Service Guide

Capacity controller

for water chiller

AK-CH 650

ADAP-KOOL® Refrigeration control systems

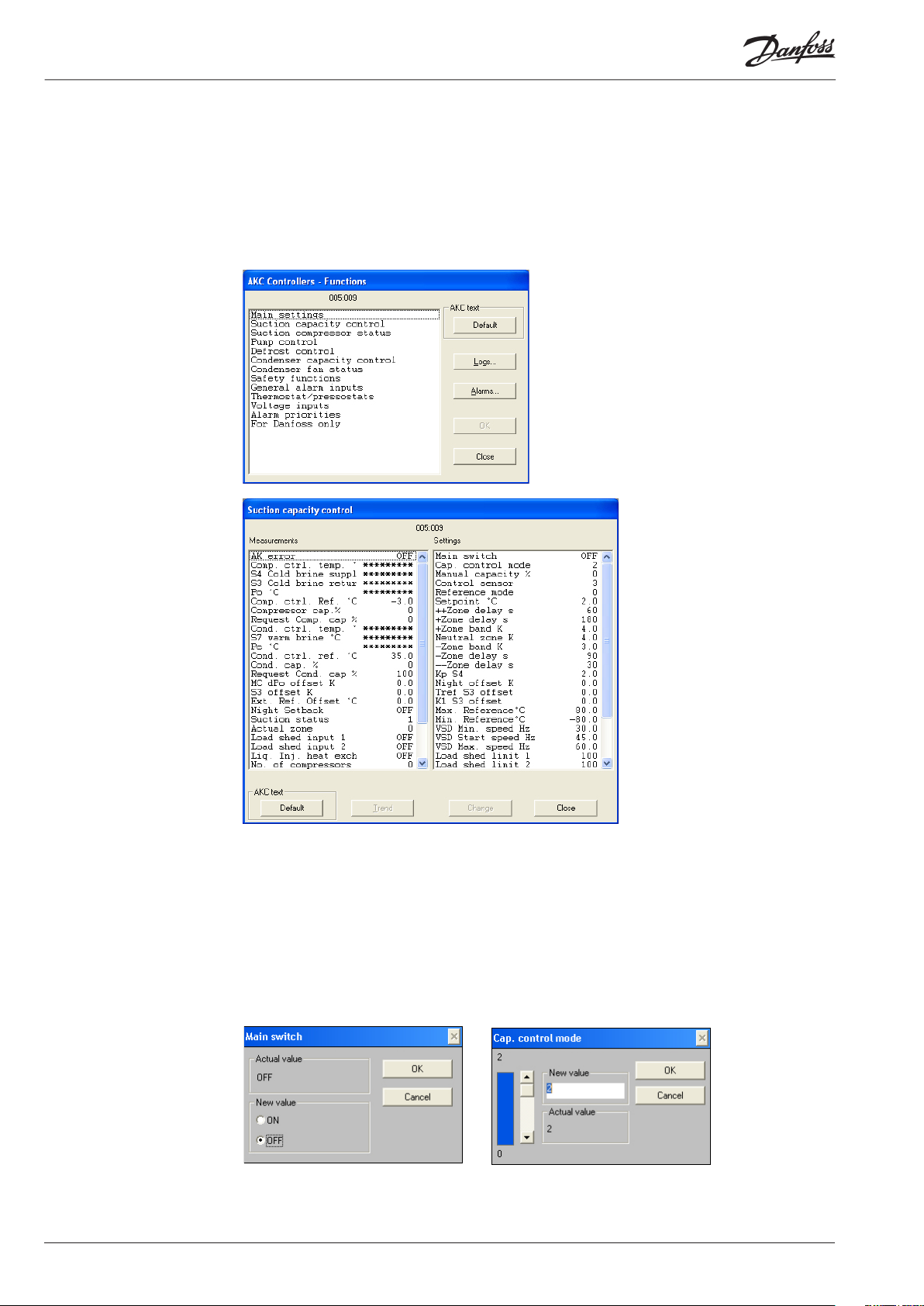

Menu list This menu function can be used together with system software type AKM. The description is divided

up into function groups that can be displayed on the PC screen. Within each group it is now possible

to show the measured values, or settings. Regarding the use of AKM, reference is made to the AKM

Manual.

Validity This menu operation (from January 2016 applies to controller type AK-CH 650, code number/

080Z0132 with programme version 2.0x.

Function groups

The operation is divided up into several

function groups. When a selection has been

made, push “OK”, and you may continue to

the next display. By way of example, “Suction

capacity control” has been selected here.

From the measure line the dierent values can be read. The values are constantly

updated.

In the list of settings the set values can be

seen. If a setting has to be changed, select

the parameter and proceed via “OK”.

Measurements The various measurements can be read directly. If a graphic display of the measurements is required,

up to eight of them can be shown. Select the required measurements and push “Trend”.

Settings Settings can only be made for the daily operation. Conguration settings cannot be seen, changed or

written out. They can only be made from the Service Tool programme.

There are four kinds of settings, ON/OFF settings, settings with a variable value, time settings and

“reset alarms”.

Set the required value and push “OK”

2 Service Guide RC8BV402 © Danfoss 2016-02 AK-CH 650 Version 2.0x

Enter the new value or move the sliding scale up or down.

The new value will apply, when “OK” is pushed.

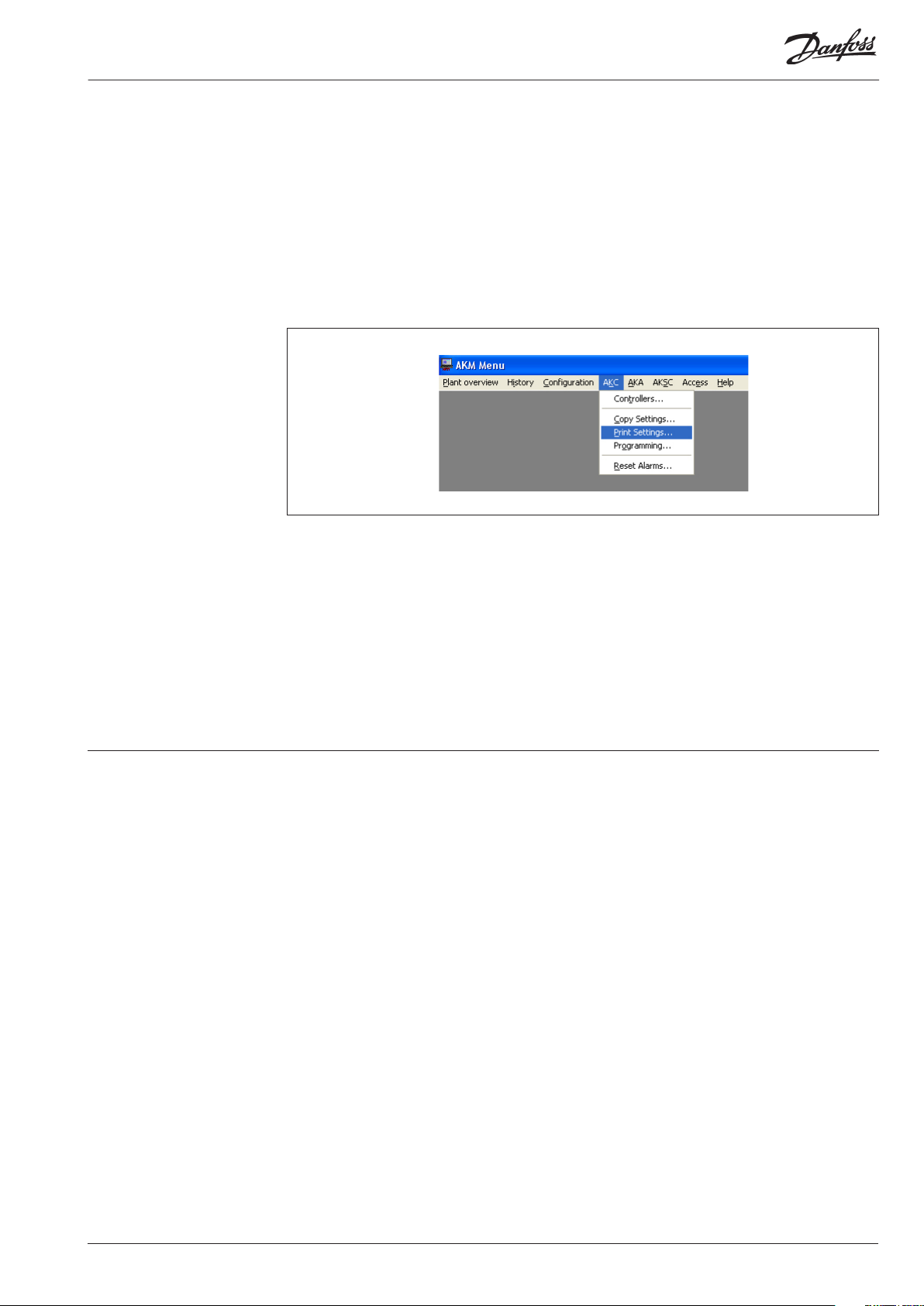

Go through the individual functions one by one and make the required settings. When settings have

been made for one controller, the set values may be used as basis in the other controllers of the same

type and with the same software version. Copy the settings by using the copy settings function in the

AKM programme, and adjust subsequently any settings where there are deviations.

NB! If a list is required for noting down the individual settings, a printout can be made of it with a function in the AKM programme. Read the next section, “Documentation”.

Documentation Documentation of the settings of the individual controllers can be made with the print function in the

AKM programme. Select the controller for which documentation of the settings is required and select

the “Print Settings” function (cf. also the AKM Manual).

Functions Shown below are function groups with corresponding measurements and settings. A printout of the

given settings can be made using the AKM function “Print Settings” (see above).

Note It has been necessary to make selections among the many measurements and settings coming from

the controller.

The operation from the AKM programme cannot contain them all.

If there is a need for access to all measurements and settings, you should make use of Service Tool

type AK-ST 500.

AK-CH 650 Version 2.0x Service Guide RC8BV402 © Danfoss 2016-02 3

Main settings

Measurements AK error When “ON”, the controller is in alarm condition.

Comp. Ctrl. temp. Actual temperature for compressor control

S4 Cold brine supply Actual cold brine supply temperature measured with S4 temp. sensor

S3 Cold brine return Actual cold brine return temperature measured with S3 temp. sensor

P0 °C Suction pressure in °C. (Measured with the pressure transmitter)

Comp. ctrl. Ref. °C Actual reference temperature for compressor control

Compressor cap. % Cut-in compressor capacity in % (of total capacity)

Request Comp. Cap % Reference for compressor capacity (deviations may be due to time delays)

Cond. ctrl. temp °C Actual temperature for control sensor (Pc or S7)

S7 warm brine °C Actual warm brine temperature for S7 media sensor

(Only used if S7 sensor is selected as regulation sensor)

Pc °C Condensing pressure in °C. (measured with the pressure transmitter)

Cond. ctrl. ref. °C Actual reference temp. for condenser capacity

(incl. external reference signal, if any)

Cond. cap. % Cut-in condenser capacity in % (of total capacity)

Request Cond. cap % Reference for condenser capacity

External Main Switch Status of input “Extern Main Switch”. In pos. “OFF” the regulation is stopped by force

Settings Main switch Main switch: ON: Regulation

OFF: Controller stopped

Conguration lock Lock of conguration.

In order to select quick setup or select refrigerant type, the conguration lock must

be “open”. Note: ”Main switch” must be OFF in order to set conguration lock in “open”

position

0: Open

1: Locked

Select quick setup Select a pre dened application. All in- and outputs will be pre-dened.

All setpoint will be adapted to the selected application. Please notice that the control

ler will make a restart when a selection has been made.

See AK-PC 840 manual for further details about the predened applications.

Refrigerant type Po Select refrigerant type

0= not selected, 1=R12. 2=R22. 3=R134a. 4=R502. 5=R717. 6=R13. 7=R13b1.

8=R23. 9=R500. 10=R503. 11=R114. 12=R142b. 13=User dened 14=R32. 15=R227.

16=R401A. 17=R507. 18=R402A. 19=R404A. 20=R407C. 21=R407A. 22=R407B.

23=R410A. 24=R170. 25=R290. 26=R600. 27=R600a. 28=R744. 29=R1270. 30=R417A

Suction capacity control

Measurements AK error When “ON”, the controller is in alarm condition.

Comp. Ctrl. temp. Actual temperature for compressor control

S4 Cold brine supply Actual cold brine supply temperature measured with S4 temp. sensor

S3 Cold brine return Actual cold brine return temperature measured with S3 temp. sensor

P0 °C Suction pressure in °C. (Measured with the pressure transmitter)

Comp. ctrl. Ref. °C Actual reference temperature for compressor control

Compressor cap. % Cut-in compressor capacity in % (of total capacity)

Request Comp. Cap % Reference for compressor capacity (deviations may be due to time delays)

Cond. ctrl. temp °C Actual temperature for control sensor (Pc or S7)

S7 warm brine °C Actual warm brine temperature for S7 media sensor

(Only used if S7 sensor is selected as regulation sensor)

Pc °C Condensing pressure in °C. (measured with the pressure transmitter)

Cond. ctrl. ref. °C Actual reference temp. for condenser capacity

(incl. external reference signal, if any)

Cond. cap. % Cut-in condenser capacity in % (of total capacity)

Request Cond. cap % Reference for condenser capacity

MC dP0 oset K Actual displacement value for the suction pressure in connection with a “P0

Optimiser” function (Master control function in AKA gateway)

S3 oset Contribution from reference displacement via S3 sensor

Ext. Ref. Oset °C Contribution from external reference displacement

Night setback Status of night setback function

ON: Night (An increase of the evaporating pressure is permitted)

OFF: Normal situation

Suction status 0: Power up Controller has been powered up (power supply re-connected)

1: Stopped Capacity control has been stopped ("Main switch" = OFF or

"Control mode" = OFF)

4 Service Guide RC8BV402 © Danfoss 2016-02 AK-CH 650 Version 2.0x

2: Manual Capacity is controlled manually ("Control mode" = MAN)

3: Alarm Capacity control is in alarm condition (fx. alarm on Po Min

or Pc Max)

4: Restart Capacity control is waiting for elapse of “Restart time”

5: Standby Capacity control is ready to start

10: Full loaded All capacity cutin

11: Running Capacity control is running

Actual Zone Actual zone for capacity regulation:

0: P0-error

1: - - Zone

2: - Zone

3: NZ

4: + Zone

5: + + Zone

Load shed input 1 Actual status on Load shed input 1

Load shed input 2 Actual status on Load shed input 2

Liq. Inj. heat exch Liquid injection can be coordinated with the compressor operation:

0: no coordination

1: Synchronization with compressor operation

2: Last compressor is stopped only after pump down

No. of compressors Dened number of compressors

Comp. application Select the compressor application required (see AK-CH 650 manual for further details)

0: Single step only

1: 1xComp. w. unloaders + Single step

2: 2xComp. w. unloaders + Single step

3: Comp. w. unloaders only

4: 1xVariable speed + Single step

5: 1xVariable speed + Comp. w. unloaders

6: 2xVariable speed + Single step

Step control mode Selected coupling pattern for compressors

Sequential: Compressors are cut in/out in strict accordance

with compressor number

Cyclic: Runtime equalisation between compressors

Best t: Compressors are cut in/out in order to

make the best possible t to actual load

0: Sequential

2: Cyclic

3: Best t

S4 Min 24h Minimum value for S4 temp. For the last 24 hours

S4 Max 24h Maximum value for S4 temp. For the last 24 hours

S4 Average 24h Average value for S4 temp. For the last 24 hours

Extra cooling req. Brine temperature is higher than desired, and the relay "extra cooling" is active.

Settings Main switch Main switch: ON: Regulation

OFF: Controller stopped

Cap. control mode 0: MAN (The compressor capacity will be controlled manually)

1: OFF (The capacity control will be stopped)

2: AUTO (The capacity is controlled by the PI controller)

Manual capacity % Manual setting of compressor capacity

The value is in % of total capacity controlled by the controller

Control sensor Choise of regulation sensor

0: P0

3: S4

Reference mode Choice of suction pressure reference

0: SP + Ext. Ref + Night + S3 oset: Used if you require override via 0-10V signal, S3

sensor or night setback.

1: SP + Po optimization: Used if you want to optimize the reference from the

refrigeration appliance (network function) which is most used

Setpoint °C Setting of required suction pressure in °C

++Zone delay s Time delay between step cut-ins in the regulation band over the “+Zone band”

Set in seconds

+Zone delay s Time delay between step cut-ins in the regulation band over the neutral zone

Set in seconds

+Zone band K Regulation band over the neutral zone

Neutral zone K Neutral zone for suction pressure

-Zone band K Regulation band under the neutral zone

-Zone delay s Time delay between step cut-outs in the regulation band under the neutral zone

Set in seconds

AK-CH 650 Version 2.0x Service Guide RC8BV402 © Danfoss 2016-02 5

--Zone delay s Time delay between step cut-outs in the regulation band under the “-Zone band”

Set in seconds.

Kp S4 Amplication factor for P0 regulation

Night oset K Displacement value for suction pressure in connection with an active night

setback signal (set in Kelvin)

Tref S3 oset Reference temperature for the temperature signal S3, i.e. when = Tref, there is no

displacement of the reference.

K1 S3 oset Displacement of the reference for the charge temperature S4 on an increase in S3

temperature in relation to ”Tref S3 oset” of 1°C (K1 = 0 gives no displacement)

Max.Reference °C Max. permissible suction pressure reference

Min.Reference °C Min. permissible suction pressure reference

VSD Min. speed Hz Minimum allowed speed before stop of Variable Speed drive (Low load condition)

VSD Start speed Hz Minimum speed for start of Variable speed drive (Must be set higher than

“VSD Min. Speed Hz”)

VSD Max. speed Hz Highest permissible speed for the compressor motor

Load shed limit 1 Set max capacity limit for load shed input 1

Load shed limit 2 Set max capacity limit for load shed input 2

Override limit Po Set max load shedding override limit for suction pressure Po

Override delay 1 min Override delay for load shed limit 1. If the suction pressure exceeds

“Override limit Po” during load shedding and the set delay has expired, the load shed

limit 1 will be cancelled

Override delay 2 min Override delay for load shed limit 2. If the suction pressure exceeds

“Override limit Po” during load shedding and the set delay has expired, the load shed

limit 2 will be cancelled

Po pump down limit °C Set the actual pump down limit for the last compressor

Initial start time The time after start-up where the cut-in capacity is limited to the rst compressor step.

1 comp. start delay On new start the start of the rst compressor is delayed by the set delay time so that the

brine pumps can bring the brine up to speed before start of the rst compressor.

Extra cooling mode A relay is reserved and it will be activated if the brine temperature is higher than

desired.

Extra cooling oset Set the value (K above the reference) where the relay is to activated

Extra cooling delay Delay time before the relay can be active. The time applies during normal regulation

Extra cooling init d. Delay time before the relay can be active. The time applies during cooling after start-up

and after defrosting.

Suction compressor status

Measurements AK error When “ON”, the controller is in alarm condition.

Comp. Ctrl. temp. Actual temperature for compressor control

S4 Cold brine supply Actual cold brine supply temperature measured with S4 temp. sensor

S3 Cold brine return Actual cold brine return temperature measured with S3 temp. sensor

P0 °C Suction pressure in °C. (Measured with the pressure transmitter)

Comp. ctrl. Ref. °C Actual reference temperature for compressor control

Compressor cap. % Cut-in compressor capacity in % (of total capacity)

Request Comp. Cap % Reference for compressor capacity (deviations may be due to time delays)

Cond. ctrl. temp °C Actual temperature for control sensor (Pc or S7)

S7 warm brine °C Actual warm brine temperature for S7 media sensor

(Only used if S7 sensor is selected as regulation sensor)

Pc °C Condensing pressure in °C. (measured with the pressure transmitter)

Cond. ctrl. ref. °C Actual reference temp. for condenser capacity

(incl. external reference signal, if any)

Cond. cap. % Cut-in condenser capacity in % (of total capacity)

Request Cond. cap % Reference for condenser capacity

VSD 1 safety Status on safety input for variable speed controller on compressor 1

ON: Alarm

OFF: No alarm

VSD 2 safety Status on safety input for variable speed controller on compressor 2

ON: Alarm

OFF: No alarm

Comp. 1 Status 0: Power up Controller has been powered up/Compressor is not used

1: Stopped Compressor hat been stopped

2: Manual Compressor capacity is controlled manually

3: Alarm Compressor is in alarm condition (cut out on safety)

4: Restart Compressor is waiting for elapse of “Recycle time”

5: Standby Compressor is ready to start

10: Full loaded All capacity cutin

11: Running Capacity control is running

6 Service Guide RC8BV402 © Danfoss 2016-02 AK-CH 650 Version 2.0x

Comp 2 … Status As above for compressor no. 2 to 6

VSD Speed % The present speed of the compressor motor controlled by the frequency converter

Comp 1 capacity % Actual cut-in capacity on this compressor

Comp 2 …capacity % As above for compressor no. 2 to 6

Comp 1 Runtime % 24 Running time for compressor 1 in percent within the past 24 hours

Comp 2 …Runtime % 24 As above for compressor no. 2 to 6

Comp 1 Cycles / 24 h Number of compressor starts during the past 24 hours

Comp 2 …Cycles / 24 h As above for compressor no. 2 to 6

Settings Main switch Main switch: ON: Regulation

OFF: Controller stopped

1 Min. ON-time m Minimum duration of ON period

2 …Min. ON-time m As above for compressor no. 2 to 6

1 Min. OFF-time m Minimum duration of OFF period

2 …Min. OFF-time m As above for compressor no. 2 to 6

1 recycle time m Minimum period of time between two successive starts.

2 …recycle time m As above for compressor no. 2 to 6

1 runtime h Compressor’s total run time in hours

2 …runtime h As above for compressor no. 2 to 6

Pump control

Measurements AK error When “ON”, the controller is in alarm condition.

Comp. Ctrl. temp. Actual temperature for compressor control

S4 Cold brine supply Actual cold brine supply temperature measured with S4 temp. sensor

S3 Cold brine return Actual cold brine return temperature measured with S3 temp. sensor

P0 °C Suction pressure in °C. (Measured with the pressure transmitter)

Comp. ctrl. Ref. °C Actual reference temperature for compressor control

Compressor cap. % Cut-in compressor capacity in % (of total capacity)

Request Comp. Cap % Reference for compressor capacity (deviations may be due to time delays)

Cond. ctrl. temp °C Actual temperature for control sensor (Pc or S7)

S7 warm brine °C Actual warm brine temperature for S7 media sensor

(Only used if S7 sensor is selected as regulation sensor)

Pc °C Condensing pressure in °C. (measured with the pressure transmitter)

Cond. ctrl. ref. °C Actual reference temp. for condenser capacity

(incl. external reference signal, if any)

Cond. cap. % Cut-in condenser capacity in % (of total capacity)

Request Cond. cap % Reference for condenser capacity

Cold pump running Reading of pump status

0: Pumps have stopped

1: Cold pump 1 is in use

2: Cold pump 2 is in use

3: Both pumps are in use

Flow switch status Current status for ow switch input

Pump 1 safety Actual status for input "Pump 1"

Pump 2 safety Actual status for input "Pump 2"

Settings Main switch Main switch: ON: Regulation

OFF: Controller stopped

Cold Pump ctrl. Choice of pump operation

0: Both pumps are stopped

1: Cold pump 1 is in constant use

2: Cold pump 2 is in constant use

3: Both pumps are in constant use

4: O set of operational time between the two pumps. Start before stop

5: O set of operational time between the two pumps. Stop before start

Pump cycle time The operational times of the pumps before pump switch is carried out (pump’s opera tional time before changeover to the other pump)

Pump switch time Overlap time during pump changeover where both pumps are in use or break time

when switching between two pumps (only relevant if "Cold Pump ctrl" is set to 4 or 5)

Pump alarm delay Delay on pump alarm before alarm is activated and automatic pump changeover car

ried out (only if "Cold Pump ctrl" is set to 4 or 5)

AK-CH 650 Version 2.0x Service Guide RC8BV402 © Danfoss 2016-02 7

Defrost control

Measurements AK error When “ON”, the controller is in alarm condition.

Comp. Ctrl. temp. Actual temperature for compressor control

S4 Cold brine supply Actual cold brine supply temperature measured with S4 temp. sensor

S3 Cold brine return Actual cold brine return temperature measured with S3 temp. sensor

P0 °C Suction pressure in °C. (Measured with the pressure transmitter)

Comp. ctrl. Ref. °C Actual reference temperature for compressor control

Compressor cap. % Cut-in compressor capacity in % (of total capacity)

Request Comp. Cap % Reference for compressor capacity (deviations may be due to time delays)

Cond. ctrl. temp °C Actual temperature for control sensor (Pc or S7)

S7 warm brine °C Actual warm brine temperature for S7 media sensor

(Only used if S7 sensor is selected as regulation sensor)

Pc °C Condensing pressure in °C. (measured with the pressure transmitter)

Cond. ctrl. ref. °C Actual reference temp. for condenser capacity

(incl. external reference signal, if any)

Cond. cap. % Cut-in condenser capacity in % (of total capacity)

Request Cond. cap % Reference for condenser capacity

Defrost status Current status for defrost function

Defrost temp. Current temperature of chosen defrost stop sensor

Defrost time Defrosting time for current or most recently completed defrost

Average defrost time Average defrosting time for the 10 most recent defrosts

Settings Main switch Main switch: ON: Regulation

OFF: Controller stopped

Start defrost Manual start of defrost

Stop defrost Manual stop of defrost

Defrost control Select if defrost function is required

Defrost stop sensor Select defrost stop method

0: Stop exclusively on time

1: Stop at S3 temp. With time as backup

2: Stop at S4 temp. With time as backup

Defrost stop temp. Temperature value for defrost stop (the defrost is stopped when the temperature of

the selected defrost sensor reached the set value)

Max. defrost time Max. permitted defrosting time in minutes (security time for stop using temperature)

Drip delay Delay time after defrost where compressors may not start so that the water has time

to run o the refrigeration surfaces before start of refrigeration

Comp. run at def. Select if compressors are permitted to run during defrost

Condenser capacity control

Measurements AK error When “ON”, the controller is in alarm condition.

Comp. Ctrl. temp. Actual temperature for compressor control

S4 Cold brine supply Actual cold brine supply temperature measured with S4 temp. sensor

S3 Cold brine return Actual cold brine return temperature measured with S3 temp. sensor

P0 °C Suction pressure in °C. (Measured with the pressure transmitter)

Comp. ctrl. Ref. °C Actual reference temperature for compressor control

Compressor cap. % Cut-in compressor capacity in % (of total capacity)

Request Comp. Cap % Reference for compressor capacity (deviations may be due to time delays)

Cond. ctrl. temp °C Actual temperature for control sensor (Pc or S7)

S7 warm brine °C Actual warm brine temperature for S7 media sensor

(Only used if S7 sensor is selected as regulation sensor)

Pc °C Condensing pressure in °C. (measured with the pressure transmitter)

Cond. ctrl. ref. °C Actual reference temp. for condenser capacity

(incl. external reference signal, if any)

Cond. cap. % Cut-in condenser capacity in % (of total capacity)

Request Cond. cap % Reference for condenser capacity

Condenser status 0: Power up Controller has been powered up (power supply re-connected)

1: Stopped Capacity control has been stopped (“Main switch” = OFF or

“Control mode” = OFF)

2: Manual Capacity is controlled manually (“Control mode” = MAN)

3: Alarm Capacity control is in alarm condition (f.ex. Pc Max or Sd Max)

4: Restart Capacity control is waiting for elapse of “Restart time”

5: Standby Capacity control is ready to start

10: Full loaded All capacity cutin

11: Running Capacity control is running

8 Service Guide RC8BV402 © Danfoss 2016-02 AK-CH 650 Version 2.0x

Air ow status 0: No RFG. select No refrigerant has been selected (monitoring of air

ow can not start)

1: Tuning Monitoring function adapts to the condenser in question

2: OFF Monitoring function is switched OFF

3: OK Air ow is OK

4: Little dirt The amount of dirt decreases the performance of the condenser,

clean when possible

5: Dirty The amount of dirt leads to considerable air ow problems, clean

as soon as possible

6: Blocking The amount of dirt might lead to high pressure problems, clean

now

Sc3 Air on °C Outdoor temperature in °C measured with Sc3 temperature sensor

VSD Speed % Status of analogue output signal “AO” for variable speed drive (in percent of

full scale f.ex. 0 -10 V d.c.)

VSD safety Status of safety monitoring input for Variable Speed Drive

ON: Alarm on VSD A safety monitoring input

OFF: No alarm on VSD A safety monitoring input

Heat rec. temp. °C Temperature at the sensor for the heat recovery function

Heat recovery Status on function "Heat recovery"

No. of fans Dened number of fans

Settings Main switch Main switch: ON: Regulation

OFF: Controller stopped

Cap. control mode 0: MAN (The condenser capacity will be controlled manually)

1: OFF (The capacity control will be stopped)

2: AUTO (The capacity is controlled by the PI controller)

Manual capacity % Manual setting of condenser capacity

The value is in % of total capacity controlled by the controller

Reference mode 0: Set point Reference = “PcA setpoint °C”

1: Floating Reference is changed as a function of the outdoor temperature

measured by the “Sc3 air on” sensor, the set “Dimensioning tm K”

and the actual compressor load.

Setpoint °C Setting of required discharge pressure in °C

Dimensioning tm K Dimensioning mean temperature dierential between air- and condensing

temperature at full load for the condenser in question (Typical 8 – 15K).

Min. tm k tm value at minimum load.

Min. Reference °C Min. permissible condensing pressure reference

Max. Reference °C Max. permissible condensing pressure reference

Heat rec. SP °C Condensing pressure reference when the thermostat for heat recovery is cut in.

Heat rec. Cut In °C Temperature value when the thermostat changes over to heat recovery.

Heat rec. CutOut °C Temperature value when the thermostat cuts out the heat recovery again

Xp P-band K Proportional band for PI controller

Tn Integr. time s Integration time for PI controller

Control type Selection of regulation type:

0: P regulation

1: PI regulation

VSD Min. speed % Minimum allowed speed before stop of Variable Speed drive (Low load condition)

VSD Start speed % Minimum speed for start of Variable speed drive (Must be set higher than

“VSD Min. Speed %”)

Cap. limit night % Capacity limitation during night operation

AK-CH 650 Version 2.0x Service Guide RC8BV402 © Danfoss 2016-02 9

Condenser fan status

Measurements AK error When “ON”, the controller is in alarm condition.

Comp. Ctrl. temp. Actual temperature for compressor control

S4 Cold brine supply Actual cold brine supply temperature measured with S4 temp. sensor

S3 Cold brine return Actual cold brine return temperature measured with S3 temp. sensor

P0 °C Suction pressure in °C. (Measured with the pressure transmitter)

Comp. ctrl. Ref. °C Actual reference temperature for compressor control

Compressor cap. % Cut-in compressor capacity in % (of total capacity)

Request Comp. Cap % Reference for compressor capacity (deviations may be due to time delays)

Cond. ctrl. temp °C Actual temperature for control sensor (Pc or S7)

S7 warm brine °C Actual warm brine temperature for S7 media sensor

(Only used if S7 sensor is selected as regulation sensor)

Pc °C Condensing pressure in °C. (measured with the pressure transmitter)

Cond. ctrl. ref. °C Actual reference temp. for condenser capacity

(incl. external reference signal, if any)

Cond. cap. % Cut-in condenser capacity in % (of total capacity)

Request Cond. cap % Reference for condenser capacity

Fan1/VSD status Status of the Fan 1

ON: Fan is running

OFF: Fan is not running

Fan2.... status As above for fan 2 to 8

Settings Main switch Main switch: ON: Regulation

OFF: Controller stopped

Fan 1 runtime Total on time for fan 1

Fan 2.... runtime Total on time for fan 2 to 8

Safety Functions

Measurements AK error When “ON”, the controller is in alarm condition.

Comp. Ctrl. temp. Actual temperature for compressor control

S4 Cold brine supply Actual cold brine supply temperature measured with S4 temp. sensor

S3 Cold brine return Actual cold brine return temperature measured with S3 temp. sensor

P0 °C Suction pressure in °C. (Measured with the pressure transmitter)

Comp. ctrl. Ref. °C Actual reference temperature for compressor control

Compressor cap. % Cut-in compressor capacity in % (of total capacity)

Request Comp. Cap % Reference for compressor capacity (deviations may be due to time delays)

Cond. ctrl. temp °C Actual temperature for control sensor (Pc or S7)

S7 warm brine °C Actual warm brine temperature for S7 media sensor

(Only used if S7 sensor is selected as regulation sensor)

Pc °C Condensing pressure in °C. (measured with the pressure transmitter)

Cond. ctrl. ref. °C Actual reference temp. for condenser capacity

(incl. external reference signal, if any)

Cond. cap. % Cut-in condenser capacity in % (of total capacity)

Request Cond. cap % Reference for condenser capacity

Ss suction gas °C Suction gas temperature in °C

Suction superheat K Superheat in suction line

Sd discharge gas °C Discharge gas temperature in °C

Anti freeze safety Actual status of general shared frost protection input for all compressors

Settings Main switch Main switch: ON: Regulation

OFF: Controller stopped

Pc max. limit °C Max. value of discharge pressure in °C

(If the value is exceeded, the entire compressor capacity will be cut out)

(At 3 K under PcA max. the entire condenser capacity will be cut in and

the compressor capacity will be reduced)

Sd max. limit °C Max. value of discharge pressure in °C

(If the value is exceeded, the entire compressor capacity will be cut out and the entire

condenser capacity will be cut in)

P0 min. limit °C Min. value of suction pressure in °C

(If the value becomes less, the entire compressor capacity will be cut out)

P0 min del at start On start of the rst compressor the security switch on the low-pressure security

function ”Po My limit” is delayed by the set time to prevent low-pressure dropout at

start.

10 Service Guide RC8BV402 © Danfoss 2016-02 AK-CH 650 Version 2.0x

P0 max. alarm °C Alarm limit for P0

P0 max. delay m Delay time before alarm for "P0 max. alarm °C"

SH min. Alarm K Alarm limit for min. superheat

SH max. Alarm K Alarm limit for max. superheat

SH Alarm delay m Time delay before alarm for “SH min limit” and “SH min limit”

Restart time m Time delay before restart of compressors

(Applies to the functions: "Sd max limit", "Pc max limit" and "P0 min limit")

Liq.inj. SH CutIn K Liquid injection in the suction line. Set superheat value where liquid injection is to

start.

Liq.inj. Sd CutIn °C Liquid injection in suction line. Set Sd temperature where liquid injection is to start.

Alarm monitoring S4 Select if alarm monitoring is required on charge temperature S4

S4 High limit High alarm limit for cold brine charge temperature

S4 High delay Delay on high charge temperature under normal regulation

S4 High del pulldown Delay on high charge temperature on start or during defrost

S4 Low limit Low alarm limit for cold bring charge temperature

S4 low delay Delay on low charge temperature

General alarm inputs

Measurements AK error When “ON”, the controller is in alarm condition.

Comp. Ctrl. temp. Actual temperature for compressor control

S4 Cold brine supply Actual cold brine supply temperature measured with S4 temp. sensor

S3 Cold brine return Actual cold brine return temperature measured with S3 temp. sensor

P0 °C Suction pressure in °C. (Measured with the pressure transmitter)

Comp. ctrl. Ref. °C Actual reference temperature for compressor control

Compressor cap. % Cut-in compressor capacity in % (of total capacity)

Request Comp. Cap % Reference for compressor capacity (deviations may be due to time delays)

Cond. ctrl. temp °C Actual temperature for control sensor (Pc or S7)

S7 warm brine °C Actual warm brine temperature for S7 media sensor

(Only used if S7 sensor is selected as regulation sensor)

Pc °C Condensing pressure in °C. (measured with the pressure transmitter)

Cond. ctrl. ref. °C Actual reference temp. for condenser capacity

(incl. external reference signal, if any)

Cond. cap. % Cut-in condenser capacity in % (of total capacity)

Request Cond. cap % Reference for condenser capacity

DI 1 Alarm Alarm status on the function dened as a DI1 alarm

ON: Alarm is active

OFF: No alarm, normal situation

DI 2.... Alarm As above, but for the alarm functions 2 to 8

Settings Main switch Main switch: ON: Regulation

OFF: Controller stopped

DI 1 Alarm delay m Time delay for the alarm "DI 1 Alarm"

DI 2.... Alarm delay m As above, but for the alarm functions 2 to 8

Thermostat/pressostats

Measurements AK error When “ON”, the controller is in alarm condition.

Comp. Ctrl. temp. Actual temperature for compressor control

S4 Cold brine supply Actual cold brine supply temperature measured with S4 temp. sensor

S3 Cold brine return Actual cold brine return temperature measured with S3 temp. sensor

P0 °C Suction pressure in °C. (Measured with the pressure transmitter)

Comp. ctrl. Ref. °C Actual reference temperature for compressor control

Compressor cap. % Cut-in compressor capacity in % (of total capacity)

Request Comp. Cap % Reference for compressor capacity (deviations may be due to time delays)

Cond. ctrl. temp °C Actual temperature for control sensor (Pc or S7)

S7 warm brine °C Actual warm brine temperature for S7 media sensor

(Only used if S7 sensor is selected as regulation sensor)

Pc °C Condensing pressure in °C. (measured with the pressure transmitter)

Cond. ctrl. ref. °C Actual reference temp. for condenser capacity

(incl. external reference signal, if any)

Cond. cap. % Cut-in condenser capacity in % (of total capacity)

AK-CH 650 Version 2.0x Service Guide RC8BV402 © Danfoss 2016-02 11

Request Cond. cap % Reference for condenser capacity

Thermostat 1 °C Temperature measurement of function dened in Thermostat 1.

Thermostat 2 °C Temperature measurement of function dened in Thermostat 2.

Thermostat 3 °C Temperature measurement of function dened in Thermostat 3.

Pressostat 1 Bar Pressure measurement of function dened in Pressure Control 1

Pressostat 2 Bar As above, but for pressostat 2

Settings Main switch Main switch: ON: Regulation

OFF: Controller stopped

Ther. 1 Cutin °C Cutin value for function dened in ”Thermostat 1”.

Ther. 1 Cutout °C Cutout value for function dened in ”Thermostat 1”.

Ther. 1 High Alarm °C High alarm limit "Thermostat 1"

Ther. 1 Low Alarm °C Low alarm limit "Thermostat 1"

Ther. 1 High ALDly m Time delay for high alarm "Thermostat 1"

Ther. 1 Low ALDly m Time delay for low alarm "Thermostat 1"

Ther. 2............ As above, but for thermostat 2

Ther. 3............ As above, but for thermostat 3

Pres. 1 Cutin bar Cutin value for function dened in ”Pressure Control 1”.

Pres. 1 Cutout bar Cutout value for function dened in ”Pressure Control 1”.

Pres. 1 High alarm bar High alarm limit "Pressostat 1"

Pres. 1 Low alarm bar Low alarm limit "Pressostat 1"

Pres. 1 High ALDly m Time delay for high alarm "Pressostat 1"

Pres. 1 Low ALDly m Time delay for low alarm "Pressostat 1"

Pres. 2............ As above, but for pressostat 2

(Use Service Tool if data concerning thermostats 4 and 5 or from pressure controls 3, 4 and 5 have to be downloaded).

Voltage inputs

Measurements AK error When “ON”, the controller is in alarm condition.

Comp. Ctrl. temp. Actual temperature for compressor control

S4 Cold brine supply Actual cold brine supply temperature measured with S4 temp. sensor

S3 Cold brine return Actual cold brine return temperature measured with S3 temp. sensor

P0 °C Suction pressure in °C. (Measured with the pressure transmitter)

Comp. ctrl. Ref. °C Actual reference temperature for compressor control

Compressor cap. % Cut-in compressor capacity in % (of total capacity)

Request Comp. Cap % Reference for compressor capacity (deviations may be due to time delays)

Cond. ctrl. temp °C Actual temperature for control sensor (Pc or S7)

S7 warm brine °C Actual warm brine temperature for S7 media sensor

(Only used if S7 sensor is selected as regulation sensor)

Pc °C Condensing pressure in °C. (measured with the pressure transmitter)

Cond. ctrl. ref. °C Actual reference temp. for condenser capacity

(incl. external reference signal, if any)

Cond. cap. % Cut-in condenser capacity in % (of total capacity)

Request Cond. cap % Reference for condenser capacity

Volt 1 readout Voltage measurement on the function dened in Volt 1.

Settings Main switch Main switch: ON: Regulation

OFF: Controller stopped

Volt 1 Cutin The value where the relay is to cut in

Volt 1 Cutout The value where the relay is to cut out

Volt 1 Cutin del. m Time delay for cutin of relay

Volt 1 Cutout del. m Time delay for cutout of relay

Volt 1 High Al.Limit The value for the high alarm limit

Volt 1 Low Al.Limit The value for the low alarm limit

Volt 1 High Al.Dly m Time delay for high alarm

Volt 1 Low Al.Dly m Time delay for low alarm

(Use Service Tool if data concerning Volt 2, 3, 4 and 5 are to be downloaded).

12 Service Guide RC8BV402 © Danfoss 2016-02 AK-CH 650 Version 2.0x

Alarm priorities

Measurements AK error When “ON”, the controller is in alarm condition.

Comp. Ctrl. temp. Actual temperature for compressor control

S4 Cold brine supply Actual cold brine supply temperature measured with S4 temp. sensor

S3 Cold brine return Actual cold brine return temperature measured with S3 temp. sensor

P0 °C Suction pressure in °C. (Measured with the pressure transmitter)

Comp. ctrl. Ref. °C Actual reference temperature for compressor control

Compressor cap. % Cut-in compressor capacity in % (of total capacity)

Request Comp. Cap % Reference for compressor capacity (deviations may be due to time delays)

Cond. ctrl. temp °C Actual temperature for control sensor (Pc or S7)

S7 warm brine °C Actual warm brine temperature for S7 media sensor

(Only used if S7 sensor is selected as regulation sensor)

Pc °C Condensing pressure in °C. (measured with the pressure transmitter)

Cond. ctrl. ref. °C Actual reference temp. for condenser capacity

(incl. external reference signal, if any)

Cond. cap. % Cut-in condenser capacity in % (of total capacity)

Request Cond. cap % Reference for condenser capacity

Settings Main switch Main switch: ON: Regulation

OFF: Controller stopped

The alarm priority of the following alarms can be changed:

High priority is dened with setting = 1

Medium priority is dened with setting = 2

Low priority is dened with setting = 3

Overriding the alarms is dened with setting = 0

Standby mode Regulation has stopped

Low P0 Minimum safety limit for suction pressure P0 has been violated

High S4 High alarm limit for S4 has been exceeded

Low S4 Low alarm limit for S4 has been exceeded

High Pc/Sd Safety limit for condensing pressure Pc /discharge gas temperature is exceeded

Superheat min/max Superheat i suction line to low / high

Load Shedding Load shedding has been activated

P0/S4 sensor error Sensor signal for P0 / S4 is defective

Misc. sensor error Sensor signal for Ss, Sd, S3, Sc3, Saux is defective

Cold pump alarm Pump alarm. One of the pumps has fallen out. Signal from ow switch

Cold pump 1 & 2 alarm Pump alarm. Both pumps has fallen out. Signal from ow swich

Anti freeze safety All compressors have been cut out on frost protection

Compr VSD safety Variable speed drive for compressor has been cut out on safety

Comp. 1 safety Compressor has been cut out on safety

Comp. 2 safety Compressor has been cut out on safety

Comp. 3 safety Compressor has been cut out on safety

Comp. 4 safety Compressor has been cut out on safety

Comp. 5 safety Compressor has been cut out on safety

Comp. 6 safety Compressor has been cut out on safety

Pc/S7 sensor error Signal from pressure transmitter /temperature sensor is defective

Blocked air ow The intelligent air ow monitoring of the condenser reports that a cleaning is due

Fan safety Variable speed drive for condenser fans has been cut out on safety

Max def. time Defrost is stopped because of too long defrost time. Check evaporator.

AKM menu: "For DANFOSS only"

This menu contains data and setting values for special internal controller functions.

Do not change the stated values.

AK-CH 650 Version 2.0x Service Guide RC8BV402 © Danfoss 2016-02 13

Danfoss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

already on order provided that such alternations can be made without subsequential changes being necessary in specications already agreed.

All trademarks in this material are property of the respecitve companies. Danfoss and Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

14 Service Guide RC8BV402 © Danfoss 2016-02 AK-CH 650 Version 2.0x

FC-SPMC

Loading...

Loading...