Page 1

User Guide

Capacity Controller

AK-PC 551

ADAP-KOOL® Refrigeration Control System

Page 2

Introduction

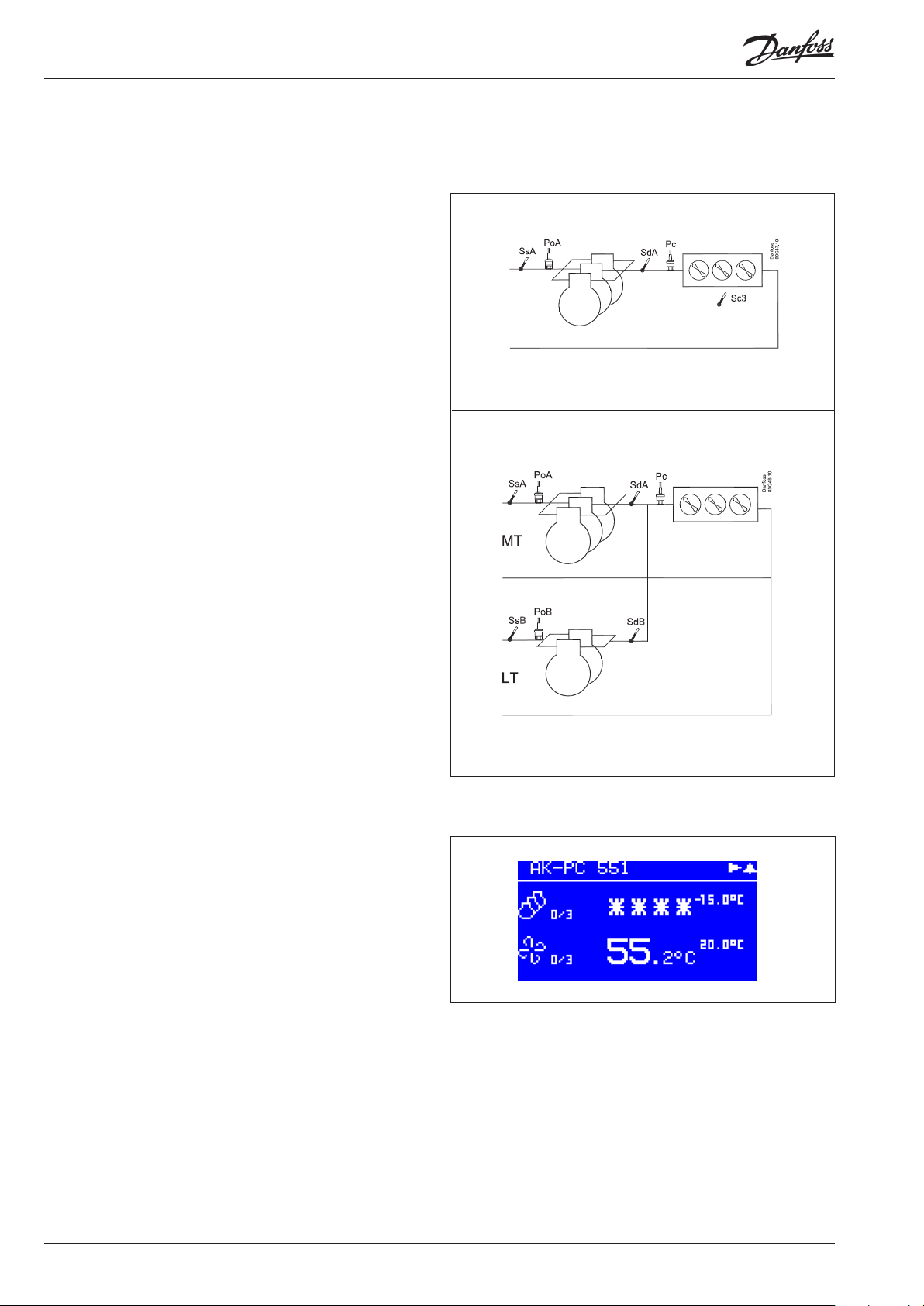

Application

The controller is used for capacity regulation of compressors

and condensers in small refrigeration applications. A maximum of

8 compressors and one condenser can be regulated. For example:

• One suction group + one condenser group

• Two suction groups + one shared condenser (max. 4 + 4 steps)

• One compressor group, max. 8 steps

• One condenser group, max. 8 steps

Advantages

• Energy savings via:

- Optimisation of suction pressure

- Night time increase

- Floating condensing pressure

- Load limitation

Input and output

There are a limited number of available inputs and outputs.

For each signal type, though, the following can be connected:

• Analogue inputs, max. 8 pcs.

Signal from pressure transmitters, temperature sensors,

voltage signal, etc.

• Digital inputs, max. 8 pcs.

Signal from automatic safety control, day/night signal, etc.

• Relay outputs, max. 6 pcs.

Connection of compressors, condenser fans

• Solid state outputs, max. 2 pcs.

- Control of capacity valve on a Copeland digital scroll

- Control of unloader on a Copeland stream compressor.

- Control of both unloaders on a Bitzer CRII

If the outputs are not used for these functions, they can be used

as ordinary relay outputs

• Analogue outputs, max. 2 pcs.

Speed control of compressors or condenser fans.

Operation

The daily operation can be set up directly on the controller or

via an external display device.

During set-up, the display images will be adjusted so that only

the relevant images are opened for additional setting and

end-user operation.

The operation is password protected, and three levels of

access can be granted.

The controller contains several languages. Select the preferred

language at start-up.

Data communication

The controller has built-in modbus data communication, and it

can be connected to an AK-SM 800 type system device.

2 User Guide RS8GY402 © Danfoss 2016-11 AK-PC 551

Page 3

Suction Group

Compressor types

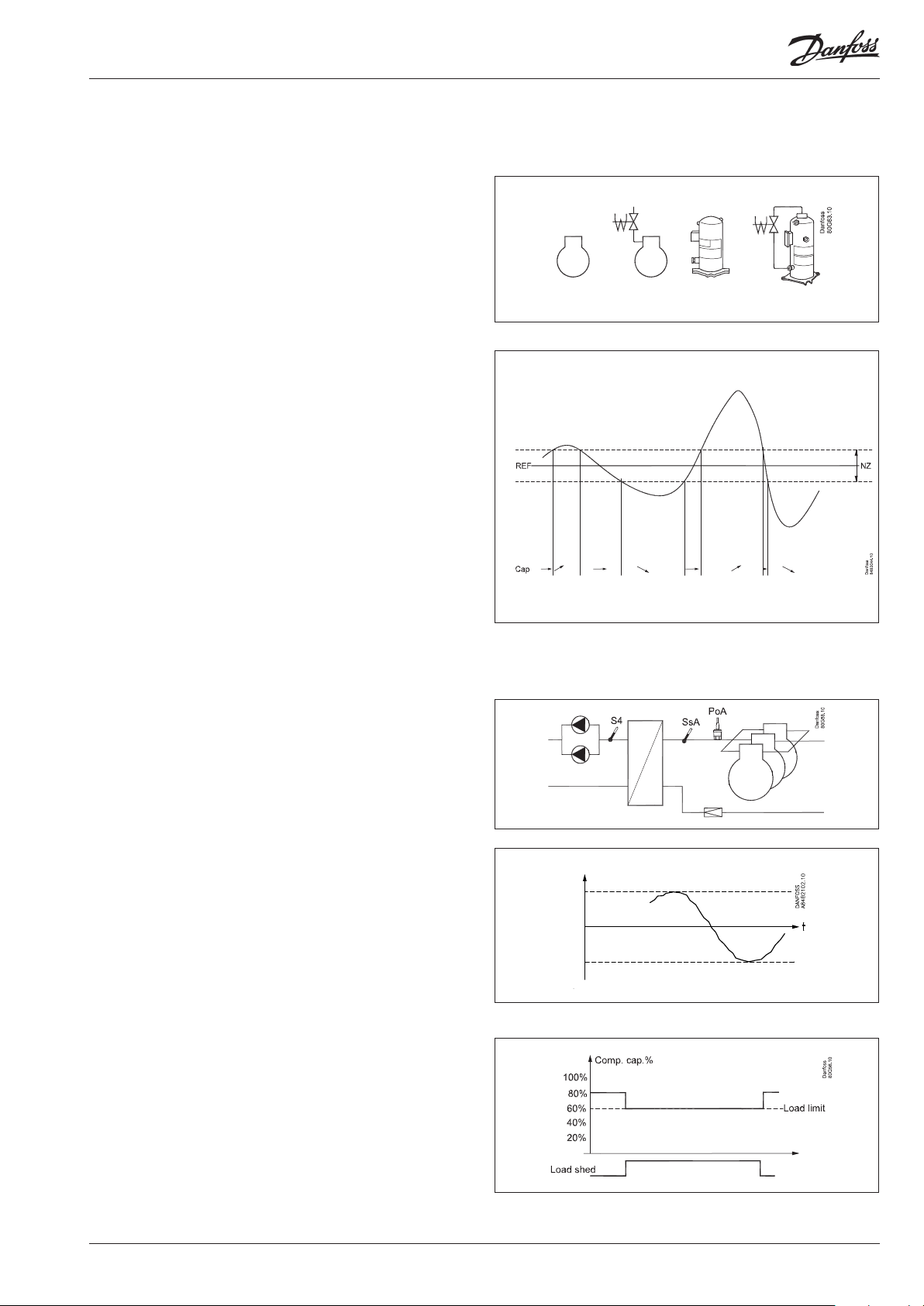

The following types of compressors can be used for regulation:

• Single-step compressors (one can be speed-regulated)

• Compressor with unloaders

• Scroll compressors (one can be a digital scroll)

• Copeland Stream compressor with one unloader (4 cylinders)

• Bitzer CRII compressor with two unloaders (4-cylinders)

Capacity regulation

The cut-in capacity is controlled by signals from the connected

pressure transmitter/temperature sensor and the set reference.

Set a neutral zone around the reference .

In the neutral zone, the regulating compressor controls the

capacity so that pressure can be maintained. When it can no

longer maintain the pressure within the neutral zone, the controller will cut out or cut in the next compressor in the sequence.

When further capacity is either cut out or cut in, the capacity

from the regulating compressor will be modified accordingly

to maintain the pressure within the neutral zone (only where

the compressor has variable capacity).

– When the pressure is higher than the “reference + a half neutral

zone”, cut-in of the next compressor (arrow up) is permitted.

– When the pressure is lower than the “reference - a half neutral

zone”, cut-out of a compressor (arrow down) is permitted.

– When the pressure is within the neutral zone, the process

will continue with the currently activated compressors.

Control sensor

Normally, a suction group is controlled based on a signal from

the Po pressure transmitter.

If control on a brine, the S4 sensor must be the control sensor. The

Po pressure transmitter must also be installed, as it is used for frost

protection.

The reference

At set or variable reference can be used for regulation. For

example, the variable reference can be used for a night time

increase or Po optimisation. Enter a set point here so that a

contribution from the Po optimisation or night time increase

is added. This contribution can raise or lower the reference,

as determined by the momentary cooling need.

To limit the reference from values that are too high or too low, set

a max. and min. limit.

Load shedding

When the load shedding function is activated, the maximum

permissible compressor capacity will be limited to the set limit.

In this way, the total electrical load in the store is limited.

The threshold value may not be set lower than the compressor’s

lowest capacity step/”Start speed”.

Po ref.

Max.

Min.

AK-PC 551 User Guide RS8GY402 © Danfoss 2016-11 3

Page 4

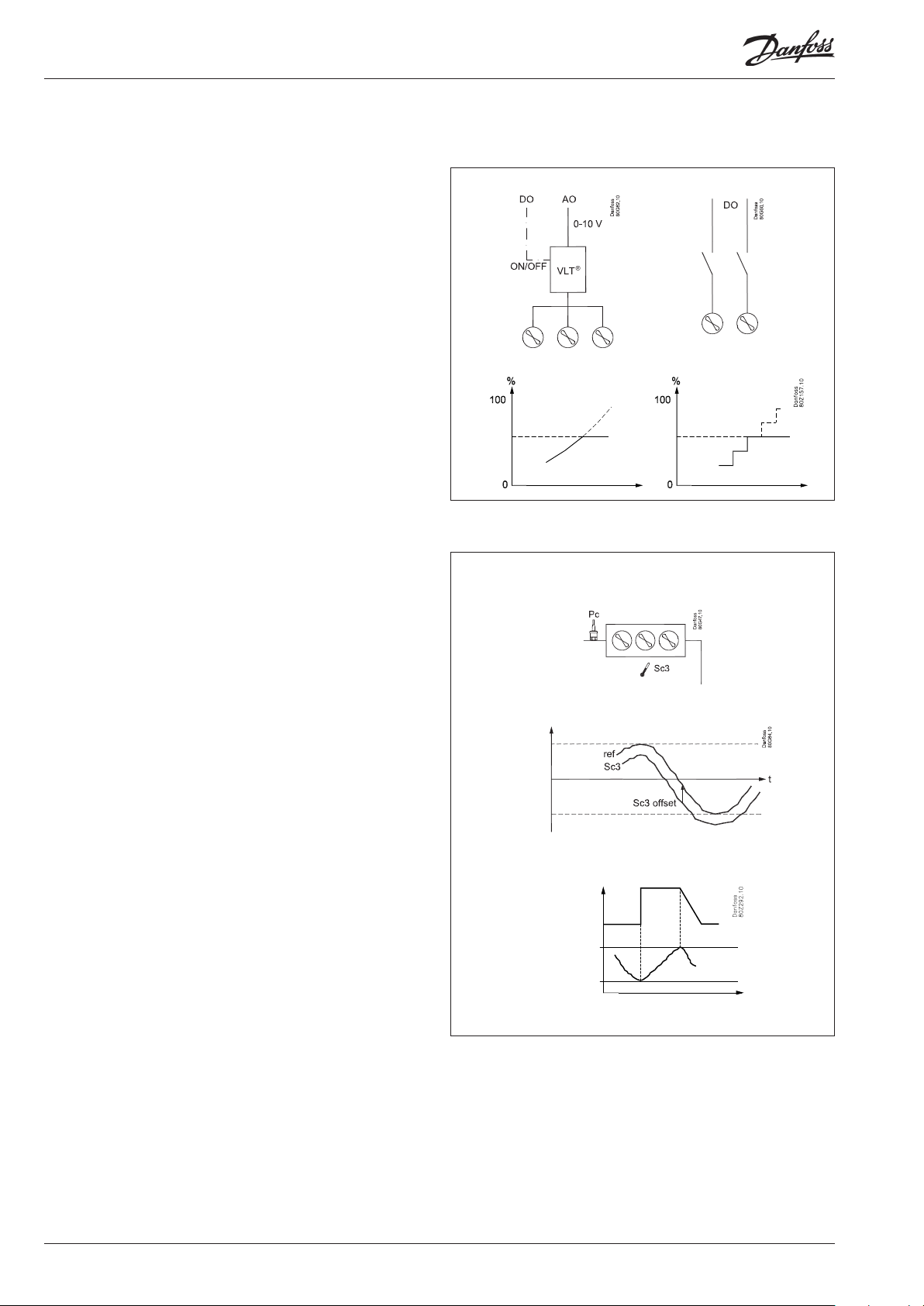

Condenser

Fan control

The fans can be controlled incrementally using the controller’s

relays, or they can be speed-controlled via the controller’s

analogue output.

Speed control can be via a frequency VLT-type transformer.

If the fans have EC motors, the 0-10 V signal can be used directly.

Step and speed simultaneously. (Parallel signals in step with each

other.) This function is primarily used to control a frequency converter, but if the frequency converter fails, external wiring will

switch over to step control.

During night operation, the noise level of the fans can be kept

down. This is done by limiting the cutin capacity.

For speed control, keep the number of revolutions low.

Omit step cutin for step-by-step activation.

The limitation is bypassed if safety functions Sd max. and

Pc max. start to function.

Control

Regulation is carried out based on a signal from the Pc pressure

transmitter or an S7 media temperature sensor. The signal is compared with the regulation reference.

The regulation reference can originate from one or more of the

following functions:

• Fixed reference

• Variable reference, which follows the outdoor temperature.

When the outdoor temperature drops, the reference will drop

by a corresponding amount.

This variable reference requires the installation of an Sc3

outdoor temperature sensor. The sensor must be positioned

so that it registers the correct outdoor temperature. In other

words, it must be shielded from direct sunlight and located

near the airway of the condenser.

This regulation requires setting a min. and max. reference,

so that the regulation process is kept within the given limits.

• Increase the reference for heat recovery.

Here the reference is raised to a fixed value when a signal is

received on a DI input. The reference value can be higher

than the set max. reference.

When the temperature of the heat recovery has been reached

and the DI signal disappears, the reference will drop once again,

though it will do so over the course of a few minutes to prevent

abrupt changes in the reference.

Media temperature

If controlling a media temperature, the control sensor

must be set to S7. This temperature sensor must be located

in the desired medium.

The Pc pressure transmitter must also be installed. It is used for

high-pressure monitoring.

Max. ref.

Min. ref.

Ref. for heat recovery

Temperature sequence for

heat recovery

4 User Guide RS8GY402 © Danfoss 2016-11 AK-PC 551

Page 5

Safety functions

Min./max. suction pressure Po

The suction pressure is recorded continuously.

If the measured value falls below the set minimum limit,

the compressors will immediately cut out.

If it exceeds the max. value, an alarm will be generated once

the time delay has elapsed.

Max. condensing pressure Pc

If the condensing pressure reaches the upper permissible value,

the controller will connect all condenser fans to keep the pressure

down. At the same time, a portion of the compressor capacity will

be disconnected. If the pressure remains near the threshold value,

even more compressors will be disconnected.

All compressors will be disconnected immediately if the threshold

value is exceeded.

LP switch

On/off signal on a DI input

If a signal is received, all compressors will immediately be stopped.

HP switch

On/off signal on a DI input

If a signal is received, all compressors will immediately be stopped.

Fan capacity will increase depending on how much the

Pc measurement exceeds the reference.

Sensor failure

If lack of signal from one of the connected temperature sensors or

pressure transmitters is registered an alarm will be given.

• In the event of a Po error, regulation will continue with a set

capacity in daytime operation (e.g. 50%), and a set capacity in

night operation (e.g. 25%), but with a minimum of one step.

• In the event of a Pc error, the condenser capacity that

corresponds to how much compressor capacity is connected

will cut in. Compressor regulation will remain normal.

• When there is an error on the Sd sensor the safety monitoring of

the discharge gas temperature will be discontinued.

• When there is an error on the Ss sensor the monitoring of the

superheat on the suction line will be discontinued.

• In the event of an error on the outdoor temperature sensor,

Sc3, the permanent setting value will be used as a reference.

• In the event of an error on the S4 sensor, regulation will continue

with the Po signal, but the reference will be lowered by 5 K.

• In the event of an error on the Saux sensor, the thermostat

output will go to the rest position.

NB: A faulty sensor must be OK within 10 minutes before a sensor

alarm is cancelled.

A sensor alarm can be reset manually by pushing the "Xbutton" for 2 seconds when the alarm is shown in the display

"Active alarms".

General DI alarms

On/off signal on a DI input

The regulator contains three general alarm inputs, to which alarm

text and delay times can be connected.

Alarm and text will appear when the delay time has elapsed.

Min./max superheating via Ss measurement

Temperature sensor on an AI input.

If superheating is higher or lower than the set limits, an alarm

will be generated once the time delay has elapsed.

Max. discharge gas temperature Sd

Temperature sensor on an AI input.

A signal can be received from a Pt 1000 Ohm sensor on

the pressure pipe.

• Common Sd for the whole compressor group

If the temperature nears the set max. temperature, the capacity

of the compressor will be reduced

• Compressor Sd

if it is an Sd from a Copeland digital scroll, a Copeland stream or

Bitzer CRII the capacity will be increased so that the compressor

can cool down itself).

The compressors will be stopped if the temperature nears

the set max. temperature value.

General thermostat

It is possible to install one general thermostat if there is a relay

output and an analogue input available.

AK-PC 551 User Guide RS8GY402 © Danfoss 2016-11 5

Page 6

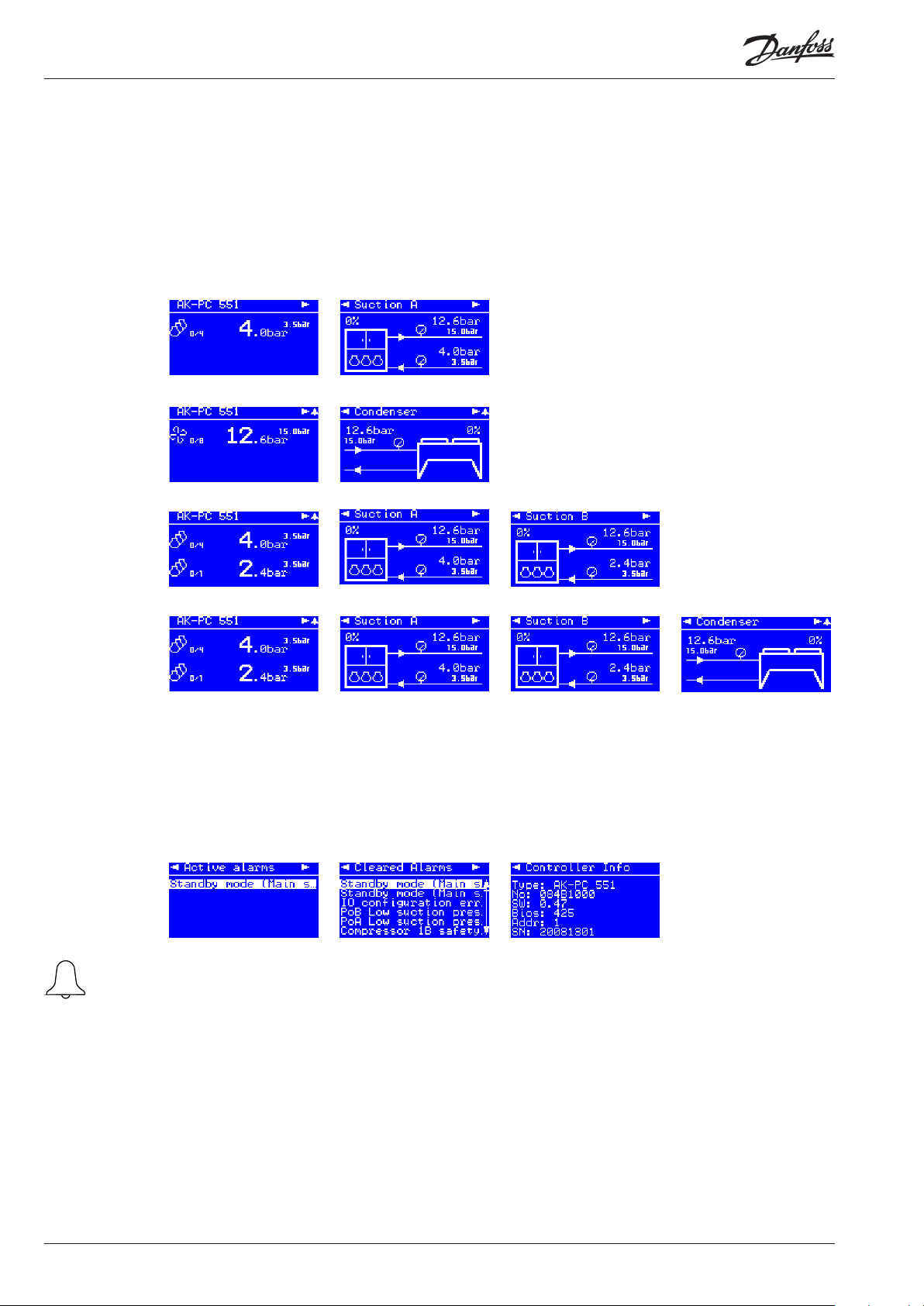

Display overview

End-user overview

The images in this daily user interface will depend on how the set-up is made. They will illustrate what is regulated.

For example: One or two suction groups, one condenser group, or a combination. See examples below:

1 suction

groupe

1 condenser

group

2 suction groups

2 suction groups

and

1 condenser

group

Each of the four rows above is continued with three additional displays.

The arrow in the top corner of the display shows the way to the next display in the same area

of operation. By clicking the right arrow you can see these three displays:

Active alarms Cleared Alarms Information on the controller

When an alarm is sent

from the controller, you

must advance to this

display to see the

alarm text.

6 User Guide RS8GY402 © Danfoss 2016-11 AK-PC 551

Page 7

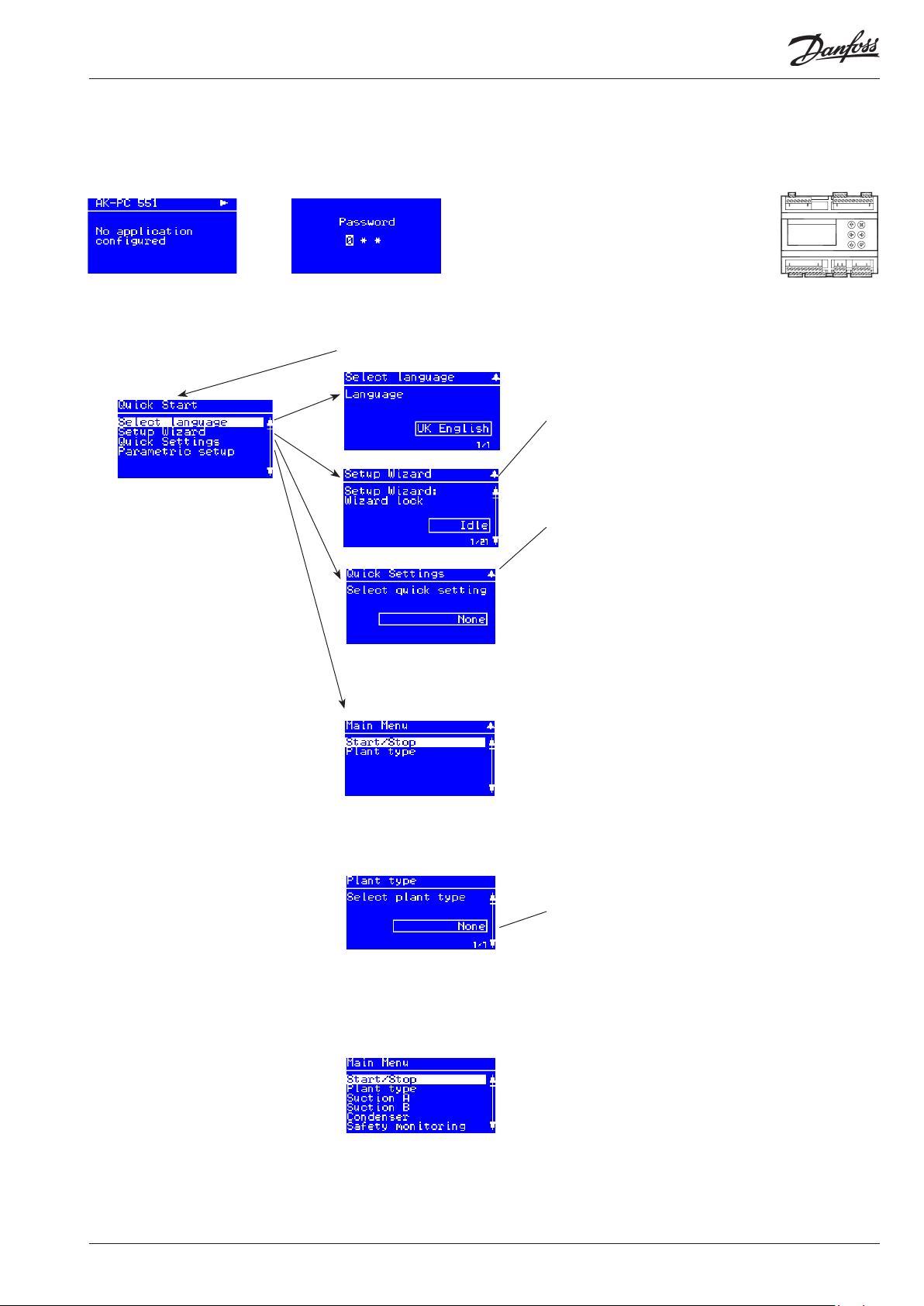

Set-up overview

There are three ways in which the controller can be set up. Select the one that is easiest for you: either “Wizard”, “Quick settings” or a

review of “all parameters”.

Start screen upon delivery

Operating principles

1. Select position using arrow keys

2. Select using “Enter”

3. Use the “X” to return

Hold “Enter” down

for 2 seconds to come to

password entry

Select a set-up method. End

by pressing “Enter”

The default password upon

delivery is 300. Use the arrow

keys to set the password. End

by pressing “Enter”

Main Menu

The first setting is the

Plant type

Wizard

Here you will be led through a series of settings, after

which the controller will be ready for start.

Image 1 of 28 is displayed here.

Quick

Select from the different combinations of compressors

and fans here.

Also see the overview on pages 18 and 19.

3CDA + 2CB + FS

2CDA + 2CB + 3F

3CSA + 2CB + FS

2CSA + 2CB + 3F

4CA + 3CB + FS

3CA + 2CB + FS

2CA + 2CB + 3F

4CDA + FS

3CDA + FS

3CDA + 3F

2CDA + 2F

4CSA + FS

Example:

3CDA + 2CB + FS =

3 Compressors,

one Digital,

suction group A

+

2 Compressors,

suction group B

+

one fan,

Speed controlled

4CA + FS

4CA + 4F

3CSA + FS

3CA + FS

3CA + 3F

None

The following options are available here:

2 Comp + 1 Cond = suction group A + B and condenser

Comp. + Cond. = suction group A and condenser

Condenser = condenser only

When the Plant type has

been selected, it will al-

Compressor = suction group A only

None

low several settings to be

made.

For example:

Continue to the next

menus.

All settings are explained

on the pages that follow.

AK-PC 551 User Guide RS8GY402 © Danfoss 2016-11 7

Page 8

Menu

Start/stop

Plant type

Suction A

Main switch Main switch

Start and stop regulating here.

The configuration settings will require that regulating is stopped.

If you try to enter a configuration setting when regulating has started, the controller will

ask if regulating should be stopped.

When all settings have been made and the main switch is set to “ON”, the controller will

enable the display of the various measurements. Regulation will start. (If an external main

switch has been defined, it must also be “ON” before regulating starts.)

Extern Main swich External main switch

It is possible to connect an external switch which can be used to start and stop regulating.

Both the internal and external main switch must be ON before regulating starts.

An external main switch can be defined in the menu “Plant type” - “Main switch via DI”.

Select Plant type Plant settings:

The following must be regulated:

• Compressor group

• Condenser group

• One compressor group (A) + One condenser group

• Two compressor groups (A) and (B) + One condenser group

Refrigerant type Refrigerant setting

Before refrigeration is started, the refrigerant must be defined. You may choose between

the following refrigerants:

R12, R22, R134a, R502, R717, R13, R13b1, R23, R500, R503, R114, R142b, user defined,

R32, R227, R401A, R507, R402A, R404A, R407C, R407A, R407B, R410A, R170, R290, R600,

R600a, R744, R1270, R417A, R422A, R413A, R422D, R427A, R438A, R513A (XP10), R407F,

R1234ze, R1234yf, R448A, R449A, R452A.

Warning: Wrong selection of refrigerant may cause damage to the compressor.

Other refrigerants: Here Setting "user defined" is selected and then three factors - fac1, fac2

and fac3 and temperature glide (if necessary).

Unit of setpoints Device for controlling compressor and condenser

Select pressure or saturation temperature.

(Can be set during initial set-up and must not be subsequently changed.)

Night signal via DI Night time operation via DI signal

Define an external switch here, so that the regulation reference can be raised and lowered

externally.

1. Set the function to “Yes”

2. Go to I/O configuration and select an available digital input. Set this input to

“Night condition”

3. Next, define whether the function is to be active when the signal is ON, or when it is OFF.

Main Switch via DI Main switch via DI

Define an external main switch here, so that regulation can be started and stopped

externally.

1. Set the function to “Yes”

2. Go to I/O configuration and select an available digital input. Set this input to “Main switch”

3. Next, define whether the function is to be active when the signal is ON, or when it is OFF.

Mains frequency Frequency

Set the net frequency

Alarm output Alarm relay

Define an alarm relay here that will be activated in the event of an alarm.

1. Select the alarm priority that will activate the relay

• No relay

• Critical alarm

• Severe alarm

• All alarms

2. Go to I/O configuration and select an available digital output. Set this output to “Alarm”

3. Next, define whether the relay will be active (pulled) when the alarm is ON, or when it is

OFF.

Alarm buzzer Alarm sound

Here the sound generator can be defined to emit a sound in the event of an alarm.

Select which alarm priority will activate the sound generator:

• No buzzer

• Critical alarm

• Severe alarm

• All alarms

(In the event of an alarm, the sound generator can be stopped by moving across the

active alarm screen; see page 6)

Control status Regulation status

SW: 1.6x

On / Off

Fac: None

Fac: None

Temp. / press

Fac: Saturated

DI-demand

No / Yes

Fac: No

DI-demand

No / Yes

Fac: No

50 Hz / 60 Hz

Fac: 50 Hz

DO-demand

Fac: No relay

Fac: No buzzer

8 User Guide RS8GY402 © Danfoss 2016-11 AK-PC 551

Page 9

Control status Read the status of the control circuit here e.g.:

• No comp. - No compressor capacity available

• Normal ctrl - Normal control

• Alarm Comp. - Cannot start compressor due to alarm condition

• ON timer - Cannot stop compressor due to ON timer restriction

• Start timer - Cannot start compressor due to Start timer restriction

• Normal ctrl - Normal control - no compressor staging

• Inj. On Delay - Waiting for injection on delay to expire

• Cascade

• 1st comp del - First compressor run timer

• Pump down - Last compressor running to pump down limit

• Sensor error - Emergency control due to sensor error

• Load shed - Load shedding function active

• Sd High - Capacity control in High Sd safety prevention mode

• Pc High - Capacity control in High Pc safety prevention mode

• Manual ctrl - Capacity control in manual mode

• Main switch OFF - OFF

Actuel zone You will be able to see how the regulation is in relation to the reference here:

P0 error: No regulation

- Zone: The desired pressure is below the reference value

NZ: The pressure is in place in relation to the reference value

+ Zone: The desired pressure is above the reference value

Control temp. The current value of the regulation sensor can be read here

Reference The total regulation reference can be read here

Running capacity Here the connected capacity can be read as a % of total capacity

Requested capacity Here the preferred connected capacity can be read as a % of total capacity

No. of running comp. The number of compressors in operation can be read here

PoA Pressure The measured pressure for the PoA pressure transmitter can be read here

ToA Saturated temp. The measured PoA pressure converted to temperature can be read here

MC PoA offset The size of a reference displacement on Po required from the system unit

(suction pressure optimisation function) can be read here

Pc Pressure The measured pressure for pressure transmitter Pc can be read here

Tc Saturated temp. The measured Pc pressure converted to temperature can be read here

Day / Night status The status of the day/night function can be read here

Load shed The status of the load shed function can be read here

Injection ON A The status of the injection ON signal sent to the evaporator controllers can be read here

MC Load Shedding The status of the load shed signal received from the system device can be read here

MC Night Setback The status of the night increase signal received from the system device can be read here

Control settings Regulation settings

Control mode Regulation type

The regulation is normally set to “Auto”, but it can be changed to “Off” or “Manual”.

When setting to “Manual”, a forced capacity setting can subsequently be entered in %.

Setpoint Enter the set point for the regulation (regulation reference = set point + different offsets) here

An offset can originate from a night increase signal or from an override function on the

system device.

Neutral zone Set the neutral zone around the reference here. Also see the illustration on page 3.

Night offset If necessary, set the value by which the reference will be raised at night.

Keep the setting at 0 if regulating with Po optimisation from a system device.

Max Reference Set the highest permissible regulation reference here

Min Reference Set the lowest permissible regulation reference here

PI control selection Set how quickly the PI regulation must react here: 1 = slowly, 10 = very quickly.

(For “Custom” setting 0, the special settings options will open, i.e. Kp, Tn and time settings

around the neutral zone. These options are only for trained staff.)

Gain factor Kp The amplification factor, Kp (can only be seen and set when the previous menu is set to “0”)

Integration time Tn Integration time Tn (see above)

+ Zone rate of change Change coefficient for + zone (see above)

- Zone rate of change Change coefficient for - zone (see above)

First step runtime At start-up, the cooling system must have time to cool down before PI regulation takes over

the regulation role and can cut in the next compressor.

Set the time before the next compressor may be started here.

MAN / OFF / AUTO

Fac: AUTO

Min: 0 %

Max: 100%

Min: -80°C (-1.0 bar)

Max: 30°C (50 bar)

Fac: -15°C (3.5 bar)

Min: 0,1 K (0.1 bar)

Max: 20 K (5.0 bar)

Fac: 6 K (0.4 bar)

Min: -25 K (-5.0 bar)

Max: 25 K (5.0 bar)

Fac: 0 K (0.0 bar)

Min: -50°C (-1.0 bar)

Max: 80°C (50.0 bar)

Fac: 80°C (40.0 bar)

Min: -80°C (-1.0 bar)

Max: 25°C (40.0 bar)

Fac: -80°C (-1.0 bar)

Min: 0 (custom)

Max: 10

Fac: 5

Min: 0 s

Max: 300 s

Fac: 120 s

AK-PC 551 User Guide RS8GY402 © Danfoss 2016-11 9

Page 10

Pump down Pump-down function

To avoid too many compressor starts/stops at a low load, it is possible to define a pumpdown function for the last compressor. In this case, the compressor will be cut out when the

current suction pressure is down at the set “Pump-down limit Po”.

(The setting must be greater than the safety limit for low suction pressure “PoA Min Limit”.)

Load shed limit Capacity limitation at “low shed signal”

Set how much compressor capacity can be cut in when a signal is received from either a DI

input or a system device via data communication.

Emergency cap. day Emergency capacity in the event of a malfunction of the regulation sensor (suction pressure

sensor)

Set the desired capacity that will apply during daytime operation.

(If the S4 media temperature sensor becomes damaged/defective, use Po for regulation.)

Emergency cap. night Emergency capacity in the event of a malfunction of the regulation sensor (suction pressure

sensor)

Set the desired capacity that will apply during night operation.

(If the S4 media temperature sensor becomes damaged/defective, use Po for regulation.)

Comp. start delay Delay of compressor start after forced closing of expansion valves (at the end of a forced

close signal)

The delay will result in the system device receiving a start signal for all the evaporator controls involved before the first compressor is started.

Injection OFF delay Delay of the forced closing of expansion valves, if the controller calls for cut in of compres-

sors, but the compressors are in a locked situation and therefore cannot start.

Configuration Configuration

Control sensor Select the regulating sensor for the suction circuit:

• Pressure transmitter Po

• Media temperature sensor S4 (brine regulation). (Po is used for safety)

Compressor mode Set the type of compressor to be used for regulation:

• Multi all:****) All compressors have unloaders

• Multi + Single:****) First compressor has unloaders. The remaining ones are one-step units

• Speed+Multi: ***) First compressor is speed-controlled. The remaining ones are with unload-

ers.

• Speed+Single: ***) First compressor is speed-controlled. The remaining ones are

one-step units

• CRII4+Multi **) First compressor is CRII4 compressor. The remaining ones are with unloaders

• CRII4+Single **) First compressor is CRII4 compressor. The remaining ones are

one-step units

• Stream 4+Multi: **) First compressor is a stream compressor. The remaining ones are with

unloaders

• Stream 4+Single: **) First compressor is a stream compressor. The remaining ones are

one-step units

• Digital scroll: *) First compressor is a digital scroll. The remaining ones are one-step units

• Single-step only: All are one-step compressors

• None:

No. of compressors Set the number of compressors on the suction circuit

This is a total amount.

(If both suction groups are selected, the max. number will be 4 for A and 4 for B.)

Lead comp. size Set the nominal compressor capacity for the first compressor (it is defined under

“Compressor mode”)

That is, the capacity of either a “Digital scroll”, “Stream”, “Variable speed CRII” or

“First compressor with unloaders”

Comp. size Set the nominal compressor capacity of the other compressors

For single-step only: All are of the same size, including the first.

For unloader all: All are of the same size, including the first.

VSD Min. speed ***: For speed

Min. speed at which the compressor will cut out

VSD Start speed ***: For speed

Minimum speed at which the compressor will start (must be set to a higher value than

“VSD Min. speed”)

VSD Max speed ***: For speed

Highest permitted speed for compressor

PWM period time *, **: For “Scroll” and “Stream”

Set the period time for the unloader valve (on time + off time)

CRII Period time **: For CRII

Set the period time for the unloader valve (on time + off time)

Yes /No

Fac: No

Min: -80°C (-1.0 bar)

Max: 30°C (50.0 bar)

Facb: -40°C (0.3 bar)

Min: 0 %

Max: 100%

Fac: 100%

Min: 0 %

Max: 100%

Fac: 50%

Min: 0 %

Max: 100%

Fac: 25%

Min: 0 s

Max: 180 s

Fac: 30 s

Min: 0 s

Max: 300 s

Fac: 120 s

AI-demand

Po / S4

Fac: Po

DO-demand /

AO-demand

Fac:

Single step only

DO-demand

Min: 1

Max: 8

Fac: 0

Min: 1 kW

Max: 100 kW

Fac: 1 kW

Min: 1 kW

Max: 100 kW

Fac: 1 kW

Min: 10 Hz

Max: 60 Hz

Fac: 30 Hz

Min: 20 Hz

Max: 60 Hz

Fac: 45 Hz

Min: 40 Hz

Max: 120 Hz

Fac: 60 Hz

Min: 10 s

Max: 20 s

Fac: 20 s

Min: 10 s

Max: 20 s

Fac: 60 s

10 User Guide RS8GY402 © Danfoss 2016-11 AK-PC 551

Page 11

Comp. 1 min cap.

*: For scroll and CRII

Minimum capacity in the time period (without a minimum capacity the compressor

will not be cooled)

Comp. 1 start cap

*: For scroll and CRII

Start capacity: the compressor will only start when the capacity requirement reaches

the value

Comp. 1 Sd temp. *, **: For “Scroll”, “Stream” and CRII

Define whether the controller should monitor the discharge gas temperature Sd from the

compressor (NTC 86K or Pt 1000 Ohm).

Comp. 1 Sd max. *, **: For Scroll, Stream, CRII and yes to “Comp.1 Sd temp”

Set the maximum Sd temperature

No.of unloaders ****: For compressor with unloaders

Set how many unloaders there are on the compressor

Comp. safety input Compressor safety circuit

Define whether a DI input should be reserved for registration of each compressor safety

circuit

LP switch via DI Low pressure safety circuit

Define whether a DI input should be reserved for registration of the signal from an LP switch

Load shedding via DI Load limitation

Define whether a DI input should be reserved for registration of the signal from

a power meter

• None:

• DI: Load limitation must follow a DI input

• Night Mode: Load limitation must follow the status of the day/night signal.

(The day/night signal can be received via a DI input, via time schedule or network.)

Sd disch. gas temp. Shared discharge temperature

Define whether signals from a common Sd sensor on the suction line (Pt 1000) should be

received

Ss suction superheat Monitoring of superheat

Define whether a signal from a common Ss sensor on the suction line should be received

Injection ON fct. Stop injection into evaporators

If the compressors are prevented from starting, stop injection into the evaporators.

Here define whether the function should be active and how the signal should be

communicated.

No: The function is not used

Network: The controller sends a signal to the system unit, which then forwards it to

the evaporator controls

Relay: The function reserves a relay that pulls in if all compressors are stopped.

All evaporator controls must be wired to this signal from the relay.

Compressor timers Compressor timers

Lead comp. Min ON Min. On-time for first compressor

Set a forced On-time here during which the compressor will remain in operation before it

can be switched off again. The setting is to prevent incorrect operation.

To prevent a compressor breakdown, the setting must be made in accordance with the

requirements of the compressor supplier.

Lead comp. Min OFF Min. Off-time for first compressor

Set the forced Off-time during which the compressor must be off before it can be switched

on again. The setting is to prevent incorrect operation.

Lead comp. Restart Min. period of time for re-starting the first compressor.

Set the forced Off-time during which the compressor must be off before it can be switched

on again. The setting is to prevent incorrect operation.

To prevent a compressor breakdown, the setting must be made in accordance with the

requirements of the compressor supplier.

Lead comp. Safety

delay

Delay time before compressor no. 1 cut out for reasons of safety

The time begins when a signal is received on the DI input (configure the DI input via

“Configuration” and “Comp. safety inlet”).

Comp. Min ON Min. On-time for remaining compressors

Set a forced On-time here during which the compressor will remain in operation before it

can be switched off again. The setting is to prevent incorrect operation.

Comp. Min OFF Min. Off-time for remaining compressors

Set the forced Off-time during which the compressor must be off before it can be switched

on again. The setting is to prevent incorrect operation.

Comp. Restart Min. period of time for restarting remaining compressors

Set the forced Off-time during which the compressor must be off before it can be

switched on again. The setting is to prevent incorrect operation.

Min: 10%

Max: 50%

Fac: 10%

Min: 10%

Max: 60%

Fac: 30%

AI-demand

No / Yes

Fac: No

Min: 0°C

Max: 195°C

Fac: 125°C

DO-demand

Min: 1

Max: 3

Fac: 1

DI-demand

Yes /No

Fac: Yes

DI-demand

Yes /No

Fac: No

DI-demand

Yes /No

Fac: No

AI-demand

Yes /No

Fac: No

AI-demand

Yes /No

Fac: No

DO-demand

No /Network /Relay

Fac: No

Min: 0 min

Max: 60 min

Fac: 0 min

Min: 0 min.

Max: 30 min

Fac: 0 min

Min: 1 min.

Max: 60 min

Fac: 4 min

Min: 1 min.

Max: 10 min

Fac: 1 min

Min: 0 min.

Max: 60 min

Fac: 0 min

Min: 0 min.

Max: 30 min

Fac: 0 min

Min: 1 min.

Max: 60 min

Fac: 4 min

AK-PC 551 User Guide RS8GY402 © Danfoss 2016-11 11

Page 12

Suction B

Condenser

Comp. Safety delay Delay time before compressors cut out for reasons of safety

The time begins when a signal is received on the DI input (configure the DI input via

“Configuration” and “Comp. safety inlet”).

Compressor status Compressor status

Comp. 1 Sd gas Read the Sd temperature of the compressor here.

Comp. 1 status Read the operating status for compressor 1 here. The following information may appear:

Alarm - Alarm situation

Main Sw. off - Compressor is stopped

Manual ctrl. - Compressor is cut out on safety input (DI safety input)

High Sd temp. - Stopped due to high Sd temperature

Ready - Compressor is ready to start

OFF timer - Compressor is waiting for Min OFF timer to expire

Min. ON timer - Compressor is waiting for Min ON timer to expire

Running - Compressor is running

Disabled - Compressor has been taken out of operation (compressor service)

Comp. 2.... The same function for the remaining compressors

Compressor capacity Compressor capacity

Comp. 1 cap Read the connected capacity of the compressor (0-100%) here

Comp. 2...... The same function for the remaining compressors

Compressor runhours Compressor run hours

Reset runtime/cycles Reset all of the hour counters and start counters for the subsequent compressors here.

Comp.1 Runtime L Read the total operating time of the compressor (in hours) here

Comp.2..... The same function for the remaining compressors

Compressor cycles Compressor cycles

Comp.1 Cycle total Read the number of times the compressor has been started here

Comp.2..... The same function for the remaining compressors

Compressor service Compressor service

Comp.1 out of service The compressor can be taken out of operation, so that the controller regulates without this

compressor.

No = Normal regulation

Yes = Regulating is carried out without this compressor, and no alarms are generated by it.

Comp.2..... The same function for the remaining compressors

Suction group B. Please see descriptions under suction group A

(Bitzer CRII can not be used in suction group B.)

Control status Regulation status

Control status Here you can read the status of the condenser circuit, e.g.:

• Main Sw. off - Main switch = OFF

• Ready - Capacity control is ready

• Running - Capacity control is in normal run mode

• Capacity control is stopped because all compressors are stopped

• Manual ctrl - Capacity control is set in manual control mode

• High Pc/Sd - Capacity forced to 100% due to High Pc/High Sd prevention functions

• Safety limit - Capacity forced to 100% due to external HP switch/HP safety/Sd safety limit

violation

• Night limit - Capacity control limited due to night silencer limitation

Control temp. The current value of the regulation sensor can be read here

Reference The total regulation reference can be read here

Running capacity Here the connected capacity can be read as a % of total capacity

Requested capacity Here the preferred connected capacity can be read as a % of total capacity

No. of running fans The number of fans in operation can be read here

Tc Saturated temp. The measured Pc pressure converted to temperature can be read here

Pc Pressure The measured pressure for pressure transmitter Pc can be read here

S7 Media Here the measured media temperature with sensor S7 can be read (only if S7 has been

selected as the regulation sensor during “Fan configuration”)

Sc3 air on cond. The measured outdoor temperature with sensor Sc3 can be read here

Heat recovery status Here the status of the heat recovery function can be read

HP safety switch The status of the HP safety switch can be read here

Control settings Control settings

Control mode Regulation type

The regulation is normally set to “Auto”, but it can be changed to “Off” or “Manual”.

When setting to “Manual”, capacity can then be forced set in %.

Setpoint Enter the set point for the condenser regulation here.

Also set a value if regulating with a fluid reference (set point value used in the event of an

outside temperature sensor error).

Min: 1 min.

Max: 10 min

Fac: 0 min

Yes /No

Fac: No

MAN / OFF / AUTO

Fac: AUTO

Min: 0 %

Max: 100%

Min: -25°C (-1.0 bar)

Max: 90°C (159 bar)

Fac: 35°C (15.0 bar)

12 User Guide RS8GY402 © Danfoss 2016-11 AK-PC 551

Page 13

Sc3 offset Temperature offset for regulation with fluid reference.

Regulation reference = Sc3 measurement + Sc3 offset

Min. reference Set the lowest permissible regulation reference here

Max. reference Set the highest permissible regulation reference here

Heat recocery SP Temperature set point for heat recovery function (only when the function is selected during

configuration)

Heat rec. ramp down Ramp-down of regulation reference after heat recovery

Set how quickly the reference for condenser pressure should be made after heat recovery

ends. Enter the change in degrees Kelvin per minute.

Capacity limit night Capacity limitation at night

The speed of the fans can be limited here when regulating using speed control.

During step-by-step activation, the start of the step-by-step process is limited.

Gain factor Kp Amplification factor for PI regulation

If the Kp value is lowered, regulation runs more smoothly

Integration time Tn Integration time for PI regulation

If the Tn value is increased, regulation will run more smoothly

Fan configuration Configuration of fans

Control sensor Selection of regulation sensor:

• Pc pressure transmitter

• S7 media temperature sensor (Pc must be installed for safety monitoring)

Reference mode Set the reference for regulation here

• Fixed reference; the reference here will be the defined set point

• Variable reference; the reference here will follow the outside temperature, which is meas-

ured with Sc3.

Capacity ctrl. mode Set the way in which the fans should be controlled here

• Variable; the fans are controlled by a 0-10 V signal from an analogue output. If it is defined in

“VSD Start via DO”, a relay will be able to start and stop the frequency converter.

• Step; on/off control of fans will be via relays

• Variable + step. The signals are parallel, so external wiring can switch over to step, e.g. if the

frequency converter fails.

No. of fans Enter the number of fans here.

For step-by-step activation, select the number of relays. The relays will cut in/out sequentially,

e.g. 123-321.

For speed control, select 1 or higher. No relay is reserved, but the setting makes it possible to

define the monitoring of fans.

Control type Normally, PI-regulation is used, but this can be changed to a P-regulation if the design of the

system necessitates this.

• PI Ctrl: Regulation is carried out here with as little deviation between the reference and

measurement as possible.

• P-band ctrl: Capacity is cut in here after proportional regulation.

VSD Start speed Set the start value of the frequency converter here.

The value must be higher than the VSD min. speed value.

VSD Min speed Set the minimum speed of the frequency converter here.

If lower capacity is required, this minimum speed should be maintained all the way down to

0% capacity. At 0% capacity, the system stops completely.

VSD Start via DO Define whether a relay should be connected to the frequency converter start/stop function

here:

• No: no relay

• Yes: the relay pulls in when the frequency converter needs to be in operation.

Monitor fan safety Define whether safety monitoring of the condenser fans should be performed.

• None: no monitoring

• Individual: a DI input is reserved for each fan

• Common: a DI input that is common for all condenser fans is reserved .

Fan at comp. OFF Select the way in which the fans should be controlled when all the compressors have

stopped.

• Normal regulation: Fans to be controlled in compliance with normal regulation.

• Energy-optimised: Fan capacity will be maintained at between 0 and 49% in a p-band of

5-15 K above reference.

Heat recovery via DI Define whether a heat recovery cycle should be started with a signal on a DI input here.

• No: No function

• Yes: A DI input is reserved. When a signal is registered, the heat recovery function reference

will become active.

Min: 0 K

Max: 20 K

Fac: 6 K

Min: -25°C (-1.0 bar)

Max: 100°C (159 bar)

Fac: 10°C (5.0 bar)

Min: -25°C (-1.0 bar)

Max: 100°C (159 bar)

Fac: 50°C (35.0 bar)

Min: 20°C (-1.0 bar)

Max: 90°C (159 bar)

Fac: 50°C (30.0 bar)

Min: 0,1 K

Max: 100 K

Fac: 1 K

Min: 0 %

Max: 100%

Fac: 100%

Min: 0.5

Max: 50

Fac: 10

Min: 10 s

Max: 900 s

Fac: 180 s

AI-demand

Pc / S7

Fac: Pc

AI-demand

Setpoint / Floating

Fac: Setpoint

AO-demand

Step / Speed

Fac: Step

DO-demand

Min: 0

Max: 8

Fac: 0

P / PI

Fac: PI

Min: 0%

Max: 60%

Fac: 35%

Min: 0%

Max: 40%

Fac: 20%

DO-demand

Yes / No

Fac: No

DI-demand

Common /Individual

Fac: None

Normal/Optimized

Fac.: Normal

DI-demand

Yes / No

Fac: No

AK-PC 551 User Guide RS8GY402 © Danfoss 2016-11 13

Page 14

Fan status Fan status

Fan speed Here a reading of the desired condenser fan capacity is provided in %

VSD start/stop Fan operation (frequency converter) status can be read here

Fan 1 The status of relay 1 (step 1 or relay for frequency transformer) is indicated here

Fan 2..... The status of relay 2, 3, etc. (step 2, 3, etc.) is indicated here

Fan Runhours Fan Run hours

VSD Runtime total The number of hours the fans have been in operation (frequency converter operation) can

Fan 1 Runtime total The number of hours fan relay 1 has been in the On-position (frequency transformer

Fan 2..... The same function for the remaining fans

Fan cycles Number of fans starting

VSD cycles The number of fan starts (frequency converter) can be read here

Fan 1 Cycles total The number of times fan relay 1 has been in the On-position (frequency converter

Fan 2... The same function for the remaining fans

Safety monitoring

PoA Min limit Safety limits for min. PoA

PoA Max alarm Alarm limit for high PoA

PoA Max delay Delay time for issuing a PoA max. alarm

Superheat Min lim A Alarm limit for insufficient superheating

Superheat Max lim A Alarm limit for excess superheating

Superheat delay A Delay time before alarm is generated for insufficient or excess superheating

SdA Max limit Safety limit for max. SdA

PoB Min limit Same settings for a suction group B

PoB Max alarm

PoB Max delay

Superheat Min lim B

Superheat Max lim B

Superheat delay B

SdB Max limit

Pc max limit Safety limit for max. Pc

Tc Max limit Safety limit for max. Tc

Pc Max delay Time delay for Pc max. alarm

HP switch via DI Signal from an HP switch

Safety restart time Delayed start-up following safety cut-out

Sensor alarm reset Reset alarm after sensor error

be read here

has been On) is indicated here

has been on) is indicated here

The controller checks that the fan has been active within the last 24 hours. If not,

it will be forced to start in 5 minutes, in rotation with the other fans.

If a low value is registered, all compressors will cut out

If a high value is registered, an alarm will be generated

If a higher value is registered during a load limitation, the load limitation will be cancelled

until Po has returned to the reference.

(Superheating is measured in the suction line by PoA and SsA.)

At 10 K under the set value, the compressor capacity will be reduced, and the entire

condenser capacity will cut in.

If the threshold is exceeded, the entire compressor capacity will cut out.

If Pc exceeds the value set here minus 3 K, the entire condenser capacity will cut in,

and compressor capacity will be reduced by 1/3 for every 30 seconds.

If Pc exceeds the threshold value, the entire compressor capacity will immediately cut out,

and an alarm will be generated when the delay time expires.

The above setting for Pc max. limit can be read as a temperature here.

The alarm will only be generated when the time delay has elapsed.

Define whether a signal is to be received on a DI input here.

The status of the signal can be read, and an alarm can be linked to it.

Once a signal is received, compressor capacity will cut out.

If a safety cut-out has occurred due to “Sd max. limit”, “Pc max. limit” or “Po min. limit”,

the compressors must be kept stopped for a defined period of time. The amount of

time can be set here.

When a sensor error has occurred, an O.K. signal must be registered within a specified

number of minutes before the controller resets the alarm. The regulation will be resumed

as soon as the sensor signal is O.K.

Min: -120°C (-1.0 bar)

Max: 30°C (159 bar)

Fac: -40°C (0.5 bar)

Min: -30°C (-1.0 bar)

Max: 100°C (159 bar)

Fac: 100°C (5.0 bar)

Min: 0 min.

Max: 240 min.

Fac: 5 min.

Min: 0 K

Max: 20 K

Fac: 0 K

Min: 20 K

Max: 80 K

Fac: 80 K

Min: 0 min.

Max: 60 min.

Fac: 5 min.

Min: 0°C

Max: 195°C

Fac: 80°C

Min: -1 bar

Max: 159 bar

Fac: 40 bar

-

Min: 0 min.

Max: 240 min.

Fac: 0 min.

DI-demand

Yes /No

Fac: No

Min: 0 min.

Max: 60 min.

Fac: 1 min.

Min: 0 min.

Max: 30 min.

Fac: 10 min.

14 User Guide RS8GY402 © Danfoss 2016-11 AK-PC 551

Page 15

General functions

Digital input alarms General on/off alarm

No. of DI alarm fct. 1. Define how many general alarms there should be

DI1 Alarm text The following alarm texts can be selected:

Di1 Alarm delay Delay time for the DI1 alarm

DI2....3 The same setting option for a DI2 alarm and a DI3 alarm.

Thermostat General thermostat

Thermostat cut in Here set the temperature value at which the thermostat will cut in

Thermostat cut out Here set the temperature value at which the thermostat will cut out

Thermostat temp. The current sensor temperature of the thermostat can be read here

System

Display Select views on the display

Language Choose from the following languages:

Engineering units Device

Pressure units Pressure unit

Temperature units Temperature unit

Time format Time format

Screen saver time Screen saver time

User logout time Log-off time

Display contrast Adjust contrast

Here you can define up to 3 alarms that are not related to the regulation function. When

a signal is received on the input, the controller will generate an alarm, but only after the

related delay time has elapsed.

The alarm can be defined to be active for an on/off signal.

An alarm text can be entered for the alarm. This text can be seen in the display and can

be sent to a system device.

1. Define the appurtenant alarm text

2. Set the delay time for the alarm

3. Go to I/O configuration and select an available digital input. Set this input to “General

alarm (no.)”

4. In the subsequent menu, define whether the alarm is to be active for an on/off signal.

• General alarm

• High pressure alarm

• Low pressure alarm

• High temperature alarm

• Low temperature alarm

• Oil level alarm

• Oil temperature alarm

• Liquid level alarm

• Leak detection alarm

• Inverter fault

One general thermostat can be defined.

1. Define the function

2. Go to I/O configuration and select an available analogue input. Set this input to

“Saux thermostat”

3. Go to I/O configuration and select an available relay output. Set the output to “thermostat”.

(But only once the sensor input has been defined and the main switch has been set to “On”.)

English, German, French, Danish, Spanish, Italian, Portuguese, Dutch, Russian, Polish, Czech,

Turkish, Hungarian, Croatian, Serbian, Romanian

Select SI or Imperial (when setting the compressor capacity with U.S. values).

Select bar or PSIG

Select °C or °F.

Choose 12-hour or 24-hour format.

If no buttons have been pushed for a specific period of time, the light in the display will be

minimised.

The light level will be restored upon renewed activity.

If buttons have not been pressed within a specified period of time, the screen will return to

the overview display. Afterwards, the user will have to log on again.

If the time is changed, the new time will apply the next time the user logs in.

If you log out here without waiting for the time-out period to elapse, go to the overview

display and hold down the “X” button for 3 seconds.

DI-demand

Min: 0

Max: 3

Fac: 0

Min: 0 min.

Max: 360 min.

Fac: 5 min.

AI-demand

Yes / No

Fac: No

Min: -50°C

Max: 150°C

Fac: 5°C

Min: -50°C

Max: 150°C

Fac: 10°C

-

-

Fac: UK English

SI / Imperial

Fac: SI

Bar / PSIG

Fac: bar

°C / °F

Fac: °C

12 / 24

Fac: 24 h

Min: 1 min.

Max: 60 min.

Fac: 1 min.

Min: 1 min.

Max: 60 min.

Fac: 2 min.

Min: 0

Max: 100

Fac: 30

AK-PC 551 User Guide RS8GY402 © Danfoss 2016-11 15

Page 16

Password Access code

Password level 1

Password level 2

Password level 3

Real time clock Date and time

Weekly schedule Weekly plan

Monday open Time of opening, Monday

Monday close Time of closing, Monday

Tuesday op..... Times for remaining weekdays

Network Network

Modbus Address Set the address of the controller here if it is connected to a system device via data communi-

Baudrate The system unit usually communicates with 38.4.

Serial mode The value must not be changed

Reset to factory Return to factory settings

I/O configuration

Here you can select functions for the individual inputs and outputs. To prevent faulty settings, only select functions that

have been set up via the configuration menus for the suction groups and the condenser.

For digital outputs, define whether the function will be active for an activated or deactivated relay.

For digital inputs, define whether the function/alarm will be active for an interrupted or shut-off switch.

For analogue outputs, define whether the output signal should be 0-5 V or 0-10 V

For analogue inputs, define:

Temperature sensors:

Normally, the sensor type is a Pt1000 model, but for digital scroll/stream discharge gas temperature monitoring, an NTC

86K@25°C can also be selected.

Calibration value (+/- 10°C)

Pressure sensors:

Signal type: 0-20mA, 4-20mA, AKS32 (1-5V) or AKS32R (10-90% ratiometric of 5 V supply voltage)

Minimum and maximum pressure range

Calibration value (+/- 5.0 bar)

If you have used “Quick configurations” or “Wizard” to set up the controller, the inputs and outputs will be automatically

set up (for additional information, see the “Quick configuration” or “Wizard” sections)

Limitations:

PWM outputs for digital scroll or stream compressors can only be selected on DO5 or DO6

Pressure transmitters with a current signal of 0-20 mA or 4-20 mA must be placed on analogue inputs AI1-AI4

Please note:

If a function has been connected to an input or output and is subsequently deselected in the configuration, the function

in question will be marked with an exclamation mark (!). In this case, you must either activate the function in the configuration, or deselect the function on the input or output in question.

Digital outputs

1:

2:

3:

4:

.

.

8:

Digital inputs

1:

2:

3:

..

8:

The settings in the controller can be protected with three levels of access codes.

Level 1: End user settings, such as changing the weekly plan

Level 2: Adjusting installer level

Level 3: Configuration of system settings (configuration menu)

The access code is a number between 001 and 999.

Used by weekly plan and alarm function.

Set the opening and closing hours of the store here

The times can be used to change the regulation reference for suction pressure and for lower

fan speeds at night.

cation.

If it is changed in the system unit to for example, "SLV" mode (19.2), setting must also be

changed to 19.2 here in the controller.

If this function is set to “YES”, all settings will be returned to factory default settings, and the

alarm list will be cleared.

On/off outputs

When a function that needs to use an output is defined, it will be possible to select

this function on one of the available relay outputs.

Select a relay and continue with the setting. In the last setting you will have the option

of selecting the function you wish to connect to the relay and whether the function is to

be active when the relay is activated or deactivated. Attention! Relay outputs must not be

inverted at unloader valves. The controller inverts the function itself.

There will be no voltage at the bypass valves when the compressor is not in operation.

Power is connected immediately before the compressor is started.

If it is a function that requires frequent switching between on/off (e.g. unloader on a scroll

compressor, a Stream or a Bitzer CRII), use the solid state relay for this connection. There are

solid state relays on output numbers 5 and 6.

On/off inputs

When a function is defined that uses an input, it will be possible to select this function

on one of the available on/off inputs.

Select an input and continue on into the setting. In the final setting you will have be able

to select which function you wish to connect to the input.

Fac: 100

Fac: 200

Fac: 300

Year, month, date

Hours, minutes

-

Hours, minutes

Hours, minutes

-

-

Min: 0 1

Max: 120

Fac: 1

Fac: 384

Fac: 8E1

On

Off

On

Off

16 User Guide RS8GY402 © Danfoss 2016-11 AK-PC 551

Page 17

Analog outputs

3:

4:

Analog inputs

1:

2:

3:

4:

.

.

8:

I/O Status

Digital outputs

1:

.

8:

Digital inputs

1:

.

8:

Analogue outputs

3:

4:

Analog inputs

1:

.

8:

I/O Summary

DO: Max 8, Used:__

DI: Max 8, Used:__

AO: Max 2, Used:__

AI: Max 8, Used:__

I/O Manual control

Digital outputs Manual control of a relay output

Analog outputs Manual control of analogue output

Alarm priorities

General

Standby mode:

Sensor error:

Refrigerant:

Output in MANUAL:

Suction group A

Low pressure:

High pressure:

Compressor safety:

Suction group B

Low pressure:

High pressure:

Compressor safety:

Condenser

High pressure:

Fan safety:

0-10 V outputs

When a function has been defined that needs to use a variable voltage outlet, it will be possible to select this function on one of the available AO outputs (only AO3 and AO4

are available).

Select one of the two outputs and continue on in the setting process. In the last setting you

will have the option of selecting which function you wish to link to the output.

Analogue inputs

When a function is defined that needs to use a temperature sensor or a pressure transmitter,

it will be possible to select this function on one of the available AI inputs.

Select an input and continue on into the setting. In the final setting you will be able to select

which function you wish to connect to the input.

Saux is a sensor for a general thermostat.

(A type AKS 2050 pressure transmitter, for high pressure, emits a signal as an AKS 32R.)

Status of on/off outputs

Here you can see if the function is on or off.

Status of on/off inputs

Here you can see the status of the function/alarm.

Status of analogue outputs

Here you can see the size of the output signals as a % of max. signal.

Status of analogue inputs

Here you can see pressure and temperature values received by the controller.

The values include calibration

Inputs and outputs used

Here you can see how many of the different inputs and outputs are available.

You can also compare this amount with how many have been configured.

If too many have been defined, an exclamation mark (!) will appear.

Under normal regulation, the function of the relay will be in “Auto”.

In the event of an override, the function will be switched to either “On” or “Off”.

Remember to switch to “Auto” when the override is to be completed.

During normal regulation, the function of the output will be “Auto”.

In the event of an override, the function must first be changed to “Manual”,

after which the output signal can be changed from 0-100%.

Remember to switch to “Auto” when the override is to be completed.

Alarm priorities

The controller will issue an alarm notification if a specific incident occurs.

Each incident is set to indicate the importance of each alarm, but it is possible to modify the

importance of each. Choose from between the following priority levels:

Critical: Important alarms that require a high level of attention.

Severe: Alarms of intermediate importance

Normal: No important alarms

Disable: Alarms set to this priority level will be cancelled.

Factory setting for the alarm can be seen on page 21.

0-10 V

0-5 V

Pressure signal:

AKS 33

AKS 32R

AKS 32

2-10 V

0-20 mA

0-10 V

0-5 V

Temperature signal:

NTC-86K

Pt 1000 ohm

None

Auto / On / Off

Auto / Man

0-100%

Critical

Servere

Normal

Disable

AK-PC 551 User Guide RS8GY402 © Danfoss 2016-11 17

Page 18

Quick setup

Quick configurations This setting will reserve inputs and outputs for the following compressors and fans:

The various connections are shown on the next page.

App. no. Display Suction group A Suction group BCondenser

Speed Digital

(Scroll / steam)

17 3CDA + 2CB + FS 1 2 2 x

16 2CDA + 2CB + 3F 1 1 2 3

15 3CSA + 2CB + FS 1 2 2 x

14 2CSA + 2CB + 3F 1 1 2 3

13 4CA + 3CB + FS 4 3 x

12 3CA + 2CB + FS 3 2 x

11 2CA + 2CB + 3F 2 2 3

10 4CDA + FS 1 3 x

9 3CDA + FS 1 2 x

8 3CDA + 3F 1 2 3

7 2CDA + 2F 1 1 2

6 4CSA + FS 1 3 x

5 4CA + FS 4 x

4 4CA + 4F 4 4

3 3CSA + FS 1 2 x

2 3CA + FS 3 x

1 3CA + 3 F 3 3

0 None After making a selection, the setting will return to “None”

After making a selection you must:

1. Set the type of refrigerant

2. Check the types of pressure transmitters

3. Check the min. and max. settings on the pressure transmitters

Factory setting:

Po A/B = AKS 32R, min=-1.0 bar, max.=12 bar

Pc = AKS 32R, min. = -1.0 bar, max. = 34 bar

SdA = NTC 86K

Setup Wizard This wizard will lead you through the necessary settings, i.e. a total of approximately

20 to 35 display screens, depending on what is selected along the way.

The selection will also result in a connection to a given input and output. You yourself

will see this connection in the IO configuration menu. If applicable, see page 20.

1-step 1-step Step Speed

18 User Guide RS8GY402 © Danfoss 2016-11 AK-PC 551

Page 19

Fan

C1A C2A C3A C1B C2B Main

safe.

Fan

safe.

Fan

safe.

Fan

safe.

safe.

Fan

safe.

Fan

safe.

Fan

safe.

Fan

safe.

Fan

safe.

Fan

safe.

Fan

safe.

Fan

safe.

Fan

safe.

Fan

safe.

Fan

safe.

Fan

safe.

Sw.

Sw.

Sw.

Sw.

C1A C2A C1B C2B Main

Digi

Digi

Sw.

Sw.

Sw.

Sw.

Sw.

Sw.

Sw.

Sw.

Sw.

Sw.

Sw.

Sw.

C1 C2 C3 C4 Main

C1 C2 C3 Main

C1 C2 C3 Main

C1 C2 Main

Digi

Digi

Digi

Digi

On/Off Analog Analog Digital

DO1 DO2 DO3 DO4 DO5 DO6 DO7 DO8 AO3 AO4 AI1 AI2 AI3 AI4 AI5 AI6 AI7 AI8 DI1 DI2 DI3 DI4 DI5 DI6 DI7 DI8

PoA PoB Pc Sc3 SdA

Alarm Fan

C2B Fan

Speed

VSD

Fan1 Fan2 Fan3 PoA PoB Pc Sc3 SdA

PWM

PWM

PoA PoB Pc Sc3 C1A C2A C3A C1B C2B Main

Fan

Alarm C1A

PoA PoB Pc Sc3 C1A C2A C1B C2B Main

Speed

Speed

VSD

PoA PoB Pc Sc3 C1A C2A C3A C4A C1B C2B C3B Fan

Speed

PoA PoB Pc Sc3 C1A C2A C3A C1B C2B Main

Speed

Alarm Fan

Speed

VSD

PoA Pc Sc3 SdA

Alarm Fan

Fan

PoA Pc Sc3 SdA

Speed

Alarm Fan

VSD

Fan

PWM

Speed

VSD

Fan2 Fan3 Alarm PoA Pc Sc3 SdA

PWM

PWM

Alarm PoA Pc Sc3 SdA

PWM

PoA Pc Sc3 C1 C2 C3 C4 Main

Fan

Alarm C1

PoA Pc Sc3 C1 C2 C3 C4 Main

Speed

Speed

Alarm Fan

VSD

Speed

VSD

PoA Pc Sc3 C1 C2 C3 Main

Fan

Alarm C1

PoA Pc Sc3 C1 C2 C3 Main

Speed

Speed

Alarm Fan

VSD

Speed

VSD

App. no. Display Output Input

Connections used in “Quick configurations”

17 3CDA + 2CB + FS C1A C2A C3A C1B C1A

16 2CDA + 2CB + 3F C1A C2A C1B C2B C1A

15 3CSA + 2CB + FS C1A C2A C3A C1B C2B Fan

14 2CSA + 2CB + 3F C1A C2A C1B C2B Fan1 Fan2 Fan3 Alarm C1A

13 4CA + 3CB + FS C1A C2A C3A C4A C1B C2B C3B Alarm Fan

12 3CA + 2CB + FS C1A C2A C3A C1B C2B Fan

11 2CA + 2CB + 3F C1A C2A C1B C2B Fan1 Fan2 Fan3 Alarm PoA PoB Pc Sc3 C1A C2A C1B CB2 Main

10 4CDA + FS C1 C2 C3 C4 C1

9 3CDA + FS C1 C2 C3 C1

8 3CDA + 3F C1 C2 C3 Fan1 C1

7 2CDA + 2F C1 C2 Fan1 Fan2 C1

6 4CSA + FS C1 C2 C3 C4 Fan

5 4CA + FS C1 C2 C3 C4 Fan

4 4CA + 4F C1 C2 C3 C4 Fan1 Fan2 Fan3 Fan4 PoA Pc Sc3 C1 C2 C3 C4 Main

3 3CSA + FS C1 C2 C3 Fan

2 3CA + FS C1 C2 C3 Fan

1 3CA + 3 F C1 C2 C3 Fan1 Fan2 Fan3 Alarm PoA Pc Sc3 C1 C2 C3 Main

0 None

Example of display view:

3CDA + 2CB + FS = 3 compressors, one is digital, suction group A + 2 compressors, suction group B + one fan, are speed-controlled

AK-PC 551 User Guide RS8GY402 © Danfoss 2016-11 19

Page 20

Connections when using Setup Wizard

If you have used the Setup Wizard for the configuration, the controller will automatically assign the selected functions

to inputs and outputs in accordance with the following prioritised order:

Digital outputs (DO1-DO8):

• Pulse output for control of the

capacity valves for digital scroll,

stream or Bitzer CRII will be

located on solid state outputs

DO5 and DO6

• Compressor start and unloaders for suction groups A and B,

respectively

• Fans

• Injection ON

• Alarm

Digital inputs (DI1-DI8):

• Compressor safety inputs for suction groups A and B, respectively

• Fan safety input

• External main switch (start/stop)

• HP safety switch

• LP safety switch for suction

groups A and B, respectively

• Night status

• Heat recovery

• Load sheeding

• General alarm inputs DI1-DI3

Analogue outputs (AO3-AO4)

• Compressor speed control for

suction groups A and B, respectively

• Condenser speed control

The assignment of functions on the respective inputs and outputs can be regulated

in “IO configuration”. Here is an example of 3 compressors and 3 fans:

Analogue inputs (AI1-AI8)

• PoA and PoB suction pressure is

located on AI1 and AI2, respectively

• Pc condensation pressure is

located on AI3

• Sc3 outside temperature is

located on AI4

S4A and S4B media temperature

• S7 media temperature, condenser

• Sd comp. 1 discharge gas temperature for digital scroll/stream

compressor for suction groups A

and B, respectively

• Ss suction gas temperature for

section groups A and B, respectively

• Sd discharge gas temperature

for suction groups A and B,

respectively

• Saux for general thermostat

In this image you can see how

many outputs and inputs your

settings have provided.

20 User Guide RS8GY402 © Danfoss 2016-11 AK-PC 551

Page 21

Alarm list

Alarm text Reason Priority

General alarms

Standby mode (Main sw. OFF) Alarm when control is stopped by internal or external Main Switch (DI input "Main Switch") Standby mode Normal

PoA sensor error Pressure transmitter signal from PoA defective

PoB sensor error Pressure transmitter signal from PoB defective

S4A sensor error Temperature signal from S4A media temp. sensor defective

S4B sensor error Temperature signal from S4B media temp. sensor defective

SsA sensor error Temperature signal from SsA suction gas temp. defective

SsB sensor error Temperature signal from SsB suction gas temp. defective

SdA sensor error Temperature signal from SdA discharge gas temp. Sd defective

SdB sensor error Temperature signal from SdB discharge gas temp. Sd defective

Pc sensor error Pressure transmitter signal from Pc defective

S7 sensor error Temperature signal from S7 media sensor on condenser defective

Sc3 sensor error Temperature signal from Sc3 air on condenser defective

Sd Comp. 1A sensor error Temperature signal from "Sd comp. 1A" discharge gas temp. on digital scroll/Stream compressor is

Sd Comp. 1B sensor error Temperature signal from "Sd comp. 1B" discharge gas temp. on digital scroll/Stream compressor is

Saux - sensor error Temperature signal from Saux thermostat sensor is defective

Refrigerant not selected Alarm if no refrigerant has been selected Refrigerant not set Normal

Output in manual mode An output is set in manual mode Output in MAN mode Normal

IO configuration error Not all inputs and output functions have been assigned to hardware Inputs or outputs* (can not be set) Normal

GA1 - "Alarm text" Alarm on general alarm input DI 1 (DI input "Gen. Alarm 1 - alarm text depend upon configured text) General alarm 1 Normal

GA2 - "Alarm text" Alarm on general alarm input DI 2 (DI input "Gen. Alarm 2 - alarm text depend upon configured text) General alarm 2 Normal

GA3 - "Alarm text" Alarm on general alarm input DI 3 (DI input "Gen. Alarm 3 - alarm text depend upon configured text) General alarm 3 Normal

Suction A alarms

PoA Low suction pressure Minimum safety limit for suction pressure PoA has been violated

LP A safety switch cut out Low safety limit for external low pressure switch has been violated (DI input "LP switch A")

PoA High suction pressure High alarm limit for PoA has been exceeded High pressure PoA Critical

SsA High superheat Superheat in suction line A too high (measured by PoA and SsA)

SsA Low superheat Superheat in suction line A too low (measured by PoA and SsA)

SdA High discharge temp. Safety prevention limit for SdA discharge temperature has been exceeded (10K below safety limit) High disch. temp.SdA Critical

Comp. 1A High disch. temp Safety limit for discharge gas temperature of digital scroll/Stream/CRII compressor has been exceeded

Compressor 1-8A safety cut

out

Suction B alarms

PoB Low suction pressure Minimum safety limit for suction pressure PoB has been violated Low pressure PoB

LP B safety switch cut out Low safety limit for external low pressure switch has been violated (DI input "LP switch B")

PoB High suction pressure High alarm limit for PoB has been exceeded High pressure PoB Critical

SsB High superheat Superheat in suction line B too high (measured by PoB and SsB)

SsB Low superheat Superheat in suction line B too low (measured by PoB and SsB)

SdB High discharge temp. Safety prevention limit for SdB discharge temperature has been exceeded (10K below safety limit) High disch. temp.SdB Critical

Comp. 1B High disch. temp Safety limit for discharge temperature of digital scroll/Stream compressor has been exceeded

Compressor 1-4B safety cut

out

Condenser alarms

Pc High condensing pressure High prevention safety limit for condensing pressure Pc has been violated (3K below safety limit)

HP safety switch cutout High safety limit for external high pressure switch has been violated (DI input "HP switch")

Common fan safety cut out A Fan is reported defective via common safety input (DI input "Fan safety")

Fan 1 safety cut out Fan no. 1-8 is reported defective via individual safety input (DI input "Fan 1-8 safety")

defective

defective

Compressor no. 1-8 A has been cut out on general safety input (DI input "Comp.1-8 A safety")

Compressor no. 1-4 B has been cut out on general safety (DI input "Comp.1-4 B safety")

setting

Sensor error Normal

Low pressure PoA Normal

Superheat A Normal

Compressor safety A Normal

Superheat B Normal

Compressor safety B Normal

High pressure Pc Critical

Fan safety Normal

Default

value

Normal

* The alarm "IO configuration error" is activated if not all IO functions have been assigned to a hardware Input or output.

Often the reason is that too many functions have been selected via the configuration of the controller.

Go to the menu point "Main menu => IO status => IO summary".

In this screen you can see if you have configured too many functions of a certain type - indicated by an exclamation mark " ! "

Please refer to the screen example, were too many DO functions have been configured.

Solve the problem by adapting the DO functions to the max. No of DO outputs.

Sensor alarms

Sensor alarms shut off automatically when the sensor has been O.K. for 10 minutes.

If you have corrected the sensor error and want to perform a manual, forced removal of the alarm, go to the “Alarm detail display”

Press and hold the “X” key for 2 seconds here.

AK-PC 551 User Guide RS8GY402 © Danfoss 2016-11 21

Page 22

ERR31

Alarm on the external display - MMIGRS2

If the communication to the display is not carried out correctly, it will send

an “ERR31” error notification.

This may be caused by the displayed terminations not being installed, or

that there have been interruptions in data communication during the time

when the display retrieves the basic information from the controller.

Once the terminations have been inspected, you should then check the

software version of the external display. This is done by holding down

the Enter key and the X key for 5 seconds, until the Bios menu appears.

Next, press the X key and read off the software version in the bottom right

corner. The software version must be 1.13 or newer.

Once the display’s software version has been checked, check the display’s

settings as follows:

1. Hold the Enter key and the X key down for 5 seconds, until the Bios

menu appears.

2. Select the “MCX selection” menu

- Select the “Clear UI” line and press Enter

- Select the “Autodetect” line and press Enter

3. Press the X key to return to the Bios menu

4. Select the “COM selection” menu

- Select the “CAN” line and press Enter

5. Press the X key to return to the Bios menu

6. Select the “Start up mode” menu

- Select the “Remote application” line and press Enter

7. Press the X key to return to the Bios menu

8. Select the “CAN” menu

- Select the “Baudrate” line and then select the “Autobaud” setting and

press Enter

- Select the “Node ID” line and set the value to 126 and press Enter

9. Press the X key to return to the Bios menu

10. Select the “Application” menu and press Enter.

The display will once again retrieve data from the controller. This process

will take about 5 minutes.

22 User Guide RS8GY402 © Danfoss 2016-11 AK-PC 551

Page 23

Connections

Connection, lower level Connection, upper level

Separate

supply!

Electric noise

Signal cables for sensors, DI inputs, data communication

DO DO1 DO2 DO3 DO4 DO5 DO6 DO7 DO8 Σ 1-8

I Max. 10 A

U All 24 V or all 230 V a.c.

Supply Voltage.

(3.5)

10 A

(3.5)

6 A

(4)

6 A

(4)

0.5 A

min. 50 mA

Ioff < 1,5 mA

0.5 A

min. 50 mA

Ioff < 1,5 mA

6 A

(4)

6 A

32 A

(4)

AO - Analogue output, 2 pcs. AO3 - AO4

The supply voltage is either 24 V or 110-230 V. See the label on

the reverse side of the controller.

÷ = Plugs normally not used

However, if connecting to an external display, a jumper must

be inserted between the connections "H" and "R".

Must be used when using a frequency converter or EC motors.

Connect 24 V on N and L (separate supply). Avoid earth fault

current. Use double-insulated transformer. The secondary side

must not be earthed.

Obtain 0-10 volts from terminals N and AO3, respectively N and

AO4. PAY ATTENTION TO THE POLARITY of N.

and display must be kept separate from high voltage

(230 V) electric cables:

- Use separate cable trays

- Keep a distance between high voltage and signal cables

of at least 10 cm

- Cables longer than 3 m at the DI input should be avoided

Warning

The supply voltage of AI may not share

the signal with other controllers.

Modbus

It is important that the installation of the data communication

cable be done correctly. Cf. separate literature No. RC8AC.

Remember termination at the bus termination.

AI - Analogue inputs, 4 pcs. AI1 - AI4

Pressure transmitters

• Ratiometric: 10-90% of supply, AKS 32R

• Signal: 1-5 V, AKS 32

• Power: 0-20 mA / 4-20 mA, AKS 33 (supply = 12 V)

Temperature sensor

DO - Digital outputs, 8 pcs. DO1 - DO8

DO5 and DO6 are solid state relays.

The relays are de-rated to the specified values.

If an alarm relay is defined, it will be driven under normal op-

• Pt 1000 ohm, AKS 11 or AKS 21.

• NTC 86K ohm @ 25°C, from digital scroll.

Factory settings

AI1=PoA, AI2=PoB, AI3=Pc, AI4=Outdoor temperature SC3.

eration and it will drop in the event of alarms and insufficient

power to the controller.

DI - Digital switch inputs, 8 pcs. DI1 - DI8