Installation Guide

Danfoss

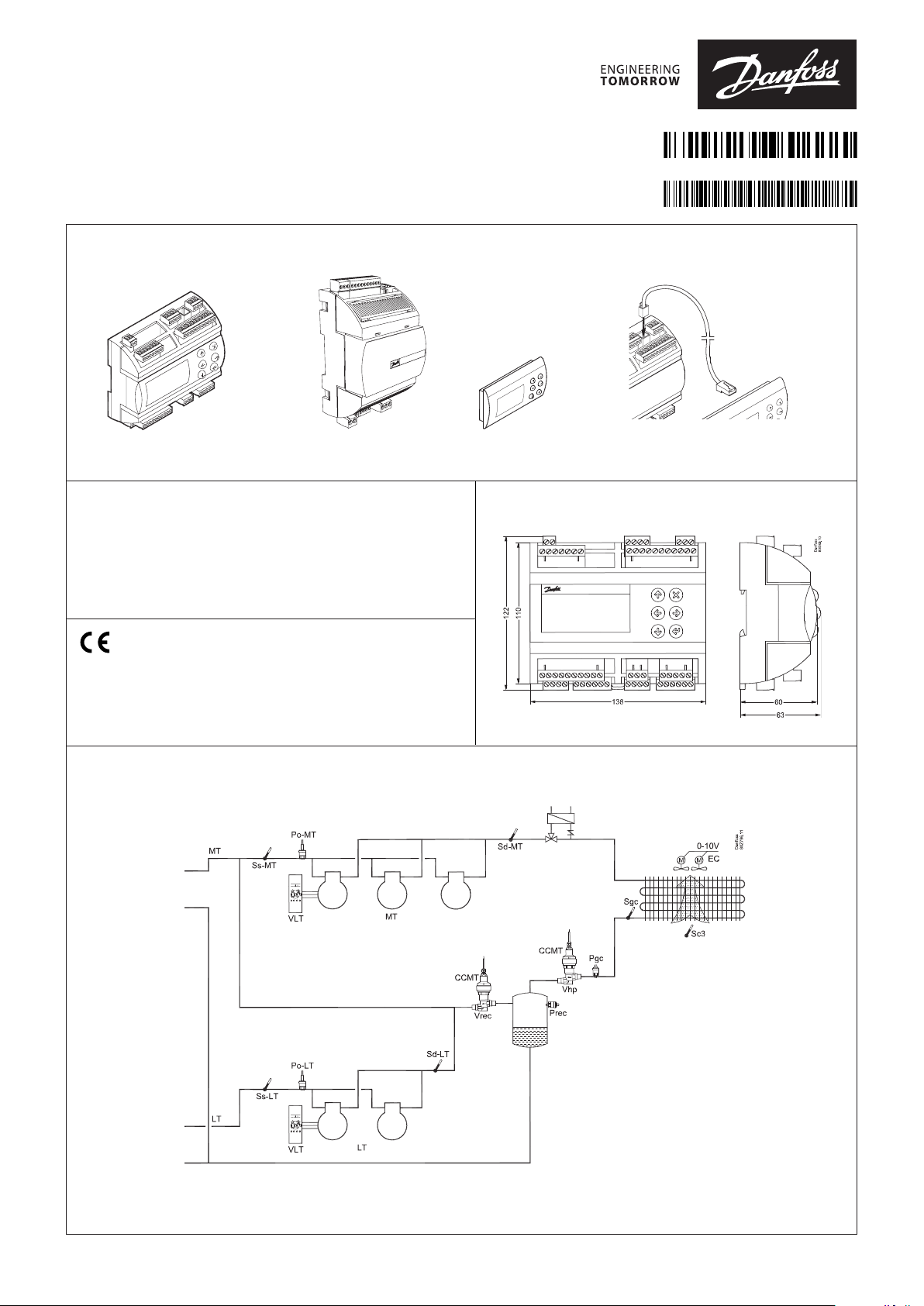

AK-PC 572

Identification | Identificação | Identificatie | Identification | Identificación

80G393

080R9330

AN29572719924701- 000201

1.5 m: 080G0075

3.0 m: 080G0076

AK-PC 572 EKE 1P

Power supply | Fonte de energia | Stroomvoorziening

Source de courant | Fuente de alimentación

AK-PC 572 24 V AC / DC 17 VA

EKE 1P 24 V AC / DC 7 – 20 VA

IP 20

-20 – 60 °C

(0 – 140 °F)

RH max. 90% non condensing

Principle | Princípio | Beginsel | Principe | Principio

MMIGRS2

Dimension | Dimensão | Dimensie | Dimension | Dimensión

© Danfoss | DCS (vt) | 2019.12

AN29572719924701-000201 | 1

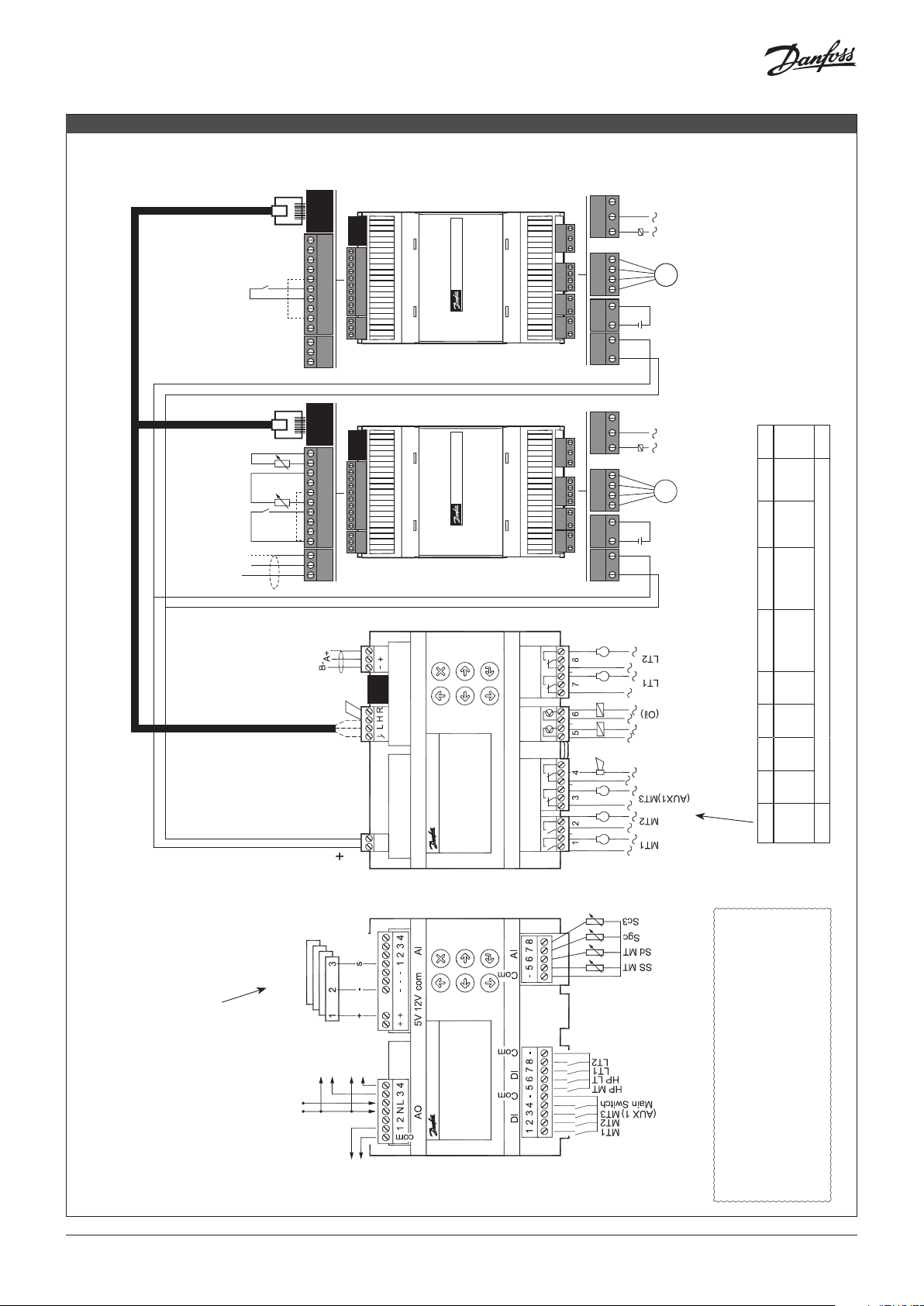

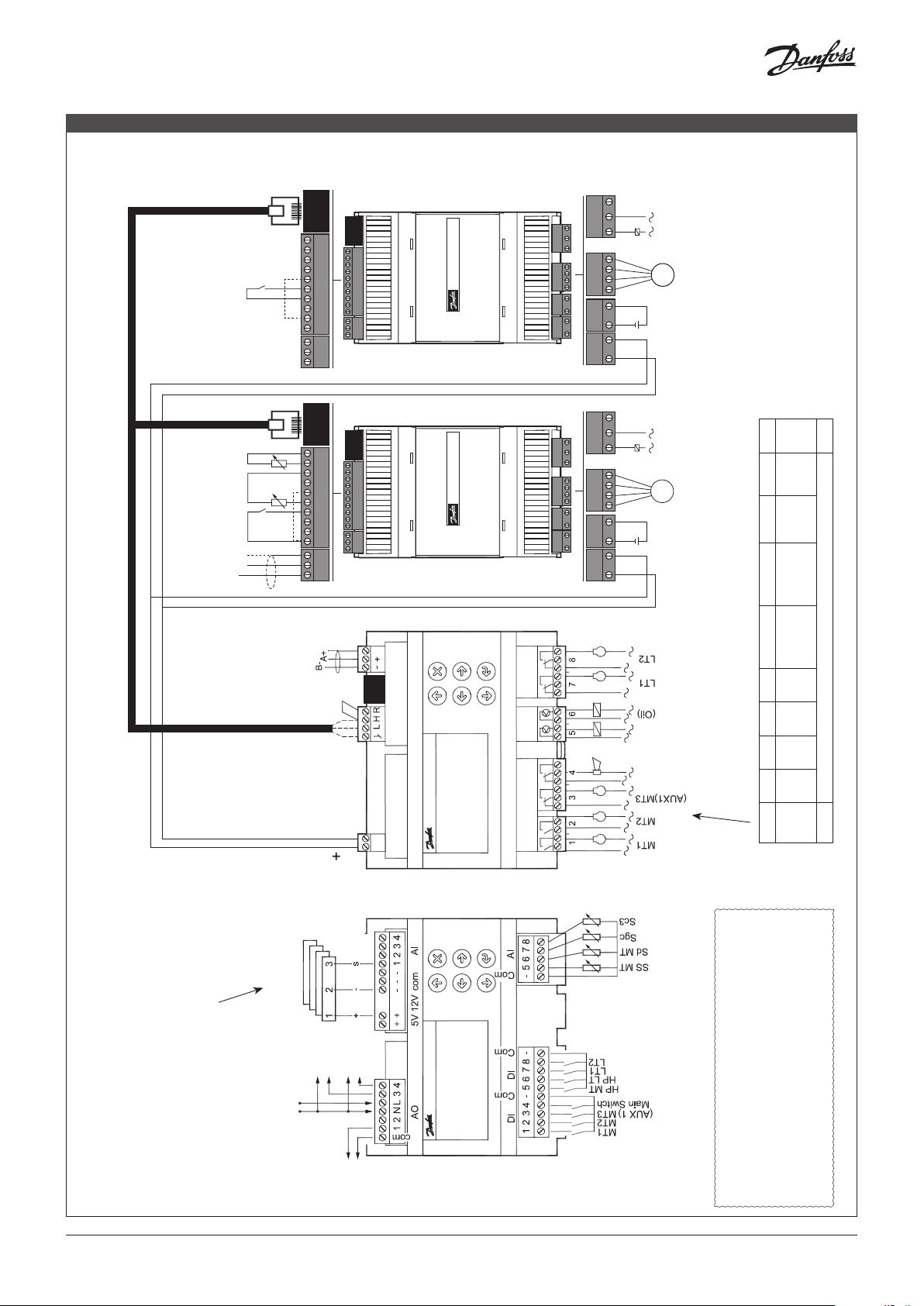

Connections

DO

HR / DO

s

80G386

ENGLISH

Danfos

CAN RJ

COM

CAN RJ

AI1

COM

AI1

AI2

AI2

AI3

AI3

AI4

AI4

COM

COM

CAN RJ

DI1

DI2

5V+

COM

RGND

D+

D –

COM

AI1

AI2

AI3

AI4

COM

DI1

DI2

5V+

COM

RGND

D+

D –

CAN RJ

DI1

DI2

5V+

COM

RGND

D+

D –

COM

AI1

AI2

AI3

AI4

COM

DI1

DI2

5V+

COM

RGND

D+

D –

EKE 1P

EKE 1P

HR / DI Aux 3

LT - SS

LT - Sd

Oil / DI Aux 2

MODBUS Field Bus

A+

B-

NC1

C1

NC1

NO1

C1

NO1

B2

B2

B1

B1

A2

A2

A1

A1

Bat+

Bat+

GND

+/~

GND

–/~

+/~

+

–/~

-

NC1

C1

NC1

NO1

C1

NO1

B2

B2

B1

B1

A2

A2

A1

A1

Bat+

Bat+

GND

+/~

GND

–/~

+/~

+

–/~

-

AUX 3

M

Vrec

Battery back-up

24 V

Power

Important!

Wait before connecting the power supply to the

modules!

In order to set the addresses 96 and 97, you must fol-

low the recommended procedure. See page 4.

AUX 2

32 A

M

Vhp

6 A

(4)

Battery back-up

24 V

6 A

(4)

Power

0.5 A

min. 50 mA

Ioff < 1.5 mA

Connection, lower level Connection, upper level

24 V AC/DC

Warning

The supply voltage

of AI may not share

the signal with

other controllers.

Separate

supply

1 = Black = +

2 = Blue = -

AKS 32R

AKS 2050

Extern

24 V

MODBUS

3 = Brown = s

MBS 8250

VSD MT

AC/DC

AI 1 = PoMT

AI 2 = PoLT

AI 3 = Pgc

AI 4 = Prec

0 – 10 V

VSD LT

0 – 10 V

CAN RJ

LN

CANBUS D- D+

DO

DO DO1 DO2 DO3 DO4 DO5 DO6 DO7 DO8 Σ 1-8

0.5 A

min. 50 mA

6 A

(4)

6 A

(4)

10 A

(3.5)

(3.5)

I Max. 10 A

Ioff < 1,5 mA

U All 24 V or all 230 V AC

2 | AN29572719924701-000201

Electric noise

Signal cables for sensors, DI inputs, data communication

and display must be kept separate from high voltage

(230 V) electric cables:

- Use separate cable trays

- Keep a distance between high voltage and signal cables

of at least 10 cm

Fan

0 – 10 V

- Cables longer than 3 m at the DI input should be avoided

© Danfoss | DCS (vt) | 2019.12

MAIN MODULE

AO - Analogue output, 3 pcs. AO1, AO3, AO4

Must be used if using frequency converters or EC motors.

Connect 24 V on N and L (separate power supply) Avoid earth fault

current.

- Use double-insulated transformer. The secondary side must not

be earthed.

Obtain 0-10 volts from terminals Com-AO1, N-AO3 and N-AO4.

PAY ATTENTION TO THE POLARITY of N.

(AO3 and AO4 are galvanically isolated. AO1 is not).

AI - Analogue inputs

Pressure transmitters, 4 pcs. AI1 - AI4

AKS 32R /

AKS 2050 /

MBS 8250

10 – 90% ratiometric

HIGH PRESSURE MODULE

Supply voltage to high pressure module

The power supply can be taken from the main module.

Battery

Ensure that the valve closes if there is no supply voltage.

Stepper valve

FX ventil type CCMT.

Connector:

A1 5: WHITE

A2 6: BLACK

B1 7: RED

B2 8: GREEN

CANBUS

Data communication to the main module.

Temperature sensors, 4 pcs. AI5 - AI8

• Pt 1000 ohm, AKS 11 or AKS 21.

DI - Digital switch inputs, 8 pcs. DI1 - DI8

The connection may be a shut-down or interruption function.

Select what is to be activated during configuration.

(DI3 can be used as an AUX1 input, but only if regulated with 2 MT

compressors).

Supply

24 V AC or DC Class II is required.

AK-PC 572 17 VA

EKE 1P 20 VA

CANBUS

Communication to the high pressure module and to the receiver

module

"L" to "L" and "H" to "H"

A jumper must be connected between "H" and "R".

Terminate on the AK-PC with a resistance of 120 ohm.

If mounting an external display, the termination must also be done

at the display. See next page.

Important!

In order to establish communication with the extension modules, you

must follow the recommended procedure. See next page.

MODBUS

It is important that the installation of the data communication

cable is carried out correctly. See separate literature no. RC8AC...

Remember termination at the termination points.

DO - Digital outputs, 8 pcs. DO1-DO8

DO5 and DO6 are solid state relays. The outputs are used for

connecting a Bitzer CRII. If a Bitzer CRII is not being connected,

output DO6 can be used for activation of an oil valve.

The relays are de-rated to the specified values.

The alarm relay will be driven under normal operation and

will drop in the event of alarms and insufficient voltage to the

controller.

(DO3 can be used as an AUX1 output, but only if regulated with 2

MT compressors).

Sensor inputs

• Pt 1000 ohm, AKS 11 or AKS 21.

Contact input AUX 2

Signal from oil level,

or input for fan alarm or another alarm.

Relay output AUX 2

Activation of de-superheating or hot gas dump.

MODBUS

Data communication with other devices.

It is important that the installation of the data communication

cable is performed correctly.

See separate literature no. RC8AC...

Remember termination at the termination points. Use a twisted

pair shielded cable, but do not connect the shield to the EKE 1P.

RECEIVER MODULE

Supply voltage to high pressure module

The power supply can be taken from the main module.

Battery

Ensure that the valve closes if there is no supply voltage.

Stepper valve

FX valve type CCMT.

Connector:

A1 5: WHITE

A2 6: BLACK

B1 7: RED

B2 8: GREEN

CANBUS

Data communication to the main module.

The section must be terminated using a 120 ohm resistor.

Contact input AUX 3

Signal from heat recovery,

or input for fan alarm or another alarm.

Relay output AUX 3

Activation of heat recovery,

or AUX 3 output for de-superheating or hot gas dump.

© Danfoss | DCS (vt) | 2019.12

AN29572719924701-000201 | 3

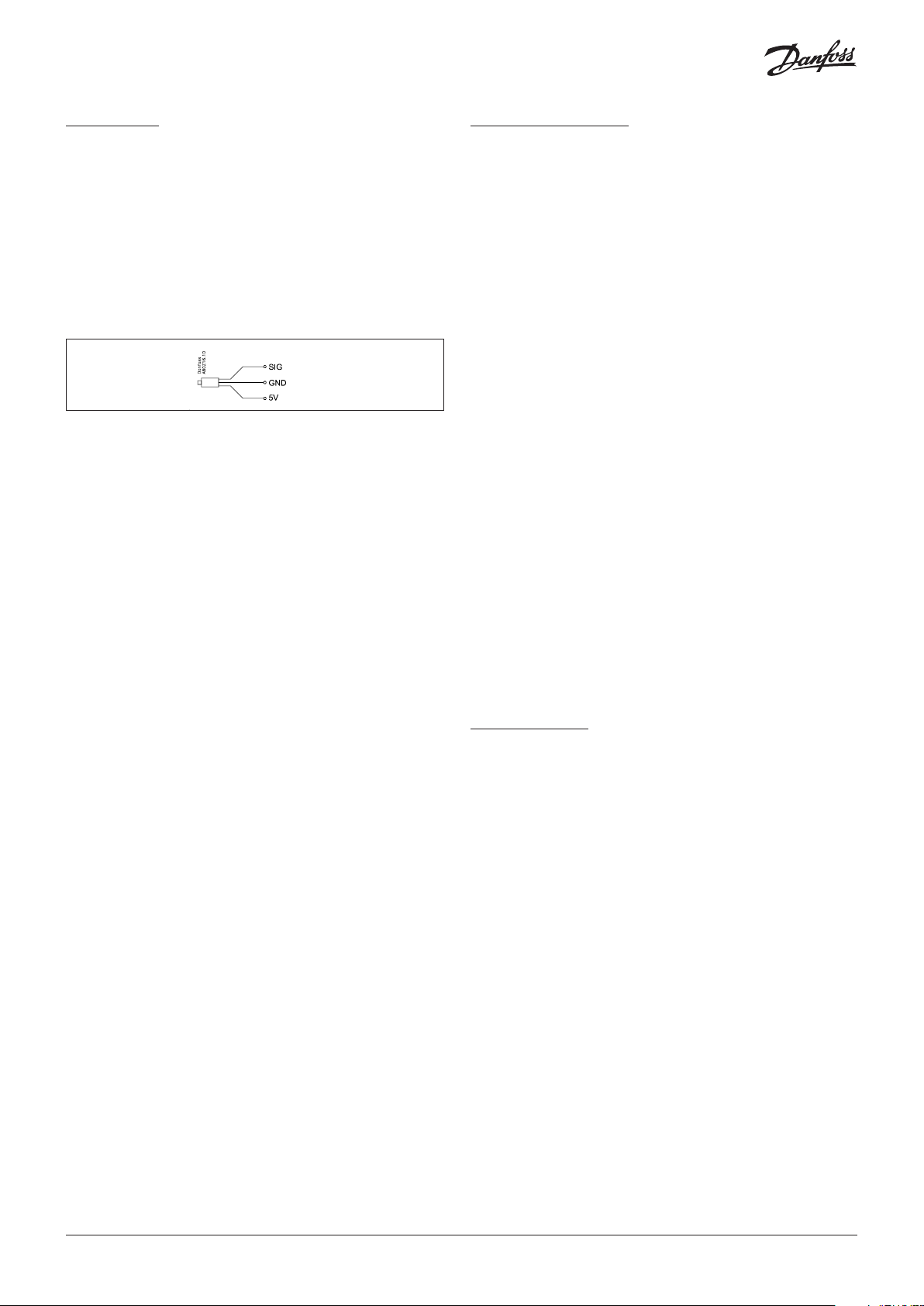

External display

80G3867

R = 1200Ω

L→H

Extension modules

MODBUS master

H - R

R120 Bridge - CAN H

CAN H Red

CAN L Green

C GND Yellow

Yellow

Green

Red

D –

D+

RGND

High pressure Receiver

Bitzer CRII

The pulse signal can also be used to control one of the CRII with 2 unloaders (4 cylinders' version).

Compressor capacity can be controlled from 10 to 100% depending on the pulsation of the unloaders.

The unloaders are connected to DO5 and DO6.

Connect compressor relay to DO-MT1.

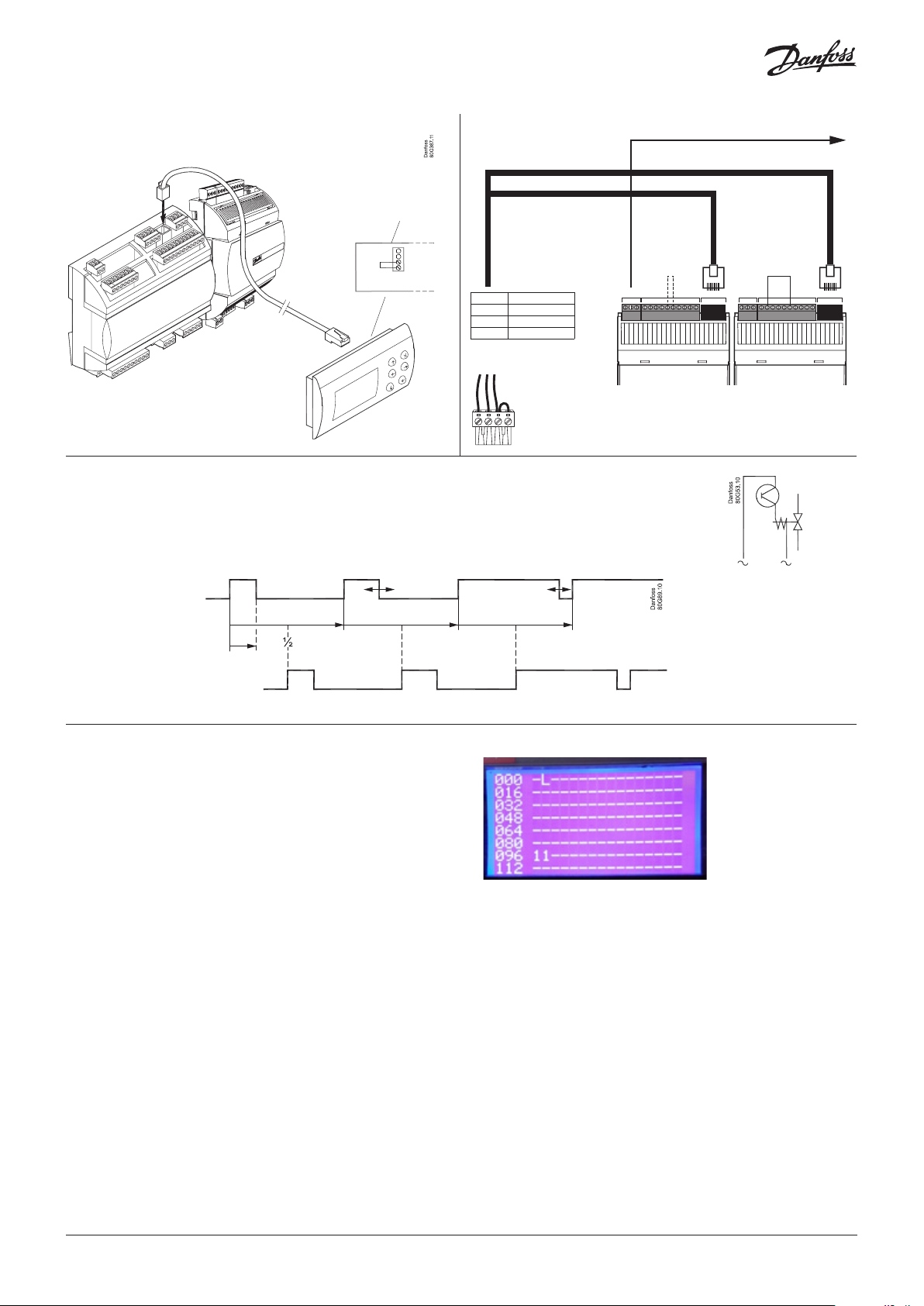

0 V / Open 5 V

ANALOGUE / DIGITAL INPUTRS-485 RS-485 CAN-RJCAN-RJ ANALOGUE / DIGITAL INPUT

COM

5V+

DI2

CAN RJ

DI1

COM

AI4

AI3

AI2

AI1

COM

COM

5V+

DI2

DI1

COM

AI4

D –

D+

AI3

RGND

Danfoss

CAN RJ

AI2

AI1

COM

Unloader 2 follows unloader 1

but is offset a ½ period.

Important

Read the following before you connect the controller and the two

valve modules to the supply voltage.

The EKE 1P is pre-configured to determine the extension module

mode based on the AI4 status of the EKE 1P:

AI4 Open circuit: high pressure module

AI4 short circuit to 5V: receiver module

Alternatively the EKE 1P configuration may be set by connecting

a graphical display to the EKE 1P. See separate EKE 1P documentation.

If you wish to check the addresses of the two valve modules, you

should carry out the following:

1. Connect all modules to the power supply.

2. Immediately press on both the "X" and "Enter" buttons while the

controller is starting up.

3. Find the display "CAN SETTINGS" > "ACTIVE NODES"

Unloader 1

Unloader 2

The two 1-digits represent the addresses 96 (HP module) and 97

(Receiver module) respectively.

If you remove the connection to a valve module, the display of

the address will also disappear.

4 | AN29572719924701-000201

© Danfoss | DCS (vt) | 2019.12

Conexões

DO

HR / DO

s

80G386

PORTUGUÊS

Danfos

CAN RJ

COM

CAN RJ

AI1

COM

AI1

AI2

AI2

AI3

AI3

AI4

AI4

COM

COM

CAN RJ

DI1

DI2

5V+

COM

RGND

D+

D –

COM

AI1

AI2

AI3

AI4

COM

DI1

DI2

5V+

COM

RGND

D+

D –

CAN RJ

DI1

DI2

5V+

COM

RGND

D+

D –

COM

AI1

AI2

AI3

AI4

COM

DI1

DI2

5V+

COM

RGND

D+

D –

EKE 1P

EKE 1P

HR / DI Aux 3

LT - SS

LT - Sd

Oil / DI Aux 2

MODBUS Field Bus

A+

B-

NC1

C1

NC1

NO1

C1

NO1

B2

B2

B1

B1

A2

A2

A1

A1

Bat+

Bat+

GND

+/~

GND

–/~

+/~

+

–/~

-

NC1

C1

NC1

NO1

C1

NO1

B2

B2

B1

B1

A2

A2

A1

A1

Bat+

Bat+

GND

+/~

GND

–/~

+/~

+

–/~

-

AUX 3

M

Vrec

Suporte da bateria

24 V

Consumo

Importante!

Espere antes de conectar a fonte de alimentação aos

módulos!

Para definir os endereços 96 e 97, é preciso seguir o

procedimento recomendado. Consulte a página 7.

AUX 2

M

Vhp

24 V

32 A

6 A

(4)

Suporte da bateria

6 A

(4)

Consumo

0.5 A

min. 50 mA

Ioff < 1,5 mA

Conexão, nível inferior Conexão, nível superior

0.5 A

min. 50 mA

Ioff < 1,5 mA

MODBUS

6 A

6 A

10 A

(4)

(4)

(3,5)

CAN RJ

CANBUS D- D+

(3,5)

DO DO1 DO2 DO3 DO4 DO5 DO6 DO7 DO8 Σ 1-8

I Max. 10 A

CA/CC de 24 V

LN

U Tudo 24 V ou tudo 230 V CA

DO

AI 1 = PoMT

AI 2 = PoLT

AI 3 = Pgc

VSD MT

0 – 10 V

AI 4 = Prec

VSD LT

0 – 10 V

Aviso

A tensão de alimentação

do AI pode não partilhar

1 = Preto = +

2 = Azul = -

3 = Castanho = s

AKS 32R

AKS 2050

MBS 8250

o sinal com outros

controladores.

© Danfoss | DCS (vt) | 2019.12

Alimentação

em separado

CA/CC de 24 V

externo

Ventoinha

0 – 10 V

Ruído elétrico

Cabos de sinal para sensores, entradas DI, comunicação de

dados e display devem ser mantidos separados de outros

alta tensão (230 V) cabos elétricos:

- Use condutores de cabos separados

- Manter uma distância entre os cabos de alta tensão e de

sinal de pelo menos 10 cm

- Cabos de extensão superior a 3 m na entrada DI devem

ser evitados

AN29572719924701-000201 | 5

MÓDULO PRINCIPAL

AO - Saída analógica, 3 pçs. AO1, AO3, AO4

Deve ser usada ao usar conversores de frequência ou motores EC.

Conecte 24 V em N e L (fonte de alimentação separada) Evite a corrente de falha de aterramento.

- Use um transformador com isolamento duplo. O lado secundário

não deve ser aterrado.

Obtenha 0-10 volts dos terminais Com-AO1, N-AO3 eN-AO4.

PRESTE ATENÇÃO À POLARIDADE de N.

(AO3 e AO4 são isolados galvanicamente. AO1 não é).

AI - Entradas analógicas

Transmissores de pressão, 4 pçs. AI1 - AI4

AKS 32R /

AKS 2050 /

MBS 8250

10 – 90% ratiometric

MÓDULO DE ALTA PRESSÃO

Tensão de alimentação para o módulo de alta pressão

A fonte de alimentação pode ser tirada do módulo principal.

Bateria

Certifique-se de que a válvula feche se não houver tensão de

alimentação.

Válvula de passo

Válvula FX tipo CCMT.

Conector:

A1 5: BRANCO

A2 6: PRETO

B1 7: Vermelho

B2 8: VERDE

CANBUS

Comunicação de dados ao módulo principal.

Sensores de temperatura, 4 pçs. AI5 - AI8

• Pt 1000 ohm, AKS 11 ou AKS 21.

DI - Entradas de interruptores digitais, 8 pçs. DI1 - DI8

A conexão pode ser um desligamento ou função de interrupção.

Selecione o que deverá ser ativado durante a configuração.

(DI3 pode ser usada como entrada AUX1, mas apenas se regulada

com 2 compressores MT).

Fonte de energia

24 V c.a. ou c.c. Classe II obrigatória.

AK-PC 572 17 VA

EKE 1P 20 VA

CANBUS

Comunicação com o módulo de alta pressão e com o módulo

receptor

"L" a "L" e "H" a "H"

É necessário conectar um jumper entre "H" e "R".

Finalize no AK-PC com uma resistência de 120 ohm.

Se montar um monitor externo, a finalização também deve ser

efetuada no monitor. Veja a página seguinte.

Importante!

Para estabelecer comunicação com os módulos de extensão, deve

seguir o procedimento recomendado. Veja a página seguinte.

MODBUS

É importante que a instalação do cabo de comunicação de dados

seja realizada corretamente. Consulte a literatura separada n°

RC8AC...

Lembre-se: terminação nos pontos de terminação.

DO - Saídas digitais, 8 pçs. DO1-DO8

DO5 e DO6 são relés de estado sólido. As saídas são usadas para

conectar um Bitzer CRII. Se não for conectado um Bitzer CRII, a

saída DO6 pode ser usada para ativação de uma válvula de óleo.

Os relés são reduzidos aos valores especificados.

O relé de alarmes será acionado durante a operação normal e

desarmará em caso de alarmes e de tensão insuficiente para o

controlador.

(DO3 pode ser usada como saída AUX1, mas apenas se regulada

com 2 compressores MT).

Entradas de Sensores

• Pt 1000 ohm, AKS 11 ou AKS 21.

Entrada de contato AUX2

Sinal do nível de óleo,

ou entrada para o alarme de ventilador ou outro alarme.

Saída do relé AUX 2

Ativação do dessuperaquecimento ou despejo de gás quente.

MODBUS

Comunicação de dados com outros dispositivos.

É importante que a instalação do cabo de comunicação de dados

seja efetuada corretamente.

Consulte o documento em separado n.º RC8AC...

Não se esqueça da finalização em ambos os pontos de finalização.

Utilize um cabo blindado de fios entrelaçados, mas não ligue a

blindagem ao EKE 1P.

MÓDULO RECEPTOR

Tensão de alimentação para o módulo de alta pressão

A fonte de alimentação pode ser tirada do módulo principal.

Bateria

Certifique-se de que a válvula feche se não houver tensão de

alimentação.

Válvula de passo

Válvula FX tipo CCMT.

Conector:

A1 5: BRANCO

A2 6: PRETO

B1 7: Vermelho

B2 8: VERDE

CANBUS

Comunicação de dados ao módulo principal.

A seção precisa ser terminada com o uso de um resistor de 120 ohms.

Entrada de contato AUX 3

Sinal da recuperação de calor,

ou entrada para o alarme de ventilador ou outro alarme.

6 | AN29572719924701-000201

Saída do relé AUX 3

Ativação da recuperação de calor,

ou saída AUX 3 para dessuperaquecimento ou despejo de gás

quente.

© Danfoss | DCS (vt) | 2019.12

Display externo

80G3867

R = 1200Ω

L→H

Módulos de extensão

Master MODBUS

H - R

0 V / Abrir 5 V

ENTRADA ANALÓGICA / DIGITAL ENTRADA ANALÓGICA / DIGITAL

R120 Ponte - CAN H

CAN H Vermelho

CAN L Verde

C GND Amarelo

Amarelo

Verde

Vermelho

RS-485 RS-485 CAN-RJCAN-RJ

COM

5V+

D –

D+

RGND

Alta pressão Recetor

Bitzer CRII

O sinal de pulso também pode ser utilizado para controlar um dos CRII com 2 descarregadores (versão

com 4 cilindros).

A capacidade do compressor pode ser controlada de 10 a 100%, dependendo da pulsação dos descarregadores. O descarregador está ligado a DO5 ou DO6.

Conecte o relé do compressor a MT1.

Danfoss

DI2

CAN RJ

DI1

COM

AI4

AI3

AI2

AI1

COM

COM

5V+

DI2

D –

D+

RGND

CAN RJ

DI1

COM

AI4

AI3

AI2

AI1

COM

O descarregador 2 segue o

descarregador 1, mas tem ½

período de deslocamento.

Importante

Leia o que se segue antes de conectar o controlador e os dois

módulos de válvula à tensão de alimentação.

Caso queira verificar os endereços dos dois módulos de válvula,

faça o seguinte:

1. conecte todos os módulos à fonte de alimentação

2. Pressione imediatamente os botões "X" e "Enter" enquanto o

controlador estiver iniciando.

3. Encontre a visualização "CAN SETTINGS" > "ACTIVE NODES"

Descarregador 1

Descarregador 2

Os dois dígitos 1 representam os endereços 96 (módulo HP) e 97

(módulo recetor) respetivamente.

Se a conexão com um módulo de válvula for removida, a

visualização do endereço também desaparecerá.

© Danfoss | DCS (vt) | 2019.12

AN29572719924701-000201 | 7

Anschluss

HR / DO

s

80G386

DEUTSCH

Danfos

CAN RJ

COM

CAN RJ

AI1

COM

AI1

AI2

AI2

AI3

AI3

AI4

AI4

COM

COM

CAN RJ

DI1

DI2

5V+

COM

RGND

D+

D –

COM

AI1

AI2

AI3

AI4

COM

DI1

DI2

5V+

COM

RGND

D+

D –

CAN RJ

DI1

DI2

5V+

COM

RGND

D+

D –

COM

AI1

AI2

AI3

AI4

COM

DI1

DI2

5V+

COM

RGND

D+

D –

EKE 1P

EKE 1P

HR / DI Aux 3

LT - SS

LT - Sd

Oil / DI Aux 2

MODBUS Field Bus

A+

B-

NC1

C1

NC1

NO1

C1

NO1

B2

B2

B1

B1

A2

A2

A1

A1

Bat+

Bat+

GND

+/~

GND

–/~

+/~

+

–/~

-

NC1

C1

NC1

NO1

C1

NO1

B2

B2

B1

B1

A2

A2

A1

A1

Bat+

Bat+

GND

+/~

GND

–/~

+/~

+

–/~

-

AUX 3

M

Vrec

Back-up batterij

24 V

Vermogen

Wichtig!

Warten Sie, bevor Sie die Spannungsversorgung an

die Module anschließen!

Sie müssen wie folgt vorgehen, um die Adressen 96

und 97 zu festzulegen. Siehe Seite 11.

DO AUX 2

M

Vhp

Back-up batterij

24 V

32 A

6 A

6 A

(4)

(4)

Vermogen

0,5 A

min. 50 mA

Ioff < 1,5 mA

Verbindung, untere Ebene Verbindung, obere Ebene

24 V AC/DC

Waarschuwing

De voedingsspanning

van AI mag het signaal

niet met andere

regelaars delen.

1 = Zwart = +

2 = Blauw = -

3 = Bruin = s

AKS 32R

AKS 2050

MBS 8250

MODBUS

AI 1 = PoMT

VSD MT

0 – 10 V

AI 2 = PoLT

AI 3 = Pgc

AI 4 = Prec

VSD LT

0 – 10 V

CAN RJ

LN

CANBUS D- D+

DO

DO DO1 DO2 DO3 DO4 DO5 DO6 DO7 DO8 Σ 1-8

0,5 A

min. 50 mA

6 A

(4)

6 A

(4)

10 A

(3,5)

(3,5)

I Max. 10 A

Ioff < 1,5 mA

U Alle 24 V oder alle 230 V AC

Aparte

8 | AN29572719924701-000201

voeding

Externe 24 V

AC/DC

Funkenstörung

Signalkabeln für Fühlern, DI-Eingängen, Datenkommunika-

tion und Display sind getrennt von Hoch Spannungs (230

V) Elektrokabeln zu verlegen:

- Separate Kabeltröge verwenden.

- Zwischen den Hochspannungs- und Signal-Kabeln einen

Abstand von mindestens 10 cm halten.

Ventilator

0 – 10 V

- Bei DI-Eingängen Kabel länger als 3 m vermeiden.

© Danfoss | DCS (vt) | 2019.12

HAUPTMODUL

AO -analoger Ausgang, 3 Stück AO1, AO3, AO4

Müssen verwendet werden, wenn Frequenzumrichter oder ECMotoren eingesetzt werden.

Schließen Sie 24 V an N und L (separate Versorgungsspannung)

an. Vermeiden Sie einen Erdschlussstrom.

- Verwenden Sie doppelt isolierte Transformatoren. Die sekundäre

Seite darf nicht geerdet werden.

0-10 Volt erhalten Sie von den Klemmen Com-AO1, N-AO3 und

N-AO4.

ACHTEN SIE AUF DIE POLARITÄT von N.

(AO3 und AO4 sind galvanisch getrennt, AO1 nicht).

AI - analoge Eingänge

Druckmessumformer, 4 Stück AI1 – AI4

HOCHDRUCKMODUL

Versorgungsspannung zum Hochdruckmodul

Die Versorgungsspannung kann vom Hauptmodul genommen

werden.

Batterie

Achten Sie darauf, dass das Ventil schließt, sobald keine Spannung

anliegt.

Schrittmotorventil

FX Ventiltyp CCMT.

Anschluss:

A1 5: WEISS

A2 6: SCHWARZ

B1 7: Rot

B2 8: GRÜN

AKS 32R /

AKS 2050 /

MBS 8250

10 – 90% ratiometric

Temperaturfühler, 4 Stück AI5 – AI8

• Pt 1000 Ohm, AKS 11 oder AKS 21.

DI - digitale Schalteingänge, 8 Stück DI1 – DI8

Der Anschluss kann als Ausschalt- oder Unterbrechungsfunktion

erfolgen. Wählen Sie während der Konfiguration, was aktiviert

wird.

(DI3 kann als Eingang AUX1 verwendet werden, aber nur bei

Regelung mit 2 MT-Verdichtern).

Spannungsversorgung

24 V Wechsel- oder Gleichspannung Klasse II ist erforderlich.

AK-PC 572 17 VA

EKE 1P 20 VA

CANBUS

CKommunikation zum Hochdruckmodul und Empfängermodul

„L“ an „L“ und „H“an „H“

Zwischen „H“ und „R“ muss eine Brücke angeschlossen werden.

Sluit af op de AK-PC met een weerstand van 120 ohm.

Bij montage van een externe display moet de afsluiting ook bij de

display gebeuren. Zie de volgende pagina.

Belangrijk!

Om communicatie met de uitbreidingsmodules tot stand te

brengen moet u de aanbevolen procedure volgen. Zie de

volgende pagina.

MODBUS

Das Datenübertragungskabel ist unbedingt korrekt anzuschließen. Siehe separate dokumentation Nr. RC8AC...

Denken Sie an die Terminierung an den Terminierungspunkten.

DO - digitale Ausgänge, 8 Stück DO1-DO8

DO5 und DO6 sind Halbleiterrelais. Die Ausgänge werden für den

Anschluss eines Bitzer CRII verwendet. Wenn kein Bitzer CRII angeschlossen wird, kann der Ausgang DO6 für die Aktivierung eines

Ölventils verwendet werden.

Die Relais wurden auf vorgegebene Werte heruntergeregelt.

Das Alarmrelais wird im normalen Betrieb aktiviert und fällt bei

Alarmen und ungenügender Spannungsversorgung des Reglers ab.

(DO3 kann als Ausgang AUX1 verwendet werden, aber nur bei

Regelung mit 2 MT-Verdichtern).

CANBUS

Datenübertragung zum Hauptmodul.

Fühlereingänge

• Pt 1000 Ohm, AKS 11 oder AKS 21.

Kontakt Eingang AUX 2

Signal von Ölstand

oder Eingang für Lüfteralarm oder anderen Alarm.

Relaisausgang AUX 2

Aktivierung der Enthitzung oder Heißgasentladung.

MODBUS

Datacommunicatie met andere apparaten.

Het is belangrijk dat de datacommunicatiekabel correct is

aangesloten.

Zie de aparte documentatie met nummer RC8AC...

Vergeet de afsluiting bij de afsluitpunten niet.

Gebruik een afgeschermde kabel met getwiste aderparen, maar

verbind de afscherming niet met de EKE 1P.

EMPFÄNGERMODUL

Versorgungsspannung zum Hochdruckmodul

Die Versorgungsspannung kann vom Hauptmodul genommen

werden.

Batterie

Achten Sie darauf, dass das Ventil schließt, sobald keine Spannung

anliegt.

Schrittmotorventil

FX Ventiltyp CCMT.

Anschluss:

A1 5: WEISS

A2 6: SCHWARZ

B1 7: Rot

B2 8: GRÜN

CANBUS

Datenübertragung zum Hauptmodul.

Dieser Abschnitt muss mit einem 120-Ohm-Widerstand

abgeschlossen werden.

Kontakt Eingang AUX 3

Signal von Wärmerückgewinnung

oder Eingang für Lüfteralarm oder anderen Alarm.

Relaisausgang AUX 3

Aktivierung der Wärmerückgewinnung

oder Ausgang AUX 3 für Enthitzung oder Heißgasentladung.

© Danfoss | DCS (vt) | 2019.12

AN29572719924701-000201 | 9

Externes Display

80G3867

R = 1200Ω

L→H

Uitbreidingsmodules

MODBUS master

H - R

0 V / Open 5 V

ANALOOG / DIGITALE INGANG ANALOOG / DIGITALE INGANG

R120 Brug – CAN H

CAN H Rood

CAN L Groen

C GND Geel

Geel

Groen

Rood

RS-485 RS-485 CAN-RJCAN-RJ

COM

5V+

DI2

D –

D+

RGND

Hoge druk Vloeistofvat

Bitzer CRII

Das Puls-signal kann auch dazu verwendet werden, um einen CRII-Verdichter mit zwei Entlastungsventile

zu regeln. (4 Zylinder Version)

Die Verdichterleistung kann von 10 bis 100% regeln abhängig von der Pulsierung der Entlastungsventile.

Die Entlastungsventile sind mit einem DO5 oder einem DO6 verbunden.

Schließen Sie das Verdichterrelais an MT1 an.

Danfoss

CAN RJ

DI1

COM

AI4

AI3

AI2

AI1

COM

COM

5V+

DI2

D –

D+

RGND

CAN RJ

DI1

COM

AI4

AI3

AI2

AI1

COM

Entlasung 2 folgt Entlasung 1

aber wird mit einer ½ Periode

verschieben. Entlasung 2 folgt

Entlasung 1 aber wird mit einer

½ Periode verschieben.

Wichtig

Lesen Sie die nachfolgenden Informationen, bevor Sie den

Regler und die zwei Ventilmodule an die Spannungsversorgung

anschließen.

Um die Adressen der beiden Ventilmodule zu überprüfen, gehen

Sie wie folgt vor:

1. Schließen Sie alle Module an die Spannungsversorgung an..

2. Drücken Sie dann sofort die Tasten „X“ und „Enter“, während der

Regler hochfährt.

3. Öffnen Sie das Display „CAN SETTINGS“ > „ACTIVE NODES“ (CANEINSTELLUNGEN > AKTIVE KNOTEN)

Entlasung 1

Entlasung 2

De twee 1-cijfers staan respectievelijk voor de adressen 96 (HPmodule) en 97 (Vloeistofvatmodule).

Wenn Sie die Verbindung zu einem Ventilmodul trennen, wird

auch die Anzeige der Adresse ausgeblendet.

10 | AN29572719924701-000201

© Danfoss | DCS (vt) | 2019.12

Raccordements

HR / DO

s

80G386

FRANÇAIS

Danfos

CAN RJ

COM

CAN RJ

AI1

COM

AI1

AI2

AI2

AI3

AI3

AI4

AI4

COM

COM

CAN RJ

DI1

DI2

5V+

COM

COM

AI1

AI2

AI3

AI4

COM

DI1

DI2

5V+

COM

RGND

D+

D –

RGND

D+

D –

CAN RJ

DI1

DI2

5V+

COM

RGND

D+

D –

COM

AI1

AI2

AI3

AI4

COM

DI1

DI2

5V+

COM

RGND

D+

D –

EKE 1P

EKE 1P

HR / DI Aux 3

LT - SS

LT - Sd

Oil / DI Aux 2

MODBUS Field Bus

A+

B-

NC1

C1

NC1

NO1

C1

NO1

B2

B2

B1

B1

A2

A2

A1

A1

Bat+

Bat+

GND

+/~

GND

–/~

+/~

+

–/~

-

NC1

C1

NC1

NO1

C1

NO1

B2

B2

B1

B1

A2

A2

A1

A1

Bat+

Bat+

GND

+/~

GND

–/~

+/~

+

–/~

-

AUX 3

M

Vrec

Batterie de secours

24 V

Puissance

Important!

Patienter avant de brancher l'alimentation sur les

modules !

Pour régler les adresses 96 et 97, suivre la procédure

conseillée. Voir page 13.

DO AUX 2

32 A

M

Vhp

6 A

(4)

Batterie de secours

24 V

6 A

(4)

Puissance

0,5 A

min. 50 mA

Ioff < 1,5 mA

Connexion, niveau inférieurConnexion, niveau supérieur

24 V CA/CC

Avertissement

La tension d'alimentation

d'AI ne peut pas partager

0,5 A

min. 50 mA

6 A

6 A

10 A

(4)

(4)

(3,5)

Ioff < 1,5 mA

MODBUS

CAN RJ

CANBUS D- D+

(3,5)

DO DO1 DO2 DO3 DO4 DO5 DO6 DO7 DO8 Σ 1-8

I Max. 10 A

LN

U Tous 24 V ou tous 230 V c.a.

DO

AI 1 = PoMT

AI 2 = PoLT

AI 3 = Pgc

VSD MT

0 – 10 V

AI 4 = Prec

VSD LT

0 – 10 V

1 = Noir = +

2 = Bleu = -

3 = Marron = s

AKS 32R

AKS 2050

MBS 8250

le signal avec d'autres

régulateurs.

Alimentation

séparée

24 V CA/CC

externe

© Danfoss | DCS (vt) | 2019.12

Ventilateur

Phénomènes de parasitage

Les câbles des sondes, des entrées DI, de la transmission de

données et l'affichage doivent être séparés de la haute

tension

(230 V) des câbles électriques:

- utiliser des chemins de câble séparés

- maintenir une distance d’au moins 10 cm entre les câbles

de haute tension et de signal

0 – 10 V

- Câbles supérieurs à 3 m à l'entrée DI doivent être évités

AN29572719924701-000201 | 11

MODULE PRINCIPAL

AO -3 sorties analogiques. AO1, AO3, AO4

Doivent être utilisées en présence de variateurs de fréquence ou

de moteurs EC.

Brancher 24 V sur N et L (alimentation distincte). Éviter le courant

de défaut à la terre.

- Utiliser un transformateur à double isolation. Le côté secondaire

ne doit pas être mis à la terre.

Obtenir 0-10 V des bornes Com-AO1, N-AO3 et N-AO4.

VEILLER À LA POLARITÉ DE N.

(AO3 et AO4 sont isolés galvaniquement. pas AO1).

AI - Entrées analogiques

4 transmetteurs de pression. AI1 – AI4

AKS 32R /

AKS 2050 /

MBS 8250

10 – 90% ratiometric

4 sondes de température. AI5 – AI8

• Pt 1000 ohm, AKS 11 ou AKS 21.

DI - 8 entrées digitales DI1 – DI8

La connexion peut être une fonction d'arrêt ou d'interruption.

Sélectionner ce qu'il faut activer pendant la configuration.

(possibilité d'utiliser DI3 en entrée AUX1, mais uniquement si

régulée avec 2 compresseurs MT).

MODULE HAUTE PRESSION

Alimentation sur module haute pression

L'alimentation peut s'effectuer via le module principal.

Batterie

Vérifier que la vanne se ferme lorsque l'appareil n'est pas sous

tension.

Vanne pas à pas

Vanne FX type CCMT.

Connecteurs :

A1 5: BLANC

A2 6: NOIR

B1 7: Rouge

B2 8: VERT

CANBUS

Bus de communication sur module principal.

Capteurs d'entrée

• Pt 1000 ohm, AKS 11 ou AKS 21.

Entrée contact AUX 2

Signal de niveau d'huile,

ou entrée pour alarme ventilateur ou autre.

Sortie de relais AUX 2

Activation de désurchauffe ou décharge de gaz chaud.

Alimentation

24 V c.a. ou c.c. Classe II requise.

AK-PC 572 17 VA

EKE 1P 20 VA

CANBUS

Communication sur le module haute pression et le module

récepteur.

« L » sur « L » et « H » sur « H »

Il faut brancher un cavalier entre « H » et « R ».

Effectuez la terminaison de l'AK-PC avec une résistance de

120 ohm.

En cas de montage d'un affichage externe, la terminaison doit

également se faire sur l'affichage. Voir page suivante.

Important !

Pour établir une communication avec les modules d'extension,

vous devez suivre la procédure recommandée. Voir page suivante.

MODBUS

Il est important que l'installation du câble du bus de

communication soit effectuée correctement. Voir documentation

spécifique réf. RC8AC...

N'oubliez pas la terminaison aux points de terminaison.

DO - 8 sorties digitales DO1-DO8

DO5 et DO6 sont des relais à semi-conducteurs. Les sorties sont

utilisées pour brancher un Bitzer CRII. Si aucun Bitzer CRII n'est

raccordé, il est possible d'utiliser la sortie DO6 pour activer une

soupape d'huile.

Les relais sont déclassés vers les valeurs spécifiées.

Le relais d'alarme sera activé en fonctionnement normal et

désactivé en cas d'alarmes et de tension insuffisante sur le

régulateur.

(possibilité d'utiliser DO3 en sortie AUX1, mais uniquement si

régulée avec 2 compresseurs MT).

MODBUS

Bus de communication avec d'autres régulateurs.

Il est important que l’installation du câble du bus de

communication soit effectuée correctement.

Voir la documentation spécifique réf. RC8AC....

N'oubliez pas la terminaison aux points de terminaison.

Utilisez une paire de câble blindé tordue, mais ne connectez pas le

blindage à l'EKE 1P.

MODULE RÉCEPTEUR

Alimentation sur module haute pression

L'alimentation peut s'effectuer via le module principal.

Batterie

Vérifier que la vanne se ferme lorsque l'appareil n'est pas sous tension.

Vanne pas à pas

Vanne FX type CCMT.

Connecteurs :

A1 5: BLANC

A2 6: NOIR

B1 7: Rouge

B2 8: VERT

CANBUS

Bus de communication sur module principal.

La terminaison de la section doit être effectuée à l'aide d'une

résistance de 120 ohms.

Entrée contact AUX 3

Signal de récupération de chaleur, ou entrée pour alarme

ventilateur ou autre.

Sortie de relais AUX 3

Activation de récupération de chaleur,

ou sortie AUX 3 pour désurchauffe ou décharge de gaz chaud.

12 | AN29572719924701-000201

© Danfoss | DCS (vt) | 2019.12

Affichage externe

80G3867

R = 1200Ω

L→H

Modules d’extension

Maître MODBUS

H - R

0 V / Ouvrir 5 V

ENTRÉE ANALOGIQUE / NUMÉRIQUE ENTRÉE ANALOGIQUE / NUMÉRIQUE

R120 Pont - CAN H

CAN H Rouge

CAN L Vert

C GND Jaune

Jaune

Vert

Rouge

RS-485 RS-485 CAN-RJCAN-RJ

COM

5V+

D –

D+

RGND

Haute pression Réservoir

Bitzer CRII

Le signal pulse peut aussi servir à réguler un compresseur CRII avec deux vannes de réduction de

puissance. (4 cylindre version).

La capacité du compresseur peut être régulée de 10 à 100 % en fonction des impulsions des réductions

de puissance. Le réducteur de puissance est connecté à DO5 ou DO6.

Brancher le relais du compresseur sur MT1.

DI2

DI1

COM

AI4

AI3

CAN RJ

AI2

AI1

COM

réducteur de

puissance 1

Danfoss

COM

5V+

DI2

D –

D+

RGND

CAN RJ

DI1

COM

AI4

AI3

AI2

AI1

COM

La réduction de puissance 2 suit

la réduction de puissance 1 mais

avec un décalage d’une demipériode.

Important

Avant de brancher le régulateur et les deux modules à vanne sur

l'alimentation, lire ce qui suit.

Pour vérifier les adresses des deux modules à vanne, procéder

comme suit :

1. Brancher tous les modules sur la prise d'alimentation.

2. Appuyer immédiatement sur les boutons « X » et « Enter » au

démarrage du régulateur.

3. Rechercher l'affichage « CAN SETTINGS » > « ACTIVE NODES ».

réducteur de

puissance 2

Les deux chiffres représentent respectivement les adresses 96

(module HP) et 97 (module réservoir).

En cas de déconnexion d'un module à vanne, l'affichage de

l'adresse disparaît également.

© Danfoss | DCS (vt) | 2019.12

AN29572719924701-000201 | 13

Conexiones

HR / DO

s

80G386

ESPAÑOL

Danfos

CAN RJ

COM

CAN RJ

AI1

COM

AI1

AI2

AI2

AI3

AI3

AI4

AI4

COM

COM

CAN RJ

DI1

DI2

5V+

COM

RGND

D+

D –

COM

AI1

AI2

AI3

AI4

COM

DI1

DI2

5V+

COM

RGND

D+

D –

CAN RJ

DI1

DI2

5V+

COM

RGND

D+

D –

COM

AI1

AI2

AI3

AI4

COM

DI1

DI2

5V+

COM

RGND

D+

D –

EKE 1P

EKE 1P

HR / DI Aux 3

LT - SS

LT - Sd

Oil / DI Aux 2

MODBUS Field Bus

A+

B-

NC1

C1

NC1

NO1

C1

NO1

B2

B2

B1

B1

A2

A2

A1

A1

Bat+

Bat+

GND

+/~

GND

–/~

+/~

+

–/~

-

NC1

C1

NC1

NO1

C1

NO1

B2

B2

B1

B1

A2

A2

A1

A1

Bat+

Bat+

GND

+/~

GND

–/~

+/~

+

–/~

-

AUX 3

M

Vrec

Batería de reserva

24 V

Potencia

Importante!

Espere antes de conectar la alimentación eléctrica a

los módulos.

Para poder ajustar las direcciones 96 y 97 se debe

seguir el procedimiento recomendado. Consulte la

página 16.

DO AUX 2

32 A

6 A

M

Vhp

(4)

Batería de reserva

6 A

24 V

(4)

Potencia

0,5 A

min. 50 mA

Ioff < 1,5 mA

Conexiones,nivel inferiorConexiones, nivel superior

24 V CA/CC

Advertencia

La tensión de alimentación

de la AI puede no

compartir la señal con otros

0,5 A

min. 50 mA

Ioff < 1,5 mA

MODBUS

6 A

6 A

10 A

(4)

(4)

(3,5)

CAN RJ

CANBUS D- D+

(3,5)

DO DO1 DO2 DO3 DO4 DO5 DO6 DO7 DO8 Σ 1-8

I Max. 10 A

U Todos los 24 V o todos los 230 V c.a.

LN

DO

AI 1 = PoMT

AI 2 = PoLT

AI 3 = Pgc

1 = Negro = +

2 = Azul = -

3 = Marrón = s

AKS 32R

AKS 2050

MBS 8250

AI 4 = Prec

controladores.

VSD MT

0 – 10 V

VSD LT

0 – 10 V

Alimentación

independiente

14 | AN29572719924701-000201

Externo

24 V CA/CC

Mantener una distancia mínima de 10 cm entre los cables

Ventilador

0 – 10 V

Ruido eléctrico

Cables de señal para los sensores, de las entradas DI,

comunicación de datos y la pantalla deberán mantenerse

alejados de alta tensión (230 V) cables eléctricos:

Cables de más de 3 m en la entrada DI deben evitarse

- Utilizar diferentes bandejas para los cables

-

de alta tensión y de señal

-

© Danfoss | DCS (vt) | 2019.12

MÓDULO PRINCIPAL

AO: salida analógica, 3 uds. AO1, AO3, AO4

Se debe utilizar si se emplean convertidores de frecuencia o

motores CE.

Conecte 24 V en N y L (fuente de alimentación independiente).

Evite la corriente de fallo a tierra.

- Utilice un transformador con aislamiento doble. El lado

secundario no debe conectarse a tierra.

Obtenga 0-10 V de los terminales Com-AO1, N-AO3 y N-AO4.

FÍJESE EN LA POLARIDAD DE N.

(AO3 y AO4 cuentan con un aislamiento galvánico. AO1 no).

AI: entradas analógicas

Transmisores de presión, 4 uds. AI1 - AI4

AKS 32R /

AKS 2050 /

MBS 8250

10 – 90% ratiometric

Sensores de temperatura, 4 uds. AI5 - AI8

• Pt 1000 ohmios, AKS 11 o AKS 21.

DI: entradas de interruptor digital, 8 uds. DI1 - DI8

La conexión puede ser una función de parada o interrupción.

Seleccione qué se activará durante la configuración.

(DI3 se puede utilizar como una entrada AUX1, pero solo si se

regula con dos compresores MT).

MÓDULO DE ALTA PRESIÓN

Tensión de alimentación al módulo de alta presión

La alimentación eléctrica se puede obtener del módulo principal.

Batería

Asegúrese de que la válvula se cierre si no hay tensión de

alimentación.

Válvula paso a paso

Válvula FX tipo CCMT.

Conector:

A1 5: BLANCO

A2 6: NEGRO

B1 7: Rojo

B2 8: VERDE

CANBUS

Comunicación de datos hacia el módulo principal.

Entradas de sensores

• Pt 1000 ohmios, AKS 11 o AKS 21.

Entrada de contacto AUX 2

Señal del nivel de aceite,

o entrada para alarma de ventilador u otra alarma.

Salida de relé AUX 2

Activación de desrecalentamiento o vertido de gas caliente.

Alimentación

24 V CA o CC. Debe ser de clase II.

AK-PC 572 17 VA

EKE 1P 20 VA

CANBUS

Comunicación con el módulo de alta presión y con el módulo

receptor

«L» a «L» y «H» a «H»

Se debe conectar un puente entre «H» y «R».

Debe haber una terminación en el AK-PC con una resistencia de

120 ohmios.

Si se monta una pantalla externa, la terminación también se debe

realizar en la pantalla. Consulte la página siguiente.

Importante:

para poder establecer la comunicación con los módulos de

extensión, debe seguir el procedimiento recomendado. Consulte

la página siguiente.

MODBUS

Es importante que la instalación del cable de comunicación de

datos se lleve a cabo correctamente. Consulte la documentación

correspondiente n.° RC8AC...

Recuerde la terminación en los puntos de terminación.

DO: salidas digitales, 8 uds. DO1-DO8

DO5 y DO6 son relés de estado sólido. Las salidas se utilizan para

conectar un Bitzer CRII. Si no se conecta un Bitzer CRII, la salida

DO6 se puede utilizar para la activación de una válvula de aceite.

Los relés se reducen a los valores especificados.

El relé de alarma se activará en condiciones normales y se

desconectará en caso de alarma y de tensión insuficiente para el

controlador.

(DO3 se puede utilizar como una salida AUX1, pero solo si se

regula con dos compresores MT).

MODBUS

Comunicación de datos con otros dispositivos.

Es importante que la instalación del cable de comunicación de

datos se realice correctamente.

Consulte la documentación correspondiente n.º RC8AC...

Recuerde la terminación en los puntos de terminación.

Utilice un cable trenzado apantallado, pero no conecte la pantalla

al EKE 1P.

MÓDULO RECEPTOR

Tensión de alimentación al módulo de alta presión

La alimentación eléctrica se puede obtener del módulo principal.

Batería

Asegúrese de que la válvula se cierre si no hay tensión de

alimentación.

Válvula paso a paso

Válvula FX tipo CCMT.

Conector:

A1 5: BLANCO

A2 6: NEGRO

B1 7: Rojo

B2 8: VERDE

CANBUS

Comunicación de datos hacia el módulo principal.

La sección se debe terminar utilizando una resistencia de 120

ohmios.

Entrada de contacto AUX 3

Señal desde recuperación de calor,

o entrada para alarma de ventilador u otra alarma.

Salida de relé AUX 3

Activación de la recuperación de calor,

o salida AUX 3 para desrecalentamiento o vertido de gas caliente.

© Danfoss | DCS (vt) | 2019.12

AN29572719924701-000201 | 15

Pantalla externa

80G3867

R = 1200Ω

L→H

Módulos de extensión

MODBUS maestro

H - R

0 V / Abierto 5 V

ENTRADA ANALÓGICA / DIGITAL ENTRADA ANALÓGICA / DIGITAL

R120 Puente: CAN H

CAN H Rojo

CAN L Verde

C GND Amarillo

Amarillo

Verde

Rojo

RS-485 RS-485 CAN-RJCAN-RJ

COM

5V+

D –

D+

RGND

Alta presión Receptor

Bitzer CRII

La señal de pulso también se puede utilizar para controlar uno de los CRII con 2 descargadores (versión

de 4 cilindros).

La capacidad del compresor se puede controlar entre un 10 y un 100 % dependiendo de la pulsación de

los descargadores. El descargador está conectado a DO5 o DO6.

Conecte el relé del compresor a MT1.

Danfoss

DI2

CAN RJ

DI1

COM

AI4

AI3

AI2

AI1

COM

COM

5V+

DI2

D –

D+

RGND

CAN RJ

DI1

COM

AI4

AI3

AI2

AI1

COM

El descargador 2 sigue

al descargador 1, pero

se desvía medio periodo.

Importante:

Lea la siguiente información antes de conectar el controlador y los

dos módulos de válvulas a la tensión de alimentación.

Si desea comprobar las direcciones de los dos módulos de

válvulas, debe llevar a cabo las siguientes acciones:

1. Conecte todos los módulos a la fuente de alimentación.

2. Pulse inmediatamente los botones «X» e «Intro» mientras el

controlador se pone en marcha.

3. Localice la pantalla «AJUSTES CAN» > «NODOS ACTIVOS».

Descargador 1

Descargador 2

Los dos dígitos 1 representan las direcciones 96 (módulo HP) y

97 (módulo receptor), respectivamente.

Si elimina la conexión a un módulo de válvula, la visualización

de la dirección también desaparecerá.

16 | AN29572719924701-000201

© Danfoss | DCS (vt) | 2019.12

The Product contains electrical components

ADAP-KOOL®

And may not be disposed together with domestic waste.

Equipment must be separate collected with Electrical and Elec-

tronic waste. According to Local and currently valid legislation.

Loading...

Loading...