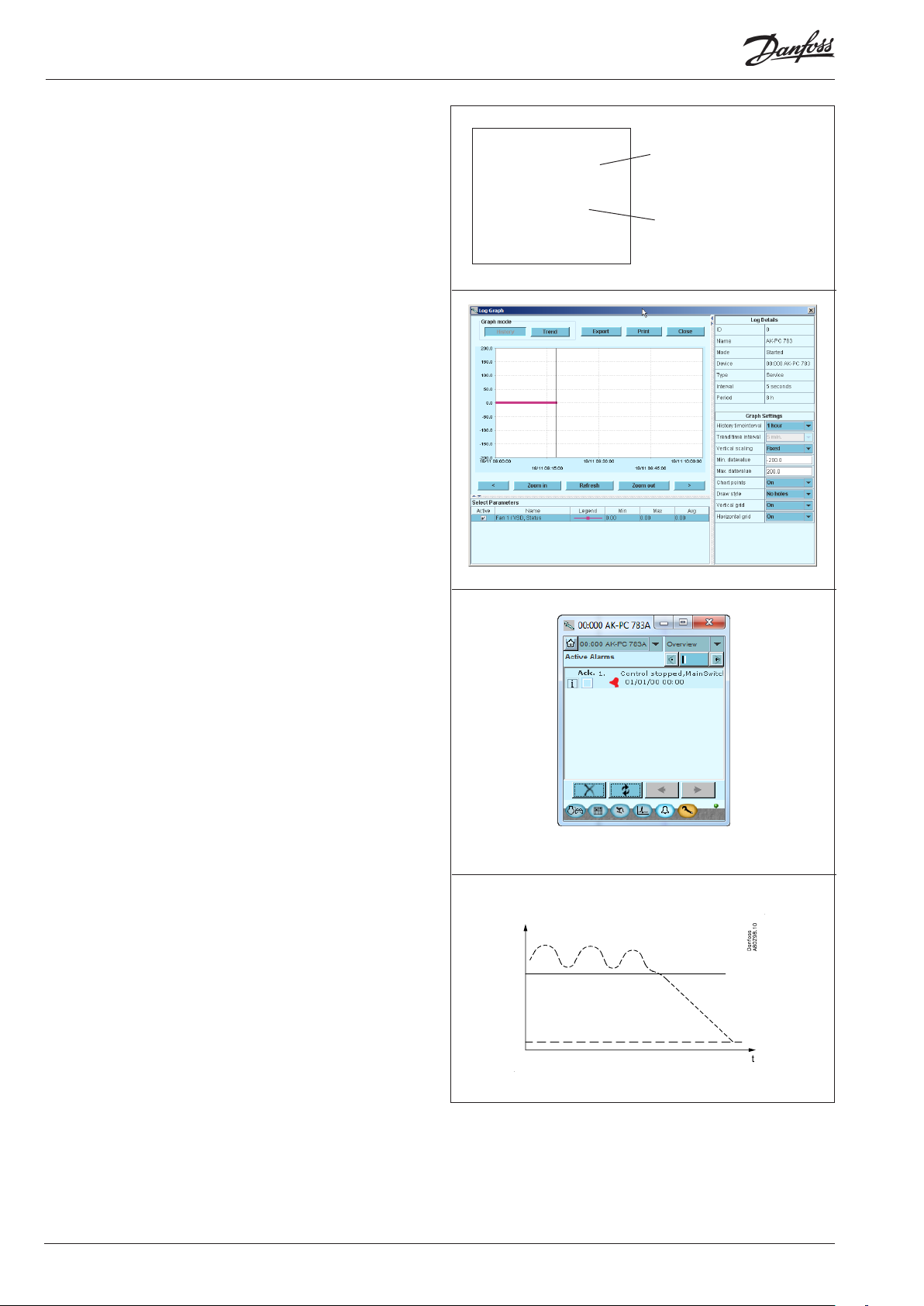

Log

From the log function you can define the measurements you wish

to be shown.

The collected values can be printed, or you may export them to a

file. You can open the file in Excel.

If you are in a service situation you can show measurements in a

trend function. The measurements are then made real-time and

displayed instantly.

■ Power

■ Comm

■ DO1 ■ Status

■ DO2 ■ Service Tool

■ DO3 ■ LON

■ DO4 ■ I/O Extension

■ DO5 ■ Alarm

■ DO6

■ DO7 ■ Display

■ DO8 ■ Service Pin

Slow flash = OK

Quick flash = answer from gateway

Constantly ON = error

Constantly OFF = error

Flash = active alarm/not cancelled

Constant ON = Active alarm/cancelled

Alarm

The display gives you an overview of all active alarms. If you wish

to confirm that you have seen the alarm you can cross it off in the

acknowledge field.

If you want to know more about a current alarm you can click on it

and obtain an information display on the screen.

A corresponding display exists for all earlier alarms. Here you can

upload information if you need further details about the alarm

history.

Trouble-shooting

The controller contains a function that continuously follows

a number of measurements and deals with them. The result

indicates whether the function is OK or whether an error may be

expected within a given period of time (“the trip down the roller

coaster has started”). At this time an alarm is transmitted about

the situation – no error has appeared as yet, but it will come.

One example may be slow clogging-up of a condenser. When the

alarm comes the capacity has been reduced, but the situation is

not serious. There will be time to plan a service call.

Alarm

Error

6 Capacity controller RS8HN102 © Danfoss 2017-11 AK-PC 783A

Page 7

2. Design of a controller

This section describes how the controller is designed.

The controller in the system is based on a uniform connection

platform where any deviations from regulation to regulation is

determined by the used top part with a specific software and

by which input and output signals the relevant application will

require. If it is an application with few connections, the controller

module (top part with belonging bottom part) may be sufficient.

If it is an application with many connections it will be necessary to

use the controller module plus one or more extension modules.

This section will give you a survey of possible connections plus

assistance in selecting the modules required by your actual

application.

AK-PC 783A Capacity controller RS8HN102 © Danfoss 2017-11 7

Page 8

Module survey

• Controller module – capable of handling minor plant requirements.

• Extension modules. When the complexity becomes greater

and additional inputs or outputs are required, modules can be

attached to the controller. A plug on the side of the module will

transmit the supply voltage and data communication between

the modules.

• Top part

The upper part of the controller module contains the intelligence. This is the unit where the regulation is defined and where

data communication is connected to other controllers in a bigger network.

• Connection types

There are various types of inputs and outputs. One type may, for

example, receive signals from sensors and switches, another may

receive a voltage signal, and a third type may be outputs with

relays etc. The individual types are shown in the table below.

Extension module with

additional analog inputs

• Optional connection

When a regulation is planned (set up) it will generate a need for

a number of connections distributed on the mentioned types.

This connection must then be made on either the controller

module or an extension module. The only thing to be observed

is that the types must not be mixed (an analog input signal must

for instance not be connected to a digital input).

• Programming of connections

The controller must know where you connect the individual

input and output signals. This takes place in a later configuration where each individual connection is defined based on the

following principle:

- to which module

- at which point (”terminals”)

- what is connected (e.g. pressure transmitter/type/

pressure range)

Extension module with additional

relay outputs and additional

analog inputs.

External display for

suction pressure etc.

Bottom part

Controller with analog inputs and

relay outputs.

Top part

Extension module with

2x analog output signals

The module with additional relay outputs is

also available in a version where the top part

is provided with change-over switches so

that the relays can be overridden.

If the row of modules needs to

be interrupted due to length or

external positioning, a communication module should be used.

8 Capacity controller RS8HN102 © Danfoss 2017-11 AK-PC 783A

Page 9

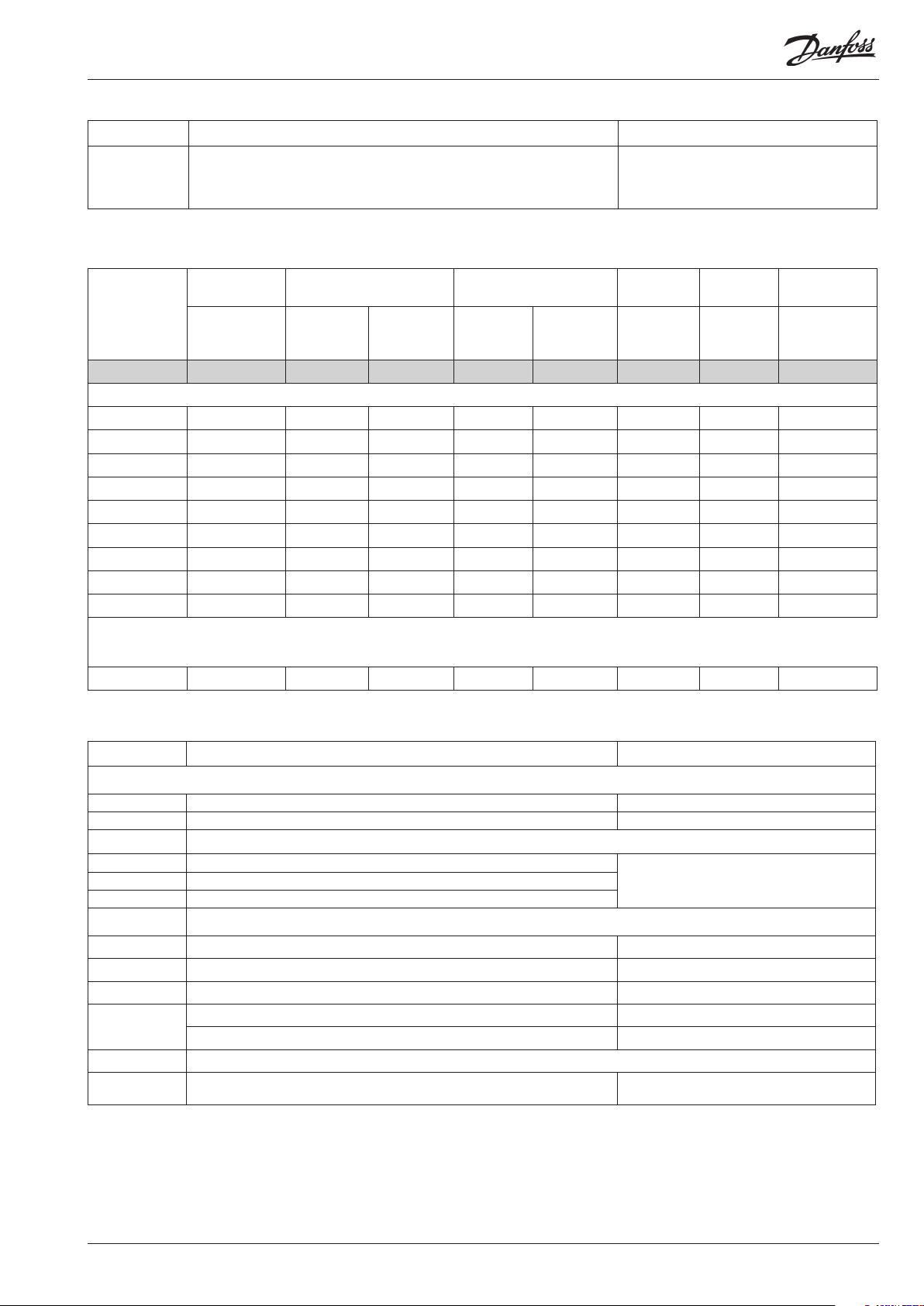

1. Controller

Type Function Application

AK-PC 783A

Controller for capacity control of compressors and condensers

12 compressors with up to 3 unloaders, 8 fans, max. 160 inputs/outputs

Compressor MT and LT/ Condenser MT/Cascade.

Oil management / Heat recovery.

2. Extension modules and survey of inputs and outputs

Type Analog

inputs

For sensors, pressure transmitters

etc.

Controller 11 4 4 - - - -

Extension modules

AK-XM 101A 8

AK-XM 102A 8

AK-XM 102B 8

AK-XM 103A 4 4

AK-XM 204A 8

AK-XM 204B 8 x

AK-XM 205A 8 8

AK-XM 205B 8 8 x

AK-XM 208C 8 4

On/Off outputs On/off supply voltage

Relay

(SPDT)

Solid state Low voltage

(DI signal)

(max. 80 V)

High voltage

(max. 260 V)

Analog

outputs

0-10 V d.c. For valves

Stepper

output

with step

control

Module with

switches

For override of

relay outputs

The following extension module can be placed on the PC board in the controller module.

There is only room for one module.

AK-OB 110 2

3. AK operation and accessories

Type Function Application

Operation

AK-ST 500 Software for operation of AK controllers AK-operation

- Cable between PC and AK controller USB-A — USB-B (standard IT cable)

Accessories Power supply module 230 V / 115 V to 24 V d.c.

AK-PS 075 18 VA

Supply for controllerAK-PS 150 36 VA

AK-PS 250 60 VA

Accessories External display that can be connected to the controller module. For showing, say, the suction pressure

EKA 163B Display

EKA 164B Display with operation buttons

MMIGRS2 Graphic display with operation buttons

-

Accessories Communication modules for controllers where modules cannot be connected continuously

AK-CM 102 Communication module

Cable between EKA display and controller Length = 2 m, 6 m

Cable between graphic display and controller Length = 1.5 m, 3.0 m

Data communication for external extension

modules

On the following pages there is data specific to each module.

AK-PC 783A Capacity controller RS8HN102 © Danfoss 2017-11 9

Page 10

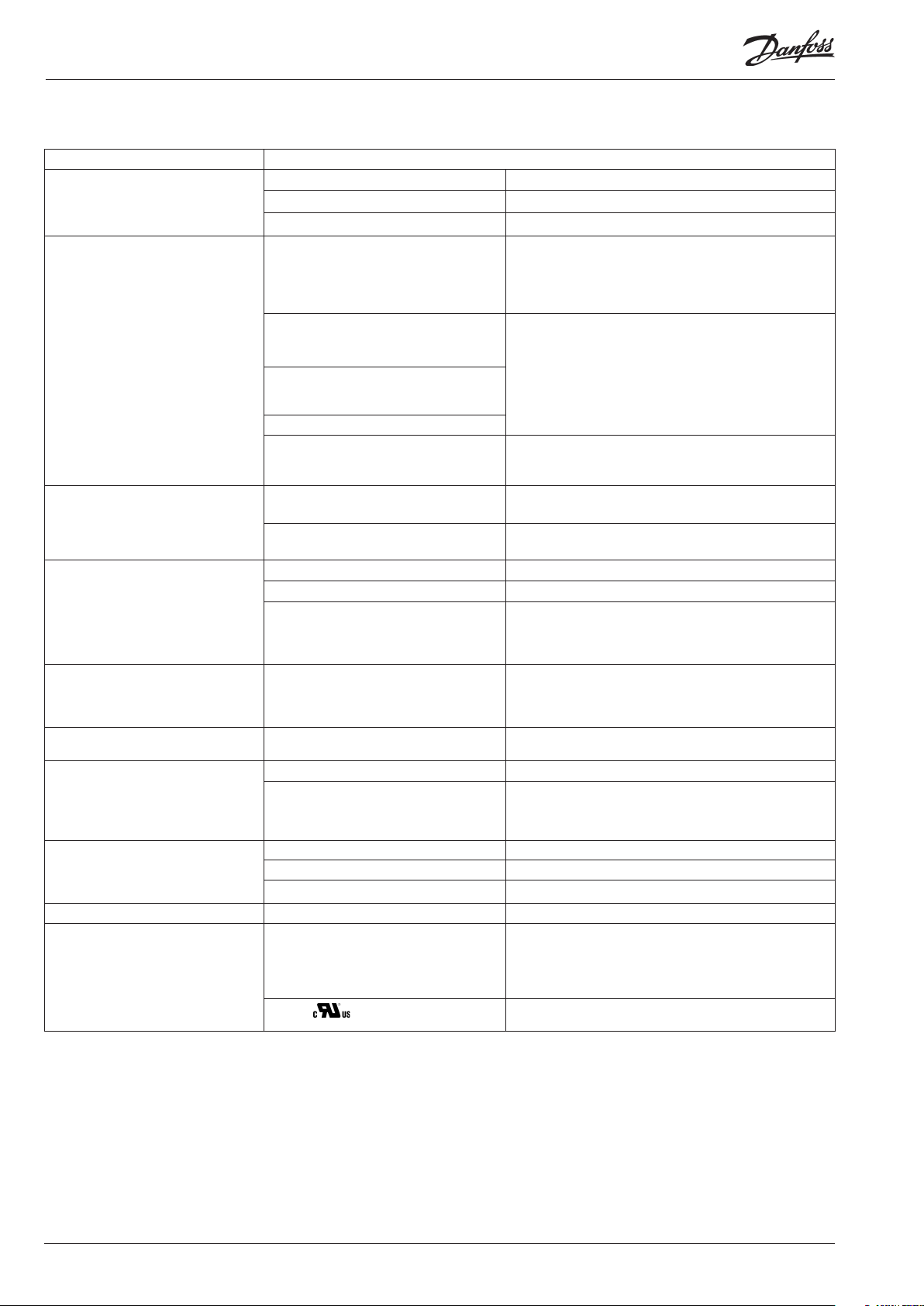

Common data for modules

Supply voltage 24 V d.c./a.c. +/- 20%

Power consumption AK-__ (controller) 8 VA

AK-XM 101, 102, 103, 107, AK-CM 102 2 VA

AK-XM 204, 205, 208 5 VA

Analog inputs Pt 1000 ohm /0°C Resolution: 0.1°C

Pressure transmitter type AKS 32R / AKS

2050

AKS 32 (1-5 V)

Other pressure transmitter:

Ratiometric signal

Min. and Max. pressure must be set

Voltage signal 0-10 V

Contact function (On/Off ) On at R < 20 ohm

On/off supply voltage inputs Low voltage

Relay outputs

SPDT

Solid state outputs Can be used for loads that are cut in and

Stepper outputs Used for valves with stepper input 20-500 step/s

Ambient temperature During transport -40 to 70°C

0 / 80 V a.c./d.c.

High voltage

0 / 260 V a.c.

AC-1 (ohmic) 4 A

AC-15 (inductive) 3 A

U Min. 24 V

out frequently, e.g. :

Oil valves, fans and AKV valves

During operation -20 to 55°C ,

Accuracy: +/- 0.5°C

+/- 0,5°C between -50°C and +50°C

+/- 1°C between -100°C and -50°C

+/- 1°C between +50°C and +130°C

Resolution:1 mV

Accuracy +/- 10 mV

Max. connection of 5 pressure transmitters on one module

Off at R > 2K ohm

(Gold -plated contacts not necessary)

Off: U < 2 V

On: U > 10 V

Off: U < 24 V

On: U > 80 V

Max. 230 V

Low and high voltage must not be connected to the same

output group

Max. 240 V a.c. , Min. 48 V a.c.

Max. 0,5 A,

Leak < 1 mA

Max. 1 AKV

Separate supply to stepper outputs : 24 d.c.

0 to 95% RH (non condensing)

No shock influences / vibrations

Enclosure Material PC / ABS

Density IP10 , VBG 4

Mounting For mounting on panel wall or DIN rail

Weight with screw terminals Modules in 100- / 200- / controller-series Ca. 200 g / 500 g / 600 g

Approvals EU low voltage directive and EMC require-

ments are complied with

UL 873,

The mentioned data applies to all modules.

If data is specific, this is mentioned together with the module in question.

LVD tested according to EN 60730

EMC tested

Immunity according to EN 61000-6-2

Emission according to EN 61000-6-3

UL file number: E166834 for XM and CM-modules

UL file number: E31024 for PC-modules

10 Capacity controller RS8HN102 © Danfoss 2017-11 AK-PC 783A

Page 11

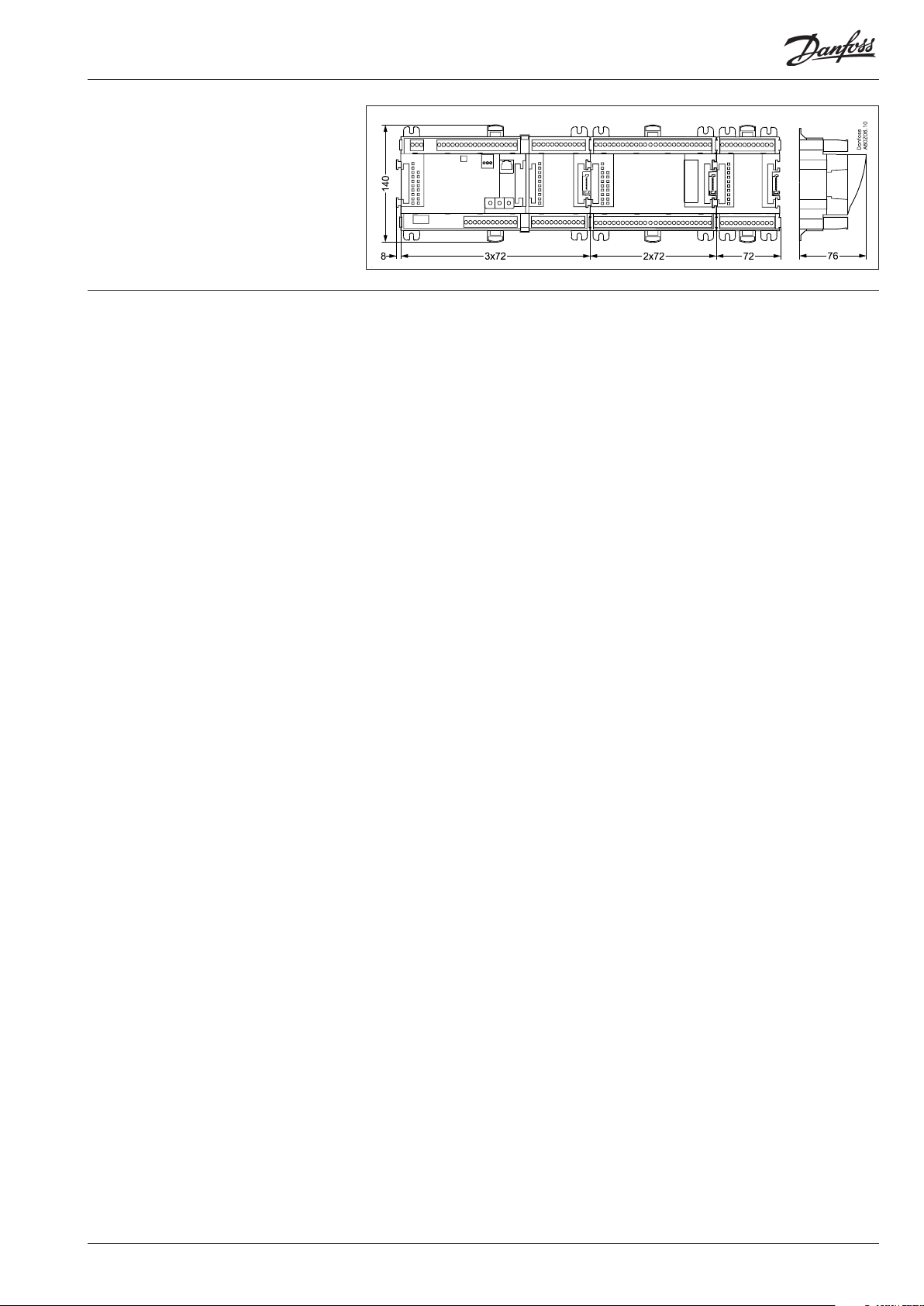

Dimensions

The module dimension is 72 mm.

Modules in the 100-series consist of one

module

Modules in the 200-series consist of two

modules

Controllers consist of three modules

The length of an aggregate unit = n x 72 + 8

AK-PC 783A Capacity controller RS8HN102 © Danfoss 2017-11 11

Page 12

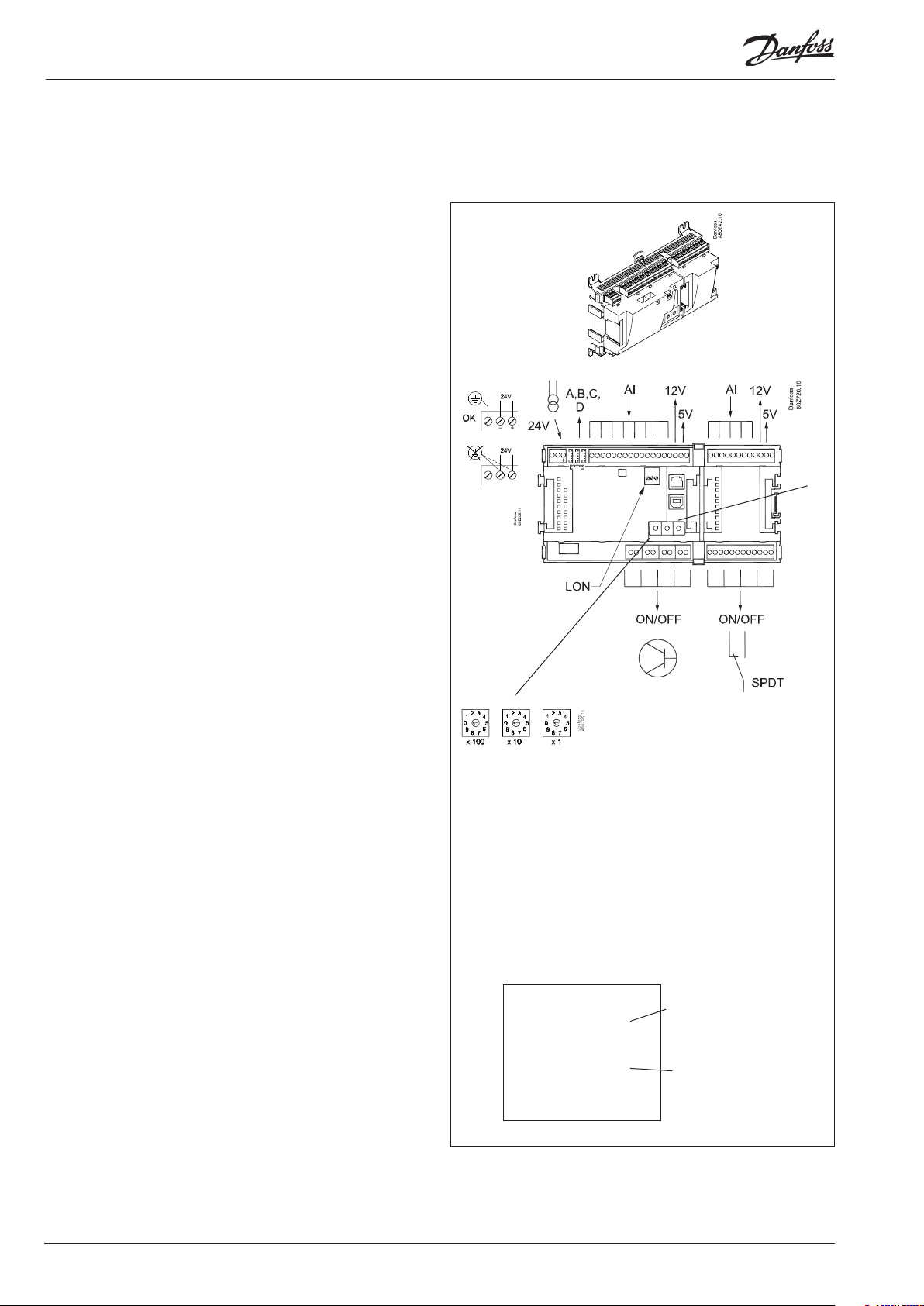

Controller

Function

There are several controllers in the series. The function is determined by the programmed software, but outwardly the controllers are identical – they all have the same connection possibilities:

11 analog inputs for sensors, pressure transmitters, voltage signals

and contact signals.

8 digital outputs, with 4 Solid state outputs and 4 relay outputs

Supply voltage

24 V a.c. or d.c. to be connected to the controller.

The 24 V must not be retransmitted and used by other controllers as it is not galvanically separated from inputs and outputs. In

other words, you must use a transformer for each controller. Class

II is required. The terminals must not be earthed.

The supply voltage to any extension modules is transmitted via

the plug on the right-hand side.

The size of the transformer is determined by the power requirement of the total number of modules.

The supply voltage to a pressure transmitter can be taken either

from the 5 V output or from the 12 V output depending on transmitter type.

PIN

Data communication

If the controller is to be included in a system, communication

must take place via the LON connection.

The installation has to be made as mentioned in the separate

instructions for LON communication.

Address setting

When the controller is connected to a gateway type AKA 245,

the controller’s address must be set between 1 and 119. (If it is a

system manager AK-SM .., then 1-999).

Service PIN

When the controller is connected to the data communication

cable the gateway must have knowledge of the new controller.

This is obtained by pushing the key PIN. The LED “Status” will flash

when the gateway sends an acceptance message.

Operation

The configuration operation of the controller must take place

from the software program “Service Tool”. The program must be

installed on a PC, and the PC must be connected to the controller

via the network plug on the front of the unit.

Light-emitting diodes

There are two rows with LED’s. They mean:

Left row:

• Voltage supply to the controller

• Communication active with the bottom PC board (red = error)

• Status of outputs DO1 to DO8

Right row:

• Software status (slow flash = OK)

• Communication with Service Tool

• Communication on LON

• Communication with AK-CM 102

• Alarm when LED flashes

- 1 LED that is not used

• Communication with display on RJ11 plug

• “Service Pin” switch has been activated

Address

■ Power

■ Comm

■ DO1 ■ Status

■ DO2 ■ Service Tool

■ DO3 ■ LON

■ DO4 ■ I/O Extension

■ DO5 ■ Alarm

■ DO6

■ DO7 ■ Display

■ DO8 ■ Service Pin

Slow flash = OK

Quick flash = answer from gateway

Constantly ON = error

Constantly OFF = error

Flash = active alarm/not cancelled

Constant ON = Active alarm/cancelled

Keep the safety

distance!

Low and high

voltage must not

be connected to

the same output

group

A small module (option board) can be placed on the bottom part

of the controller. The module is described later in the document.

12 Capacity controller RS8HN102 © Danfoss 2017-11 AK-PC 783A

Page 13

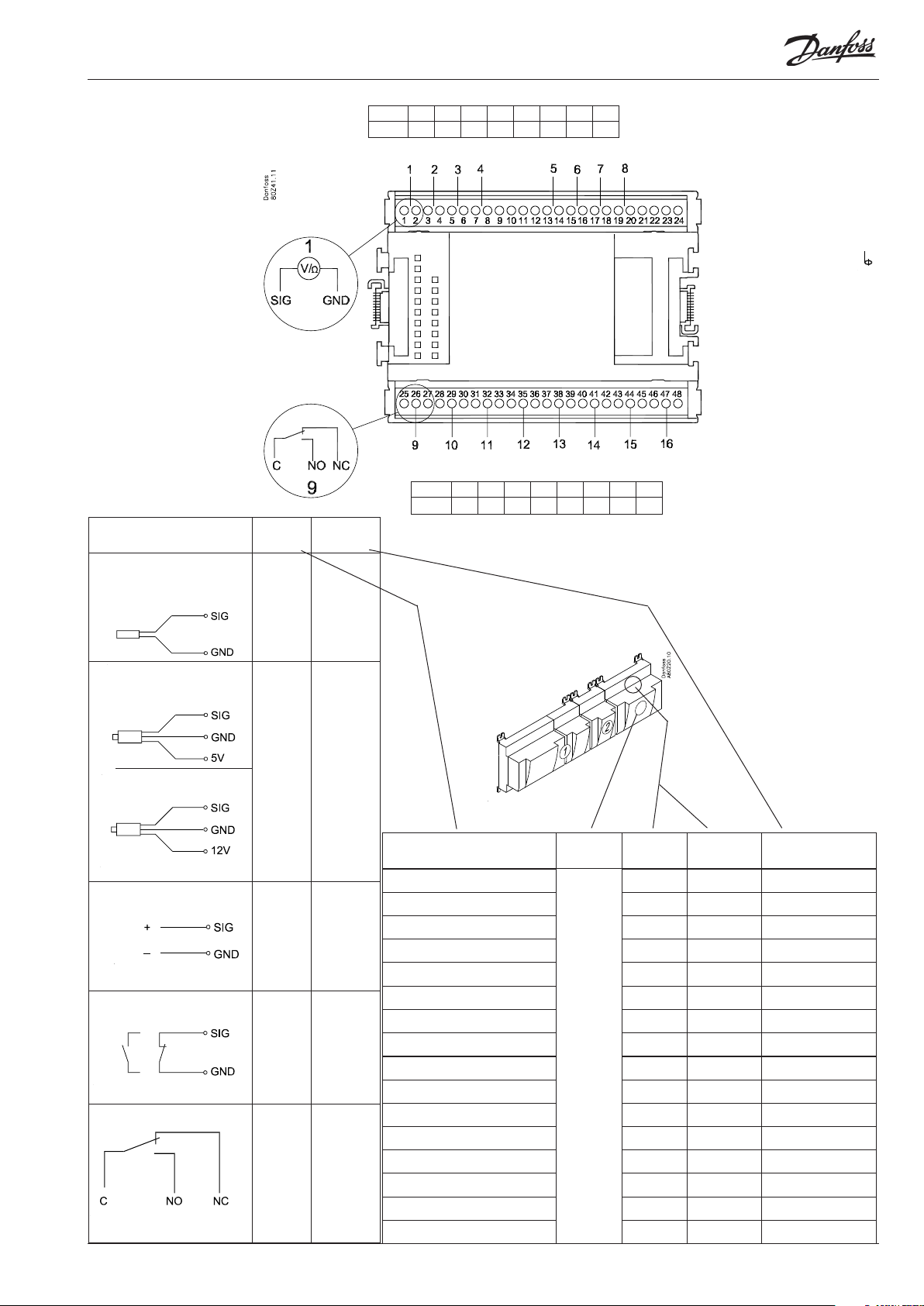

Point

Point 1 2 3 4 5 6 7 8 9 10 11

Type AI1 AI2 AI3 AI4 AI5 AI6 AI7 AI8 AI9 AI10 AI11

Terminal 15: 12 V

Terminal 16: 5 V

Terminal 27: 12 V

Terminal 28: 5 V

Analog

inputs

on 1 - 11

Solid state outputs

on 12 - 15

Relay or AKV coil

fx 230 V a.c.

Signal Signal

S

Pt 1000 ohm/0°C

S2

Saux_

SsLT

SdMT

Shr

Stw

Scasc

P

AKS 32R

3: Brown

2: Blue

1: Black

P0LT

P0MT

Pc LT

AKS 32

3: Brown

2: Black

1: Red

PcMT

Paux

U

...

On/Off Ext.

Main

switch

Day/

Night

Door

Level

switch

DO

AKV

AKV

PWM

Comp 1

Comp 2

Fan 1

Alarm

Light

Solenoid

valve

Option Board

Please see the signal

on the page with the

module.

24 and 25 used

only when "Option board fitted"

type

Pt 1000

AKS 32R /

AKS 2050 /

MBS 8250

-1 - xx bar

AKS 32

-1 - zz bar

0 - 5 V

0 - 10 V

Active at:

Closed

/

Open

Active at:

On

/

Off

Point 12 13 14 15 16 17 18 19

Type DO1 DO2 DO3 DO4 DO5 DO6 DO7 DO8

Signal Module Point

1 (AI 1) 1 - 2

2 (AI 2) 3 - 4

3 (AI 3) 5 - 6

4 (AI 4) 7 - 8

5 (AI 5) 9 - 10

6 (AI 6) 11 - 12

7 (AI 7) 13 - 14

8 (AI 8) 19 - 20

9 (AI 9) 21 - 22

10 (AI 10) 23 - 24

11 (AI 11) 25 - 26

1

12 (DO 1) 31 - 32

13 (DO 2) 33 - 34

14 (DO 3) 35 - 36

15 (DO 4) 37 - 38

16 (DO 5) 39 - 40- 41

17 (DO6) 42 - 43 - 44

18 (DO7) 45 - 46 - 47

19 (DO8) 48 - 49 - 50

24 -

25 -

Terminal

17, 18, 29, 30:

(Cable screen)

Relay outputs on

16 - 19

Terminal

Signal type /

Active at

AK-PC 783A Capacity controller RS8HN102 © Danfoss 2017-11 13

Page 14

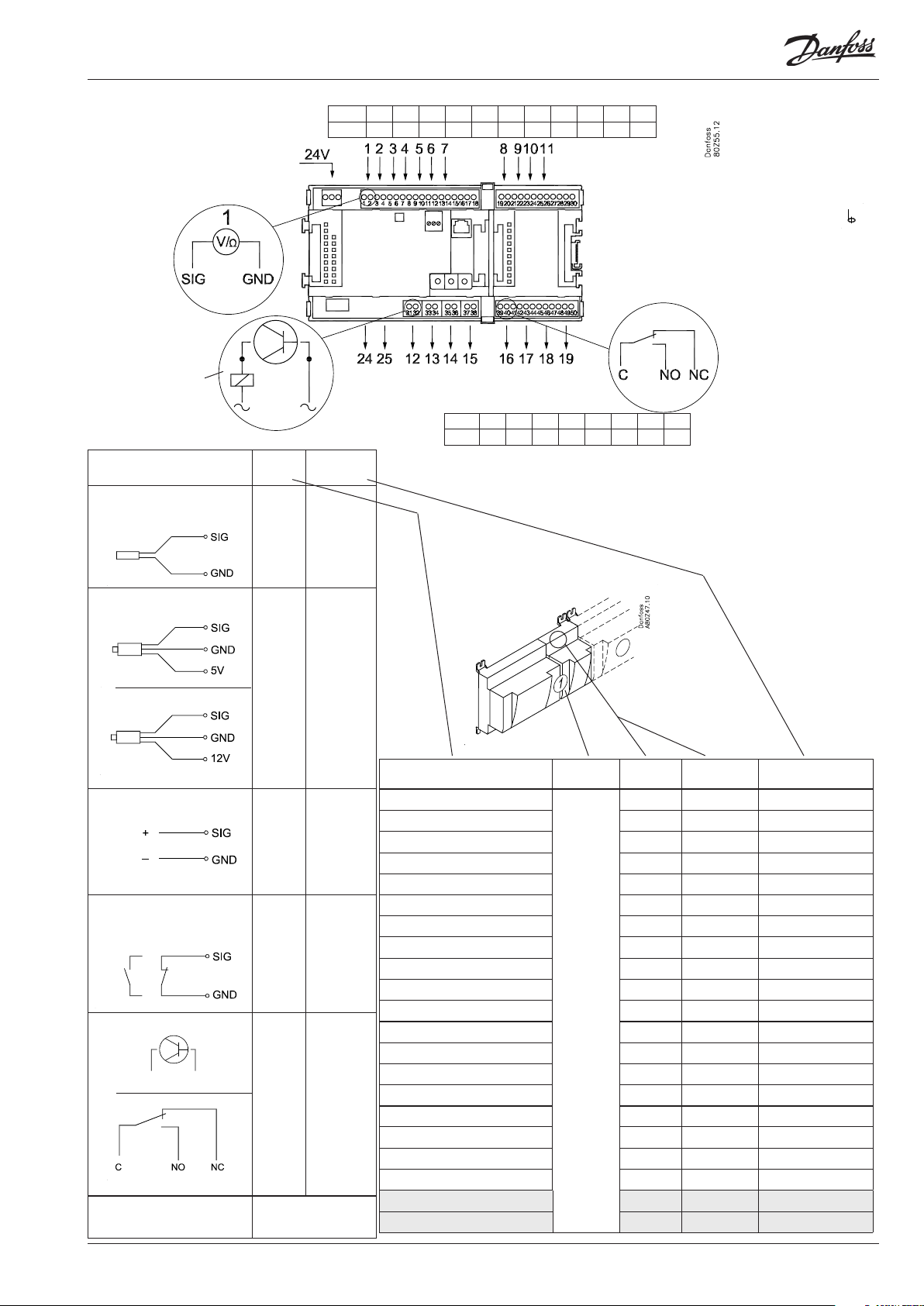

Extension module AK-XM 101A

Function

The module contains 8 analog inputs for sensors, pressure transmitters, voltage signals and contact signals.

Supply voltage

The supply voltage to the module comes from the previous module in the row.

Supply voltage to a pressure transmitter can be taken from either

the 5 V output or the 12 V output depending on transmitter type.

Light-emitting diodes

Only the two top LED’s are used. They indicate the following:

• Voltage supply to the module

• Communication with the controller is active (red = error)

14 Capacity controller RS8HN102 © Danfoss 2017-11 AK-PC 783A

Page 15

Point

Point 1 2 3 4

Type AI1 AI2 AI3 AI4

Terminal 9: 12 V

Terminal 10: 5 V

S

Pt 1000 ohm/0°C

P

AKS 32R

AKS 32

At the top the

signal input is

the left of the

two terminals.

At the bottom

the signal input

is the right of the

two terminals.

3: Brown

2: Blue

1: Black

3: Brown

2: Black

1: Red

Signal Signal

type

S2

Saux

SsLT

Pt 1000

SdMT

Shr

Stw

Sscac

AKS 32R /

P0LT

P0MT

Pc LT

PcMT

Paux

AKS 2050 /

MBS 8250

-1 - xx bar

AKS 32

-1 - zz bar

Terminal 15: 5 V

Terminal 16: 12 V

Terminal

11, 12, 13, 14:

(Cable screen)

Point 5 6 7 8

Type AI5 AI6 AI7 AI8

U

On/Off

...

Ext.

Main

switch

Day/

Night

Door

Level

switch

0 - 5 V

0 - 10 V

Active at:

Closed

/

Open

Signal Module Point

1 (AI 1) 1 - 2

2 (AI 2) 3 - 4

3 (AI 3) 5 - 6

4 (AI 4) 7 - 8

5 (AI 5) 17 - 18

6 (AI 6) 19 - 20

7 (AI 7) 21 - 22

8 (AI 8) 23 - 24

Terminal

Signal type /

Active at

AK-PC 783A Capacity controller RS8HN102 © Danfoss 2017-11 15

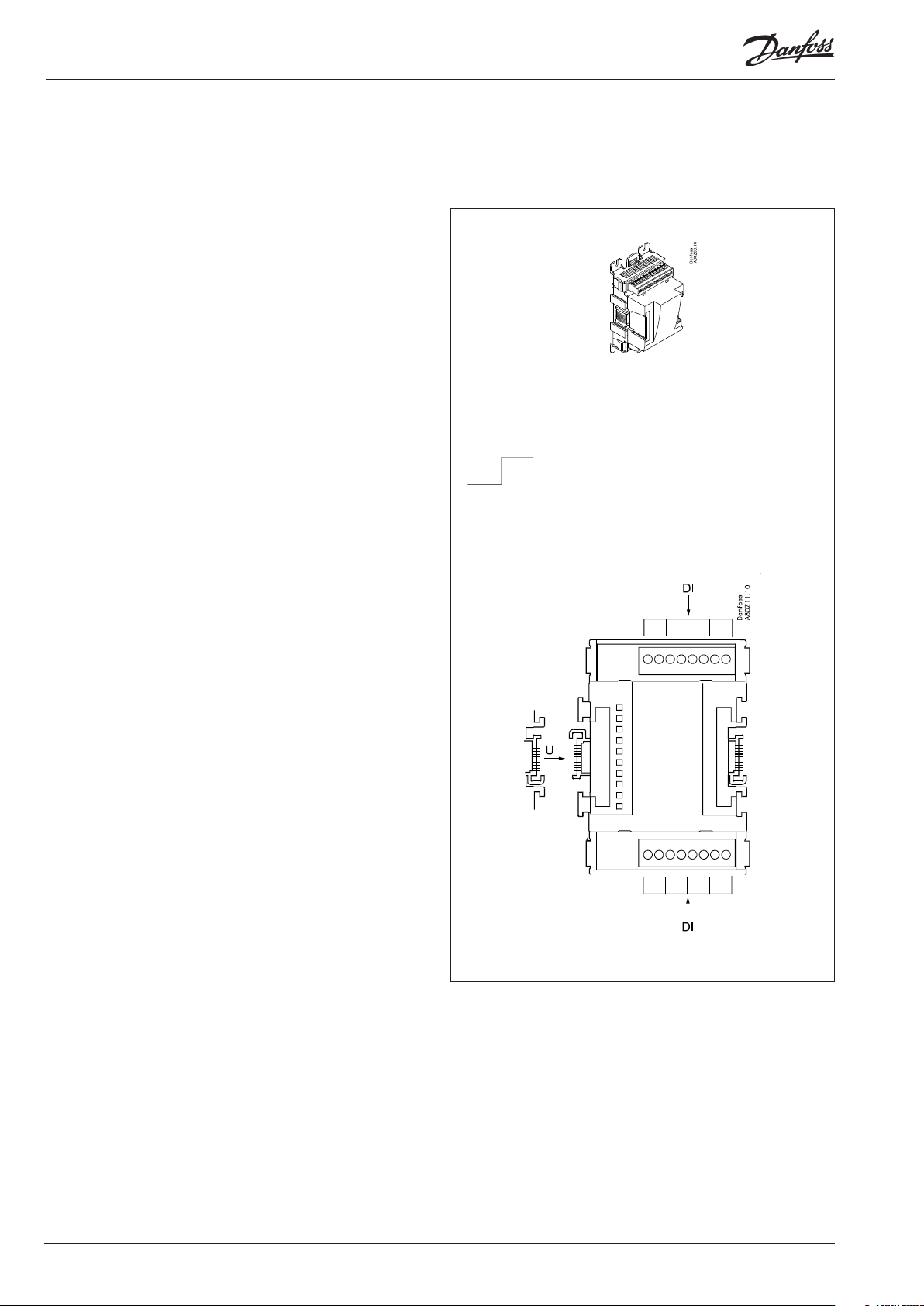

Page 16

Extension module AK-XM 102A / AK-XM 102B

Function

The module contains 8 inputs for on/off voltage signals.

Signal

AK-XM 102A is for low voltage signals.

AK-XM 102B is for high voltage signals.

Supply voltage

The supply voltage to the module comes from the previous

module in the row.

Light-emitting diodes

They indicate:

• Voltage supply to the module

• Communication with the controller is active (red = error)

• Status of the individual inputs 1 to 8 (when lit = voltage)

AK-XM 102A

Max. 24 V

On/Off:

On: DI > 10 V a.c.

Off: DI < 2 V a.c.

AK-XM 102B

Max. 230 V

On/Off:

On: DI > 80 V a.c.

Off: DI < 24 V a.c.

16 Capacity controller RS8HN102 © Danfoss 2017-11 AK-PC 783A

Page 17

Point

DI

AK-XM 102A: Max. 24 V

AK-XM 102B: Max. 230 V

Signal Active at

Ext.

Main

switch

Day/

Night

Comp.

safety 1

Comp.

safety 2

Level

switch

Closed

(voltage on)

/

Open

(voltage off)

Point 1 2 3 4

Type DI1 DI2 DI3 DI4

Point 5 6 7 8

Type DI5 DI6 DI7 DI8

(The module can not register a pulse signal from

e.g. a reset function.)

Signal Module Point Terminal Active at

1 (DI 1) 1 - 2

2 (DI 2) 3 - 4

3 (DI 3) 5 - 6

4 (DI 4) 7 - 8

5 (DI 5) 9 - 10

6 (DI 6) 11 - 12

7 (DI 7) 13 - 14

8 (DI 8) 15 - 16

AK-PC 783A Capacity controller RS8HN102 © Danfoss 2017-11 17

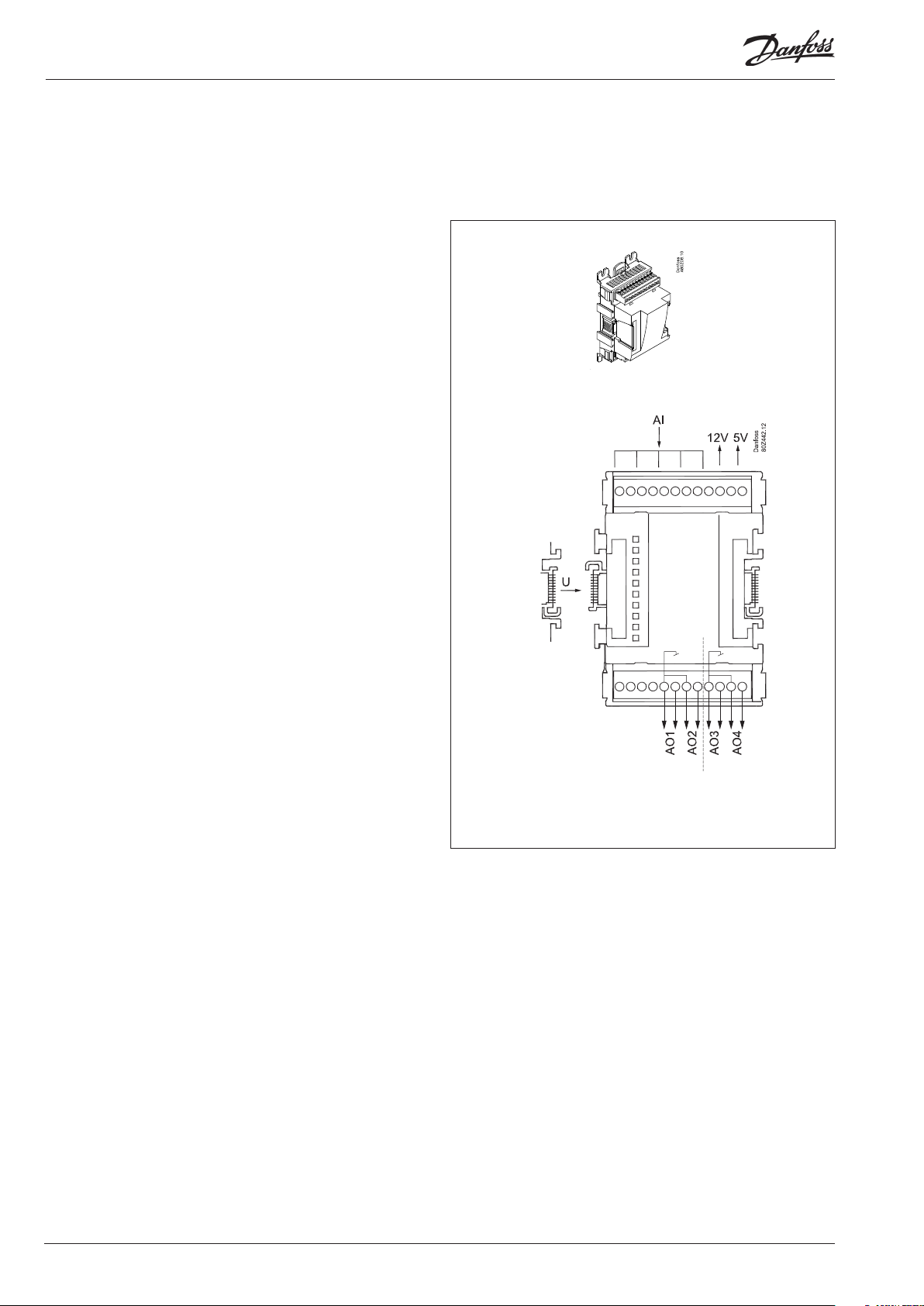

Page 18

Extension module AK-XM 103A

Function

The module contains :

4 analog inputs for sensors, pressure transmitters, voltage signals

and contact signals.

4 analog voltage outputs of 0 - 10 V

Supply voltage

The supply voltage to the module comes from the previous

module in the row.

Supply voltage to a pressure transmitter can be taken from either

the 5 V output or the 12 V output depending on transmitter type.

Galvanic isolation

The inputs are galvanically separated from the outlets.

The outlets AO1 and AO2 are galvanically separated from AO3 and

AO4.

Light-emitting diodes

Only the two top LED’s are used. They indicate the following:

• Voltage supply to the module

• Communication with the controller is active (red = error)

Max. load

I < 2.5 mA

R > 4 kΩ

18 Capacity controller RS8HN102 © Danfoss 2017-11 AK-PC 783A

Page 19

Point

Point 1 2 3 4

Type AI1 AI2 AI3 AI4

Terminal 9: 12 V

Terminal 10: 5 V

S

Pt 1000 ohm/0°C

P

AKS 32R

AKS 32

At the top the

signal input is

the left of the

two terminals.

At the bottom

the signal input

is the right of the

two terminals.

3: Brown

2: Blue

1: Black

3: Brown

2: Black

1: Red

Signal Signal

type

S2

Saux

Ss

Pt 1000

Sd

Shr

Stw

Scasc

AKS 32R /

P0LT

P0MT

Pc LT

PcMT

Paux

AKS 2050 /

MBS 8250

-1 - xx bar

AKS 32

-1 - zz bar

Terminal

11, 12:

(Cable screen)

Galvanic isolation:

AI 1-4 ≠ AO 1-2 ≠ AO 3-4

Point 5 6 7 8

Type AO1 AO2 AO3 AO4

U

...

On/Off Ext.

Main

switch

Day/

Night

Door

Level

switch

AO

0 - 5 V

0 - 10 V

Active at:

Closed

/

Open

0-10 V

Signal Module Point Terminal Signal type /Active at

1 (AI 1) 1 - 2

2 (AI 2) 3 - 4

3 (AI 3) 5 - 6

4 (AI 4) 7 - 8

5 (AO 1) 17 - 18

6 (AO 2) 19 - 20

7 (AO 3) 21 - 22

8 (AO 4) 23 - 24

AK-PC 783A Capacity controller RS8HN102 © Danfoss 2017-11 19

Page 20

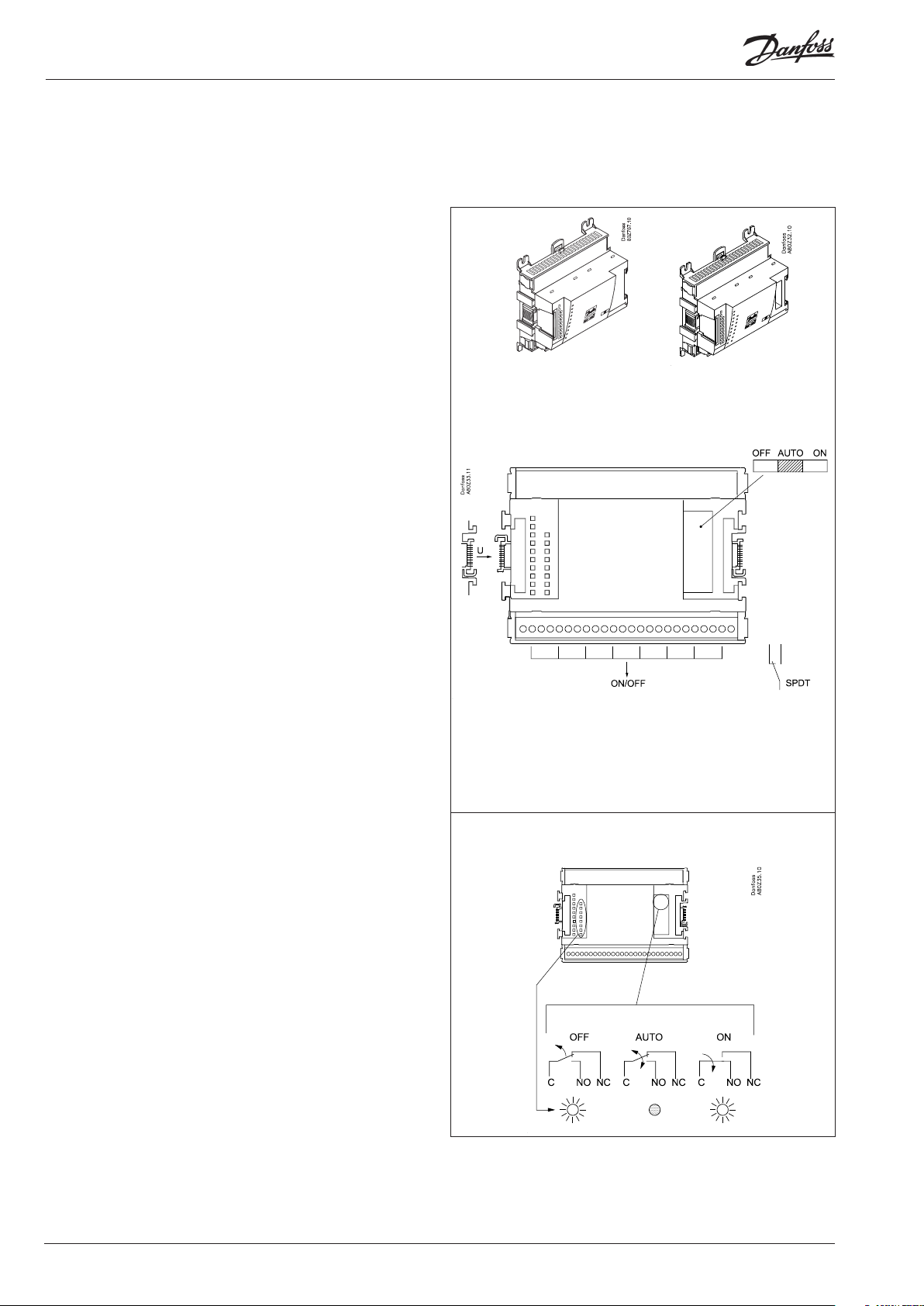

Extension module AK-XM 204A / AK-XM 204B

Function

The module contains 8 relay outputs.

Supply voltage

The supply voltage to the module comes from the previous module in the row.

AK-XM 204B only

Override of relay

Eight change-over switches at the front make it possible to override the relay’s function.

Either to position OFF or ON.

In position Auto the controller carries out the control.

Light-emitting diodes

There are two rows with LED’s. They mean:

Left row:

• Voltage supply to the controller

• Communication active with the bottom PC board (red = error)

• Status of outputs DO1 to DO8

Right row: (AK-XM 204B only):

• Override of relays

ON = override

OFF = no override

Fuses

Behind the upper part there is a fuse for each output.

AK-XM 204A AK-XM 204B

Max. 230 V

AC-1: max. 4 A (ohmic)

AC-15: max. 3 A (Inductive)

Keep the safety distance!

Low and high voltage

must not be connected to

the same output group

AK-XM 204B

Override of relay

Note

If the changeovers are used to override the compressor operation,

it is necessary to wire a safety relay into the circuit for oil management. Without this safety relay, the controller will fail to stop the

compressor if it should run out of oil. See Regulating functions.

20 Capacity controller RS8HN102 © Danfoss 2017-11 AK-PC 783A

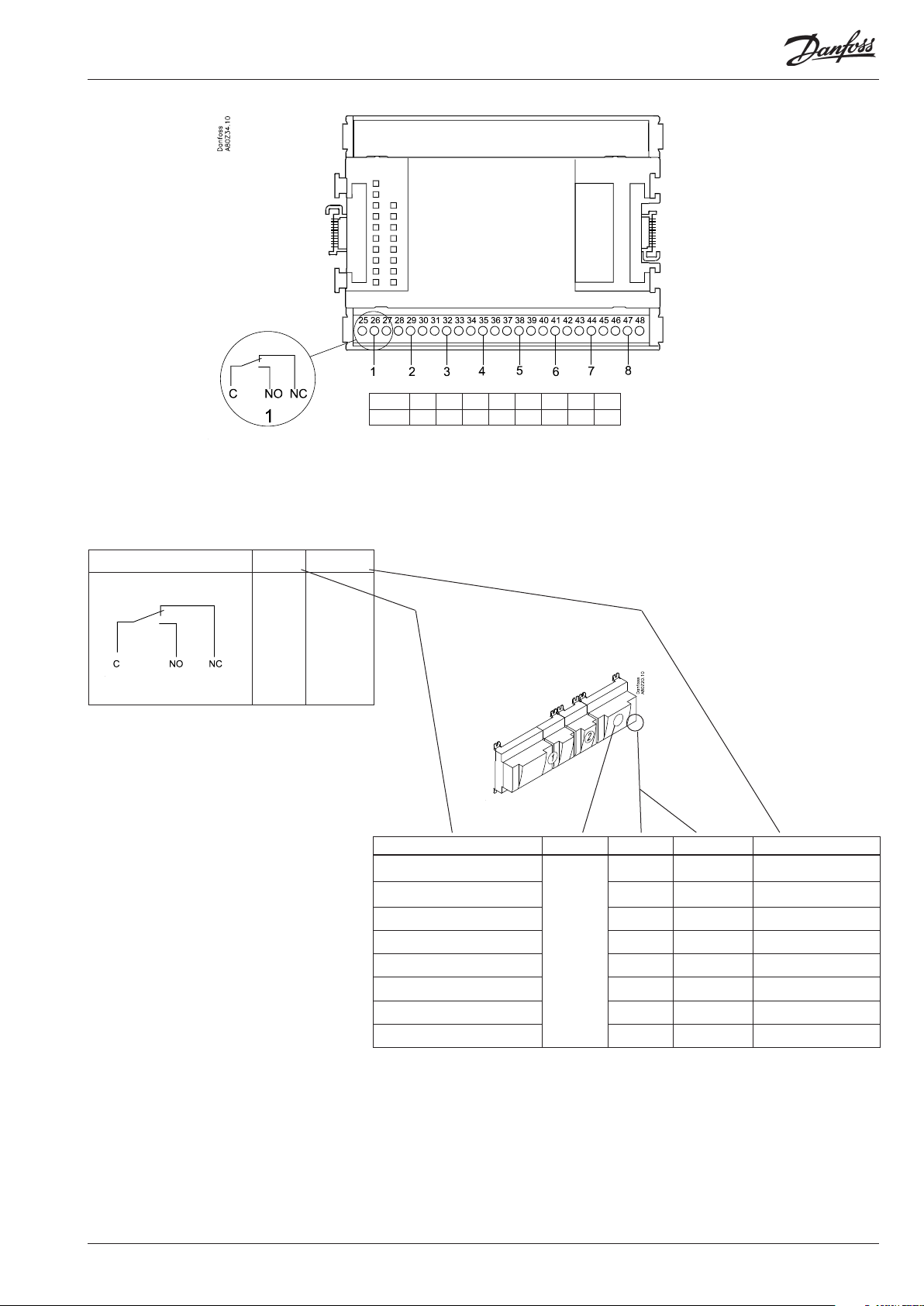

Page 21

Point

DO

Signal Active at

Comp. 1

Comp. 2

Fan 1

Alarm

Solenoid

valve

On

/

Off

Point 1 2 3 4 5 6 7 8

Type DO1 DO2 DO3 DO4 DO5 DO6 DO7 DO8

Signal Module Point Terminal Active at

1 (DO 1) 25 - 27

2 (DO 2) 28 - 30

3 (DO 3) 31 - 33

4 (DO 4) 34 -36

5 (DO 5) 37 - 39

6 (DO 6) 40 - 41 - 42

7 (DO 7) 43 - 44 - 45

8 (DO 8) 46 - 47 - 48

AK-PC 783A Capacity controller RS8HN102 © Danfoss 2017-11 21

Page 22

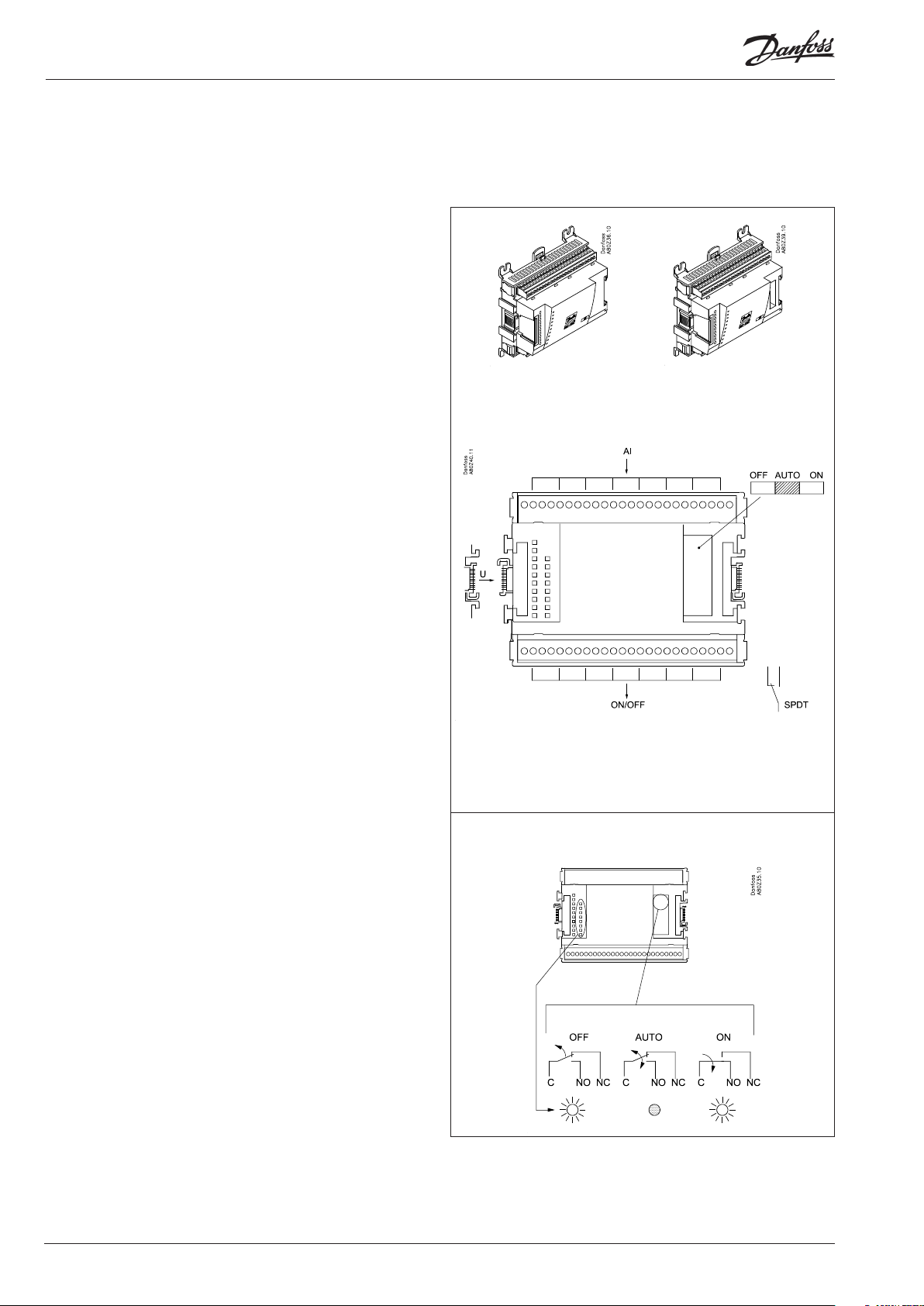

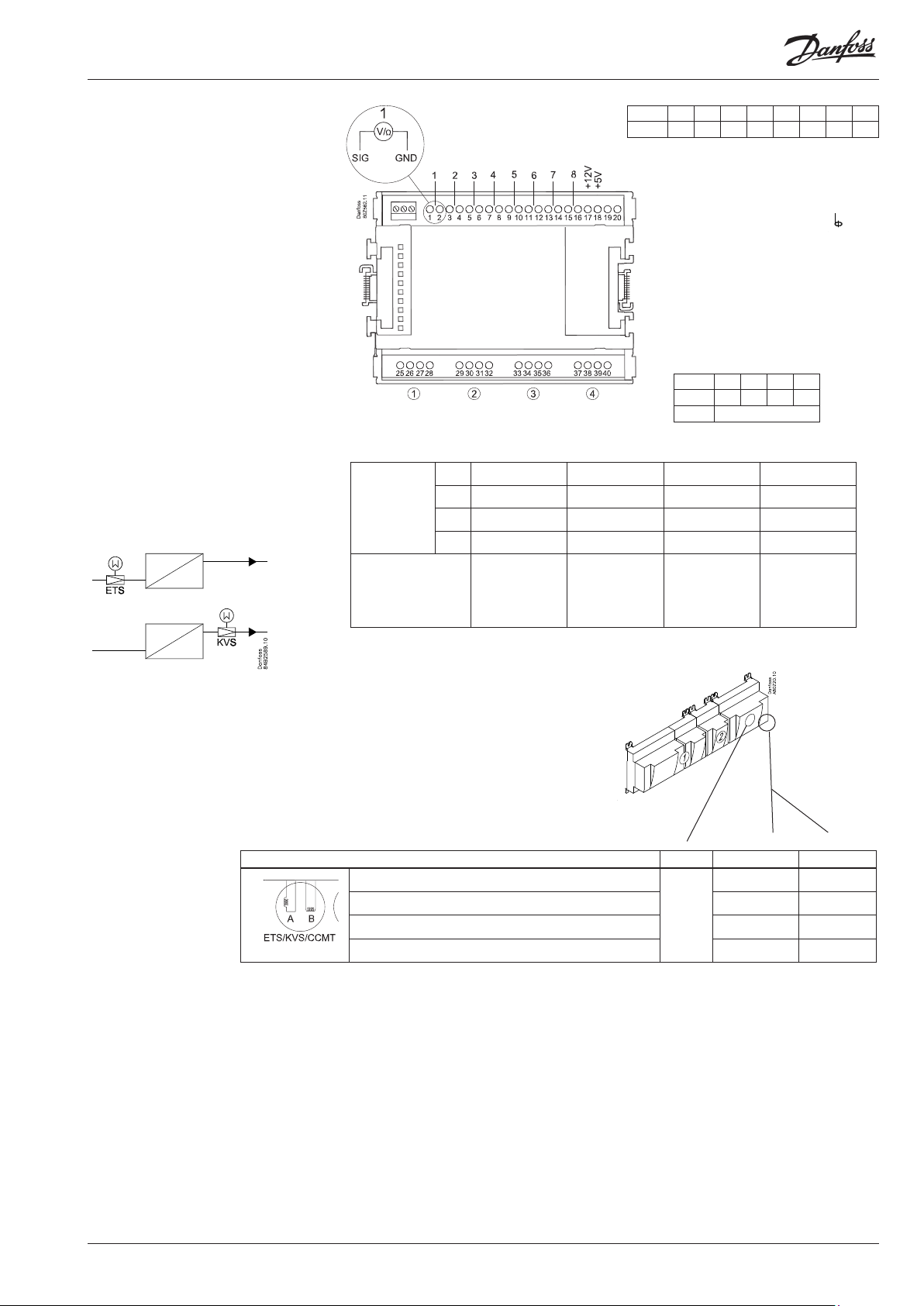

Extension module AK-XM 205A / AK-XM 205B

Function

The module contains:

8 analog inputs for sensors, pressure transmitters, voltage signals

and contact signals.

8 relay outputs.

Supply voltage

The supply voltage to the module comes from the previous module in the row.

AK-XM 205B only

Override of relay

Eight change-over switches at the front make it possible to override the relay’s function.

Either to position OFF or ON.

In position Auto the controller carries out the control.

Light-emitting diodes

There are two rows with LED’s. They mean:

Left row:

• Voltage supply to the controller

• Communication active with the bottom PC board (red = error)

• Status of outputs DO1 to DO8

Right row: (AK-XM 205B only):

• Override of relays

ON = override

OFF = no override

AK-XM 205A AK-XM 205B

max. 10 V

Fuses

Behind the upper part there is a fuse for each output.

Note

If the changeovers are used to override the compressor operation,

it is necessary to wire a safety relay into the circuit for oil management. Without this safety relay, the controller will fail to stop the

compressor if it should run out of oil. See Regulating functions.

Max. 230 V

AC-1: max. 4 A (ohmic)

AC-15: max. 3 A (Inductive)

AK-XM 205B

Override of relay

Keep the safety distance!

Low and high voltage

must not be connected to

the same output group

22 Capacity controller RS8HN102 © Danfoss 2017-11 AK-PC 783A

Page 23

Point

S

Pt 1000 ohm/0°C

P

AKS 32R

AKS 32

U

On/Off

DO

3: Brown

2: Blue

1: Black

3: Brown

2: Black

1: Red

Signal Signal

type

S2

Saux

Ss

Pt 1000

Sd

Shr

Stw

Scasc

AKS 32R /

P0MT

P0LT

PcMT

Pc LT

Paux

Prec

AKS 2050 /

MBS 8250

-1 - xx bar

AKS 32

-1 - zz bar

0 - 5 V

...

Ext. Main

switch

Day/

Night

Door

0 - 10 V

Active at:

Closed

Open

Level

switch

Active at:

Comp 1

Comp 2

on

Fan 1

Alarm

Light

Off

Solenoid

valve

Point 1 2 3 4 5 6 7 8

Type AI1 AI2 AI3 AI4 AI5 AI6 AI7 AI8

Point 9 10 11 12 13 14 15 16

Type DO1 DO2 DO3 DO4 DO5 DO6 DO7 DO8

Signal Module Point

/

/

Terminal 9: 12 V

Terminal 10: 5 V

Terminal 21: 12 V

Terminal 22: 5 V

Terminal 11, 12, 23, 24 :

(Cable screen)

Terminal

1 (AI 1) 1 - 2

2 (AI 2) 3 - 4

3 (AI 3) 5 - 6

4 (AI 4) 7 - 8

5 (AI 5) 13 - 14

6 (AI 6) 15 - 16

7 (AI 7) 17 - 18

8 (AI 8) 19 -20

9 (DO 1) 25 - 26 - 27

10 (DO 2) 28 - 29 - 30

11 (DO 3) 31 - 30 - 33

12 (DO 4) 34 - 35 - 36

13 (DO 5) 37 - 36 - 39

14 (DO6) 40 - 41 - 42

15 (DO7) 43 - 44 - 45

16 (DO8) 46 - 47 - 48

Signal type /

Active at

AK-PC 783A Capacity controller RS8HN102 © Danfoss 2017-11 23

Page 24

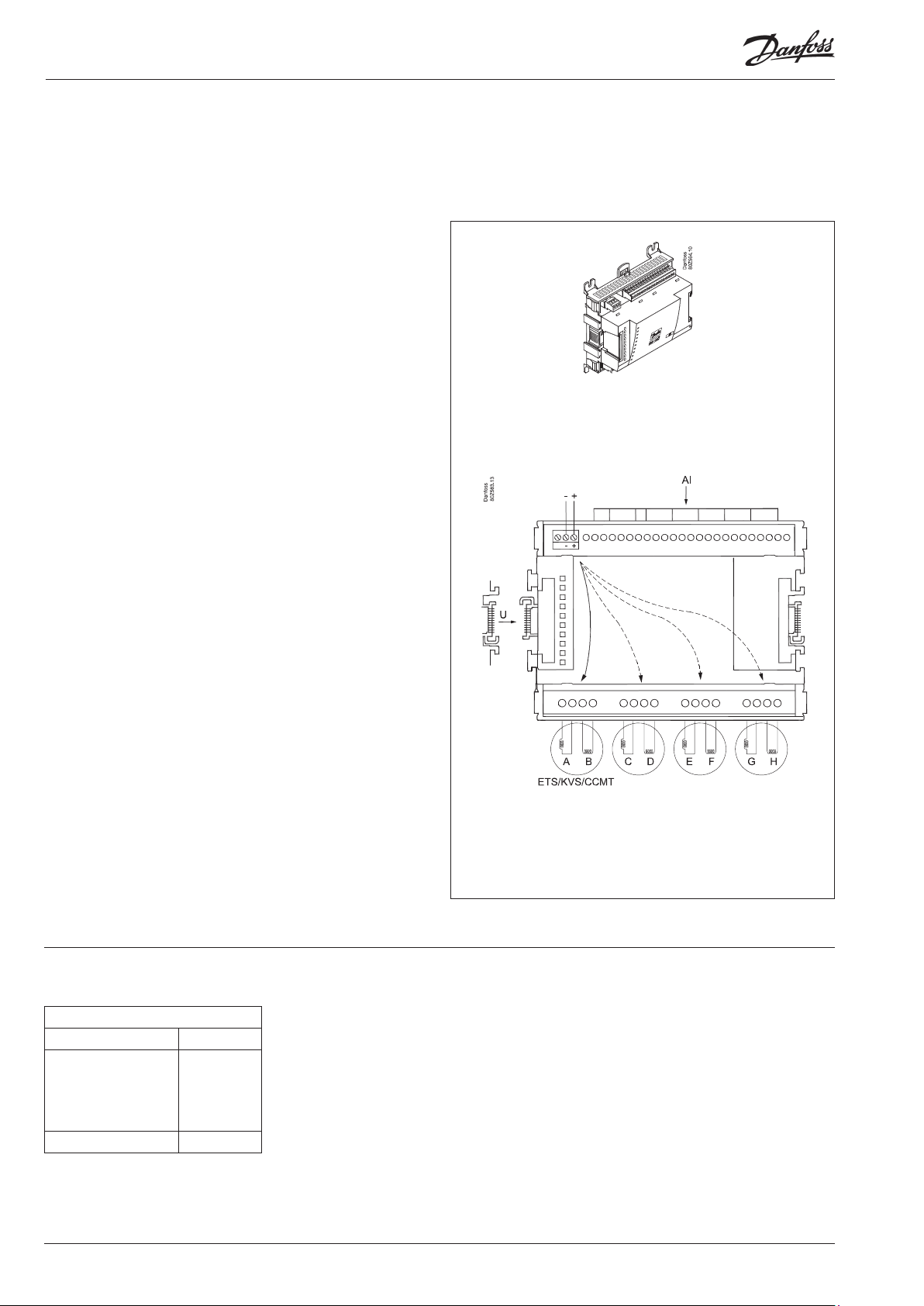

Extension module AK-XM 208C

Function

The module contains:

8 analog inputs for sensors, pressure transmitters, voltage signals

and contact signals.

4 outputs for stepper motors.

Supply voltage

The supply voltage to the module comes from the previous module in the row. Here supplied with 5 VA.

The supply voltage to the valves must be from a separate supply,

which must be galvanically separated from the supply for the

control range.

(Power requirements: 7.8 VA for controller + xx VA per valve).

A UPS may be necessary if the valves need to open/close during a

power failure.

Light-emitting diodes

There is one row with LED’s. It indicate the following:

• Voltage supply to the module

• Communication active with the bottom PC board (red = error)

• Step1 to step4 OPEN: Green = Open

• Step1 to step4 CLOSE: Green = Close

• Red flash = Error on motor or connection

Separate voltage supply is

required

24 V a.c./d.c. / fx. 13 VA

max. 10 V

Valve data

Type P

ETS 12.5 - ETS 400

KVS 15 - KVS 42

CCMT 2 - CCMT 8

CCM 10 - CCM 40

CTR 20

CCMT 16 - CCMT 42 5.1 VA

1.3 VA

Output:

24 V d.c.

20-500 step/s

Max phase current = 800 mA RMS

∑ P

= max. 21 VA

out

Power supply to AK-XM 208C:

Fx: 7.8 + (4 x 1.3) = 13 VA AK-PS 075

Fx: 7.8 + (4 x 5.1) = 28.2 VA AK-PS 150

24 Capacity controller RS8HN102 © Danfoss 2017-11 AK-PC 783A

Page 25

Point

CCMT

Step /

Terminal

ETS

CCM / CCMT

CTR

KVS

Point 1 2 3 4 5 6 7 8

Type AI1 AI2 AI3 AI4 AI5 AI6 AI7 AI8

Terminal 17: 12 V

Terminal 18: 5 V

Terminal 19, 20:

(Cable screen)

Point 9 10 11 12

Step 1 2 3 4

Type AO

1 25 26 27 28

2 29 30 31 32

3 33 34 35 36

4 37 38 39 40

White Black Red Green

Valve Module Step Terminal

1 (point 9) 25 - 28

2 (point 10) 29 - 32

3 (point 11) 33 - 36

4 (point 12) 37 - 40

AK-PC 783A Capacity controller RS8HN102 © Danfoss 2017-11 25

Page 26

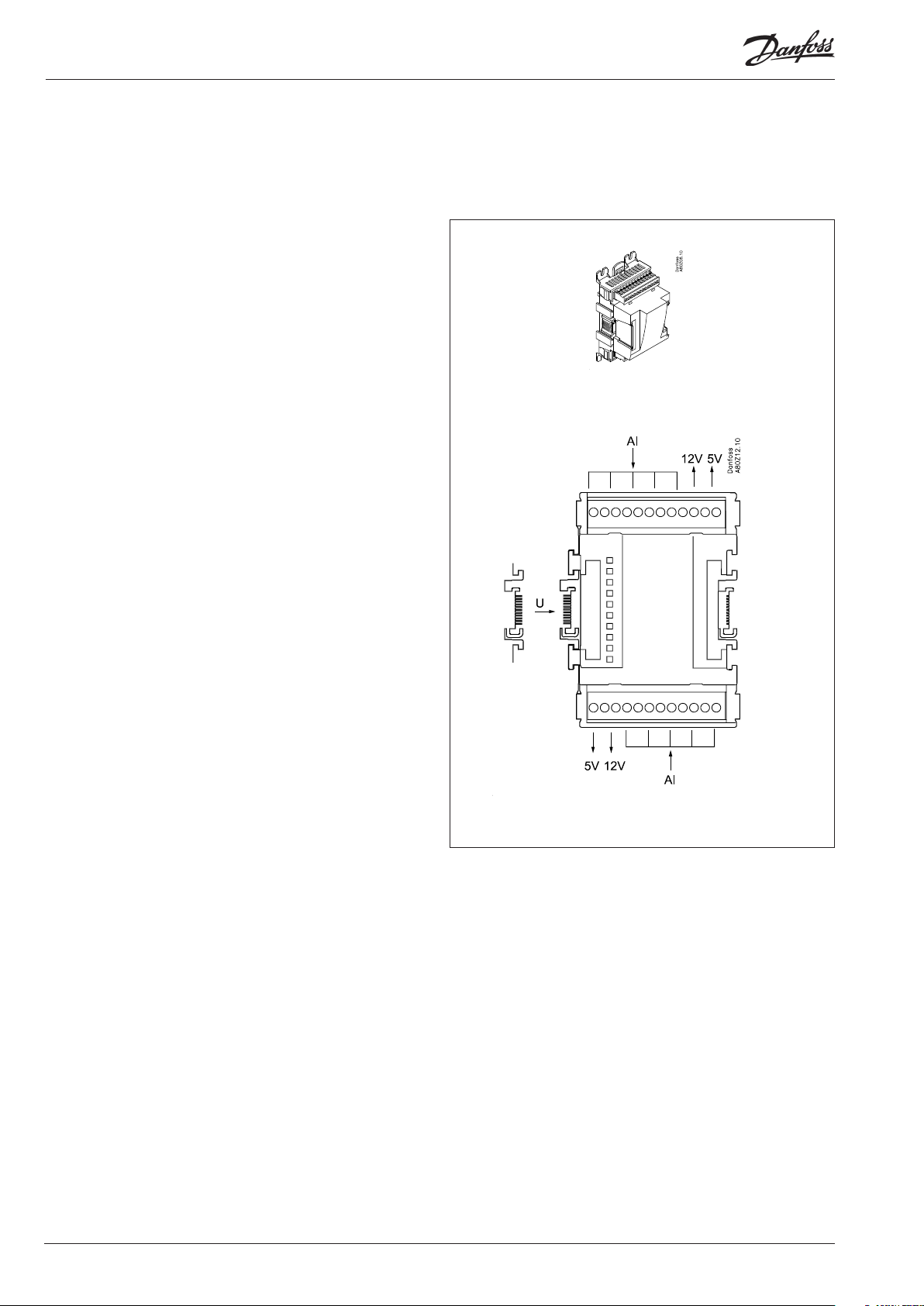

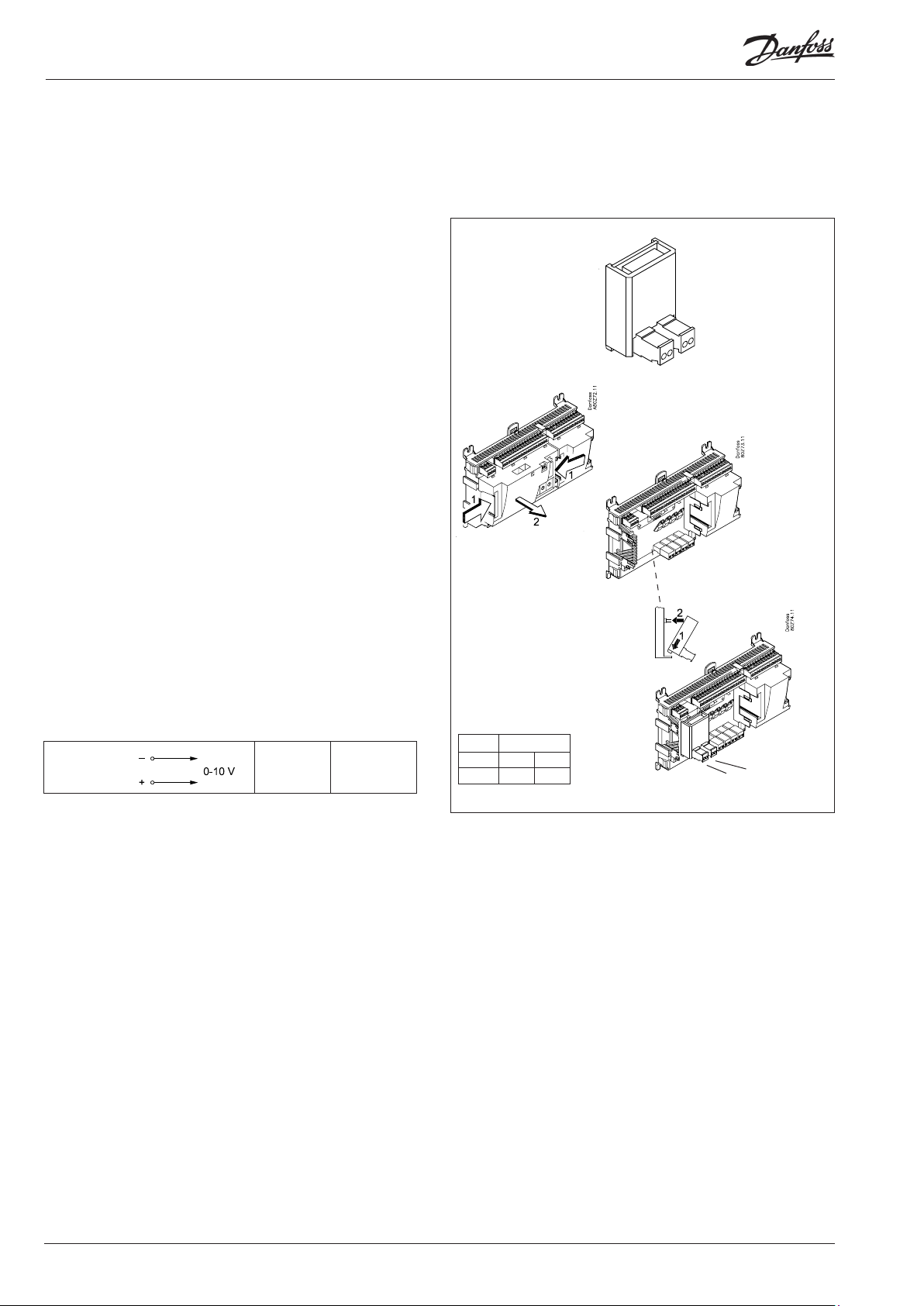

Extension module AK-OB 110

Function

The module contains two analog voltage outputs of 0 – 10 V.

Supply voltage

The supply voltage to the module comes from the controller

module.

Placing

The module is placed on the PC board in the controller module.

Point

The two outputs have points 24 and 25. They are shown on the

earlier page where the controller is also mentioned.

Max. load

I < 2.5 mA

R > 4 kohm

AO

AO 0 - 10 V

Module

Point 24 25

Type AO1 AO2

1

AO2

AO1

26 Capacity controller RS8HN102 © Danfoss 2017-11 AK-PC 783A

Page 27

Extension module EKA 163B / EKA 164B

Function

Display of important measurements from the controller, e.g. ap-

pliance temperature, suction pressure or condensing pressure.

Setting of the individual functions can be performed by using the

display with control buttons.

It is the controller used that determines the measurements and

settings that can occur.

Connection

The extension module is connected to the controller module via

a cable with plug connections. You have to use one cable per

module. The cable is supplied in various lengths.

Both types of display (with or without control buttons) can be

connected to either display output A, B, C and D.

Ex.

A: P0. Suction pressure in °C.

B: Pc. Condensing pressure in °C.

When the controller starts up, the display will show the output

that is connected.

- - 1 = output A

- - 2 = output B

etc.

EKA 163B EKA 164B

Placing

The extension module can be placed at a distance of up to 15 m

from the controller module.

Point

No point has to be defined for a display module – you simply connect it.

Graphic display MMIGRS2

Function

Setting and display of values in the controller.

Connection

The display connects to the controller via a cable with RJ11 plug

connections.

Supply voltage

Received from the controller via cable and RJ11 connector.

Termination

The display must be terminated. Mount a connection between the

terminals H and R.

(AK-PC 783A is terminated internally.)

Placing

The display can be placed at a distance of up to 3 m from the

controller.

Point / Address

No point has to be defined for a display – you simply connect it.

However, the address must be verified. See the instructions accompanying the controller.

AK-PC 783A Capacity controller RS8HN102 © Danfoss 2017-11 27

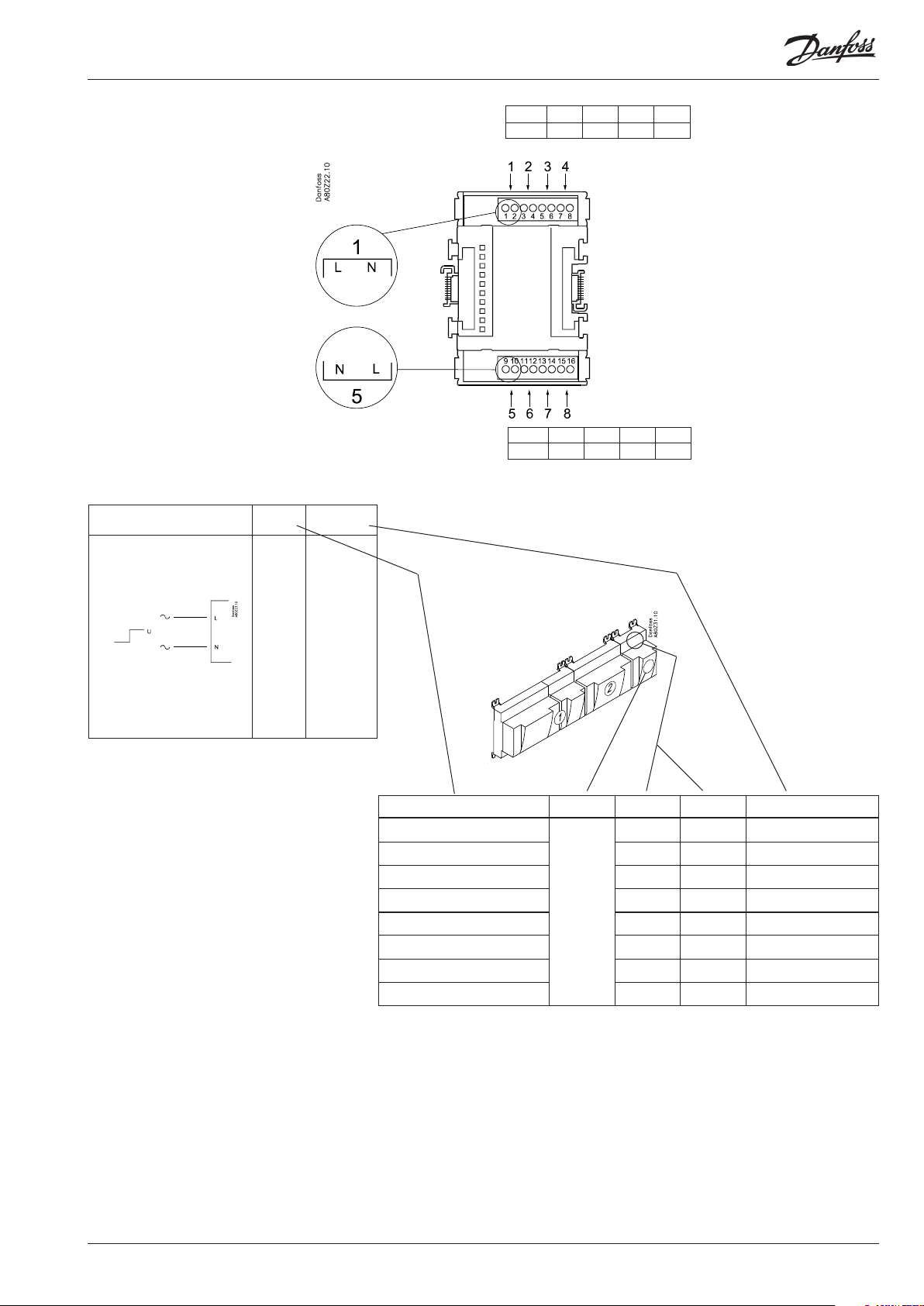

Page 28

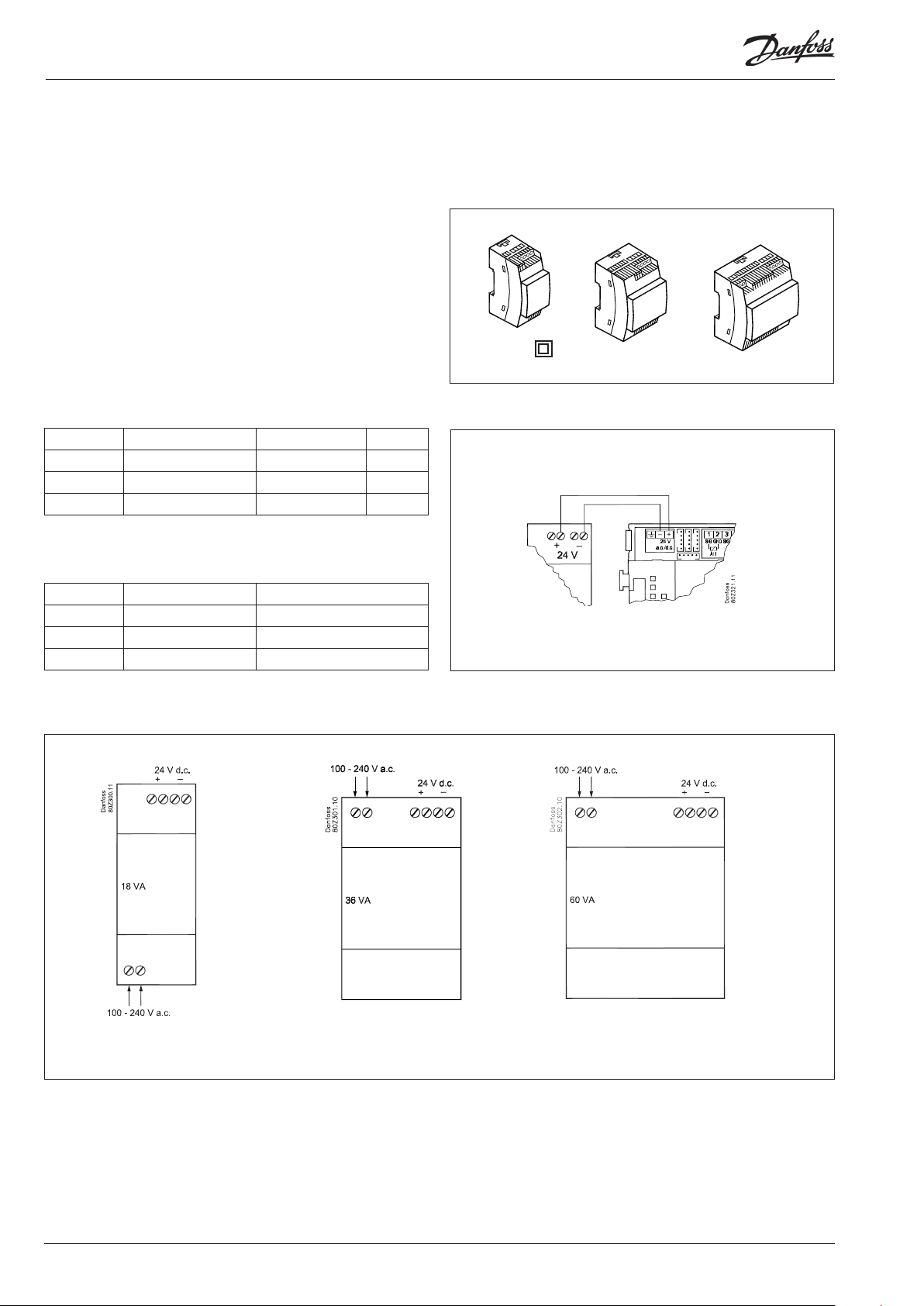

Power supply module AK-PS 075 / 150 / 250

Function

24 V supply for controller.

Supply voltage

230 V a.c or 115 V a.c. (from 100 V a.c. to 240 V a.c.)

Placing

On DIN-rail

Effect

Type Output tension Output current Power

AK-PS 075 24 V d.c. 0.75 A 18 VA

AK-PS 150 24 V d.c. (adjustable) 1.5 A 36 VA

AK-PS 250 24 V d.c. (adjustable) 2.5 A 60 VA

Dimension

Type High Width

AK-PS 075 90 mm 36 mm

AK-PS 150 90 mm 54 mm

AK-PS 250 90 mm 72 mm

Connections

Class II

Supply to a controller

AK-PS 075

AK-PS 150

AK-PS 250

28 Capacity controller RS8HN102 © Danfoss 2017-11 AK-PC 783A

Page 29

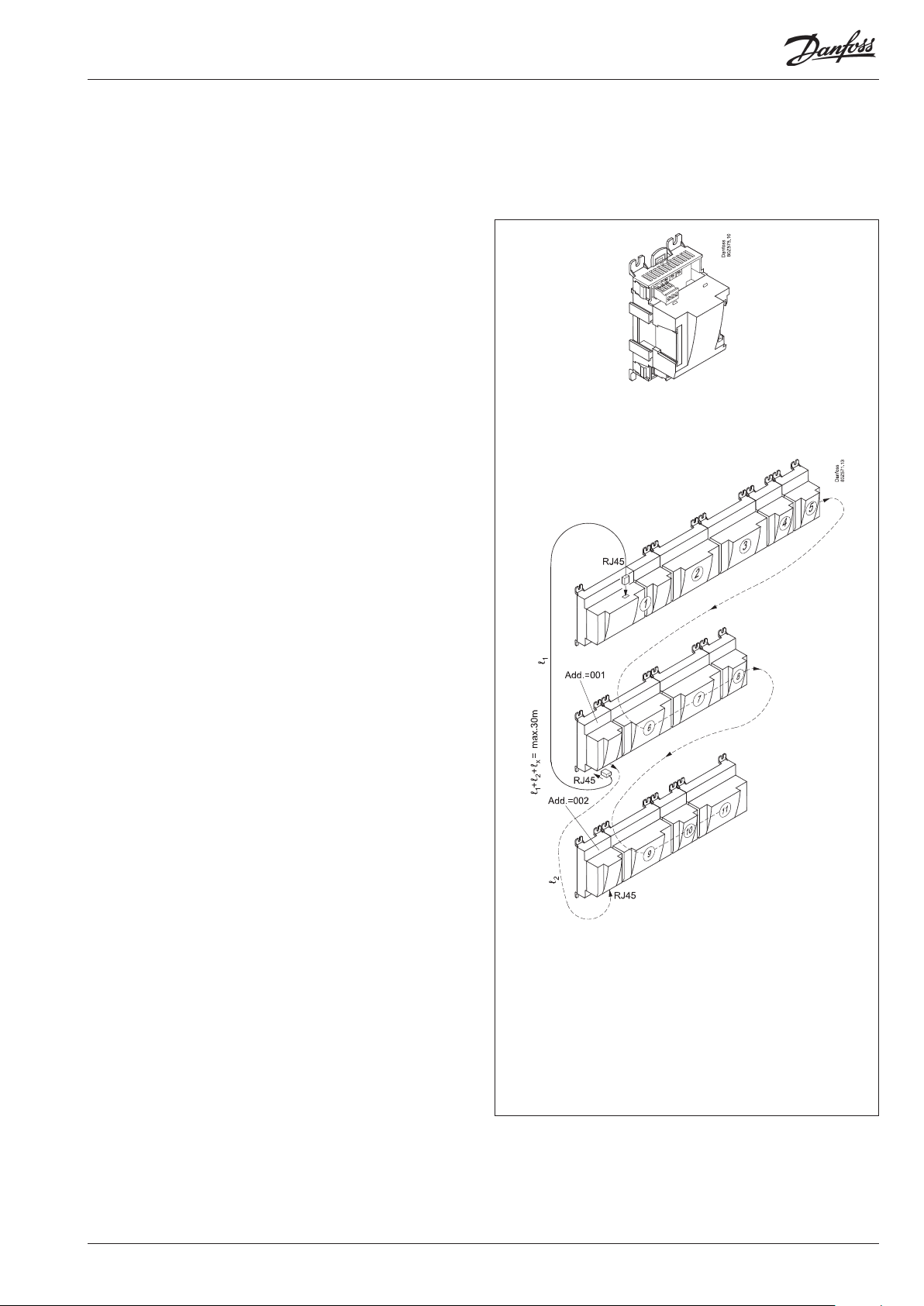

Communication module AK-CM 102

Function

The module is a new communication module, meaning the row of

extension modules can be interrupted.

The module communicates with the regulator via data communication and forwards information between the controller and the

connected extension modules.

Connection

Communication module and controller fitted with RJ 45 plug connectors.

Nothing else should be connected to this data communication; a

maximum of 5 communication modules can be connected to one

controller.

Communication cable

One metre of the following is enclosed:

ANSI/TIA 568 B/C CAT5 UTP cable w/ RJ45 connectors.

Positioning

Max. 30 m from the controller

(The total length of the communication cables is 30 m)

Max. 32 VA

Supply voltage

24 volt AC or DC should be connected to the communication

module.

The 24 V can be sourced from the same supply that supplies the

controller. (The supply for the communication module is galvanically separated from the connected extension modules).

The terminals must not be earthed.

The power consumption is determined by the power consumption of the total number of modules.

The controller strand load must not exceed 32 VA.

Each AK-CM 102 strand load must not exceed 20 VA.

Point

Connection points on the I/O modules should be defined as if the

modules were an extension of each other.

Address

The address for the first communication module should be set to

1. Any second module should be set to 2. A maximum of 5 modules can be addressed.

Termination

The termination switch on the final communication module

should be set to ON.

The controller should permanently be set to = ON.

Warning

Additional modules may only be installed following the installation of the final module. (Here following module no. 11; see the

sketch.)

After configuration, the address must not be changed.

Max. 20 VA

Max. 20 VA

AK-PC 783A Capacity controller RS8HN102 © Danfoss 2017-11 29

Page 30

Preface to design

Be aware of the following when the number of extension modules

is being planned. A signal may have to be changed, so that an additional module may be avoided.

• An ON/OFF signal can be received in two ways. Either as a

contact signal on an analog input or as voltage on a low or highvoltage module.

• An ON/OFF output signal can be given in two ways. Either with a

relay switch or with solid state. The primary difference is the permitted load and that the relay switch contains a cutout switch.

Mentioned below are a number of functions and connections that

may have to be considered when a regulation has to be planned.

There are more functions in the controller than the ones mentioned here, but those mentioned have been included in order

that the need for connections can be established.

Functions

Clock function

Clock function and change-over between summer time and winter time are contained in the controller.

The clock setting is maintained for at least 12 hours at a power

failure.

The clock setting is kept updated if the controller is linked up in a

network with a system manager.

Start/stop of regulation

Regulation can be started and stopped via the software. External

start/stop can also be connected.

Warning

The function stops all regulation.

Excess pressure can lead to a loss of charge.

Start/stop of compressors

External start/stop can be connected.

Alarm function

If the alarm is to be sent to a signal transmitter, a relay output will

have to be used.

I'm alive function

A relay can be reserved which is pulled during normal regulation.

The relay will be released if the regulation stops with the main

switch or if the controller fails.

Extra temperature sensors and pressure sensors

If additional measurements have to be carried out beyond the

regulation, sensors can be connected to the analog inputs.

Forced control

The software contains a forced control option. If an extension

module with relay outputs is used, the module’s top part can be

with change-over switches – switches that can override the individual relays into either OFF or ON position.

Wiring should be done with a safety relay. See Regulating functions.

Data communication

The controller module has terminals for LON data communication.

The requirements to the installation are described in a separate

document.

30 Capacity controller RS8HN102 © Danfoss 2017-11 AK-PC 783A

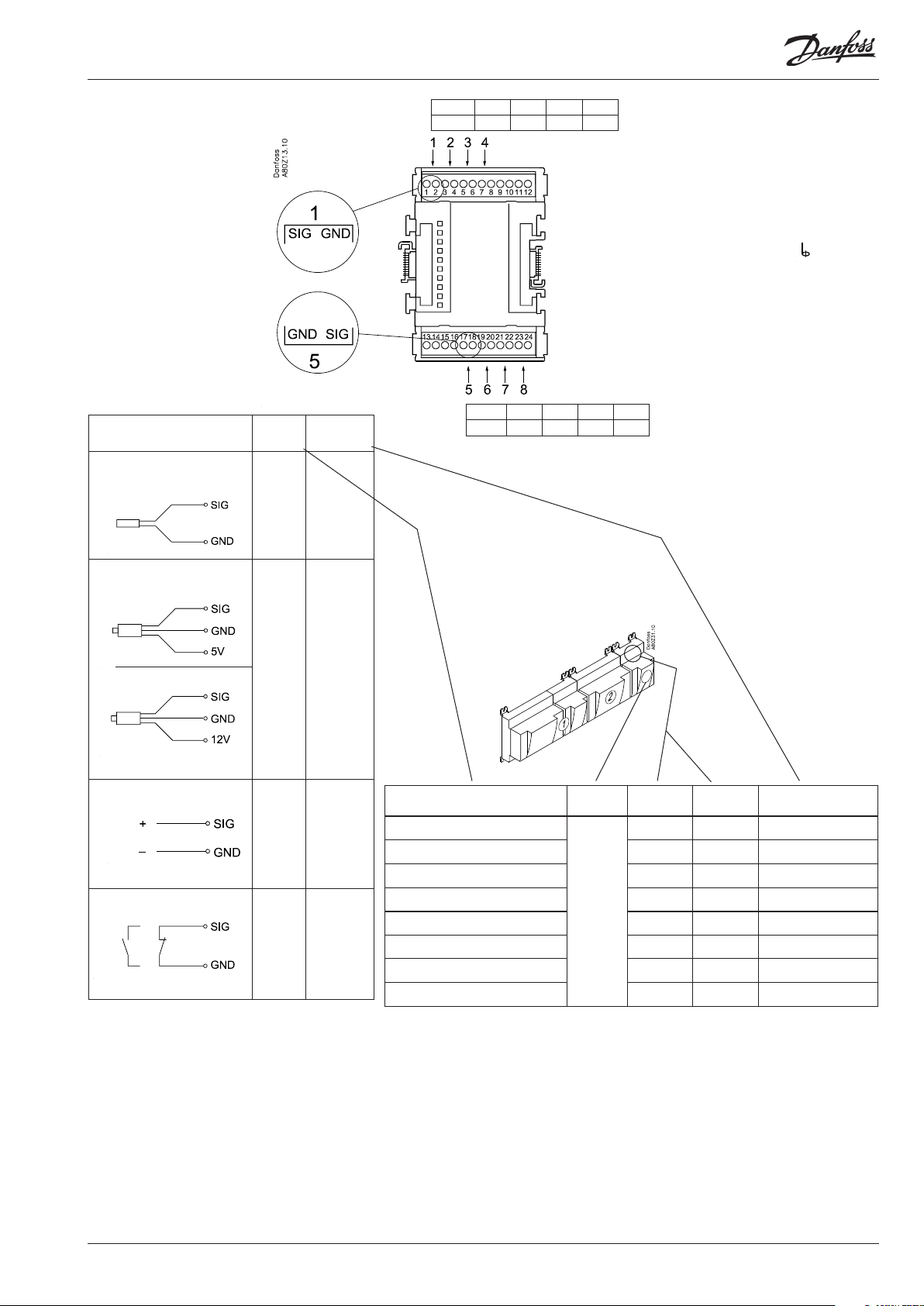

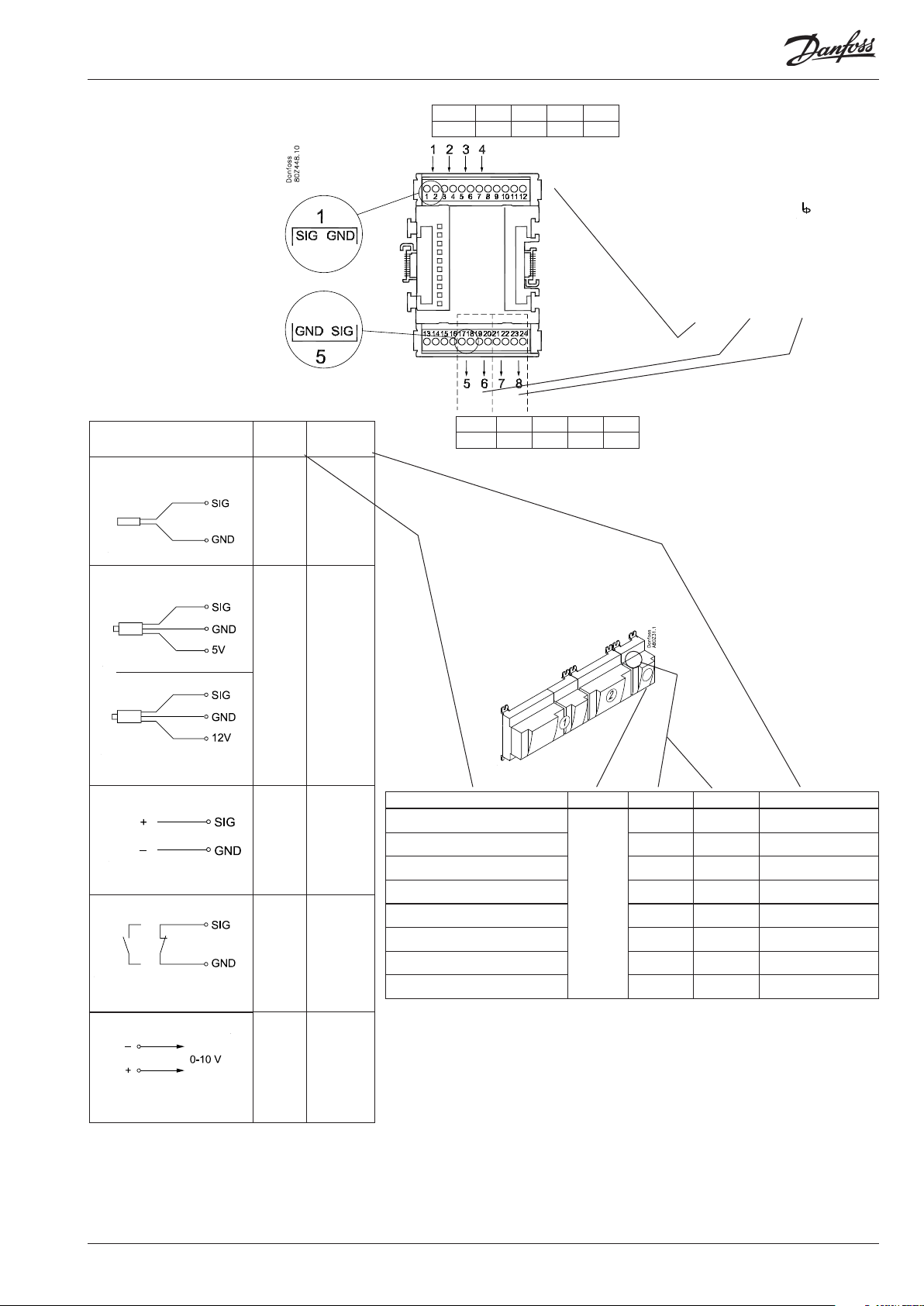

Page 31

Connections

In principle there are the following types of connections:

Analog inputs ”AI”

This signal must be connected to two

terminals.

Signals can be received from the following

sources:

• Temperature signal from Pt 1000 ohm

temperature sensor

• Contact signal where the input is shortcircuited or ”opened”, respectively

• Voltage signal from 0 to 10 V

• Signal from pressure transmitter AKS 32,

AKS 32R, AKS 2050 or MBS 8250.

The supply voltage is supplied from the

module’s terminal board where there is

both a 5 V supply and a 12 V supply.

When programming the pressure transmitter’s pressure range must be set.

ON/OFF voltage inputs ”DI”

This signal must be connected to two

terminals.

• The signal must have two levels, either 0 V

or ”voltage” on the input.

There are two different extension

modules for this signal type:

- low-voltage signals, e.g. 24 V

- high-voltage signals, e.g. 230 V

When programming the function must be set:

• Active when the input is without voltage

• Active when voltage is applied to the

input.

ON/OFF output signals ”DO”

There are two types, as follows:

• Relay outputs

All relay outputs are with change-over

relay so that the required function can be

obtained when the controller is without

voltage.

• Solid state outputs

Reserved for AKV valves, but output can

cut an external relay in and out, as with a

relay output.

The output is only found on the

controller module.

When programming the function must be set:

• Active when the output is activated

• Active when the output is not activated.

Analog output signal ”AO”

This signal is to be used if a control signal is

to be transmitted to an external unit, e.g. a

frequency converter.

When programming the signal range must

be defined: 0-5 V, 1-5 V, 0-10 V or 2-10 V.

Pulse signal for the stepper motors.

This signal is used by valve motors of the

type ETS, KVS, CCM and CCMT.

The valve type should be set during programming.

Limitations

As the system is very flexible regarding the number of connected

units you must check whether your selection complies with the

few limitations there are.

The complexity of the controller is determined by the software,

the size of the processor, and the size of the memory. It provides

the controller with a certain number of connections from which

data can be downloaded, and others where coupling with relays

can be performed.

✔ The sum of connections cannot exceed 160 (AK-PC 783A).

✔ The number of extension modules must be limited so that the

total power in a row will not exceed 32 VA (including controller).

If the AK-CM 102 communication module is used, each row of

AK-CM 102 must not exceed 20 VA (incl. AK-CM 102).

There must not be more than a total of 12 modules (controller

+ 11 modules).

AK-PC 783A Capacity controller RS8HN102 © Danfoss 2017-11 31

✔ No more than 5 pressure transmitters may be connected to one

controller module.

✔ No more than 5 pressure transmitters may be connected to one

extension module.

Common pressure transmitter

If several controllers receive a signal from the same pressure transmitter, the supply to the affected controllers must be wired so that

it is not possible to switch off one of the controllers without also

switching off the others. (If one controller is switched off, the signal will be pulled down, and all the other controllers will receive a

signal which is too low)

Page 32

Design of a compressor and condenser control

Procedure:

1. Make a sketch of the system in question

2. Check that the controller’s functions cover the required

application

3. Consider the connections to be made

4. Use the planning table. / Note down the number of connections

./ add up

5. Are there enough connections on the controller module? – If

not, can they be obtained by changing an ON/OFF input signal

from voltage signal to contact signal, or will an extension

module be required?

6. Decide which extension modules are to be used

7. Check that the limitations are observed

8. Calculate the total length of modules

9. The modules are linked together

10. The connection sites are established

11. Draw a connection diagram or a key diagram

12. Size of supply voltage/transformer

1

Follow these 12

steps

Sketch

Make a sketch of the system in question.

2

Compressor and condenser functions

Application

Regulation of a compressor groups on MT and LT x

Regulation of a condenser groups on MT x

Regulation of up to 2 cascade heat exchangers x

Regulation of compressor capacity

Control sensor = P0 x

PI-regulation x

Max. number of compressors

Max. number of unloaders each compressor 3

Identical compressor capacities x

Different compressor capacities x

Speed regulation of 1 or 2 compressors x

Run time equalisation x

Min. restart time x

Min. On-time x

Liquid injection in suction line x

Liquid injection in cascade heat exchanger x

Liquid injection in screw compressor x

External start/stop of compressors x

AK-PC 783A

6 MT + 6 LT /

7 MT + 5 LT /

8 MT + 4 LT

Oil management

Oil injection in compressor. Shared or individual x

Receiver pressure control x

Monitoring of oil level in receiver x

Management of oil level in oil separator x

Reset of oil management x

Cutout of compressors at oil failure x

Safety relays during forced compressor control x

Suction pressure reference

Override via P0 optimization x

Override via “night setback” x

Override via "0 -10 V signal" x

Regulation of condenser capacity

Control sensor = PcMT x

Step regulation x

Max. number of steps 8

Speed regulation x

Step and speed regulation x

Speed regulation first step x

32 Capacity controller RS8HN102 © Danfoss 2017-11 AK-PC 783A

Page 33

Limitation of speed during night operation x

Heat recovery function x

Trouble-shooting function FDD on condenser x

Condenser pressure reference

Floating condensing pressure reference x

Setting of references for heat recovery functions x

Cascade regulation

Control sensor =Scasc2 and Scasc3 (app. SdLT) x

Expansion valve = ETS, CCMT or AKV. Parallel valve can be mounted x

Regulation of two cascade exchangers in parallel x

Safety functions

Min. suction pressure x

Max. suction pressure x

Max. condensing pressure x

A bit more about the functions

Max. discharge gas temperature x

Min. / Max. superheat x

Safety monitoring of compressors x

Common high pressure monitoring of compressors x

Safety monitoring of condenser fans x

General alarm functions with time delay 10

Miscellaneous

Extra sensors 7

Inject On function x

Option for connection of separate display 2

Separate thermostat functions 3

Separate pressostat functions 3

Separate voltage measurements 3

PI regulation 3

Max. input and output 160

Compressor

Regulation of up to 12 compressors and up to 3 unloaders each

compressor.

Compressor No. 1 or 2 can be speed-regulated.

The following can be used as control sensor:

1) P0 - Suction pressure

2) S4 - Cold brine temperature

(P0-LT is also used for 2, but for low-pressure safety.)

Condenser

Regulation of up to 8 condenser steps.

Fans can be speed-regulated. Either all on one signal or only the first

fan of several. EC motor can be used.

Relay outputs and solid state outputs may be used, as desired.

The following can be used as control sensor:

1) Pc - Condensing pressure

2) S7 - Warm brine temperature (Pc is used here for high-pressure

safety.)

Connection between high-pressure and low-pressure circuits (MT

and LT circuits)

All control between the MT and LT circuit must be performed internally in the controller.

Speed regulation of condenser fans

The function requires an analog output module.

A relay output may be used for start/stop of the speed regulation.

The fans may also be cut in and out by relay outputs.

Heat recovery

A thermostat function can be selected that will engage when desired

for heating.

Digital scroll

When using a digital scroll, the unloading of the compressor should

be connected to one of the four solid state outputs in the controller.

Safety circuit

If signals are to be received from one or more parts of a safety circuit,

each signal must be connected to an ON/OFF input.

Day/night signal for raising the suction pressure

The clock function can be used, but an external ON/OFF signal may be

used instead.

If the “P0 optimization” function is used, no signal will be given concerning the raising of the suction pressure. The P0 optimization will

see to this.

“Inject ON” override function

The function closes expansion valves on evaporator controls when all

compressors are prevented from starting.

The function can take place via the data communication, or it may be

wired via a relay output.

Separate thermostat and pressure control functions

A number of thermostats can be used according to your wishes. The

function requires a sensor signal and a relay output. In the controller

there are settings for cutin and cutout values. An associated alarm

function may also be used.

Separate voltage measurements

A number of voltage measurements can be used according to your

wishes. The signal can for example be 0-10 V. The function requires a

voltage signal and a relay output. In the controller there are settings

for cutin and cutout values. An associated alarm function may also be

used.

Separate PI regulations

A series of PI regulations can be set up as desired.

If you want to know more about the functions, go to chapter 5.

3

Connections

Here is a survey of the possible connections. The texts can be read in

context with the table on the following page.

Analog inputs

Temperature sensors

• S4 (Cold brine temperature)

Must be used when the control sensor for compressor control has been

selected as S4.

• Ss (suction gas temperature)

Must always be used in connection with compressor regulation.

• Sd (discharge gas temperature)

Must always be used in connection with compressor regulation.

• Sc3 (outdoor temperature)

To be used when monitoring function FDD is used.

To be used when regulation is performed with floating condenser reference.

• S7 (warm brine return temperature)

Must be used when the control sensor for condenser has been selected

as S7.

• Saux (1-4), any extra temperature sensors

Up to four additional sensors for monitoring and data collection may be

connected. These sensors can be used for general thermostat functions.

• Scasc2, Scasc3

Control sensors for cascade

(The SdLT signal can be used instead of the Scasc3 signal, but only if

nothing else is mounted in the pressure pipe).

• Shrec

Temperature sensor for heat recovery

AK-PC 783A Capacity controller RS8HN102 © Danfoss 2017-11 33

Page 34

Pressure transmitters

• P0 Suction Pressure

Must always be used in connection with compressor regulation

(frost protection).

• Pc Condensing Pressure

Must always be used in connection with compressor or condenser

regulation

• Prec. Oil receiver pressure. Must be used for receiver pressure regulation.

• Paux (1-3)

Up to 3 extra pressure transmitters can be connected for monitoring and

data collection.

These sensors can be used for general pressure switch functions.

Note. A pressure transmitter type AKS 32 or AKS 32R can supply signals to

a maximum of five controllers.

Voltage signal

• Ext. Ref

Used if a reference override signal is received from another control.

• Voltage inputs (1-3)

Up to 3 extra voltage signals can be connected for monitoring and data

collection. These signals are used for general voltage input functions.

On/Off-inputs

Contact function (on an analog input) or

voltage signal (on an extension module)

• Common safety input for all compressors (e.g. common high-pressure/

low-pressure pressure switch)

• Up to 6 signals from the safety circuit of each compressor

• Signal from the condenser fans safety circuit

• Any signal from the frequency converter’s safety circuit

• External start/stop of regulation

• External stop of cascade heat exchanger regulation (1 input for each

cascade)

• External day/night signal (raise/lower the suction pressure reference). The

function is not used if the “P0 optimization” function is used.

• DI alarm (1-10) inputs

Up to 10 no. extra on/off signals for general alarm for monitoring and

data collection can be connected.

• Level contacts

On/off-outputs

Relay outputs

• Compressors

• Unloaders

• Fan motor

• Injection On function (signal for evaporator controls. One per suction

group).

• Start/stop of liquid injection in heat exchanger

• Start/stop of liquid injection in suction line

• Start/stop of 3-way valves at heat recovery

• ON/OFF signal for start/stop of speed regulation

• Alarm relay. I'm alive relay.

• On/off signals from general thermostats (1-3), pressure switches (1-3) or

voltage input functions (1-3).

• Oil valves

• Safety relays for cutouts of compressors at oil failure

Solid state outputs

The solid state outputs on the controller module may be used for the

same functions as those mentioned under “relay outputs”. (The output will

always be “OFF” when the controller has a power failure).

Analog output

• Speed regulation of the condenser’s fans.

• Speed regulation of the compressor

• Stepper signal for expansion valve on cascade heat exchanger

Example

Compressor group:

• MT circuits and LT circuits

• Refrigerant MT=134a LT=CO2 (R744)

• 4 and 2 compressors with "cyclic" operation.

• Speed control of first compressor

• Safety monitoring of each compressor

• Common high-pressure monitoring in each circuit

• ToMT Setpoint =-10°C, ToLT = -30°C

• P0 optimisation

• Oil management of each LT compressor

• Pulse reset for stopped compressor (lack of oil)

Condenser:

• Fans with EC motors, speed controlled

• Pc-MT regulates flooating based on temperature sensor

Sc3

Cascade exchanger

• Control sensor =Scasc3

• Valves = Stepper valve ETS and Solenoid valve EVR

Receivers:

• Control of pressure in oil receiver

Safety functions:

• Monitoring of Po, Pc, Sd and superheat in suction line

• Monitoring of low and high level in oil receiver

Data from this example is used on the next page.

The result is that the following modules should be used:

• AK-PC 783 controller

• AK-XM 204A input and output module

• AK-XM 208C stepper output module

• AK-XM 102B digital input module

• AK-XM 103A analog input and output module

34 Capacity controller RS8HN102 © Danfoss 2017-11 AK-PC 783A

Page 35

4

Planning table

The table helps you establish whether there are enough

inputs and outputs on the basic controller.

If there are not enough of them, the controller must be

extended by one or more of the mentioned extension

modules.

Note down the connections you will require and add

them up

Analog inputs

Temperature sensors, Ss, Sd, Sc3, S4, S7, Stw.., Shr.., 7

Extra temperature sensor / separate thermostats /PI-regulation 0

Pressure transmitters, P0, Pc, Prec / separate pressostats 5 P = Max. 5 / module

Voltage signal from other regulation, separate signals

Heat recovery via thermostat

On/off inputs Contact 24 V 230 V

Safety circuits, common for all compressors 2 Max.2

Safety circuits, Oil pressure Max. 1/ Comp.

Safety circuits, comp. Motor protection

Safety circuits, comp. Motor temp.

Safety circuits, comp. High pres. thermostat

Safety circuits, comp. High pres. pressostat

Safety circuits, general for each compressor 6

Safety circuits, condenser fans, frequency converter Max. 1/ fan

Safety circuits, flow switch

External start/stop

External start/stop of each cascade heat exchanger regulation

Night setback of suction pressure

Separate alarm functions via DI

Load shedding

Start of Heat recovery

Liquid level, Oil level 5

Impulse pressure, Pulse reset of oil management 1

On/off outputs

Compressors, motors 6

Unloaders

Fan motors, circulation pumps 1

Alarm relay, I'm alive relay

Inject ON Max. 2

Separate thermostat and pressostat functions and voltage measurements

Heat recovery function via thermostat Max.1

Liquid injection in suction line / heat exchanger 1

Signal for external cascade control

Solenoid valve for Oil. 3

3-way valve

Analog control signal, 0-10 V

Frequency converter, Compressor, fans, pumps, valves etc. 3

Valves with stepper motor. Parallel valves, if applicable 1

Sum of connections for the regulation 18 0 8 11 3+1 Sum = max. 160

Number of connections on a controller module 11 11 0 0 0 0 8 8 0 0 0

Missing connections, if applicable 7 - 8 3 3+1

5

Analog input signal

Example

On/off voltage signal

Example

On/off voltage signal

Example

On/Off output signal

Example

Analog output signal 0-10 V

Stepper output

Example

Max. 5+5+5

7

Limitations

The example:

None of the 3 limitations are exceeded => OK

The missing connections to be supplied by one or more extension modules:

6

AK-XM 101A (8 analog inputs) ___ pcs. á 2 VA = __

AK-XM 102A (8 digital low voltage inputs) ___ pcs. á 2 VA = __

AK-XM 102B (8 digital high voltage outputs) 1 ___ pcs. á 2 VA = __

AK-XM 103A (4 analog inputs, 4 analog outputs) 1 1 ___ pcs. á 2 VA = __

AK-XM 204A / B (8 relay outputs) ___ pcs. á 5 VA = __

AK-XM 205A / B (8 analog inputs. + 8 relay output) 1 ___ pcs. á 5 VA = __

AK-XM 208C (8 analog inputs + 4 stepper outputs) 1 1 ___ pcs. á 5 VA = __

AK_OB 110 (2 analog outputs) ___ pcs. á 0 VA = 0

AK-PC 783A Capacity controller RS8HN102 © Danfoss 2017-11 35

Sum of power

1 pcs. á 8 VA = 8

Sum =

Sum = max. 32 VA

Page 36

8

Length

If you use many extension modules the controller’s length will

grow accordingly. The row of modules is a complete unit which

cannot be broken.

If the row becomes longer than desired, the row can be broken by

using AK-CM 102.

The module dimension is 72 mm.

Modules in the 100-series consist of one module

Modules in the 200-series consist of two modules

The controller consist of three modules

The length of an aggregate unit = n x 72 + 8

or in an other way:

Module Type Number at Length

Controller module 1 x 224 = 224 mm

Extension module 200-series _ x 144 = ___ mm

Extension module 100-series _ x 72 = ___ mm

Total length = ___ mm

9

Linking of modules

Start with the controller module and then mount the selected

extension modules. The sequence is of no importance.

However, you must not change the sequence, i.e. rearrange the

modules, after you have made the setup where the controller

is told which connections are found on which modules and on

which terminals.

The modules are attached to one another and kept together by a

connection which at the same time transmits the supply voltage

and the internal data communication to the next module.

Example continued:

Controller module + 2 extension modules in 200-series + 2 extension module in 100 series =

224 + 144 + 144 + 72 + 72 = 656 mm.

Example continued

Mounting and removal must always be performed when there is

no voltage.

The protective cap mounted on the controller’s plug connection

must be moved to the last vacant plug connection so that the

plug will be protected against short-circuit and dirt.

When the regulation has started the controller will all the time

check whether there is connection to the connected modules. This

status can be followed by the light-emitting diode.

When the two catches for the DIN rail mounting are in open position the module can be pushed into place on the DIN rail – no

matter where in the row the module is found.

Removal is likewise carried out with the two catches in the open

position.

36 Capacity controller RS8HN102 © Danfoss 2017-11 AK-PC 783A

Page 37

10

Determine the connection points

All connections must be programmed with module and point, so

in principle it does not matter where the connections are made, as

long as it takes place on a correct type of input or output.

• The controller is the first module, the next one is 2, etc.

• A point is the two or three terminals belonging to an input or

output (e.g. two terminals for a sensor and three terminals for a

relay).

The preparation of the connection diagram and the subsequent

programming (configuration) should take place at the present

time. It is most easily accomplished by filling in the connection

survey for the relevant modules.

Principle:

Name On module On Point Function