Design Guide

Capacity controller

AK-PC 710

ADAP-KOOL® Refrigeration control systems

Contents

1. Introduction ............................................................................. 3

Application .................................................................................................. 3

Function overview ............................................................................ 3

Principles...................................................................................................... 4

2. Design of the controller ..........................................................7

Module survey ........................................................................................... 8

Common data for modules .................................................................10

Controller ...........................................................................................12

Extension module AK-XM 102A / AK-XM 102B .....................14

Extension module AK-XM 204A / AK-XM 204B .....................16

Extension module AK-OB 110 ....................................................18

Extension module AK-OB 101A..................................................19

Extension module EKA 163B / EKA 164B / EKA 166 ............ 20

Power supply module AK-PS 075 ..............................................21

Select application ................................................................................... 22

General ................................................................................................ 22

Applications ...................................................................................... 22

Ordering ..................................................................................................... 33

3. Mounting and wiring .............................................................35

Mounting ................................................................................................... 36

Mounting of analog output module ........................................ 36

Mounting of extension module on the basic module ....... 37

Wiring .......................................................................................................... 38

4. Conguration and operation ................................................39

Conguration via service tool AK-ST 500 .......................................41

Connect PC or PDA ......................................................................... 41

Authorization .................................................................................... 42

Unlock the conguration of the controllers ..........................43

System setup ....................................................................................44

Set plant type ................................................................................... 45

Set control of compressors ..........................................................46

Setup control of condenser .........................................................49

Conguration of inputs and outputs .......................................50

Set alarm priorities..........................................................................52

Lock conguration ..........................................................................54

Check conguration .......................................................................55

Check of connections ............................................................................ 57

Check of settings.....................................................................................59

Schedule function .................................................................................. 61

Installation in network .......................................................................... 62

First start of control ................................................................................63

Start the control ............................................................................... 64

Manual capacity control ............................................................... 65

Quick setup ............................................................................................... 66

EKA 164, EKA 166 or AKM operation ...............................................67

5. Regulating functions .............................................................73

Suction group ..........................................................................................74

Controlling sensor...........................................................................74

Reference ...........................................................................................74

Capacity control of compressors ...............................................75

Capacity distribution methods ........................................... 76

Power pack types – compressor combinations ............77

Compressor timers ..................................................................79

Load shedding ..........................................................................80

Injection ON .............................................................................. 80

Safety functions ............................................................................... 81

Condenser ................................................................................................. 82

Capacity control of condenser ...................................................82

Reference for condensing pressure ..........................................82

Capacity distribution ..................................................................... 84

Step regulation ........................................................................................84

Speed regulation ....................................................................................84

Condenser couplings .....................................................................84

Safety functions for condenser .................................................. 85

Separate monitoring functions .........................................................85

Miscellaneous ..........................................................................................86

Appendix A – Compressor combinations and coupling pat-

terns ............................................................................................................. 89

2 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

1. Introduction

Application

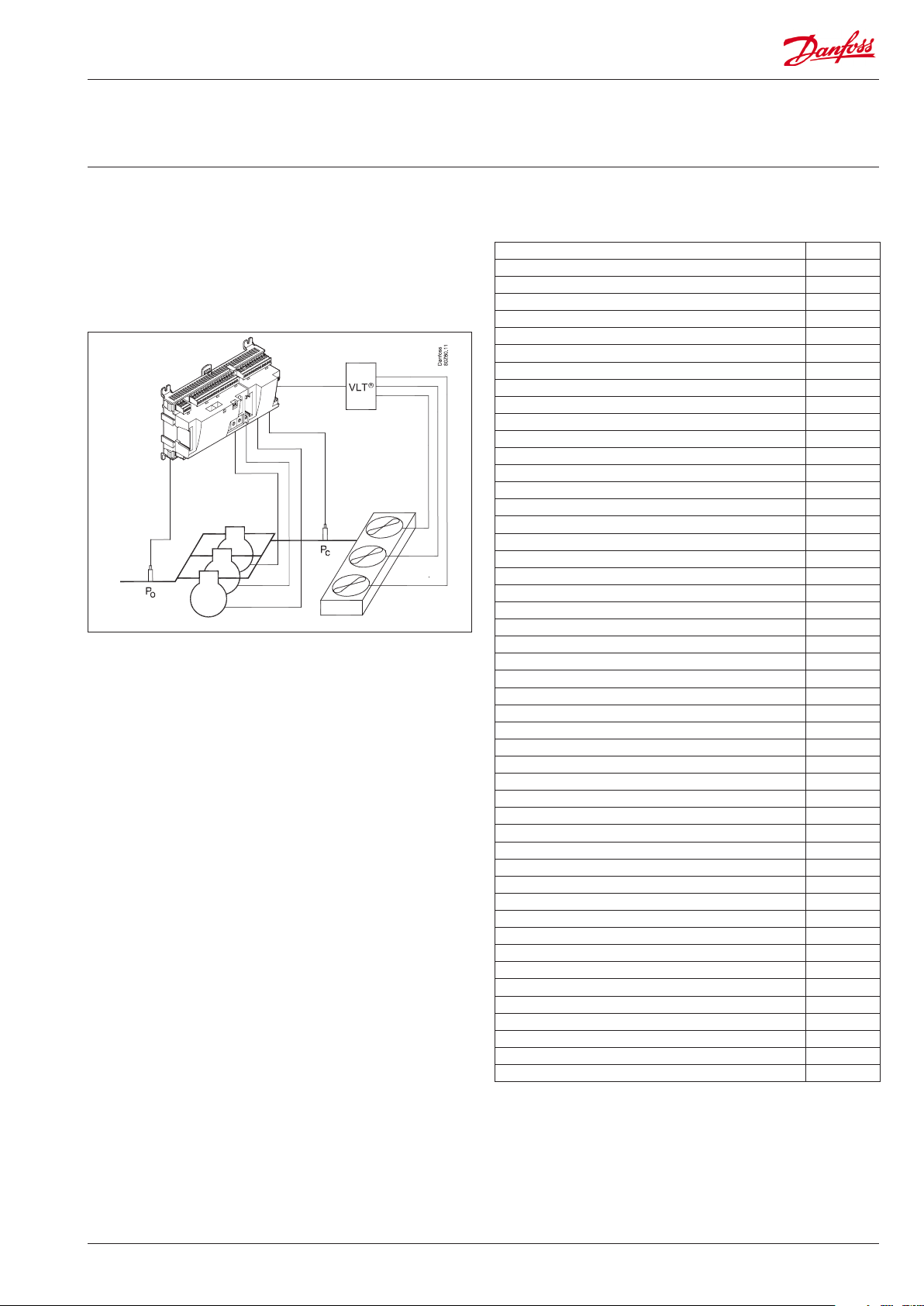

AK-PC 710 is a complete regulating unit for capacity control of

compressors and condensers in refrigeration systems.

In addition to capacity control the controllers can give signals to

other controllers about the operating condition, e.g. forced closing of expansion valves, alarm signals and alarm messages.

Function overview

AK-PC 710

Application

Regulation of a compressor group x

Both compressor group and condenser group x

Regulation of compressor capacity

Regulation sensor P0

PI-regulation x

Max. number of compressor steps 6

Identical compressor capacities x

Dierent compressor capacities x

Sequential operation (rst in / last out) x

Speed regulation of 1 compressor x

Run time equalisation x

Min. restart time x

Min. On-time/ Min O time x

Suction pressure reference

Override via P0 optimization x

Override via “night setback” x

The controller’s main function is to control compressors and

condensers so that operation all the time takes place at the

energy-optimum pressure conditions. Both suction pressure

and condensing pressure are controlled by signals from pressure

transmitters.

Capacity control can be carried out by suction pressure P0.

Among the dierent functions are:

- Capacity control of up to 6 compressors

- Speed control of one compressor

- One safety input for each compressor

- Option for capacity limitation to minimize consumption peaks

- When the compressor stops, signals can be transmitted to appliance controllers so that the electronic expansion valves will be

closed (signal via data communication)

- Safety monitoring of high pressure / low pressure / discharge

temperature

- Capacity control of up to 6 fans

- Step coupling, speed regulation or a combination

- Floating reference with regard to outside temperature

- Safety monitoring of fans

- The status of the outputs and inputs is shown by means of lightemitting diodes on the front panel

- Alarm signals can be generated directly from the controller and

via data communication

- Alarms are shown with texts so that the cause of the alarm is

easy to see.

- Plus some completely separate functions that are totally independent of the regulation – such monitoring of liquid level and

room temperature.

Regulation of condenser capacity

Regulation sensor Pc

Step regulation x

Max. number of steps 6

Speed regulation x

Step and speed regulation x

Condenser pressure reference

Floating condensing pressure reference x

Safety functions

Min. suction pressure x

Max. suction pressure x

Max. condensing pressure x

Max. discharge gas temperature x

Min. / Max. superheat x

Safety monitoring of compressors x

Common high pressure monitoring of compressors x

Common low pressure monitoring of compressors x

Safety monitoring of condenser fans x

Monitoring of room temperature x

Monitoring of liquid level x

Monitoring of frequency converter (VSD) x

Miscellaneous

Inject On function via data communication x

Option for connection of separate display 2

Option for connection of graphic display 1

SW = 1.4

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 3

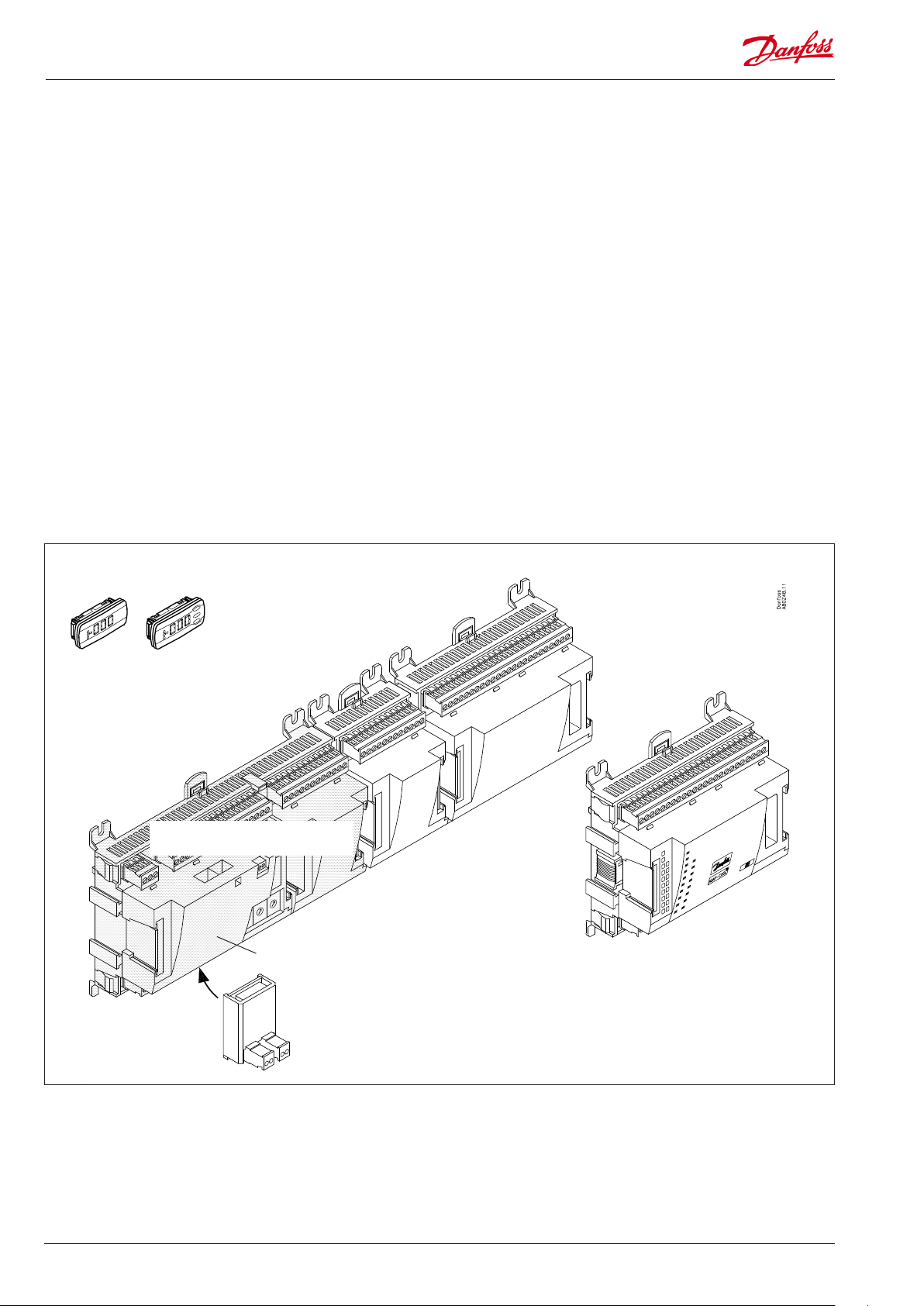

Principles

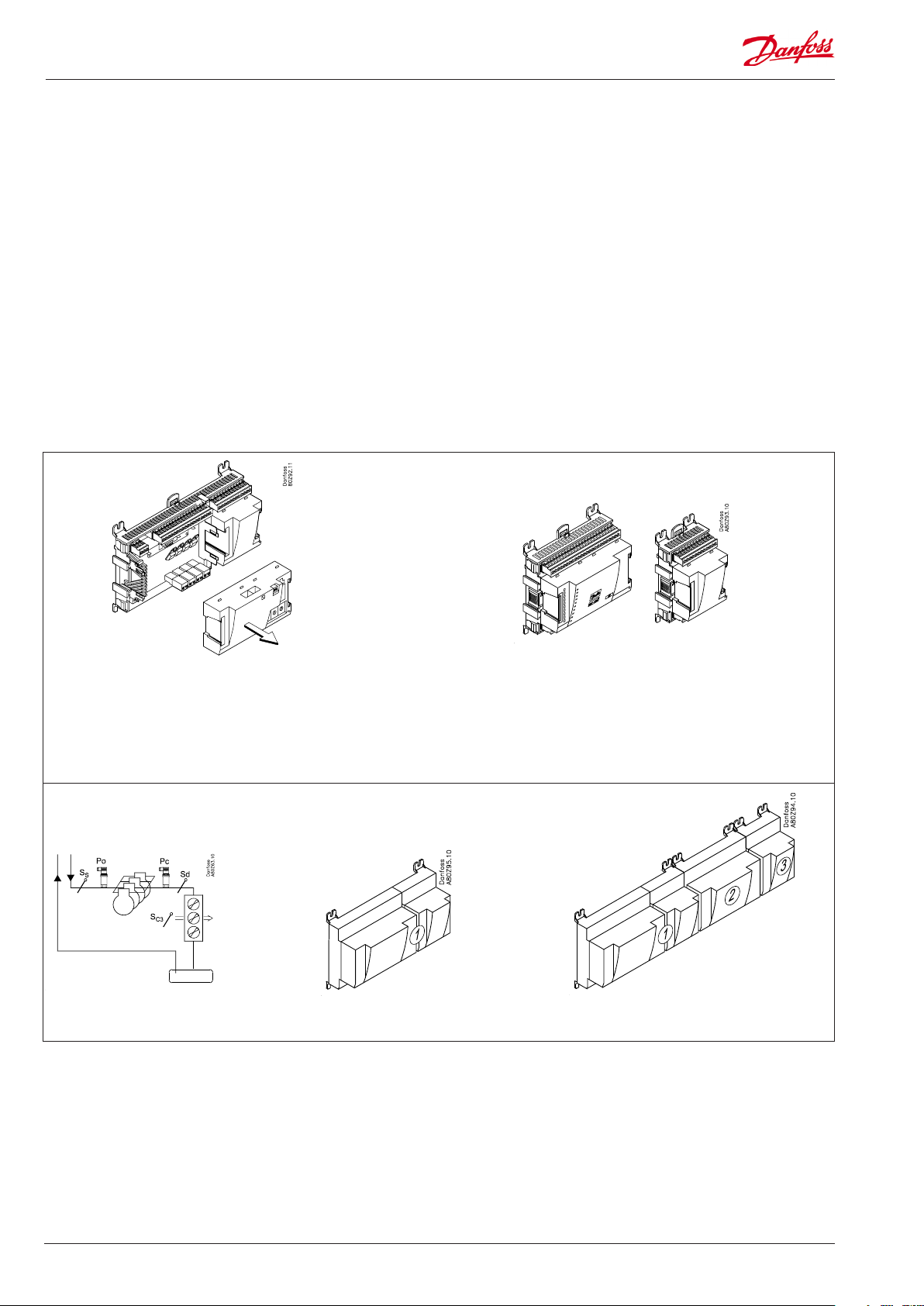

The great advantage of this series of controllers is that it can

be extended as the size of the plant is increased. It has been

developed for refrigeration control systems, but not for any

specic application – variation is created through the read-in

software and extension with up to 3 modules.

It is the same modules that are used for each regulation and the

composition can be changed, as required. With these modules

(building blocks) there is up to 40 various kinds of regulations.

But it is you who must help adjusting the regulation to the actual

needs – these instructions will assist you to nd your way through

all the questions so that the regulation can be dened and the

connections made.

Controller

Top part

Advantages

• The controller’s size can “grow” as systems grow

• The software can be set for one or more regulations

• Several regulations with the same components

• Extension-friendly when systems requirements are changed

• Flexible concept:

- Controller series with common construction

- One principle – many regulation uses

- modules are selected for the actual connection requirements

- The same modules are used from regulation to regulation

Extension modules

Bottom part

The controller is the cornerstone of the regulation. The module has inputs and

outputs capable of handling small systems.

• The bottom part – and hence the terminals – are the same for all controller types.

• The top part contains the intelligence with software. This unit will vary according

to controller type. But it will always be supplied together with the bottom part.

• In addition to the software the top part is provided with connections for data

communication and address setting.

Examples

A regulation with few connections can

be performed with the controller module

alone

If the system grows and more functions have to be controlled, the regulation can be

extended.

With extra modules more signals can be received and more relays cut in and out

– how many of them – and which – is determined by the relevant application.

If there are many connections one or more

extension modules must be mounted

4 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

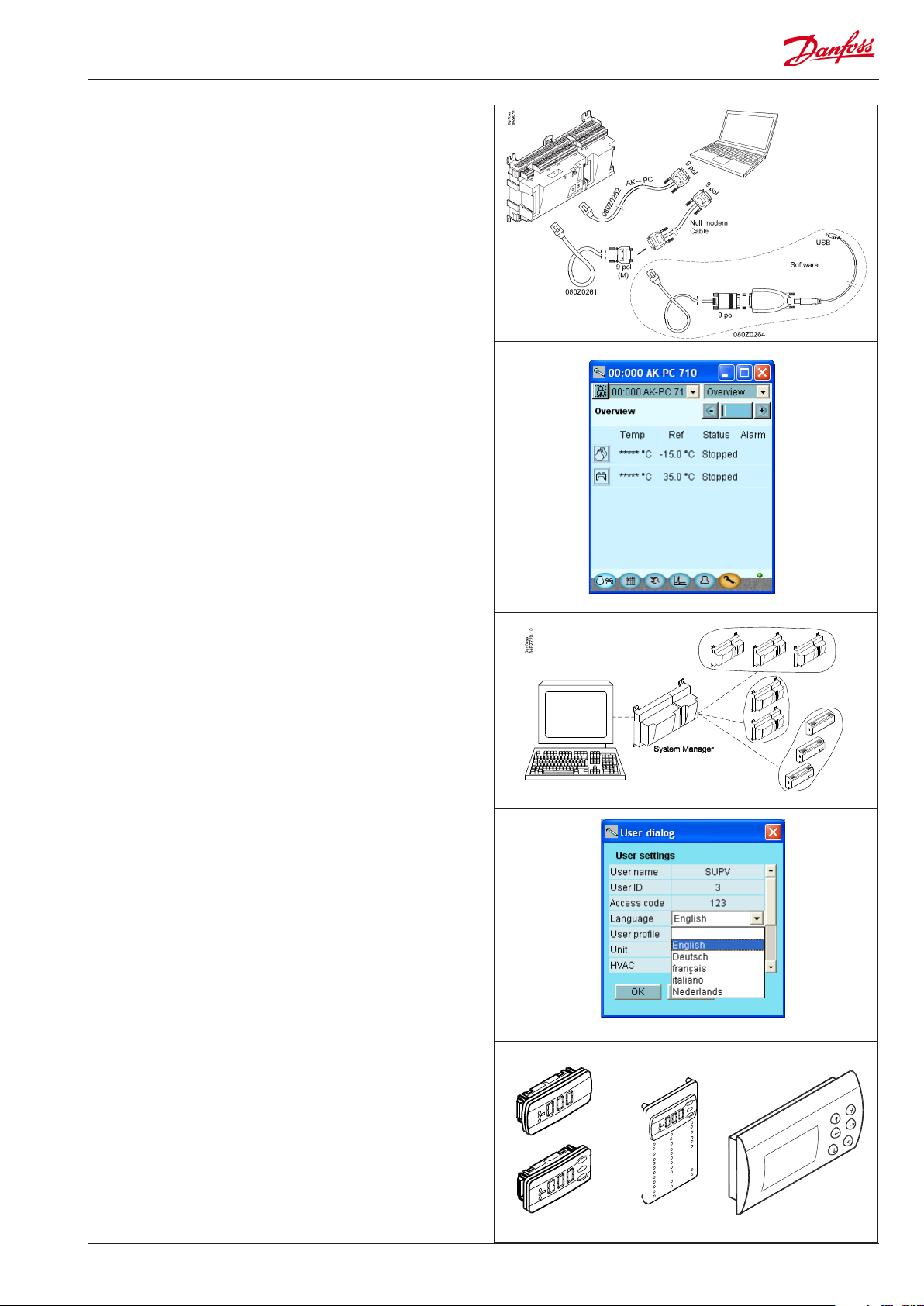

Direct connection

Setup and operation of an AK controller must be accomplished via

the “AK-Service Tool” software program.

The programme is installed on a PC, and setup and operation of

the various functions are carried out via the controller’s menu

displays.

Displays

The menu displays are dynamic, so that dierent settings in one

menu will result in dierent setting possibilities in other menus.

A simple application with few connections will give a setup with

few settings.

A corresponding application with many connections will give a

setup with many settings.

From the overview display there is access to further displays for

the compressor regulation and the condenser regulation.

At the bottom of the display there is access to a number of general

functions, such as “time table”, “manual operation”, “log function”,

“alarms”, and “service” (conguration).

Network linking

The controller can be linked up into a network together with other

controllers in an ADAP-KOOL® refrigeration control system. After

the setup operation can be performed at a distance with, say, our

software program type AKM.

Users

The controller comes supplied with several languages, one of

which can be selected and employed by the user. If there are

several users, they may each have their choice of language. All

users must be assigned a user prole which either gives access to

full operation or gradually limits the operation to the lowest level

that only allows you “to see”.

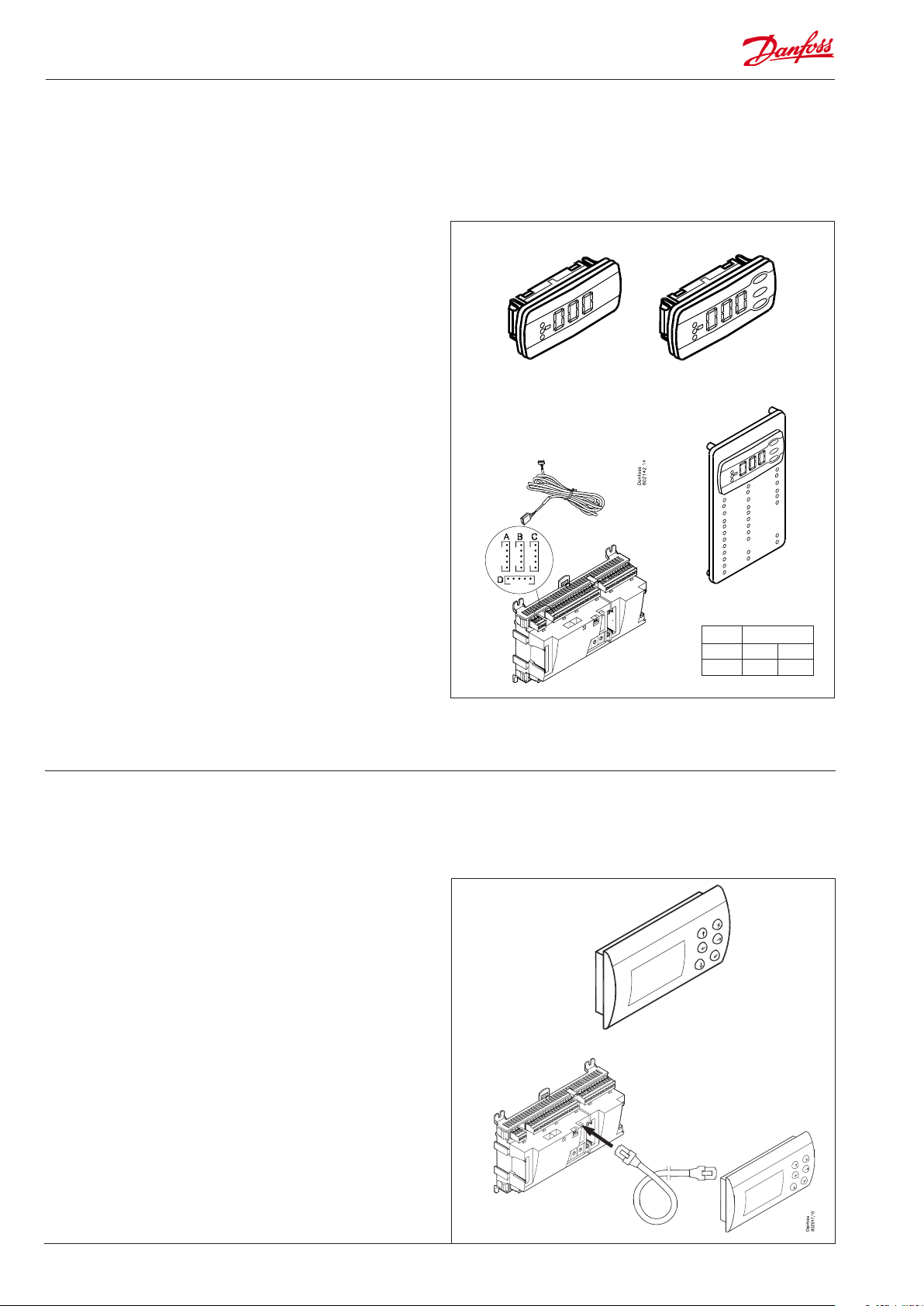

External display

An external display can be tted in order for P0 (Suction) and Pc

(Condensing) readings to be displayed.

The setup can be carried out on a display with control buttons.

The various functions are selected via a menu system.

If display of operational compressors, fans and functions is required, display type EKA 166 can be tted.

Med det graske display AK-MMI kan der både foretages opsætning og udlæsning.

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 5

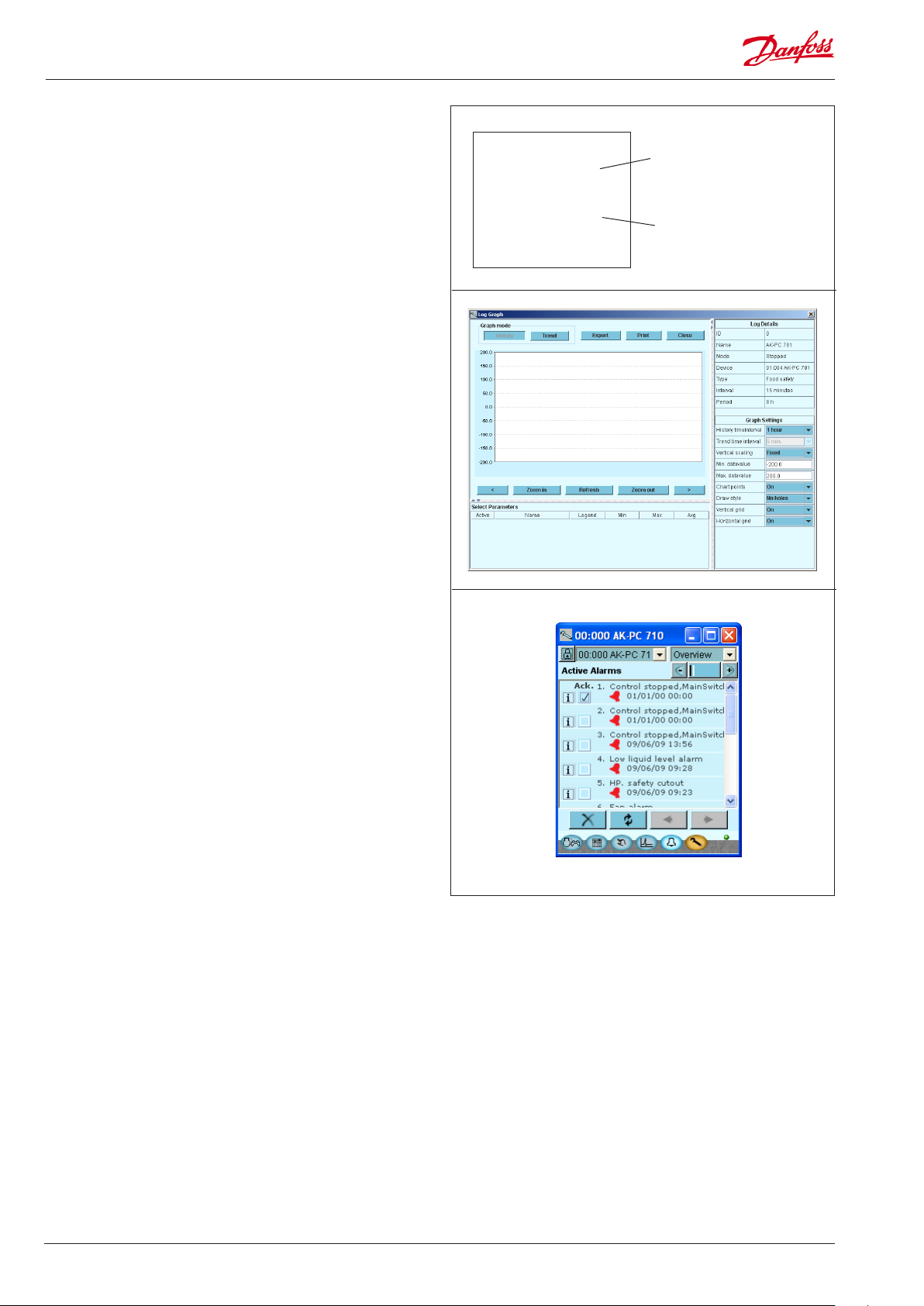

Light-emitting diodes

A number of light-emitting diodes makes it possible to follow the

signals that are received and transmitted by the controller.

Log

From the log function you can dene the measurements you wish

to be shown.

The collected values can be printed, or you may export them to a

le. You can open the le in Excel.

If you are in a service situation you can show measurements in a

trend function. The measurements are then made real-time and

displayed instantly.

■ Power

■ Comm

■ DO1 ■ Status

■ DO2 ■ Service Tool

■ DO3 ■ LON

■ DO4

■ DO5 ■ Alarm

■ DO6

■ DO7

■ DO8 ■ Service Pin

Slow ash = OK

Quick ash = answer from gateway

Constantly ON = error

Constantly OFF = error

Flash = active alarm/not cancelled

Constant ON = Active alarm/cancelled

Alarm

The display gives you an overview of all active alarms. If you wish

to conrm that you have seen the alarm you can cross it o in the

acknowledge eld.

If you want to know more about a current alarm you can click on it

and obtain an information display on the screen.

A corresponding display exists for all earlier alarms. Here you can

upload information if you need further details about the alarm

history.

6 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

2. Design of the controller

This controller can be congured to one of the 40 xed applications.

• There are 20 applications with dierent numbers of compressors

and condenser fans.

• The same applications can also be carried out with speed control

of one compressor.

• The condenser fans can be connected in steps or speed controlled.

The selected application has xed dened connecting points.

These cannot be changed.

In addition to the controller module, one or more of the following

modules should be used. The selected application determines:

• Output module with relays

• Input module for registering on/o signals

• Analogue output module for controlling one or two frequency

converters. One for one compressor and one for the condenser

fans.

This section denes the application and which modules should be

used.

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 7

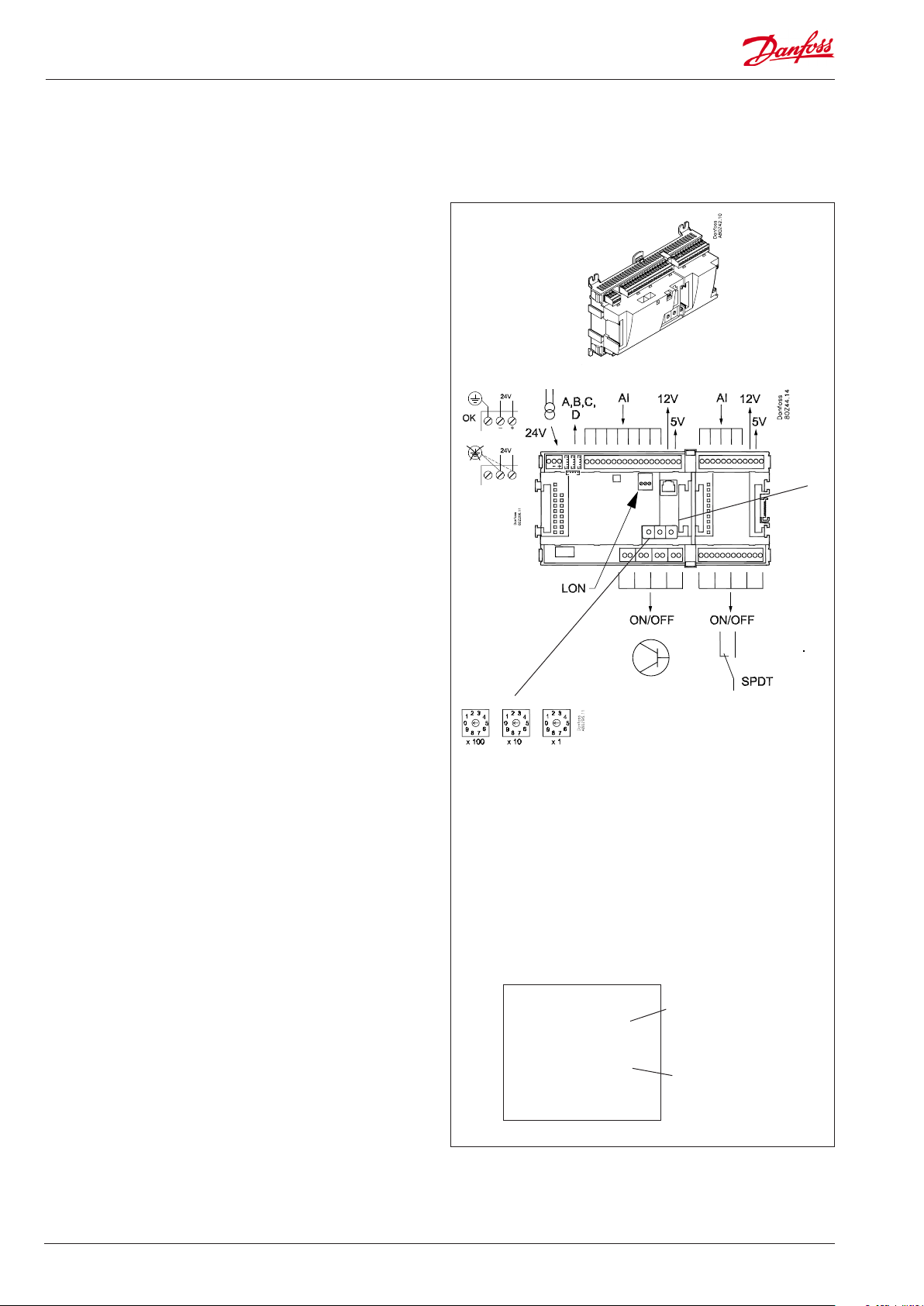

Module survey

• Controller module – capable of handling minor plant requirements.

• Extension modules. When the complexity becomes greater

and additional inputs or outputs are required, modules can be

attached to the controller. A plug on the side of the module will

transmit the supply voltage and data communication between

the modules.

• Top part

The upper part of the controller module contains the

intelligence. This is the unit where the regulation is dened and

where data communication is connected to other controllers in a

bigger network.

Extension module with

additional analog inputs

External display for

suction pressure etc.

• Connection types

There are various types of inputs and outputs. One type may, for

example, receive signals from sensors and switches, another may

receive a voltage signal, and a third type may be outputs with

relays etc. The individual types are shown in the table below.

• Fixed connection

When a regulation is planned (set up) it will generate a need

for a number of connections distributed on the mentioned

types. This connection must be made as shown in the following

diagrams.

Extension module with additional

relay outputs and additional

analog inputs.

Controller with analog inputs and

relay outputs.

Top part

Extension module with

2x analog output signals

The module with additional relay outputs is

also available in a version where the top part

is provided with change-over switches so

that the relays can be overridden.

8 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

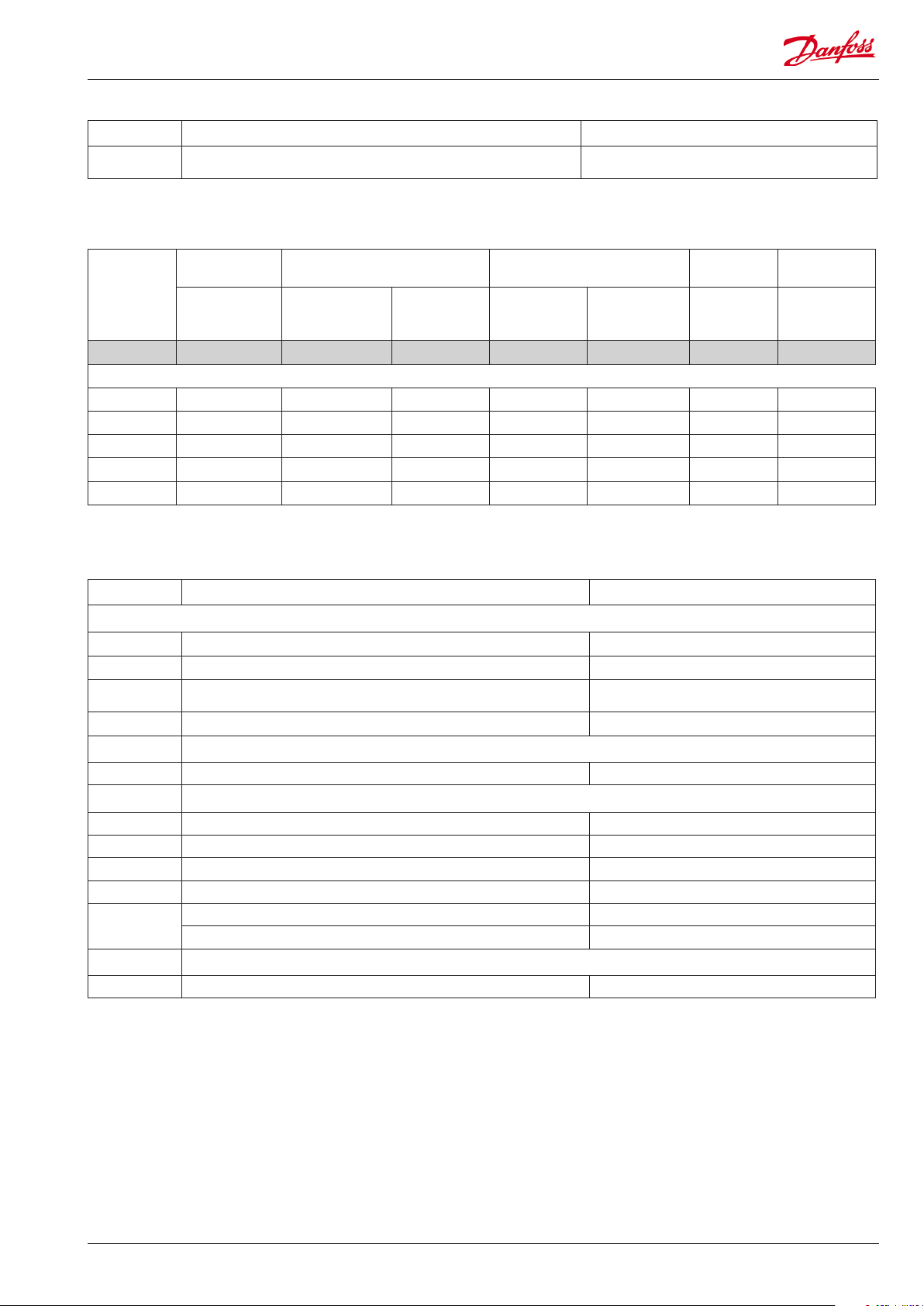

1. Controller

Type Function Application

AK-PC 710

Controller for capacity control of up to 6 compressors and up to 6 condenser fans

Compressor / Condenser / Both

2. Extension modules and survey of inputs and outputs

Type Analog

inputs

For sensors, pressure transmitters

etc.

Controller 11 4 4 - - - -

Extension modules

AK-XM 102A 8

AK-XM 102B 8

AK-XM 204A 8

AK-XM 204B 8 x

AK-OB 110 2

On/O outputs On/o supply voltage

Relay

(SPDT)

Solid state Low voltage

(DI signal)

(max. 80 V)

High voltage

(max. 260 V)

Analog

outputs

0-10 V d.c. For override of

Module with

switches

relay outputs

3. AK operation and accessories

Type Function Application

Operation

AK-ST 500 Software for operation of AK controllers AK-operation

- Cable between PC and AK controller AK - Com port

-

- Cable between PC and AK controller AK- USB

Accessories Power supply module 230 V / 115 V to 24 V

AK-PS 075 18 VA Supply for controller

Accessories External display that can be connected to the controller module. For showing, say, the suction pressure

EKA 163B Display

EKA 164B Display with operation buttons

EKA 166 Display with operation buttons and LED's for inputs and outputs

AK-MMI Graphic display with operation

-

Accessories Real time clock for use in controllers that require a clock function, but are not wired with data communication.

AK-OB 101A Real time clock with battery backup. To be mounted in an AK controller

Cable between zero modem cable and AK controller /

Cable between PDA cable and AK controller

Cable between display and controller Length = 2 m, 6 m

Cable between graphic display and controller Length = 0.8 m, 1.5 m, 3 m

AK - RS 232

On the following pages there is data specic to each module.

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 9

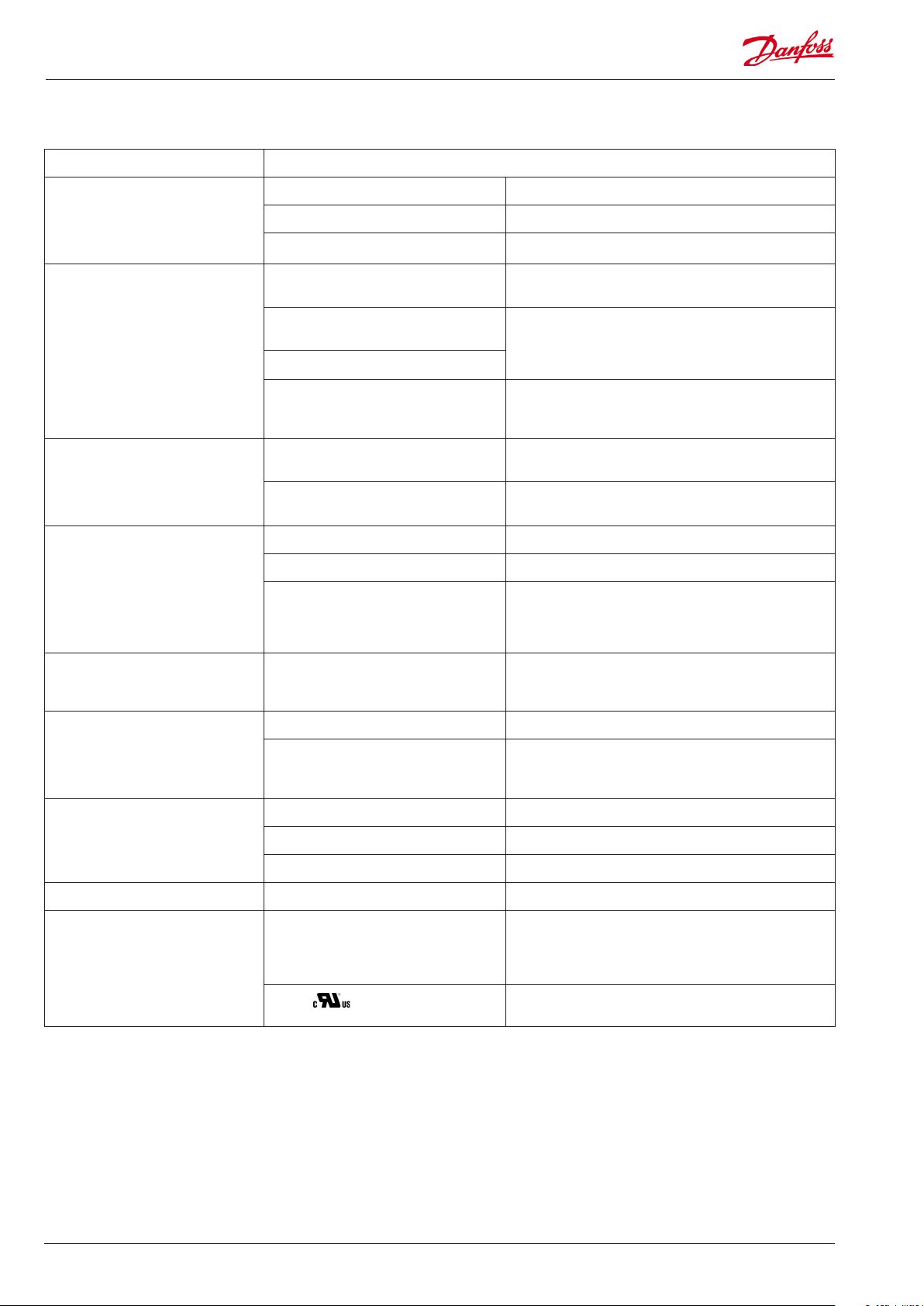

Common data for modules

Supply voltage 24 V d.c./a.c. +/- 20%

Power consumption AK-__ (controller) 8 VA

AK-XM 102 2 VA

AK-XM 204 5 VA

Analog inputs Pt 1000 ohm /0°C Resolution: 0.1°C

Pressure transmitter type AKS 32R /

AKS 32 (1-5 V)

Voltage signal 0-10 V

Contact function (On/O) On at R < 20 ohm

On/o supply voltage inputs Low voltage

Relay outputs

SPDT

Solid state outputs Used for control of compressor relay Max. 240 V a.c. , Min. 48 V a.c.

Ambient temperature During transport -40 to 70°C

0 / 80 V a.c./d.c.

High voltage

0 / 260 V a.c.

AC-1 (ohmic) 4 A

AC-15 (inductive) 3 A

U Min. 24 V

Accuracy: +/- 0.5°C

Resolution:1 mV

Accuracy +/- 10 mV

Max. connection of 5 pressure transmitters on one module

O at R > 2K ohm

(Gold -plated contacts not necessary)

O: U < 2 V

On: U > 10 V

O: U < 24 V

On: U > 80 V

Max. 230 V

Low and high voltage must not be connected to the same

output group

Max. 0.5 A,

Leak < 1 mA

During operation -20 to 55°C ,

0 to 95% RH (non condensing)

No shock inuences / vibrations

Enclosure Material PC / ABS

Class IP10 , VBG 4

Mounting For mounting on panel wall or DIN rail

Weight with screw terminals modules in100- / 200- / controller-series Ca. 200 g / 500 g / 600 g

Approvals EU low voltage directive and EMC require-

ments are complied with

UL 873,

The mentioned data applies to all modules.

If data is specic, this is mentioned together with the module in question.

Capacitive load

The relays cannot be used for the direct connection of capacitive loads such as LEDs

and on/o control of EC motors.

All loads with a switch mode power supply must be connected with a suitable contactor or similar.

LVD tested according to EN 60730

EMC tested

Immunity according to EN 61000-6-2

Emission according to EN 61000-6-3

UL le number: E166834 for XM

UL le number: E31024 for PC

10 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

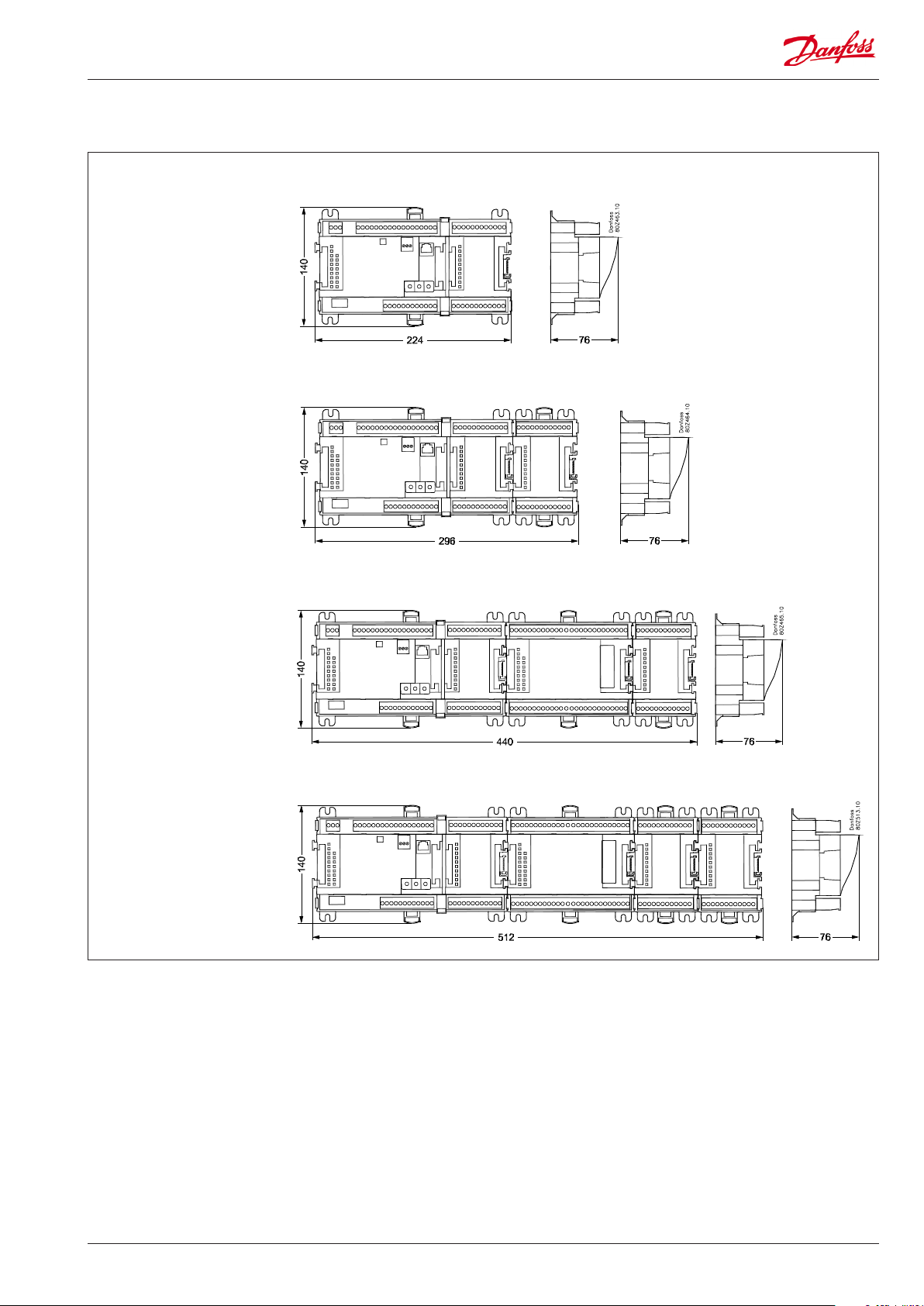

Dimensions

AK-PC 710

AK-PC 710 + AK-XM 102

AK-PC 710 + AK-XM 204 + AK-XM 102

AK-PC 710 + AK-XM 204 + AK-XM 102 + AK-XM 102

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 11

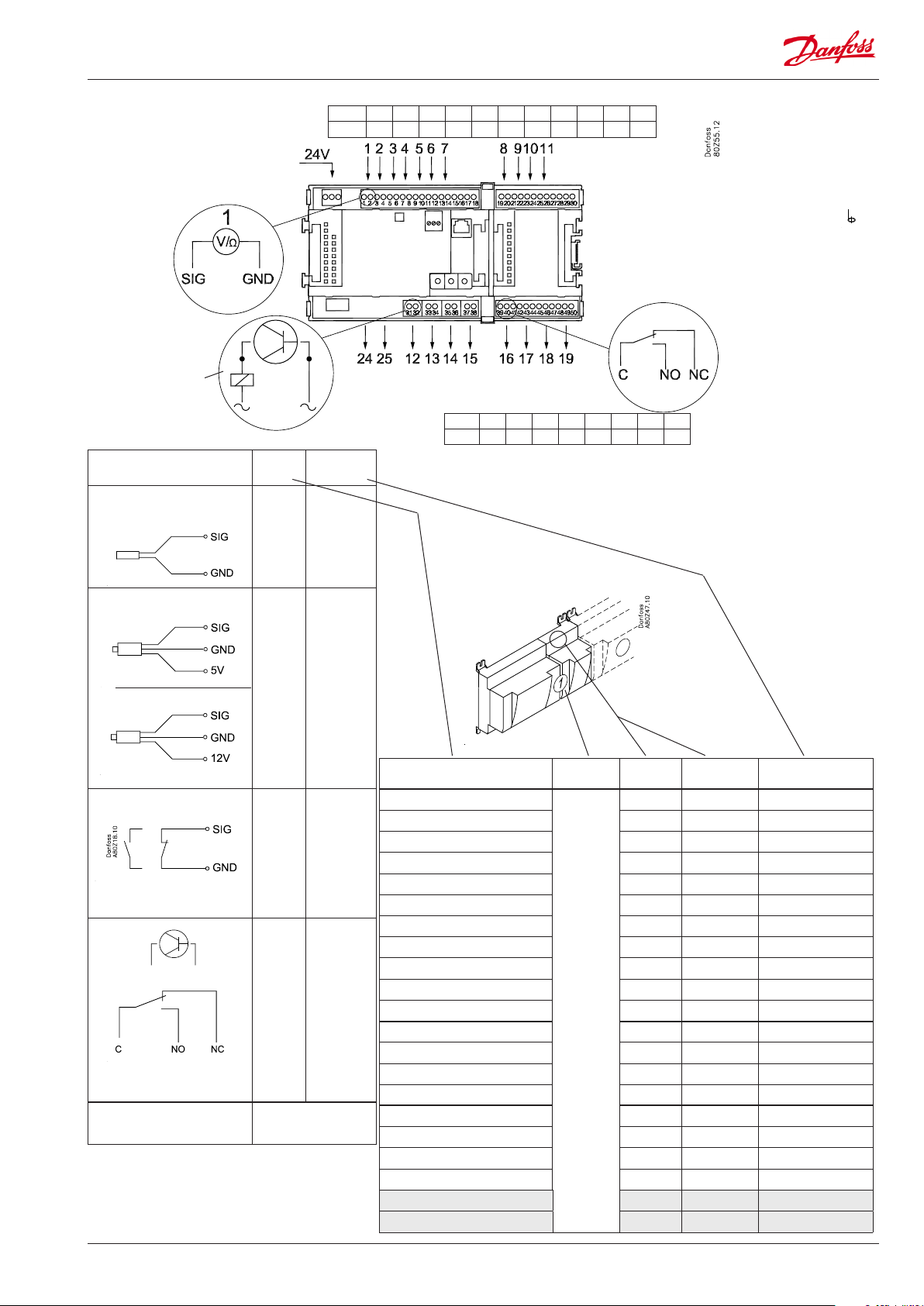

Controller

Function

There are several controllers in the series. The function is

determined by the programmed software, but outwardly the

controllers are identical – they all have the same connection

possibilities:

11 analog inputs for sensors, pressure transmitters, voltage signals

and contact signals.

8 digital outputs, with 4 Solid state outputs and 4 relay outputs

Supply voltage

24 V a.c. or d.c. to be connected to the controller.

The 24 V must not be retransmitted and used by other controllers

as it is not galvanically separated from inputs and outputs. In

other words, you must use a transformer for each controller. Class

II is required. The terminals must not be earthed.

The supply voltage to any extension modules is transmitted via

the plug on the right-hand side.

The size of the transformer is determined by the power

requirement of the total number of modules.

The supply voltage to a pressure transmitter can be taken either

from the 5 V output or from the 12 V output depending on

transmitter type.

PIN

Data communication

If the controller is to be included in a system, communication

must take place via the LON connection.

The installation has to be made as mentioned in the separate

instructions for LON communication.

Address setting

When the controller is connected to a gateway type AKA 245,

the controller’s address must be set between 1 and 119. (If it is a

system manager AK-SM .., then 1-999).

Service PIN

When the controller is connected to the data communication

cable the gateway must have knowledge of the new controller.

This is obtained by pushing the key PIN. The LED “Status” will ash

when the gateway sends an acceptance message.

Operation

The conguration operation of the controller must take place from

the software programme “Service Tool”. The program must be

installed on a PC, and the PC must be connected to the controller

via the network plug on the front of the unit.

Light-emitting diodes

There are two rows with LED’s. They mean:

Left row:

• Voltage supply to the controller

• Communication active with the bottom PC board (red = error)

• Status of outputs DO1 to DO8

Right row:

• Software status (slow ash = OK)

• Communication with Service Tool

• Communication on LON

• Alarm when LED ashes

- 3 LED’s that are not used

• “Service Pin” switch has been activated

Address

Keep the safety

distance!

Low and high

voltage must not

be connected to

the same output

group

■ Power

■ Comm

■ DO1 ■ Status

■ DO2 ■ Service Tool

■ DO3 ■ LON

■ DO4

■ DO5 ■ Alarm

■ DO6

■ DO7

■ DO8 ■ Service Pin

Slow ash = OK

Quick ash = answer from gateway

Constantly ON = error

Constantly OFF = error

Flash = active alarm/not cancelled

Constant ON = Active alarm/cancelled

A small module (option board) can be placed on the bottom part

of the controller. The module is described later in the document.

12 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

Point

Point 1 2 3 4 5 6 7 8 9 10 11

Type AI1 AI2 AI3 AI4 AI5 AI6 AI7 AI8 AI9 AI10 AI11

Terminal 15: 12 V

Terminal 16: 5 V

Terminal 27: 12 V

Terminal 28: 5 V

Analog

inputs

on 1 - 11

Solid state outputs

on 12 - 15

Relay

fx 230 V a.c.

Signal Signal

S

Pt 1000 ohm/0°C

Saux1

Sc3

SS

Sd

P

AKS 32R

3: Brown

2: Blue

1: Black

P0

Pc

AKS 32

3: Brown

2: Black

1: Red

On/O Ext.

Main

switch

Day/

Night

PLP

PHP

LL

DO

Comp 1-6

Fan 1

Alarm

Option Board

Please see the signal

on the page with the

module.

24 and 25 used

only when "Option board tted"

type

Pt 1000

AKS 32R/

AKS 2050

-1 - xx bar

AKS 32

-1 - zz bar

Active at:

Closed

/

Open

Active at:

On

/

O

Relay outputs on

16 - 19

Point 12 13 14 15 16 17 18 19

Type DO1 DO2 DO3 DO4 DO5 DO6 DO7 DO8

Signal Module Point

Terminal

1 (AI 1) 1 - 2

2 (AI 2) 3 - 4

3 (AI 3) 5 - 6

4 (AI 4) 7 - 8

5 (AI 5) 9 - 10

6 (AI 6) 11 - 12

7 (AI 7) 13 - 14

8 (AI 8) 19 - 20

9 (AI 9) 21 - 22

10 (AI 10) 23 - 24

11 (AI 11) 25 - 26

1

12 (DO 1) 31 - 32

Function and terminal number is mentioned in the actual diagram

13 (DO 2) 33 - 34

14 (DO 3) 35 - 36

15 (DO 4) 37 - 38

16 (DO 5) 39 - 40- 41

17 (DO6) 42 - 43 - 44

18 (DO7) 45 - 46 - 47

19 (DO8) 48 - 49 - 50

24 -

25 -

Terminal

17, 18, 29, 30:

(Cable screen)

Signal type /

Active at

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 13

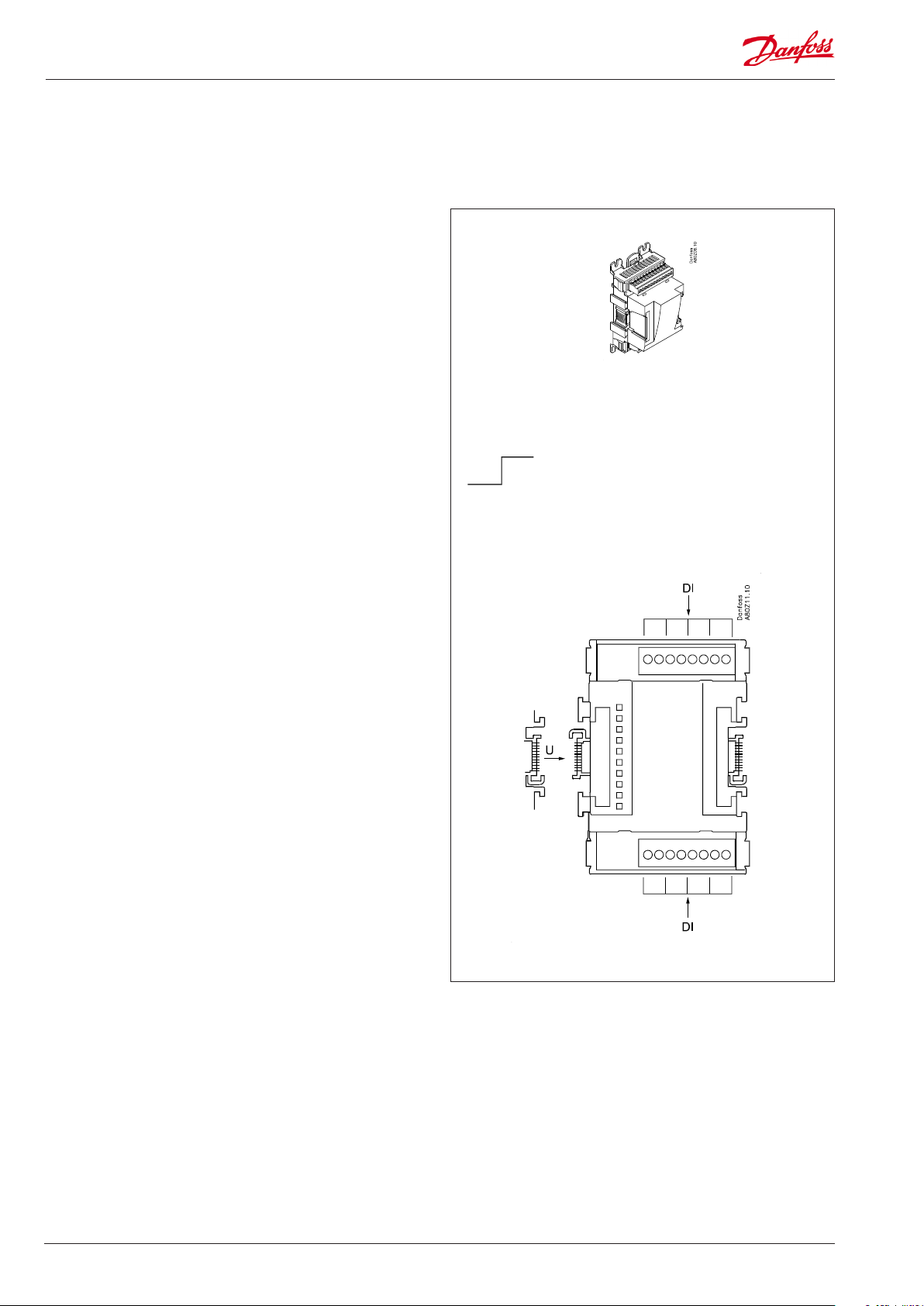

Extension module AK-XM 102A / AK-XM 102B

Function

The module contains 8 inputs for on/o voltage signals.

Signal

AK-XM 102A is for low voltage signals.

AK-XM 102B is for high voltage signals.

Supply voltage

The supply voltage to the module comes from the previous

module in the row.

Light-emitting diodes

They indicate:

• Voltage supply to the module

• Communication with the controller is active (red = error)

• Status of the individual inputs 1 to 8 (when lit = voltage)

AK-XM 102A

Max. 24 V

On/O:

On: DI > 10 V a.c.

O: DI < 2 V a.c.

AK-XM 102B

Max. 230 V

On/O:

On: DI > 80 V a.c.

O: DI < 24 V a.c.

14 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

Point

DI

Point 1 2 3 4

Type DI1 DI2 DI3 DI4

Point 5 6 7 8

Type DI5 DI6 DI7 DI8

Signal Active at

AK-XM 102A: Max. 24 V

AK-XM 102B: Max. 230 V

Day/

Night

Comp.

safety 1-6

Cond.fan

safety

Closed

(voltage on)

/

Open

(voltage o)

Signal Module Point Terminal Active at

1 (DI 1) 1 - 2

2 (DI 2) 3 - 4

3 (DI 3) 5 - 6

4 (DI 4) 7 - 8

3 (2)

Function and terminal number is mentioned in the actual diagram

5 (DI 5) 9 - 10

6 (DI 6) 11 - 12

7 (DI 7) 13 - 14

8 (DI 8) 15 - 16

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 15

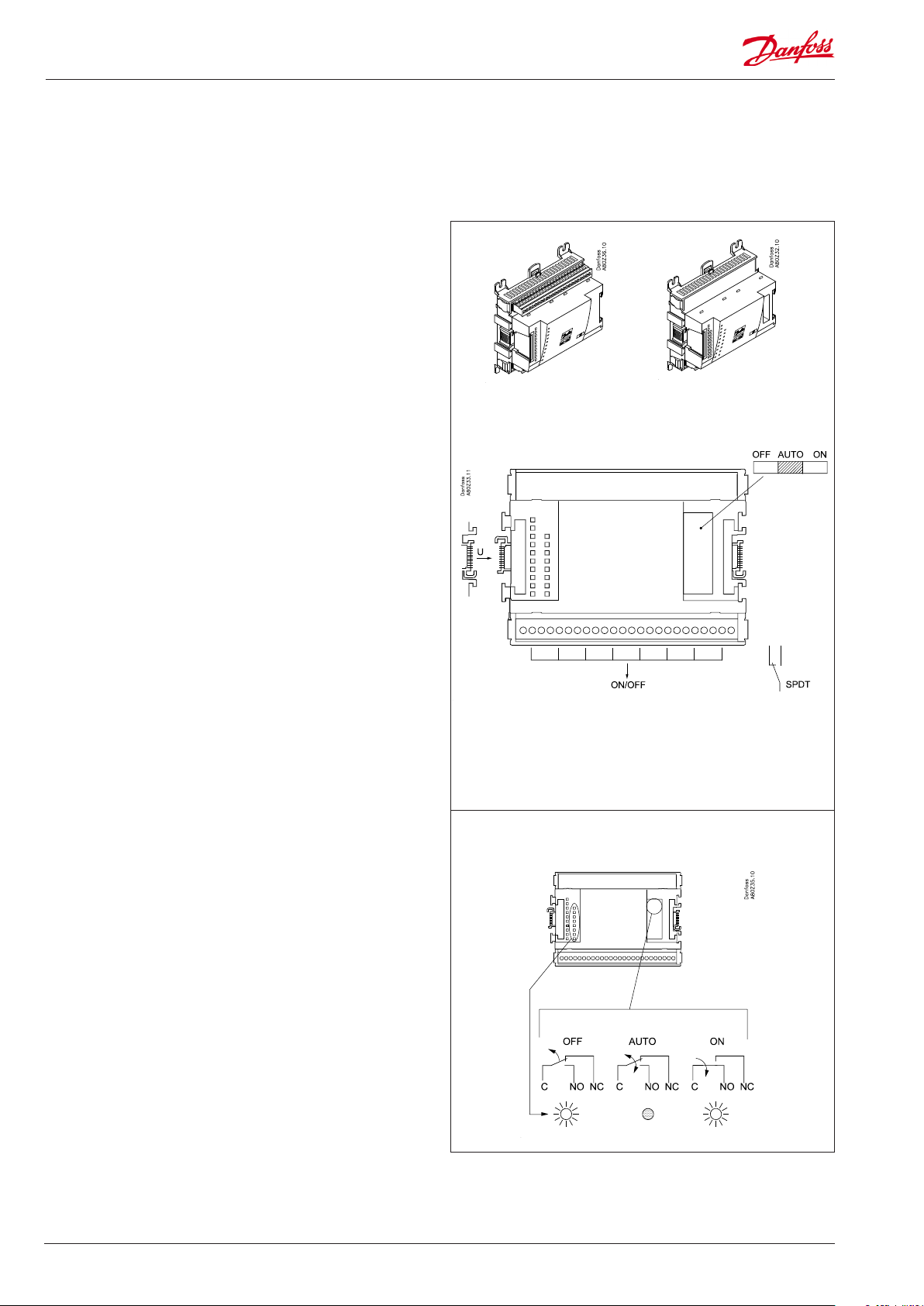

Extension module AK-XM 204A / AK-XM 204B

Function

The module contains 8 relay outputs.

Supply voltage

The supply voltage to the module comes from the previous

module in the row.

AK-XM 204B only

Override of relay

Eight change-over switches at the front make it possible to

override the relay’s function.

Either to position OFF or ON.

In position Auto the controller carries out the control.

Light-emitting diodes

There are two rows with LED’s. They indicate the following:

Left row:

• Voltage supply to the controller

• Communication active with the bottom PC board (red = error)

• Status of outputs DO1 to DO8

Right row: (AK-XM 204B only):

• Override of relays

ON = override

OFF = no override

AK-XM 204A AK-XM 204B

Fuses

Behind the upper part there is a fuse for each output.

Max. 230 V

AC-1: max. 4 A (ohmic)

AC-15: max. 3 A (Inductive)

AK-XM 204B

Override of relay

Keep the safety distance!

Low and high voltage

must not be connected to

the same output group

16 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

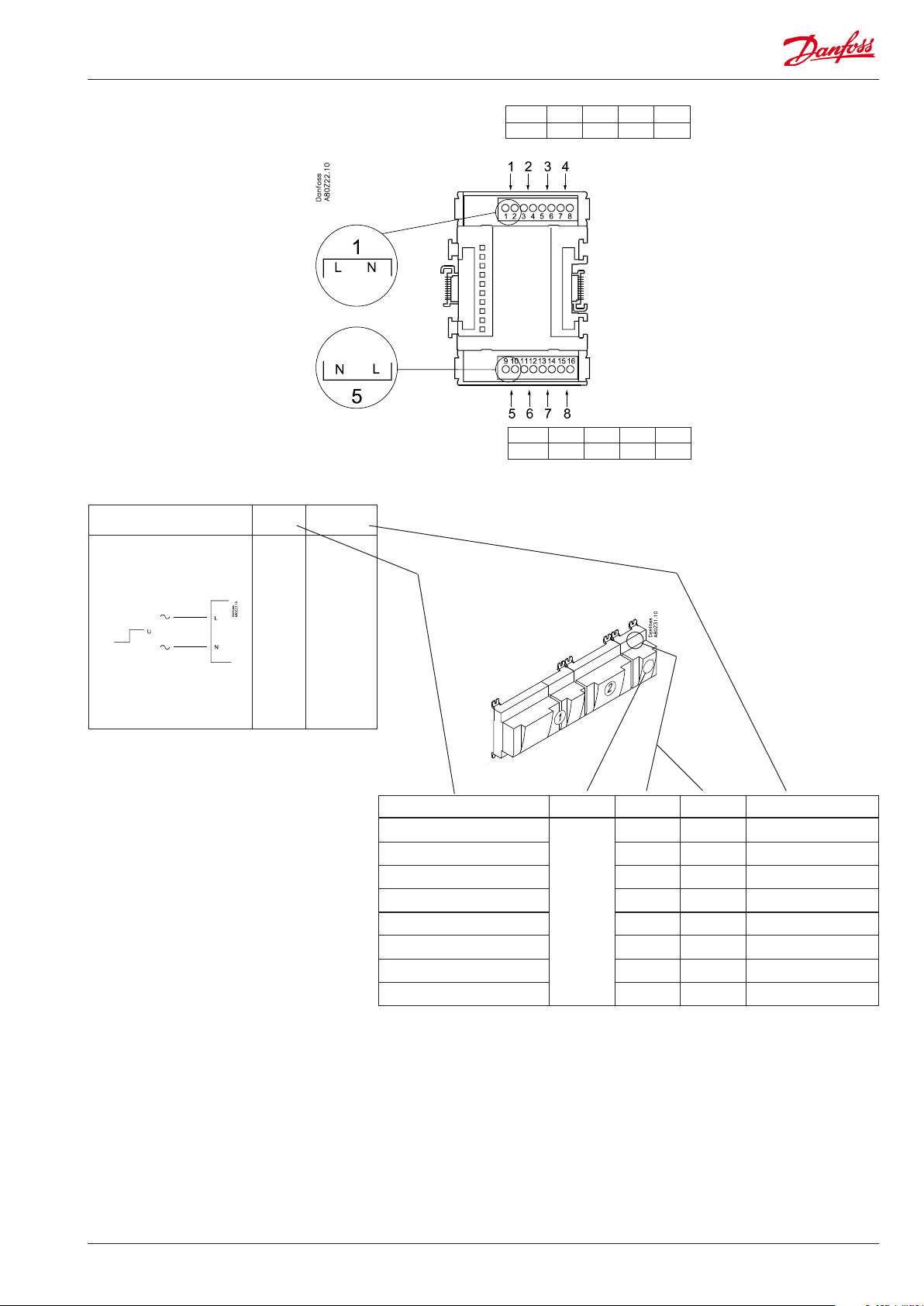

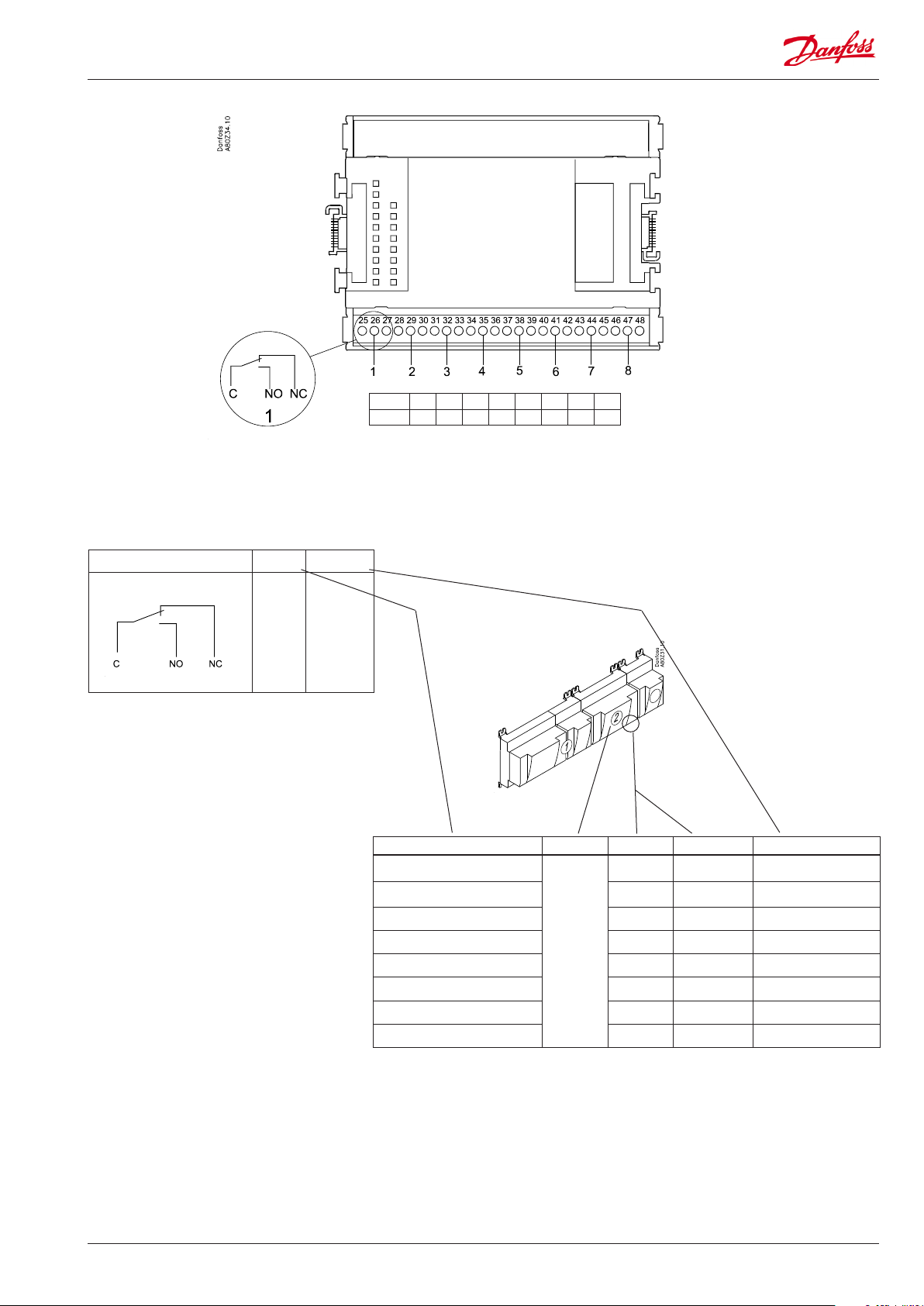

Point

DO

Signal Active at

On

Fans 1

Alarm

/

O

Point 1 2 3 4 5 6 7 8

Type DO1 DO2 DO3 DO4 DO5 DO6 DO7 DO8

Signal Module Point Terminal Active at

1 (DO 1) 25 - 27

2 (DO 2) 28 - 30

3 (DO 3) 31 - 33

2

4 (DO 4) 34 -36

5 (DO 5) 37 - 39

6 (DO 6) 40 - 41 - 42

7 (DO 7) 43 - 44 - 45

Function and terminal number is mentioned in the actual diagram

8 (DO 8) 46 - 47 - 48

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 17

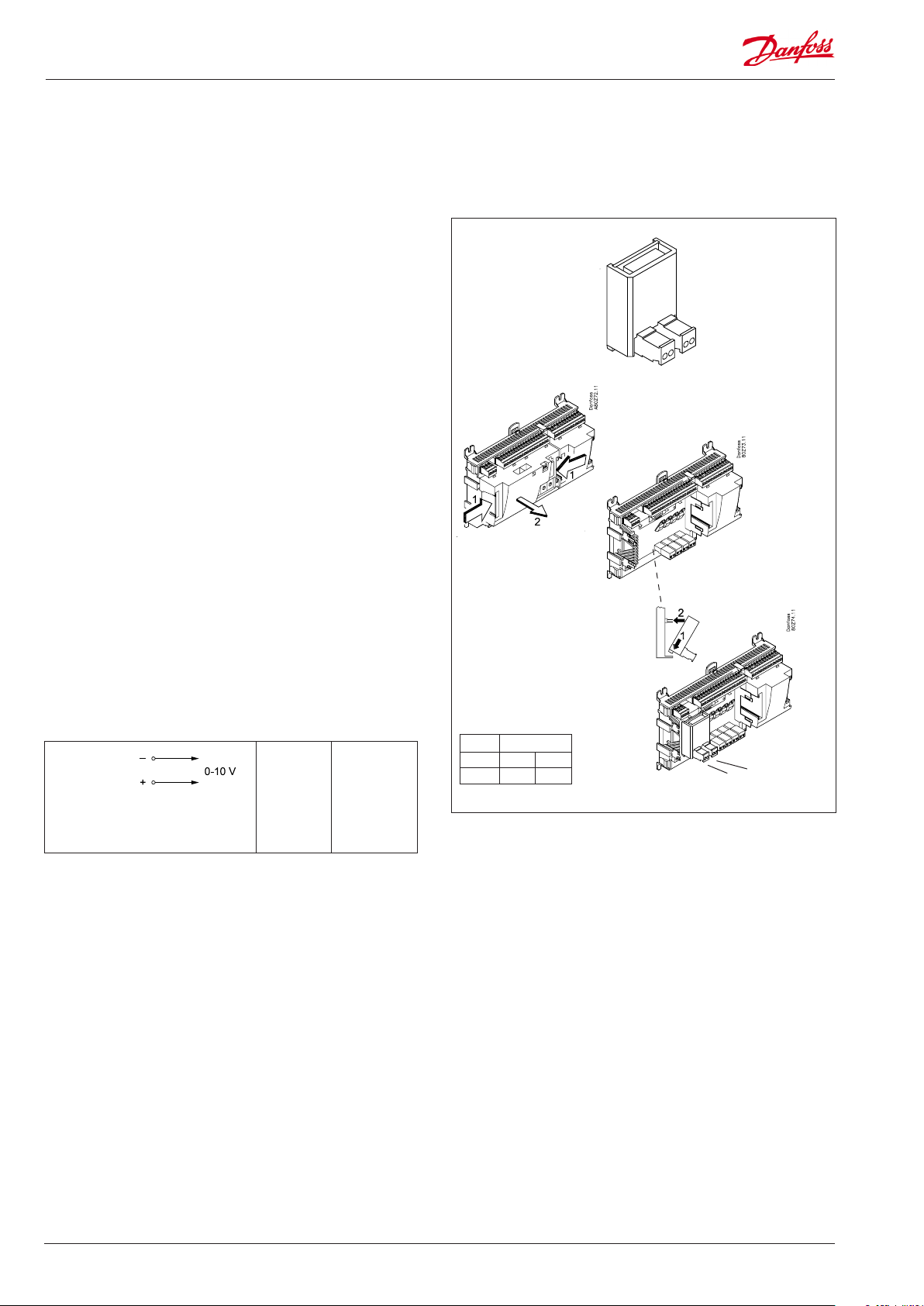

Extension module AK-OB 110

Function

The module contains two analog voltage outputs of 0 – 10 V.

Supply voltage

The supply voltage to the module comes from the controller

module.

Placing

The module is placed on the PC board in the controller module.

Point

The two outputs have points 24 and 25. They are shown on the

earlier page where the controller is also mentioned.

Max. load

I < 2.5 mA

R > 4 kohm

AO AO1:

Comp.speed

AO2:

Cond.speed

0 - 10 V

Module

Point 24 25

Type AO1 AO2

1

AO2

AO1

18 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

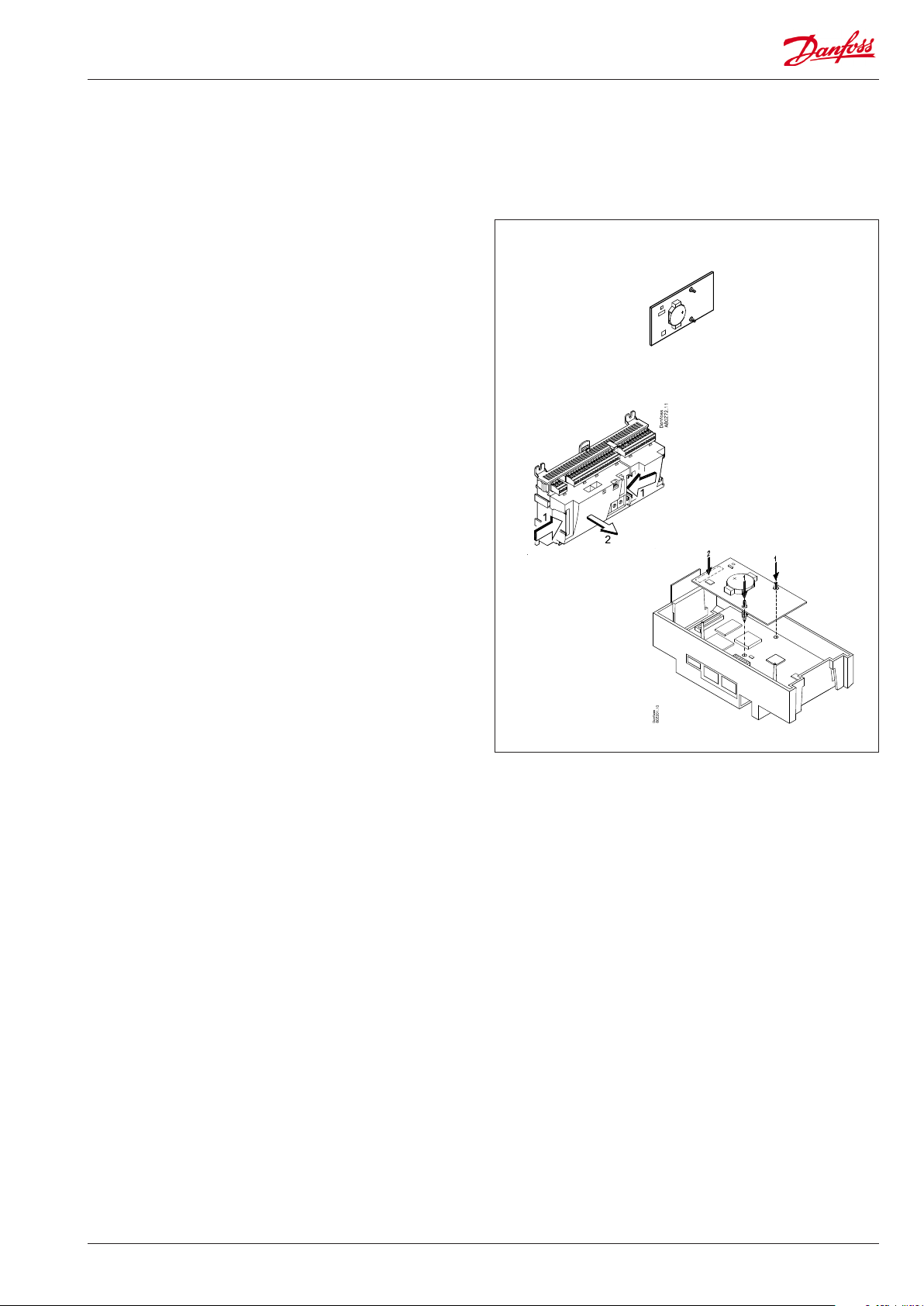

Extension module AK-OB 101A

Function

The module is a real time clock module with battery backup.

The module can be used in controllers that are not linked up in

a data communication unit together with other controllers. The

module is used here if the controller needs battery backup for the

following functions

• Clock function

• Fixed times for day/night change-over

• Saving of alarm log in case of power failure

• Saving of temperature log in case of power failure

Connection

The module is provided with plug connection.

Placing

The module is placed on the PC board inside the top part.

Point

No point for a clock module to be dened – just connect it.

Working life of the battery

The working life of the battery is several years – even if there are

frequent power failures.

An alarm is generated when the battery has to be replaced.

After the alarm there are still several months of operating hours

left in the battery.

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 19

Extension module EKA 163B / EKA 164B

Function

Display of important measurements from the controller, e.g.

suction pressure or condensing pressure.

Setting of the individual functions can be performed by using the

display with control buttons.

Connection

The extension module is connected to the controller module via

a cable with plug connections. You have to use one cable per

module. The cable is supplied in various lengths.

Both types of display (with or without control buttons) can be

connected to either display output A, and B.

A = P0 . Suction pressure in °C

B = Pc. Condensing pressure in °C

EKA 166 further includes a number of LEDs to make it possible to

follow individual functions.

When the controller starts up, the display will show which output

is connected. - - 1 = output A, - - 2 = output B, etc.

Placing

The extension module can be placed at a distance of up to 15 m

from the controller module.

EKA 163B EKA 164B

EKA 166

Module

Point - -

Type - -

1

Point

No point has to be dened for a display module – you simply

connect it.

Graphic display AK-MMI

Function

Setting and display of values in the controller.

Connection

The display connects to the controller via a cable with plug connections. Use plug RJ45 to connect to the controller; the same

plug is also used for service tool AK-ST 500.

Supply voltage

24 V a.c. / d.c. 1.5 VA.

Placing

The display can be placed at a distance of up to 3 m from the

controller.

Point

No point has to be dened for a display – you simply connect it.

20 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

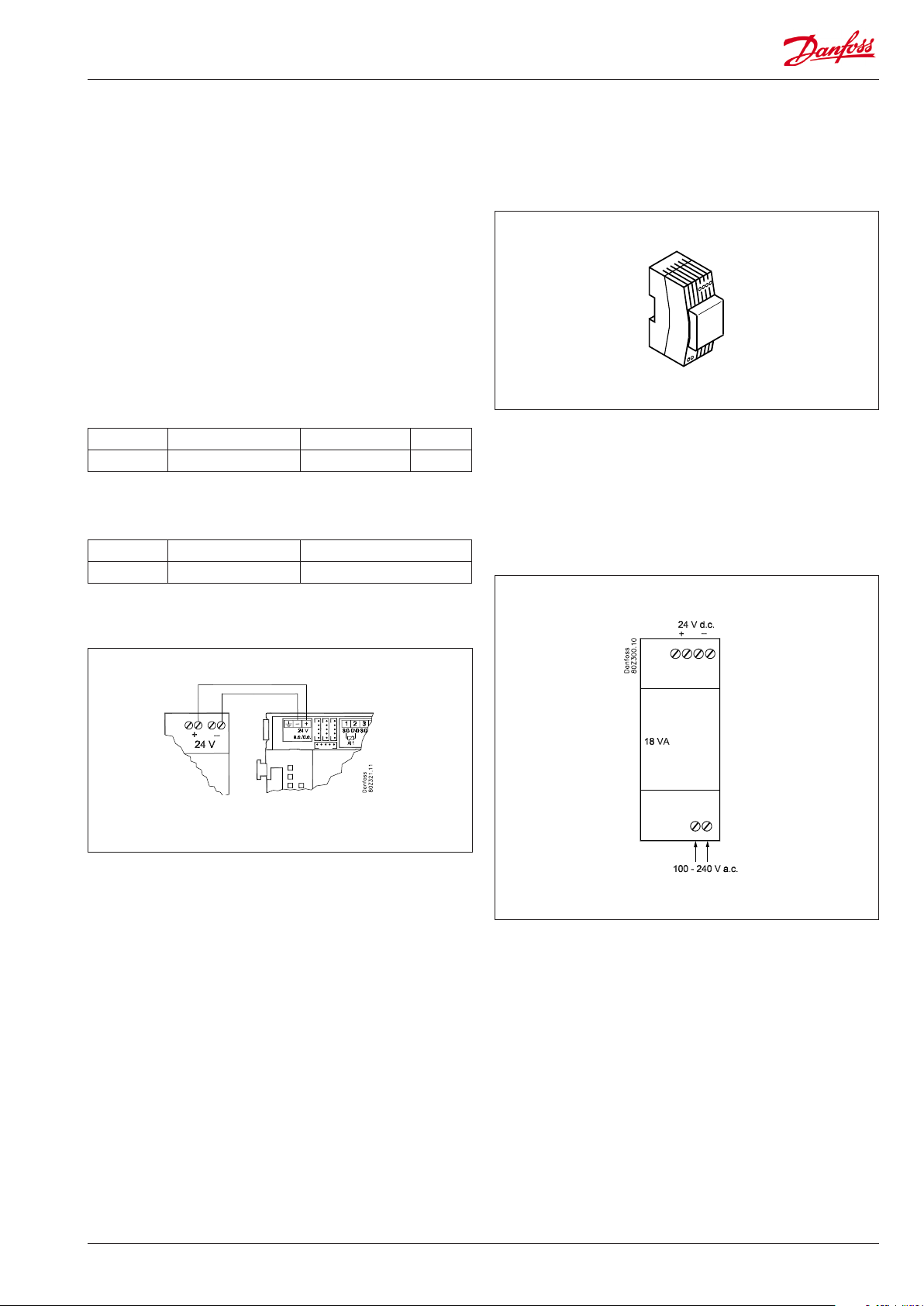

Power supply module AK-PS 075

Function

24 V supply for controller.

Supply voltage

230 V a.c or 115 V a.c. (from 100 V a.c. to 240 V a.c.)

Placing

On DIN-rail

Eect

Type Output tension Output current Power

AK-PS 075 24 V d.c. 0.75 A 18 VA

Dimension

Type High Width

AK-PS 075 90 mm 36 mm

Connections

Supply to a controller

AK-PS 075

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 21

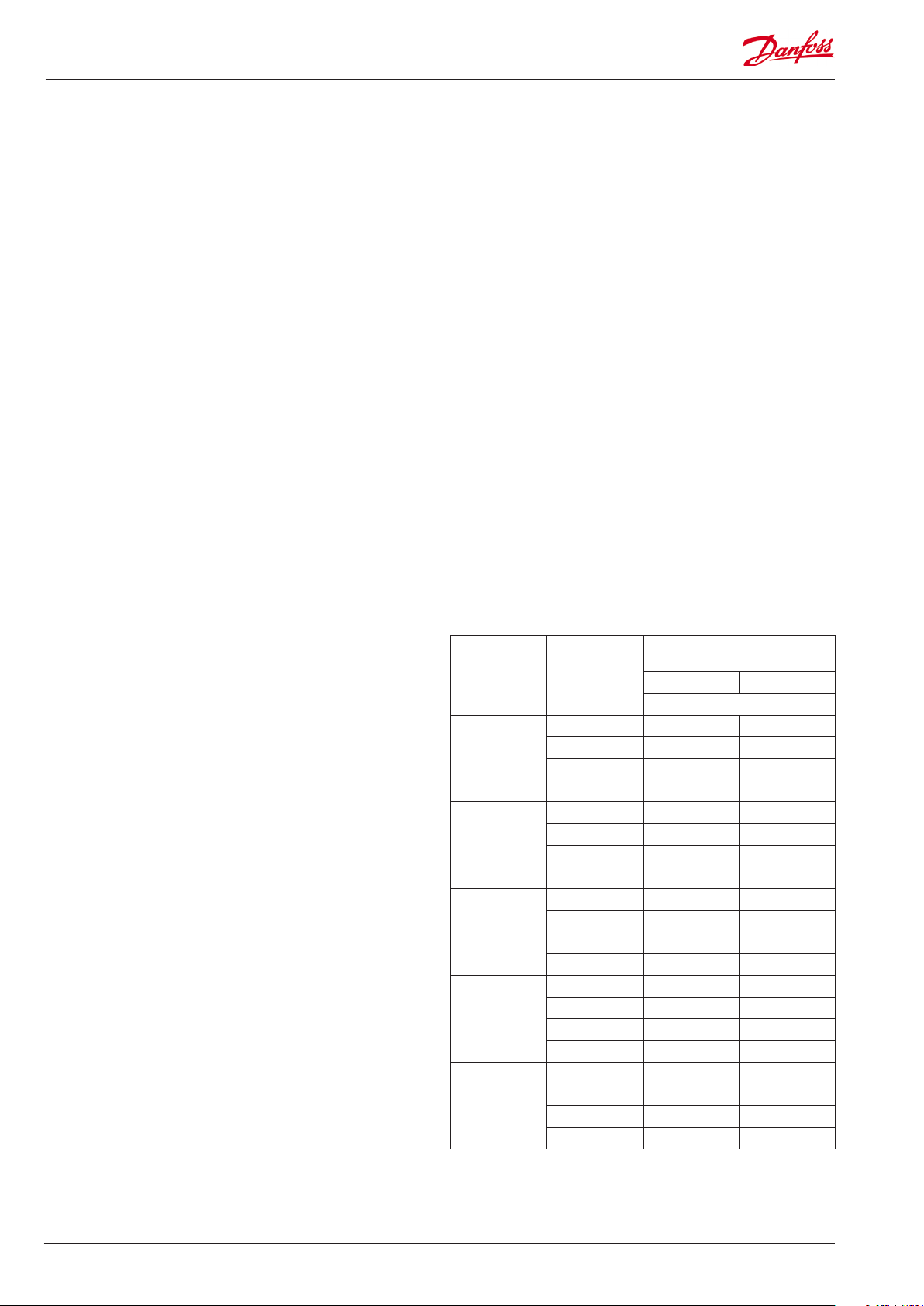

Select application

General

Clock function

Clock function and change-over between summer time and

winter time are contained in the controller.

The clock is zeroset when there is power failure.

The clock’s setting is maintained if the controller is linked up in a

network with a gateway, a system manager or a clock module can

be mounted in the controller.

Start/stop of regulation

Regulation can be started and stopped via the software or via an

input on the controller module

Application

40 examples of application are shown in the following: Select the

one that ts your system.

Wiring should be done as shown, and the controller should be

set for this application.

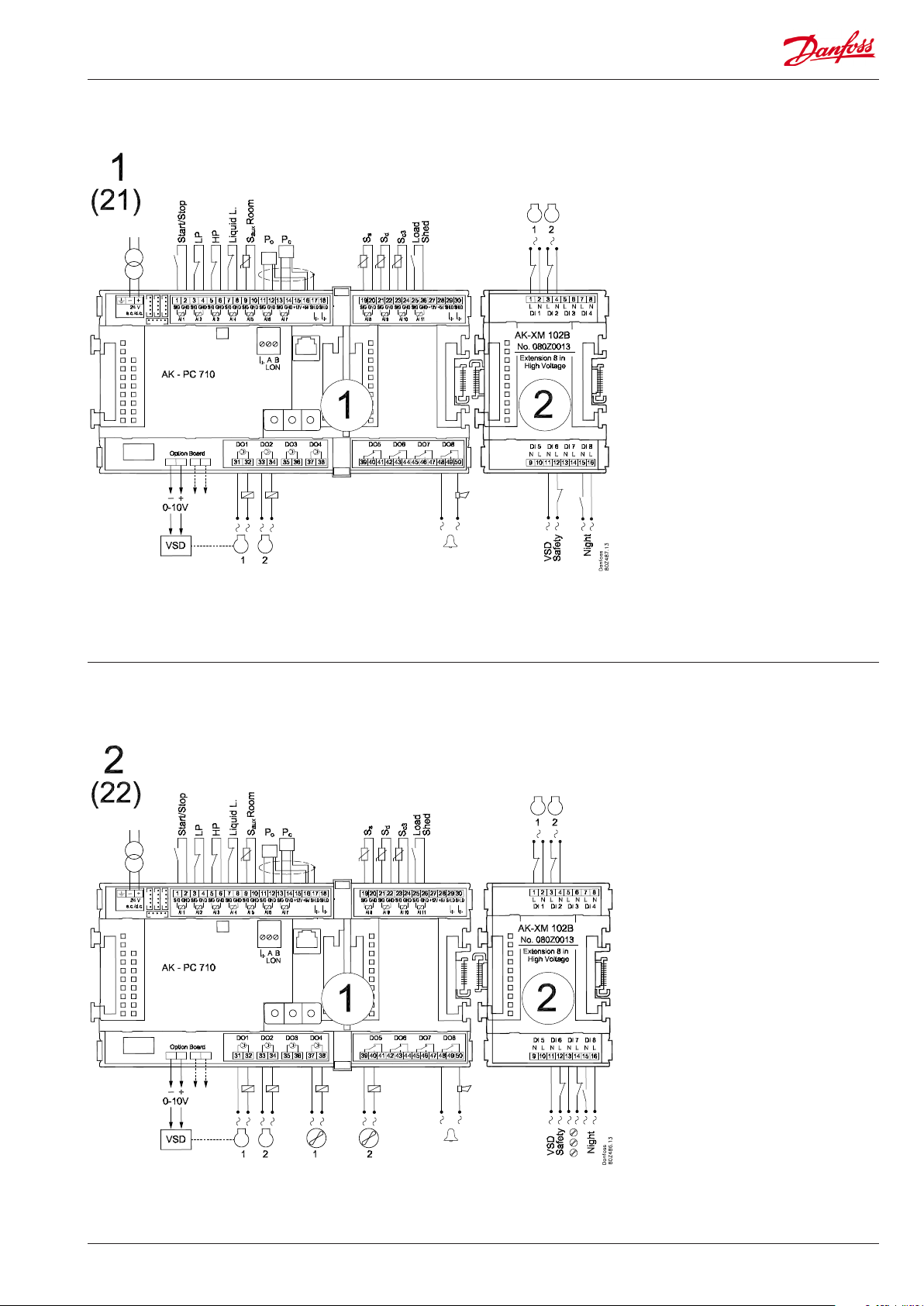

Regarding speed regulation

An option board has 2 outputs:

No. 1 is dedicated to the compressor

No. 2 is dedicated to the condenser fans

If you do not use speed control, disregard the shown 0-10 V

outputs.

It is only the compressor connection that is shown in all examples,

but output 2 can be used for condenser fans at will.

If the speed control needs a start/stop signal, this should be taken

from output "Compressor 1" or from "Fan 1".

Forced control

The software contains a forced control option. If an extension

module with relay outputs is used, the module’s top part can

be with change-over switches – switches that can override the

individual relays into either OFF or ON position.

Data communication

The controller module has terminals for LON data communication.

The requirements to the installation are described in a separate

document.

Number of

compressors

2 0 1 21

3 0 5 25

4 0 9 29

5 0 13 33

6 0 17 37

Number of

condenser fans

2 2 22

3 3 23

4 4 24

3 6 26

4 7 27

5 8 28

3 10 30

4 11 31

5 12 32

4 14 34

5 15 35

6 16 36

4 18 38

5 19 39

6 20 40

Speed regulation on one compressor

Yes No

Application no.

22 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

Application 1 and 21 (for 21 leave out the VSD connection on the option board)

Application 2 and 22 (for 22 leave out the VSD connection on the option board)

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 23

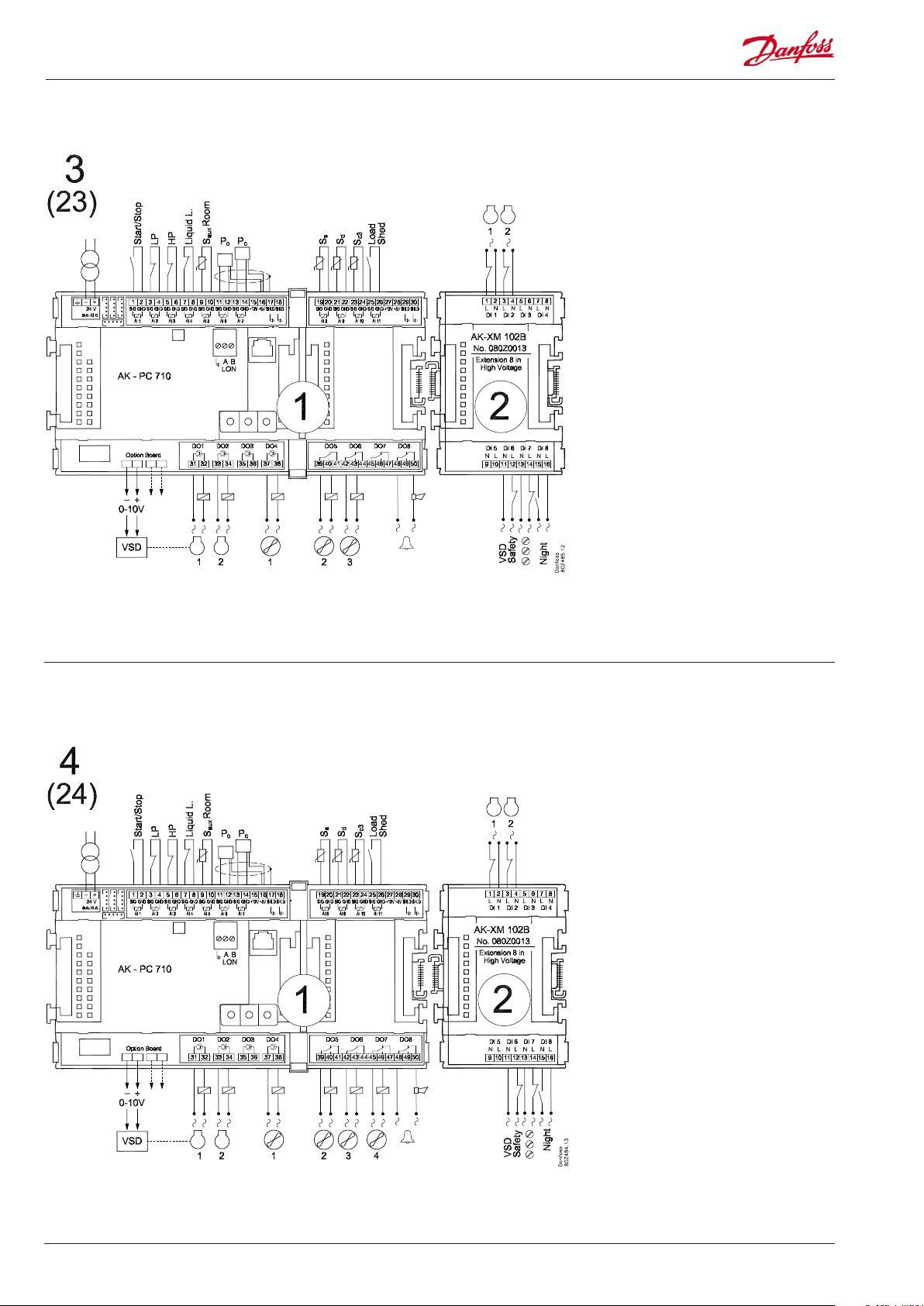

Application 3 and 23 (for 23 leave out the VSD connection on the option board)

1

Application 4 and 24 (for 24 leave out the VSD connection on the option board)

24 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

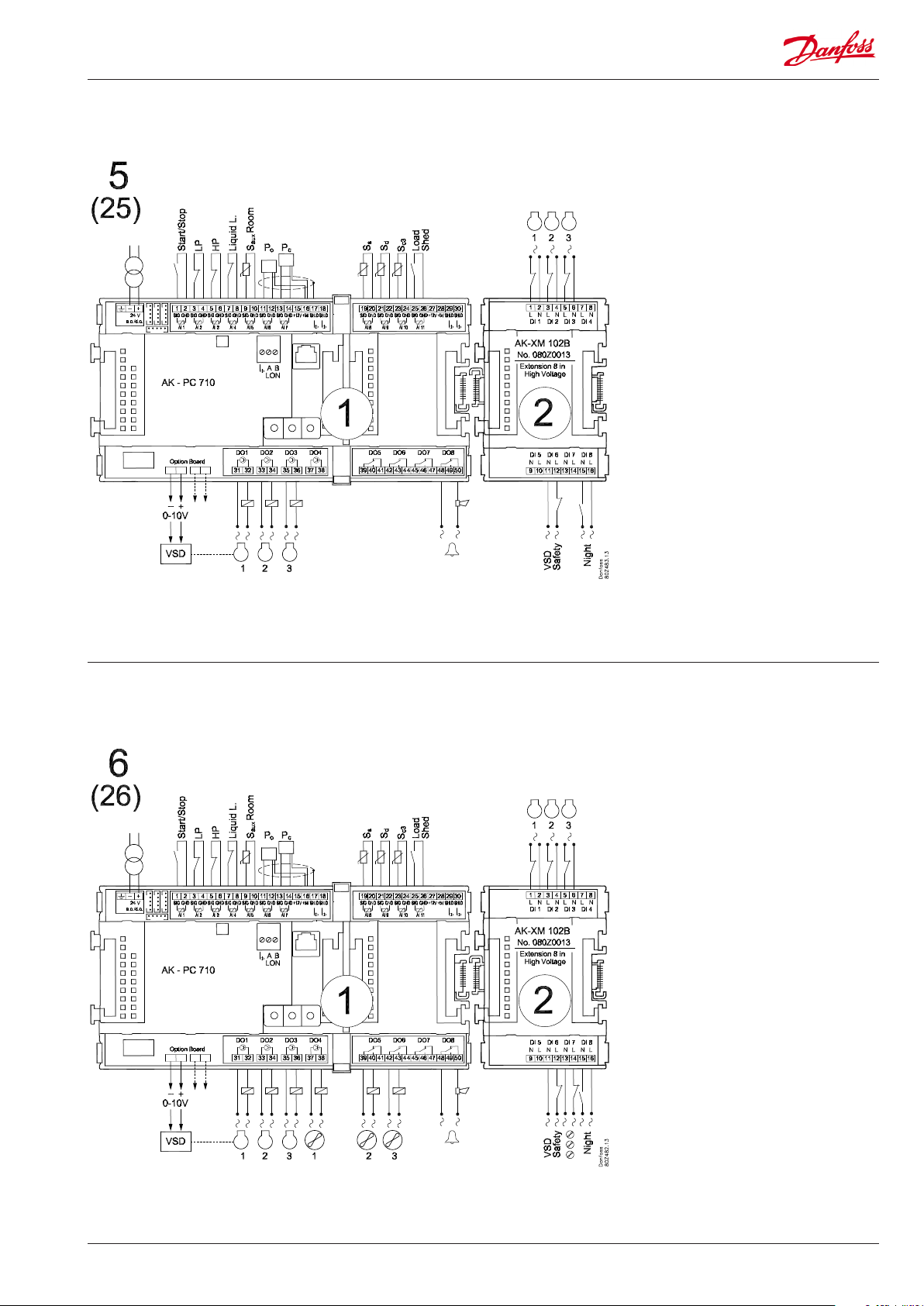

Application 5 and 25 (for 25 leave out the VSD connection on the option board)

Application 6 and 26 (for 26 leave out the VSD connection on the option board)

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 25

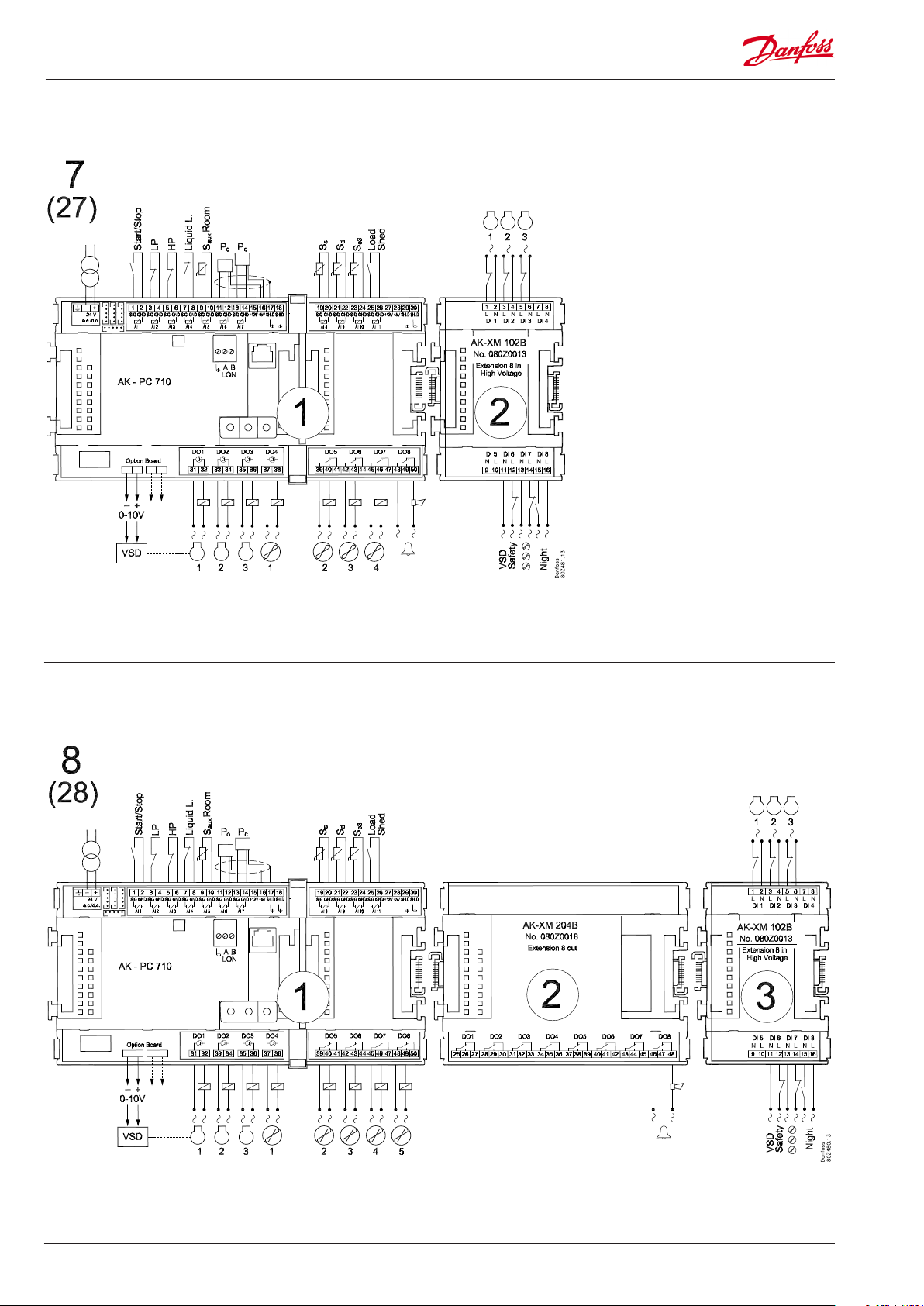

Application 7 and 27 (for 27 leave out the VSD connection on the option board)

Application 8 and 28 (for 28 leave out the VSD connection on the option board)

26 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

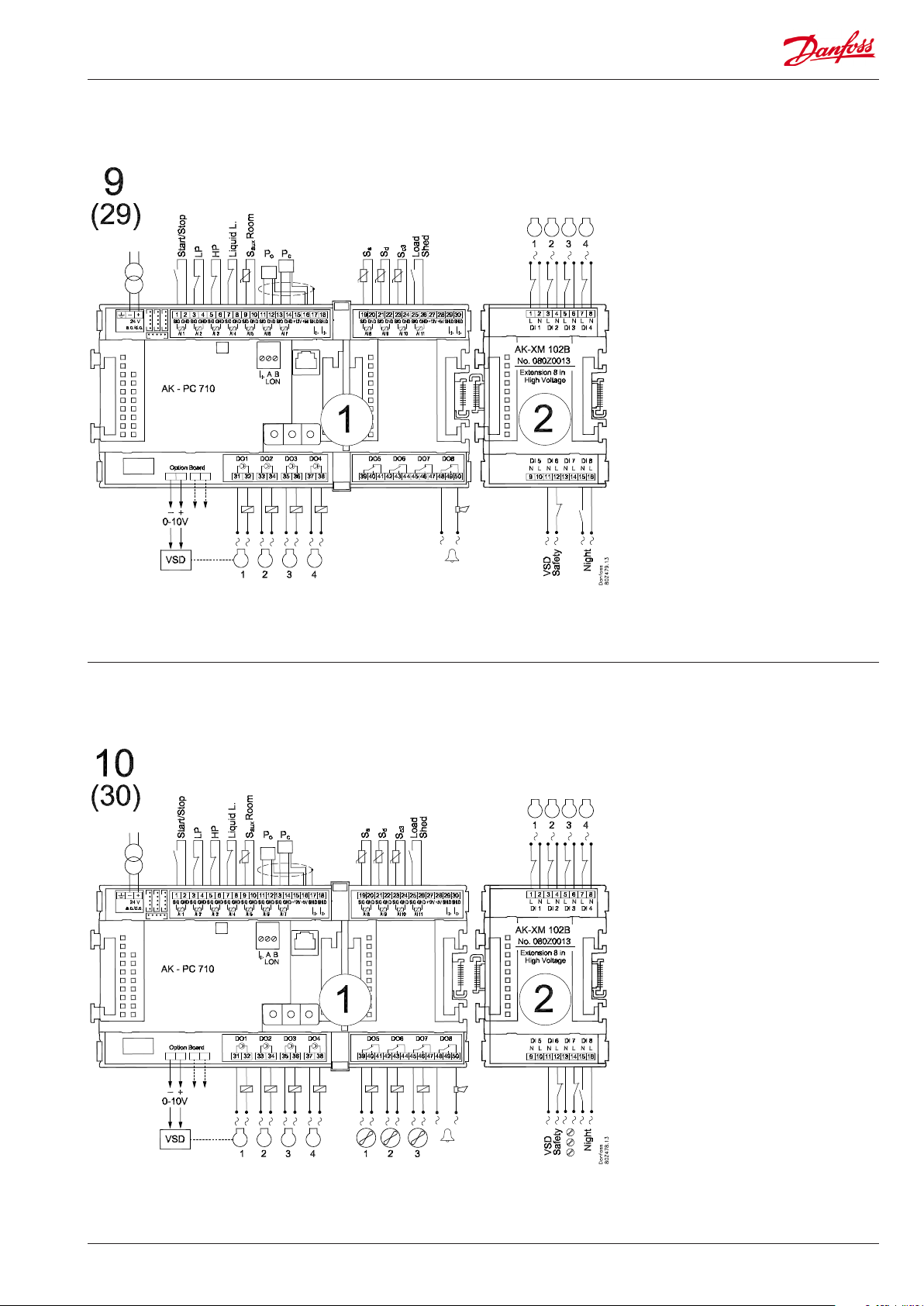

Application 9 and 29 (for 29 leave out the VSD connection on the option board)

Application 10 and 30 (for 30 leave out the VSD connection on the option board)

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 27

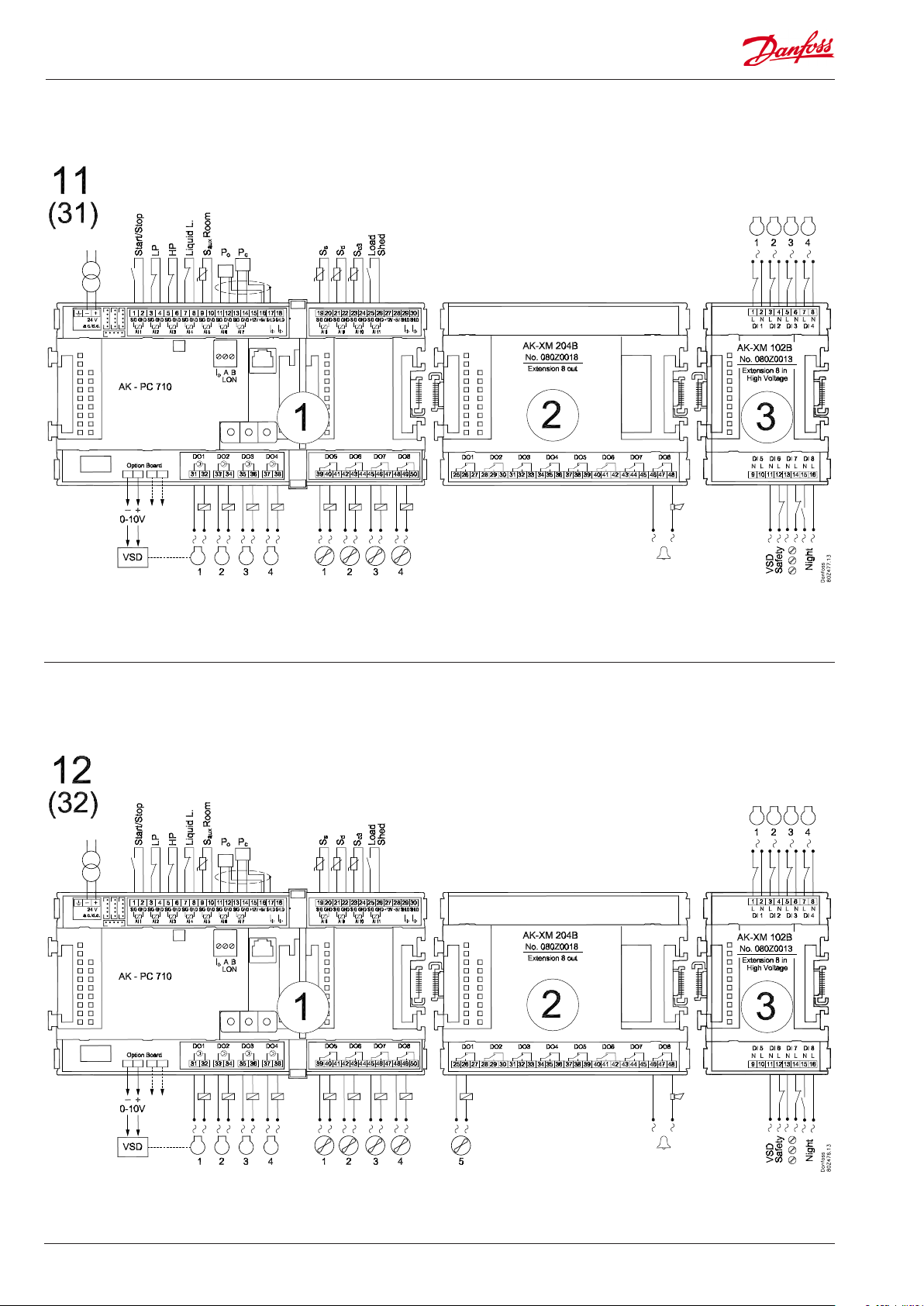

Application 11 and 31 (for 31 leave out the VSD connection on the option board)

Application 12 and 32 (for 32 leave out the VSD connection on the option board)

28 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

Application 13 and 33 (for 33 leave out the VSD connection on the option board)

Application 14 and 34 (for 34 leave out the VSD connection on the option board)

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 29

Application 15 and 35 (for 35 leave out the VSD connection on the option board)

Application 16 and 36 (for 36 leave out the VSD connection on the option board)

30 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

Application 17 and 37 (for 37 leave out the VSD connection on the option board)

Application 18 and 38 (for 38 leave out the VSD connection on the option board)

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 31

Application 19 and 39 (for 39 leave out the VSD connection on the option board)

Application 20 and 40 (for 40 leave out the VSD connection on the option board)

32 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

Ordering

1. Controller

Type Function Language Code no.

AK-PC 710 Controller for capacity control of up to 6 compressors and up to 6 condenser fans

2. Extension modules and survey for inputs and outputs

Type Analog

inputs

For sensors,

pressure

transmitters

etc.

Controller 11 4 4 - - - - -

Extension modules

AK-XM 102A 8 080Z0008

AK-XM 102B 8 080Z0013

AK-XM 204A 8 080Z0011

AK-XM 204B 8 x 080Z0018

AK-OB 110 2 080Z0251

On/O outputs On/o supply voltage

Relay

(SPDT)

Solid state Low voltage

(DI signal)

(max. 80 V)

High voltage

(max. 260 V)

English, German, French,

Dutch, Italian, Spanish

Analog

outputs

0-10 V d.c. For override

Module with

switches

of relay

outputs

080Z0106

Code no.

With screw

terminals

3. AK operation and accessories

Type Function Application Code no.

Operation

AK-ST 500 Software for operation of AK controllers AK-operation 080Z0161

- Cable between PC and AK controller AK - Com port 080Z0262

-

Accessories Power supply module 230 V / 115 V to 24 V

AK-PS 075 18 VA Supply for controller 080Z0053

Accessories External display that can be connected to the controller module. For showing, say, the suction pressure

EKA 163B Display 084B8574

EKA 164B Display with operation buttons 084B8575

EKA 166 Display with operation buttons and LED's for inputs and outputs 084B8578

AK-MMI Graphic display with operation 080G0311

- Cable between EKA display and controller

- Cable between graphic display and controller

Cable between zero modem cable and AK controller /

Cable between PDA cable and AK controller

Cable between PC and AK controller AK - USB 080Z0264

AK - RS 232 080Z0261

Length = 2 m 084B7298

Length = 6 m 084B7299

Length = 0.8 m 080G0074

Length = 1.5 m 080G0075

Length = 3 m 080G0076

Accessories Real time clock for use in controllers that require a clock function, but are not wired with data communication.

AK-OB 101A Real time clock with battery backup. To be mounted in an AK controller 080Z0252

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 33

34 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

3. Mounting and wiring

This section describes how the controller:

• Is tted

• Is connected

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 35

Mounting and wiring - continued

Mounting

Mounting of analog output module

1. Lift the top part o the basic module

The basic module must not be connected to voltage.

Press in the plate on the left-hand side of the light-emitting

diodes and the plate on the right-hand side for the red address

changers.

Lift the top part o the basic module.

The analog extension module will supply a signal to the variable frequency drive.

2. Mount the extension module in the basic module

3. Put the top part back on the basic module

36 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

Mounting and wiring - continued

Mounting of extension module on the

basic module

1. Move the protective cap

Remove the protective cap from the connection plug on the

right-hand side of the basic module.

Place the cap on the connection plug to the right of the extension module that is to be mounted on the extreme right-hand

side of the AK assembly.

2. Assemble the extension module and the basic

module

The basic module must not be connected to voltage.

When the two snap catches for the DIN rail mounting are in the open

position, the module can be pushed into place on the DIN rail – regardless of where the module is on the row.

Disassembly is thus done with the two snap catches in the open position.

The sequence is determined by the shown electrical diagram

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 37

Mounting and wiring - continued

Wiring

Decide during planning which function is to be connected and

where this will be.

1. Connect inputs and outputs

See the earlier selected electrical diagram:

2. Connect LON communication network

The installation of the data communication must comply with

the requirements set out in document RC8AC.

3. Connect supply voltage

Is 24 V, and the supply must not be used by other controllers or

devices. The terminals must not be earthed.

4. Follow light-emitting diodes

When the supply voltage is connected the controller will go

through an internal check. The controller will be ready in just

under one minute when the light-emitting diode ”Status” starts

ashing slowly.

5. When there is a network

Set the address and activate the Service Pin.

6. The controller is now ready to be congured.

Example

The screen on the pressure transmitter

cables must only be connected at the

end of the controller.

Internal communication

between the modules:

Quick ash = error

Constantly On = error

■ Power

■ Comm

■ DO1 ■ Status

■ DO2 ■ Service Tool

■ DO3 ■ LON

■ DO4

■ DO5 ■ Alarm

■ DO6

■ DO7

■ DO8 ■ Service Pin

Status on output 1-8

Slow ash = OK

Quick ash = answer from gateway

in 10 min. after network

installation

Constantly ON = error

Constantly OFF = error

External communication

Flash = active alarm/not cancelled

Constant ON = Active alarm/cancelled

Network installation

Warning

Keep signal cables separate from

cables with high voltage.

38 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

4. Conguration and operation

This section describes how the controller:

• Is congured

• Is operated

We have decided to work on the basis of application no. 16, i.e.

compressor control with 5 compressors and condenser control

with 6 fans.

The example is shown overleaf.

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 39

Refrigerating plant example

We have decided to describe the setup by means of an example

comprising a compressor group and a condenser.

The example is the same as the one given in the "Application no.

16", i.e. the controller is an AK-PC 710 + 3 extension modules.

Compressor pack:

• Refrigerant R134a

• 1 only speed-regulated compressor (30 kW, 30-60 Hz)

• 4 only compressors (15 kW) with working-hour equalisation

• Safety monitoring of each compressor

• Common high-pressure monitoring

• Common low-pressure monitoring

• Po setting -15°C, night displacement 5 K

Condenser:

• 6 fans, step regulation

• Pc regulates based on outdoor temperature Sc3

Receiver:

• Monitoring of liquid level in receiver

Plant room

• Monitoring of temperature in plant room

Safety functions:

• Monitoring of Po, Pc, Sd and superheat on suction line

• Po max = -5°C, Po min = -35°C

• Pc max = 50 °C

• Sd max = 120°C

• SH min = 5 °C, SH max = 35 °C

Other:

• Alarm output used

• External main switch used

• Monitoring of frequency converter (VSD)

For the example shown we use the following modules:

• AK-PC 710 basic module

• AK-XM 204B relay module

• AK-XM 102B digital input module

• AK-OB 110 analog output module

NB!

The capacity of the compressor with speed adjustment should be

greater than that of the other compressors.

This ensures that there are no "gaps" in the cut in capacity.

See chapter 5, Adjustment functions.

There is also an internal main switch as a setting. Both must be “ON”

before any adjustment is made.

The used modules is selected in the Design phase.

40 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

Conguration via service tool

AK-ST 500

Connect PC

PC with the program “Service Tool” is connected to the controller.

The controller must be switched on rst and the LED “Status” must

ash before the Service Tool programme is started.

Start Service Tool programme

For connecting and operating the "AK service tool" software,

please see the manual for the software.

The rst time the Service Tool is connected to a new version of a controller the start-up of the Service Tool will take longer than usual while

information is retrieved from the controller.

Time can be followed on the bar at the bottom of the display.

Login with user name SUPV

Select the name SUPV and key in the access code.

When the controller is supplied the SUPV access code is 123.

When you are logged into the controller an overview of it will always

appear.

In this case the overview is empty. This is because the controller has not

yet been set up.

The red alarm bell at the bottom right tells you that there is an active

alarm in the controller. In our case the alarm is due to the fact that the

time in the controller has not yet been set.

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 41

Conguration - continued

Authorization

1. Go to Conguration menu

Press the orange setup button with the spanner at the bottom

of the display.

2. Select Authorization

3. Change setting for the user ‘SUPV‘

When the controller is supplied it has been set with standard authorization for dierent user interfaces. This setting should be changed and

adapted to the plant. The changes can be made now or later.

You will use this button again and again whenever you want to get to

this display.

On the left-hand side are all the functions not shown yet. There will be

more here the further into the setup we go.

Press the line Authorization to get to the user setup display.

4. Select username and access code

5. Carry out a new login with the user name and the

new access code

Mark the line with the user name SUPV.

Press the button Change

This is where you can select the supervisor for the specic system and a

corresponding access code for this person.

In earlier versions of the service tool AK-ST 500 it was possible to select

the language in this menu.

An updated version of the service tool will be released in the spring of

2009. If the controller is operated with the new version, language selection will happen automatically in connection with the conguration of

the service tool.

The controller will utilize the same language that is selected in the

service tool but only if the controller contains this language. If the

language is not contained in the controller, the settings and readings

will be shown in English.

To activate the new settings you must carry out a new login to the controller with the new user name and the relevant access code.

You will access the login display by pressing the padlock at the top left

corner of the display.

42 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

Conguration - continued

Unlock the conguration of the

controllers

1. Go to Conguration menu

2. Select Lock/Unlock conguration

The controller can only be congured when it is unlocked.

The values can be changed when it is locked, but only for those settings

that do not aect the conguration.

3. Select Conguration lock

Press the blue eld with the text Locked

4. Select Unlocked

Select Unlocked and press OK.

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 43

Conguration - continued

System setup

1. Go to Conguration menu

2. Select System setup

3. Set system settings

All system settings can be changed by pressing in the blue eld with the

setting and then indicating the value of the required setting.

In the rst eld you enter a name for what the controller will be controlling.

When the time is set the PC’s time can be transferred to the controller.

When the controller is connected to a network, date and time will

automatically be set by the system unit in the network. This also applies

to change-over Daylight saving.

If the controller is installed in a network, "automatic acknowledgement

of alarms" should be set to "disable" - Hereby the alarm processing and

acknowledgement is transferred to the system unit.

If the controller is installed without a network, "automatic acknowledgement of alarms" should be set to "enable" - Hereby the controller

acknowledges the alarms itself.

44 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

Conguration - continued

Set plant type

1. Go to Conguration menu

2. Select plant type

Press the line Select plant type.

3. Set plant type

This setting refers to applications. See page 22.

After conguration of this function, the controller will shut down

and restart. After the restart, a large number of settings will have

been made. These include the connection points. Continue with the

settings and check the values. If you change some of the settings,

the new values will.

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 45

Conguration - continued

Set control of compressors

1. Go to Conguration menu

2. Select Suction group

3. Set values for the reference

Press the +-button to go on to the

next page

4. Set values for capacity control

The conguration menu in the Service

Tool has changed now. It shows the pos-

sible settings for the selected plant type.

In our example we select the settings:

- Suction set point = -15°C

- Night oset value = 5 K.

The settings are shown here in the display.

There are several pages, one after the

other.

The black bar in this eld tells you which

of the pages is currently displayed.

Move between the pages using the +

and - buttons.

In our example we select:

- Refrigerant = R134a

- Equalisation of working hours

- Value for speed regulation

Speed regulation can always only be on

compressor number 1.

The settings are shown here in the

display.

Not all compressors can have their speed

adjusted. If there is any doubt, contact your

compressor supplier.

If you want to know more about the dierent conguration options, they are listed below.

The number refers to the number and picture in the

column on the left.

The screen only shows the settings and readings that

are required for a given set-up.

3 - Po-Reference

Reference = set reference + night oset + oset

from P0 optimization

Setpoint ( -80 to +30°C)

Setting of required suction pressure in °C

Night Oset (-25 to +25 K)

Displacement value for suction pressure in connection with an active night setback signal (set in

Kelvin)

Changing to night-time operation can be carried

out with a signal sent via the data communication,

with a signal on the input "night" or via the weekly

schedule in the controller.

Max reference (-50 to +80 °C)

Max. permissible suction pressure reference

Min reference (-80 to +25 °C)

Min. permissible suction pressure reference

4 - Compressor application

Po refrigerant type

Select refrigerant type

Po refrigerant factors K1, K2, K3

Only used if “Po refrigerant type” is set to custom

(contact Danfoss for information)

Step control mode

Select coupling pattern for compressors

Sequential: Compressors are cut in/out in strict accordance with compressor number (FILO)

Cyclic: Runtime equalisation between compressors

(FIFO) (same sized compressors)

Best t: Compressors are cut in/out in order to

make the best possible t to actual load (dierent

sized compressors)

Pump down

Select whether a pump down function is required

on the last running compressor

Pump down limit (-80 to +30 °C)

Set the actual pump down limit for the last compressor

VSD min speed (0.5 – 60.0 Hz)

Min. speed where the compressor must cutout

VSD start speed (20.0 – 60.0 Hz)

Minimum speed for start of Variable speed drive

(Must be set higher than “VSD Min. Speed Hz”)

VSD max speed (40.0 – 120.0 Hz)

Highest permissible speed for the compressor

motor

Load shed limit

Set max capacity limit for load shed Load Shed"

Override limit Po

If the P0 exceeds the value, a time delay is started. If

the time delay runs out, the load limit is cancelled

Override delay

Max. time for capacity limit, if P0 is too high

Kp Po (0.1 – 10.0)

Amplication factor for P0 regulation

Advanced control settings

Select whether the adv. settings must be visible

Min. capacity change (0 – 100 %)

Set the minimum capacity change needed before

the capacity distributor connects or disconnects

compressors

Minimize cycling

The control zone may vary for connections and

disconnections. See Section 5.

Initial start time (15 – 900 s)

The time after start-up where the cut-in capacity is

limited to the rst compressor step.

46 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

Conguration - continued

Press the +-button to go on to the

next page

5. Set values for capacity of the

compressors

Press the +-button to go on to the

next page

6. Set values for safe operation

Press the +-button to go on to the

next page

In our example we select:

- Speed-controlled compressor

of 30 kW (compressor 1)

- Four compressors of 25 kW

The example settings are shown

here in the display.

(For cyclic operation, all one-step

compressors have the same size.

This is why there is only one setting, but it covers all 4.)

In our example we select:

- Safety limit for discharge

temperature = 120°C

- Safety limit for high condensing

pressure = 50°C

- Safety limit for low suction

pressure = -35°C

- Alarm limit for high suction

pressure = -5°C

- Alarm limit for min. and max.

superheat, respectively = 5 and

35 K.

5 - Compressors

In this screen the capacity distribution between the compressors is dened.

Capacities that need to be set depend upon the “compressor

application” and “Step control mode” that has been selected.

Nominal capacity (0.0 – 99.9 kW)

Set the nominal capacity for the compressor in question.

For compressors with variable speed drive the nominal

capacity must be set for the mains frequency (50/60 Hz)

6 - Safety

Delay time for liquid level alarm

Set the delay time (from the time the signal is lost on the

input to the time when the alarm is sent)

Delay time for VSD-alarm

Set the delay time

Temperature alarm limit

Set the threshold value for the temperature alarm

Delay time for the temperature alarm

Set the delay time

Emergency cap. day

The desired cut-in capacity for daily use in the case of emergency operations resulting from error in the suction pressure

sensor/ media temperature sensor.

Emergency cap. night

The desired cut-in capacity for night operations in the case

of emergency operations resulting from error in the suction

pressure sensor/ media temperature sensor.

Sd max limit

Max. value for discharge gas temperature

10 K below the limit, the compressor capacity should be

reduced and the entire condenser capacity will be cutin.

If the limit is exceeded, the entire compressor capacity will

be cutout

Pc Max limit

Maximum value for the condenser pressure in °C

3 K below the limit, the entire condenser capacity will be

cutin and the compressor capacity reduced.

If the limit is exceeded, the entire compressor capacity will

be cutout.

Pc Max delay

Time delay for the alarm Pc max

P0 Min limit

Minimum value for the suction pressure in °C

If the limit is reduced, the entire compressor capacity will be

cutout.

P0 Max alarm

Alarm limit for high suction pressure P0

P0 Max delay

Time delay before alarm for high suction pressure P0.

Safety restart time

Common time delay before restarting the compressor.

(Applicable to the functions: "Sd max. limit", Pc max. limit"

and "P0 min. limit).

SH Min alarm

Alarm limit for min. superheat in suction line.

SH Max alarm

Alarm limit for max. superheat in suction line.

SH alarm delay

Time delay before alarm for min./max. superheat in suction

line.

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 47

Conguration - continued

7. Set operation time for compressor

Press the +-button to go on to the

next page

8. Set times for safety cutouts

Set min. OFF-time for the compressor relay

Set min. ON-time for the compressor relay

Set how often the compressor is

allowed to start

If the restrictions overlap, the

controller will use the longest

restriction time.

7 - Minimum operation times

Congure the operation times here so "unnecessary operation" can be avoided.

Min. OFF time

The time the compressor should be idle before it should start

again.

Min. ON time

The time the compressor should operate before it should

stop.

Restart time

The lowest time interval between two consecutive starts.

8 - Safety timer

Cutout delay

The time delay resulting from drop-out of automated safety

measures and until the compressor-error is reported.

Restart delay

Minimum time that a compressor should be OK after a safety

cut-out. After this interval it can start again.

(An alarm which is triggered by the automatic safety function

will be maintained until the restart delay has expired.)

48 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

Conguration - continued

Setup control of condenser

1. Go to Conguration menu

2. Select Condenser

3. Set control mode and reference

In our example the condenser

pressure is controlled on the

basis of the outdoor temperature

(oating reference).

The settings shown here in the

display.

3 - PC reference

Reference Mode

Choice of condenser pressure reference

Fixed setting: Used if a permanent reference is required =

“Setting”

Floating: Used if the reference is changed as a function of Sc3

the external temperature signal, the congured "Dimensioning tm K"/"Minimum tm K" and the actual cut in compressor

capacity.

Setpoint

Setting of desired condensing pressure in °C. It should also be

set when oating references are used. The value is used as a

reference if the Sc3 sensor becomes defective.

Min. tm

Minimum average temperature dierence between Sc3 air

and Pc condensing temperature when no compressors are in

operation.

Dimensioning tm

Dimensioning average temperature dierential between Sc3

air and Pc condensing temperature at maximum load (tm

dierence at max load, typically 8-15 K).

Min reference

Min. permitted condenser pressure reference

Max reference

Max. permitted condenser pressure reference

Press the +-button to go on to the

next page

4. Set values for capacity regulation

Used in our example are six stepcontrolled fans.

The settings shown here in the

display.

4 - Capacity control

Capacity control mode

Select control mode for condenser

Step: Fans are step-connected via relay outputs

Step/speed: The fan capacity is controlled via a combination

of speed control and step coupling

Speed: The fan capacity is controlled via speed control (frequency converter)

Control type

Choice of control strategy

P-band: The fan capacity is regulated via P-band control. The

P band is congured as "Proportional band Xp"

PI-Control: The fan capacity is regulated by the PI controller.

Capacity curve

Choice of capacity curve type

Linear: The same amplication in the entire area

Square: Square curve shape, which gives higher amplication

at higher loads.

VSD start speed

Minimum speed for start of speed control (Must be congured higher than "VSD Min. Speed %")

VSD min Speed

Minimum speed whereby speed control is cut-out (low load).

Proportional band Xp

Proportional band for P/PI controller

Integration time Tn

Integration time for PI controller

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 49

Conguration - continued

Conguration of inputs

and outputs

1. Go to Conguration menu

2. Select I/O conguration

3. Conguration of Digital outputs

Press the +-button to go on to the

next page

4. Setup On/o input functions

The outputs are enabled by On (relay activated)

!!! The alarm is inverted so that there will be an alarm if the supply

voltage to the controller fails.

Select for each input whether the function is to be active when the

input is in pos. Closed or Open.

Open has been selected here for all the safety circuits. This means

that the controller will receive signal under normal operation and

register it as a fault if the signal is interrupted.

Press the +-button to go on to the

next page

50 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

Conguration - continued

5. Conguration of Analog

outputs

Press the +-button to go on to

the next page

6. Conguration of Analog

Input signals

We set up the analog outputs for control of the compressor speed.

We set up the analog inputs for the sensors.

5 - Analog outputs

The possible signals are

the following:

0 -10 V

2 – 10 V

0 - 5 V

1 – 5V

6 - Analog inputs

The possible signals are

the following:

Temperature sensors:

• Pt1000

• PTC 1000

Pressure transmitters:

• AKS 32, -1 – 6 Bar

• AKS 32R, -1 – 6 Bar

• AKS 32, - 1 – 9 Bar

• AKS 32R, -1 – 9 Bar3

• AKS 32, - 1 – 12 Bar

• AKS 32R, -1 – 12 Bar

• AKS 32, - 1 – 20 Bar

• AKS 32R, -1 – 20 Bar

• AKS 32, - 1 – 34 Bar

• AKS 32R, -1 – 34 Bar

• AKS 32, - 1 – 50 Bar

• AKS 32R, -1 – 50 Bar

• AKS 2050, -1 – 59 Bar

• AKS 2050, -1 – 99 Bar

• AKS 2050, -1 – 159 Bar

• Customised ratiometric

application: Here, the

transmitters min. and

max. pressure areas are

set (relative pressure

reading)

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 51

Conguration - continued

Set alarm priorities

1. Go to Conguration menu

2. Select Alarm priorities

3. Set priorities for Suction group

Very many functions have an alarm connected.

Your choice of functions and settings has connected all the relevant

alarms that are current. They will be shown with text in the three

pictures.

All alarms that can occur can be set for a given order of priority:

• ”High” is the most important one

• ”Log only” has lowest priority

• ”Disconnected” gives no action

The interdependence between setting and action can be seen in the

table.

Setting

High X X X 1

Medium X X 2

Low X X 3

Log only X 4

Disconnected

In our example we select the settings shown here in the display

Log Alarm relay Network AKM- dest.

Press the +-button to go on to the next page

4. Set alarm priorities for condenser

In our example we select the settings shown here in the display

Press the +-button to go on to the next page

52 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

Conguration - continued

5. Set alarm priorities for

temperature alarm and Digital signals

In our example we select the settings shown here in the display

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 53

Conguration - continued

Lock conguration

1. Go to Conguration menu

2. Select Lock/Unlock conguration

3. Lock Conguration

Press in the eld against Conguration lock.

Select Locked.

Press OK.

The setup of the controller has now been locked. If you subsequently

want to make any changes in the controller’s setup, remember rst to

unlock the conguration.

The controller will now make a comparison of selected functions and dene inputs and outputs. The result can be seen in

the next section where the setup is controlled.

54 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

Conguration - continued

Check conguration

1. Go to Conguration menu

2. Select I/O conguration

3. Check conguration of Digital Outputs

This control requires that the setup is locked

(Only when the setup is locked are all settings for in- and outputs activated.)

An error has occurred, if you see the

following:

A 0 – 0 next to a dened function.

If a setting has reverted to 0-0, you must control

the setup again.

Press the +-button to go on to the next page

4. Check conguration of Digital Inputs

Press the +-button to go on to the next page

The error is caused by the two modules connected

to the controller being switched.

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 55

Conguration - continued

5. Check conguration of Analog Outputs

Press the +-button to go on to the next page

6. Check conguration of Analog Inputs

(If no speed control of the condenser fans is used, the module and point

number can be 0 -0.)

56 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

Check of connections

1.Go to Conguration menu

2. Select I/O status and manual

Before the control is started we check that all inputs and outputs have

been connected as expected.

This controls requires that the setup is locked

3. Check Digital Outputs

Press the +-button to go on to the next page

4. Check Digital Inputs

By means of the manual control of each output it can be checked

whether the output has been correctly connected.

AUTO The output is controlled by the controller

MAN OFF The output is forced to pos. OFF

MAN ON The output is forced to pos ON

Cut out the safety circuit for compressor 1.

Check that LED DI1 on the extension module (module 3) goes out.

Check that the value of the alarm for the safety monitoring of compressor 1 changes to ON.

The remaining digital inputs are checked in the same way.

Press the +-button to go on to the next page

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 57

Check of connections - continued

5. Check Analog outputs

Set Control of output voltage to manual

Press in the Mode eld.

Select MAN.

Press OK.

Press in the Value eld

Select for example 50%.

Press OK.

On the output you can now measure the expected value: In this

example 5 volts

6. Put the control of the output voltage back to automatic

Press the +-button to go on to the next page

7. Check Analog inputs

Example of the connection between a dened output signal

and a manual set value.

Denition Setting

0 % 50 % 100 %

0 - 10 V 0 V 5 V 10 V

1 - 10 V 1 V 5.5 V 10 V

0 - 5 V 0 V 2.5 V 5 V

2 - 5 V 2 V 3.5 V 5 V

Check that all sensors show sensible values.

In our case we have no value for the suction gas temperature Ss and

the two sensors. This may be due to the following:

• The sensor has not been connected.

• The sensor is short-circuited.

• The point or module number has not been set up correctly.

• The conguration is not locked.

58 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

Check of settings

1.Go to the overview

2. Select suction group

Before the control starts, we check that all the settings are as they should

be.

The overview display will now show one line for each of the general

functions. Behind each icon there is a number of displays with the

dierent settings. It is all these settings that have to be checked.

3. Move on through all the individual displays for the

suction group

Change displays with the +- button. Remember the settings at

the bottom of the pages – the ones that can only be seen via

the ”Scroll bar”.

4. Safety limits

5. Go back to the overview

The last page contains safety limits and restart times.

6. Select condenser group

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 59

Check of settings - continued

7. Move on through all the individual displays for the

condenser group.

Change displays with the +- button. Remember the settings at

the bottom of the pages – the ones that can only be seen via

the ”Scroll bar”.

8. Safety limits

9. The controller setup has been completed.

The last page contains safety limits and restart times.

60 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

Schedule function

1. Go to Conguration menu

2. Select schedule

3. Setup schedule

For your information

This setting is not necessary in the example. The signal comes in via DI8.

In other cases where the controller is installed in a network with one

system unit, this setting may be made in the system unit which will then

transmit a day/night signal to the controller.

This setting can only be used, if the controller stands alone and is tted

with a clock module.

Press a weekday and set the time for the day period.

Continue with the other days.

A complete weekly sequence is shown in the display.

AK-PC 710 Capacity controller RS8FT502 © Danfoss 08-2015 61

Installation in network

1. Set the address (here, for example 3)

Turn the right-hand address switch so that the arrow will point

at 3.

The arrow of the two other address switches must point at 0.

2. Push the Service Pin

Press down the service pin and keep it down until the Service

Pin LED lights up.

The controller has to be remote-monitored via a network. In this net-

work we assign address number 3 to the controller.

The same address must not be used by more than one controller in the

same network.

Requirement to the system unit

The system unit must be a gateway type AKA 245 with software version

6.0 or higher. It is capable of handling up to 119 AK controllers.

3. Wait for answer from the system unit

Depending on the size of the network it may be up to one

minute before the controller receives an answer as to whether

it has been installed in the network.

When it has been installed the Status LED will start to ash

faster than normal (once every half second). It will continue

with this for about 10 minutes

4. Carry out new login via Service Tool

If the Service Tool was connected to the controller while you

installed it in the network, you must carry out a new login to

the controller via the Service Tool.

Alternatively, it can be an AK-SM 720. It is capable of handling up to 200

AK controllers.

If there is no answer from the system unit

If the Status LED does not start ashing faster than normal, the controller has not been installed in the network. The reason for this may be

one of the following:

The controller has been assigned an address out of range

Address 0 cannot be used.

If the system unit in the network is an AKA 243B Gateway only the addresses between 1 and 10 can be used.

The selected address is already being used by another controller or

unit in the network:

The address setting must be changed to another (vacant) address.

The wiring has not been carried out correctly.

The termination has not been carried out correctly.

The data communication requirements are described in the document:

”Data communication connections to ADAP-KOOL® Refrigeration Controls” RC8AC.

62 Capacity controller RS8FT502 © Danfoss 08-2015 AK-PC 710

First start of control

Check alarms

1. Go to the overview

Press the blue overview button with the compressor and condenser at the bottom left of the display.

2. Go to the Alarm list