AK-PC 551 Refrigeration Controller

Technical brochure

2 Technical brochure RC8CF102 © Danfoss 08-2014 AK-PC 551

Content

Introduction ������������������������������������������������������������������������������� 4

Applications 4

Compressor combinations 5

Condenser combinations 5

Inputs and outputs 5

Basic Operation ������������������������������������������������������������������������� 6

Status 6

Password 6

Logout 6

Setup & service 6

View parameters 8

Change parameters 8

Day / night schedule 8

First time start up ��������������������������������������������������������������������� 9

Conguration 9

Example: Application ������������������������������������������������������������ 10

Application: Digital scroll 10

Example: Wiring Diagram ���������������������������������������������������� 11

Electrical wiring 11

Connection, lower level 11

Electrical diagram 11

Connection, upper level 11

Example: Wizard ���������������������������������������������������������������������� 12

Wizard setup 12

Example: Check IO conguration ������������������������������������� 14

Wizard assignment of inputs and outputs (I/0) 14

Assignment of inputs and outputs 14

IO conguration error 15

Example: Add extra I/O ������������������������������������������������������� 16

Example: Check I/O wiring �������������������������������������������������� 17

Initialize the controllers IO conguration 17

Network setup ������������������������������������������������������������������������� 18

Example: Quick conguration ������������������������������������������� 19

Quick conguration 19

Application table 20

Frequently asked questions (FAQ) ������������������������������������ 22

AK-PC 551 Technical brochure RC8CF102 © Danfoss 08-2014 3

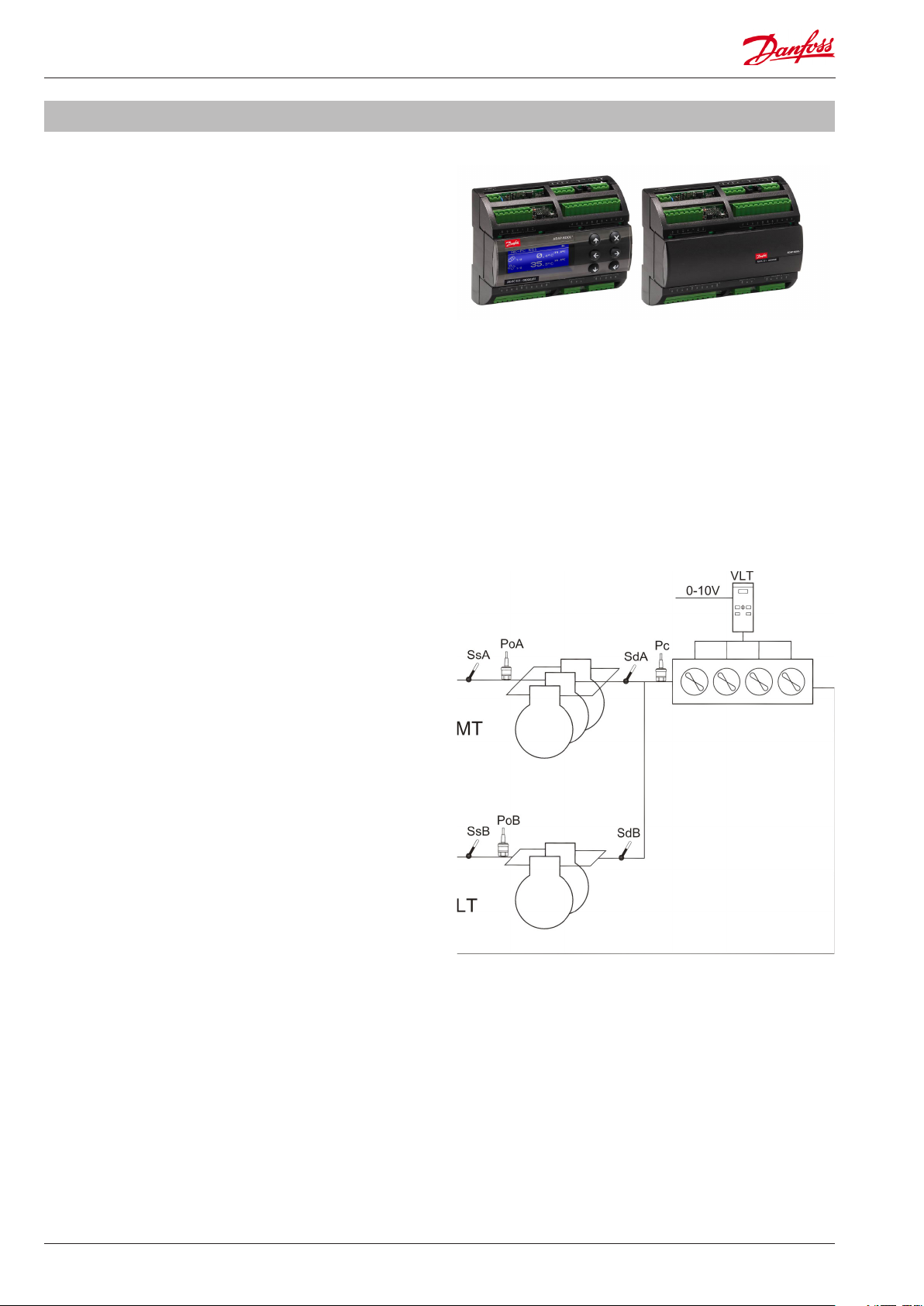

Introduction

This technical brochure will give you a short introduction to

the AK-PC 551 pack controller� With an application example, it

is shown how easy the controller is congured and operated

through the graphical display�

The AK-PC 551 is a pack controller for 1 or 2 suction groups of

compressors and a common condenser�

AK-PC 551 supports a variety of compressor combinations

including variable speed, Digital scroll and Stream 4 cylinder

compressors� Additionally it oers a large number of energy

saving functions and optimization features�

AK-PC 551 can be fully congured through a LCD display� The LCD

display can be built in and/or be a remote connected display�

AK-PC 551 has a compact size of 8 DIN modules� All inputs and

outputs can be congured for a variety of functions making the

controller highly adaptable to any pack application�

AK-PC 551 can be connected into a MODBUS communication

network and is available with 24 Vac or 110-230 Vac power supply�

Applications

AK-PC 551 is used for capacity control of compressors and

condenser fans on small to medium sized refrigeration

systems� It covers the following main applications:

• One compressor group (max� 8 relays) and one condenser

group

• Two compressor groups (max� 4 relays per group) and a

common condenser

4 Technical brochure RC8CF102 © Danfoss 08-2014 AK-PC 551

Introduction

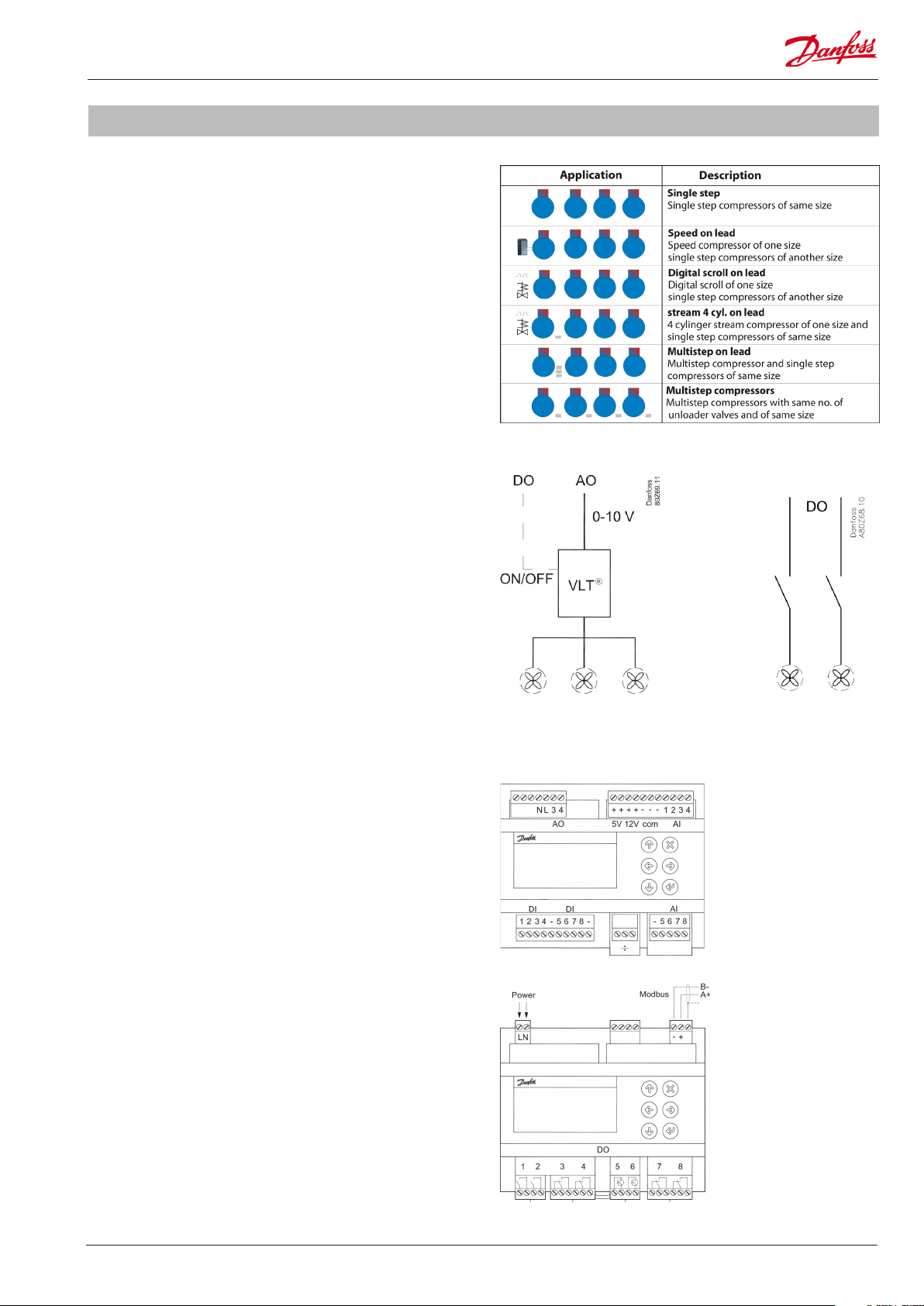

Compressor combinations

The compressor capacity can be controlled according to the

suction pressure Po or a media temperature sensor S4�

AK-PC 551 covers a variety of compressor combinations�

Condenser combinations

The condenser capacity can be controlled according to the

condensing pressure Pc or a media temperature sensor S7

The condenser can be controlled in two ways:

• Speed control of all fans

• Step control of single fans

Inputs and outputs

All in- and outputs of an AK-PC 551 controller can be congured

for various functions and signal types:

• 8 analogue inputs for pressure transmitters and temperature

sensors�

• 6 digital relay outputs for compressors, fans, alarm�

• 2 digital solid state outputs for PWM control of Digital scroll

or Stream compressor� If not used for this purpose they can

be used as normal relay outputs�

• 2 analogue outputs for speed control of compressors and

condenser fans�

Speed control of all fans Step control of all fans

AK-PC 551 Technical brochure RC8CF102 © Danfoss 08-2014 5

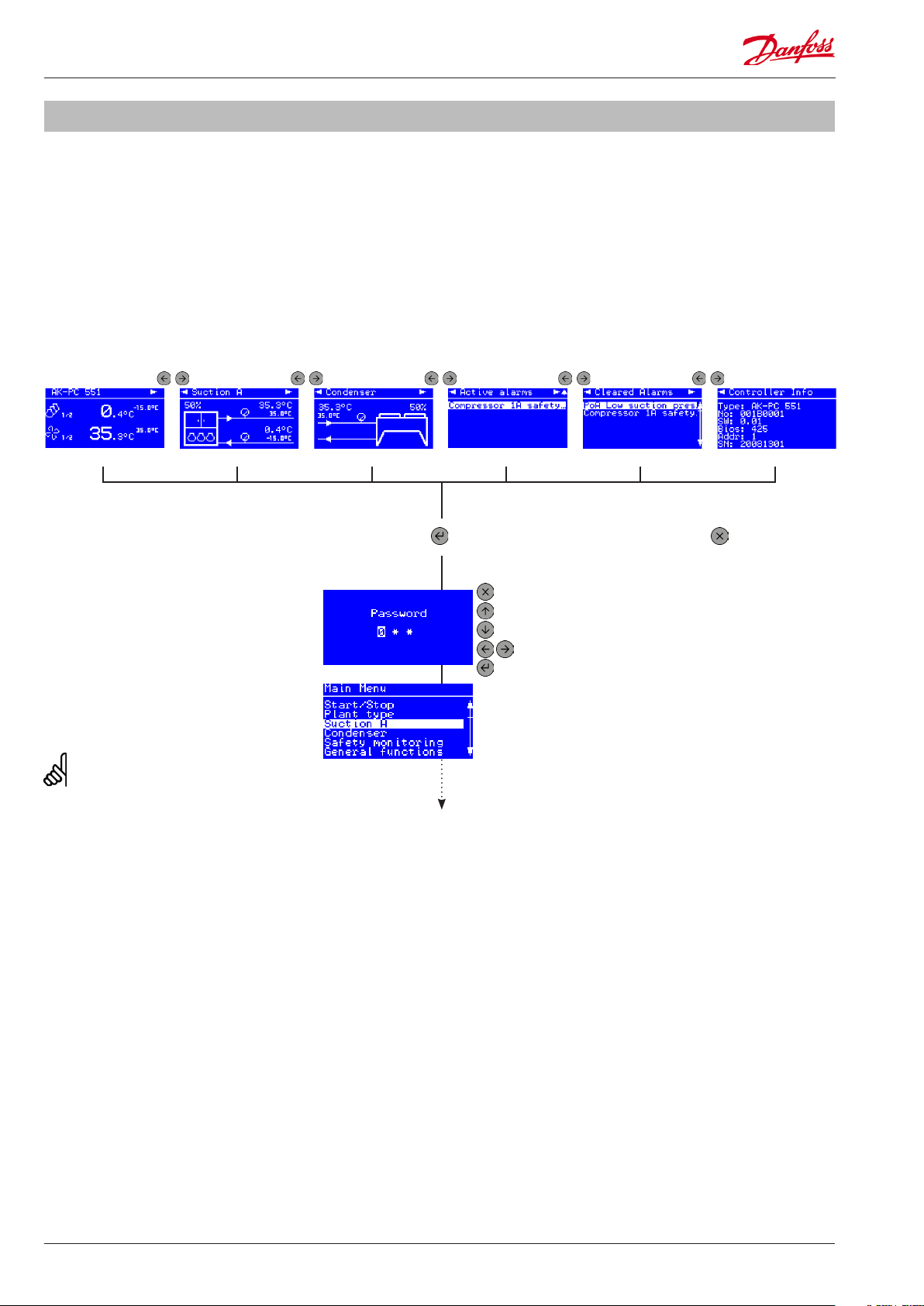

Basic Operation

Conguration and daily operation of AK-PC 551 is done via the

built-in display or via a remote connected display� The display

supports multiple languages and engineering units�

For a full description of the controller parameters please see the

manual RS8GY

Status

Get an overview of how the system is running in the status

screens� Use the LEFT / RIGHT buttons to view the status screens�

Suction statusHome Condenser status Active alarms Cleared alarms Controller information

Password

Parameters and menus are protected by a

password that gives access on 3 dierent

user levels�

Level 0: See parameters (000)

Level 1: Change weekly schedule (100)

Level 2: Change control setpoints (200)

Level 3: Change conguration setpoints (300)

The password cannot be reset, so please

remember the (level 3) password�

Logout

Go to the "Home" screen and hold down the

X key for 5 seconds to logout�

Setup & service

In the main menu you will nd all control

parameters divided into sub menus�

From any status screen press ENTER for

2 sec� to access main menu

Press ESCAPE to go back to status

Press UP to decrease digit

Press DOWN to increase digit

Press LEFT / RIGHT to go to next / previous digit

Press ENTER to login

Press ESCAPE to

go one level back

6 Technical brochure RC8CF102 © Danfoss 08-2014 AK-PC 551

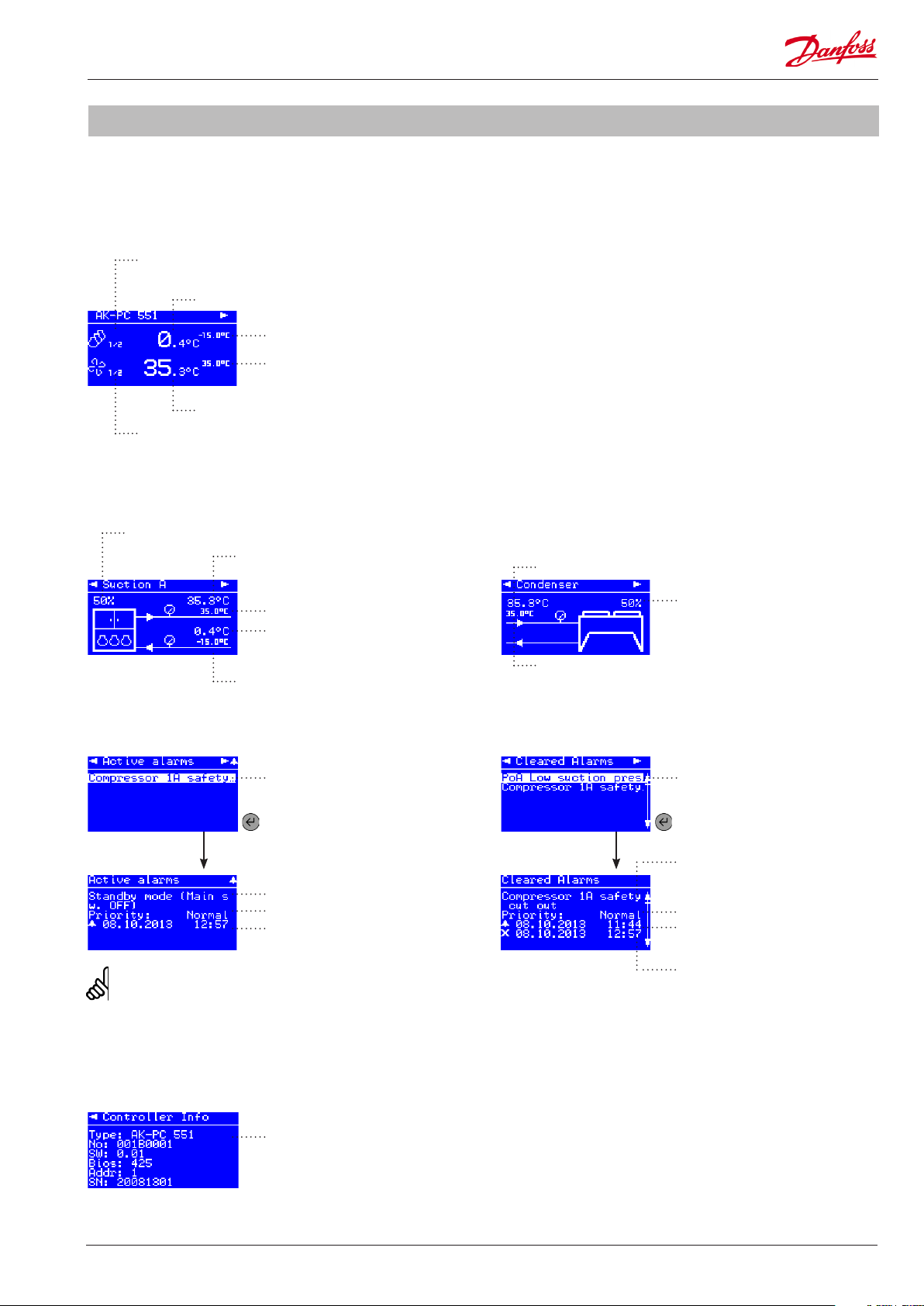

Basic Operation

The number of status screens and the presented data depends

upon the congured application�

Home

Number of compressors running

(1 of 2 compressors is running)

Suction control sensor readout

Suction reference

Condenser reference

Condenser control sensor readout

Number of fans running

(1 of 2 fans is running)

Suction status

Running compressor capacity

Condenser control sensor

Condenser status

Condenser control sensor

Condenser reference

Suction control sensor

Suction reference

Active alarms

Active alarm

Press ENTER to see

alarm details

Alarm text

Alarm priority

Alarm activated at

To clear an alarm press ESC (X) for 2 sec�

Running fan capacity

Condenser reference

Cleared alarms

? temperature

Cleared alarm

Press ENTER to see

cleared alarm details

Alarm text

Alarm priority

Alarm activated at

Alarm cleared at

Controller information

Technical controller information

like code number and software

version etc�

AK-PC 551 Technical brochure RC8CF102 © Danfoss 08-2014 7

Basic Operation

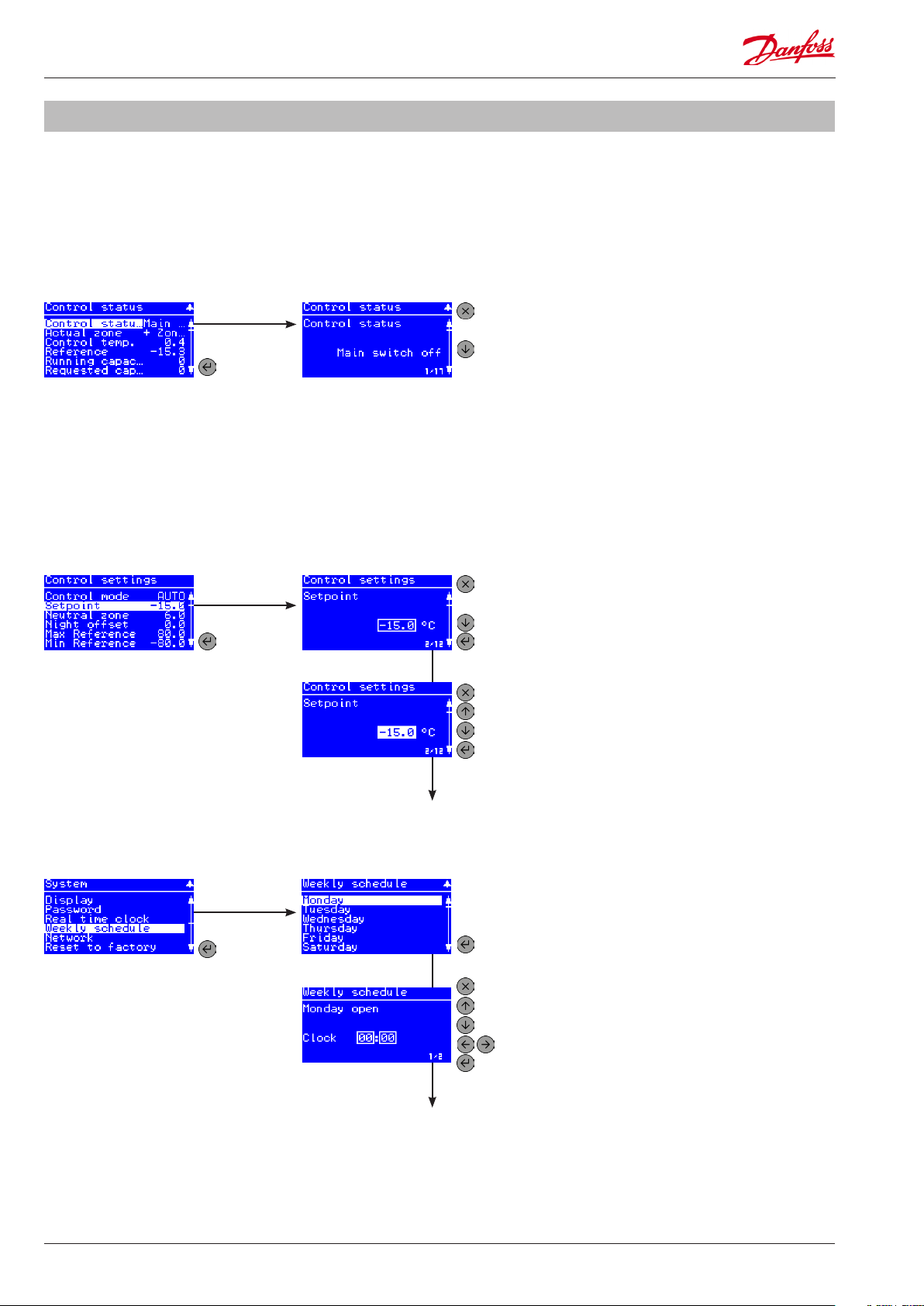

View parameters

The display will only present parameters that are valid for the

congured application e�g� if 4 compressors are selected only 4 are

showed�

A partly highlighted row indicates that a parameter can be viewed

and not changed�

Press ENTER

Control status menu

Change parameters

A full highlighted row indicates that a parameter can be changed�

A changable parameter has a frame around the setting�

to select

control

status

Control status readout

Press ESCAPE to go back one level

Press DOWN to see next parameter

Control settings menu

Day / night schedule

System menu

to select

setpoint

Press ENTER

to select

weekly

schedule

Setpoint readout

Setpoint selected

Weekly schedule

Monday open time

Press ESCAPE to go one level back

Press DOWN to see next parameter

Press ENTER to edit a parameterPress ENTER

Press ESCAPE to go one level back

Press UP to increace the setpoint

Press DOWN to decrease the setpoint

Press ENTER to save the setpoint

Press ENTER to select day

Press ESCAPE to go one level back

Press UP to increace the time

Press DOWN to decrease the time

Press LEFT / RIGHT to go to hour / minute

Press ENTER to save the setting

8 Technical brochure RC8CF102 © Danfoss 08-2014 AK-PC 551

First time start up

Conguration

After installation the controller must be congured for an

application� Once power is applied to the controller, the "Power

on" screen will appear�

Use one of the three options to congure the controller:

• Setup wizard

• Quick configuration

• Parametric setup

Setup wizard

Setup wizard is a step by step up and running guideline, setting

up inputs and outputs automatically�

Quick conguration

Quick conguration is a series of precongured applications,

setting up inputs and outputs automatically�

Parametric setup

Parametric setup is for the expert user, who wants to set each

parameter individually, adjust or netune settings�

Power on screen

Quick start

Press ENTER for 2 sec�

and enter password (300)

to access quick start

AK-PC 551 Technical brochure RC8CF102 © Danfoss 08-2014 9

Example: Application

Application: Digital scroll

The conguration and daily operation of the AK-PC 551 will be

explained via an application example:

AK-PC 551 controls a refrigeration system with two suction

groups of compressors and a common air cooled condenser�

Refrigerant: R404A

Suction group MT:

1 digital scroll compressor

2 single step scroll compressors

Control according to suction pressure Po

Set point -15 °C

Monitoring of discharge temperature of digital scroll

Suction group LT:

2 single step scroll compressors

Control according to suction pressure Po

Set point -30°C

Condenser:

Speed control of 4 fans

Common safety monitoring of fans

Relay output for start/stop of VSD

Control according to condensing pressure Pc

Floating reference according to Sc3 outdoor temp�

10 Technical brochure RC8CF102 © Danfoss 08-2014 AK-PC 551

Example: Wiring Diagram

Electrical wiring

The electrical wiring is laid out according to the wizard rules for

assigning functions to the inputs and outputs

DO Function DI Function AO Function AI Function

DO1 Com� 1A DI1 Comp� 1A safety AO3 Fan VSD AI1 PoA suction pressure

DO2 Comp� 2A DI2 Comp� 2A safety AO4 AI2 PoB suction pressure

DO3 Comp� 3A DI3 Comp� 3A safety AI3 Pc condensing pressure

DO4 Comp� 1B DI4 Comp� 1B safety AI4 Sc3 outdoor temp�

DO5 Comp� 1A PWM DI5 Comp� 2B safety AI5 Sd Comp� 1A

DO6 Comp� 2B DI6 Fan safety AI6

DO7 Fan VSD DI7 AI7

DO8 DI8 AI8

DO8 DI8 AI8

Connection, lower level

Electrical diagram

Connection, upper level

AK-PC 551 Technical brochure RC8CF102 © Danfoss 08-2014 11

Example: Wizard

Wizard setup

In this example we will use the wizard to congure the controller�

Press ENTER for 2 sec�

and enter password (300)

to access quick start

Press ENTER

to select the

wizard

General

In the rst general screens you must select

how data are presented in the display�

Please note that the “Control setup unit”

decides whether the control set points are

presented in pressure units or temperature

units (saturated temperature)�

Press ESCAPE to

leave the wizard

Press ENTER to

start the wizard

Wizard screens: Settings:

Language: English

Control setup unit: Sat. temp

Temperature units: °C

Pressure units: Bar

Plant type

Select the overall application of the

controller and the refrigerant type�

Suction A and B

Set the compressor combination as well

as the compressor sizes, control sensor

and set point� The pressure range of the

pressure transmitter can be set�

Select plant type: 2 comp + 1 cond

Refrigerant type: R404A

Suction A

Po sensor max� range: 12.0 bar

Po sensor min� range: -1.0 bar

Setpoint: -15 °C

Compressor mode: Digital scroll

No� of compressors: 3

Lead compressor size: 5 kW

Comp� size: 5 kW

Suction B

Po sensor max� range: 12 bar

Po sensor min� range: -1.0 bar

Setpoint: -30 °C

Compressor mode: Single step

No� of compressors: 2

Comp� size: 3 kW

12 Technical brochure RC8CF102 © Danfoss 08-2014 AK-PC 551

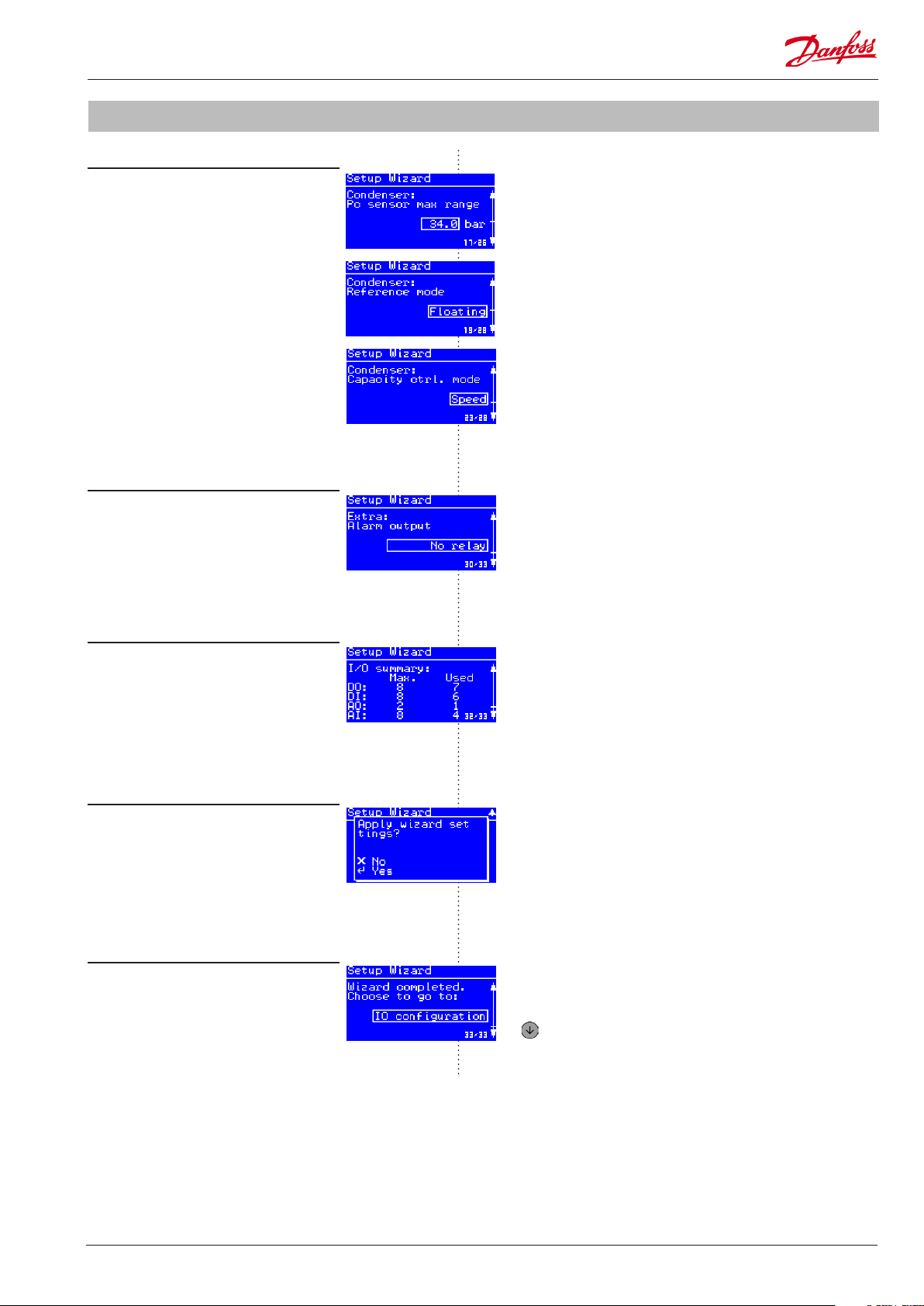

Example: Wizard

Condenser

Set the condenser control as well as control

sensor and reference settings� The pressure

range of the pressure transmitter can be

set�

Extra

Select whether to use an alarm relay and

Modbus network address�

Pc sensor max� range: 34.0 bar

Pc sensor min� range: -1.0 bar

Reference mode: Floating

Setpoint: 30 °C

Min� reference: 15 °C

Max� reference: 45 °C

Capacity ctrl� mode: Speed

No� of fans: 1

VSD Start via DO: Yes

Monitor fan safety: Common

Alarm output: No relay

Modbus address: 100

Summary

Get an overview of the inputs and outputs

generated by the wizard�

Apply wizard settings

Press ENTER to apply the wizard settings

to the controller including automatic

assignment requested inputs and outputs�

Next step

Select which main menu to go to� Press

DOWN to go to the selected menu�

It is recommended to check the IO (input /

output) conguration before starting the

controller�

Press DOWN to go to the selected menu and nish the

wizard

AK-PC 551 Technical brochure RC8CF102 © Danfoss 08-2014 13

Example: Check IO conguration

Wizard assignment of inputs and outputs (I/0)

Once the wizard is applied, the IO functions are automatically

assigned to hardware inputs and outputs�

The screens below shows how the IO functions are assigned

according to the example�

Press ENTER to select

Main menu IO conguration menu

Digital outputs Digital inputs Analog outputs Analog inputs

I/O conguration

Press ENTER to select

digital and analog I/O

Assignment of inputs and outputs

The table indicates rules for assignment of inputs and outputs via the wizard�

Digital outputs (DO1-DO8) Digital inputs (DI1-DI8) Analog outputs (AO3 – AO4) Analog inputs(AI1-AI8)

PWM outputs for capacity

control of Digital scroll or

Stream 4 compressor are placed

on the solid state relays DO5

and DO6

Starting from DO1: Fan safety inputs Speed control of condenser Pc condensing pressure is

Compressor start relays

followed by unloading valves

for respectively suction group

A and B

Condenser fan HP safety switch* S4A and S4B suction media

Injection ON for A/B * LP safety switch * S7 condenser media

Alarm relay Night setback * Sd komp� 1 discharge temp�

Compressor safety inputs for

respectively suction group A

and B

External Main switch (ON/

OFF) *

Heat recovery * Ss suction gas temperature for

Load shedding * Sd discharge temperature for

General alarm inputs 1-3 * Saux for general thermostat *

Speed control of compressor

for respectively suction group A

and B

PoA og PoB suctionpressure are

placed on AI1 and AI2

placed on AI3

Sc3 outdoor temperature is

placed on AI4

temperature sensors *

temperature sensor *

sensor for digital scroll/Stream

compressor for suction A and B

suction group A and B *

suction A and B *

* Special features to be enabled through conguration screens. Not part of the wizard setup.

14 Technical brochure RC8CF102 © Danfoss 08-2014 AK-PC 551

Example: Check IO conguration

IO conguration error

If you get an “IO conguration error” alarm after setting main

switch in ON position, the reasons can be:

• Not all enabled IO functions have been assigned to a

hardware input or output

• The number of enabled IO functions exceeds the number of

available inputs or outputs of the controller

IO summary

Go to Main menu -> IO Status -> IO summary

If the number of enabled IO functions exceeds the maximum

number supported by the hardware, an exclamation mark “!” will

be shown at the IO type in question� This means that you will have

to disable some of the IO functions via the conguration menus

of the suction groups and condenser in order not to exceed the

maximum available inputs or outputs�

If no exclamation mark is shown it means that at least one IO

function has not been assigned to a hardware input or output�

This means that you will have to go into the IO conguration

menu of each IO type, select a free input/output and select the

missing function (if a function is selectable this is the reason for

the IO conguration error alarm)�

Alarm:

IO conguration error

I/O summary

An exclamation mark is shown

when max. number of IO is

exceeded !

AK-PC 551 Technical brochure RC8CF102 © Danfoss 08-2014 15

Example: Add extra I/O

Add extra I/O

The wizard covers all basic functions of the AK-PC 551

pack controller� Additional features can be set through the

conguration screens of the suction group or the condenser�

In this example we will add a Sd discharge temperature

monitoring of both suction groups�

1. Enable Sd temperature monitoring in suction group A and B

Go to Main menu -> Suction A ->Conguration

2. Assign the two Sd discharge temperature sensors to free

analog inputs

Go to Main menu -> IO conguration of analog inputs (AI)

Conguration menu

Sd discharge temp.

3. Select the Sd A and Sd B discharge sensors for respectively

AI6 and AI7

Please notice that it is only functions that are enabled in the

suction/condenser conguration menus that are selectable in the

IO conguration�

PWM outputs for Digital scroll or Stream compressors can only be

selected on the solid state relays DO5 and DO6�

Pressure transmitters with current signals of 0-20mA or 4-20mA

are only supported on AI1-AI4�

If a function has been assigned to an input or output and the

same function has been deselected in the suction/condenser

conguration afterwards, the IO conguration will show an

exclamation mark at the function� This is done in order to show

that an IO point is occupied by a function which is not used by the

controller�

Analog inputs menu

Analog input (AI) no. 6

AI no. 6 function

Analog inputs

An exclamation mark is shown

when an IO point is occupied by

a function which is not used by

the controller.

In this situation you should either enable the function again in the

suction/condenser conguration menus or deselect the function

in the IO conguration�

16 Technical brochure RC8CF102 © Danfoss 08-2014 AK-PC 551

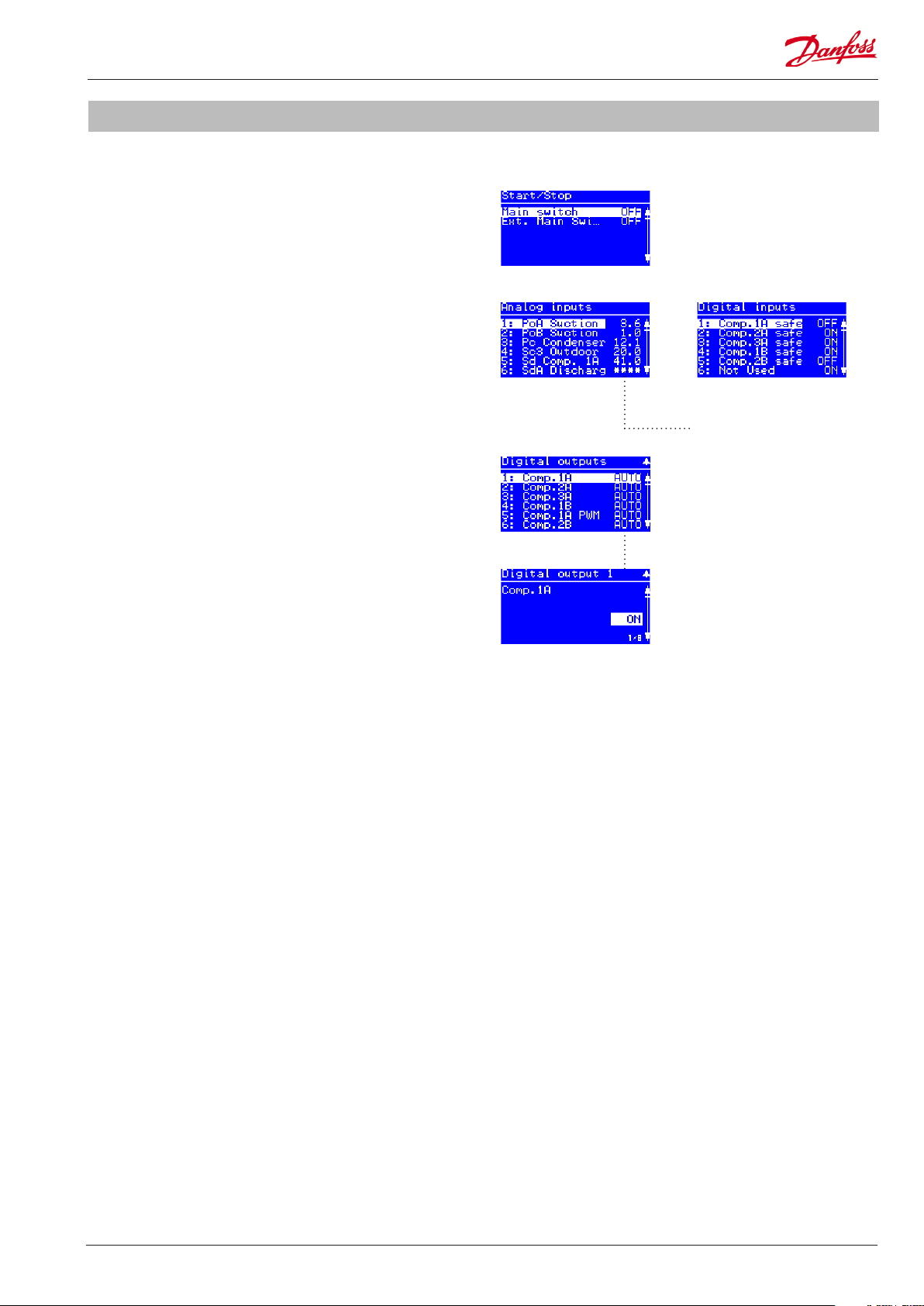

Example: Check I/O wiring

Initialize the controllers IO conguration

1. Set main switch in ON position

Go to Main menu -> Start/Stop

Set main switch ON

2. Check correct reading of inputs and outputs in the IO status

menus

Go to Main menu -> IO Conguration -> Analog/Digital inputs

Check correct status of all inputs�

3. Check correct wiring of the outputs via the IO manual

control menus

Go to Main menu -> IO Conguration -> Analog/Digital outputs

Check correct electrical wiring by manually overriding the

outputs�

Main switch menu

Analog inputs Digital inputs

The stars "****" indicates that

sensor error is detected or not

intialized (main switch ON).

Digital outputs

Digital output 1 ON

AK-PC 551 Technical brochure RC8CF102 © Danfoss 08-2014 17

Network setup

AK-PC 551 can be integrated into a Modbus communication

network� It is important that the installation of the communication

cable is done correctly� Also remember correct termination at

both ends of the cable�

Please refer to separate literature no� RC8AC

When AK-PC 551 is integrated into an ADAP-KOOL® network

with a system manager of the types AK-SC 355 or AK-SM 850 it is

important that some settings are set correctly�

1. Set unit of setpoints

Go to Main menu -> Plant type

The "Unit of setpoints" has to be set up before the controller is

scanned on the network� This is required in order for the front

end (AK-SC 355 or AK-SM 850) to present settings/readings in the

correct units (saturated temperature or pressure)�

2. Set network address

Go to Main menu -> System -> Network

3. Set the Modbus address in the range 1-199

- assuring that the selected address is not occupied by another

controller on the network�

Unit of setpoints

Network

4. Make sure that the Baud rate of the controller is set to “384”

(38400 bits per second)

5. Make sure that the serial mode is set “8E1”

When a network scan is carried out the controller will be identied

as:

• "AK-PC 551 - xxxx (MC250000)" - if the control setup unit is

saturated temperature�

• "AK-PC 551 - xxxx (MC250001)" - if the control setup unit is

pressure�

You can check the scanned controller in the front end in the menu

entry:

Conguration -> Network Nodes -> Scan Status

The AK-SM 850/AK-SC 355 must have software version G03�090 or

higher in order to support AK-PC 551� The software version can be

found in menu entry:

Info -> Information -> SW version

Modbus address and

Baudrate

Scanned controllers shown in the front end

18 Technical brochure RC8CF102 © Danfoss 08-2014 AK-PC 551

Example: Quick conguration

Quick conguration

As an alternative to the wizard, the controller can be set up by

selecting one of the precongurations dened in the controller�

Please refer to the application table (on page 18) for a full

description of all selectable precongurations and the associated

input and output wiring�

A quick conguration is done in ve steps:

1� Select a quick setting

2� Set language

3� Set unit of setpoints

4� Set refrigerant type

5� Set main switch on

1. Select quick setting

Go to Main menu -> Quick setup or select Quick settings at start

up�

In this example is used the preconguration number 17:

3CDA + 2CB+FS

Press ENTER to select

Quick Start menu

The Quick setup can

(after rst time setup) be

accessed from the main

menu.

2. Set language

Go to Main menu -> System -> Display

the quick settings

Quick setting

No plant type selected

After pressing ENTER the selection

goes back to "None" and the selected

preconguration is loaded into the

controller.

Plant type selected

Default is "English"

Language

3. Set unit of setpoints

Go to Main menu -> Plant type

Unit of setpoints

AK-PC 551 Technical brochure RC8CF102 © Danfoss 08-2014 19

Default is "Sat. Temp."

Example: Quick conguration

4. Set refrigerant type

Go to Main menu -> Plant type

By default the Quick conguration will assign AKS32R type

pressure transmitters for the suction and condensing pressure

with -1 to 12 bar and -1 to 34 bar pressure ranges�

It is recommended to check the IO (input / output) conguration

before starting the controller�

5. Set main switch ON

Go to Main menu -> Start/Stop -> Main switch

Default is "None"

Refrigerant menu

Refrigerant type R404A

Start/Stop menu

Main switch on

Application table

The application table shows the selectable precongurations

number, type of compressors and condensor fans� For more

details see the quick conguration table�

App. no. Display views Suction group A Suction group B Condenser

Speed Digital

(Scroll / steam)

17 3CDA + 2CB + FS 1 2 2 x

16 2CDA + 2CB + 3F 1 1 2 3

15 3CSA + 2CB + FS 1 2 2 x

14 2CSA + 2CB + 3F 1 1 2 3

13 4CA + 3CB + FS 4 3 x

12 3CA + 2CB + FS 3 2 x

11 2CA + 2CB + 3F 2 2 3

10 4CDA + FS 1 3 x

9 3CDA + FS 1 2 x

8 3CDA + 3F 1 2 3

7 2CDA + 2F 1 1 2

6 4CSA + FS 1 3 x

5 4CA + FS 4 x

4 4CA + 4F 4 4

3 3CSA + FS 1 2 x

2 3CA + FS 3 x

1 3CA + 3 F 3 3

0 None After selection the setting returns to "None"

1-step 1-step Step Speed

20 Technical brochure RC8CF102 © Danfoss 08-2014 AK-PC 551

Quick conguration table

Fan

safe�

Fan

safe�

Fan

safe�

Fan

safe�

safe�

Fan

Sw�

Sw�

Sw�

Sw�

C1A C2A C3A C1B C2B Main

C1A C2A C1B C2B Main

Digi

Digi

safe�

Fan

safe�

Fan

safe�

Fan

safe�

Fan

safe�

Fan

safe�

Fan

safe�

Fan

safe�

Fan

safe�

Fan

safe�

Fan

safe�

Fan

safe�

Sw�

Sw�

Sw�

Sw�

Sw�

Sw�

Sw�

Sw�

Sw�

Sw�

Sw�

Sw�

C1 C2 C3 C4 Main

C1 C2 C3 Main

C1 C2 C3 Main

C1 C2 Main

Digi

Digi

Digi

Digi

On/O Analog Analog Digital

DO1 DO2 DO3 DO4 DO5 DO6 DO7 DO8 AO3 AO4 AI1 AI2 AI3 AI4 AI5 AI6 AI7 AI8 DI1 DI2 DI3 DI4 DI5 DI6 DI7 DI8

PoA PoB Pc Sc3 SdA

Alarm Fan

C2B Fan

Speed

VSD

Fan1 Fan2 Fan3 PoA PoB Pc Sc3 SdA

PWM

PWM

PoA PoB Pc Sc3 C1A C2A C3A C1B C2B Main

Fan

Alarm C1A

PoA PoB Pc Sc3 C1A C2A C1B C2B Main

Speed

Speed

VSD

PoA PoB Pc Sc3 C1A C2A C3A C4A C1B C2B C3B Fan

Speed

PoA PoB Pc Sc3 C1A C2A C3A C1B C2B Main

Speed

Alarm Fan

Speed

VSD

PoA Pc Sc3 SdA

Alarm Fan

Fan

PoA Pc Sc3 SdA

Speed

Alarm Fan

VSD

Fan

PWM

Speed

VSD

Fan2 Fan3 Alarm PoA Pc Sc3 SdA

PWM

PWM

Alarm PoA Pc Sc3 SdA

PWM

PoA Pc Sc3 C1 C2 C3 C4 Main

Fan

Alarm C1

PoA Pc Sc3 C1 C2 C3 C4 Main

Speed

Speed

Alarm Fan

VSD

Speed

VSD

PoA Pc Sc3 C1 C2 C3 Main

Fan

Alarm C1

PoA Pc Sc3 C1 C2 C3 Main

Speed

Speed

Alarm Fan

VSD

Speed

VSD

App. no. Display views Outputs Inputs

17 3CDA + 2CB + FS C1A C2A C3A C1B C1A

16 2CDA + 2CB + 3F C1A C2A C1B C2B C1A

15 3CSA + 2CB + FS C1A C2A C3A C1B C2B Fan

14 2CSA + 2CB + 3F C1A C2A C1B C2B Fan1 Fan2 Fan3 Alarm C1A

13 4CA + 3CB + FS C1A C2A C3A C4A C1B C2B C3B Alarm Fan

12 3CA + 2CB + FS C1A C2A C3A C1B C2B Fan

11 2CA + 2CB + 3F C1A C2A C1B C2B Fan1 Fan2 Fan3 Alarm PoA PoB Pc Sc3 C1A C2A C1B CB2 Main

10 4CDA + FS C1 C2 C3 C4 C1

9 3CDA + FS C1 C2 C3 C1

8 3CDA + 3F C1 C2 C3 Fan1 C1

7 2CDA + 2F C1 C2 Fan1 Fan2 C1

6 4CSA + FS C1 C2 C3 C4 Fan

5 4CA + FS C1 C2 C3 C4 Fan

4 4CA + 4F C1 C2 C3 C4 Fan1 Fan2 Fan3 Fan4 PoA Pc Sc3 C1 C2 C3 C4 Main

3 3CSA + FS C1 C2 C3 Fan

2 3CA + FS C1 C2 C3 Fan

1 3CA + 3 F C1 C2 C3 Fan1 Fan2 Fan3 Alarm PoA Pc Sc3 C1 C2 C3 Main

0 None

AK-PC 551 Technical brochure RC8CF102 © Danfoss 08-2014 21

Frequently asked questions (FAQ)

Question Solution

How to connect

variable speed drive

(VSD)?

The analogue outputs AO3 and AO4 of the AK-PC 551 pack

controller is galvanic separated from the other inputs and outputs

of the controller� So if the AK-PC 551 controller is ordered for 24Vac

supply voltage, you can use the same 24Vac transformer for power

supply of the controller and for supply of the analogue outputs�

It is recommended to use a double isolated transformer (Class II) as

this type does not need to be connected to protective earth on the

secondary side� This will prevent any ground loops between the

AK-PC 551 pack controller and the variable speed drive connected

to AO3 or AO4�

Example: Variable speed drive connected

to AO3

How to connect the

PWM valve of a digital

scroll compressor?

The Pulse Width Modulated valve (PWM) of a digital scroll

compressor must be connected to one of the solid state relays

(SSR) of AK-PC 551 - which are the outputs DO5 or DO6� The PWM

valve function cannot be selected for any of the other digital

outputs�

The PWM valve of the digital scroll compressor works in such a

way that when voltage is supplied to the valve, the digital scroll

compressor is unloaded and when no voltage is supplied to the

valve, the digital scroll compressor is loaded�

When the PWM valve signal is selected for DO5 or DO6, the

polarity of the output signal is by default inverted and thereby

the PWM valve of the digital scroll compressor can be connected

directly to the AK-PC 551 without any intermediate relays�

Example: Wiring of PWM valve of digital

scroll compressor to DO5/DO6 of AK-PC

551

22 Technical brochure RC8CF102 © Danfoss 08-2014 AK-PC 551

Question Solution

How to start and stop

an AK-PC 551 pack

controller?

The AK-PC 551 controller has two options for start/stop of control�

Parameter set via the display:

The parameter “Main switch” is used to start/stop control (see

screen dumps)

Optional start/stop via digital input signal:

The AK-PC 551 controller can also be controlled via a digital input

signal� This function is enabled in the Plant type menu and then

set up in the IO conguration of digital inputs�

If any of the two “Main switch” signals is in OFF position, the AK-PC

551 will stop all control, set all outputs in standby position and

clear all active alarms�

At the same time the controller will generate a special alarm

“Standby mode alarm” in order to indicate that the controller has

been stopped�

How to setup and

connect a pressure

transmitter with 0-20

mA or 4-20 mA current

signals?

How does the wizard

assign functions to

inputs and outputs?

Pressure transmitters with current output signals of 0-20 mA

or 4-20 mA MUST be connected to one of the analogue input

terminals AI1, AI2, AI3 or AI4�

The signal type and signal range of the pressure transmitter is

setup in the “IO conguration” menu for analogue inputs�

In the example the suction pressure signal for suction group A, has

been selected for analogue input 1 and the signal type is selected

as “4-20mA”� Please be aware that the minimum and maximum

pressure ranges are set in relative pressure�

The power supply for pressure transmitters with current signal

must be connected to the 12 Vdc terminal of AK-PC 551� The signal

wire must be connected to the analogue input pin in question�

If the AK-PC 551 controller is congured via the wizard, the

required functions are automatically assigned to inputs and

outputs�

At the end of the Setup wizard, the user is asked whether the

controller should apply the settings made in the wizard� Please be

aware that the wizard will overwrite all previous congurations, if

the user selects to apply the wizard settings�

Once the user selects to apply the wizard settings, the required

functions are assigned to inputs and outputs based on simple

priority rules� The rules can be seen in detail in the paragraph

“Example: Check IO conguration”

AK-PC 551 Technical brochure RC8CF102 © Danfoss 08-2014 23

Question Solution

How to connect a

remote display?

The remote MMIGRS2 display is connected to the controller via a

cable that can be ordered with dierent lengths�

When connecting the remote display, please remember to make a

short circuit of the two rightmost terminals on the terminal block

to the left of the cable connection – please refer to drawing�

When are alarms

cleared?

Normally alarms are automatically cleared as soon as the alarm

condition is cleared�

However, some safety alarms require that a safety restart delay has

to expire before the alarm condition is cleared and normal control

is resumed� This goes for the following safety alarms:

• High condensing pressure

• Low suction pressure

• High discharge temperature

Furthermore sensor alarms have a clearance delay of 10 minutes

(default), which means that the sensor has to be OK for 10 minutes

before the alarm is cleared� However normal control procedure will

be resumed as soon as the sensor signal is OK� The reason for the

delay is to avoid numerous alarms if a sensor has a bad electrical

connection�

Alarms can also be cleared manually by entering the alarm detail

picture and pressing the “X” button for 3 seconds� If the alarm

condition of a manually cleared alarm is still active the alarm will

be raised again�

Press the X (escape) button for 3 seconds

to clear alarms manually

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material� Danfoss reserves the right to alter its products without notice� This also applies to products

already on order provided that such alternations can be made without subsequential changes being necessary in specications already agreed�

All trademarks in this material are property of the respecitve companies� Danfoss and Danfoss logotype are trademarks of Danfoss A/S� All rights reserved�

24 Technical brochure RC8CF102 © Danfoss 08-2014 AK-PC 551

ADAP-KOOL®

Loading...

Loading...