Instructions

AK-PC 520

Identication

Principle

084B8012

Dimensions

Danfoss

84B2330.11

RI8NM252 12-2009

NZ control PI or P control

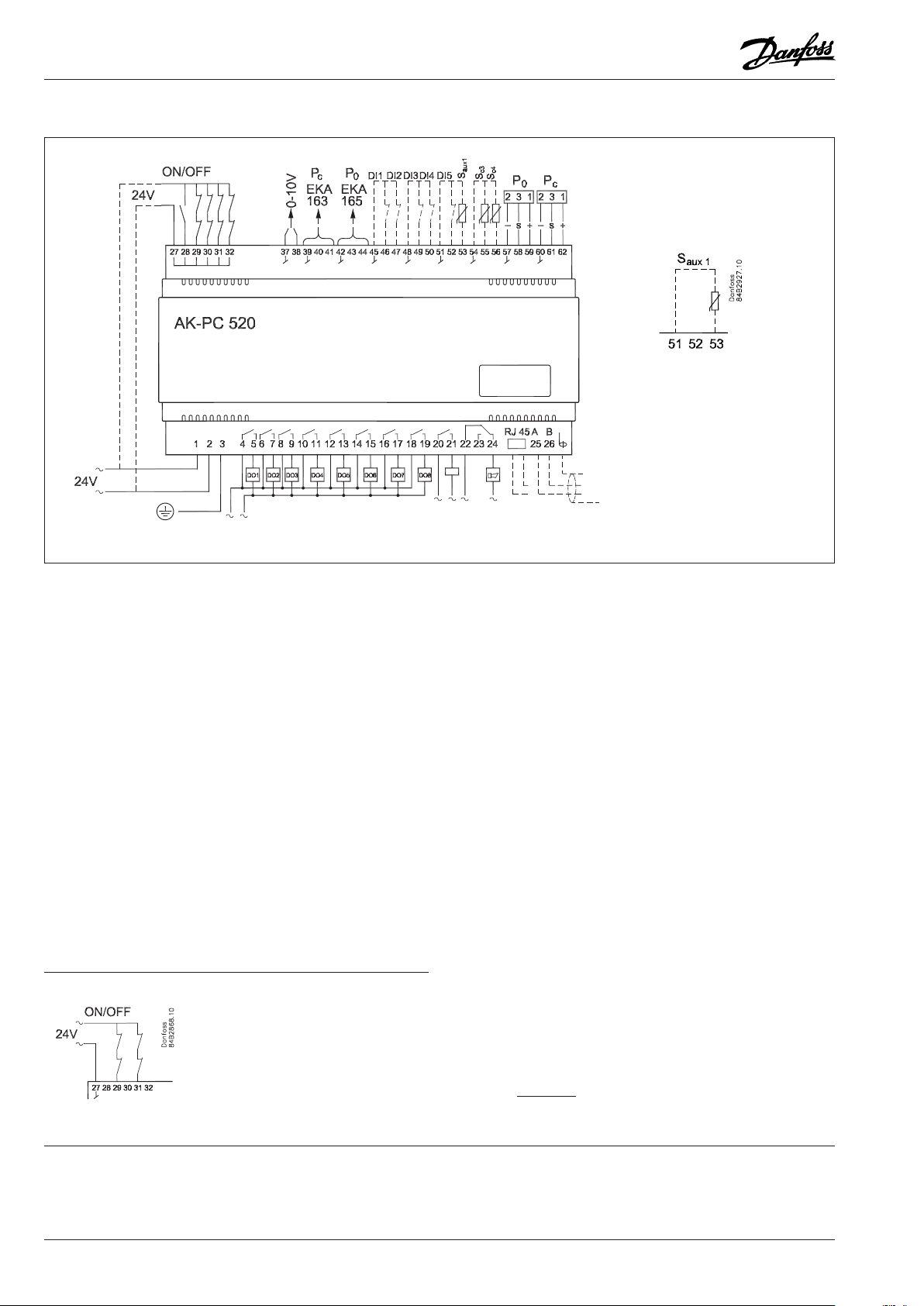

Connections

ENGLISH

Danfoss

84B2869.10

P0/Pc: AKS 32R:

1 = Black = +

2 = Blue = 3 = Brown = s

Compressor control

with temperature

o06 = 0

o81 = 1

All inputs are low-voltage.

All relay outputs may be

high-voltage.

Necessary connections

Terminals:

1-2 Supply voltage 24 V a.c.

4- 19 Relay outputs for either compressors, unloaders or fan mo-

tors

22-24 Alarm relay

There is connection between 22 and 24 in alarm situa tions

and when the controller is dead

27-28 24 V signal to start / stop of regulation

27-29 24 V signal from the safety circuit DO 1

27-30 24 V signal from the safety circuit DO 2

27-31 24 V signal from the safety circuit DO 3

27-32 24 V signal from the safety circuit DO 4

57-59 Suction pressure. Voltage signal from AKS 32R **

60-62 Condenser pressure. Voltage signal from AKS 32R **

Unloader

If an output is used for an unloader it is

not neccessary to wire the belonging

safety circuit.

Ex. with an unloader on DO2 a connection on terminal 30 can be left out

Application dependent connections

20-21 AKD start/stop *

The relay cutin when the frequency converter have to

start.

37-38 Voltage signal to external condenser control

39-41 Possibility of connecting an external display type EKA 163

or display of Pc

42-44 Possibility of connecting an external display type EKA 163

for display of P0, or EKA 165 for operation and display of

P0

45-46 DI1 - Contact function for alarm signal

45-47 DI2 - Contact function for alarm signal

48-49 DI3 - Contact function for alarm signal

48-50 DI4 - Contact function for displacement of the suction

pressure reference or for alarm signal.

51-52 DI5 - Contact function for displacement of the condenser

pressure reference or for alarm signal.

51-53 Separate sensor Saux1. Sensor signal fra AKS 11, AKS 12 or

EKS 111

54-55 Out temperature (Sc3). Sensor signal from AKS 11, AKS 12

or EKS 111 (mounted if r33 =2 or 4)

54-56 Air temperature at condenser outlet. Sensor signal from

AKS 11, AKS 12 or EKS 111

Data communication

25-26 Mount only, if a data communication module has been

mounted.

For ethernet communication the plug connection RJ45

must be used. (LON FTT10 can also be connected in this

way.

It is important that the installation of the data communi-

cation cable be done correctly. Cf. separate literature No.

RC8AC.

*)

Relay DO9 may in special cases be recongurated.

**)

• If the controller has to control only the comrpessor or the fans, respectively Pc and

P0 sensor can be dispensed

• In brine systems temperature measurement at terminals 57-58 and 60-61 may be

used instead of pressure measurement with AKS 32R. See also o06.

2 Instructions RI8NM252 © Danfoss 12/2009 AK-PC 520

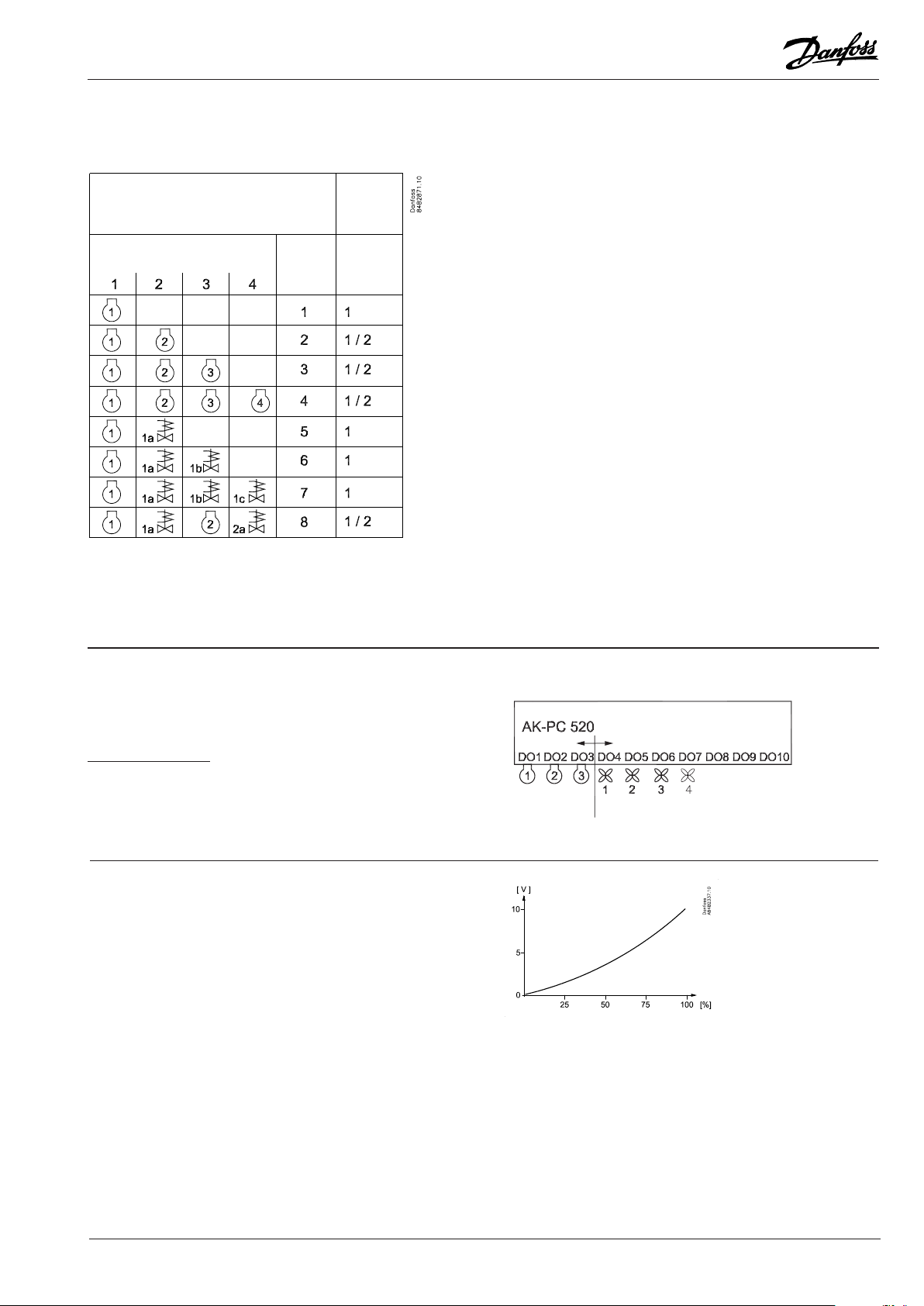

Compressor conguration when o61 =1 or 2 (This is where you can choose between the options shown.)

Setting "c16" will dene the conguration.

Setting "c08" will dene coupling mode.

Compressor connections

Relay no.

Set

"c16"

to

Coupling

mode

Set

"c08"

to

Capacity step

All capacity steps are presumed to be identical.

Coupling mode

Coupling mode 1 = sequential operation.

Coupling mode 2 = cyclic operation.

Couplings

When there is cyclic operation and connections with unloaders there

will in some capacity cutins and cutouts be overlappings where the

unloaders from either one compressor or another may be active.

In such cases the unloaders on the compressor with the lowest number

of hours will be cut in, and the others cut out.

The changeover will take place at 6-second intervals.

Condenser couplings

When the compressor relays have been established the turn

comes to the fan relays.

The rst vacant relay (DO1-DO5) will become the rst fan relay. It

will be followed by the subsequent relays.

If the entire condenser capacity is to be controlled by

a frequency converter, AK-PC 520 must send an analog

signal about the required capacity (“c29” = 9).

The signal varies from 0 to 10 V. Signal and capacity

have the following context.

Danfoss

84B2870.10

AK-PC 520 Instructions RI8NM252 © Danfoss 12/2009 3

Operation

Data communication

If the controller is extended with data communication, the operation can be performed from a system unit.

The importance of the alarms that are sent can be dened with

the setting: 1 (High), 2 (Medium), 3 (Low) or 0 (No alarm).

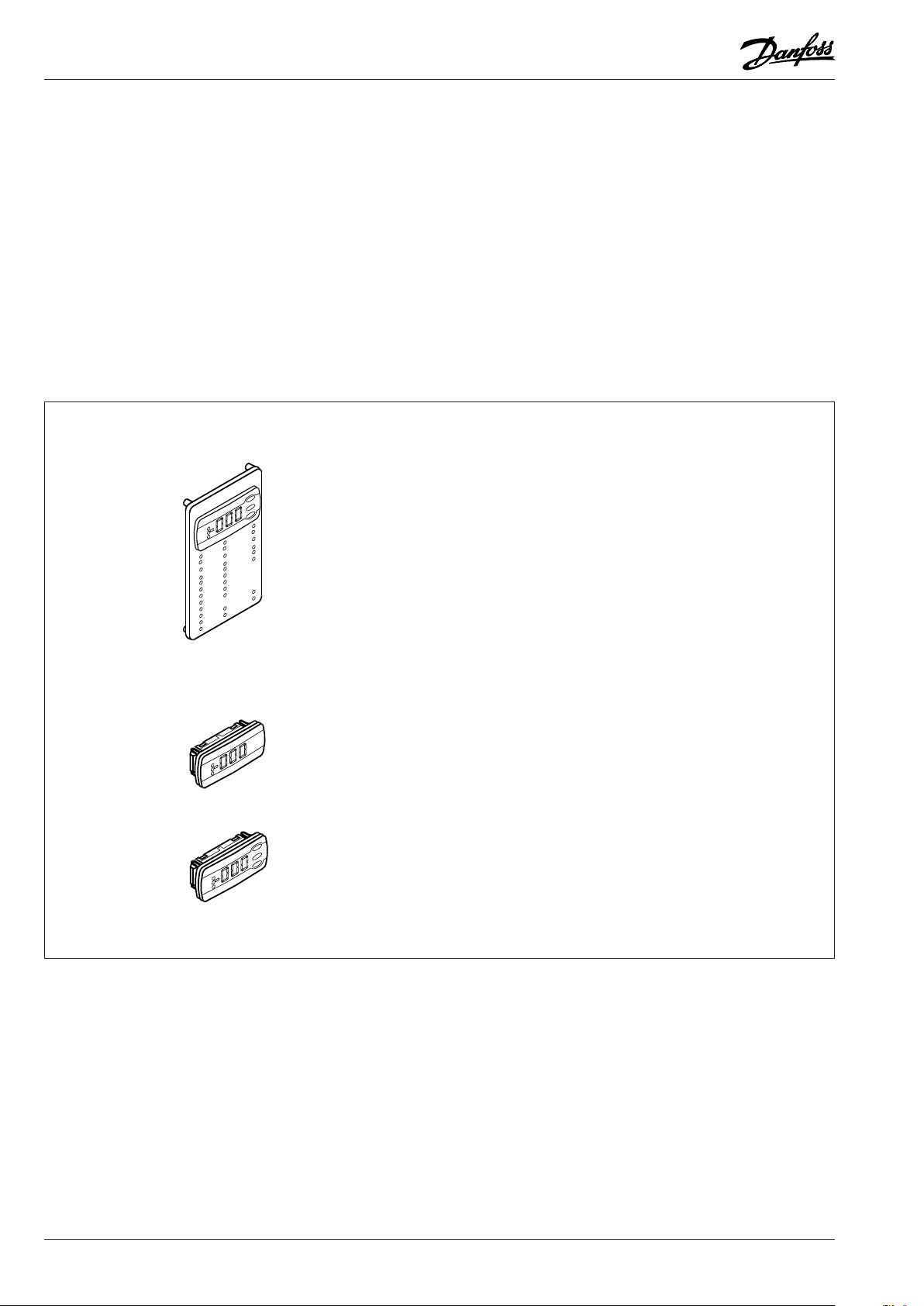

Operation via external display

The values will be shown with three digits, and with a setting you

can determine whether the pressures are to be shown in SI units

(°C / bar) or US units (°F / psig.).

There are three options for the display.

EKA 165

To operate the controller and view the evaporation pressure.

If the lowermost key is pressed, the condensation pressure will

be shown briey in the display. (If regulation is based only on the

condensation pressure, the display will always show Pc).

During normal operation the light-emitting diodes in the display

will indicate where regulation is taking place.

Highest + second highest : ++Zone

Second highest : +Zone

"None" : Neutral zone

Second lowest : -Zone

Lowest+ second lowest : - - Zone

EKA 165

EKA 163

EKA 164

The buttons on the display

When you want to change a setting, the upper and the lower

buttons will give you a higher or lower value depending on the

button you are pushing. But before you change the value, you

must have access to the menu. You obtain this by pushing the

upper button for a couple of seconds - you will then enter the

column with parameter codes. Find the parameter code you want

to change and push the middle button. When you have changed

the value, save the new value by once more pushing the middle

button.

The other LEDs on the display will show the functions that are

active:

• Relays for compressors

• Relays for fans

• Input signals for the digital inputs

• The optimisation LED will light up when the reference is 2 K or

more over the set point.

EKA 163

If the condensation pressure is to be shown constantly, a display

without operating keys can be connected.

EKA 164

To operate the controller and view the evaporation pressure.

If the lowermost key is pressed, the condensation pressure will be

shown briey in the display.

Like the EKA 165, the LEDs in the display will show where the

regulation is located.

Or short:

1. Push the upper button (long push) until a parameter is shown

2. Push one of the buttons and nd the parameter you want to

change

3. Push the middle button until the setting value is shown

4. Push one of the buttons and select the new value

5. Push the middle button again to conclude the setting

( A brief pushing wil show the active alarm codes.)

4 Instructions RI8NM252 © Danfoss 12/2009 AK-PC 520

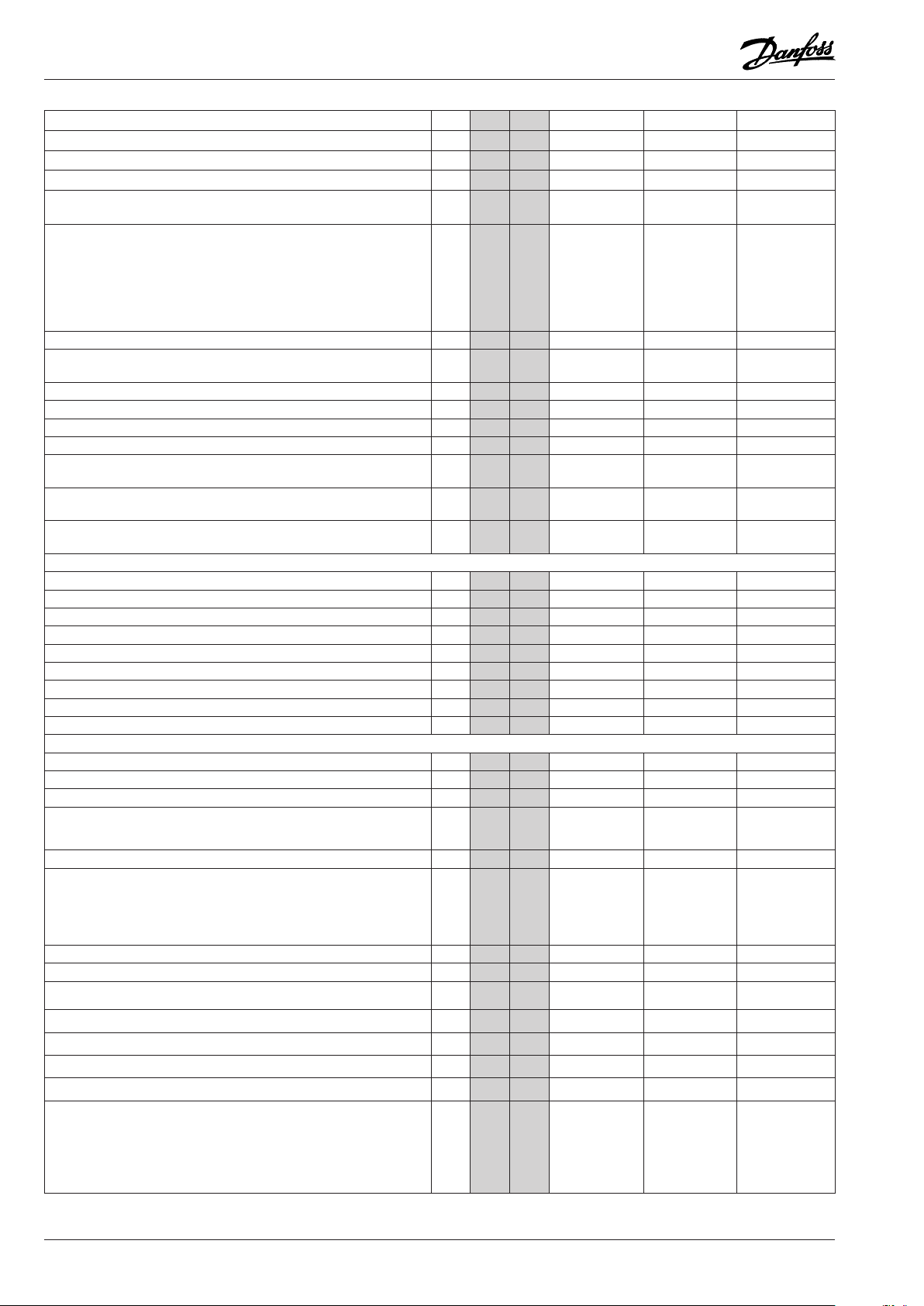

Menu survey

Sequence

1. o61 must be set as the rst parameter. This parameter determines which of the two operating interfaces (application mode) are

activated. This must be set via the display keys. It cannot be set via data communication. (Active functions are shown below in shaded

elds.)

2. Quick- start

To get the system up and running quickly so that cooling can be commenced, start it by setting the following parameters (these parameters can only be set when the regulation is stopped, r12=0):

r23, r28 c08, c09, c16, c29, o06, o30, o75, o76, o81 and nally r12=1.

3. Once the regulation is under way, you can go through the other parameters and adjust them in situ.

SW: 1.0x

Function

Normal display

Shows P0 in EKA 165 (display with buttons) - °C P °C / bar

Shows Pc in EKA 163 - °C P °C / bar

P0 reference

Neutral zone r01 0.1°C / 0.1 bar 20°C /5.0 bar 4.0°C / 0.4 bar

Correction of signal from P0 sensor r04 -50°C /-5.0 bar 50°C / 5.0 bar 0.0

Select view; SI or US. 0=SI (bar /°C), 1=US (Psig /°F) r05 0 1 0

Start/Stop of regulation

Reference oset for P0 (see also r27) r13 -50°C / -5.0 bar 50°C / 5.0 bar 0.0

Set regulation setpoint for P0 r23 -99°C / -1 bar 30°C / 60.0 bar 0.0°C / 3.5 bar

Shows total P0 reference

( r23 + various displacements)

Limitation: P0 reference max. value

(also applies to regulation with reference displacement)

Limitation: P0 referencen min. value

(also applies to regulation with reference displacement)

Displacement of P0 (ON=active “r13”) r27 OFF ON OFF

Pc reference

Set regulation setpoint for Pc r28 -25°C / 0.0 bar 75°C / 110.0 bar 35°C / 15.0 bar

Shows total Pc reference r29 °C / bar

Limitation: Pc referencen max. value r30 -99.9°C / -0.0 bar 99.9°C/130.0bar 55.0°C / 60.0 bar

Limitation: Pc referencen min. value r31 -99.9°C / 0.0 bar 99.9°C / 60.0 bar -99.9°C / 0.0 bar

Correction of signal from Pc sensor r32 -50°C / -5.0 bar 50°C / 5.0 bar 0.0

Pc reference variation.1 and 2 are PI-regulation

1: Fixed reference. “r28” is used

2: Variable reference. Outdoor temperature (Sc3) included in the reference

3: As 1, but with P-regulation (Xp-band)

4: As 2, but with P-regulation (Xp-band)

Reference oset for Pc r34 -50°C / -5.0 bar 50°C / 5.0 bar 0.0

The mean temperature dierence across the condenser at maximum load

(dim tm K)

The mean temperature dierence across the condenser at the lowest

relevant compressor capacity (min tm K)

This is where you can see the actual pressure (P0) that is being measured

by the pressure transmitter.

This is where you can see the actual pressure (T0) that is part of the regu-

lation. From the sensor which is dened in “o81”

Capacity

Min. ON time for relays c01 0 min 30 min. 0

Min. time period between cutins of same relay c07 0 min. 60 min 4

Denition of regulation mode

1: Sequential (step mode / FILO)

2: Cyclic (step mode / FIFO)

If a regulation mode with unloaders is selected, the relay must be dened

to:

0: Cut in when more capacity is required

1: Cut out when more capacity is required

Regulation parameter for + Zone

Regulation parameter for + Zone

Parameter

r12 OFF ON OFF

r24 °C / bar

r25 -99°C / -1.0 bar 30°C / 60.0 bar 30.0°C / 40.0 bar

r26 -99°C / -1.0 bar 30°C / 40.0 bar -99.9°C / -1.0 bar

r33 1 4 1

r35 3.0 50.0 10.0

r56 3.0 50.0 8.0

r57 °C / bar

r58 °C

c08 1 2 1

c09 0 1 0

c10 0.1 K / 0.1 bar 20 K / 2.0 bar 4.0 / 0.4 bar

c11 0.1 min 60 min 4.0

o61 =

1 2

Min. Max. Factory

setting

To be continued

AK-PC 520 Instructions RI8NM252 © Danfoss 12/2009 5

Regulation parameter for ++ Zone c12 0.1 min. 20 min 2.0

Regulation parameter for - Zone

c13 0.1 K / 0.1 bar 20 K / 2.0 bar 4.0 / 0.3 bar

Regulation parameter for - Zone c14 0.1 min. 60 min 1.0

Regulation parameter for - - Zone c15 0.02 min. 20 min 0.5

Denition of compressor connections.

See options on page 3

c16 1 8 0

Denition of condenser:

1-4: Total number of fan relay

5-8: Not used

9: Only via analog output and start of frequency converter

c29 0/OFF 14 0

10: Not used

11- 14: Total number of fan relays (1-4) which are to be connected with

alternating start-up.

Cut in compressor capacity with manual control. See also “c32” c31 0% 100% 0

Manual control of compressor capacity (when ON, the value in “c31” will

be used)

c32 OFF ON OFF

Pump down limit. Limit value where the last compressor is cut out. c33 -99.9°C / -1.0 bar 100°C / 60 bar 100°C / 60 bar

Proportinal band Xp for (P= 100/Xp) condenser regulation n04 0.2 K / 0.2 bar 40.0 K / 10.0 bar 10.0 K / 3.0 bar

I: Integration time Tn for condenser regulation n05 30 s 600 s 150

Cutin condenser capacity with manual control. See also “n53” n52 0% 100% 0

Manual control of condenser capacity (when ON, the value in “n52” will

be used)

Start speed The voltage for the speed regulation is kept at 0V until the

regulation requires a higher value than the value set here.

Min. speed. The voltage for the speed regulation switches to 0V when the

regulation requires a lower value than the value set here.

n53 OFF ON OFF

n54 0% 75% 20%

n55 0% 50% 10%

Alarm

Delay time for a A32 alarm A03 0 min. 90 min. 0 min.

Low alarm and safety limit for P0 A11 -99°C / -1.0 bar 30°C / 40 bar -40°C / 0.5 bar

Delay time for a DI1 alarm A27 0 min. (-1=OFF) 999 min. OFF

Delay time for a DI2 alarm A28 0 min. (-1=OFF) 999 min. OFF

Delay time for a DI3 alarm A29 0 min. (-1=OFF) 999 min. OFF

Upper alarm and safety limit for Pc A30 -10 °C / 0.0 bar 200°C/200.0 bar 60.0°C / 60.0 bar

Upper alarm limit for sensor "Saux1" A32 1°C (0=OFF) 140°C OFF

Delay time for a P0 alarm A44 0 min. (-1=OFF) 999 min. 0 min.

Delay time for a Pc alarm A45 0 min. (-1=OFF) 999 min. 0 min.

Miscellaneous

Controllers address o03* 1 990

On/o switch (service-pin message) o04* - Access code

o05 1 (0=OFF) 100 OFF

Used sensor type for Sc3, Sc4 and "Saux1"

0=PT1000, 1=PTC1000

o06 0 7 (1) 0

2-7=variations with temperature sensor on P0 and Pc. See manual.

Set supply voltage frequency o12 50 Hz 60 H 0

Manual control of outputs:

0: No override

1-10: 1 will cut in relay 1, 2 relay 2, etc.

o18 0 18 0

11-18: Gives voltage signal on the analog output. (11 gives 1.25 V, and so

on in steps of 1.25 V

P0 pressure transmitter’s working range - min. value o20 -1 bar 0 bar -1.0

P0 pressure transmitter’s working range - max. value o21 1 bar 200 bar 12.0

Use of DI4-input

0=not used. 1=P0 displacement. 2=alarm function. Alarm="A31"

o22 0 2 0

Operating hours of relay 1 (value time 1000) o23 0.0 h 99.9 h 0.0

Operating hours of relay 2 (value time 1000) o24 0.0 h 99.9 h 0.0

Operating hours of relay 3 (value time 1000 o25 0.0 h 99.9 h 0.0

Operating hours of relay 4 (value time 1000) o26 0.0 h 99.9 h 0.0

Setting of refrigerant

1=R12. 2=R22. 3=R134a. 4=R502. 5=R717. 6=R13. 7=R13b1. 8=R23.

9=R500. 10=R503. 11=R114. 12=R142b. 13=User dened. 14=R32.

15=R227. 16=R401A. 17=R507. 18=R402A. 19=R404A. 20=R407C.

o30 0 31 0

21=R407A. 22=R407B. 23=R410A. 24=R170. 25=R290. 26=R600.

27=R600a. 28=R744. 29=R1270. 30=R417A. 31=R422A.

* this setting is only possible if data communication module is mounted in the controller

To be continued

6 Instructions RI8NM252 © Danfoss 12/2009 AK-PC 520

Use of DI5-input

0=not used. 1=Pc displacment. 2=alarm function. Alarm="A32"

Pc pressure transmitter’s working range - min. value o47 -1 bar 0 bar -1.0

Pc pressure transmitter’s working range - max. value o48 1 bar 200 bar 34.0

Read temperature at sensor "Saux1" o49 °C

Operating hours of relay 5 (value time 1000)

Operating hours of relay 6 (value time 1000) o51 0.0 h 99.9 h 0.0

Operating hours of relay 7 (value time 1000) o52 0.0 h 99.9 h 0.0

Operating hours of relay 8 (value time 1000) o53 0.0 h 99.9 h 0.0

Selection of application

1. Show temperature in display

2: Show pressure in display

Function for relay output DO9:

0. Start / stop of speed regulation

1. Inject on signal for evaporator control

2. Boost ready (at least one compressor is on)

3. Start /stop of condenser fan

Function for relay output DO10:

0. Alarm relay

1. Start / stop of condenser fan

Denition of alarm message at DI1 signal:

0. Not used

1. Fan failure (A34)

2. DI1 alarm (A28)

Settings at water cooler application

Denition of signal input to the compressor regulation when regulation

with temperature signal:

0. Temperature sensor on 57-58

1. Temperature sensor on Saux

2. Temperature sensor on Sc4

If frost protection is required, the setting must be 1 or 2.

Display connection

O: EKA 164

On: EKA 165 (extended display with light-emitting diodes)

Service

Status on DI1 input u10

Status on DI2 input u37

Read temperature at sensor "Sc3" u44 °C

Read temperature at sensor "Sc4" u45 °C

Status on DI3 input u87

Status on DI4 input u88

Status on DI5 input u89

Messages can be brought up on the display by briey pressing the

uppermost key. If there is more than one alarm, they can be scrolled

through

o37 0 2 0

o50 0.0 h 99.9 h 0.0

o61 1 2 1 2 1

o75 0 3 0

o76 0 1 0

o78 0 2 0

o81 0 2 0

o82 O On O

Factory setting

If you need to return to the factory-set values, it can be done in this way:

- Cut out the supply voltage to the controller

- Keep the upper and the lower button depressed at the same time as

you recon nect the supply voltage

AK-PC 520 Instructions RI8NM252 © Danfoss 12/2009 7

The controller can give the following messages

E1 Error

message

E2 Regulation is outside the range, or the control

A2 Alarm

message

A11 Refrigerant not selected

A17 High Pc

A19 Compressor 1 error

A20 Compressor 2 error

A21

A22

A27 Room temperature alarm (Saux1 temp.)

A28 DI 1 alarm. Terminal 46 interrupted

A29 DI 2 alarm. Terminal 47 interrupted

A30 DI 3 alarm. Terminal 49 interrupted

A31 DI 4 alarm. Terminal 50 interrupted

A32 DI 5 alarm. Terminal 52 interrupted

A34 Fan alarm. There is no signal on DI1 input

A45 Regulation stopped

S0 Status

message

S2 Wait for “c01”

S5 Wait for “c07”

S8 Wait for “c11” or “c12”

S9 Wait for “c14” or “c15”

S10 Refrigeration stopped by the internal or external

S25 Manual control of outputs

S34 Safety cutout. Setting A30 is exceeded or all

PS Info Access code is required before you have access to

Fault in controller

signal is defective

Low P0

The actual compressors

safety circuit is

interrupted.

Compressor 3 error

Compressor 4 error

Regulation

start/stop function

safety inputs (29-32) are open

the settings

That is to say the signal

is missing on one of the

terminals 29-32

8 Instructions RI8NM252 © Danfoss 12/2009 AK-PC 520

Tilslutninger

DANSK

Danfoss

84B2869.10

P0/Pc: AKS 32R:

1 = Sort = +

2 = Blå = 3 = Brun = s

Kompressorregulering

efter temperatur

o06 = 0

o81 = 1

Alle indgange er lavvolt.

Alle relæudgange kan

være højvolt.

Nødvendige tilslutninger

Klemme:

1-2 Forsyningsspænding 24 V a.c.

4- 19 Relæudgange til enten kompressorer, aastninger eller

ventilatormotorer

22-24 Alarmrelæet

Der er forbindelse imellem 22 og 24 i alarmsituationer, og

når regulatoren er spændingsløs.

27-28 24 V signal til start / stop af reguleringen

27-29 24 V signal fra sikkerhedskredsen DO 1

27-30 24 V signal fra sikkerhedskredsen DO 2

27-31 24 V signal fra sikkerhedskredsen DO 3

27-32 24 V signal fra sikkerhedskredsen DO 4

57-59 Sugetryk. Spændingssignal fra AKS 32R **

60-62 Kondensatortryk. Spændingssignal fra AKS 32R **

Aastning

Hvis en udgang anvendes til en aastning, er det ikke nødvendigt, at fortråde

den tilhørende sikkerhedskreds.

Fx. ved en aastning på DO2 kan en

tilslutning på klemme 30 udelades

Applicationbestemte tilslutninger

20-21 AKD start/stop *

Relæet slutter når frekvensomformeren skal starte.

37-38 Spændingssignal til ekstern kondensatorstyring

39-41 Mulighed for at tilslutte et eksternt display type EKA 163

(Pc-visning)

42-44 Mulighed for at tilslutte et eksternt display type EKA 163

til P0-visning, eller EKA 165 til betjening og P0-visning

45-46 DI1 - Kontaktfunktion til alarmsignal

45-47 DI2 - Kontaktfunktion til alarmsignal

48-49 DI3 - Kontaktfunktion til alarmsignal

48-50 DI4 - Kontaktfunktion til forskydning af sugetryksreferen-

cen eller til alarmsignal.

51-52 DI5 - Kontaktfunktion til forskydning af kondensatortryks-

referencen eller til alarmsignal.

51-53 Separat føler Saux1. Følersignal fra AKS 11, AKS 12 eller EKS

111

54-55 Udetemperatur (Sc3). Følersignal fra AKS 11, AKS 12 eller

EKS 111 (monteres hvis r33 = 2 eller 4).

54-56 Lufttemperatur ved kondensatorens afgang. Følersignal fra

AKS 11, AKS 12 eller EKS 111

Datakommunikation

25-26 Monteres kun, hvis der også er monteret et datakommuni-

kationsmodul.

Hvis det er en ethernetkommunikation skal stiktilslut-

ningen RJ45 anvendes. (LON FTT10 kan også tilsluttes på

denne måde.)

Det er vigtigt, at installationen af datakommunikations-

kablet udføres korrekt.

Se separat litteratur nr. RC8AC..

*)

DO9 kan i specialtilfælde omkongureres.

**)

• Hvis regulatoren kun skal styre kompressorer eller kun skal styre ventilatorer, kan Pc

henholdsvis P0 føleren undværes.

• På brineanlæg kan der i stedet for trykmåling med AKS 32R anvendes temperatur-

måling på klemme 57-58 og 60-61. Se også o06.

AK-PC 520 Instructions RI8NM252 © Danfoss 12/2009 9

Kompressorkonguration når o61 = 1 eller 2 (Her kan du vælge imellem de viste muligheder.)

84B2870.10

Indstilling "c16" vil denere kongurationen.

Indstilling "c08" vil denere koblingsmåden.

Kompressortilslutninger

Relæ nr.

Indstil

"c16"

til

Koblings-

måde

Indstil

"c08"

til

Kapacitetstrin

Alle kapacitetstrin forudsættes at være lige store.

Koblingsmåde

Koblingsmåde 1 er sekventiel drift.

Koblingsmåde 2 er cyklisk drift.

Omkoblinger

Ved cyklisk drift og tilslutninger med aastninger, vil der ved

nogle kapacitetsindkoblinger være overlapninger, hvor aastningerne fra enten den ene eller den anden kompressor kunne være

aktiv.

I disse tilfælde vil aastningerne på kompressoren med det laveste timetal blive koblet ind, og de andre blive koblet ud. Omkoblingen vil ske med et interval på 6 sekunder.

Kondensatorkoblinger

Når kompressorrelæerne er lagt fast, kommer turen til ventilatorrelæerne.

Det første ledige relæ (DO1-DO5) bliver det første ventilatorrelæ.

Derefter kommer de efterfølgende.

Hvis hele kondensatorkapaciteten skal styres af en frekvensomformer, skal AK-PC 520 afgive et analogt signal om den ønskede

kapacitet ("c29"=9).

Signalet varierer fra 0 til 10 V. Signal og kapacitet har følgende sammenhæng.

Danfoss

10 Instructions RI8NM252 © Danfoss 12/2009 AK-PC 520

Betjening

Datakommunikation

Hvis regulatoren bliver udbygget med datakommunikation kan

betjeningen foretages fra en systemenhed.

Vigtigheden af de sendte alarmer kan deneres med indstillingen:

1 (høj), 2 (middel), 3 (lav) eller 0 (ingen alarm).

Betjening via eksternt display

Værdierne bliver vist med tre cifre, og med en indstilling kan du

bestemme, om trykket skal vises i SI-enheder (°C /bar) eller USenheder (°F / psig).

Der er tre muligheder for display

EKA 165

Til betjening af regulatoren og visning af fordampningstrykket.

Ved kort tryk på den nederste knap kan kondenseringstrykket

vises kortvarigt i displayet. (Hvis der kun reguleres på kondenseringstrykket vil displayet altid vise Pc.)

Under normaldrift viser lysdioderne i displayet hvor reguleringen

bender sig.

Øverste + næst øverste : ++Zonen

Næst øverste : +Zonen

"Ingen" : Neutralzonen

Næst nederste : -Zonen

Nederste + næst nederste : - - Zonen

EKA 165

EKA 163

EKA 164

Knapperne på displayet

Når du vil ændre en indstilling, vil den øverste og den nederste

knap give en højere eller en lavere værdi. Men før du kan ændre

værdien, skal du have adgang ind i menuen. Det får du ved at

trykke på den øverste knap i et par sekunder – så kommer du ind i

rækken med parameterkoder. Find den parameterkode du vil ændre, og tryk så på den midterste knap. Når du har ændret værdien,

gemmer du den nye værdi ved igen at trykke på den midterste

knap.

De øvrige lysdioder på pladen viser hvilke funktioner, der er aktive:

• Relæer til kompressorer

• Relæer til ventilatorer

• Indgangssignaler på de digitale indgange

• Optimeringslysdioden vil lyse, når referencen er 2 K eller mere

over setpunktet.

EKA 163

Hvis der er behov for en konstant visning af kondenseringstrykket,

kan der tilsluttes et display uden betjeningsknapper.

EKA 164

Til betjening af regulatoren og visning af fordampningstrykket.

Ved kort tryk på den nederste knap kan kondenseringstrykket

vises kortvarigt i displayet.

Lysdioderne i displayet vil i lighed med EKA 165 vise, hvor reguleringen bender sig.

Eller kort:

1. Tryk på den øverste knap (langt tryk) til der vises en parameter

2. Tryk på en af knapperne og nd hen til den parameter, du vil

indstille

3. Tryk på den midterste knap så indstillingsværdien vises

4. Tryk på en af knapperne og vælg den nye værdi

5. Tryk igen på den midterste knap for at afslutte indstillingen.

(Et kort tryk vil vise de alarmkoder, der er aktive.)

AK-PC 520 Instructions RI8NM252 © Danfoss 12/2009 11

Menuoversigt

Rækkefølge

1. o61 skal indstilles som den første parameter. Den bestemmer hvilke af de 2 betjeningsader (application mode), der bliver aktiveret.

Den skal indstilles via displayets knapper. Den kan ikke indstilles via datakommunikation. (Aktive funktioner er vist herunder med

tonede felter.)

2. Quick- start

Hvis du vil have anlægget igang i en fart, så nedkølingen kan påbegyndes, kan du starte med at indstille følgede parametre (de kan

kun indstilles, når reguleringen er stoppet, r12=0):

r23, r28, c08, c09, c16, c29, o06, o30, o75, o76, o81 og til sidst r12=1.

3. Når reguleringen derefter er igang, kan du gå igennem de øvrige parametre og justere dem på plads.

Funktion

Normalbillede

P0 vises i EKA 165 (den med betjeningsknapper) - °C P °C / bar

Pc vises i EKA 163 - °C P °C / bar

P0 reference

Neutralzone r01 0.1°C / 0.1 bar 20°C /5.0 bar 4.0°C / 0.4 bar

Korrektion af signalet fra P0-føleren r04 -50°C /-5.0 bar 50°C / 5.0 bar 0.0

Vælg SI eller US visning 0=SI (bar, °C). 1=US (Psig / °F) r05 0 1 0

Start/Stop af kølingen r12 OFF ON OFF

Referenceoset for P0 (se også r27) r13 -50°C / -5.0 bar 50°C / 5.0 bar 0.0

Setpunktindstillingen for P0 r23 -99°C / -1 bar 30°C / 60.0 bar 0.0°C / 3.5 bar

Her vises den samlede P0-reference

( r23 + diverse forskydninger)

Begrænsning: P0-referencens max. værdi

(gælder også ved regulering med referenceforskydning)

Begrænsning: P0-referencens min. værdi

(gælder også ved regulering med referenceforskydning)

Forskydning af P0 (ON=aktiv "r13") r27 OFF ON OFF

Pc reference

Setpunktsindstillingen for Pc r28 -25°C / 0.0 bar 75°C / 110.0 bar 35°C / 15.0 bar

Her vises den samlede Pc-reference r29 °C / bar

Begrænsning: Pc-referencens max. værdi r30 -99.9°C / -0.0 bar 99.9°C/130.0bar 55.0°C / 60.0 bar

Begrænsning: Pc-referencens min. værdi r31 -99.9°C / 0.0 bar 99.9°C / 60.0 bar -99.9°C / 0.0 bar

Korrektion af signalet fra Pc-føleren r32 -50°C / -5.0 bar 50°C / 5.0 bar 0.0

Pc-referencens variation.

1 og 2 er PI regulering

1: Fast reference. "r28" anvendes

2: Variabel reference. Udetemperaturen (Sc3) indgår i referencen

3: Som 1, men med P-regulering (Xp-bånd)

4: Som 2, men med P-regulering (Xp-bånd)

Parameter

r24 °C / bar

r25 -99°C / -1.0 bar 30°C / 60.0 bar 30.0°C / 40.0 bar

r26 -99°C / -1.0 bar 30°C / 40.0 bar -99.9°C / -1.0 bar

r33 1 4 1

o61 =

1 2

Min. Max. Fabriks-

indstilling

SW: 1.0x

Referenceoset for Pc r34 -50°C / -5.0 bar 50°C / 5.0 bar 0.0

Middeltemperaturdierencen over kondensatoren ved maksimum

belastning (dim tm K)

Middeltemperaturdierencen over kondensatoren ved den laveste aktu-

elle kompressorkapacitet (min tm K)

Her kan du aæse det aktuelle tryk (P0), der måles med tryktransmitteren r57 °C / bar

Her kan du aæse det aktuelle tryk (T0), der indgår i reguleringen. Fra

føleren der er deneret i "o81"

Kapacitet

Min. On-tid for relæer c01 0 min 30 min. 0

Min. periodetid imellem indkobling af det samme relæ c07 0 min. 60 min 4

Denition af reguleringsmåden

1: Sekventiel (step mode / FILO)

2: Cyklisk (step mode / FIFO)

Hvis der vælges en reguleringsmåde med aastninger skal relæet deneres til at:

0: Slutte ved krav om mere kapacitet

1: Bryde ved krav om mere kapacitet

Reguleringsparameter for + Zone c10 0.1 K / 0.1 bar 20 K / 2.0 bar 4.0 / 0.4 bar

Reguleringsparameter for + Zone c11 0.1 min 60 min 4.0

Reguleringsparameter for ++ Zone c12 0.1 min. 20 min 2.0

Reguleringsparameter for - Zone c13 0.1 K / 0.1 bar 20 K / 2.0 bar 4.0 / 0.3 bar

r35 3.0 50.0 10.0

r56 3.0 50.0 8.0

r58 °C

c08 1 2 1

c09 0 1 0

Fortsættes

12 Instructions RI8NM252 © Danfoss 12/2009 AK-PC 520

Reguleringsparameter for - Zone c14 0.1 min. 60 min 1.0

Reguleringsparameter for - - Zone c15 0.02 min. 20 min 0.5

Denition af kompressortilslutninger.

Se mulighederne side 11.

Denition af kondensator:

1-4: Total antal ventilatorrelæer eller spændingstrin på spændingsudgangen

5-8: Benyttes ikke

9: Kun via analog udgang og start af frekvensomformer

10: Benyttes ikke

11- 14: Total antal ventilatorrelæer (1-4), der skal koble med skiftevis start

Indkoblet kompressorkapacitet ved manuel styring. Se også "c32" c31 0% 100% 0

Manuel styring af kompressorkapacitet (ved ON bliver værdien i "c31"

anvendt)

Pump down grænse. Grænseværdi hvor den sidste kompressor bliver

udkoblet

Proportionalbånd Xp for (P = 100/Xp) kondensatorreguleringen n04 0.2 K / 0.2 bar 40.0 K / 10.0 bar 10.0 K / 3.0 bar

I: Integrationstid Tn for kondensatorreguleringen n05 30 s 600 s 150

Indkoblet kondensatorkapacitet ved manuel styring. Se også "n53" n52 0% 100% 0

Manuel styring af kondensatorkapacitet (ved ON bliver værdien i "n52"

anvendt)

Start hastighed. Spændingen til hastighedsreguleringen bliver holdt på 0

V, indtil reguleringen kræver en højere værdi end den her indstillede

Min. hastighed. Spændingen til hastighedsreguleringen skifter til 0 V, når

reguleringen kræver en lavere værdi end den her indstillede

Alarm

Forsinkelsestid for en A32 alarm A03 0 min. 90 min. 0 min.

Nedre alarm- og sikkerhedsgrænse for P0 A11 -99°C / -1.0 bar 30°C / 40 bar -40°C / 0.5 bar

Forsinkelsestid for en DI1-alarm A27 0 min. (-1=OFF) 999 min. OFF

Forsinkelsestid for en DI2-alarm A28 0 min. (-1=OFF) 999 min. OFF

Forsinkelsestid for en DI3-alarm A29 0 min. (-1=OFF) 999 min. OFF

Øvre alarm- og sikkerhedsgrænse for Pc A30 -10 °C / 0.0 bar 200°C/200.0 bar 60.0°C / 60.0 bar

Øvre alarmgrænse for føleren "Saux1" A32 1°C (0=OFF) 140°C OFF

Forsinkelsestid for en P0 alarm A44 0 min. (-1=OFF) 999 min. 0 min.

Forsinkelsestid for en Pc alarm A45 0 min. (-1=OFF) 999 min. 0 min.

Diverse

Regulatorens adresse o03* 1 990

On/o omskifter (service-pin meddelelse) o04* - Adgangskode o05 1 (0=OFF) 100 OFF

Anvendt følertype til Sc3, Sc4 og "Saux1"

0=Pt1000, 1=PTC1000

2-7= variationer med temperaturføler på P0 og Pc.

Se manual Side 21.

Indstille forsyningsspændingens frekvens o12 50 Hz 60 H 0

Manuel styring af udgange:

0: Ingen overstyring

1-10: 1 vil trække relæ 1, 2 relæ 2, osv.

11-18: Giver spændingssignal på den analoge udgang. (11 giver 1,25 V

og ellers videre i step på 1,25 V.)

P0-tryktransmitterens arbejdsområde - min. værdi o20 -1 bar 0 bar -1.0

P0-tryktransmitterens arbejdsområde - max. værdi o21 1 bar 200 bar 12.0

DI4-indgangens anvendelse

0=benyttes ikke. 1=P0-forskydning. 2=alarmfunktion. Alarm="A31"

Driftstid af relæ 1 (værdi gange 1000) o23 0.0 h 99.9 h 0.0

Driftstid af relæ 2 (værdi gange 1000) o24 0.0 h 99.9 h 0.0

Driftstid af relæ 3 (værdi gange 1000) o25 0.0 h 99.9 h 0.0

Driftstid af relæ 4 (værdi gange 1000) o26 0.0 h 99.9 h 0.0

Kølemiddelindstilling

1=R12. 2=R22. 3=R134a. 4=R502. 5=R717. 6=R13. 7=R13b1. 8=R23.

9=R500. 10=R503. 11=R114. 12=R142b. 13=Brugerdeneret. 14=R32.

15=R227. 16=R401A. 17=R507. 18=R402A. 19=R404A. 20=R407C.

21=R407A. 22=R407B. 23=R410A. 24=R170. 25=R290. 26=R600.

27=R600a. 28=R744. 29=R1270. 30=R417A. 31=R422A.

DI5-indgangens anvendelse

0=benyttes ikke. 1=Pc-forskydning. 2=alarmfunktion. Alarm="A32"

c16 1 8 0

c29 0/OFF 14 0

c32 OFF ON OFF

c33 -99.9°C / -1.0 bar 100°C / 60 bar 100°C / 60 bar

n53 OFF ON OFF

n54 0% 75% 20%

n55 0% 50% 10%

o06 0 7 (1) 0

o18 0 18 0

o22 0 2 0

o30 0 31 0

o37 0 2 0

*) Denne indstilling vil kun være mulig, hvis der er monteret et datakommunikationsmodul i regulatoren. Fortsættes

AK-PC 520 Instructions RI8NM252 © Danfoss 12/2009 13

Pc-tryktransmitterens arbejdsområde - min. værdi o47 -1 bar 0 bar -1.0

Pc-tryktransmitterens arbejdsområde - max. værdi o48 1 bar 200 bar 34.0

Aæse temperaturen ved føleren "Saux1" o49 °C

Driftstid af relæ 5 (værdi gange 1000) o50 0.0 h 99.9 h 0.0

Driftstid af relæ 6 (værdi gange 1000) o51 0.0 h 99.9 h 0.0

Driftstid af relæ 7 (værdi gange 1000) o52 0.0 h 99.9 h 0.0

Driftstid af relæ 8 (værdi gange 1000) o53 0.0 h 99.9 h 0.0

Valg af application

1. Temperaturvisning i display

2. Trykvisning i display

Funktion for relæudgang DO9:

0. Start / stop af hastighedsstyring

1. Inject on signal til fordamperstyringer

2. Boost ready (mindst en kompressor er on)

3. Start /stop af kondensatorblæser

Funktion for relæudgang DO10:

0. Alarmrelæ

1. Start / stop af kondensatorblæser

Denition af alarmmeddelelse ved DI1-signal:

0. Benyttes ikke

1. Blæser fejl (A34)

2. DI1 alarm (A28)

Indstilling ved vandkøleranvendelse

Denition af signalindgang til kompressor-reguleringen, når der reguleres med temperatursignal:

0. Temperaturføler til 57-58

1. Temperaturføler til Saux

2. Temperaturføler til Sc4

Kræves frostsikring skal indstillingen være 1 eller 2:

Displaytilslutning

O: EKA 164

On: EKA 165 (udvidet display med lysdioder)

Service

Status på DI1-indgangen u10

Status på DI2-indgangen u37

Aæse temperaturen ved føleren "Sc3" u44 °C

Aæse temperaturen ved føleren "Sc4" u45 °C

Status på DI3-indgangen u87

Status på DI4-indgangen u88

Status på DI5-indgangen u89

o61 1 2 1 2 1

o75 0 3 0

o76 0 1 0

o78 0 2 0

o81 0 2 0

o82 O On O

Meddelelser kan kaldes frem i displayet ved et kort tryk på den øverste

knap. Er der mere end en alarm, kan de "rulles" igennem.

Fabriksindstilling

Hvis du får behov for at vende tilbage til de fabriksindstillede værdier,

kan det ske således:

- Afbryd forsyningsspændingen til regulatoren

- Hold den midterste knap inde samtidig med at du igen tilslutter forsy-

ningsspændingen.

14 Instructions RI8NM252 © Danfoss 12/2009 AK-PC 520

Regulatoren kan give følgende meddelelser:

E1 Fejl-

meddelelse

E2

A2 Alarm-

meddelelse

A11 Der er ikke valgt kølemiddel

A17 Høj Pc

A19 Kompressor 1 fejl

A20 Kompressor 2 fejl

A21 Kompressor 3 fejl

A22 Kompressor 4 fejl

A27 Rumtemperaturalarm (Saux1 temp.)

A28 DI 1 alarm. Klemme 46 er afbrudt

A29 DI 2 alarm. Klemme 47 er afbrudt

A30 DI 3 alarm. Klemme 49 er afbrudt

A31 DI 4 alarm. Klemme 50 er afbrudt

A32 DI 5 alarm. Klemme 52 er afbrudt

A34

A45 Reguleringen er stoppet

S0 Status-

meddelelser

S2 Afventer "c01"

S5 Afventer "c07"

S8 Afventer "c11" eller "c12"

S9 Afventer "c14" eller "c15"

S10

S25 Manuel styring af udgange

S34

PS Info

Fejl i regulatoren

Reguleringen er uden for området, eller styre-

signalet er defekt

Lav P0

Den aktuelle kompressors sikkerhedskreds

er afbrudt. Dvs. der

mangler signal på en af

klemmerne 29-32.

Blæseralarm. Der er ingen signal på DI1indgangen

Der reguleres

Kølingen er stoppet med den interne eller

eksterne start/stop

Sikkerhedsudkobling.

Indstilling A 30 er overskredet, eller alle sikkerhedsindgange (29-32) er åbne.

Adgangskoden er påkrævet inden du får adgang

til indstillinger.

AK-PC 520 Instructions RI8NM252 © Danfoss 12/2009 15

Anschlüsse

DEUTSCH

Danfoss

84B2869.10

P0/Pc: AKS 32R:

1 = Schwarz = +

2 = Blau = -

3 = Braun = s

Verdichterregelung

nach Temperatur

o06 = 0

o81 = 1

Alle Eingänge sind nur für

Niederspannung geeignet.

Alle Relaisausgänge sind

für Hochspannung ausgelegt.

Benötigte Anschlüsse

Klemme:

1-2 Versorgungsspannung 24 V a.c.

4- 19 Relaisausgänge für entweder Verdichter, Entlastungen

oder Lüftermotoren

22-24 Alarmrelais

Es besteht Verbindung zwischen 22 und 24 in Alarmsituationen, und wenn der Regler Spannungslos ist.

27-28 24 V Signal für Start / Stop der Regelung

27-29 24 V Signal vom Sicherheitskreis DO 1

27-30 24 V Signal vom Sicherheitskreis DO 2

27-31 24 V Signal vom Sicherheitskreis DO 3

27-32 24 V Signal vom Sicherheitskreis DO 4

57-59 Saugdruck. Spannungssignal vom AKS 32R **

60-62 Verüssigungsdruck. Spannungssignal vom AKS 32R **

Entlastungen

Wird ein Ausgang für eine Entlastung

benutzt, ist Verdrahtung zu den zugehörigen Sicherheitskreis nicht notwendig.

z.B. bei einer Entlastung auf DO2 kann

ein Anschluss an Klemme 30 ausgelassen

werden

Anwendungsbestimte Anschlüsse

20-21 AKD Start/stop *

Das Relais schliesst wenn der Frequenzumrichter starten

soll.

37-38 Spannungssignal für eksterne Verüssigerregelung

39-41 Anschlussmöglichkeit für ein externes Display von Typ

EKA 163 (Pc-anzeige)

42-44 Anschlussmöglichkeit für ein externes Display von Typ

EKA 163 für P0-anzeige, oder EKA 165 zur Bedienung und

P0-Anzeige

45-46 DI1 - Kontaktfunktion für Alarmsignal

45-47 DI2 - Kontaktfunktion für Alarmsignal

48-49 DI3 - Kontaktfunktion für Alarmsignal

48-50 DI4 - Kontaktfunktion für verschiebung des Saugdruck

Sollwerts oder für Alarmsignal.

51-52 DI5 - Kontaktfunktion für verschiebung des Verüssiger-

druck Sollwerts oder für Alarmsignal.

51-53 Separate Fühler Saux1. Fühlersignal von AKS 11, AKS 12

oder EKS 111

54-55 Aussentemperatur (Sc3). Fühlersignal vom AKS 11, AKS 12

oder EKS 111 (wird montiert wenn r33 =2 oder 4 ist)

54-56 Lufttemperatur am Verüssiger abgang. Fühlersignal von

AKS 11, AKS 12 oder EKS 111

Datenkommunikation

25-26 Nur bei montiertem Datenkommunikationsmodul anzu

schließen.

Erfolgt die Kommunikation über ein Ethernet, sind Steck-

anschlüsse RJ45 anzuwenden. (LON FTT10 kann ebenfalls

auf diese Weise angeschlossen werden.)

Bitte beachten, dass die Installation des Datenkommuni-

kationskabels korrekt vorgenommen wird.

Siehe separate Literatur Nr. RC8AC.

*)

Das Relais DO9 lässt sich in speziellen Fällen umkongurieren.

**)

• Wenn der Regler nur die Verdichter oder die Lüfter regeln soll, kann Pc beziehungs-

weise P0 Fühler entbehrt werden.

• Bei Soleanlagen kann anstatt der Druckmessung mittels AKS 32R eine Temperatur-

messung an den Klemmen 57-58 und 60-61 erfolgen. Siehe auch o06.

16 Instructions RI8NM252 © Danfoss 12/2009 AK-PC 520

Verdichterkonguration wenn = 1 oder 2 (Hier haben Sie die Auswahl unter den gezeigten Möglichkeiten.)

Einstellung "C16" wird die Konguration denieren

Einstellung "C08" wird die Konguration denieren

Verdichteranschluss

Relais Nr.

Einstellung

"C16"

Schaltungs-

art

Einstellung

"C08"

Leistungsstufen

Es wird vorausgesetzt, dass alle Leistungsstufen gleich groß sind.

Schaltungsart

Schaltungsart 1 gilt für sequenziellen Betrieb.

Schaltungsart 2 gilt für zyklischen Betrieb.

Umschaltungen

Bei zyklischem Betrieb und Anschlüssen mit Entlastungen treten bei bestimmten Leistungszuschaltungen Überlappungen auf, wobei die Entlastungen entweder des einen oder anderen Verdichters aktiv sein können.

In diesen Fällen werden die Entlastungen des Verdichters mit der niedrigsten Betriebsstundenzahl ein- und die anderen abgeschaltet. Die Umschaltung erfolgt mit einem Intervall von 6 Sekunden.

Verüssigerschaltungen

Nachdem die Verdichterrelais festgelegt wurden, sind die Lüfterrelais an der Reihe.

Das erste freie Relais (DO1-DO5) wird zum ersten Lüfterrelais.

Anschließend alle weiteren.

Soll die gesamte Verüssigerleistung mit einem Frequenzumrichter geregelt werden, muss AK-PC 520 ein

der gewünschten Leistung entsprechendes analoges

Signal (“c29”=9) abgeben.

Das Signal variiert von 0 bis 10 V. Signal und Leistung

hängen wie folgt zusammen.

Danfoss

84B2870.10

AK-PC 520 Instructions RI8NM252 © Danfoss 12/2009 17

Bedienung

Datenkommunikation

Wenn der Regler um Datenkommunikation erweitert wird, kann

die Bedienung von der Systemeinheit aus erfolgen.

Die Wichtigkeit der übermittelten Alarme kann mit folgenden

Einstellungen deniert werden: 1 (hoch), 2 (mittel), 3 (niedrig)

oder 0 (kein Alarm).

Bedienung durch externes Display

Die Wertdarstellung erfolgt dreistellig. Es besteht die Wahl zwischen Anzeige in SI-Einheiten (°C / Bar) oder ob die Anzeige in

US-Einheiten (°F / psig) sein soll.

Es gibt drei verschiedene Displays

EKA 165

Zur Bedienung des Reglers und zur Anzeige des Verdampfdrucks.

Durch Antippen der unteren Taste wird der Verüssigungsdruck

kurz im Display angezeigt. (Wenn nur der Verüssigungsdruck

geregelt wird, zeigt das Display immer Pc.)

Bei Normalbetrieb zeigen die Leuchtdioden im Display den Regelzustand an.

Oberste + zweitoberste : ++Zone

Zweitoberste : +Zone

"Keine" : Neutralzone

Zweitunterste : -Zone

Unterste + zweitunterste : - - Zone

EKA 165

EKA 163

EKA 164

Tasten am Display

Mit den Tasten lassen sich die Einstellungen ändern. Je nachdem,

welche Taste Sie betätigen, ergibt sich ein höherer oder niedrigerer Wert. Bevor Werte geändert werden können, muss Zugang

zum Menü hergestellt werden. Durch einige Sekunden langes

Betätigen der obersten Taste erhält man Zugang zu einer Reihe

von Parametercodes. Wählen Sie den zu ändernden Parametercode aus, und betätigen Sie anschließend die mittlere Taste. Nach

Änderung des Werts lässt sich der neue Wert speichern, indem

erneut die mittlere Taste betätigt werden.

Die sonstigen Leuchtdioden auf der Tafel zeigen, welche Funktionen aktiv sind:

• Relais für Verdichter

• Relais für Lüfter

• Eingangssignale an den digitalen Eingängen

• Die LED „Optimierung“ leuchtet auf, wenn der Wert 2 K oder

mehr über dem Sollwert liegt.

EKA 163

Wenn Bedarf an einer konstanten Anzeige des Verüssigungsdrucks besteht, kann ein Display ohne Bedientasten angeschlossen werden.

EKA 164

Zur Bedienung des Reglers und zur Anzeige des Verdampfdrucks.

Durch Antippen der unteren Taste wird der Verüssigungsdruck

kurz im Display angezeigt.

Die Leuchtdioden im Display zeigen wie beim EKA 165 an, wo die

Regelung steht.

Kurz zusammengefasst:

1. Die oberste Taste betätigen (lange drucken), bis ein Parameter

zur Anzeige gelangt.

2. Eine der Tasten betätigen, um zum gewünschten Parameter zu

gelangen.

3. Die mittlere Taste betätigen, bis der Wert des Parameters zur

Anzeige kommt.

4. Eine der Tasten betätigen, und einen neuen Wert festlegen.

5. Erneut die mittlere Taste betätigen, um den Einstellvorgang zu

beenden.

(Ein kurzes Drücken zeigt, welche Alarmmitteilungen aktiv sind.)

18 Instructions RI8NM252 © Danfoss 12/2009 AK-PC 520

Menüübersicht

Reihenfolge

1. o61 muss als erster Parameter eingestellt werden. Er bestimmt, welche der 2 Bedienächen (application mode) aktiviert wird. Er muss

über die Tasten des Displays eingestellt werden. Er kann nicht per Datenkommunikation eingestellt werden. (Aktive Funktionen werden untenstehend grau hinterlegt angezeigt.)

2. Schnell-Start

Soll die Anlage schnell angefahren werden, um die Abkühlung zu beginnen, lassen sich folgende Parameter einstellen. (Sie lassen sich

nur Einstellen, wenn die Regelung gestoppt ist, r12=0):

r23, r28, c08, c09, c16), c29, o06, o30, o75, o76, o81 und zuletzt r12=1.

3. Nach Anlauf der Regelung kann sie mittels der übrigen Parameter zweckgemäß eingestellt werden.

SW: 1.0x

Funktion

Normalbild

P0 anzeige in EKA 165 (mit Bedienungstasten)

Pc anzeige in EKA 163 - °C P °C / bar

P0 Sollwert

Neutralzone r01 0.1°C / 0.1 bar 20°C /5.0 bar 4.0°C / 0.4 bar

Korrektion des Signals vom P0 Fühler r04 -50°C /-5.0 bar 50°C / 5.0 bar 0.0

Wähle SI oder US Anzeige. 0=SI (bar/°C). 1=US (Psig /°F)

Start/Stop der Regelung r12 OFF ON OFF

Sollwert oset für P0 (siehe auch r27) r13 -50°C / -5.0 bar 50°C / 5.0 bar 0.0

Setpunkt-Einstellung für P0 r23 -99°C / -1 bar 30°C / 60.0 bar 0.0°C / 3.5 bar

Hier wird die gesamte P0-sollwert angeziegt

( r23 + diverse Verschiebungen)

Begrenzung: P0-Sollwert max. Wert

(gilt auch bei Regelung mit Sollwert Verschiebung)

Begrenzung: P0-Sollwert min. Wert

(gilt auch bei Regelung mit Sollwert Verschiebung)

Verschiebung des P0 (ON=aktiv "r13") r27 OFF ON OFF

Pc Sollwert

Setpunkt-Einstellung für Pc r28 -25°C / 0.0 bar 75°C /110.0 bar 35°C / 15.0 bar

Hier wird die gesamte Pc-sollwert angeziegt r29 °C / bar

Begrenzung: Pc-Sollwert max. Wert

Begrenzung: Pc-Sollwert min. Wer r31 -99.9°C / 0.0 bar 99.9°C / 60.0 bar -99.9°C / 0.0 bar

Korrektion des Signals vom Pc Fühler r32 -50°C / -5.0 bar 50°C / 5.0 bar 0.0

Pc-Sollwert Variation.

1 und 2 sind PI-Regelung

1: Fester Sollwert. "r28" wird verwendet

2: Variabler Sollwert. Aussentemperatur (Sc3) ist im Soll-wert eingeschlossen

3: Wie 1, aber mit P-Regelung (Xp-Band)

4: Wie 2, aber mit P-Regelung (Xp-Band)

Sollwert oset für Pc r34 -50°C / -5.0 bar 50°C / 5.0 bar 0.0

Die mittlere Temperaturdierenz über dem Verüssiger bei maximaler

Belastung (dim tm K)

Die mittlere Temperaturdierenz über dem Verüssiger bei niedrigster

aktueller Verdichterleistung (min tm K)

Hier lässt sich der aktuelle, mit dem Druckmessumformer ermittelte

Druck (P0) ablesen.

Hier lässt sich der aktuelle Druck (T0) ablesen, der mit dem Fühler (de-

niert in o81) ermittelt wurde.

Leistung

Min. On-Zeit für Relais c01 0 min 30 min. 0

Min. Periodendauer zwischen Zusschaltungen des gleichen Relais c07 0 min. 60 min 4

Festlegung des Regelverfahrens

1: Sequenziell (step mode / FILO)

2: Zyklisch (step mode / FIFO)

Wenn ein Regelverfahren mit Entlastungen gewählt wird müssen die

Relais wie folgt festgelegt werden:

0: Schließen bei Mehrbedarf an Leistung

1: Önen bei Mehrbedarf an Leistung

Regelungsparameter für + Zone c10 0.1 K / 0.1 bar 20 K / 2.0 bar 4.0 / 0.4 bar

Regelungsparameter für + Zone c11 0.1 min 60 min 4.0

Parameter

- °C P °C / bar

r05 0 1 0

r24 °C / bar

r25 -99°C / -1.0 bar 30°C / 60.0 bar 30.0°C / 40.0 bar

r26 -99°C / -1.0 bar 30°C / 40.0 bar -99.9°C / -1.0 bar

r30 -99.9°C / -0.0 bar 99.9°C/130.0bar 55.0°C / 60.0 bar

r33 1 4 1

r35 3.0 50.0 10.0

r56 3.0 50.0 8.0

r57 °C / bar

r58 °C

c08 1 2 1

c09 0 1 0

o61 =

1 2

Min. Max. Werks-

einstellung

AK-PC 520 Instructions RI8NM252 © Danfoss 12/2009 19

Regelungsparameter für ++ Zone c12 0.1 min. 20 min 2.0

Regelungsparameter für - Zone

Regelungsparameter für - Zone c14 0.1 min. 60 min 1.0

Regelungsparameter für - - Zone c15 0.02 min. 20 min 0.5

Denition der Verdichteranschlüsse.

Siehe Möglichkeiten Seite 17

Denition des Verüsigers:

1-4: Totale Anzahl von Lüfterrelais oder Spannungsstufe am Spannungsausgang

5-8: Wird nicht benutzt

9: Nur bei Analogen Ausgang und bei star von Druckmessumformern

10: Wird nicht benutzt

11- 14: Gesamtanzahl Lüfterrelais (1-4), die mit wechselweisem Start

geschaltet werden sollen

Eingeschaltete Verdichterleistung bei manueller Steuerung. Siehe auch

“c32”

Manuelle Steuerung der Verdichterleistung (bei ON wird der Wert in “c31”

verwendet)

Absauggrenzwert (Pump down). Hierbei handelt es sich um den Grenz-

wert, bei dem der letzte Verdichter abschaltet.

Proportionalband Xp für (P = 100/Xp) Verüssigerregelung n04 0.2 K / 0.2 bar 40.0 K / 10.0 bar 10.0 K / 3.0 bar

I: Integrationszeit für Verüssigerregelung n05 30 s 600 s 150

Eingeschaltete Verüssigerleistung bei manueller regelung. Siehe auch

"n53"

Manuelle Regelung der Verüssigerleistung (bei ON wird der Wert in

"n52" angewandt)

Startgeschwindigkeit. Die Spannung zur Geschwindigkeitsregelung

wird auf 0 V gehalten, bis die Regelung einen höheren Wert als den hier

eingestellten anfordert

Mindestgeschwindigkeit. Die Spannung zur Geschwindigkeitsregelung

wechselt auf 0 V, wenn die Regelung einen niedrigeren Wert als den hier

eingestellten anfordert

Alarm

Verzögerungszeit eines A32 alarms A03 0 min. 90 min. 0 min.

Untere Alarm- und Sicherheitsgrenze für P0

Verzögerungszeit für einen DI1-Alarm A27 0 min. (-1=OFF) 999 min. OFF

Verzögerungszeit für einen DI2-Alarm A28 0 min. (-1=OFF) 999 min. OFF

Verzögerungszeit für einen DI3-Alarm A29 0 min. (-1=OFF) 999 min. OFF

Obere Alarm- und Sicherheitsgrenze für Pc A30 -10 °C / 0.0 bar 200 °C / 200 bar 60.0°C / 60.0 bar

Obere Alarmgrenze für den Fühler "Saux1" A32 1°C (0=OFF) 140°C OFF

Verzögerungszeit für ein P0 Alarm A44 0 min. (-1=OFF) 999 min. 0 min.

Verzögerungszeit für ein Pc Alarm A45 0 min. (-1=OFF) 999 min. 0 min.

Sonstiges

Regleradresse o03* 1 990

AUS/EIN-Wechselschalter (Service-PIN-Mitteilung) o04* - Zugangskode o05 1 (0=OFF) 100 OFF

Angewandter Fühlertype für Sc3, Sc4 und "Saux1"

0=PT1000, 1=PTC1000

2-7= variationen mit Temperaturfühler an P0 und Pc. Siehe das Manual

Seite 21.

Einstellungs der Spannungsversorgungsfrequen o12 50 Hz 60 H 0

Manueller Betrieb der Ausgänge:

0: Keine übersteuerung

1-10: 1 Schliesst das Relais 1, 2 Relais 2, usw.

11-18: Gibt Spannungssignal an den Analogen ausgang. (11 bringt 1,25 V

und so weiter in Stufen von 1,25 V.)

P0-Arbeitsbereich des Druckmessumformers - min. Wert o20 -1 bar 0 bar -1.0

P0-Arbeitsbereich des Druckmessumformers - max. Wert

DI4-Eingang festlegen:

0=wird nicht benutzt. 1=P0-verschiebung. 2=Alarmfunktion. Alarm="A31"

Betriebszeit von Relais 1 (Wert x 1000) o23 0.0 h 99.9 h 0.0

Betriebszeit von Relais 2 (Wert x 1000) o24 0.0 h 99.9 h 0.0

Betriebszeit von Relais 3 (Wert x 1000) o25 0.0 h 99.9 h 0.0

Betriebszeit von Relais 4 (Wert x 1000)

c13 0.1 K / 0.1 bar 20 K / 2.0 bar 4.0 / 0.3 bar

c16 1 8 0

c29 0/OFF 14 0

c31 0% 100% 0

c32 OFF ON OFF

c33 -99.9°C / -1.0 bar 100°C / 60 bar 100°C / 60 bar

n52 0% 100% 0

n53 OFF ON OFF

n54 0% 75% 20%

n55 0% 50% 10%

A11 -99°C / -1.0 bar 30°C / 40 bar -40°C / 0.5 bar

o06 0 7 (1) 0

o18 0 18 0

o21 1 bar 200 bar 12.0

o22 0 2 0

o26 0.0 h 99.9 h 0.0

20 Instructions RI8NM252 © Danfoss 12/2009 AK-PC 520

Kältemitteleinstellung

1=R12. 2=R22. 3=R134a. 4=R502. 5=R717. 6=R13. 7=R13b1. 8=R23.

9=R500. 10=R503. 11=R114. 12=R142b. 13=Benutzerdef. 14=R32.

15=R227. 16=R401A. 17=R507. 18=R402A. 19=R404A. 20=R407C.

21=R407A. 22=R407B. 23=R410A. 24=R170. 25=R290. 26=R600.

27=R600a. 28=R744. 29=R1270. 30=R417A. 31=R422A.

DI5-Eingang festlegen

0=wird nicht benutzt. 1=Pc-verschiebung2=Alarmfunktion. Alarm="A32"

Pc-Arbeitsbereich des Druckmessumformers - min. Wert o47 -1 bar 0 bar -1.0

Pc-Arbeitsbereich des Druckmessumformers - max. Wert o48 1 bar 200 bar 34.0

Temp. anzeige beim Fühler "Saux1" o49 °C

Betriebszeit von Relais 5 (Wert x 1000) o50 0.0 h 99.9 h 0.0

Betriebszeit von Relais 6 (Wert x 1000) o51 0.0 h 99.9 h 0.0

Betriebszeit von Relais 7 (Wert x 1000) o52 0.0 h 99.9 h 0.0

Betriebszeit von Relais 8 (Wert x 1000) o53 0.0 h 99.9 h 0.0

Wahl der Anwendung

1. Temperaturanzeige im Display

2: Druckanzeige im Display

Funktion für Relaiausgang DO9:

0. Start / stop der Geschwindigkeitsregelung

1. Inject on signal für Verdampferregelungen

2. Boost ready (mindestens ein Verdichter ist on)

3. Start /stop der Verüssigerlüfter

Funktion für Relais ausgang DO10:

0. Alarmrelais

1. Start / stop der Verüssigerlüfter

Denition der Alarmmitteilung vei DI1 Signal:

0. Wird nicht benutzt

1. Lüfter fehler (A34)

2. DI1 Alarm (A28)

Einstellung bei Wasser Kühler Anwendung

Denition des Signaleingang für Verdichter-Regelung, wenn mit Temperatursignal geregelt wird:

0. Temperaturfühler an 57-58

1. Temperaturfühler an Saux

2. Temperaturfühler Sc4

Ist eine Frostsicherung erforderlich, muss die Einstellung 1 oder 2 betragen.

Displayanschluss

O: EKA 164

On: EKA 165 (erweitertes Display mit Leuchtdioden)

Service

Status am DI1-Eingang u10

Status am DI2-Eingang u37

Anzeige der Temperatur am Fühler "Sc3" u44 °C

Anzeige der Temperatur am Fühler "Sc4" u45 °C

Status am DI3-Eingang u87

Status am DI4-Eingang u88

Status am DI5-Eingang u89

o30 0 31 0

o37 0 2 0

o61 1 2 1 2 1

o75 0 3 0

o76 0 1 0

o78 0 2 0

o81 0 2 0

o82 O On O

Mitteilungen können durch Antippen der oberen Taste im Display angezeigt werden. Gibt es mehr als einen Alarm, kann “geblättert” werden.

Werkseinstellung

Die Rückkehr zu den ab Fabrik eingestellten Werten lässt sich wie folgt

vornehmen:

- Die Spannungszufuhr zum Regler unterbrechen.

- Die oberste und unterste Taste betätigt halten und gleichzeitig die

Spannungszufuhr wieder einschalten.

AK-PC 520 Instructions RI8NM252 © Danfoss 12/2009 21

Der Regler kann folgende Mitteilungen geben:

E1 Fehler-

mitteilung

E2

A2 Alarm-

mitteilung

A11 Kältemittel nicht gewählt

A17 Hoch Pc

A19 Verdichter 1 Fehler

A20 Verdichter 2 Fehler

A21 Verdichter 3 Fehler

A22 Verdichter 4 Fehler

A27 Raumtemperaturalarm (Saux1 temp.)

A28 DI 1 Alarm. Klemme 46 ist unterbrochen

A29 DI 2 Alarm. Klemme 47 ist unterbrochen

A30 DI 3 Alarm. Klemme 49 ist unterbrochen

A31 DI 4 Alarm. Klemme 50 ist unterbrochen

A32 DI 5 Alarm. Klemme 52 ist unterbrochen

A34 Lüfteralarm. Kein Signal am DI1-Eingang

A45 Die Regelung ist gestoppt

S0 Status-

mitteilungen

S2 "c01" abwarten

S5 "c07" abwarten

S8 "c11" oder "c12" abwarten

S9 "c14" oder "c15" abwarten

S10

S25 Manuelle Regelund der Ausgänge

S34

PS Info

Fehler im Regler

Die Regelung ist auserhalb des Bereiches oder

das Steuersignal ist Defekt

Niedrig P0

Der aktuelle Sicherheitskreis des Verdichters is unterbrochen.

D.h. es fehlt ein Signal

an einer der Klemmen

29-32.

Es wird geregelt

Die Kühlung ist gestoppt mit der internen oder

die externe Start/Stopp

Sicherheitsausschaltung. Einstellung A30 ist

überschritten oder alle Sicherheitseingänge (29-

32) sind oen.

Zugangskode ist erfordert bevor zugang zu den

Einstellungen gegeben wird

22 Instructions RI8NM252 © Danfoss 12/2009 AK-PC 520

Raccordements

FRANÇAIS

Danfoss

84B2869.10

P0/Pc: AKS 32R:

1 = Noir = +

2 = Bleu = 3 = Marron = s

Régulation du compresseur

avec la température

o06 = 0

o81 = 1

Toutes les entrées sont à bas

voltage.

Toutes les sorties de relais

peuvent être à haut voltage

Raccordements nécessaires

Bornes :

1-2 Tension d’alimentation 24 V c.a.

4- 19 Sorties de relais pour compresseurs, étages de compres-

sion ou moteurs de ventilateurs

22-24 Relais d'alarme

Il y a liaison entre 22 et 24 en cas d’alarme et si le régula-

teur est hors tension.

27-28 Signal 24 V pour marche/arrêt de la régulation

27-29 Signal 24 V provenant du circuit de protection du DO 1

27-30 Signal 24 V provenant du circuit de protection du DO 2

27-31 Signal 24 V provenant du circuit de protection du DO 3

27-32 Signal 24 V provenant du circuit de protection du DO 4

57-59 Pression d’aspiration. Signal de tension de l’AKS 32R **

60-62 Pression de condensation. Signal de tension de l’AKS 32R **

Etages de capacité

Si une sortie est aectée à un étage de capacité, il n’est pas nécessaire de connecter

le circuit de sécurité annexe.

Ex. avec un réducteur de puissance sur

DO2, une connexion sur la borne 30 peut

être omise.

Raccordements selon les applications

20-21 Marche/arrêt AKD*

Le relais se ferme lorsque le variateur de fréquence doit

démarrer.

37-38 Signal de tension pour une commande externe de

condenseur.

39-41 Raccordement possible d’un acheur externe EKA 163

(achage Pc)

42-44 Raccordement possible d’un acheur externe EKA 163

pour achage P0 ou EKA 165 pour programmation et

achage P0

45-46 DI1 - Fonction de contact pour signal d’alarme

45-47 DI2 - Fonction de contact pour signal d’alarme

48-49 DI3 - Fonction de contact pour signal d’alarme

48-50 DI4 - Fonction de contact pour décalage de la référence de

pression d’aspiration ou pour un signal d’alarme.

51-52 DI5 - Fonction de contact pour décalage de la référence de

pression de condensation ou pour un signal d’alarme.

51-53 Sonde à part Saux1. Signal provenant du capteur AKS 11,

AKS 12 ou EKS 111

54-55 Température extérieure (Sc3). Signal provenant du capteur

AKS 11, AKS 12 ou EKS 111 (A raccorder si r33 = 2 ou 4).

54-56 Température de l’air à la sortie du condenseur. Signal

provenant du capteur AKS 11, AKS 12 ou EKS 111

Transmission de données éventuelle

25-26 Ne faire ce raccordement qu’après installation du module

de transmission de données.

S’il s’agit d’une ligne Ethernet, utiliser le connecteur RJ45.

(On peut aussi raccorder LON FTT10 de cette façon.)

Il es très important que l'intallation du câble du transmis-

sion soit eectuée correctement. Se reporter au document

spécique RC8AC---.

*)

Le relais DO9 peut être reconguré dans des cas particuliers.

**)

• Si le régulateur doit commander uniquement des compresseurs ou uniquement

des ventilateurs, on peut se passer de la pression P0 et du capteur Pc.

• Pour les installations à la saumure, on peut remplacer le contrôle de pression avec

AKS 32R par un contrôle de température aux bornes 57-58 et 60-61. Voir aussi o06.

AK-PC 520 Instructions RI8NM252 © Danfoss 12/2009 23

Conguration de compresseur quand o61 = 1 ou 2 (C’est là qu’on choisira entre les possibilités achées.)

Le réglage « c16 » dénit la conguration.

Le réglage « c08 » dénit le mode d’enclenchement/déclenchement.

Raccords de compresseurs

Relais n°

Régler

« C16 » à

Mode de

déclenche-

ment/

réenclenche-

ment

Régler

« C08 » à

Etages de capacité

Tous les étages de capacité sont présumés être égaux.

Mode de déclenchement/réenclenchement

Le mode d’enclenchement 1 est le fonctionnement séquentiel.

Le mode 2 est le fonctionnement cyclique.

Réenclenchements

En cas de fonctionnement cyclique avec étages raccordés, certains

enclenchements de capacité sont susceptibles de créer des chevauchements puisque les étages de l’un ou de l’autre des compresseurs risquent

d’être actifs.

Les étages du compresseur ayant assuré le moins d’heures de fonctionnement seront alors enclenchés, les autres déclenchés. Le réenclenchement

a lieu en l’espace de 6 secondes.

Enclenchements de condenseurs

Une fois les relais de compresseurs dénis, on passe à la dénition

des relais ventilateurs.

Le premier relais disponible (DO1-DO5) sera le premier relais de

ventilateur. Ensuite viennent les suivants.

Si toute la capacité de condensation doit être régulée

par un variateur de vitesse, l’AK-PC 520 doit émettre un

signal analogique concernant la capacité désirée (« c29

» = 9).

Ce signal varie entre 0 et 10 V. Le rapport entre signal et

capacité est le suivant :

Danfoss

84B2870.10

24 Instructions RI8NM252 © Danfoss 12/2009 AK-PC 520

Utilisation

Transmission de données

Si le régulateur a été équipé de transmission de données, sa gestion peut être assurée par une unité du système.

L’importance des alarmes émises peut être graduée de la façon

suivante : 1 (haute), 2 (moyenne), 3 (basse) ou 0 (aucune alarme).

Commande via un achage externe

Les valeurs sont achées avec trois chires, et avec une mise au

point vous pouvez dénir si la pression doit s’acher en SI unités

(C°/bar) ou US unités (°F/psig)

Il y a trois possibilités d’achage :

EKA 165

EKA 163

EKA 165

Pour la commande du régulateur et l’achage de la pression

d’évaporation.

En tapant brièvement sur le bouton inférieur on peut faire

apparaître brièvement la pression de condensation à l’achage.

(S’il sut de réguler la pression de condensation l’écran achera

toujours Pc.)

En fonctionnement normal, les diodes indiquent où se trouve

actuellement la régulation.

Diode sup. + second : Zone++

second : Zone+

« Néant » : Zone neutre

avant dernière : ZoneDiode inf. + l’avant dernière : Zone- -

Les autres LED du tableau montrent les entrées et les sorties qui

sont en fonctions :

• Relais compresseurs

• Relais ventilateurs

• Signaux d’entrées

• La diode d’optimisation s’allumera quand la référence est de 2 K

ou plus au-dessus du point de réglage

EKA 163

Si l’on a besoin d’un achage permanent de la pression de

condensation, on peut connecter un écran sans boutons de

commande.

EKA 164

EKA 164

Les boutons à l’achage

Quand vous désirez modier un réglage, les boutons supérieurs et

inférieurs indiqueront une valeur supérieure ou inférieure. Mais il

faut d’abord avoir accès au menu: appuyer quelques secondes sur

le bouton supérieur. Apparaissent alors la série de codes de paramétrage. Chercher le code à modier et appuyer sur le bouton

central. Après la modication, mémoriser la nouvelle valeur en

appuyant à nouveau sur celui-ci.

AK-PC 520 Instructions RI8NM252 © Danfoss 12/2009 25

Pour la commande du régulateur et l’achage de la pression

d’évaporation.

En tapant brièvement sur le bouton inférieur on peut faire apparaître brièvement la pression de condensation à l’achage.

Les leds de l’achage montreront de même qu’avec EKA 165 où

se trouve la régulation.

Ou bref:

1. Appuyer sur le bouton supérieur jusqu’à apparition d’un para-

mètre.

2. Appuyer sur l’un des boutons pour trouver le paramètre à

régler.

3. Appuyez sur le bouton central et la valeur de réglage s’achera

4. Appuyer sur l’un des boutons pour choisir la nouvelle valeur.

5. Appuyer à nouveau sur le bouton central pour valider le ré-

glage.

(Une courte pression achera les codes d’alarmes qui sont

armées.)

Sommaire des menus

Séquencement

1. o61 doit être programmé comme premier paramètre. Il détermine laquelle des 2 zones d’utilisation est activée (application mode). La

mise au point doit être eectuée par les boutons de l’écran d’achage. Cette conguration ne peut pas s’eectuer par voie informatique de transmission de données (fonctions actives achées ci-dessous par zones colorées).

2. Démarrage rapide

Si vous désirez obtenir un démarrage éclair du dispositif pour que la réfrigération puisse commencer, vous pouvez commencer par

programmer les paramètres suivants (programmables si la régulation est arrêtée, r12=0) :

r23, r28, c08, c09, c16, c29, o06, o30, o75, o76, o81 et enn r12=1.

3. Après la mise en route de la régulation, procéder à l’ajustage correct des autres paramètres. SW 1.0x

Fonction

Image normale

P0 sera indiqué sur l’EKA 165 (appareil à boutons) - °C P °C / bar

Pc sera indiqué sur l’EKA 163 - °C P °C / bar

P0 référence

Zone neutre r01 0.1°C / 0.1 bar 20°C /5.0 bar 4.0°C / 0.4 bar

Correction du signal du capteur P0 r04 -50°C /-5.0 bar 50°C / 5.0 bar 0.0

Choix SI ou US 0=bar et °C. 1=Psig et °F) r05 0 1 0

Marche/arrêt de la réfrigération r12 OFF ON OFF

Oset de référence pour P0 (voir aussi r27) r13 -50°C / -5.0 bar 50°C / 5.0 bar 0.0

Réglage du point de consigne P0 r23 -99°C / -1 bar 30°C / 60.0 bar 0.0°C / 3.5 bar

Limitation : Valeur maxi, référence P0

( r23 + divers décalages)

Limitation : Valeur maxi, référence P0

(vaut également pour la régulation par décalage de référence)

Limitation : Valeur mini, référence P0

(vaut également pour la régulation par décalage de référence)

Décalage de P0 (ON = actif « r13 ») r27 OFF ON OFF

Pc référence

Réglage du point de consigne Pc r28 -25°C / 0.0 bar 75°C / 110.0 bar 35°C / 15.0 bar

Achage de la référence Pc totale r29 °C / bar

Limitation : Valeur maxi, référence Pc r30 -99.9°C / -0.0 bar 99.9°C/130.0 bar 55.0°C / 60.0 bar

Limitation : Valeur mini, référence Pc r31 -99.9°C / 0.0 bar 99.9°C / 60.0 bar -99.9°C / 0.0 bar

Correction du signal du capteur Pc r32 -50°C / -5.0 bar 50°C / 5.0 bar 0.0

Variation de la référence Pc

1 et 2 : régulation PI

1: Référence xe. « r28 » est utilisé.

2: Référence variable. La température extérieure (Sc3) est incluse dans la

référence.

3: Comme 1, mais avec régulation P (bande Xp)

4: Comme 2, mais avec régulation P (bande Xp)

Oset de référence pour Pc r34 -50°C / -5.0 bar 50°C / 5.0 bar 0.0

La diérence de température moyenne au condenseur en charge maximum (dim. tm K).

Diérence de température moyenne au condenseur en capacité de compresseur actuelle la plus basse (min. tm K).

Là, vous pouvez relever la pression réelle (P0) mesurée par le transmetteur de pression.

Là, vous pouvez relever la pression réelle (T0) qui participe de la régulation. De la sonde qui est dénie dans "o81"

Capacité

Temps de marche min. pour relais c01 0 min 30 min. 0

Période min. entre deux enclenchements du même relais c07 0 min. 60 min 4

Dénition du mode de régulation

1 : séquentiel (step mode / FILO)

2 : cyclique (step mode / FIFO)

En mode de régulation utilisant les étages de compression, il faut dénir

le relais comme suit :

0: : fermeture à la demande de plus de capacité

1 : ouverture à la demande de plus de capacité

Paramètre de régulation pour +Zone c10 0.1 K / 0.1 bar 20 K / 2.0 bar 4.0 / 0.4 bar

Paramétre

r24 °C / bar

r25 -99°C / -1.0 bar 30°C / 60.0 bar 30.0°C / 40.0 bar

r26 -99°C / -1.0 bar 30°C / 40.0 bar -99.9°C / -1.0 bar

r33 1 4 1

r35 3.0 50.0 10.0

r56 3.0 50.0 8.0

r57 °C / bar

r58 °C

c08 1 2 1

c09 0 1 0

o61 =

1 2

Min. Max. Réglage départ

usine

à suivre

26 Instructions RI8NM252 © Danfoss 12/2009 AK-PC 520

Paramètre de régulation pour +Zone c11 0.1 min 60 min 4.0

Paramètre de régulation pour ++Zone c12 0.1 min. 20 min 2.0

Paramètre de régulation pour –Zone c13 0.1 K / 0.1 bar 20 K / 2.0 bar 4.0 / 0.3 bar

Paramètre de régulation pour –Zone c14 0.1 min. 60 min 1.0

Paramètre de régulation pour – Zone c15 0.02 min. 20 min 0.5

Dénition des raccordements de compresseurs.. Reportez-vous à page 24

pour connaître les possibilités.

Dénition du condenseur :

1-4: Nombre total de relais de ventilateurs ou le seuil de tension à la sortie

de tension

5-8: Ne s’utilise pas

9: Uniquement par une sortie analogique et un variateur de vitesse

10: Ne s’utilise pas

11- 14: Nombre total de ventilateurs (1-4) qui doivent être connectés en

démarrages alternatifs

Capacité de compresseur enclenchée en mode manuel. Voir aussi « c32 » c31 0% 100% 0

Commande manuelle de capacité de compresseur (avec ON la valeur de «

c31 » est utilisée)

Le seuil pump down. La valeur limite quand le dernier compresseur a été

débrayé

Bande proportionnelle Xp pour la régulation de condensation (P = 100/

Xp)

I: Temps d’intégration Tn pour la régulation de condensation n05 30 s 600 s 150

Capacité de condenseur enclenchée en mode manuel. Voir aussi « n 53 » n52 0% 100% 0

Commande manuelle de capacité de condenseur (avec ON la valeur de «

c52 » est utilisée)

Vitesse de démarrage. La tension de la régulation de vitesse est maintenue à 0 V, jusqu’à ce que la régulation exige une valeur supérieure à celle

qui était dénie

Vitesse min. La tension de la régulation de vitesse passe à 0 V, quand la

régulation exige une valeur inférieure à celle qui était dénie

Alarme

Temporisation de l’alarme A32 A03 0 min. 90 min. 0 min.

Limite inférieure d’alarme et de protection pour P0 A11 -99°C / -1.0 bar 30°C / 40 bar -40°C / 0.5 bar

Temps de retard d’une alarme DI1 A27 0 min. (-1=OFF) 999 min. OFF

Temps de retard d’une alarme DI2 A28 0 min. (-1=OFF) 999 min. OFF

Temps de retard d’une alarme DI3 A29 0 min. (-1=OFF) 999 min. OFF

Limite supérieure d’alarme et de protection pour Pc A30 -10 °C / 0.0 bar 200°C / 200.0 bar 60.0°C / 60.0 bar

Limite supérieure d’alarme pour la sonde « Saux1 » A32 1°C (0=OFF) 140°C OFF

Temps de retard d’une alarme P0 A44 0 min. (-1=OFF) 999 min. 0 min.

Temps de retard d’une alarme Pc A45 0 min. (-1=OFF) 999 min. 0 min.

Divers

Adresse du régulateur o03* 1 990

Commutateur ON/OFF (message broche service) o04* - Code d’accés o05 1 (0=OFF) 100 OFF

Type de sonde installé pour Sc3, Sc4 et “Saux1”

0=PT1000, 1=PTC1000

2-7 = variations avec la sonde de température sur P0 et Pc. Voir le manuel

page 21.

Choisir la fréquence d’alimentations o12 50 Hz 60 H 0

Commande manuelle des sorties :

0: Aucune régulation

1-10: 1 enclenche le relais n* 1, 2 le relais n* 2 et ainsi de suite.

11-18: Donne un signal de tension sur la sortie analogique. (11 donne

1,25 V et ainsi de suite par crans de 1,25 V.)

P0-Plage du transmetteur de pression, valeur min. o20 -1 bar 0 bar -1.0

P0-Plage du transmetteur de pression, valeur max. o21 1 bar 200 bar 12.0

Utilisation de l’entrée DI4

0 = inutilisée 1 = décalage P0 2 = fonction d’alarme Alarme = « A31 »

Temps de marche relais 1 (valeur multipliée par 1000) o23 0.0 h 99.9 h 0.0

Temps de marche relais 2 (valeur multipliée par 1000) o24 0.0 h 99.9 h 0.0

Temps de marche relais 3 (valeur multipliée par 1000) o25 0.0 h 99.9 h 0.0

Temps de marche relais 4 (valeur multipliée par 1000) o26 0.0 h 99.9 h 0.0

c16 1 8 0

c29 0/OFF 14 0

c32 OFF ON OFF

c33 -99.9°C / -1.0 bar 100°C / 60 bar 100°C / 60 bar

n04 0.2 K / 0.2 bar 40.0 K / 10.0 bar 10.0 K / 3.0 bar

n53 OFF ON OFF

n54 0% 75% 20%

n55 0% 50% 10%

o06 0 7 (1) 0

o18 0 18 0

o22 0 2 0

* Ce réglage n'est possible qui si un module de transmission de données est installé dans le régulateur.

AK-PC 520 Instructions RI8NM252 © Danfoss 12/2009 27

Dénition du réfrigérant

1=R12. 2=R22. 3=R134a. 4=R502. 5=R717. 6=R13. 7=R13b1. 8=R23.

9=R500. 10=R503. 11=R114. 12=R142b. 13=utilisateur. 14=R32. 15=R227.

16=R401A. 17=R507. 18=R402A. 19=R404A. 20=R407C. 21=R407A.

22=R407B. 23=R410A. 24=R170. 25=R290. 26=R600. 27=R600a.

28=R744. 29=R1270. 30=R417A. 31=R422A.

Utilisation de l’entrée DI5

0 = inutilisée 1 = décalage Pc 2 = fonction d’alarme Alarme = « A32 »

Pc-Plage du transmetteur de pression, valeur min. o47 -1 bar 0 bar -1.0

Pc-Plage du transmetteur de pression, valeur max. o48 1 bar 200 bar 34.0

Relever la température du capteur "Saux1" o49 °C

Temps de marche relais 5 (valeur multipliée par 1000) o50 0.0 h 99.9 h 0.0

Temps de marche relais 6 (valeur multipliée par 1000) o51 0.0 h 99.9 h 0.0

Temps de marche relais 7 (valeur multipliée par 1000) o52 0.0 h 99.9 h 0.0

Temps de marche relais 8 (valeur multipliée par 1000) o53 0.0 h 99.9 h 0.0

Choix d’application

1. L'achage de température

2: L'achage de pression

Fonction de sortie relais DO9 :

0. Début/Arrêt de commande de vitesse

1. Fonction arrêt détendeurs commandes d’évaporateur

2. Fonction booster autorisée (au moins un compresseur est en marche)

3. Début/Arrêt de ventilateur de condenseur

Fonction de sortie relais DO10 :

0. Relais d’alarme

1. Début/Arrêt de ventilateur de condenseur

Dénition du message d’alarme en signal DI1 :

0. Ne s’utilise pas

1. Défaut ventilateur (A34)

2. DI1 alarme (A28)

Réglages pour une application de refroidisseur de liquide.

Dénition de l’entrée de signal pour la régulation de compresseur en cas

de régulation avec un signal de température

0. Sonde de température à borne 57-58

1. Sonde de température Saux

2. Sonde de température Sc4

S’il faut une protection antigel, le réglage doit se faire sur 1 ou 2 :

Connexion d’achage

O : EKA 164

On : EKA 165 (achage amélioré avec Leds)

Service

État d’entrée DI1 u10

État d’entrée DI2 u37

Relever la température du capteur "Sc3" u44 °C

Relever la température du capteur "Sc4" u45 °C

État d’entrée DI3 u87

État d’entrée DI4 u88

État d’entrée DI5 u89

o30 0 31 0

o37 0 2 0

o61 1 2 1 2 1

o75 0 3 0

o76 0 1 0

o78 0 2 0

o81 0 2 0

o82 O On O

Les messages peuvent être sollicités à l’achage par une courte pression

sur le bouton supérieur. S’il y a plus d’une alarme, elles peuvent être «

déroulées »

Réglage départ usine

Pour retrouver éventuellement les valeurs réglées en usine, procéder

ainsi :

- Couper la tension d’alimentation du régulateur.

- Maintenir les boutons supérieur et inférieur enfoncés en remettant le

régulateur sous tension.

28 Instructions RI8NM252 © Danfoss 12/2009 AK-PC 520

Le régulateur peut émettre les messages suivants :

E1 Message

d’erreure

E2

A2 Message

d’alarme

A11 Omission du choix de réfrigérant

A17 Pc haut

A19 Compresseur 1 erreur

A20 Compresseur 2 erreur

A21 Compresseur 3 erreur

A22 Compresseur 4 erreur

A27 Alarme température intérieure (Saux1 temp.)

A28 Alarme DI1. La borne 46 est ouverte

A29 Alarme DI2. La borne 47 est ouverte

A30 Alarme DI3. La borne 49 est ouverte

A31 Alarme DI4. La borne 50 est ouverte

A32 Alarme DI5. La borne 52 est ouverte

A34

A45 La régulation a été arrêtée

S0 Message

d'etat

S2 Attente « c01 »

S5 Attente "c07"

S8 Attente "c11" ou "c12"

S9 Attente "c14" ou "c15"

S10