Page 1

User Guide

Capacity controller for dry cooler

AK-PC 420

ADAP-KOOL® Refrigeration control systems

Page 2

Introduction

Application

The controller is used for capacity regulation of a dry cooler

including fans, three-way valve and pumps.

Advantages

• Complete dry cooler control

• Several combination options for sensor selection

• Heat recovery acc. to external voltage signal.

Regulation

Capacity regulation can include fans combined with a three-way

valve or just fans. The following sensor signals can be used in

regulation:

• Condensing pressure Pc

• Brine temperature S7, located immediately after the three-way

valve outlet

• Brine temperature S8, located by the outlet from the dry cooler

• Outdoor temperature sensor Sc3, located by the air inlet to the

dry cooler.

• Either S7, Pc or S8 can be used as a regulation sensor.

Functions

• Three-way valve control

• Speed regulation or step-by-step coupling of up to six fans

• Safety monitoring of fans

• Overriding of reference acc. to external voltage signal or outdoor

temperature

• Separate reference for heat recovery

• Control and monitoring of twin pumps

• Monitoring of ow switch

• Contact inputs to alarms

• External start/stop of regulation

• Data communication via extra module

Operation

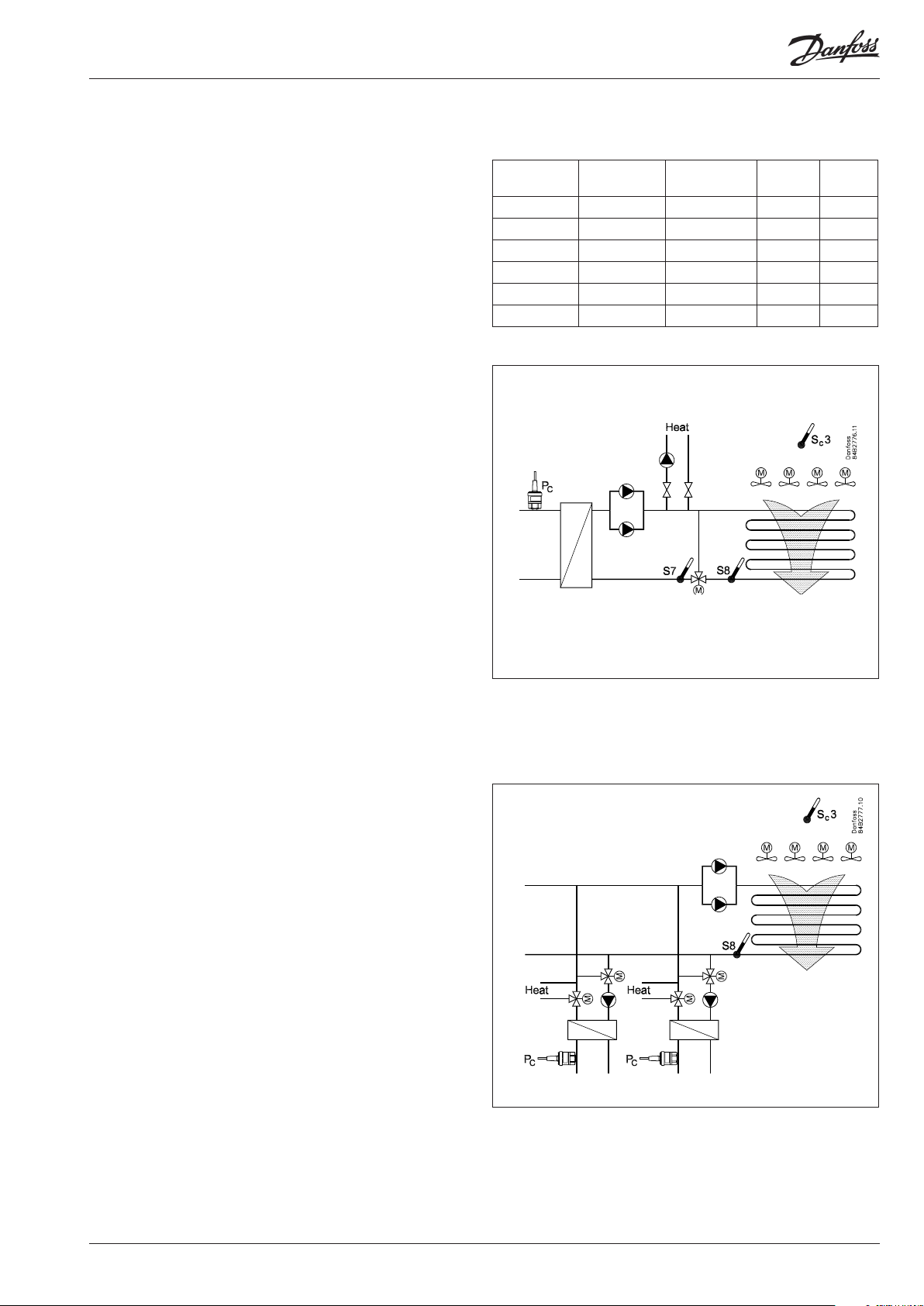

All operation takes place either via data communication or via

connection of a display type EKA 164 .

Contents

Introduction ....................................................................................................... 2

Function ............................................................................................................... 3

Survey of functions .......................................................................................... 8

Operation .......................................................................................................... 13

Menu survey .....................................................................................................14

Connections ..................................................................................................... 16

Data ..................................................................................................................... 17

Ordering ............................................................................................................17

Montage ............................................................................................................ 17

Appendix - Reference and regulation .....................................................18

2 Manual RS8EL402 © Danfoss 03-2010 AK-PC 420

Page 3

Function

Application

Regulation sensor and system type are selected via one single setting. The setting will dene both the regulation sensor, if a threeway valve is being used, and how the fans are to be controlled.

The fans are controlled either in steps or together with a speed

control. If steps are used, up to six fans can be controlled.

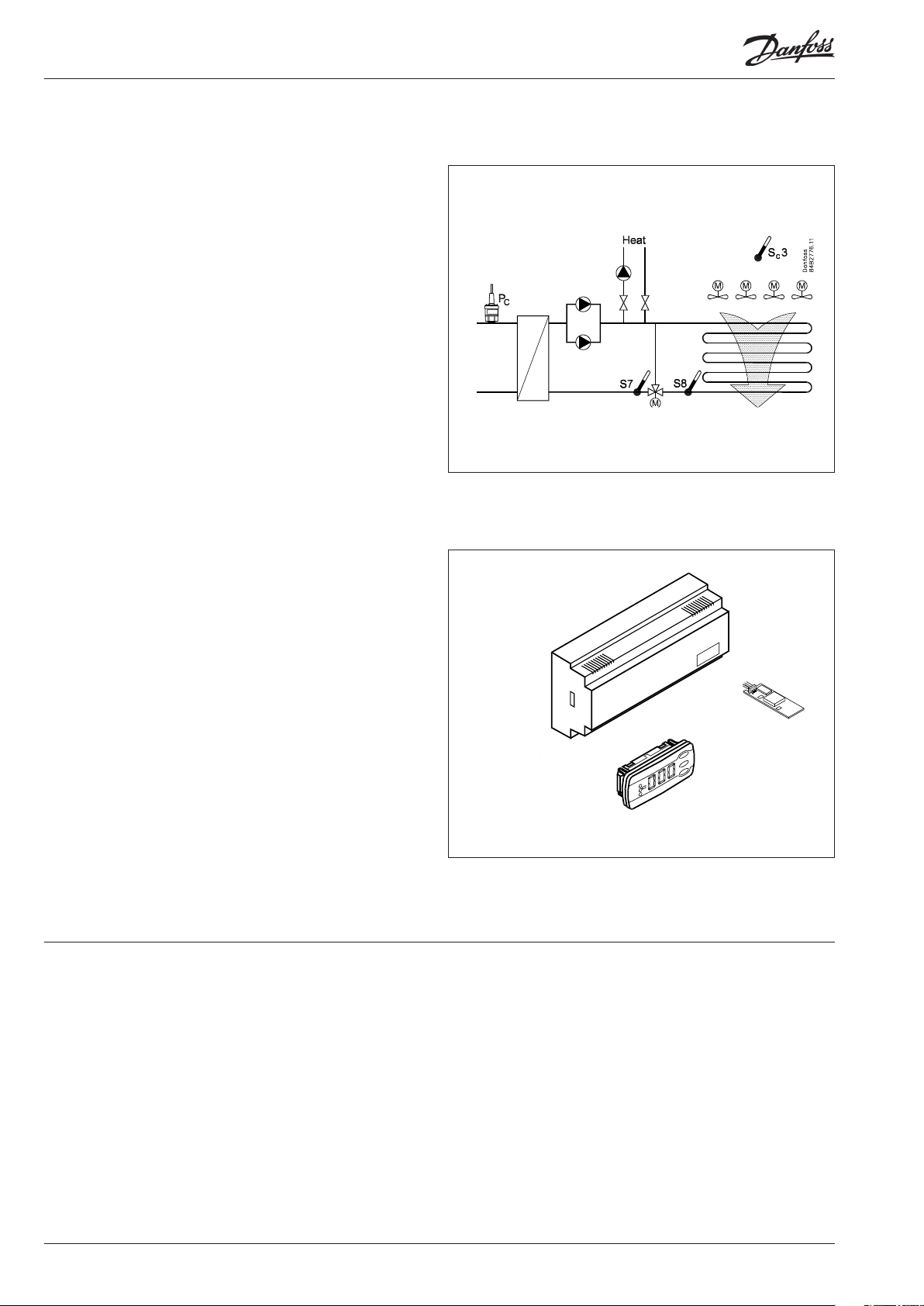

Application 1-4

The capacity here is controlled via the fans combined with a threeway valve.

Applications 1 and 2 use brine return temperature S7 at the

three-way valve outlet as regulation sensor and the fan capacity is

controlled either in steps or via speed control.

The S8 sensor, which is tted to the dry cooler’s outlet should be

used in the control if there is a large distance between the dry

cooler and the three-way valve. Use of the S8 sensor will provide

more robust regulation, which takes long pipe lengths into account. The S8 sensor must be tted close to the dry cooler’s outlet.

Regulation

(o61)

1 S7 S8 (P + PI) x Step

2 S7 S8 (P + PI) x Speed

3 Pc S7 / S7+S8 (PI) x Step

4 Pc S7 / S7+S8 (PI) x Speed

5 S8 Step

6 S8 Speed

Regulation

sensor

Optional

sensor

3-way

valve

Fan

control

Applications 3 and 4 use brine condensation pressure Pc as regulation sensor and the fan capacity is controlled either in steps or via

speed control.

For PI control the use of the S7 and S8 sensors is optional but they

should be tted if there is a large distance between the dry cooler

and the three-way valve. Use of the sensors will provide more

robust regulation, which takes long pipe lengths into account. The

S8 sensor must be tted close to the dry cooler’s outlet.

For P control the S7 and S8 sensors are not used in the regulation,

but they can be tted to ensure that the emergency control functions in the even of the Pc signal failing.

Applications 5-6

Here the capacity is controlled via step-by-step coupling or speed

control on the basis of the dry cooler’s discharge temperature S8.

This application is used in particular when another controller takes

care of the regulation of the three-way valve, e.g. to cool several

parallel-coupled condensers.

NB.

The sensors Pc and S7 must not be located in positions other than

those specied, as they are used for emergency regulation if the

primary regulation sensor develops a fault.

The S8 sensor can be located in a dierent position than the one

indicated if it is not used in the control.

If the S8 sensor is required in the control, the setting "o96, S8

optional" must be selected as ON.

If the S8 sensor is not used in the regulation, it can be located

anywhere.

AK-PC 420 Manual RS8EL402 © Danfoss 03-2010 3

Page 4

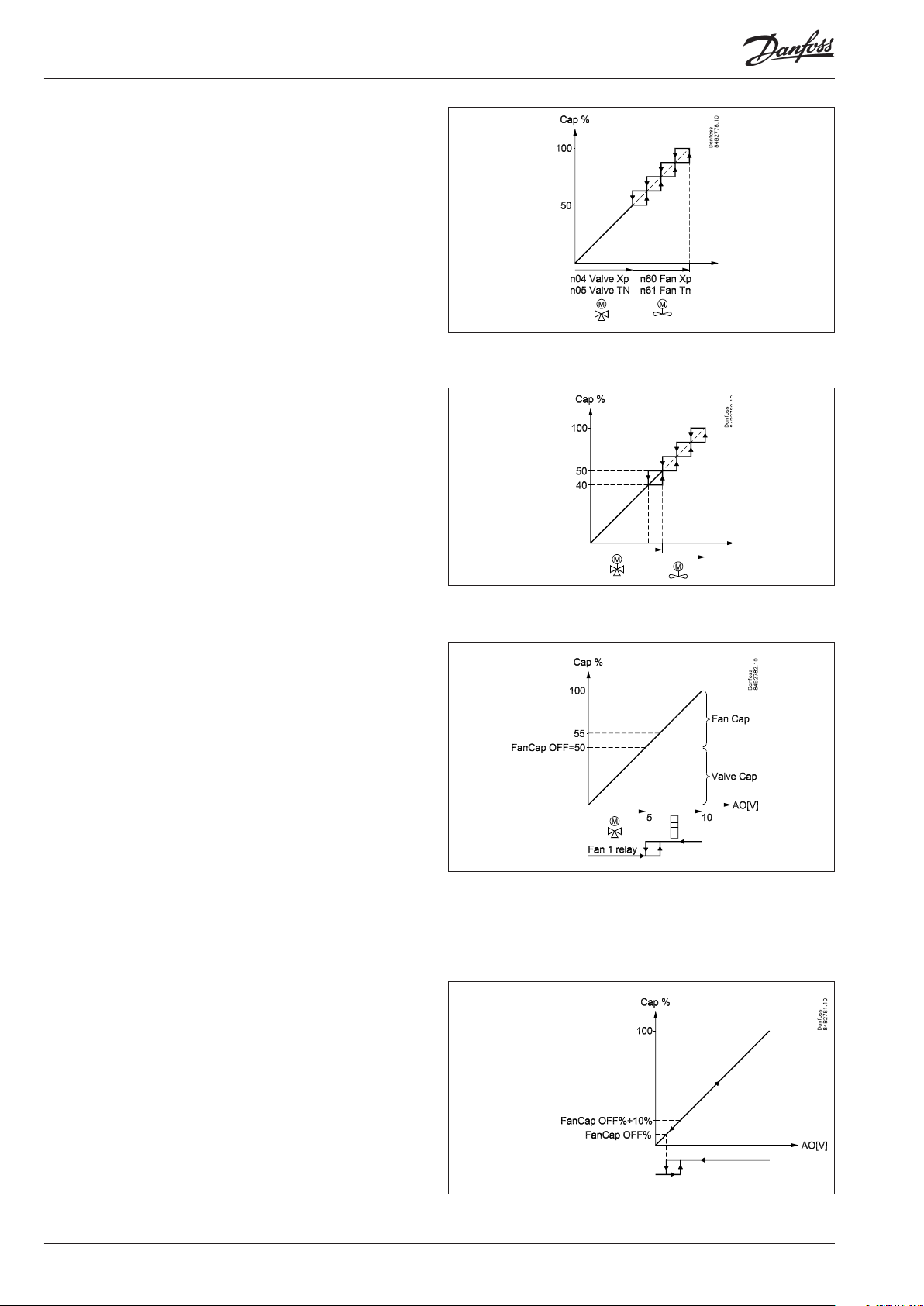

Capacity regulation

Three-way valve + step-by-step coupling of fans (applications 1 and 3)

Capacity regulation takes place via a P or PI regulation, which controls the three-way valve and subsequent step-by-step coupling of

the fans.

First of all regulation takes place on the three-way valve via the analogue output. The output can be set at 0-10 V or 10-0 V, depending on which valve function is desired. Only when the three-way

valve is fully open do the fans start up.

The capacity of the three-way valve is 50% of the total capacity.

The P/PI controller has separate regulation settings (proportional

band and integration time) for the three-way valve and the fans

respectively.

Capacity overlap – start of fans

As mentioned above, the three-way valve comprises a xed 50% of

the total capacity. In some systems it may be necessary to start the

fans slightly before (or slightly after) the three-way valve has been

fully opened. An overlap is created here between the three-way

valve and the start of the fans. This is done by changing the setting

“FanCap OFF%” from 50% to, for example, 40% (the setting denes

the capacity at which the last fan stops). In this case the fans are

started before the three-way valve is fully open.

Three-way valve + speed control of fans (applications 2 and 4)

Capacity regulation takes place via a P or PI regulator, which

controls the three-way valve and subsequent speed control of

the fans. Here the analogue output signal is divided between the

three-way valve and the frequency converter (50% of the analogue output signal is always used for the three-way valve), i.e.

if the analogue output signal is set at 0-10V, 0-5 V is used for the

three-way valve.

The frequency converter/fans are controlled via the relay output

for fan 1 on the basis of the setting “FanCapOFF%”.

In the event of falling capacity, the relay output for fan 1 will be

disabled when the actual capacity has fallen to “FanCap OFF%”.

To achieve hysteresis when starting/stopping the frequency converter, the relay output for fan 1 will, when capacity is increasing,

be enabled when the desired capacity is “FanCap OFF%” + “10%

fan capacity”.

If “FanCapOFF%” is set at above or below 50%, the frequency

converter can be started after or before the three-way valve is fully

opened.

The P/PI controller has separate regulation settings (proportional

band and integration time) for the three-way valve and the fans

respectively.

Fan control only (applications 5 and 6)

Capacity regulation takes place via a P or PI regulator, which controls the fans either with step-by-step coupling or speed control.

The analogue output and a frequency converter are used for

speed control. The relay output for fan 1 is used to start/stop the

frequency converter.

In the event of falling capacity, the relay output for fan 1 will be

disabled when the actual capacity has fallen to “FanCap OFF%”.

To achieve hysteresis when starting/stopping the frequency converter, the relay will become enabled when the desired capacity

is the fan capacity above “FanCap OFF%” ( The 10% fan capacity

will correspond to hysteresis of 1 V in the analogue output signal,

when the signal is 0-10 V.)

The P/PI controller only uses regulation settings (proportional

band and integration time) for the fans.

4 Manual RS8EL402 © Danfoss 03-2010 AK-PC 420

Page 5

Linear/non-linear capacity curve for fans

The rst fan step provides relatively more capacity than the subsequent capacity steps. The increase in capacity that an extra step/

speed will generate falls gradually, as more and more steps are

connected/the speed is increased.

The fan regulation therefore has a crooked capacity curve, which

provides optimal reinforcement at both high and low capacities.

However, for some systems a straight curve is required for capacity

regulation, e.g. if the analogue signal is used for more than controlling fans. In this instance the capacity curve can be set at linear.

(The capacity curve for the three-way valve will always be straight.)

Step-by-step coupling of fans

The fans can either be connected in the sequence dened for

them (sequentially) or they can be connected in rotation (sequentially with alternating start).

In sequential operation all fans are enabled at least once every 24

hours, so no fan rusts up due to being inactive for a longer period

of time.

In rotation the various fans take turns in being rst.

Monitoring fans

The controller must receive a signal of the status of each dened

condenser step’s safety circuit. The signal is taken directly from the

safety circuit and connected to a “DI” input.

If the safety circuit is broken, the controller will lose the signal and

emit an alarm.

The associated relay output will not be disconnected. The reason

is that fans are often connected in pairs, but with one single safety

circuit. If there is a fault in one fan, the other will continue to operate.

If no monitoring is desired, the input must be permanently wired

at 24 V.

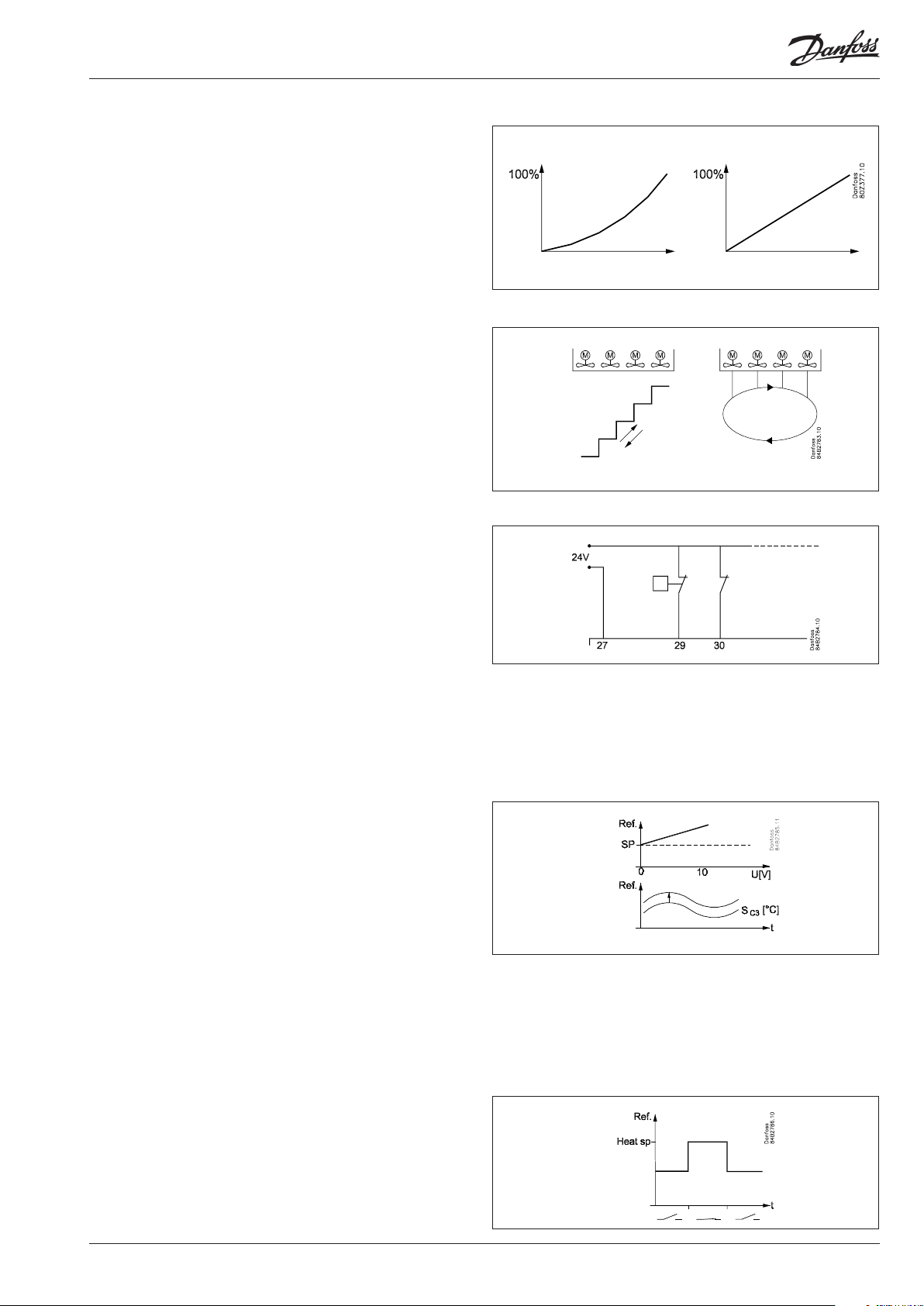

Reference

Regulation reference

The regulation reference can be dened in one of the following

two ways:

• Fixed setting

The set point for the regulation sensor is set in °C.

If displacement is required, the reference can be displaced

with a 0-10 V signal. During setup you dene how great the

displacement is to be at the signal’s max. and min. value.

• Floating reference according to outdoor temperature

This function allows the reference to vary according to the

outdoor temperature within a dened range.

The outdoor temperature is measured with the Sc3 sensor,

and the reference will always fall within a xed value (min. tm)

above the measured outdoor temperature.

Heat recovery

When heat recovery is enabled via the digital input, the reference

will switch to another set point “Heat SP”, although this too can

be overridden via the external 0-10 V signal. At the same time the

relay for heat recovery is enabled, which then transmits a signal to

either a pump or a valve. The reference's max. value (r30) is overriden from the set value to 99.9° C.

If heat recovery is in progress and the temperature by the regulation sensor is lower than the reference’s set minimum value, the

following happens (see also the following section on limiting the

reference):

AK-PC 420 Manual RS8EL402 © Danfoss 03-2010 5

Page 6

The heat recovery relay is disconnected and can only be re-enabled once the temperature by the regulation sensor has reached 2

K above the reference’s minimum setting.

Ramp function

To avoid overswing and underswing of the reference, a ramp

function has been included to guarantee that the reference cannot

change more quickly than the preset ramp in Kelvin/minute.

Limitation of reference

To protect against regulation reference that is too high or too low,

a limit must be set for the reference. The limit is valid under normal

regulation, but is increased during heat recovery to 99.9° C.

The upper limit is always an absolute value. The lower limit can

either be an absolute value or it can vary in accordance with the

outside temperature Sc3 whereby the limit has a xed value ("r56,

Min tm") above the outside temperature. This means that a reference below the minimum value, making all fans run continuously,

can be avoided.

Ref. Max.

Ref. Min.

Ref. Max.

P or PI regulation with oating or xed reference

See appendix.

Safety functions

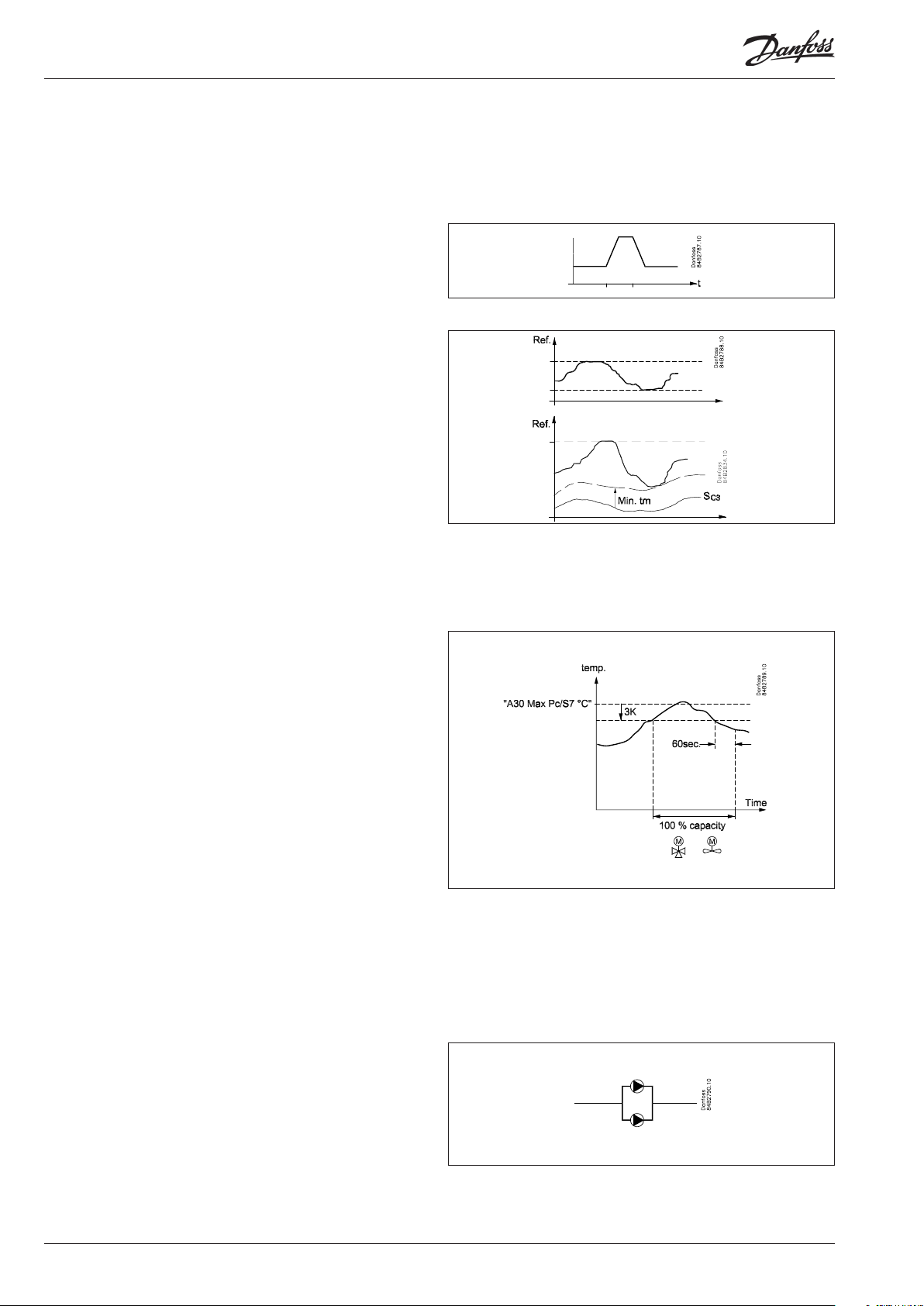

Monitoring of condensation pressure

The controller has a safety function that provides protection

against the condensation pressure being too high.

The function can be enabled in two ways.

• Digital input - HP safety

When the digital input is connected, full capacity is cut in to

both fans and three-way valve. An alarm is emitted at the same

time.

The capacity remains cut in until the digital input is interrupted, at which point the alarm is also cancelled. The digital

input can possibly be connected to an external safety pressure

control.

• Measuring the Pc/S7 temperature

This function always uses condensation pressure Pc if the

pressure signal is connected. If Pc is not tted, brine return

temperature S7 is used instead.

The function cuts in all condenser steps and emits an alarm

if the measured temperature is higher than 3 K below the set

limit “S7/Pc max ”.

Normal capacity regulation is restored when the temperature

(pressure) has once more fallen to 3 K below the limit, and a

delay time of 60 seconds has passed.

Ref. Min.

Pump controL

The controller can control and monitor one or two pumps that

circulates the brine.

If two pumps are used and operating time equalisation is selected,

the controller can also execute a switch between the two pumps if

operating alarms occur.

Pump selection is performed using the following settings:

0: Both pumps are stopped

1: Pump 1 is started

2: Pump 2 is started

3: Both pumps are started

4: Automatic switch between the pumps is permitted. Start before

stop

5: Automatic switch between the pumps is permitted. Stop before

start

6 Manual RS8EL402 © Danfoss 03-2010 AK-PC 420

Page 7

Automatic switch between the pumps. Start before stop

(only for setting = 4)

This setting allows a rotation between the two pumps, enabling a

kind of operating time equalisation. The period time between the

pump switches can be set as “p37 PumpCycle”.

When switching, the pump will be kept running for the time “p36

PumpDel” until it stops.

Automatic switch between the pumps. Stop before start

(only for setting = 5)

This setting allows a rotation between the two pumps, enabling a

kind of operating time equalisation. The period time between the

pump switches can be set as “p37 PumpCycle”.

When switching, the pumps will be stopped in the time "p36

PumpDel".

Monitoring pumps

The controller monitors the pumps’ operation via the safety input

“Flowswitch”. The signal may, for example, originate from a pressure dierence pressure switch or a ow switch.

Also set a delay time to dene how the alarm is to be activated.

The delay time is the time from when the input loses the signal

until the controller emits an alarm and executes a pump switch if

necessary.

Special information about operating time equalisation

If the pumps are operating with operating time equalisation, the

controller can perform a switching of the pumps in the event of

a lack of ow (however, the pump switch will only be performed

when the delay time on the alarm has expired).

Depending on whether the pump switch recties the alarm situation or not, the following happens:

1) The pump switch recties the alarm situation

If the pump switch recties the alarm situation, the non-faulty

pump, which is now in operation, will run until the normal cycle

time has expired. It then switches back to the “faulty pump”, as

it is assumed that this has been repaired. At the same time the

alarm situation is reset (the alarm is acknowledged).

If the “faulty pump” has not been repaired, another alarm will be

triggered and cause one more switch to the non-faulty pump.

This is repeated until the situation has been rectied.

2) The pump switch does not rectify the alarm situation

If, however, the alarm is still active after the pump switch, the

controller will also emit an alarm for the other pump. At the

same time both pump outputs are enabled in an attempt to

create sucient ow for the alarm situation to be rectied. The

controller will then have both pump outputs enabled until the

normal cycle time has expired. A normal pump switch is then

conducted and the active alarms are reset.

Separate alarm priorities can be set for the failure of one pump

and the failure of both pumps. See section entitled “Alarms and

messages”.

AK-PC 420 Manual RS8EL402 © Danfoss 03-2010 7

Page 8

Survey of functions

Function Para-

meter

Normal display

If the two displays are mounted:

The regulation temperature is displayed on EKA 164 (the one with buttons) (Pc or S7

or S8)

Pc will be shown on EKA 163. Both readouts will be in temperature

Reference Condenser control

Unit

Here you can select whether the display is to indicate temperatures in °C or °F

0: Will give °C / bar

1: Will give °F / psig

Start/stop of refrigeration

Start/stop of refrigeration may also be performed with an external contact function

connected to the input named “ON input”. (The input must be wired).

Set point

When “r33 ctrl.mode” is set at 1 or 3, it is regulated according to the set value + a possible displacement from a 0-10 V signal.

See also page 18.

Reference variation. See also page 18.

Regulation with setting 1 (or 2 if the reference is to vary with the outdoor temperature) will give the best regulation if the system is in balance. But if a lot of fans are

connected, it may be necessary to select setting 3 instead (or 4, if there is regulation

with the outdoor temperature). (Settings 3 and 4 will generally be preferable if a oset can be accepted between the reference and the actual regulation temperature)

1: No change of the reference. Regulation based on set setpoint + displacement with

a 0-10 V signal.

If there is a heat recovery signal, the reference will switch to the preset set point in

"r64".

2: Outdoor temperature forms part of the reference. The outdoor temperature is

measured with Sc3 sensor and the reference will always have a xed value “r56 Min

tm K” over the measured outdoor temperature.

If there is a heat recovery signal, the reference will switch to the preset set point in

"r64".

Setting 1 and 2 operate with a PI regulation, but if the system is unstable and the PI

regulation not satisfactory the I element may be left out, so that the controller will be

with P regulation only.

3: As 1, but with P regulation (xp-band)

4: As 2, but with P regulation (xp-band)

5: As for 1, but with a minimum reference limit in accordance with outdoor tempera-

ture Sc3

6: As for 3, but with a minimum reference limit in accordance with outdoor temperature Sc3

Reference

The regulation reference is shown here.

Set point limitation

With these settings the setpoint can only be set between the two values.

(This also applies to regulations where the Xp band lies above the reference).

Max. permissible setpoint value. (Is set as an absolute value)

Min. permissible setpoint value. (Is set as an absolute value when "r33" = 1-4)

Correction of pressure measurement Pc

An oset adjustment of the registered pressure can be made.

Dimensioning temperature Min tm

The mean temperature dierence across the condenser at low capacity (tm dierence at max. load). This is the temperature dierence between the air and condensing

temperature.

When “r33 Ctrl. Mode” is set at 2 or 4, regulation takes place according to a reference

that is “Min tm” over the measured outdoor temperature.

Reading of regulation temperature

This is where you can see the actual temperature being measured by the sensor chosen for capacity regulation. The value is displayed in °C.

Set point value for heat recovery

When a heat recovery signal is received, regulation takes place according to the value

set here + any displacement via 0-10 V signal.

Average value for reference changes

A switch in the reference will be ramped up or down over this period of time. Set in

Kelvin/minute.

Parameter by operation via

data communication

S7 °C

Pc °C

S8 °C

r05 Unit

(In AKM only °C is used, whatever the

setting)

r12 Main Switch

r28 Set Point °C

r33 Ctrl. mode

r29 Ref. °C

r30 RefMax °C

r31 RefMin °C

r32 AdjustPc

r56 Min tm K

r58 Ctrl temp

r64 Heat SP°C

r65 RefRamp

8 Manual RS8EL402 © Danfoss 03-2010 AK-PC 420

Page 9

Reference displacement at max. signal (Ext. ref.)

Here the value is set by which the reference is to be displaced when the input signal

Ext. ref. is max. (10 V).

Reference displacement at min. signal (Ext. ref.)

Here the value is set by which the reference is to be displaced when the input signal

Ext. ref. is min. (0 V).

Correction of signal from S7

Compensation possibility due to long sensor cable

Correction of signal from S8

Compensation possibility due to long sensor cable

Condenser capacity Condenser cong.

Denition of condenser and number of fans (may only be set if step-by-step

coupling is being run, i.e. “o61 Applic mode” is set at 1, 3 or 5).

Here you set how many fan steps are to be used for regulation (to max. 6).

1-6: All fans are connected with relays. Relay 1 is assigned fan 1, the next one number

2, etc.

7-10: Not used

11-16: Total number of fan relays (as 1-6), but here the starting sequence is altered

after each time all fans have been stopped.

NB

The controller must receive a signal of the status of each condenser step’s safety

circuit. The signal must be connected to the associated DI input.

Denition of output voltage to valve/speed control

Output signal is 0-10 V or 10-0 V. The signal can be either linear or un-linear, so that it

can be adapted to the desired characteristics.

1: 0-10 V, linear

2: 10-0 V linear (not at shunt and fan speed)

3: 0-10 V, unlinear

4: 10-0 V unlinear (not at shunt and fan speed)

Regulation parameters

r68 ExtRefMax

r69 ExtRefMin

r72 Adjust S7

r73 Adjust S8

c29 Fan mode

c34 AO type

- - - - Cond Cap %

Read cut-in condenser capacity

Proportional band xp for valve regulation (P = 100/Xp)

If the Xp value is increased, the regulation becomes steadier

I: Integration time Tn for valve regulation

If the Tn value is increased, the regulation becomes steadier

Manual control of condenser capacity

This sets the capacity that is to be cut in when switching to manual control.

Manual control

Manual control of the condenser capacity is enabled here.

When set to ON, the capacity that is specied in “n52” is cut in.

The setting will fall back to “O” if the Main switch is set to O or if there is a power

outage.

P: Proportional band xp for fan regulation (P = 100/Xp)

If the Xp value is increased, the regulation becomes steadier

I: Integration time Tn for fan regulation

If the Tn value is increased, the regulation becomes steadier

Capacity overlap between valve and fans

In valve regulation the rst 50% of the capacity is controlled by the valve. When the

valve is fully open continues with fan cut-in.

The fans then take over.

If the fans are to start before the three-way valve is fully open, a value must be set

that is lower than 50%.

If the fans are only to start after the three-way valve is fully open, a value must be set

that is higher than 50%.

Alarm Alarm settings

The controller can give alarm in dierent situations. When there is an alarm the lightemitting diodes (LED) will ash on the display and the alarm relay will cut in.

Pc max. (Alarm and safety function, see also page 18.)

Here you set when the alarm at too high condensing pressure is to enter into eect.

The value is set as an absolute value.

Alarm delay DI1 (an interrupted input will give alarm).

The time delay is set in minutes. At min. setting the alarm is cancelled.

n04 Valve Xp K

n05 Valve Tn s

n52 ConManCap%

n53 ConManCap

n60 Fan XP K

n61 Fan Tn s

n62 FanCap OFF %

A30 Max. Pc. / S7

A27 DI1AlrmDelay

AK-PC 420 Manual RS8EL402 © Danfoss 03-2010 9

Page 10

Alarm delay DI2 (an interrupted input will give alarm).

The time delay is set in minutes. At min. setting the alarm is cancelled.

Alarm delay DI3 (an interrupted input will give alarm).

The time delay is set in minutes. At min. setting the alarm is cancelled.

Pump alarm delay

The time delay is set in seconds. At min. setting the alarm is cancelled.

Give the top button a brief push to zeroset the alarm and to have the message shown

on the display.

Miscellaneous Miscellaneous

Choice of application

The regulator can be congured in various ways. The application that is required out

of the six applications available is set here.

1: S7 + 3-way valve + Step of fans

2: S7 + 3-way valve + VSD (speed) of fans

3: Pc + 3-way valve + Step of fans

4: Pc + 3-way valve + VSD (speed) of fans

5: S8 + Step of fans

6: S8 + VSD (speed) of fans

Sensor type (Sc3, S7 and S8)

Normally a Pt1000 sensor with great signal accuracy is used for temperature measurement. But a PTC sensor may also be used (r25 = 1000) in special situations.

0=Pt1000

1=PTC1000

Pressure transmitter’s working range

Depending on the pressure, a pressure transmitter with a given working range is

used. This working range must be set in the controller (e.g.: -1 to 34 bar

The values must be set in bar if display in °C has been selected. And in psig, if °F has

been selected.

Pc-Min. value o47 PcMinTrsPres

A28 DI2AlrmDelay

A29 DI3AlrmDelay

A63 Pump Al. Del

Reset alarm

The function zerosets all alarms when

set in pos. ON.

With data communication the importance of the individual alarms can be

dened. Setting is carried out in the

“Alarm destinations” menu.

o61 Applic.Mode

o06 Sensor type

If the values are to be set from the

AKM programme, they must be set in

bar.

Pc-Max. value o48 PcMaxTrsPres

Use of DI4 input

The digital input can be connected to a contact function, and the contact can now be

used for one of the following functions:

Setting / function:

0: DI input not used

1: Safety signal from high-pressure pressure control. If the signal is cut o, all capacity

is cut in. There is no time delay.

Operating hours

The operating hours for the pomp relays can be read and set in the following menus.

The read value is multiplied by 1000 to obtain the number of hours (fx. shows 2.1 for

2100 hours). On reaching 99.9 hours the counter stops and must now be reset to, say,

0. There will be no alarm or error message for counter overow.

Value for relay number 7 (pump 1) o52 DO7 run hour

Value for relay number 8 (pump 2) o53 DO8 run hour

Refrigerant setting (only if a Pc pressure transmitter is tted)

Before refrigeration is started, the refrigeration must be dened. You may choose

between the following refrigerants:

1=R12. 2=R22. 3=R134a. 4=R502. 5=R717. 6=R13. 7=R13b1. 8=R23. 9=R500.

10=R503. 11=R114. 12=R142b. 13=User dened. 14=R32. 15=R227. 16=R401A.

17=R507. 18=R402A. 19=R404A. 20=R407C. 21=R407A. 22=R407B. 23=R410A.

24=R170. 25=R290. 26=R600. 27=R600a. 28=R744. 29=R1270. 30=R417A.

31=R422A. 32=R413A. 33=R422D. 34=R427A. 35=R438A.

Warning: Wrong selection of refrigerant may cause damage to the compressor.

Other refrigerants: Select setting 13 here, and subsequently three factors have to be

set – fac1, fac2 and fac3 – via AKM.

o22 DI4 control

(In the AKM display the hour number

has not been multiplied)

o30 Refrigerant

10 Manual RS8EL402 © Danfoss 03-2010 AK-PC 420

Page 11

Manuel operation (only via display and only when regulation has stopped

(r12=o))

From this menu the relays can be cut in and out manually. 0 gives no override, but a

number between 1 and 10 will cut in a belonging relay. 1 will cut in relay number 1, 2

relay 2, etc.

11-18 will produce voltage on the analog output. Setting 11 will give a voltage of

1.25 V, setting 12 will give 2.5 V, etc.

Frequency

Set the net frequency.

Use of S8 sensor

If application (o61) is selected to 1, 2, 3 or 4, the S8 sensor can be used for regulation

or for monitoring.

The S8 sensor, which has to be located near by the outlet of the dry cooler, should be

used in the regulation if the distance between the dry cooler and the 3-way-valve is

long. If the S8 sensor is want to be used in the regulation set o96 to ON. Is the S8 sensor not used in the regulation it can be located optional for monitoring purpose (o96

has to be set to OFF).

Address

If the controller is built into a network with data communication, it must have an

address, and the master gateway of the data communication must then know this

address.

These settings can only be made when a data communication module has been

mounted in the controller and the installation of the data communication cable has

been completed.

This installation is mentioned in a separate document “RC8AC”.

The address is set between 1 and 240 (gateway determined) o03

The address is sent to the gateway when the menu is set in pos. ON o04

Access code

If the settings in the controller are to be protected by a numerical code, you can set a

numerical value between 0 and 100. If not, you can cancel the function with setting

OFF.

Status on relay outputs

Status on relay 1 (fan 1 or start/stop of speed control) p25 Fan 1 status

Status on relay 2 (fan 2) p26 Fan 2 status

Status on relay 3 (fan 3) p27 Fan 3 status

Status on relay 4 (fan 4) p28 Fan 4 status

Status on relay 5 (fan 5) p29 Fan 5 status

Status on relay 6 (fan 6) p30 Fan 6 status

Status on relay 7 (pump 1) p31 Pump 1

Status on relay 8 (pump 2) p32 Pump 2

Status on relay 9 (Heat recovery) p33 Heat recovery

Status on relay 10 (alarm) p34 Alarm

Pump control

Here you dene how the pumps are to be controlled:

0: Both pumps are stopped

1: Only pump 1 is started

2: Only pump 2 is started

3: Both pump 1 and pump 2 are started

4: Automatic switch between pumps 1 and 2. Start before stop

5: Automatic switch between pumps 1 and 2. Stop before start

Pump-stop delay

During pump switching both pumps can run for a short overlap. Here you set how

many seconds.

Run period in cyclic operation

This is where you set the number of hours the pump will run. You then switch over to

the other pump. Repeat this.

Status on DI 1 u10 DI 1 Status

Status on DI 2 u37 DI 2 Status

Reading temperature at Sc3 sensor u44 Sc3 Status

Status on DI 3 u87 DI 3 Status

Status on DI 4 u88 HP safety

Status on DI 5 u89 Heat recov.

Reading temperature at S8 sensor u93 S8 temp

Status on Flow switch input u94 Flow switch

Read o the actual reference displacement received in the analogue input Ext. Ref. u96 Ext. Ref°C

Read o the value on the analogue output to the valve/frequency converter. u97 AO Volt

Reading temperature at S7 sensor u98 S7 temp

o18 - - -

o12 50 / 60 Hz

(50=0, 60=1)

o96 S8 optional

Following installation of a data communication module, the controller can

be operated on a par with the other

controllers in ADAP-KOOL® refrigeration controls.

o05

p35 Pump ctrl.

p36 Pump del.

p37 Pump cycle

AK-PC 420 Manual RS8EL402 © Danfoss 03-2010 11

Page 12

Operating status

The controller goes through some regulating situations where it is just waiting for the next

point of the regulation. To make these “why is nothing happening” situations visible, you can

Ctrl state

(0 = regulation)

see an operating status on the display. Push briey (1s) the upper button. If there is a status

code, it will be shown on the display. The individual status codes have the following meanings

S10: Regulation stopped with the internal and external start/stop 10

S25: Manual regulation of outputs 25

Alarm messages Alarms "Destinations"

A11: No refrigerant has been selected (cf. o30) A11 No RFG Sel

A17: High Pc A17 Hi Pc alarm

A28, A29, A30: External alarm. Interrupted signal on input "DI1" /2/3 A28 ...... A30 DI_ Alarm

A34, A35, A36, A37, A46, A47: Fan alarm. Fan 1, 2, 3, 4, 5, 6 A34 ...... A37, A46, A47 Fan_fault

A45: Regulation stopped with setting or with external switch A45 Stand by

A77: Interrupted signal on input "Flow switch" while pump 1 was operating A77 Pump 1 fault

A78: Interrupted signal on input "Flow switch" while pump 2 was operating A78 Pump 2 fault

A79: Interrupted signal on input "Flow switch" while pump 1 and 2 were operating A79 PMP1&2 fault

E1: Error in the controller E1 Ctrl. fault

E2: Control signal outside the range (short-circuited/interrupted) E2 Out of range

Safety functions

Criterion Reference / control sensor Capacity

Pc or S7 > Pc/S7 max (A30) - 3 No change 100% capacity until the signal has fallen below the

Pc signal failure S7 is used instead and the reference is lowered 5 K. Normal regulation

S7 signal failure Pc is used instead and the reference is raised 5 K. Normal regulation

Pc and S7 signal failure No change 100% capacity

Sc3 signal failure The oating reference is removed, and regulation takes

place according to the set value for the reference – “r29”.

S8 signal failure No change When using app. 1-4, regulation continues without

limit for 60 seconds.

Normal regulation

S8 sensor.

When using app. 5-6, 100% capacity is cut in.

12 Manual RS8EL402 © Danfoss 03-2010 AK-PC 420

Page 13

Operation

Data communication

If the controller is extended with data communication, the operation can be performed from a system unit. The parameter names

for the functions can be viewed in the right-hand column on

pages 8–12.

The importance of the alarms that are sent can be dened with

the setting: 1 (High), 2 (Medium), 3 (Low) or 0 (No alarm).

Operation via external display

The values will be shown with three digits, and with a setting you

can determine whether the pressures are to be shown in °C or in

°F (bar/psig).

There are two options for the display.

EKA 164

EKA 164

To operate the controller and view the regulation temperature.

If the lowermost key is pressed, the temperature from one of the

other sensors will be shown briey in the display.

Regulation Normal display Alternative view

Regulation sensor (lowermost key)

1 and 2 S7 Pc

3 and 4 Pc S7

5 and 6 S8 S7

EKA 163

The buttons on the display

When you want to change a setting, the upper and the lower

buttons will give you a higher or lower value depending on the

button you are pushing. But before you change the value, you

must have access to the menu. You obtain this by pushing the

upper button for a couple of seconds - you will then enter the

column with parameter codes. Find the parameter code you want

to change and push the middle button. When you have changed

the value, save the new value by once more pushing the middle

button.

EKA 163

If the alternative temperature is to be shown constantly, a display

without operating keys can be connected.

Or short:

1. Push the upper button (long push) until a parameter is shown

2. Push one of the buttons and nd the parameter you want to

change

3. Push the middle button until the setting value is shown

4. Push one of the buttons and select the new value

5. Push the middle button again to conclude the setting

( A brief pushing will show the active alarm codes. See page 15.)

AK-PC 420 Manual RS8EL402 © Danfoss 03-2010 13

Page 14

Menu survey

Conguration parameters can only be set when the regulation is

stopped, r12=0.

SW: 1.2x

Para-

Function

Normal display

A display of the regulated temperature

can be seen in EKA 164. (display with

buttons)

Shows Pc in EKA 163 - °C

Reference

Select unit (0=bar and °C, 1=Psig and

°F)

Start/Stop of regulation r12 OFF ON OFF

Set regulation setpoint r28 -25°C 75°C 30°C

Shows the total reference r29 °C

Limitation: reference max. value r30 -99.9°C 99.9°C 55.0°C

Limitation: reference min. value r31 -99.9°C 99.9°C -99.9°C

Correction of signal from Pc-sensor r32 -50 K 50 K 0.0

Pc reference variation.1 and 2 are PIregulation

1: Fixed reference. “r28” is used

2: Variable reference. Outdoor temperature (Sc3) included in the reference

3: As 1, but with P-regulation (Xp-band)

4: As 2, but with P-regulation (Xp-band)

5: As 1, but with min.-reference acc. to

outdoor temperature

6: As 3, but with min.-reference acc. to

outdoor temperature

The mean temperature dierence

across the condenser at the lowest

relevant capacity (min tm K)

This is where you can see the actual

temperature that is part of the regulation.

Set point settings for heat recovery r64 -25°C 75°C 35°C

Average period for reference changes. r65

Displacement of reference at external

signal = 10 V

Displacement of reference at external

signal = 0 V

Correction of signal from S7-sensor r72 -50 K 50 K 0.0

Correction of signal from S8-sensor r73 -50 K 50 K 0.0

Capacity

Denition of fan relay

1-6: Total number of fan relays in

sequential operation.

7-10: Not used

11- 16: Total number of fan relays in

cyclic operation.

Denition of the analoge output voltage 0-10 V

1: 0-10 V, linear

2: 10-0 V, linear

3: 0-10 V, unlinear

4: 10-0 V, unlinear

Proportional band Xp for (P= 100/Xp)

valve regulation

I: Integration time Tn for valve regulation

Cutin condenser capacity with manual

control. See also “n53”

Min. Max. Fac.

meter

- °C

r05 0 1 0

r33 1 6 1

r56 3.0 50.0 8.0

r58 °C

0.1 K/

min.

r68 -50 K 50 K 0.0

r69 -50 K 50 K 0.0

c29 0/OFF 16 0

c34 1 4 1

n04 0.2 K 40.0 K 10.0 K

n05 30 s 600 s 120

n52 0 % 100 % 0

50

K/min.

sett.

10

K/min.

Manual control of condenser capacity

(when ON, the value in “n52” will be

used)

Proportional band Xp for (P= 100/Xp)

fan regulation

I: Integration time Tn for fan regulation n61 30 s 600 s 240

Denition of where the rst fan is

connected. Set as a % of the total

refrigeration capacity. Ex. 50%, if a

three-way valve is also used.

Alarm

Delay time for a DI1 alarm

Delay time for a DI2 alarm A28

Delay time for a DI3 alarm A29

Upper alarm and safety limit for Pc A30 -10 °C 200°C 60.0°C

Pump alarm delay A63 1 s 600 s 15 s

Miscellaneous

Controllers address o03* 1 990

On/o switch (service-pin message) o04* - -

Access code o05

Used sensor type for Sc3, S7 and S8

0=Pt1000, 1=PTC1000

Set supply voltage frequency o12 50 Hz 60 H 0

Manual control of outputs:

0: No override

1-10: 1 will cut in relay 1, 2 relay 2, etc.

11-18: Gives voltage signal on the

analog output. (11 gives 1.25 V, and so

on in steps of 1.25 V

Use of DI4-input

0=not used. 1=Safety signal from high

pressure pressostat

Setting of refrigerant

1=R12. 2=R22. 3=R134a. 4=R502.

5=R717. 6=R13. 7=R13b1. 8=R23.

9=R500. 10=R503. 11=R114.

12=R142b. 13=User dened. 14=R32.

15=R227. 16=R401A. 17=R507.

18=R402A. 19=R404A. 20=R407C.

21=R407A. 22=R407B. 23=R410A.

24=R170. 25=R290. 26=R600.

27=R600a. 28=R744. 29=R1270.

30=R417A. 31=R422A. 32=R413A.

33=R422D. 34=R427A. 35=R438A.

Pc pressure transmitter’s working range

- min. value

Pc pressure transmitter’s working range

- max. value

Operating hours of relay 7 (value time

1000)

Operating hours of relay 8 (value time

1000)

* this setting is only possible if data communication module is mounted in

the controller

n53 OFF ON OFF

n60 0.2 K 40.0 K 20.0 K

n62 0 % 70 % 50 %

0 min.

A27

(-1=OFF)

0 min.

(-1=OFF)

0 min.

(-1=OFF)

1

(0=OFF)

o06 0 1 0

o18 0 18 0

o22 0 1 0

o30 0 35 0

o47 -1 bar 0 bar -1.0

o48 1 bar

o52 0.0 h 99.9 h 0.0

o53 0.0 h 99.9 h 0.0

999

OFF

min.

999

OFF

min.

999

OFF

min.

100 OFF

200

34.0

bar

To be continued

14 Manual RS8EL402 © Danfoss 03-2010 AK-PC 420

Page 15

Selection of application

Regulation sensor and output are:

1: S7 + 3-way valve + Step of fans

2: S7 + 3-way valve + VSD (speed) of

fans

3: Pc + 3-way valve + Step of fans

4: Pc + 3-way valve + VSD (speed) of

fans

5: S8 + Step of fans

6: S8 + VSD (speed) of fans

Use of S8

On: for regulation

O: for monitoring

Service etc.

Status on relay 1 (fan 1) p25

Status on relay 2 (fan 2) p26

Status on relay 3 (fan 3) p27

Status on relay 4 (fan 4) p28

Status on relay 5 (fan 5) p29

Status on relay 6 (fan 6) p30

Status on relay 7 (pump 1) p31

Status on relay 8 (pump 2) p32

Status on relay 9 (heat recovery) p33

Status on relay 10 (alarm) p34

Pump control:

0: Both pumps stops

1: Pump 1 only

2: Pump 2 only

3: Both pump 1 and pump 2

4: 2 pumps + rotation. Start before

stop

5: 2 pumps + rotation. Stop before

start

Pump setting. Operating time with

two pumps when switching takes

place.

Pump setting. After the operating

time you then switch over to the other

pump.

Status on DI1 input u10

Status on DI2 input u37

Read temperature at sensor "Sc3" u44 °C

Status on DI3 input u87

Status on DI4 input u88

Status on DI5 input u89

Read temperature at sensor "S8" u93

Status on "Flow switch"-input u94

Read reference displacement from the

external signal

Read the value of the analogue output

in V

Read temperature at sensor "S7" u98

o61 1 6 1

o96 O/0 On/1 O/0

p35 0 5 1

p36 0 s 60 s 10 s

p37 1 h 500 h 24 h

u96

u97

The controller can give the following messages

E1 Error

message

E2 Regulation is outside the range, or the control

Alarm

A11

message

A17 High Pc

A28 DI 1 alarm. Terminal 46 interrupted

A29 DI 2 alarm. Terminal 47 interrupted

A30 DI 3 alarm. Terminal 49 interrupted

A34 Fan 1 alarm. Terminal 29 is open

A35 Fan 2 alarm. Terminal 30 is open

A36 Fan 3 alarm. Terminal 31 is open

A37

A45 Regulation stopped

A46 Fan 5 alarm. Terminal 33 is open

A47 Fan 6 alarm. Terminal 34 is open

A77 Pump 1 alarm. Terminal 36 interrupted

A78 Pump 2 alarm. Terminal 36 interrupted

A79 Pump 1 and 2 alarm. Terminal 36 interrupted

Status

S10

message

S25 Manual control of outputs

PS Info

Fault in controller

signal is defective

Refrigerant not selected

Fan 4 alarm. Terminal 32 is open

Refrigeration stopped by the internal or external

start/stop function

Access code is required before you have access to

the settings

Messages can be brought up on the display by briey pressing

the uppermost key. If there is more than one alarm, they can be

scrolled through

Factory setting

If you need to return to the factory-set values, it can be done in

this way:

- Cut out the supply voltage to the controller

- Keep the upper and the lower button depressed at the same

time as you recon nect the supply voltage

Factory settings are indicated for standard units (see code numbers, page 1). Other

code numbers have customized settings.

AK-PC 420 Manual RS8EL402 © Danfoss 03-2010 15

Page 16

Connections

Pc: AKS 32R:

1 = Black = +

2 = Blue = 3 = Brown = s

All inputs are low-voltage. All

relay outputs may be highvoltage.

Terminals:

1-2 Supply voltage 24 V a.c.

4- 15 Relay outputs for fan motors

16-19 Relay output to pump 1 and pump 2

20-21 Relay output to heat recovery

22-24 Alarm relay

There is connection between 22 and 24 in alarm situa tions

and when the controller is dead

27-28 24 V signal to start / stop of regulation

27-29 24 V signal from the safety circuit fan 1

27-30 24 V signal from the safety circuit fan 2

27-31 24 V signal from the safety circuit fan 3

27-32 24 V signal from the safety circuit fan 4

27-33 24 V signal from the safety circuit fan 5

27-34 24 V signal from the safety circuit fan 6

27-35 (not used)

27-36 24 V signal from ow switch

37-38 Output signal 0-10 V d.c. to either 3-way valve or frequen-

cy transformer for fans

39-41 Possibility of connecting an external display type EKA 163

for display of Pc

42-44 Possibility of connecting an external display type EKA 164

for operation and temperature display

45-46 DI1 - Contact function for alarm signal

45-47 DI2 - Contact function for alarm signal

48-49 DI3 - Contact function for alarm signal

48-50 HP safety - contact function for receiving of high pressure-

safety signal

51-52 Heat recovery - Contact function for receive of signal to

start of heat recovery

51-53 S7 sensor. Sensor signal from AKS 11, AKS 12 or EKS 111

54-55 Sc3 sensor. Sensor signal from AKS 11, AKS 12 or EKS 111

54-56 S8 sensor. Sensor signal from AKS 11, AKS 12 or EKS 111

57-58 Signal for displacement of reference. 0-10 V d.c.

60-62 Condenser pressure. Voltage signal from AKS 32R.

Data communication

25-26 Mount only, if a data communication module has been

mounted.

For Ethernet communication the plug connection RJ45

must be used. (LON FTT10 can also be connected in this

way.

It is important that the installation of the data communication cable be done correctly. Cf. separate literature No.

RC8AC.

Common Pc signal

If AK-PC 420 is used together with another control for compressors, e.g.:

AK-PC 530

AK-PC 730

AK-PC 840

AK-CH 650

the same AKS 32R can emit a signal to both controls. But in this

case separate 24 V power supplies must be used for the two controllers. In addition to this, the safety limit for “high condensation

pressure” is set at the same value in the two controllers.

16 Manual RS8EL402 © Danfoss 03-2010 AK-PC 420

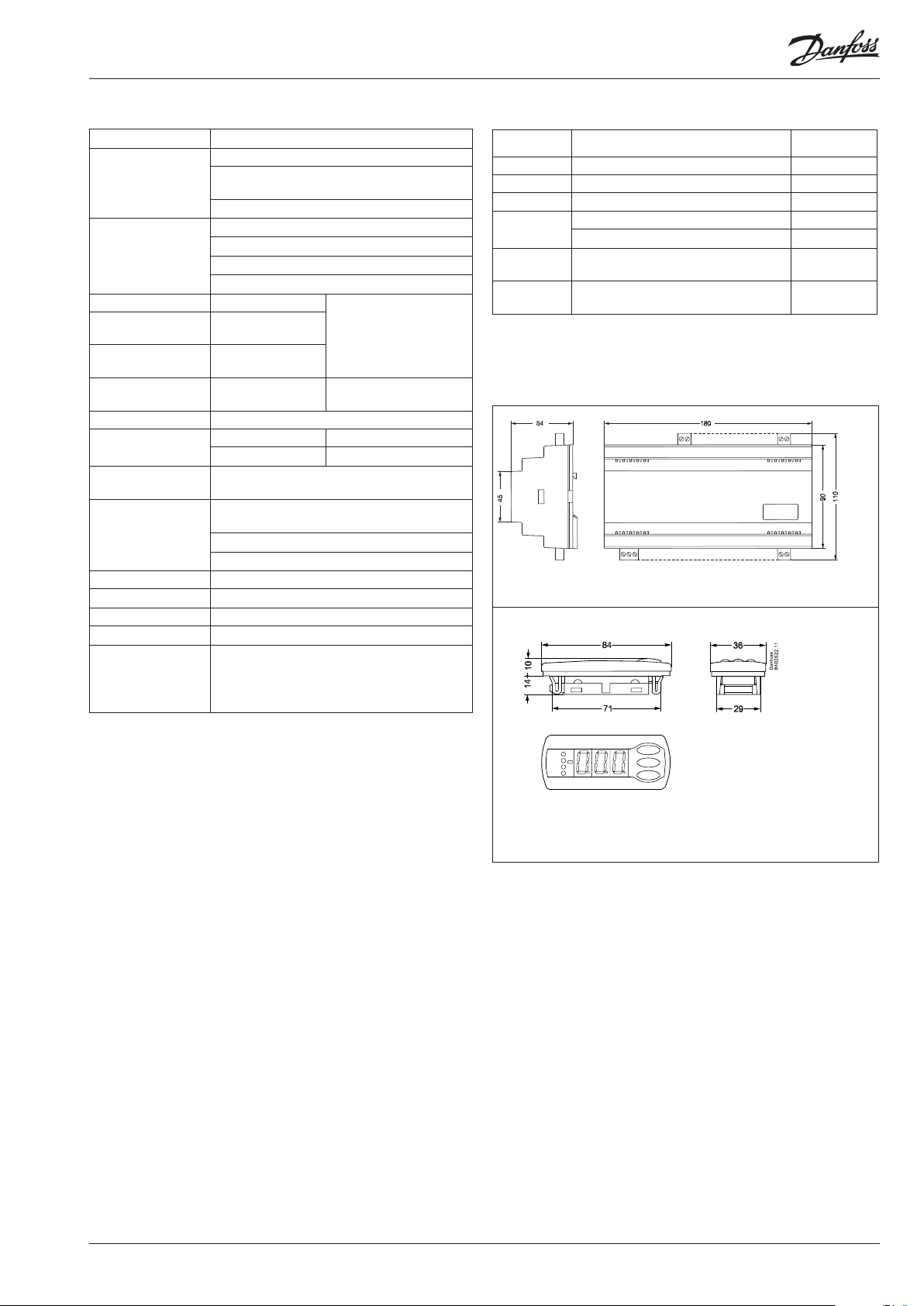

Page 17

Data Ordering

Danfoss

84B2330.11

Supply voltage 24 V a.c. +/-15% 50/60 Hz, 5 VA

1 pcs. pressure transmitter type AKS 32R

Input signal

Digital input from

contact function.

Relay output for fans 8 pcs. SPST

Relay output for twin

pump

Relay output heat

recovery

Alarm relay 1 pcs. SPDT

Voltage output 0-10 V d.c.

Display outputs

Data communication

Environments

Enclosure IP 20

Weight 0.4 kg

Mounting DIN rail or on wall

Terminals max. 2.5 mm2 multicore

Approvals

3 pcs. temperature sensor input for PT 1000

ohm/0°C or PTC 1000 ohm/25°C

External reference signal: 0-10 V d.c.

1 pcs. for Start/stop of regulation

8 pcs. for monitoring of safety circuits

3 pcs. for alarm function

1 pcs. for start of heat recovery

2 pcs. SPST

1 pcs. SPST

EKA 163 Pc display

EKA 164 Operation, S7 display

Possible to connect a data communication

module

0 - 55°C, during operation

-40 - 70°C, during transport

20 - 80% Rh, not condensing

No shock inuence / vibrations

EU Low voltage Directive and EMC demands re

CE-marking complied with.

LVD-tested acc. to EN 60730-1 and EN 60730-2-9

EMC-tested acc. to EN61000-6-2 and 3

AC-1: 3 A (ohmic)

AC-15: 2 A (inductive)

AC-1: 6 A (ohmic)

AC-15: 3 (inductive)

Type Function Ordering

AK-PC 420 Capacity controller for dry cooler 084B8008

EKA 163B Display unit 084B8574

EKA 164B Display unit with operation buttons 084B8575

EKA 174

EKA 178B

Montage

AK-PC 420

Cable for display unit 2 m, 1 pcs. 084B7298

Cable for display unit 6 m, 1 pcs. 084B7299

Data communication module, LON RS

485 (with galvanic separation)

Data communication module, MOD-bus

(with galvanic separation)

084B7124

084B8571

Pressure transmitter / temperature sensor

Please refer to catalogue RK0YG...

Only for front mounting (IP 40)

Only connection via plugs

Display type EKA 163 / EKA 164

Installation considerations

Accidental damage, poor installation, or site conditions, can give

rise to malfunctions of the control system, and ultimately lead to a

plant breakdown.

Every possible safeguard is incorporated into our products to

prevent this. However, a wrong installation, for example, could still

present problems. Electronic controls are no substitute for normal,

good engineering practice.

Danfoss will not be responsible for any goods, or plant components, damaged as a result of the above defects. It is the installer's

responsibility to check the installation thoroughly, and to t the

necessary safety devices.

Special reference is made to the necessity of signals to the

controller when the compressor is stopped and to the need of

liquid receivers before the compressors.

Your local Danfoss agent will be pleased to assist with further

advice, etc.

AK-PC 420 Manual RS8EL402 © Danfoss 03-2010 17

Page 18

Appendix - Reference and regulation

The regulation functions are explained in more detail below.

With parameter r33 Ctrl. Mode it is possible to choose between six dierent forms of regulation.

As a starting point 1, 2 or 5 are recommended. However, if the system is unstable it might be necessary to switch to 3, 4 or 6.

r33 Ctrl.

1. PI regulation. Fixed reference i.e. constant condensing pressure.

2. PI regulation. Floating reference with outdoor temperature Sc3 i.e. variable condensing pressure.

3. As ”1”, but with P regulation. A higher condensing pressure than indicated by the reference must be accepted here.

4. As ”2”, but with P regulation. A higher condensing pressure than indicated by the reference must be accepted here.

5. and 6. As 1 and 3, but with outdoor temperature dependent min. reference.

The dierent regulation modes are as follows:

(For the sake of simplicity, in the example no consideration is given to any possible overriding with external reference signal 0-10 V.)

type

1 PI r28 SP+Ext. Ref r64 SP+Ext. Ref r31 Ref Min. r30 Ref Max.

2 PI Sc3+Min.tm r64 SP+Ext. Ref r31 Ref Min. r30 Ref Max.

3 P r28 SP+Ext. Ref r64 SP+Ext. Ref r31 Ref Min. r30 Ref Max.

4 P Sc3+Min.tm r64 SP+Ext. Ref r31 Ref Min. r30 Ref Max.

5 PI r28 SP+Ext. Ref r64 SP+Ext. Ref Sc3+Min. tm K r30 Ref Max.

6 P r28 SP+Ext. Ref r64 SP+Ext. Ref Sc3+Min. tm K r30 Ref Max.

No heat recovery Heat recovery Minimum Maximum

1. PI regulation with xed reference

Reference Reference delimitation

Important setting to avoid

unwanted alarms

When r33 = 1,2 or 5:

Pc Ref max. must be set at least 5 K

below Pc max. (A30).

When r33 = 3, 4 or 6:

Pc Ref max. must be set at least (”n04

Valve Xp” + ”n60 Fan Xp” +5) K below Pc

max. (A30).

Heat recovery = on

In PI regulation the controller will make sure that the actual regulation

temperature deviates as little as possible from the actual reference.

The reference at any time, on the basis of which the controller regulates,

can be seen in ”r29”.

During normal regulation the setting “r28 SetPoint” is used as a reference.

For heat recovery the reference is changed to R64 Heat SP °C, and r30 is

raised to 99.9°C

2. PI regulation with oating reference

Heat recovery = on

In PI regulation the controller will make sure that the actual regulation

temperature deviates as little as possible from the actual reference.

The reference is at a xed value (r56 Min tm K) above the actual measured

outdoor temperature Sc3 and can be seen in “r29 Ref °C”.

If the outdoor temperature falls one degree, the reference will also fall

one degree. For heat recovery the reference is changed to r64 Heat SP °C,

and r30 is raised to 99.9°C

Raising/lowering of the reference takes place via a ramp function dened

at “r65 RefRamp”.

The capacity of the three-way valve is controlled via regulation parameters

“n04 Valve Xp” and “n05 valve Tn s”, and the fans are controlled via regulation parameters “n60 Fan Xp” and “n61 Fan Tn s”.

Raising/lowering of the reference takes place via a ramp function dened

at “r65 RefRamp”.

If there is a sensor failure on the outdoor temperature sensor, the reference

will switch to the setting of “r28 SetPoint”.

The capacity of the three-way valve is controlled via regulation parameters

“n04 Valve Xp” and “n05 valve Tn s”, and the fans are controlled via regula-

tion parameters “n60 Fan Xp” and “n61 Fan Tn s”.

18 Manual RS8EL402 © Danfoss 03-2010 AK-PC 420

Page 19

3. P regulation with xed setting

Heat recovery = on

As point 1, but with P regulation the actual regulation temperature will

always deviate in relation to the actual reference. The reason is that the

actual cut-in capacity is solely dependent on how far the measured

regulation temperature is from the actual reference.

The capacity of the three-way valve is controlled via proportional band

“n04 Valve Xp” and the fans are controlled via proportional band “n60

4. P regulation with oating reference

Heat recovery = on

As point 2, but with P regulation the actual regulation temperature will

always deviate in relation to the actual reference. The reason is that the

actual cut-in capacity is solely dependent on how far the measured

regulation temperature is from the actual reference.

The capacity of the three-way valve is controlled via proportional band

“n04 Valve Xp” and the fans are controlled via proportional band “n60

Fan Xp”. This means that the three-way valve will be fully open when the

temperature is “n04 S7/Pc Xp” over the actual reference, and the fans will

provide full capacity when the temperature is “n04 S7/Pc Xp” + “n60 S8 Xp”

above the actual reference.

The cutin and cutout of fans are shown in the drawing.

If the entire fan capacity is controlled by speed regulation, the capacity will

be indicated on the broken line.

Fan Xp”. This means that the three-way valve will be fully open when the

temperature is “n04 S7/Pc Xp” over the actual reference, and the fans will

provide full capacity when the temperature is “n04 S7/Pc Xp” + “n60 S8 Xp”

above the actual reference.

The cutin and cutout of fans are shown in the drawing.

If the fan capacity is controlled by speed regulation, the capacity will be

indicated on the broken line.

AK-PC 420 Manual RS8EL402 © Danfoss 03-2010 19

Page 20

5. PI regulation with xed reference and with min. reference which depends on the outdoor temperature

Heat recovery = on

In PI regulation the controller will make sure that the actual regulation

temperature deviates as little as possible from the actual reference.

The reference at any time, on the basis of which the controller regulates,

can be seen in ”r29”.

During normal regulation the setting “r28 SetPoint” is used as a reference.

Ref. min. = Sc3 + Min. tm K

For heat recovery the reference is changed to R64 Heat SP °C, and r30 is

raised to 99.9°C

Raising/lowering of the reference takes place via a ramp function dened

at “r65 RefRamp”.

The capacity of the three-way valve is controlled via regulation parameters

“n04 Valve Xp” and “n05 valve Tn s”, and the fans are controlled via regulation parameters “n60 Fan Xp” and “n61 Fan Tn s”.

6. P regulation with xed setting and with min. reference which depends on the outdoor temperature

Heat recovery = on

As point 1, but with P regulation the actual regulation temperature will

always deviate in relation to the actual reference. The reason is that the

actual cut-in capacity is solely dependent on how far the measured

regulation temperature is from the actual reference.

The capacity of the three-way valve is controlled via proportional band

“n04 Valve Xp” and the fans are controlled via proportional band “n60

Ref. min. = Sc3 + Min. tm K

Fan Xp”. This means that the three-way valve will be fully open when the

temperature is “n04 S7/Pc Xp” over the actual reference, and the fans will

provide full capacity when the temperature is “n04 S7/Pc Xp” + “n60 S8 Xp”

above the actual reference.

The cutin and cutout of fans are shown in the drawing.

If the entire fan capacity is controlled by speed regulation, the capacity will

be indicated on the broken line.

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alternations can be made without subsequential changes being necessary in specications already agreed.

All trademarks in this material are property of the respecitve companies. Danfoss and Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

20 Manual RS8EL402 © Danfoss 03-2010 AK-PC 420

FC-SPMC

Loading...

Loading...