Page 1

User Guide

Case/room controller (EEV)

Type AK-CC55 Single Coil and

AK-CC55 Single Coil UI

SW Ver. 1.7x

For refrigeration appliances and cold storage rooms.

Page 2

AK-CC55 Single Coil and AK-CC55 Single Coil UI

Contents

Introduction 6

Portfolio overview 7

Function overview 7

Connectivity 8

Data communication 8

AK-CC55 Single Coil and Single Coil UI 9

External display 9

Controller functionality 10

Functions 10

Injection control 10

Adaptive superheat control 10

Adaptive liquid control 11

Liquid injection by use of stepper valve 11

Oil recovery 11

Adaptive liquid control (option 1 and 2) 12

Fixed opening degree (option 3 and 4) 12

Safety 12

Temperature control 12

Food temperature sensor 13

Temperature monitoring 13

Thermostat bands 13

Night setback of thermostat value 13

Temperature sensor types 14

Appliance cleaning 15

Appliance shutdown 15

Defrost control 16

Electrical defrosting 16

Hot gas defrosting 16

Natural defrost 16

Start of defrost 17

Stop of defrost 17

Defrost sequence 17

Real-time clock 19

Coordinated defrost 19

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 2

Page 3

AK-CC55 Single Coil and AK-CC55 Single Coil UI

Adaptive defrosting 19

4 dierent adaptive defrost modes 19

Melt function 20

Control of two compressors (only with custom set-up) 20

Rail heat 21

Fan 22

Light function 23

Night blind 24

Humidity control 24

Heating function (only with custom set-up) 26

Digital inputs 26

Forced closing 27

Door contact 27

Display 27

Override 28

Applications 29

AK-CC55 connections and application options 30

Application set-ups and IO connections 31

Product identication 34

AK-CC55 Single Coil connections 35

Data communication 35

AKV info 35

External solid state relay for rail heat 35

AKS 32R info 36

Coordinated defrost via cable connections 36

External display AK-UI55 36

Connections 37

Replacing AK-CC 550 with AK-CC55 38

Operation 40

Operation via data communication 40

Direct operation 40

Operation via AK-UI55 Set 40

Parameter groups when operating via display 42

Get a good start 42

AK-UI55 display menu (SW ver. 1.7x) 44

Thermostat 44

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 3

Page 4

AK-CC55 Single Coil and AK-CC55 Single Coil UI

Alarm settings 44

Compressor 45

Defrost 45

Injection control 46

Fan control 46

Defrost schedule 46

Humidity control 47

Miscellaneous 47

Control 49

DO cong and manual 50

Service 51

Operation via AK-UI55 Bluetooth 53

AK-CC55 connect menu (SW ver. 1.7x) 54

Start / Stop 54

Conguration 54

Thermostat control 56

Alarm limits and delays 57

Humidity control 59

Injection control 59

Defrost control 60

Defrost schedules 62

Compressor 63

Fan control 63

Railheat control 64

Light/Blinds/Cleaning control 64

Display control 65

Alarm relay priorities 66

Miscellaneous 66

Advanced 67

Fault message 69

Operating status 71

Product specication 72

Technical data 72

Electrical specications 72

Sensor and measuring data 72

Input and output relay specications 72

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 4

Page 5

AK-CC55 Single Coil and AK-CC55 Single Coil UI

Function data 73

Environmental conditions 73

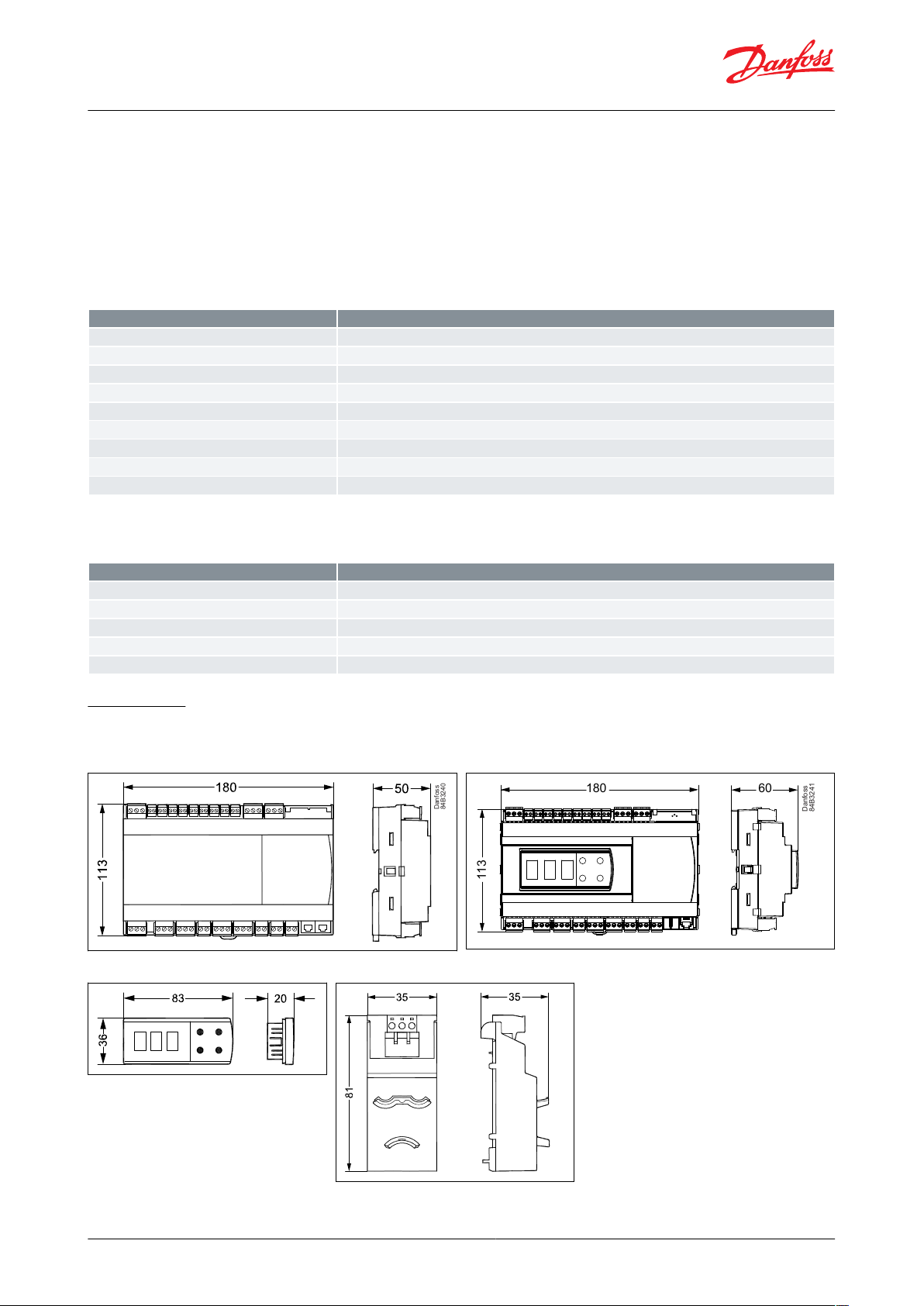

Dimensions 73

Ordering 74

Certicates, declarations, and approvals 75

Statements for the AK-UI55 Bluetooth display 75

Online support 77

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 5

Page 6

AK-CC55 Single Coil and AK-CC55 Single Coil UI

Introduction

Application

Complete refrigeration appliance control with great exibility to adapt to refrigeration appliances and cold storage

rooms.

Advantages:

• Universal controller for several dierent refrigeration appliances

• Quick set-up with predened settings

• Easy conguration and service using a mobile app with Bluetooth

• Energy optimization of the whole refrigeration appliance

• Adaptive Minimum Stable Superheat (MSS) control is performed with lowest possible superheat

• Allows the suction pressure to be raised several degrees

• Adaptive Liquid Control (ALC) can be performed with superheat down to 0 degrees on transcritical CO2 systems

with liquid ejectors

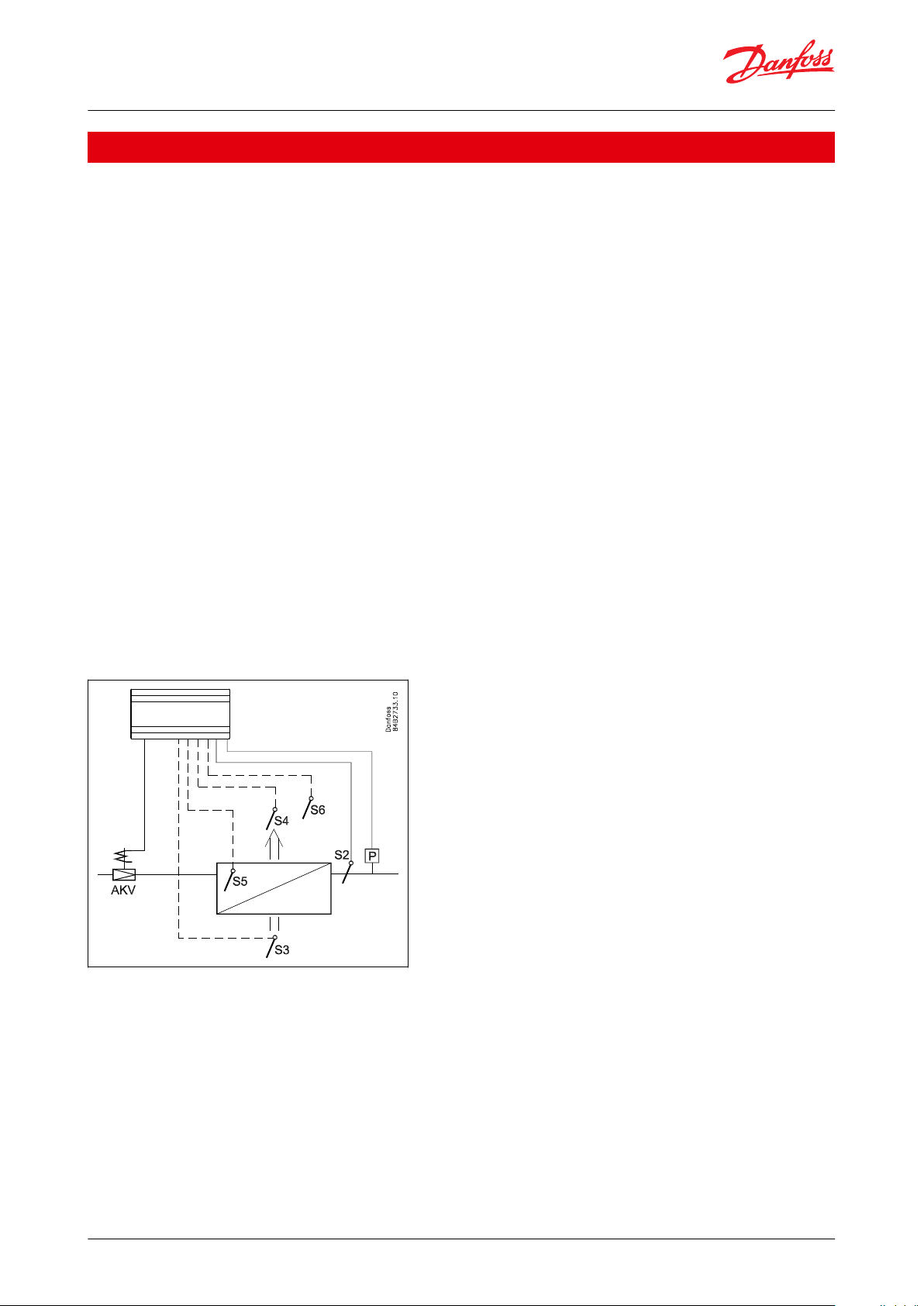

Principle

The temperature in the appliance is registered by one or two temperature sensors which are located in the air ow

before the evaporator (S3) or after the evaporator (S4) respectively. A setting for thermostat, alarm thermostat and

display reading determines the inuence the two sensor values should have for each individual function.

In addition, product sensor S6, which can be optionally placed in the appliance, can be used for registration and

alarming of the temperature near the food items.

The temperature of the evaporator is registered with the S5 sensor which can be used as a defrosting sensor.

In addition to the output of the electronic AKV injection valve, the controller has relay outputs which are dened by

the application setting.

Figure 1: AK-CC55 with evaporator, AKV valve and sensor positions

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 6

Page 7

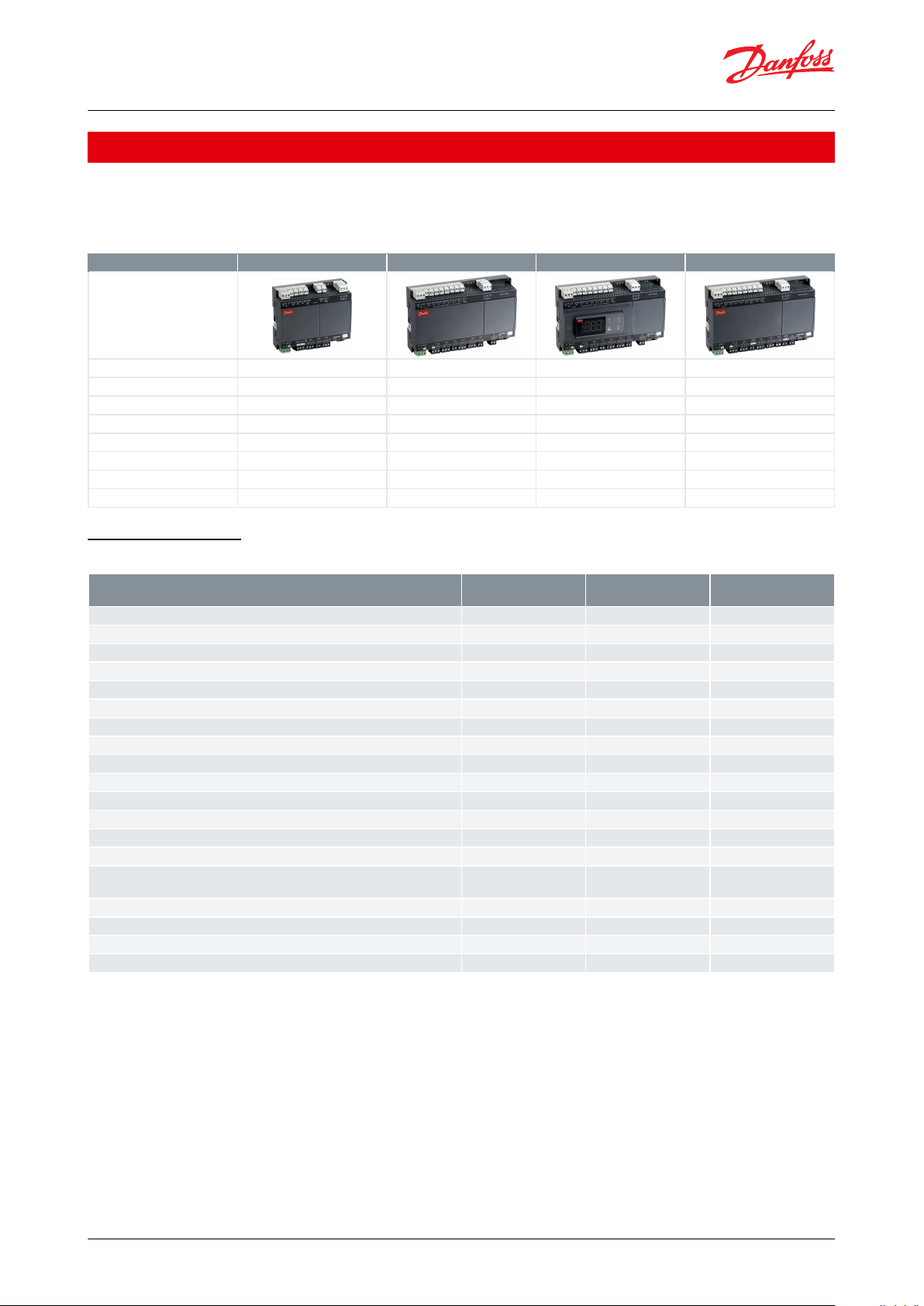

AK-CC55 Compact

AK-CC55 Single Coil

AK-CC55 Single Coil UI

AK-CC55 Multi Coil

Product image

Valve

1 x TXV or AKV

1 x AKV

1 x AKV

3 x AKV

Digital Output3554

Digital input

1 (2)

3 (2)

3 (2)

3 (2)

Analogue Output1111

Analogue Input

5 (4)

6 (7)

6 (7)

6 (7)

Display

1 remote

2 remote

1 remote + 1 Integrated

2 remote

Comm. module

Modbus

Modbus

Modbus

Modbus

Optional comm. module

LON module

LON module

LON module

Application

AK-CC55 Compact

AK-CC55 Single Coil

AK-CC55 Single Coil UI

AK-CC55 Multi Coil

AKV - application (electrically operated expansion valve)

xxx

0 – 10 V to control external stepper driver

x

TXV - application (thermostatic expansion valve + solenoid valve or compressor)

x

Remote hot gas - application

x

One valve, one evaporator, one refrigeration section

xxx

One valve, one evaporator, two refrigeration sections

x

One valve and two evaporators, two refrigeration sections

x

Two valves and two evaporators (same refrigeration section)

x

Three valves and three evaporators (same refrigeration section)

x

Custom conguration of relay outputs

x

x

Two compressorsxx

Heating functionxx

Control of air humidity

x

x

Adaptive superheat

xxx

Adaptive liquid control

(zero superheat control for transcritical CO2 systems with liquid ejectors)

xxx

Adaptive defrosting

x

Product sensor

x

Oil recovery

x

RS485 Lon, option (AK-OB55)

x

x

AK-CC55 Single Coil and AK-CC55 Single Coil UI

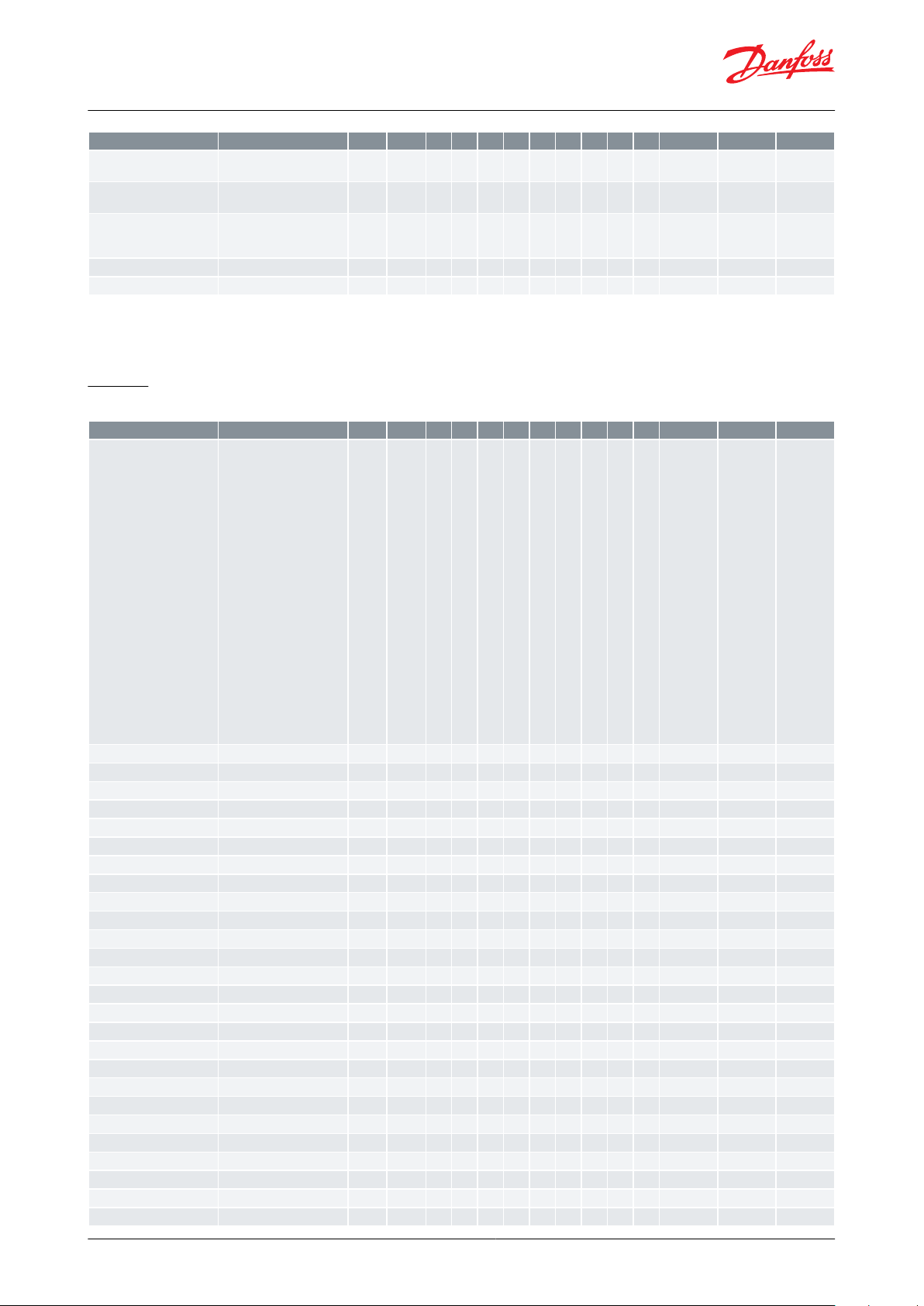

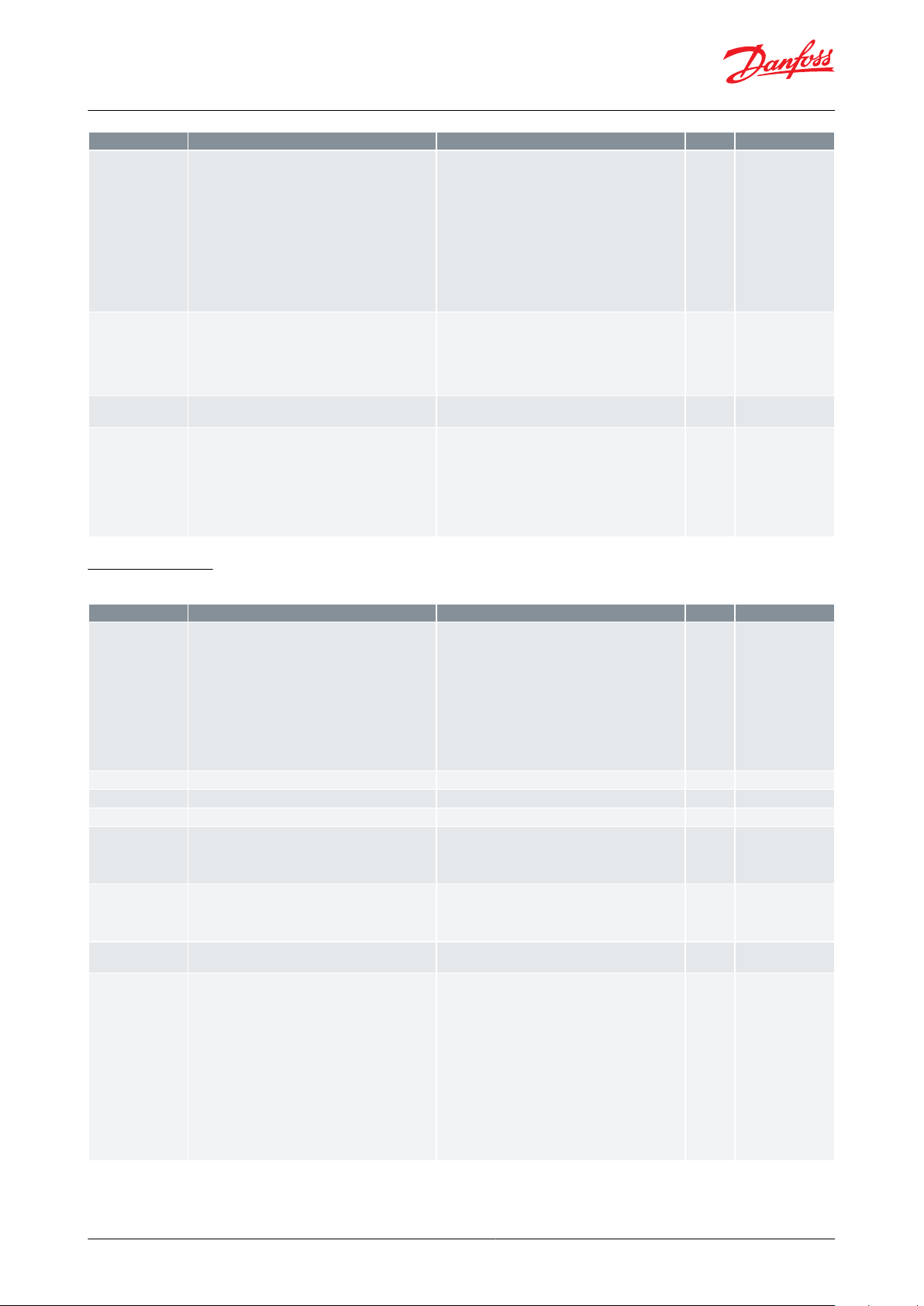

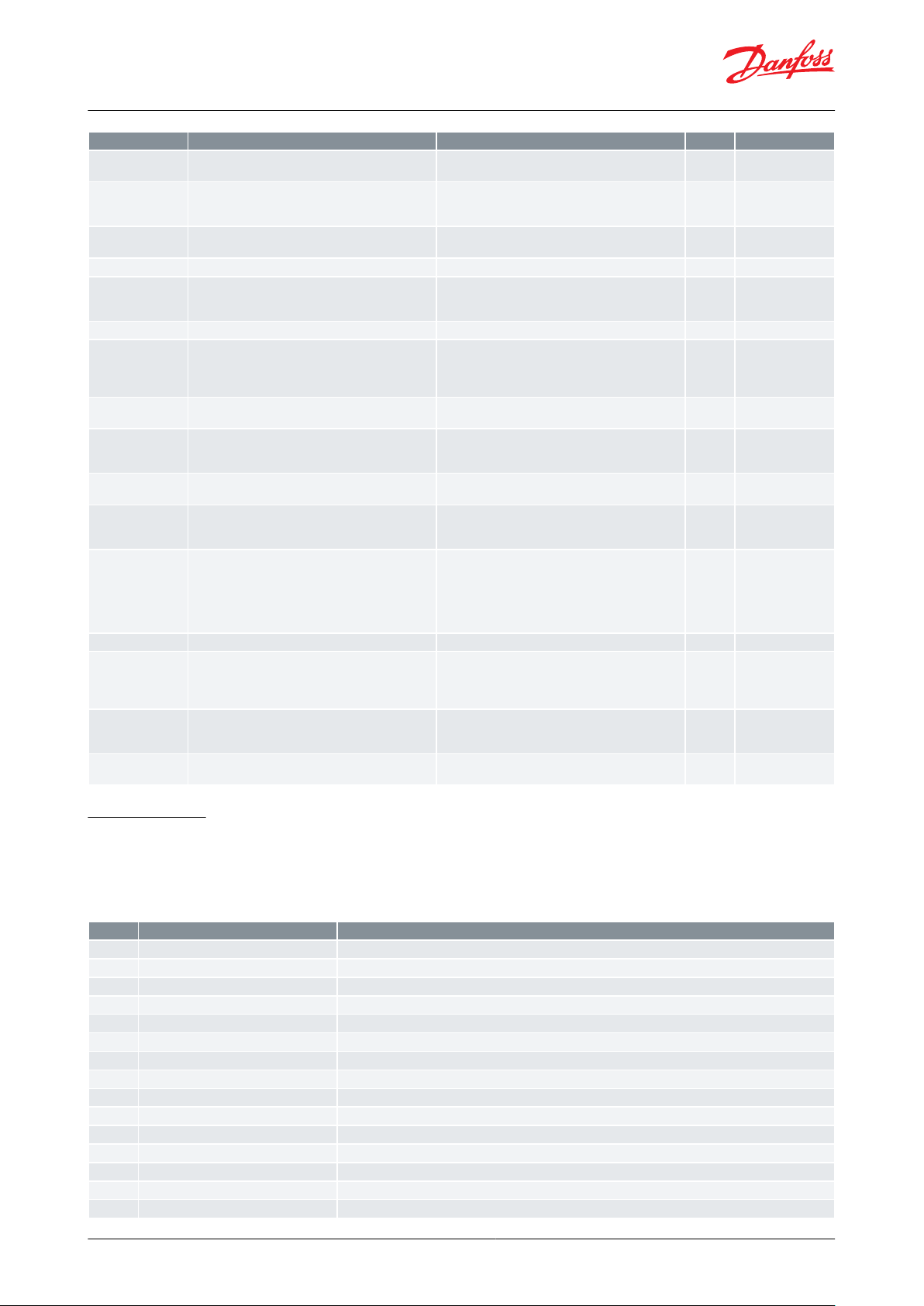

Portfolio overview

The AK-CC55 portfolio contains four controllers with dierent functionalities and application settings, as outlined in

the table.

Table 1: AK-CC55 Portfolio

Function overview

Table 2: AK-CC55 function overview by type

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 7

Page 8

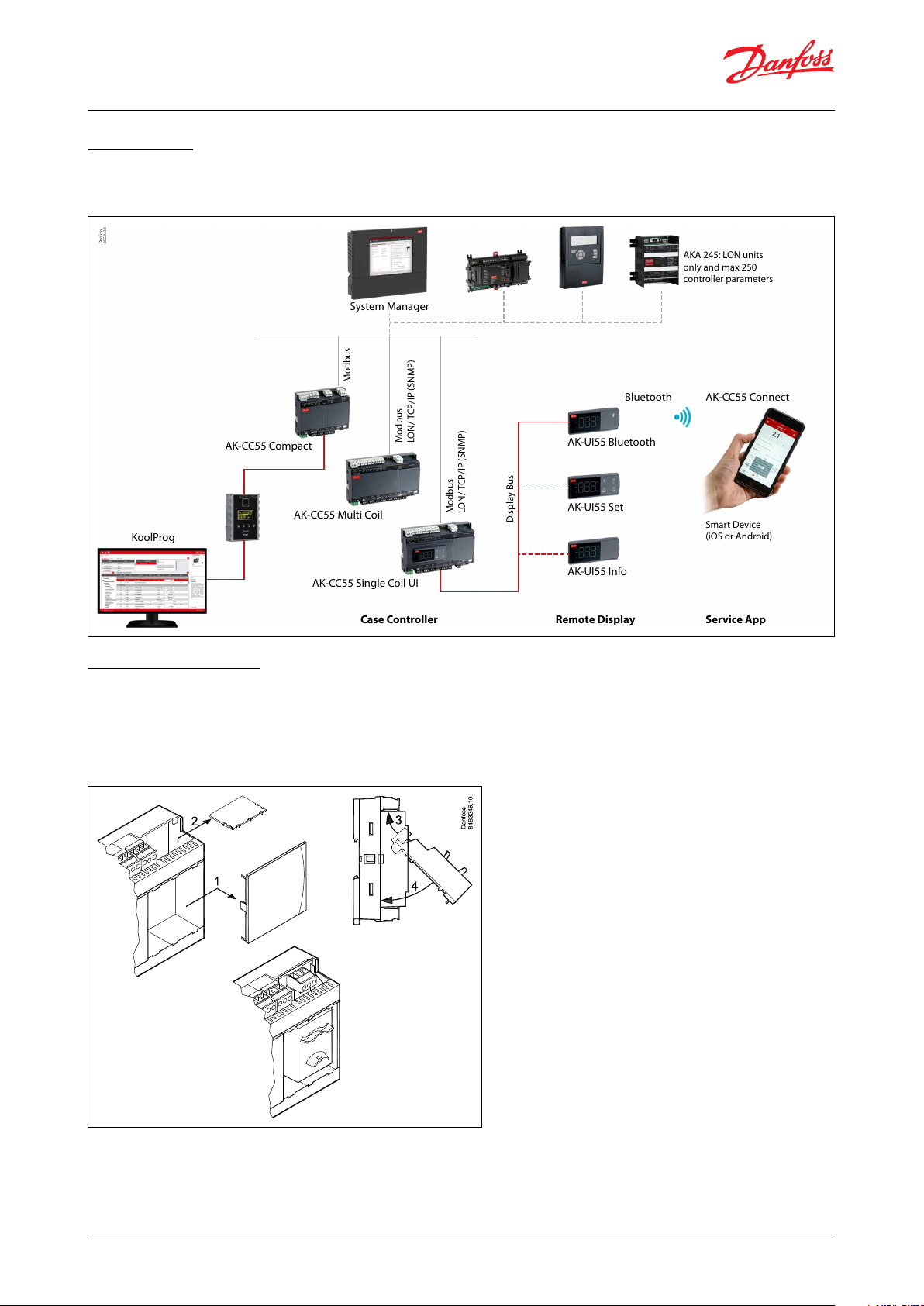

Remote Display Service App

AKA 245: LON units

only and max 250

controller parameters

System Manager

Display Bus

Modbus

Modbus

LON/ TCP/IP (SNMP)

Modbus

LON/ TCP/IP (SNMP)

Bluetooth

AK-UI55 Bluetooth

AK-UI55 Set

AK-UI55 Info

Smart Device

(iOS or Android)

AK-CC55 Connect

AK-CC55 Single Coil UI

AK-CC55 Multi Coil

AK-CC55 Compact

KoolProg

Case Controller

Danfoss

80G8333

AK-CC55 Single Coil and AK-CC55 Single Coil UI

Connectivity

The diagram outlines the connectivity options presented by AK-CC55 for the design of system functionality.

Figure 2: Connectivity

Data communication

The controller has built-in MODBUS data communication. If there is a requirement for a dierent form of data

communication, a Lon RS 485 module can be inserted in the controller.

The connection must then be to the module.

Figure 3: Mounting of communication module

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 8

Page 9

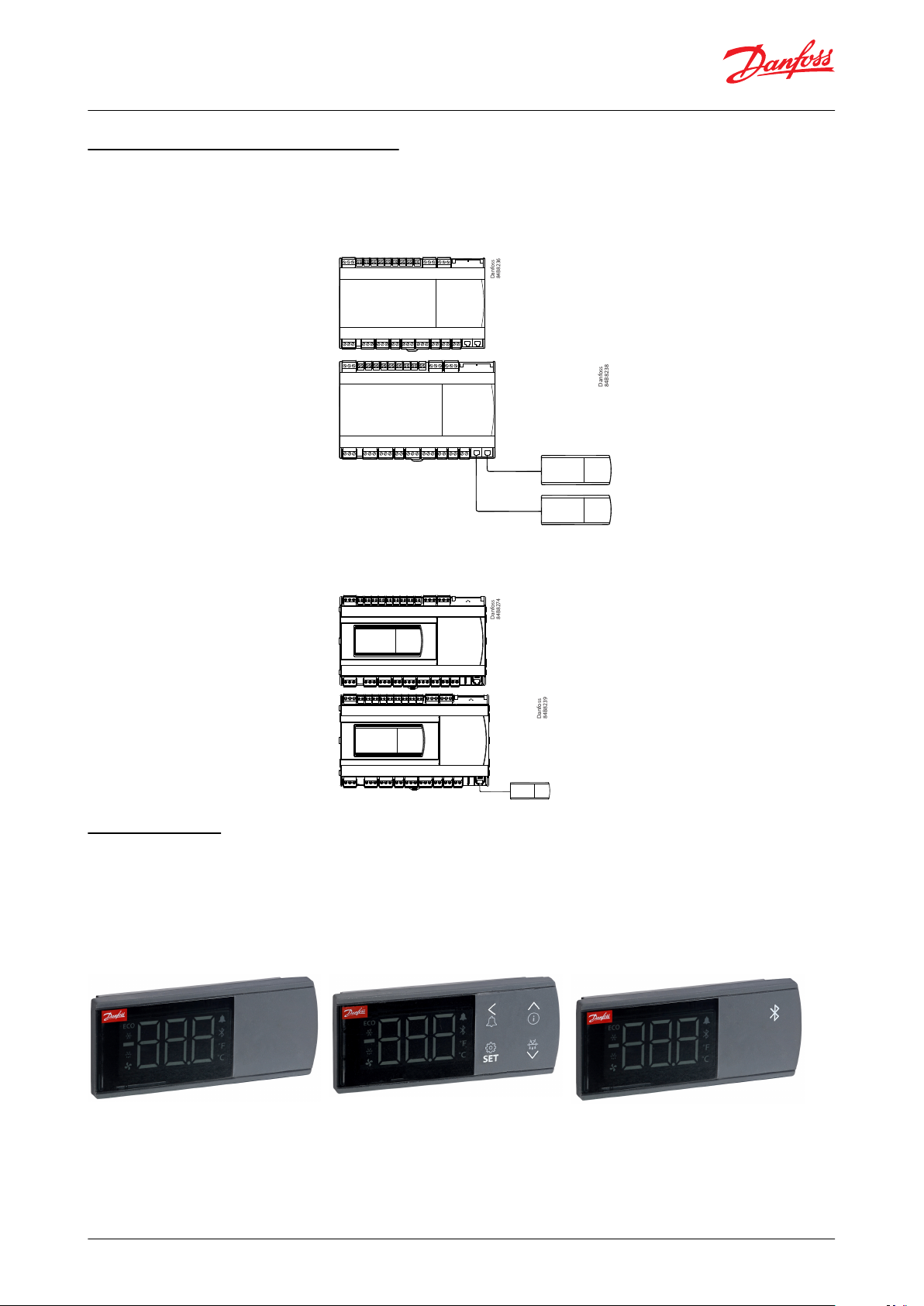

Standard enclosure. Typically used for display cases

where the controller is mounted in a tray.

Danfoss

84B8236

The standard enclosure can be expanded with one or

two external displays.

Danfoss

84B8238

Enclosure with built-in setting display. Typically used

for cold rooms.

Danfoss

84B8274

For controllers with built-in, only one external display

can be connected.

Danfoss

84B8239

AK-CC55 Single Coil and AK-CC55 Single Coil UI

AK-CC55 Single Coil and Single Coil UI

AK-CC55 Single Coil – Controlling one EEV valve.

An application mode setting will congure inputs and outputs for the desired use. There are nine applications to

choose from. Regulation is performed using an AKV expansion valve or an external stepper driver via Analogue

Output A01.

AK-CC55 Single Coil UI

Single Coil controller with built-in display. Same functionalities as AK-CC55 Single Coil.

External display

There are three versions available with dierent functions:

• AK-UI55 Info: Temperature display.

• AK-UI55 Set: Temperature display with control buttons on the front.

• AK-UI55 Bluetooth: Temperature display with Bluetooth communication, for use with AK-CC55 Connect Mobile

app.

Figure 4: AK-UI55 Info Figure 5: AK-UI55 Set Figure 6: AK-UI55 Bluetooth

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 9

Page 10

Danfoss

84B2732

S2

AKV

p

e

AK-CC55 Single Coil and AK-CC55 Single Coil UI

Controller functionality

Functions

• Day/night thermostat with ON/OFF or modulating principle

• Product sensor S6 with separate alarm limits

• Switch between thermostat settings via digital input

• Adaptive control of superheat

• Adaptive liquid control

• Oil recovery (ushing oil back to condensing unit)

• Adaptive defrosting based on diagnostics

• Start of defrost via schedule, digital input, network or setting display

• Natural, electric or hot gas defrost

• Stop of defrost on time and/or temperature

• Coordination of defrosting among several controllers in a line-up

• Pulsing or ECO control of fans when thermostat is satised

• Appliance cleaning function for documentation of HACCP procedure

• Rail heat control via day/night load or dewpoint

• Humidity control in cold storage rooms

• Door function

• Control of two compressors

• Control of night blinds

• Light control

• Heat thermostat

• High accuracy inputs will guarantee a better measuring accuracy than stated in the standard EN ISO 23953-2

without subsequent calibration (Pt 1000 ohm sensor)

• Support of user-dened temp. sensor type

• Integrated MODBUS communication with the option of mounting a LonWorks communication card

Injection control

Adaptive superheat control

Liquid injection in the evaporator is controlled by an electronic injection valve of the type AKV. The valve operates

as both expansion valve and solenoid valve. The controller opens and closes the valve based on sensor readings.

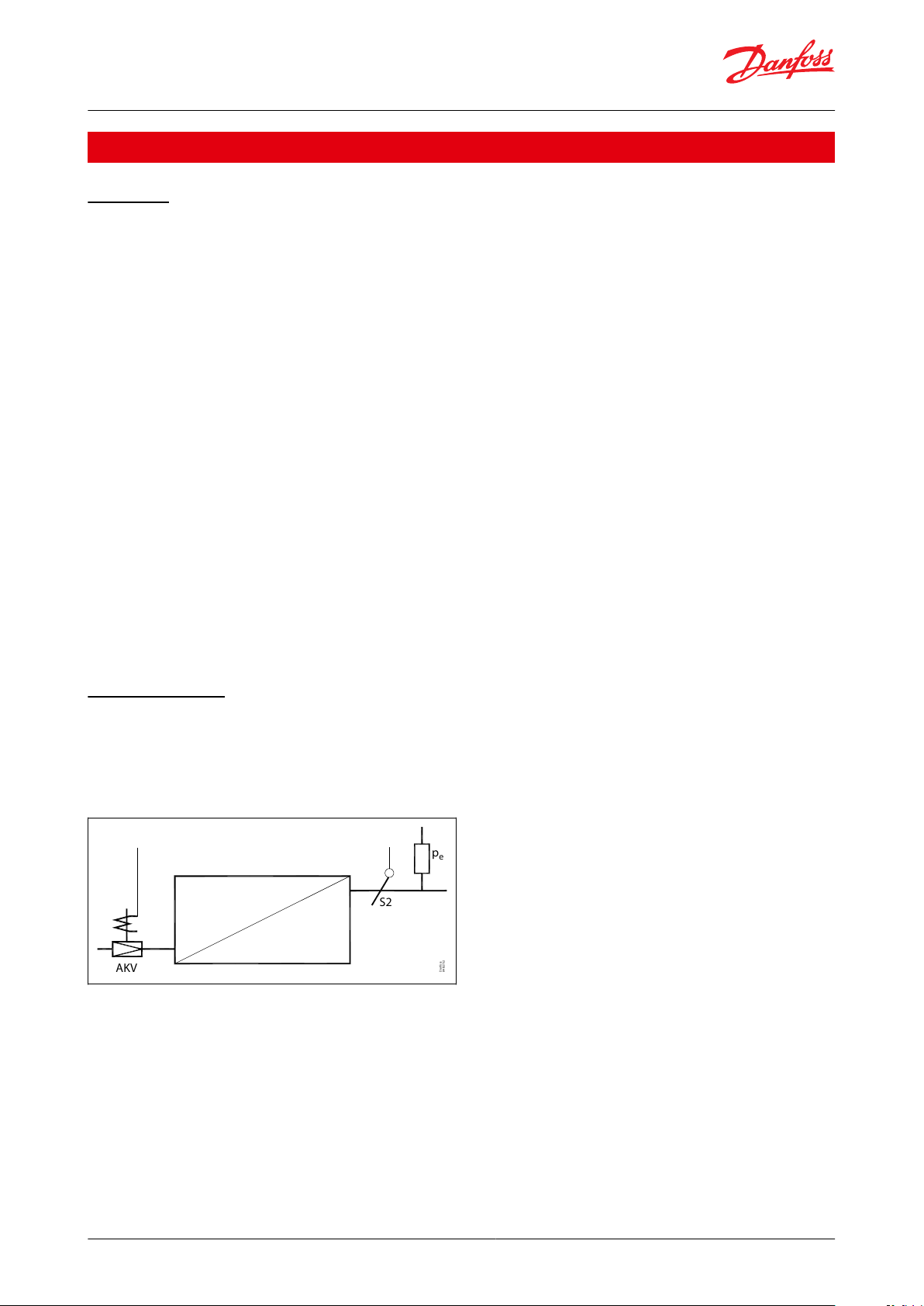

Figure 7: Adaptive superheat control with AKV valve

The superheat is measured via a pressure sensor Pe and temperature sensor S2. By using a pressure sensor, and

temperature sensor a correct measurement of superheat is achieved under all conditions which ensures a very

robust and precise control. The signal from one pressure transmitter can be shared by max. 10 controllers, but only if

there is no signicant pressure dierence between the evaporators in question.

The function contains an adaptive algorithm which independently adjusts the valve’s opening so that the

evaporator constantly supplies optimum amount of refrigerant.

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 10

Page 11

S2

P

EKF

0 – 10 V

ETSLLSV

M

Danfoss

84Z8230

AK-CC55 Single Coil and AK-CC55 Single Coil UI

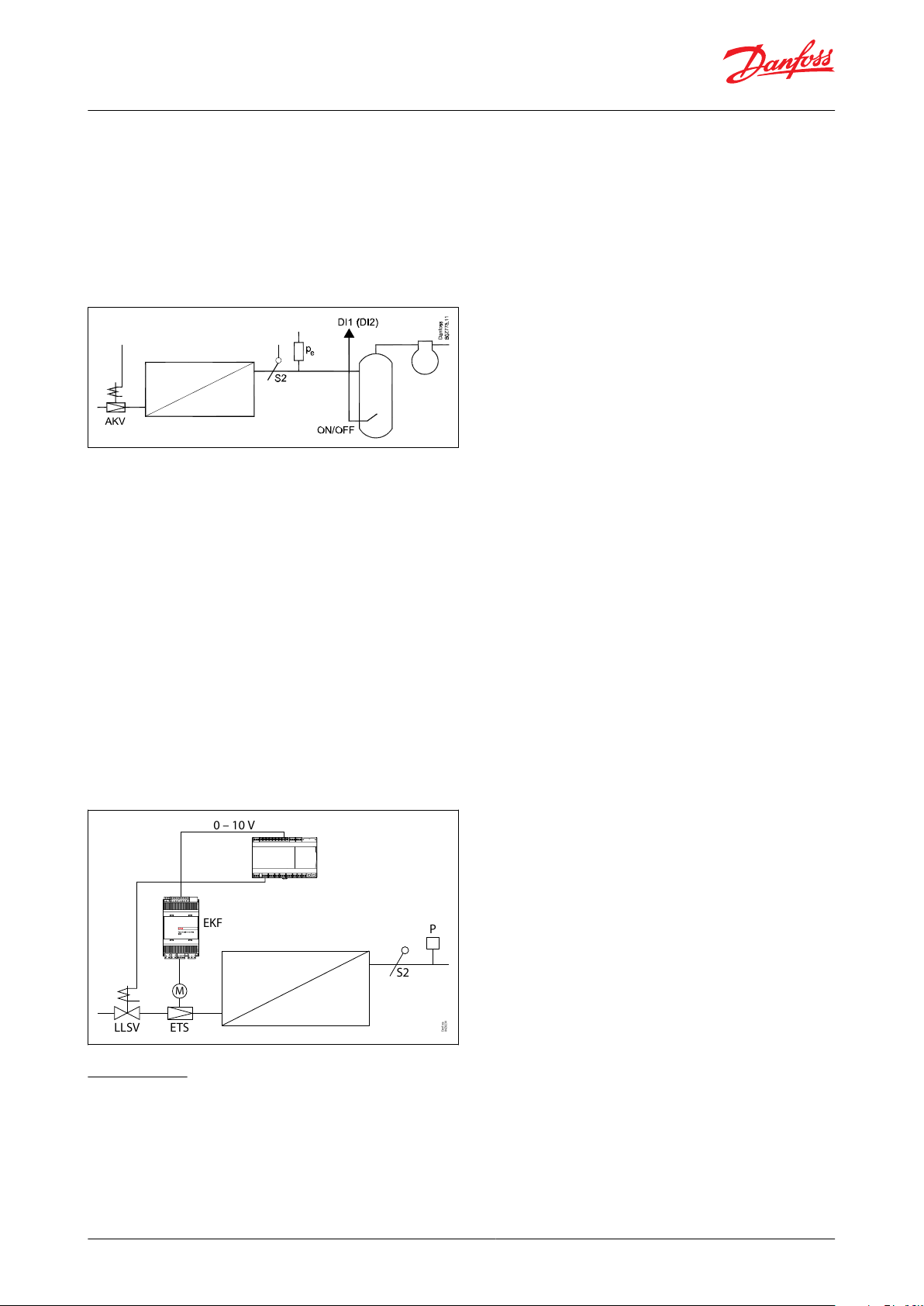

Adaptive liquid control

Adaptive liquid control is used in trans-critical CO2 ejector systems, which allow liquid ow. When adaptive liquid

control is initiated, the superheat of the evaporator will be minimized so that a controlled amount of liquid is

present at the outlet of the evaporator.

This type of control requires that the controller receives an on/o signal from (for example) a suction accumulator in

the suction line.

Figure 8: Adaptive liquid control with AKV valve

A level switch in the tank will register when the liquid level exceeds the max. level. When this happens, the

controller will switch to dry expansion, and then back to liquid control when the liquid level has dropped. The

function is dened in setting o02, o37 or o84.

The function can also be activated via data communication from a system unit. If the adaptive liquid control signal is

lost, the controller will automatically switch back to dry expansion.

WARNING:

Accidental actuation may allow liquid throughput to the compressor. It is the installer’s responsibility to ensure that

signal loss to the controller will not result in liquid throughput to the compressor. Danfoss accepts no responsibility

for damage resulting from inadequate installation.

Liquid injection by use of stepper valve

Instead of AKV, an external stepper driver can be connected to AO1 (0 – 10 V) to drive a stepper valve. DO1 (AKV

output) is then congured to close a liquid line solenoid valve (LLSV) when the stepper valve output is 0%. The LLSV

is also closed at power failure.

Figure 9: Injection control via step motor valve and liquid

line solenoid valve (LLSV)

Oil recovery

In some multi evaporator systems, oil might accumulate in the evaporators over time. The oil recovery feature will

help to get the oil back to the compressors/suction accumulator.

Oil recovery can be initiated via a digital input signal or as a network signal. When oil recovery is initiated, the valve

opening degree will be increased to ush the oil out of the evaporator.

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 11

Page 12

y

x

D

E

A

B

C

Danfoss

84B8328

xyABCDE

Time

Temp%

AKV OD%

Superheat

SH ref

Adaptive liquid control forced cooling

Oil recovery

AK-CC55 Single Coil and AK-CC55 Single Coil UI

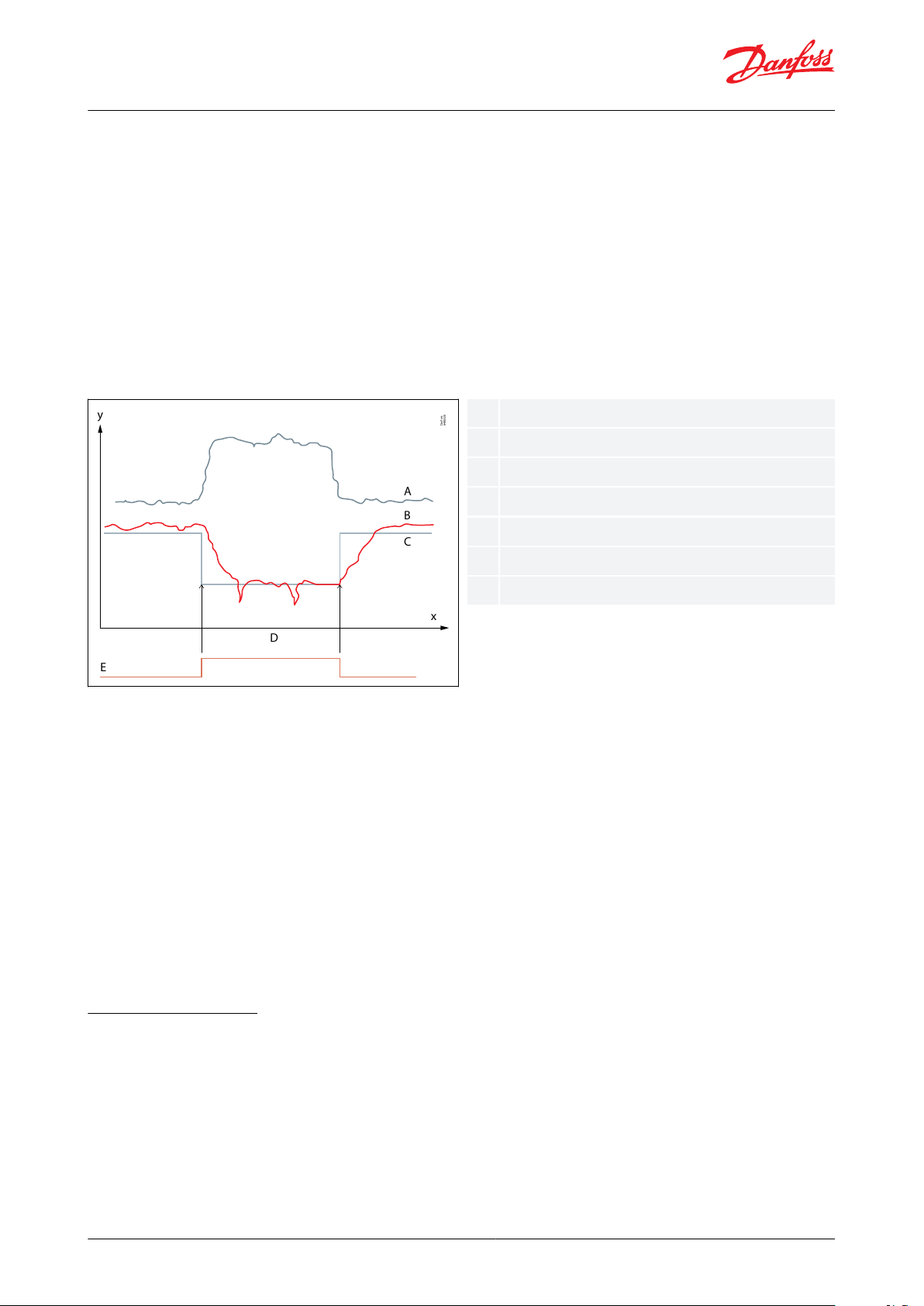

Oil recovery has the following control options:

0 = No oil recovery

1 = Adaptive liquid control + Normal fan control

2 = Adaptive liquid control + Fan OFF

3 = Fixed opening degree of valve + Normal fan control

4 = Fixed opening degree of valve + Fan OFF

Adaptive liquid control (option 1 and 2)

When oil recovery is initiated, the injection function will switch to adaptive liquid control, decreasing the superheat

reference, increasing the valve opening degree and thereby achieving a controlled amount of liquid refrigerant at

the outlet of the evaporator. As the compressor controller at the same time runs with a higher capacity/speed, this

combination will result in a higher amount of returned oil.

Figure 10: Adaptive liquid control increases valve opening degree during oil return

Fixed opening degree (option 3 and 4)

When oil recovery is initiated, the injection function will switch to a user-dened opening degree to ood the

evaporator with refrigerant and thereby ush the oil back to the compressor/suction accumulator. However, this

option provides no control or monitoring of the superheat and it is solely up to the user to ensure that the system

design provides a safeguard of the compressors.

Safety

A couple of safety functions are in place to protect the preserved food from too low temperatures during an oil

recovery cycle.

If an oil recovery has been ongoing for a longer period than the set “Max. oil recovery time”, oil recovery will be

stopped, and normal control resumed.

Oil recovery is stopped if the alarm air temperature decreases below the set low alarm limit.

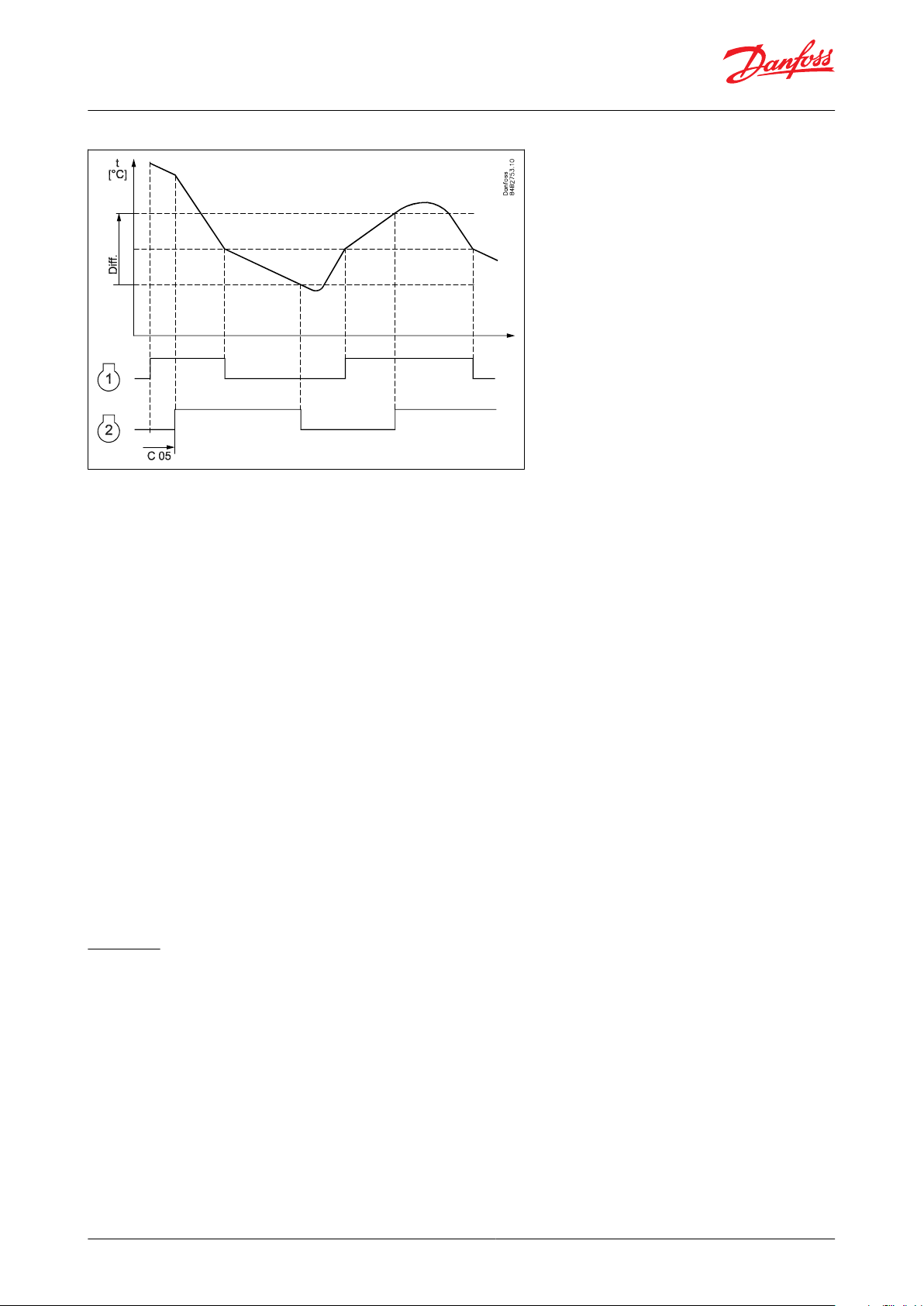

Temperature control

The temperature in the appliance is registered by one or two temperature sensors which are located in the return air

before the evaporator (S3) or after the evaporator (S4) respectively. A setting for the thermostat, night thermostat,

alarm thermostat and display reading determines how much the two sensor values should inuence each individual

function, e.g. 50% of S4 will produce an equal value from both sensors.

The actual temperature control can take place in two ways:

1.

As an ordinary ON/OFF regulation with a dierential, or

2.

As a modulating control where the temperature variation will not be nearly as high as in ON/OFF control

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 12

Page 13

ON/OFF control

Modulating control

AK-CC55 Single Coil and AK-CC55 Single Coil UI

There is, however, a limit to the use of a modulating control as it can only be used in remote cabinets. It is not

recommended to use modulating thermostat control in low temperature applications. In applications with one

evaporator and one compressor the thermostat function with ON/OFF control should be selected. In remote

cabinets, the thermostat function may either be selected for ON/OFF control or modulating control.

Table 3: Control methods

Food temperature sensor

A separate optional product sensor S6, which may be placed in the appliance, can also be used and can register and

monitor the food temperature in the appliance. There are separate alarm limits and time delays for the product

sensor.

Temperature monitoring

Just as is possible for the thermostat, the alarm monitoring can be set with a weighting between S3 and S4 so that

you can decide how much the two sensor values should inuence the alarm monitoring. Minimum and maximum

limits can be set for alarm temperature and time delays. A longer time delay can be set for high temperature alarm.

This time delay is active for pull-down after defrosting, appliance cleaning and start-up.

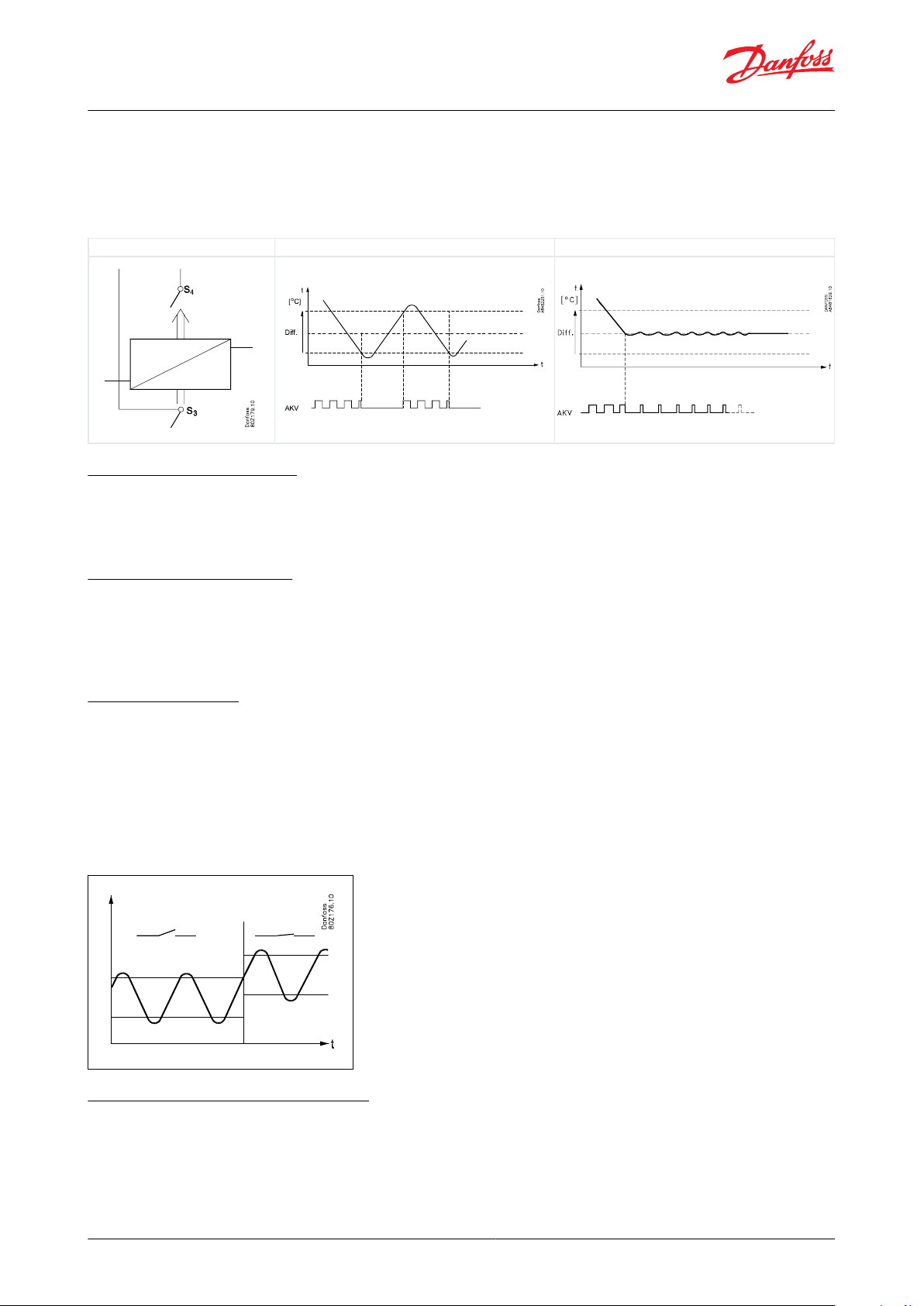

Thermostat bands

Thermostat bands can be used benecially for appliances where dierent product types are stored, which requires

dierent temperature conditions. It is possible to change between the two dierent thermostat bands via a contact

signal on a digital input. Separate thermostat and alarm limits can be set for each thermostat band – also for the

product sensor.

For the defrost control, separate defrost stop temperature and max. defrost time can be set for each thermostat

band. For the compressor control it is possible to disable the second compressor in thermostat band 2 if required.

Figure 11: Thermostat band function with two dierent band settings

Night setback of thermostat value

In refrigeration appliances there may be big load dierences between the shop’s opening and closing hours,

especially if night lids/blinds are used. The thermostat reference may be raised here without it having any eect on

the product temperature.

Change-over between day and night operation can take place as follows:

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 13

Page 14

AK-CC55 Single Coil and AK-CC55 Single Coil UI

• via an external switch connected to a digital input

• via a signal from the data communication system

Figure 12: Thermostat band function with Night setback

Temperature sensor types

The S2 and S6 sensors always have to be Pt1000 sensors due to the high measuring accuracy.

For the S3, S4 and S5 sensors, the user can select between the following sensor types:

0=Pt1000 (Danfoss AKS 11)

1=PTC1000 (Danfoss EKS 111)

2=NTC 5k (Danfoss EKS 211)

3=NTC 10k (Danfoss EKS 221)

4 = User-dened

If “User-dened” is selected, three sensor measuring points must be provided and based on these three sensor

points, a sensor characteristic is generated.

A sensor point is dened by setting a temperature value and the corresponding resistance value at this temperature.

The resistance value is set via two values for kohm and ohm respectively. These values can be found in the data

sheet for the sensor.

The three sensor points must be:

1.

Lowest temperature in wanted measuring range

2.

Highest temperature value in wanted temperature range

3.

Temp. value in the middle where a high measuring accuracy is required

A sensor error is detected at temperature values below/above the min./max. temperature values typed in for the

sensor points.

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 14

Page 15

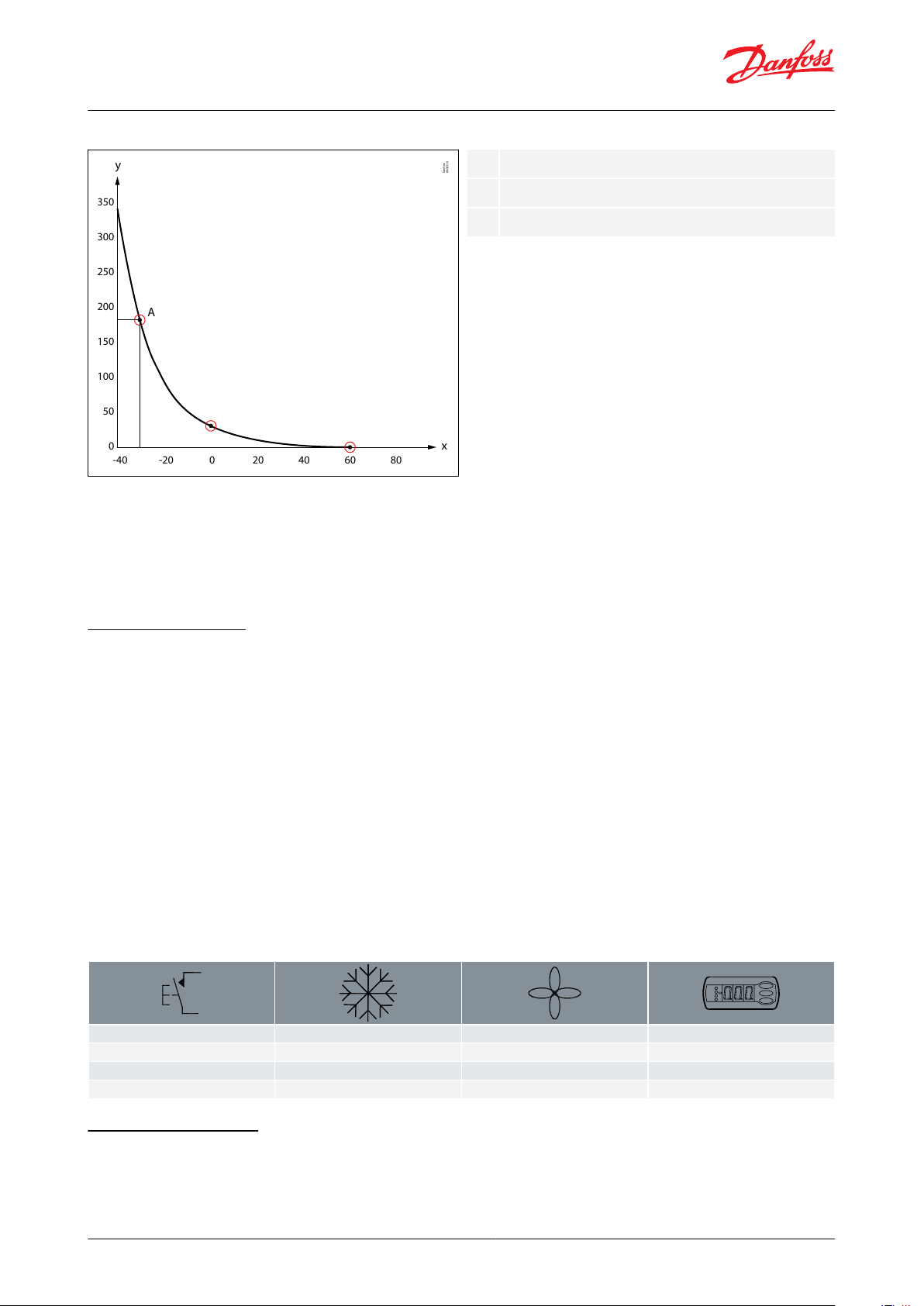

y

x

A

350

300

250

200

150

100

50

0

-40 -20 0 20 40 60 80

Danfoss

80G8338

xyA

Temp [°C]

R [kohm]

Sensor point (-30 °C, 180 kΩ)

-++°C1÷+

Fan2÷÷O3++°C

AK-CC55 Single Coil and AK-CC55 Single Coil UI

Figure 13: Example of sensor points from a NTC sensor

Limitations:

A user dened temperature sensor can only be be dened within the temperature range from -40 – +60 °C and

within the resistance range from 400 – 179.999 ohm.

When applying a new user dened sensor type, please contact Danfoss for validation of compliance and measuring

accuracy.

Appliance cleaning

This function makes it easy for the shop’s sta to carry out a cleaning of the appliance according to a standard

procedure. Appliance cleaning is activated via a pulse signal – as a rule via a key switch placed on the appliance or

via the AK-CC55 Connect mobile app.

Appliance cleaning is carried out via three phases:

1.

At the rst activation, the refrigeration is stopped, but the fans keep on operating in order to defrost the

evaporators. ”Fan” is shown on the display.

2.

At the second activation, the fans are also stopped and the appliance can now be cleaned. ”OFF” is shown on the

display.

3.

At the third activation, refrigeration is recommenced. The display will show the actual appliance temperature,

o97 setting.

When appliance cleaning is activated, a cleaning alarm is transmitted to the normal alarm recipient. A later

processing of these alarms will document that the appliance has been cleaned as often as planned.

There are no temperature alarms during appliance cleaning.

Table 4: Appliance cleaning function

Appliance shutdown

The function closes the AKV valve and all outputs are switched o. The cooling appliance is stopped like the “Main

switch”, but this happens without an “A45 standby alarm”. The function can be enabled by a switch on the DI input

or via a setting through data communication.

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 15

Page 16

A

B

C

Danfoss

84B8329

S

3

S

4

S

5

M M

ABC

Bypass valve

Suction valve

Hot gas valve

Danfoss

84B8330

S

3

S

4

S

5

M M

Danfoss

84B8331

S

3

S

4

S

5

M M

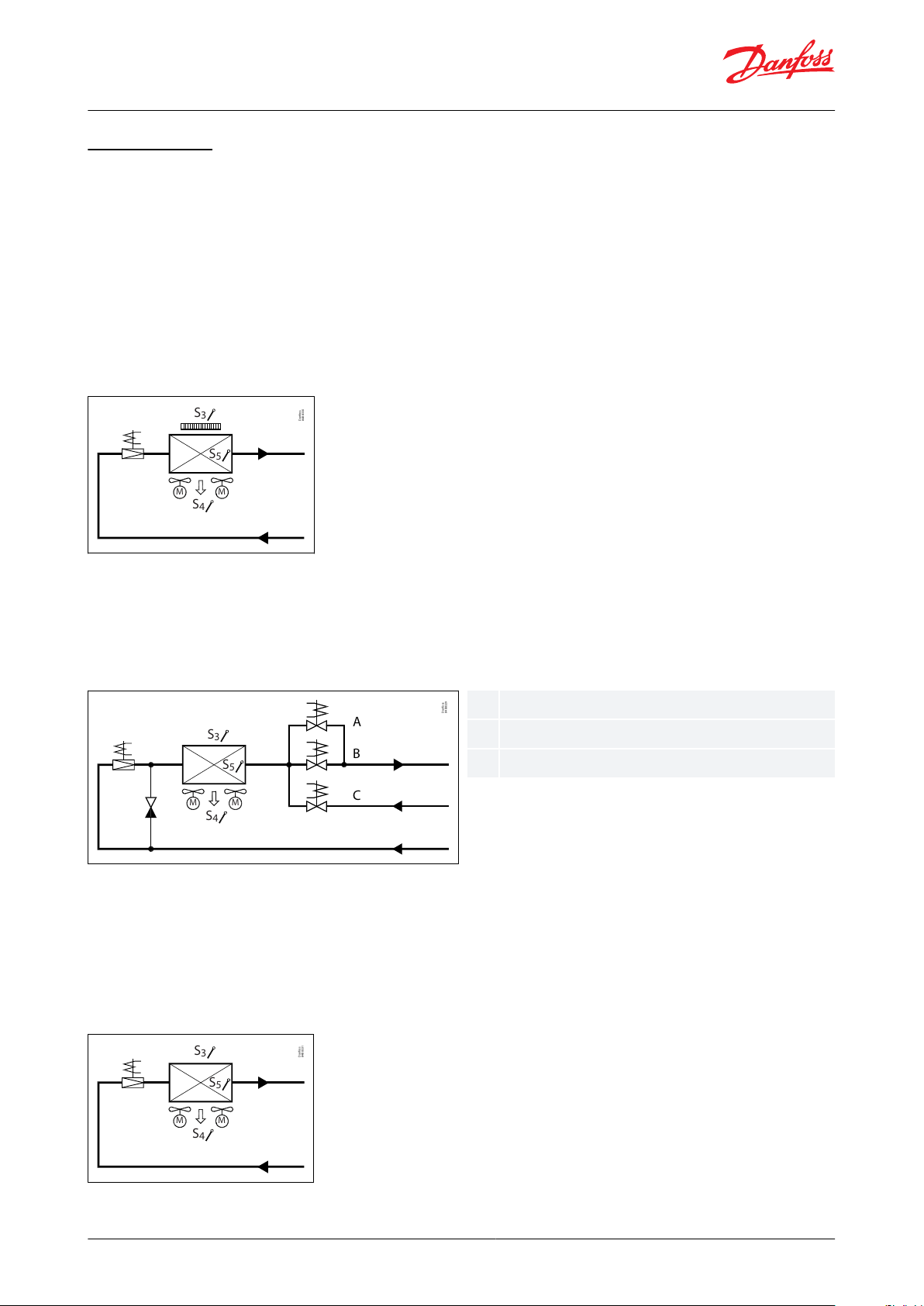

AK-CC55 Single Coil and AK-CC55 Single Coil UI

Defrost control

Defrost method

The following defrost methods can be selected:

0: None

1: Electrical

2: Hot gas defrost (Simple)

3: Natural

Electrical defrosting

At electrical defrost, an electrical heater is placed in front of the evaporator and the fan will “pull” the hot air through

the evaporator during defrosting.

Figure 14: Electrical defrosting

Hot gas defrosting

Remote hot gas defrost is supported in application mode 5. The hot gas defrost sequence covers control of the hot

gas valve, suction valve and drain valve. It is intended for smaller systems in e.g. supermarkets – the functional

content has not been adapted to industrial systems with large refrigerant charges.

Figure 15: Hot gas defrosting

Simple hot gas defrosting

If hot gas defrost is selected in application 1-3, the compressor will be running during defrost and a hot gas valve

(HGV) is bypassing the compressor discharge gas to the evaporator inlet and thereby the evaporator is defrosted.

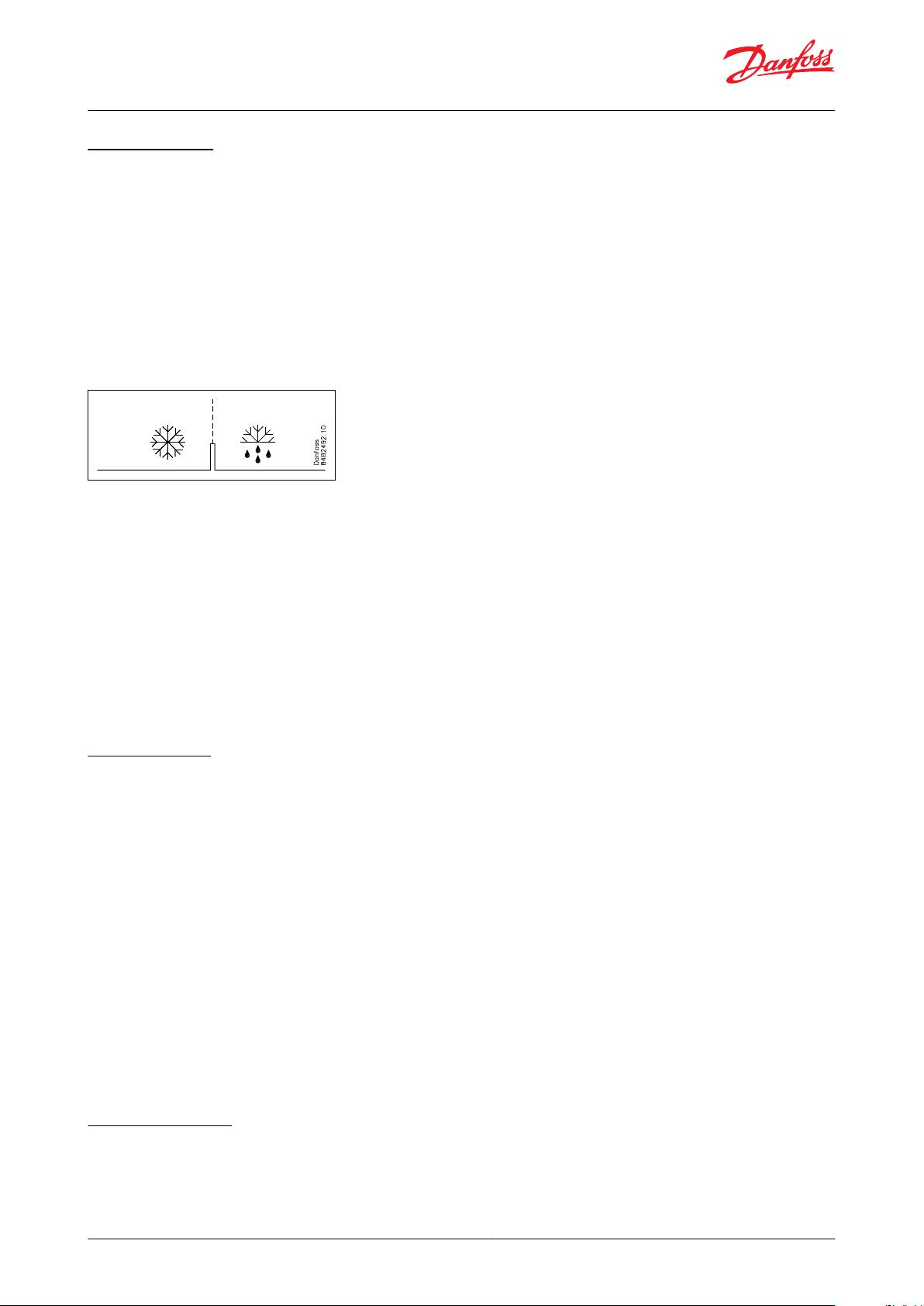

Natural defrost

At natural defrost, the ice is melted by running the fans and thereby circulating warm air through the evaporator.

Figure 16: Natural defrost

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 16

Page 17

AK-CC55 Single Coil and AK-CC55 Single Coil UI

Start of defrost

A defrost can be started in dierent ways:

Interval:

Defrost is started at xed time intervals like e.g. every eighth hour. An interval must ALWAYS be set to a "higher"

value than the period set between two defrostings when a schedule or network signal is used.

Week schedule:

Here defrost can be started at xed times of the day and night. However, max. 6 defrosts per day.

Contact:

Defrost is started with a contact signal on a digital input.

Figure 17: Defrost start

Network:

The defrost start signal is received from a system manager via data communication.

Adaptive defrost:

Here defrosting is started based on intelligent registering of evaporator performance.

Max. thermostat runtime:

When the aggregate time has passed a preset value, a defrost will be initiated.

Manual:

An extra defrost can be activated from the defrost button on the AK-UI55 Set display (though, not with application

5) or via a parameter setting. All the mentioned methods can be used in parallel – if just one of them is activated, a

defrost will be started.

Stop of defrost

Defrosting can be stopped by either:

• Time

• S4A temperature (with time as safety)

• S5A temperature (with time as safety)

• S5A and S5B temperatures (with time as safety)

When the selected defrost stop sensor reaches the set defrost stop limit, the defrost is terminated. If the defrost stop

sensor does not reach the set defrost stop limit within the set max. defrost time, the defrost will be terminated on

time.

Minimum defrost time

When using hot gas for defrosting, the heat is coming from within the evaporator, and this means that the S5 sensor

is rising fast when the inner layer of ice is melted. This will sometimes cause parts of the evaporator not to be

defrosted when defrost is terminated on S5 evaporator temperature.

To prevent this, the user is given the option of setting a minimum defrost time. When a defrost is initiated, it will

have to run for the set minimum time even if the set defrost stop limit has been reached by the selected defrost stop

sensor.

Defrost sequence

When a defrost is initiated, the controller will run through the following sequence:

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 17

Page 18

BA C D E

Danfoss

84B8332

X

AKV

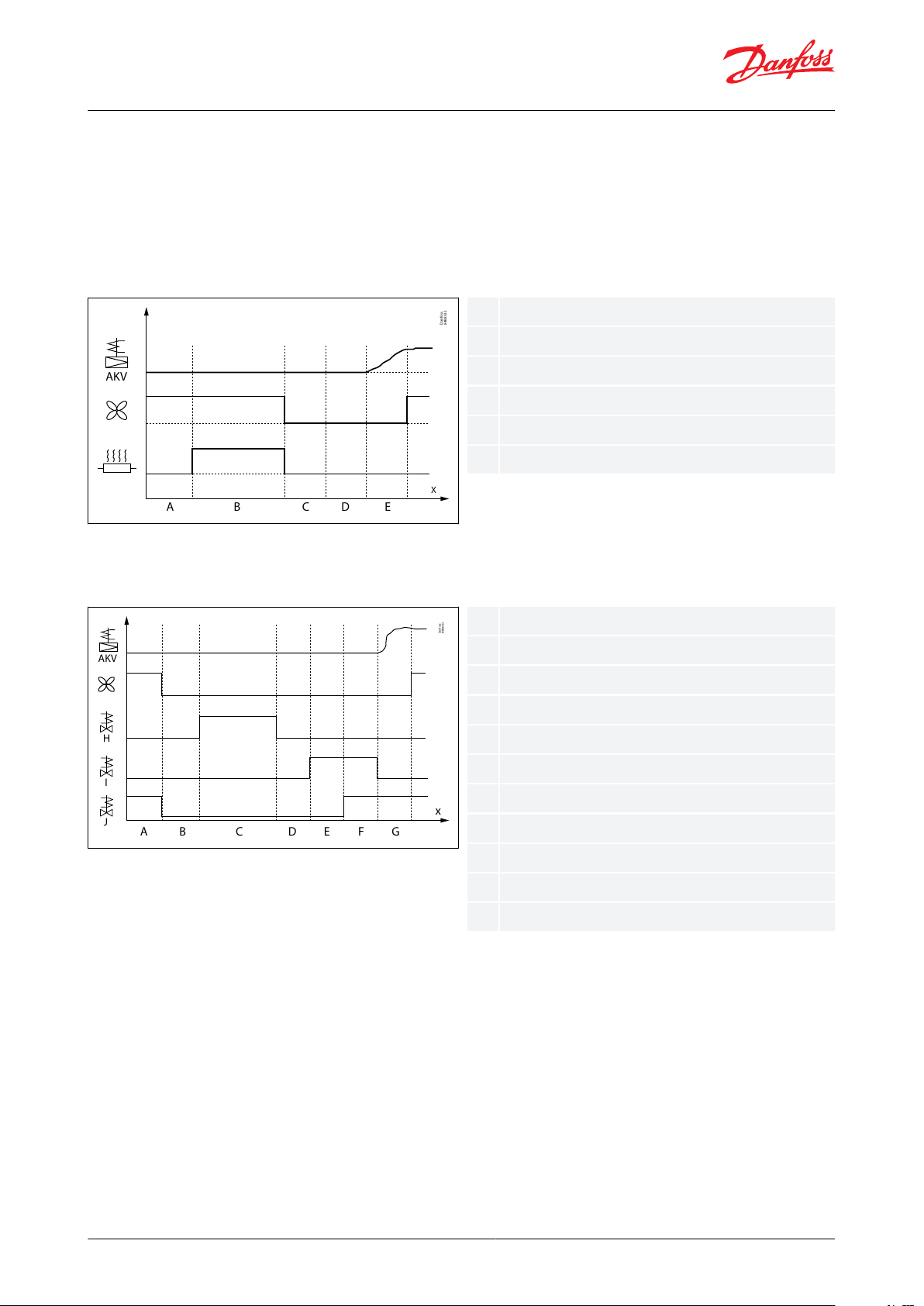

xABCDETime

Pump down

Defrost

Hold

Drip

Fan delay

Danfoss

84B8333

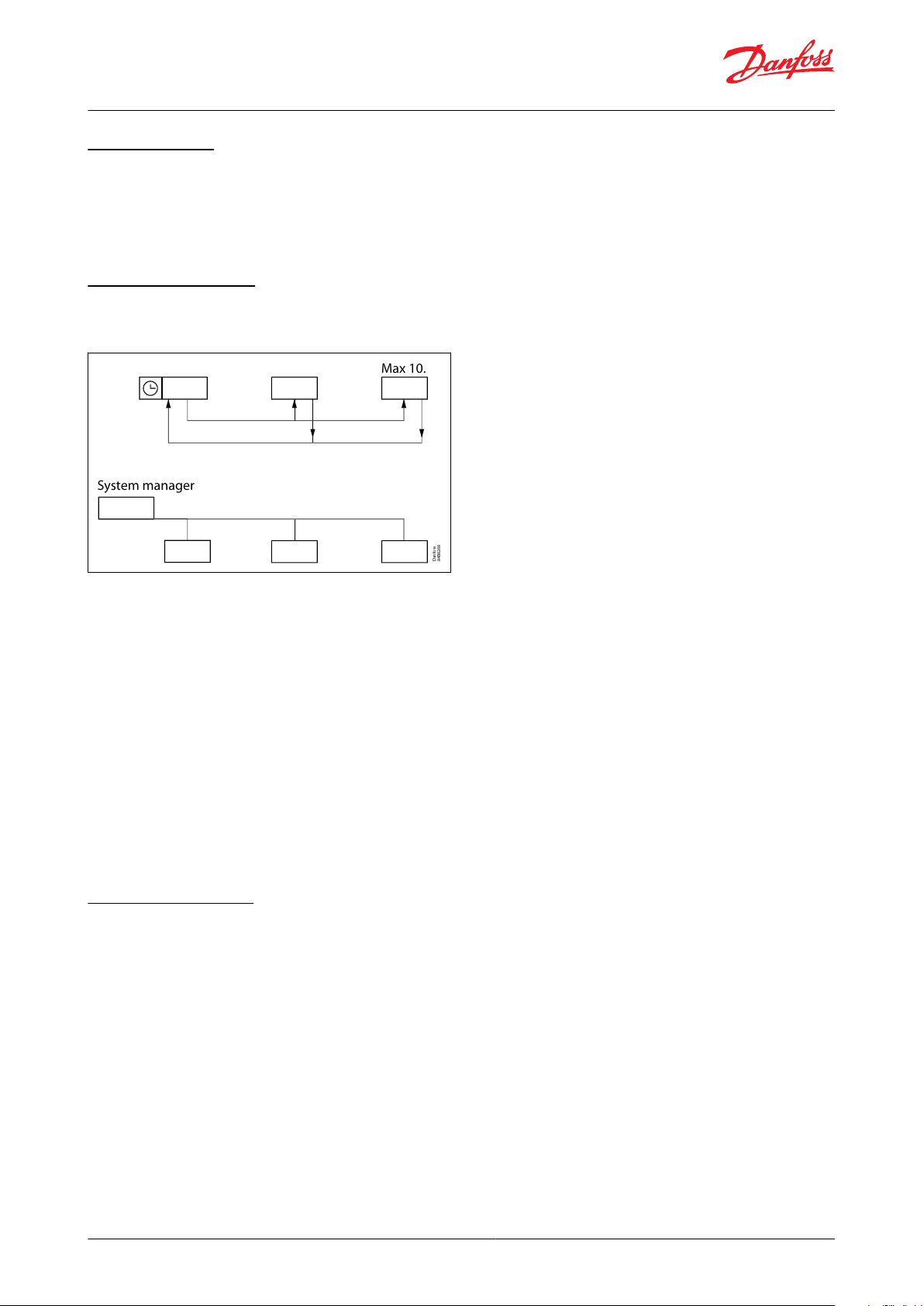

A B C D E F G

x

H

I

J

AKV

xABCDEFGHIJ

Time

Pump down

Hot gas injection delay

Defrost

Hold

Drain

Drip

Fan delay

Hot gas valve

Drain

Suction

AK-CC55 Single Coil and AK-CC55 Single Coil UI

1.

Pump down: where the evaporator is emptied of refrigerant

2.

Hot gas inj. delay (Hot gas only): where suction valve is given time for closing

3.

Defrost: where the ice on the evaporator is melted

4.

Hold after defrosting: where multiple controllers wait for each other (coordinated defrost)

5.

Drip o: where remaining water is dripping o evaporator

6.

Drain delay (Hot gas only): where the drain valve is opened to drain the liquid refrigerant

7.

Fan delay: where the fans are restarted when the remaining water on the evaporator has turned into ice

Figure 18: Electrical defrost sequence

During an electrical defrost sequence where the defrost heater is ON during defrost, AKV valve is closed and fans are

running during defrost but stopped during drip.

Figure 19: Remote hot gas defrost sequence

Remote hot gas defrost sequence where suction valve and drain valves are closed while hot gas valve is injecting

hot gas into the evaporator. After defrost, the drain valve is opening to drain the evaporator for liquid refrigerant

and then the suction valve is opening. When the water has dripped o the evaporator, liquid injection is started via

the AKV valve and the fans start when the evaporator temperature has reached the fans' start temperature.

Fan control during defrost

During the defrost sequence, the evaporator fans can be controlled in one of the following ways:

1.

The fan is OFF in the entire defrost sequence

2.

The fan is ON during the entire defrost sequence except during fan delay state

3.

The fan is ON during defrost state and is OFF in the rest of the defrost sequence

4.

Like option 2, however the fans can be stopped if the selected defrost stop sensor exceeds a set fan stop limit

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 18

Page 19

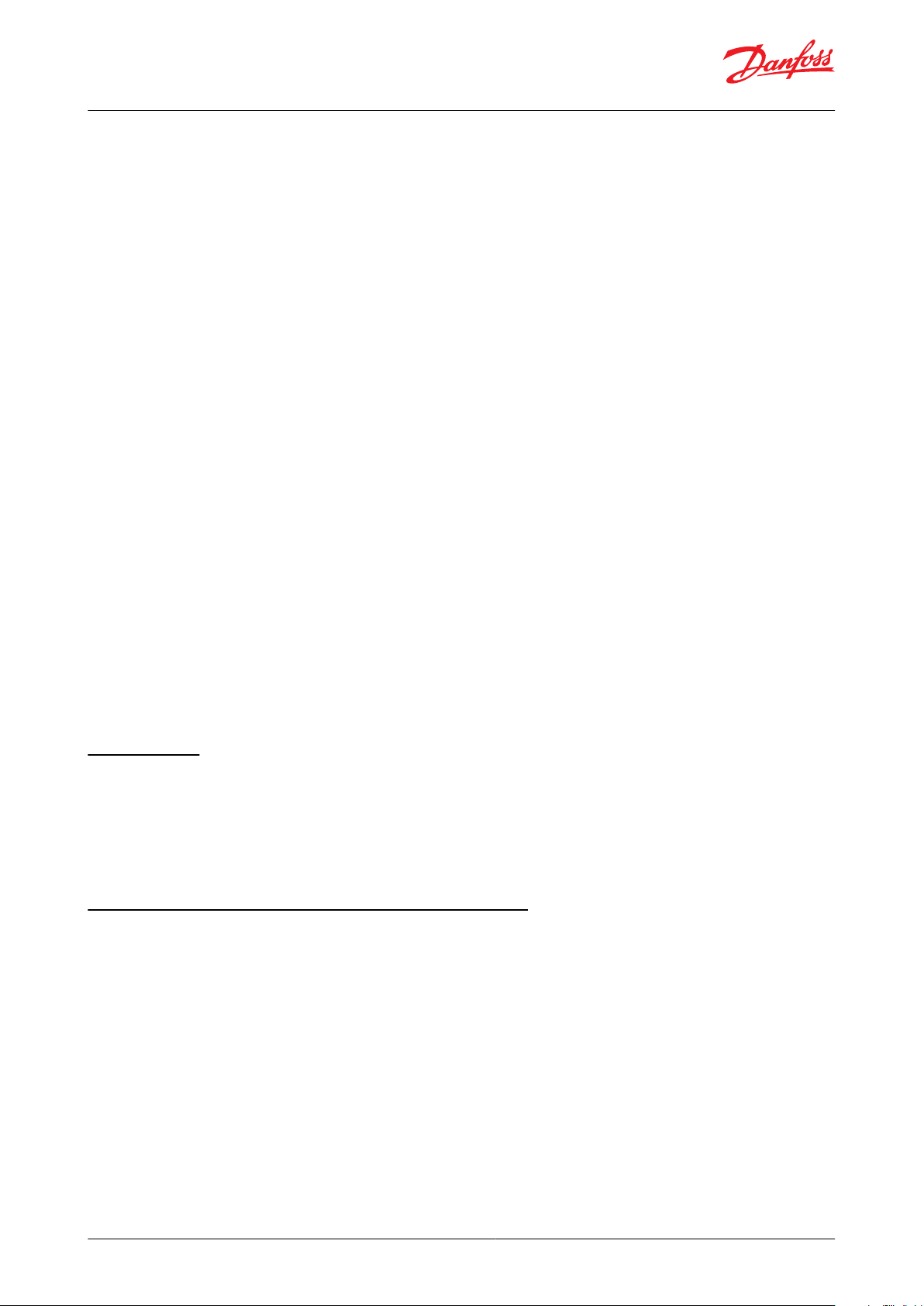

System manager

Max 10.

Danfoss

84B8268

AK-CC55 Single Coil and AK-CC55 Single Coil UI

Real-time clock

The controller has a built-in real-time clock which can be used to start defrosts. This clock has a power reserve of

four days.

If the controller is equipped with data communication, the clock will automatically be updated from a Danfoss

system manager.

Coordinated defrost

There are two ways in which coordinated defrost can be arranged.

Figure 20: Coordinated defrost options

Either with wire connections between the controllers or via data communication:

Wire connections

The digital input DI2 must be congured for coordinated defrost and wiring must be connected between the

relevant controllers. When one controller starts a defrost, all the other controllers will follow suit and likewise start a

defrost. After the defrost, the individual controllers will move into waiting position. When all are in waiting position

there will be a change-over to refrigeration.

Coordination via data communication

Here the system manager handles the coordination.

The controllers are gathered in defrosting groups and the system manager ensures that defrosting is started in the

group according to a weekly schedule.

When a controller has completed defrosting, it sends a message to the system manager and then goes into a

waiting position. When every controller in the group is in a waiting position, refrigeration is again permitted in all

the individual controllers.

Adaptive defrosting

The Danfoss adaptive defrost algorithm detects the amount of ice build-up and cancels a scheduled defrost if it is

not needed, or it can be set up to only perform defrost if the evaporator air ow is getting interrupted by frost or ice.

The overall concept is based on comparison of the energy uptake on the refrigerant ow side with the energy

emission on the air ow side. When the evaporator is clean, an energy balance is assumed, while a growing

imbalance can be identied when ice formation is build up on the evaporator surface ending up with blocked

airow.

4 dierent adaptive defrost modes

0 O

1. Monitoring

Can be set up in parallel to other defrost methods and generate an alarm in case of blocked air ow / ice-up of the

evaporator. If ash gas issues are detected on the refrigerant ow side, a ash gas alarm is generated.

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 19

Page 20

AK-CC55 Single Coil and AK-CC55 Single Coil UI

2. Adaptive skip day:

Allows the controller to cancel (skip) defrosts scheduled within day time. Defrosts scheduled at night operation will

be carried through and not skipped. Only defrosts that are set up via a schedule in the frontend using master

control functions or set up via the internal defrost schedule in the controller can be skipped.

3. Adaptive skip day and night:

With this set-up, the controller can allow to cancel (skip) defrosts scheduled both within day time and within night

time. For both adaptive skip day and night max. 3 consecutive defrosts can be skipped, whereafter the 4th

scheduled defrost will be performed even if only little ice should be present.

4. Full adaptive:

Full Adaptive mode is ideal for applications where defrost is not requested to be performed at a certain time, but

can be performed whenever ice is starting to interrupt the airow. It makes sense to combine this mode with the

defrost interval timer as a safety timer.

Adaptive defrosting requires the following connections:

• Expansion valve type AKV

• Pe evaporator pressure and S2 gas out temperature

• Temperature signal from both S3 and S4. Sensors must be placed in the airow/channel immediately before / after

the evaporator.

• Condensing temperature Tc is distributed via the network from the system manager. If Tc is not received by the

case controller, the adaptive defrost function is using default back-up values.

NOTE:

Adaptive parameters will be reset after a defrost has been initiated or at main switch in stopped or service mode. At

start up with a warm evaporator (measured with S2 sensor), the evaporator is presumed clean. If the evaporator

temperature is measured below 0.1 °C, adaptive defrost will request a defrost start to secure a clean evaporator.

Min. time between defrosts

There is a preset 2 hours minimum time between defrosts. This avoids that planned defrosts in accordance with the

weekly schedule are carried out immediately after an adaptive defrost has been carried out. The time applies from

when an adaptive defrost has been completed to when a planned defrost is again permitted. The adaptive defrost

will not start defrosting with a shorter interval than the 2 hours either.

Melt function

This function will prevent the air ow in the evaporator from being reduced by frost created by uninterrupted

operation for a long time.

The function is activated if the thermostat temperature has remained in the range between -5 °C and +10 °C for a

longer period than the set melting interval. The refrigeration will then be stopped during the set melting period.

The frost will be melted so that the air ow and hence the evaporator’s capacity will be greatly improved.

Control of two compressors (only with custom set-up)

Two compressor steps can be controlled cyclic or sequentially. At cyclic control, two compressors must be of the

same size, while in sequential control compressor step 1 can be larger than step 2.

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 20

Page 21

AK-CC55 Single Coil and AK-CC55 Single Coil UI

Figure 21: Control of two compressors

Cyclic control

When the controller demands refrigeration, it will rst cut in the compressor with the shortest operating time. After

the time delay, the second compressor will be cut in.

When the temperature has dropped to ”the middle of the dierential”, the compressor with the longest operation

time will be cut out.

The running compressor will continue until the temperature has reached the cut-out value. Then it will cut out.

When the temperature again reaches the middle of the dierential, a compressor will again be started.

If one compressor cannot maintain the temperature within the dierential, the second compressor will also be

started.

If one of the compressors has run on its own for two hours, the compressors will be changed over so that

operational time is balanced.

The two compressors must be of a type that can start up against a high pressure.

The compressor's settings for ”Min. On time” and ”Min. O time” will always have top priority during normal

regulation. But if one of the override functions is activated, like e.g. defrost, door open function, case shutdown,

forced closing, the ”Min. On time” will be disregarded.

Sequential control

Compressor steps are controlled in the same manner as described for cyclic control, but compressor step 1 will

always be started rst and cut out as the last one. No time equalization is available in sequential control mode.

Rail heat

It is possible to pulse-control the power to the rail heat in order to save energy. Pulse control can either be

controlled according to day/night load or dew point.

Relay or analogue output

A relay output can be used when long cycle times are permitted. If fast pulsing is required, the AO1/PWM output

can be used. The output must be connected to an external power solid state relay. The cycle time must be

congured for the relay output in o43 or for analogue output in P82.

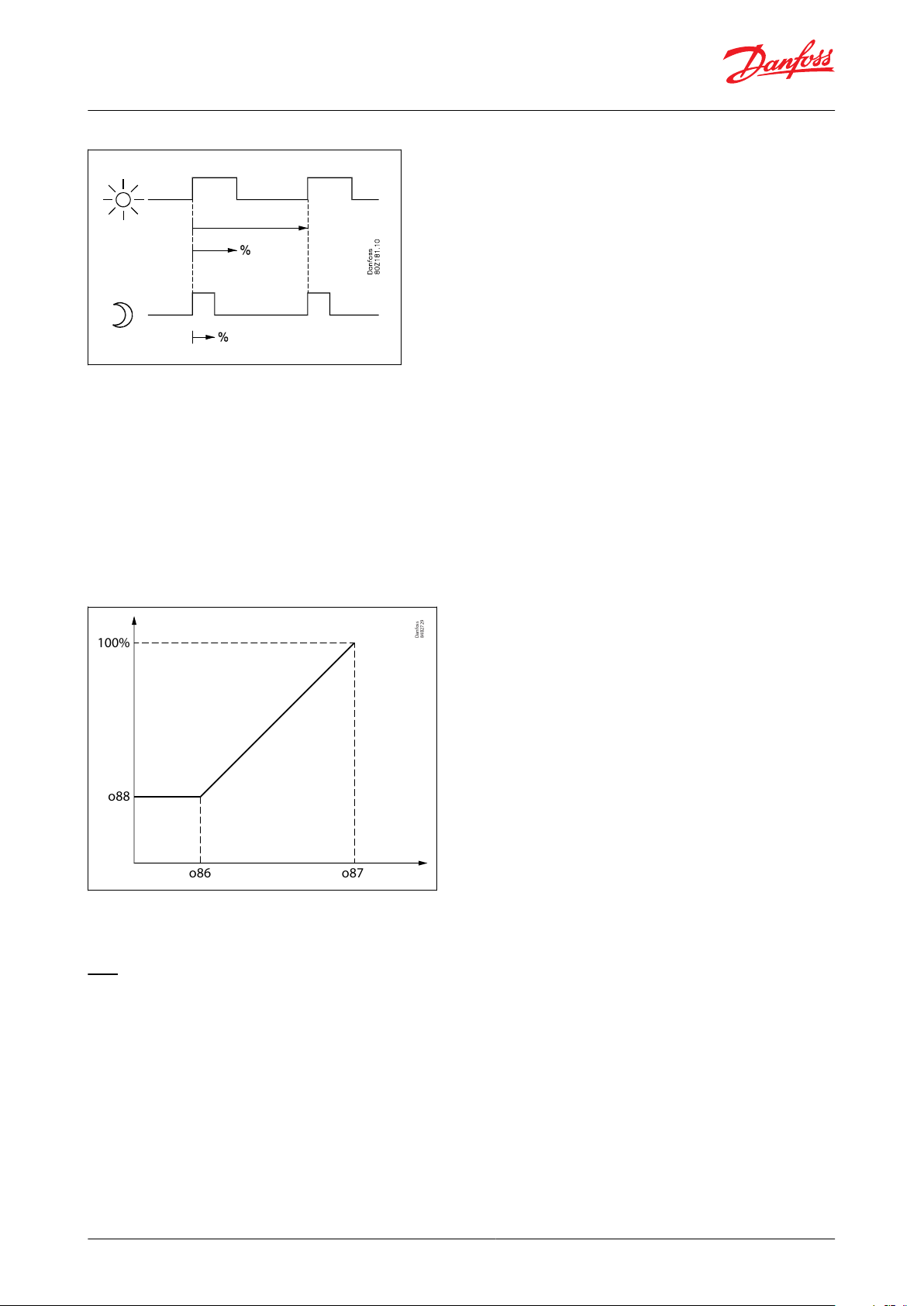

Pulse control according to day and night

Various ON periods can be set for day and night operation. A cycle time is set as well as the percentage part of the

period in which the rail heat is ON.

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 21

Page 22

Danfoss

84B2729

o88

o86

100%

o87

AK-CC55 Single Coil and AK-CC55 Single Coil UI

Figure 22: Rail heat control, day/night load

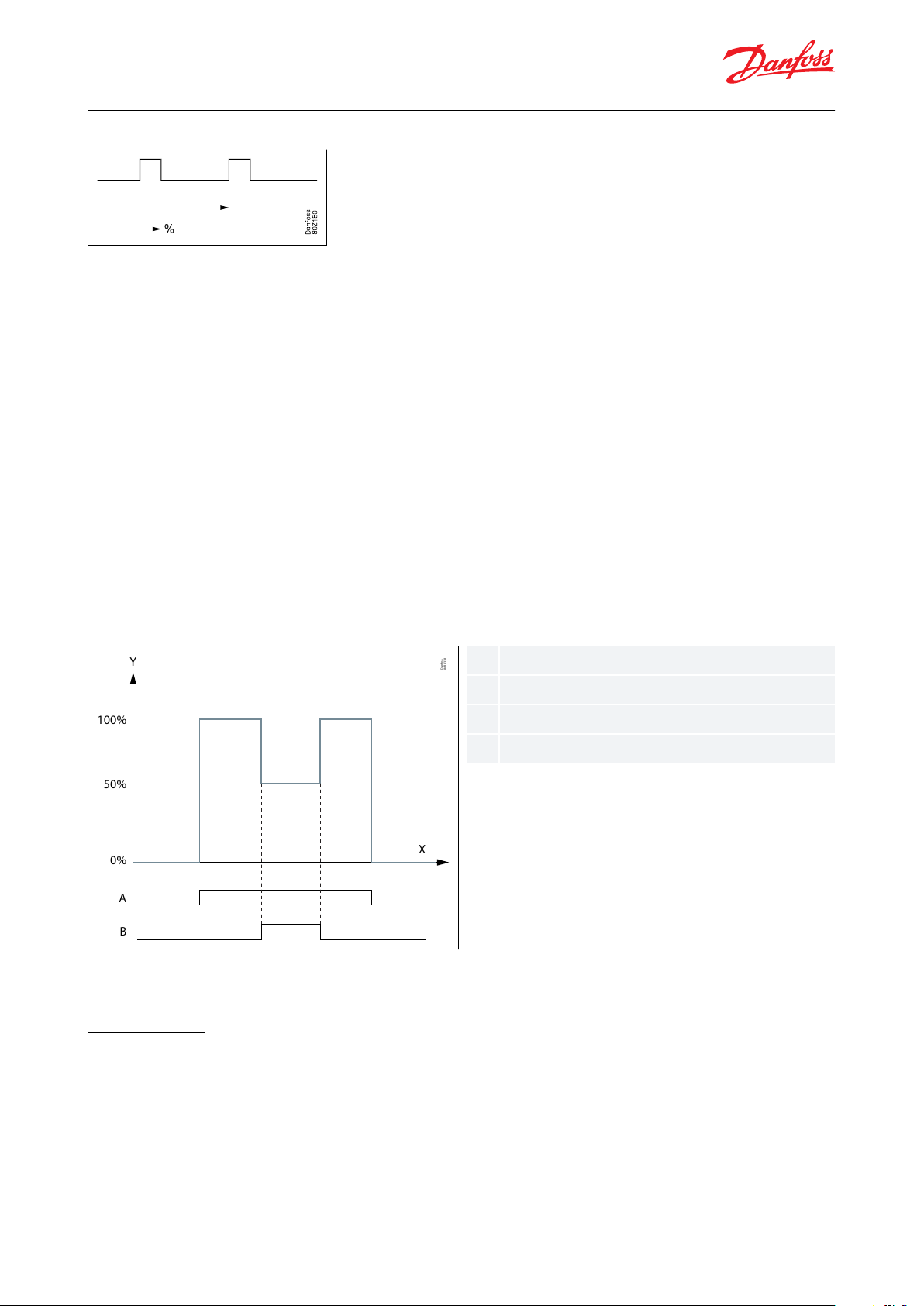

Pulse control according to dewpoint

In order to use this function, a system manager of the type AK-SM is required which can measure ambient

temperature and humidity to calculate dew point and distribute to the appliance controllers. For this the rail heat’s

ON period is controlled according to the distributed dewpoint.

Two dew point values are set in the appliance control:

• One where the eect must be max. i.e. 100%. (o87)

• One where the eect must be min. (o86)

At a dewpoint which is equal to or lower than the value in 086, the eect will be the value indicated in o88. In the

area between the two dew point values, the controller will manage the power to be supplied to the rail heat.

Figure 23: Rail heat control, dew point

During defrosting

During defrosting rail heat will be active, as selected in setting d27.

Fan

Pulse control

To obtain energy savings, it is possible to pulse control the power supply to the evaporator fans.

Pulse control can be accomplished in one of the following ways:

• during the thermostat’s cut-out period (cold room)

• during night operation and during the thermostat’s cut-out period (appliance with night blinds)

(The function is not actual when r14=2, i.e. modulating regulation).

A period of time is set as well as the percentage of this period of time where the fans have to be operating.

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 22

Page 23

Y

X

100%

50%

0%

A

B

Danfoss

84B8318

XYABTime

Fan speed

Fan

Fan ECO

AK-CC55 Single Coil and AK-CC55 Single Coil UI

Figure 24: Fan cycle time

Cut-out of fans during plant breakdowns

If the refrigeration in a breakdown situation stops, the temperature in the cold room may rise quickly as a result of

the emission of heat from large fans. In order to prevent this situation, the controller can stop the fans if the

temperature at S5 exceeds a set limit value. The fans will start running again when the S5 temperature has dropped

2K below the set limit. (The function can also be used as a type of MOP function. Here the load on the compressors

is limited until the S5 temperature has fallen below the congured value).

Fan ECO operation (only custom set-up)

Fan ECO operation is used to reduce fan speed during night operation – typically on cabinets with night blinds.

The function is enabled when a relay has been congured for Fan ECO function in one of the applications with

custom set-up of relay functions.

The fan economy control (fan speed) is controlled via the two fan outputs:

• Fan output

• Fan Eco output

If the Fan output is activated, then the fan is running with 100% speed.

If the Fan ECO output is also activated, then the fan is running with reduced speed (typically 50%).

If both fan outputs are de-activated, then the fans are stopped.

Figure 25: Fan ECO control – Fan speed reduced to 50% during night operation

The fans will always run with full speed during day operation, rst stage of case cleaning, defrost, forced cooling and

when air heating is active.

Light function

The function can be used for controlling the light in a refrigeration appliance or in a cold room. It can also be used

for controlling a motorised night blind.

The light function can be dened in several ways:

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 23

Page 24

AK-CC55 Single Coil and AK-CC55 Single Coil UI

1.

The light is controlled via the day/night function. A digital input setup for light control can switch light ON, if the

light is switched o during night

2.

The light is controlled by a system manager via the parameter o39. A digital input setup for light control can

switch light ON, if the light is switched o by the system manager.

3.

Light is controlled via the door switch. Light is switched ON when door is opened and switched OFF 2 minutes

after the door has been closed.

4.

Like option 2, but here the light is switched ON automatically if the communication to the system manager has

been lost for 15 minutes

5.

Light is only controlled via a digital input setup for light control

The light load must be connected to the NC terminals on the relay.

This ensures that the light remains ON in the appliance if power to the controller should fail.

A setting denes how light is controlled when regulation is stopped via r12 Main switch = OFF (see o98). The light is

switched o when the appliance cleaning function is activated.

Night blind

Motorised night blinds can be controlled automatically from the controller either through the custom set-up night

blind output or via the NO connector on the light relay. The night blinds will follow the status of the light function.

When the light is switched on, the night blinds open, and when the light is switched o, the night blinds close

again. When the night blinds are closed, it is possible to open them using a switch signal on the digital input. If this

pulse signal is activated, the night blinds will open and the refrigeration appliance can be lled with new products.

If the pulse signal is activated again, the blinds close.

When the night blind function is used, the thermostat function can control with dierent weighting between the S3

and S4 sensors. A weighting during day operation and another when the blind is closed.

A night blind is opened when the appliance cleaning function is activated.

A setting can dene that the night blind is opened when "r12" (Main switch) is set to o (see o98).

When the night blind rolls down, the fan will be stopped for the set time. The night blind can thereby roll down to

the correct position.

Humidity control

In application 8 when setup for room control it is possible to dene if humidity control should be done via a

humidier or a dehumidier.

When humidity control is enabled, the second display will read out the actual humidity.

The controller measures the humidity via a 0 – 10 V signal from a humidity sensor and by means of a DO relay it can

activate a humidier or a de-humidier.

High and low humidity alarm limits can be set to generate a humidity alarm.

Humidity control is disabled when main switch is OFF, at manual control, at case shutdown, at forced closing mode,

at door open, if cooling is stopped, at humidity sensor error and at case cleaning.

It is possible to dene whether humidity control is enabled during defrost or not.

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 24

Page 25

Danfoss

80G8330

y

x

A

B

C

xyABC

Time

Temperature

Humidity max temp. dierence

Humidity min temp. dierence

Humidity control enabled

Danfoss

80G8221

y

x

A

SP

B

100%

xyASPB

Time

Humidity

Humidity dierence

Setpoint

Humidier

Danfoss

80G8332

y

x

A

100%

SP

B

xySPAB

Time

Humidity

Setpoint

Humidity dierence

Dehumidier

AK-CC55 Single Coil and AK-CC55 Single Coil UI

Figure 26: Humidity control

A Max and Min temperature range can be dened wherein the humidity control is enabled. Upper and lower

dierential is xed at 1K.

It can be dened whether humidity control is active during defrost or not.

Figure 27: Humidier control

If the humidity gets below the SP, then humidication is started via a DO signal to a humidier.

If the humidity increases to SP + humidity dierential, then humidication is stopped.

Figure 28: Dehumidier control

If the humidity rises above the SP, then dehumidication is started via a DO signal to a dehumidier.

If the humidity drops below the SP – Humidity dierential, then dehumidication is stopped.

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 25

Page 26

Danfoss

84B8269

A

r01

r01

t

º C

r62

B

C

ABC

Refrigeration

Neutral zone

Heat

Function

Input / Settings menu

Setting

DI1

DI2

DI3

o02

o37

o84

None+++0

DI Status+++1

Door function+++2

Door alarm+++3

Defrost start+++4

Main switch+++5

Night setback+++6

Thermostat band

+++

7

Alarm at closed++

8

Alarm at open++

9

Case cleaning+++10

Forced cooling+++11

Open blinds+++12

Coordinated defrost

+

13

Forced closing+++14

Shutdown+++15

Light control+++16

Leak detection+++20

Adaptive liquid control

+++

21

Valve driver alarm at open

++22

Fan alarm at open

++23

Door fan stop+++29

Oil recovery+++30

AK-CC55 Single Coil and AK-CC55 Single Coil UI

Heating function (only with custom set-up)

The heating function is used to prevent the temperature from becoming too low, e.g. in a cold room, etc. The limit

for when the heating function cuts o is set as an oset value below the current cut-out limit for the refrigeration

thermostat. This ensures that refrigeration and heating do not occur simultaneously. The dierence for the heating

thermostat has the same value as for the refrigeration thermostat. To prevent that the heating thermostat cuts in

during short-term drops in air temperature, a time delay can be set for when to change from refrigeration to

heating.

Figure 29: Heating function

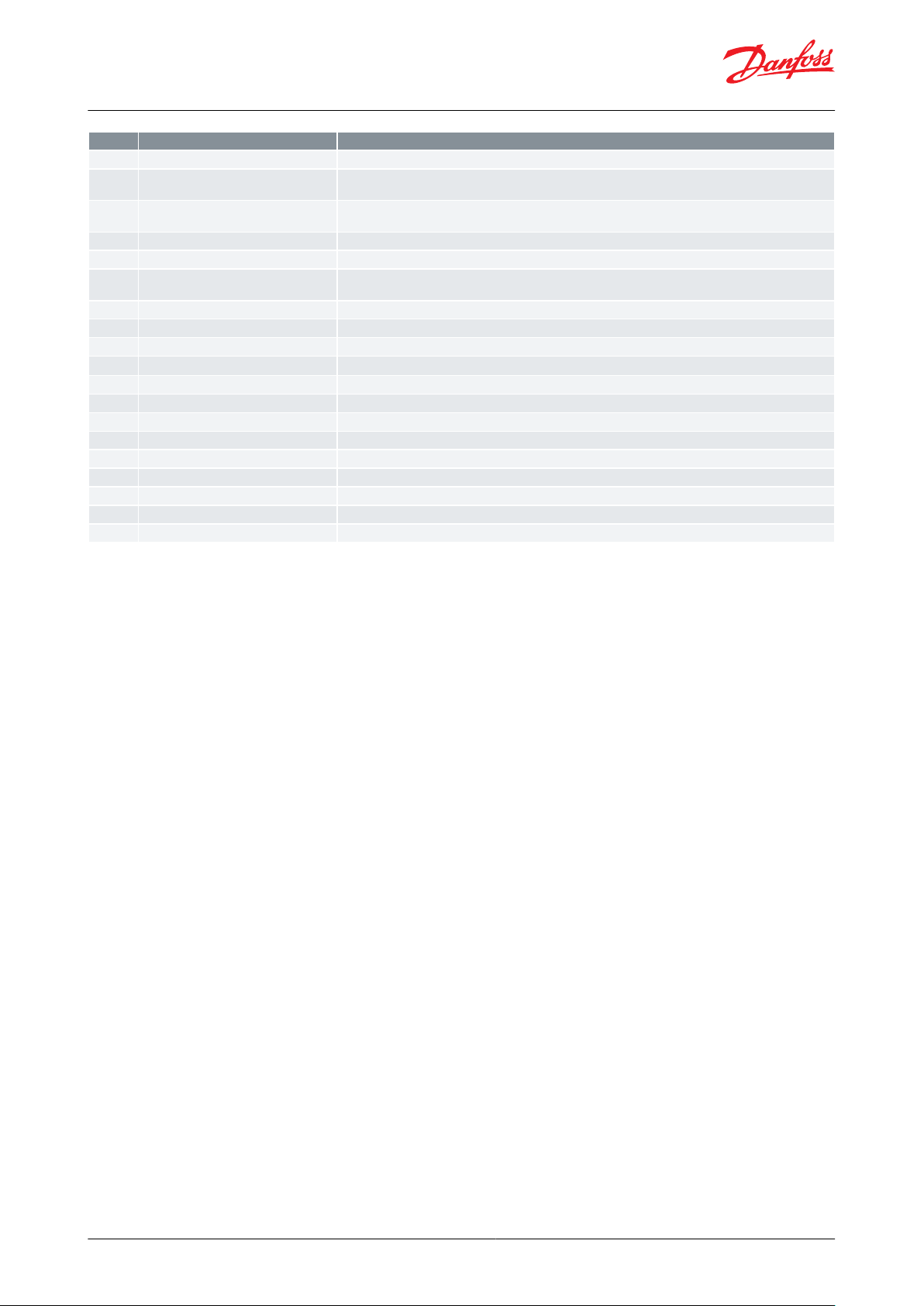

Digital inputs

There are two digital inputs, DI1 and DI2, with dry contact function, and one digital input DI3 with high voltage

signal.

They can be used for the following functions:

Table 5: Function table and DI settings

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 26

Page 27

Danfoss

84B8238

AK-CC55 Single Coil and AK-CC55 Single Coil UI

Example: If DI1 is to be used to start a defrost, o02 must be set to 4.

Forced closing

The AKV valves can be closed with an external signal ("Forced closing").

The function must be used in connection with the compressor’s safety circuit, so that there will be no injection of

liquid into the evaporator when the compressor is stopped by the safety controls and cannot start again (however

not at low pressure – LP).

Via a setting (see o90 Fan at forced closing) it is possible to dene whether the fan should be ON or OFF during

forced closing and whether an ongoing defrost is suppressed (i.e. put in standby position for a period of up 10

minutes before it is cancelled) - this feature can be used in CO2 systems to eliminate excessive heating while

compressors cannot run.

The signal can be received from the DI-input or via the data communication.

Door contact

The door contact function can via the digital inputs be dened for two dierent applications:

Alarm monitoring:

The controller monitors the door contact and delivers an alarm message if the door has been opened for a longer

period than the set alarm delay.

Alarm monitoring and stop of refrigeration:

When the door is opened, the refrigeration is stopped, i.e. the injection, the compressor and the fan are stopped and

light switches on. If the door remains open for a longer time than the set restart time, refrigeration will be resumed.

This will ensure that refrigeration is maintained even if the door is left open or if the door contact should be

defective. If the door remains open for a longer period than the set alarm delay, an alarm will also be triggered.

Alarm monitoring and stop of fans:

When the door is opened, only the fans are stopped. If the door remains open for a longer time than the set alarm

delay, an alarm is triggered and the fans will start running again.

Display

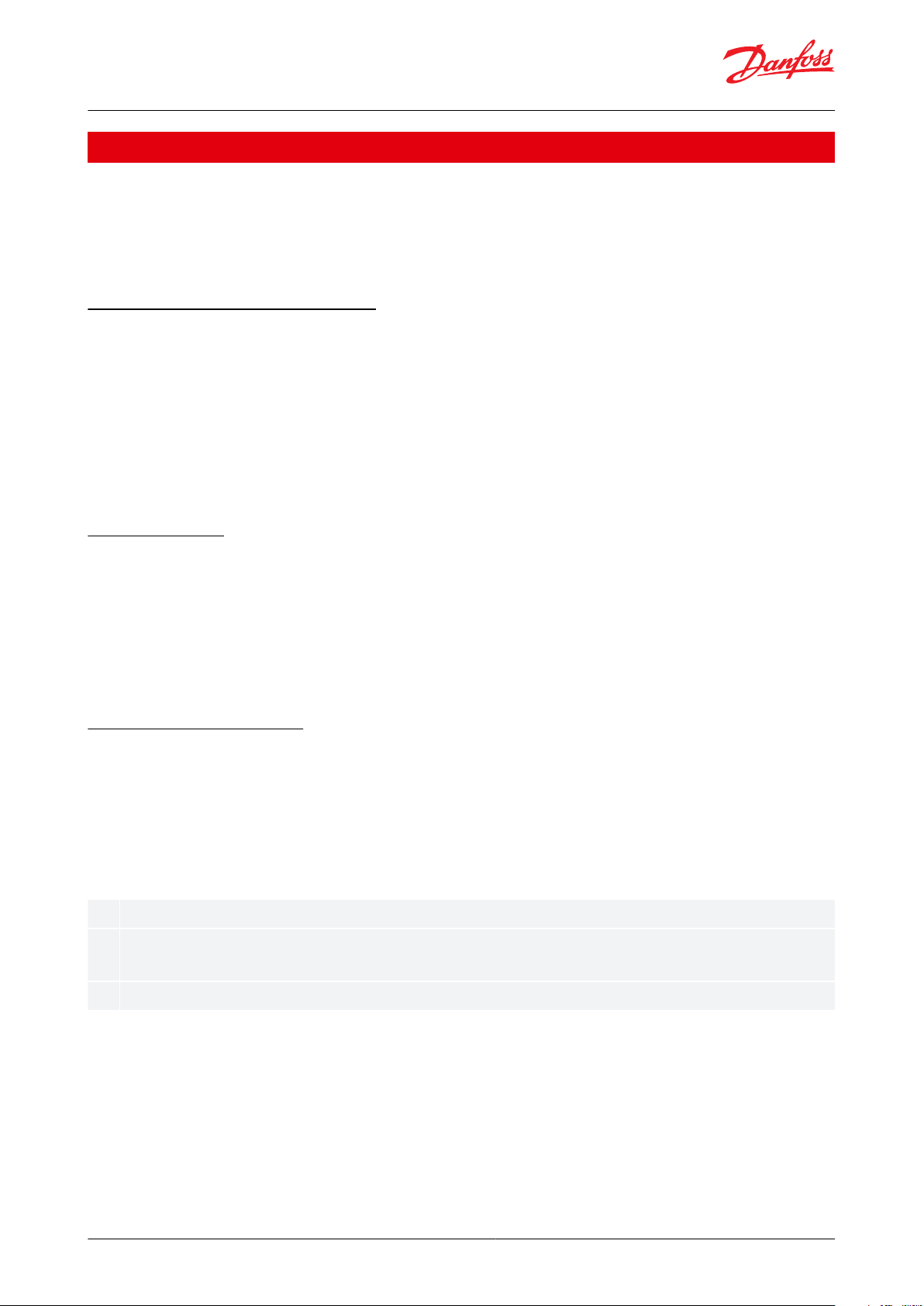

The controller has one or two plugs for an external display.

One of the following display types can be connected to a plug:

• AK-UI55 Info (temperature display)

• AK-UI55 Set (temperature display and operation)

• AK-UI55 Bluetooth (temperature display and app interface)

The connection between the display and the controller must be made using an AK-UI55 cable.

The distance between the controller and the display must not exceed 100 m.

If there are two external displays, it will be the sum of the two distances that cannot exceed 100 m.

Figure 30: Controller with two displays

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 27

Page 28

Master control function

Description

MC Ther. toggle

Master control signal used for switching case load ON/OFF depending on the load condition

MC Load request

Master control signal used to control the load balance between multiple case controllers on the same suction line

MC Max. Te oset

Requested oset to actual evaporating temperature in order to keep the air temperature at the actual setpoint

MC Liquid control

Master control signal allowing switch to adaptive liquid control

MC Night setback

Master control signal for changing between day and night time operation

MC Case shutdown

Master control signal used to shut down a case for a time period. During shutdown there will be no alarm monitoring

MC Forced closing

Master control signal that will close the injection valve

MC Forced cooling

Master control signal that will provide forced cooling

MC Defrost start

Master control signal for starting a defrost. At adaptive defrost the defrost might be skipped if the defrost is not needed

MC Defrost state

Read out the actual state of the defrost

MC Hold after defrost

Master control signal used for co-ordinated defrost control to hold cabinets from returning to normal refrigeration after a defrost

until all cabinets have terminated defrost

MC Stop defrost

Master control signal used to prevent a defrost start in a controller.

MC Request next defrost

Master control signal used by system manager to see if a controller is requesting that the next defrost has to be carried out

MC Light signal

Master control signal for control of light via a data communication signal from the system manager

MC Actual dewpoint

Master control signal sending the actual measured dewpoint from the system manager to the controller over the network.

MC Tc temp. mean

Master control signal distributing the condensing temperature signal to the case controllers that are using adaptive defrost. At transcritical CO2 sites the receiver pressure is distributed to the case controllers. This function needs to be set up in the system manager.

MC Po load factor

Calculated load factor for the refrigerated appliance. Used for suction pressure optimization.

MC Key/Bluetooth lock

Master control signal that will lock down all Bluetooth data communication and optionally also lock the display keyboard (parameter P89)

MC Min. delta T

Required minimum delta temperature across evaporator (S3 - Te) in order to keep the air temperature at the actual setpoint

MC Oil Recovery

Master control signal used for starting and stopping an oil recovery sequence

AK-CC55 Single Coil and AK-CC55 Single Coil UI

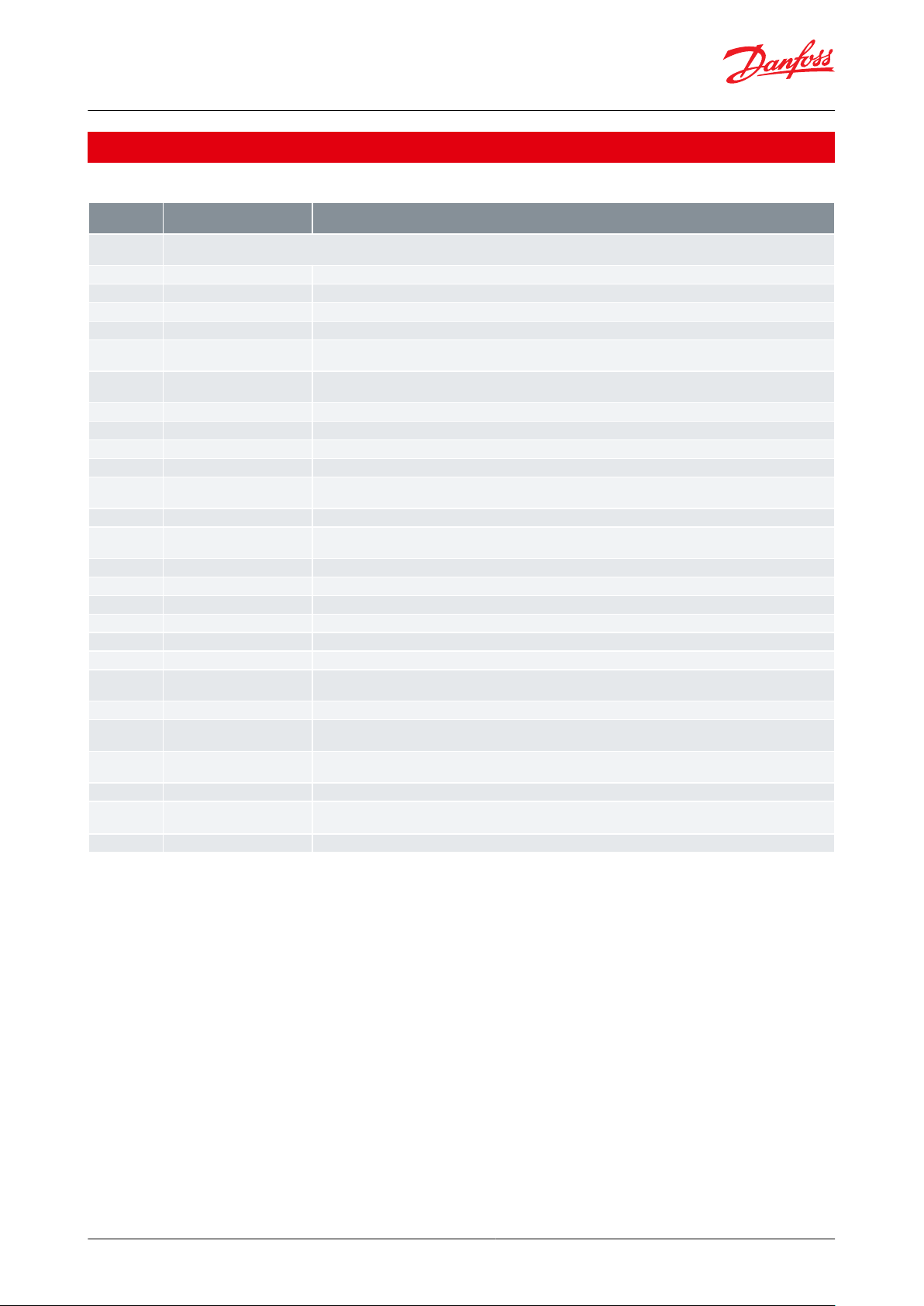

Override

The controller contains a number of override functions which can be used together with Master Control functions in

the Danfoss gateway/system manager:

Table 6: Override functionality

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 28

Page 29

Danfoss

84B8277

S₆

S₄

S₃

S₅

S₂

S₃

S₆

S₅

S₄

AK-CC55 Single Coil and AK-CC55 Single Coil UI

Applications

The chapter outlines application examples:

• Standard display case

• Cases with one valve, one evaporator and two refrigeration sections

• Cases with one valve, two evaporators and two refrigeration sections

• Cold rooms

An application setting will congure inputs and outputs so that the controller’s operation interface is reecting the

selected application.

In application 9, users can custom dene the functions of relay 2 (DO1 is always AKV), e.g.:

• Controlling two compressors

• Controlling the night blind

• Controlling the heat function

• ECO operations of fans

Figure 31: Standard display case, upright or normal, with

one evaporator

Figure 32: Back-to-back cabinet with one evaporator

Figure 33: Back-to-back cabinet with two evaporators and

one AKV valve

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 29

Page 30

40

41

42

5V

s

AI1

43

44

AI2

45

46

AI3

47

48

AI4

49

50

AI5

51

52

AI6

53

54

DI1/

AI7*

60

61

DI2

70

71

AO1*

PWM

83

84

85

B

A

MODBUS

115 - 230V AC

L

N

1

2

3

8

9

7

10

11

12

DO2

13

14

DO3

15

16

17

DO4

18

19

20

DO5

21

22

DO6

115-230V AC

30

31

DI3

Danfoss

84B3234

Application 1-3

Plugin cabinets. Cabinets with dierent output combinations of alarm, rail heat and light.

Application 4

Remote cabinet including alarm, rail heat, defrost, light and fan.

Application 5

Remote hot gas defrost with suction, drain and hot gas valve.

Application 6

Back-to-back cabinet with one evaporator.

Application 7

Back-to-back cabinet with two evaporators.

Application 8

Cold storage room with defrost and simple humidity control.

Application 9

Custom

dened application, where the outputs can be congured according to custom requirements

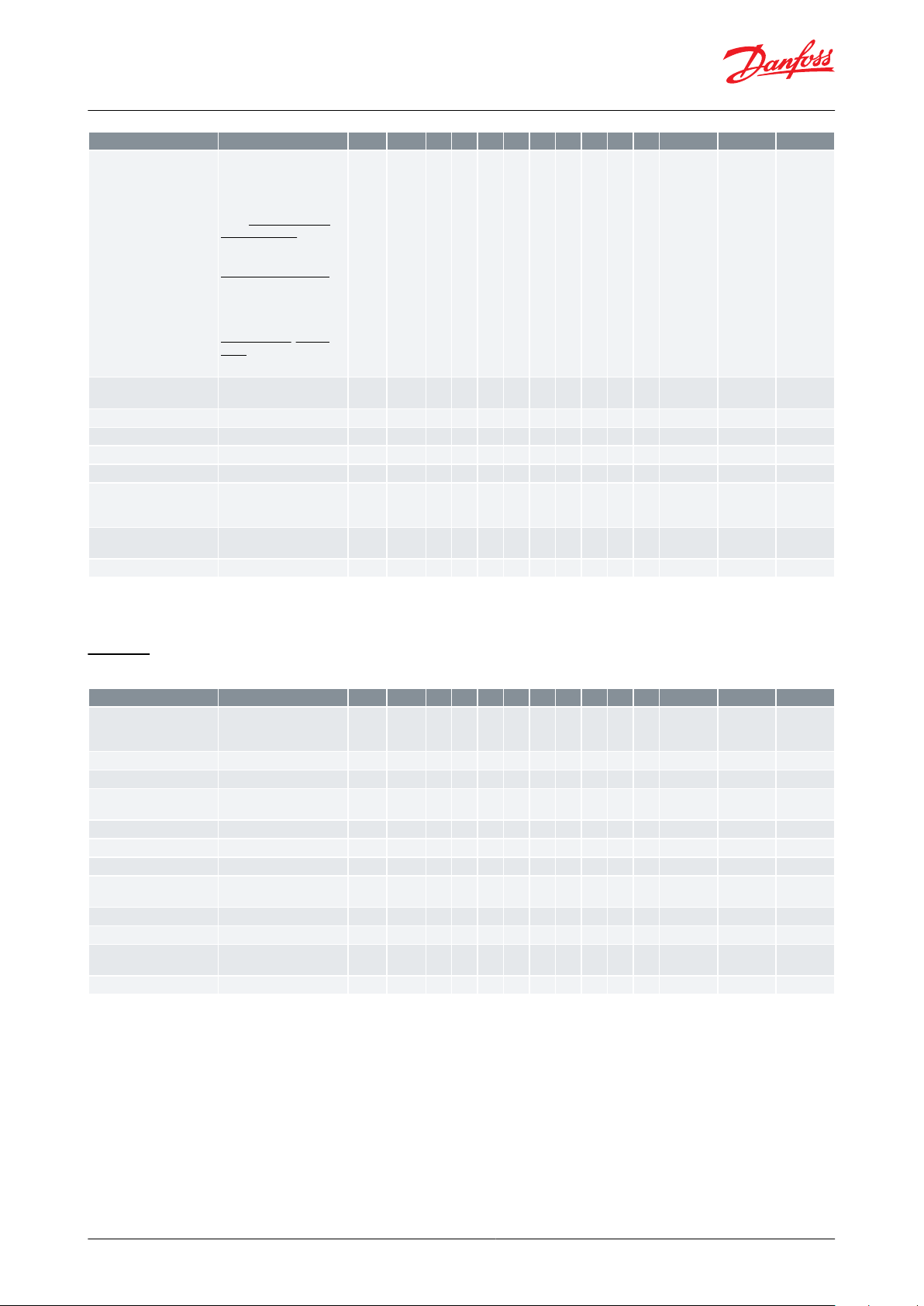

No.

Application description

DO1

DO2

DO3

DO4

DO5

DO6

AO1

1

Plug-in cabinet

2

Plug-in cabinet

3

Plug-in cabinet

4

Remote cabinet

5

Remote Hot gas defrost

(Suction)

(Drain)

(Hot gas)

6

Back-to-back cabinet

7

Back-to-back cabinet

B

A

8

Cold storage room

humidity

9

User def. cong.

User def.

User def.

User def.

User def.

User def.

AK-CC55 Single Coil and AK-CC55 Single Coil UI

Figure 34: Cold room conguration with door and light

heat control function

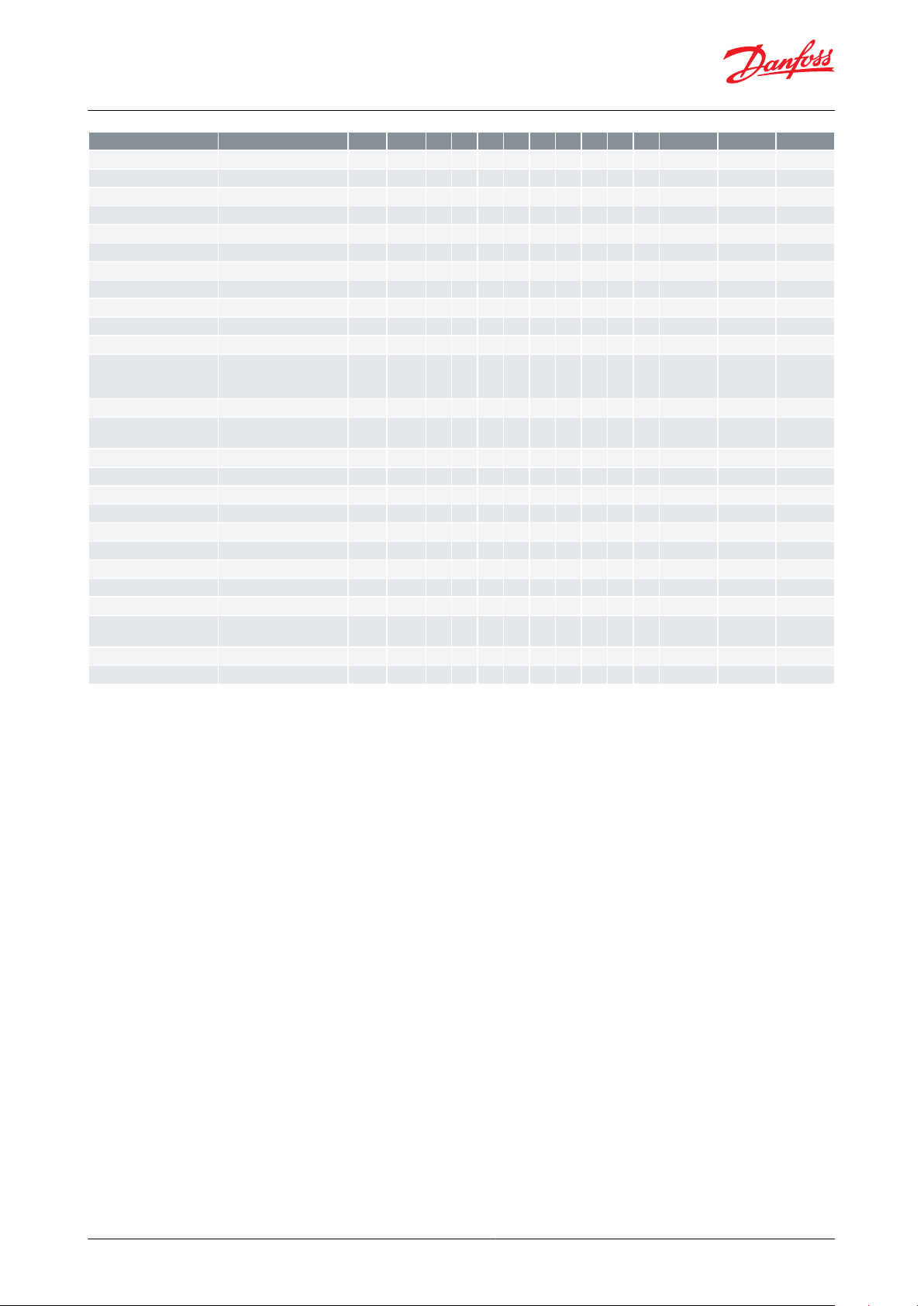

AK-CC55 connections and application options

Upper and lower connection labels are laid out as shown in gure:

Figure 35: Electrical connections AK-CC55 Single Coil

AK-CC55 Single Coil is optimised for control of one expansion valve + dierent combinations of light, rail heat and

alarm relays. It has 6 Digital Outputs (DO), known as DO1 – DO6, one Analogue Output (AO), known as AO1, 6

Analogue Inputs (AI), known as AI1 – AI6, an input that can be used as either DI1 (Digital Input) or AI7 (Sensor Input),

and 2 Digital Inputs, known as DI2 - DI3. AI7 (DI1) can be congured as S5B defrost sensor in application 1-6 and

application 9.

DO1 will be congured for a liquid line solenoid valve if the analogue output AO1 is congured for control of a

stepper valve driver.

Table 7: The controller covers the following nine applications:

Table 8: Application with digital and analogue output specication

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 30

Page 31

Pe

Evaporating pressure

S2

Gas outlet of evaporator

S3

Return air temperature

S4

Discharge air temperature

S5

Evaporator temperature

S6

Product temperature

S3B

Return air temperature on second cooling section

S5B

Evaporator temperature on second evaporator or extra evaporator sensor on single evaporator

RH%

Relative humidity sensor

No.

Application description

AI1

AI2

AI3

AI4

AI5

AI6

AI7/DI1

DI2

DI3

1

Plug-in cabinet

PeS2S3S4S5S62

Plug-in cabinet

PeS2S3S4S5S63

Plug-in cabinet

PeS2S3S4S5S64

Remote cabinet

PeS2S3S4S5S65

Remote Hot gas defrost

PeS2S3S4S5S66

Back-to-back cabinet

PeS2S3S4S5

S3B

7

Back-to-back cabinet

PeS2S3S4S5

S3B

S5B

8

Cold storage room

PeS2S3S4S5S6RH%

9

User def. cong.

PeS2S3S4S5

S6

115 – 230 V AC

AKV Alarm Comp. Defrost Light Fan

DI3

115 – 230 V AC

1 2 3 7 8 9 10 11 12 13 14 21 22 30 3115 16 17 18 19 20

L N

40

5V

s

Pe

0 – 10 V/

PWM

S2 S3 S4 S5 S6 DI1/

AI7

DI2 AO1

1

41 42 43 44 45 46 47 48 49 50 51 52 53 54 60 61 70 71 83 84

B-A

+

MODBUS

85

P

1 3 2

Danfoss

84B3247

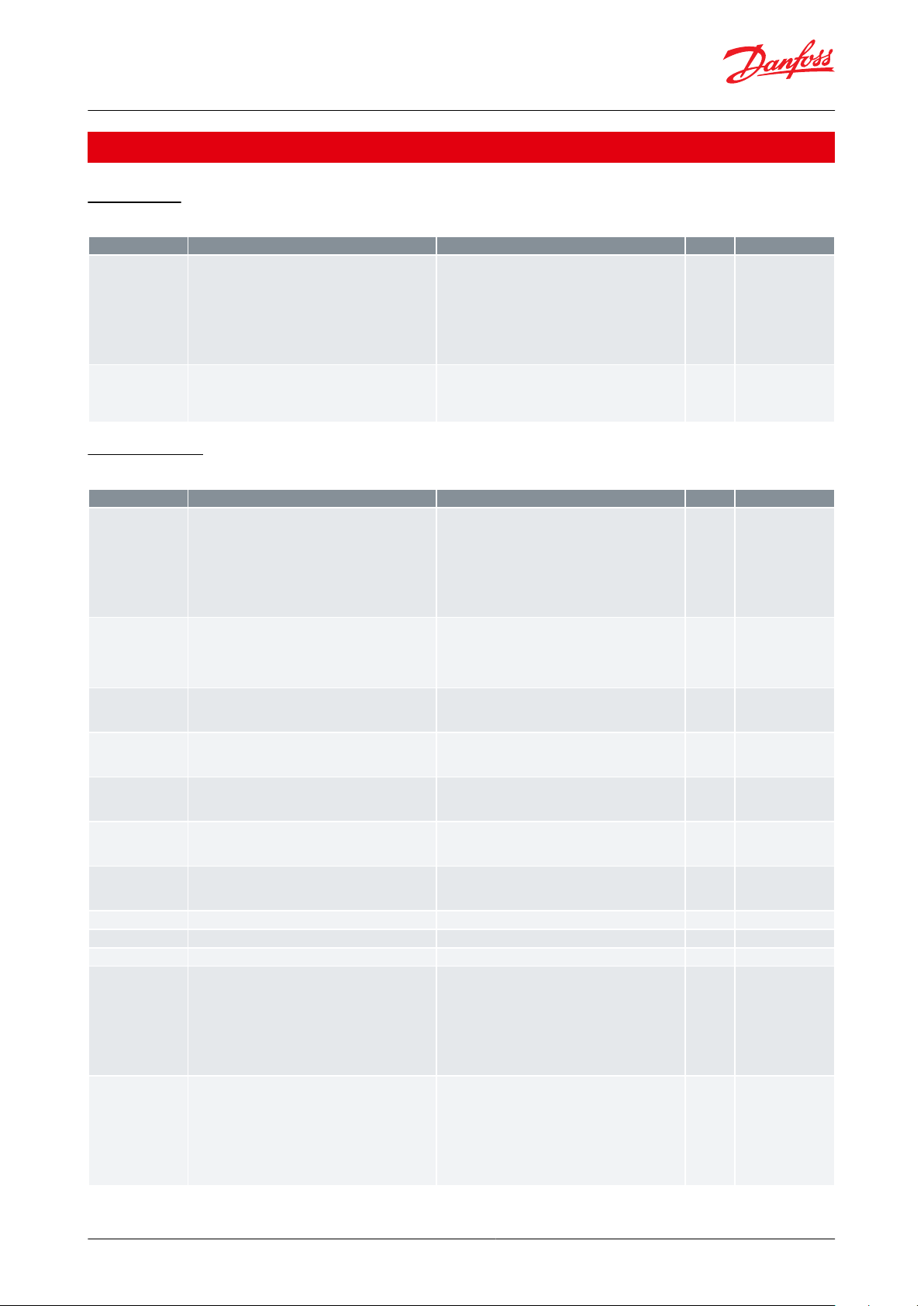

AK-CC55 Single Coil and AK-CC55 Single Coil UI

= Optional use

Table 9: Sensor description

Table 10: Application with digital and analogue output specication

= Optional use

Application set-ups and IO connections

Figure 36: Connections for application 1

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 31

Page 32

115 – 230 V AC

AKV Railheat Comp. Defrost Light Fan

DI3

115 – 230 V AC

1 2 3 7 8 9 10 11 12 13 14 21 22 30 3115 16 17 18 19 20

L N

40

5V

s

Pe

0 – 10 V/

PWM

S2 S3 S4 S5 S6 DI2 AO1

2

41 42 43 44 45 46 47 48 49 50 51 52 53 54 60 61 70 71 83 84

B-A

+

MODBUS

85

P

1 3 2

Danfoss

84B3248

DI1/

AI7

115 – 230 V AC

AKV Alarm Comp. Defrost Railheat Fan

DI3

115 – 230 V AC

1 2 3 7 8 9 10 11 12 13 14 21 22 30 3115 16 17 18 19 20

L N

40

5V

s

Pe

0 – 10 V/

PWM

S2 S3 S4 S5 S6 DI2 AO1

3

41 42 43 44 45 46 47 48 49 50 51 52 53 54 60 61 70 71 83 84

B-A

+

MODBUS

85

P

1 3 2

Danfoss

84B3249

DI1/

AI7

115 – 230 V AC

AKV Alarm Railheat Defrost Light Fan

DI3

115 – 230 V AC

1 2 3 7 8 9 10 11 12 13 14 21 22 30 3115 16 17 18 19 20

L N

40

5V

s

Pe

0 – 10 V/

PWM

S2 S3 S4 S5 S6 DI2 AO1

4

41 42 43 44 45 46 47 48 49 50 51 52 53 54 60 61 70 71 83 84

B-A

+

MODBUS

85

P

1 3 2

Danfoss

84B3250

DI1/

AI7

AK-CC55 Single Coil and AK-CC55 Single Coil UI

Figure 37: Connections for application 2

Figure 38: Connections for application 3

Figure 39: Connections for application 4

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 32

Page 33

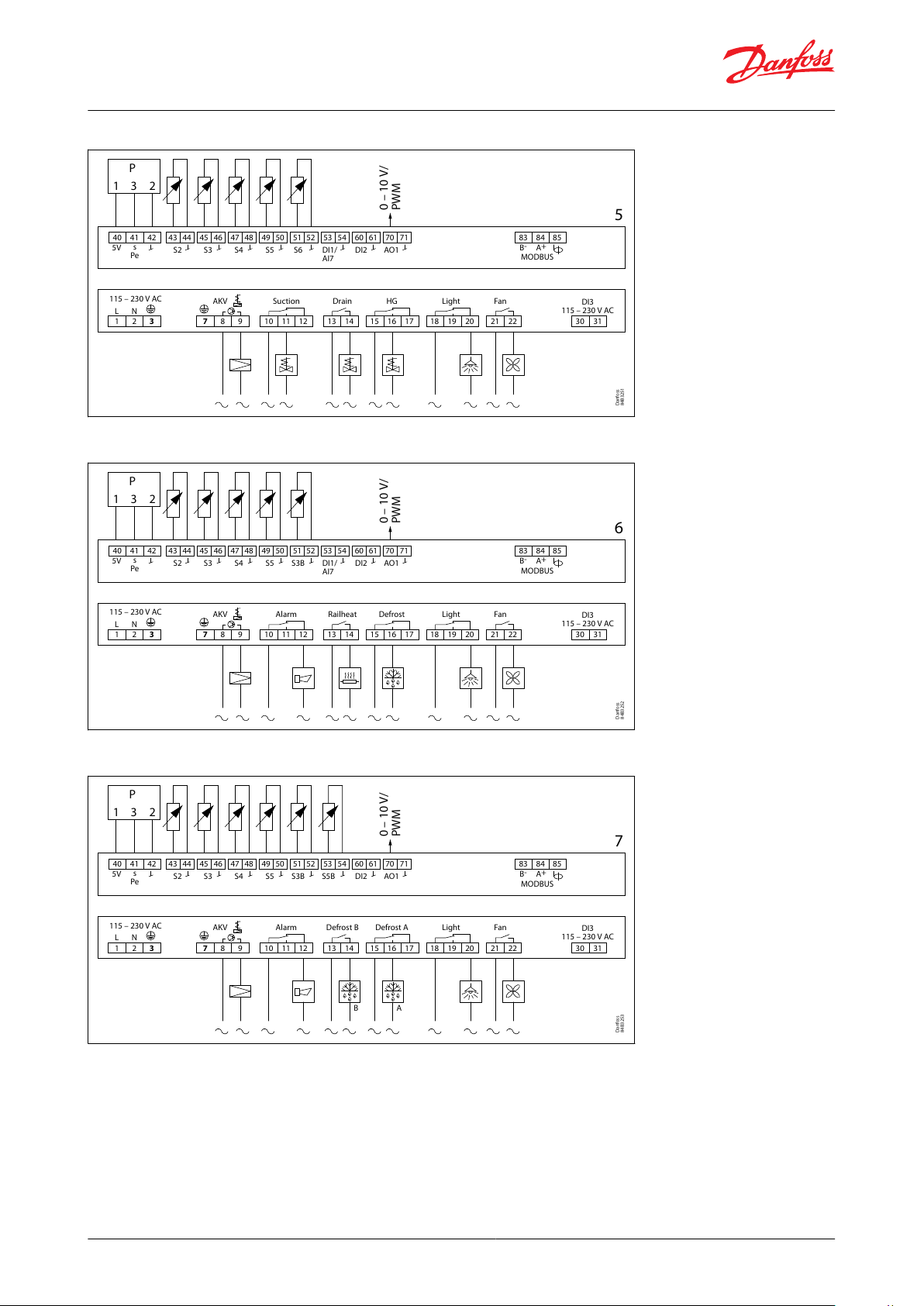

115 – 230 V AC

AKV Suction Drain HG Light Fan

DI3

115 – 230 V AC

1 2 3 7 8 9 10 11 12 13 14 21 22 30 3115 16 17 18 19 20

L N

40

5V

s

Pe

0 – 10 V/

PWM

S2 S3 S4 S5 S6 DI2 AO1

5

41 42 43 44 45 46 47 48 49 50 51 52 53 54 60 61 70 71 83 84

B-A

+

MODBUS

85

P

1 3 2

Danfoss

84B3251

DI1/

AI7

115 – 230 V AC

AKV Alarm Railheat Defrost Light Fan

DI3

115 – 230 V AC

1 2 3 7 8 9 10 11 12 13 14 21 22 30 3115 16 17 18 19 20

L N

40

5V

s

Pe

0 – 10 V/

PWM

S2 S3 S4 S5 S3B DI2 AO1

6

41 42 43 44 45 46 47 48 49 50 51 52 53 54 60 61 70 71 83 84

B-A

+

MODBUS

85

P

1 3 2

Danfoss

84B3252

DI1/

AI7

115 – 230 V AC

AKV Alarm Defrost B Defrost A Light Fan

DI3

115 – 230 V AC

1 2 3 7 8 9 10 11 12 13 14 21 22 30 3115 16 17 18 19 20

L N

AB

40

5V

s

Pe

0 – 10 V/

PWM

S2 S3 S4 S5 S3B S5B DI2 AO1

7

41 42 43 44 45 46 47 48 49 50 51 52 53 54 60 61 70 71 83 84

B-A

+

MODBUS

85

P

1 3 2

Danfoss

84B3253

AK-CC55 Single Coil and AK-CC55 Single Coil UI

Figure 40: Connections for application 5

Figure 41: Connections for application 6

Figure 42: Connections for application 7

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 33

Page 34

115 – 230 V AC

AKV Alarm Humidity Defrost Light Fan

DI3

115 – 230 V AC

1 2 3 7 8 9 10 11 12 13 14 21 22 30 3115 16 17 18 19 20

L N

40

5V

s

Pe

0 – 10 V/

PWM

S2 S3 S4 S5 S6 DI2 AO1

8

41 42 43 44 45 46 47 48 49 50 51 52 53 54 60 61 70 71 83 84

B-A

+

MODBUS

85

P

1 3 2

RH

U

0 10

Danfoss

84B3254

DI1/

AI7

115 – 230 V AC

AKV DO2 DO3 DO4

Custom set-up

DO5 DO6

DI3

115 – 230 V AC

1 2 3 7 8 9 10 11 12 13 14 21 22 30 3115 16 17 18 19 20

L N

40

5V

s

Pe

0 – 10 V/

PWM

S2 S3 S4 S5 S6 DI2 AO1

9

41 42 43 44 45 46 47 48 49 50 51 52 53 54 60 61 70 71 83 84

B-A

+

MODBUS

85

P

1 3 2

Danfoss

84B3266

DI1/

AI7

Danfoss

84B8271

AK-CC55 Single Coil and AK-CC55 Single Coil UI

Figure 43: Connections for application 8

Figure 44: Connections for application 9

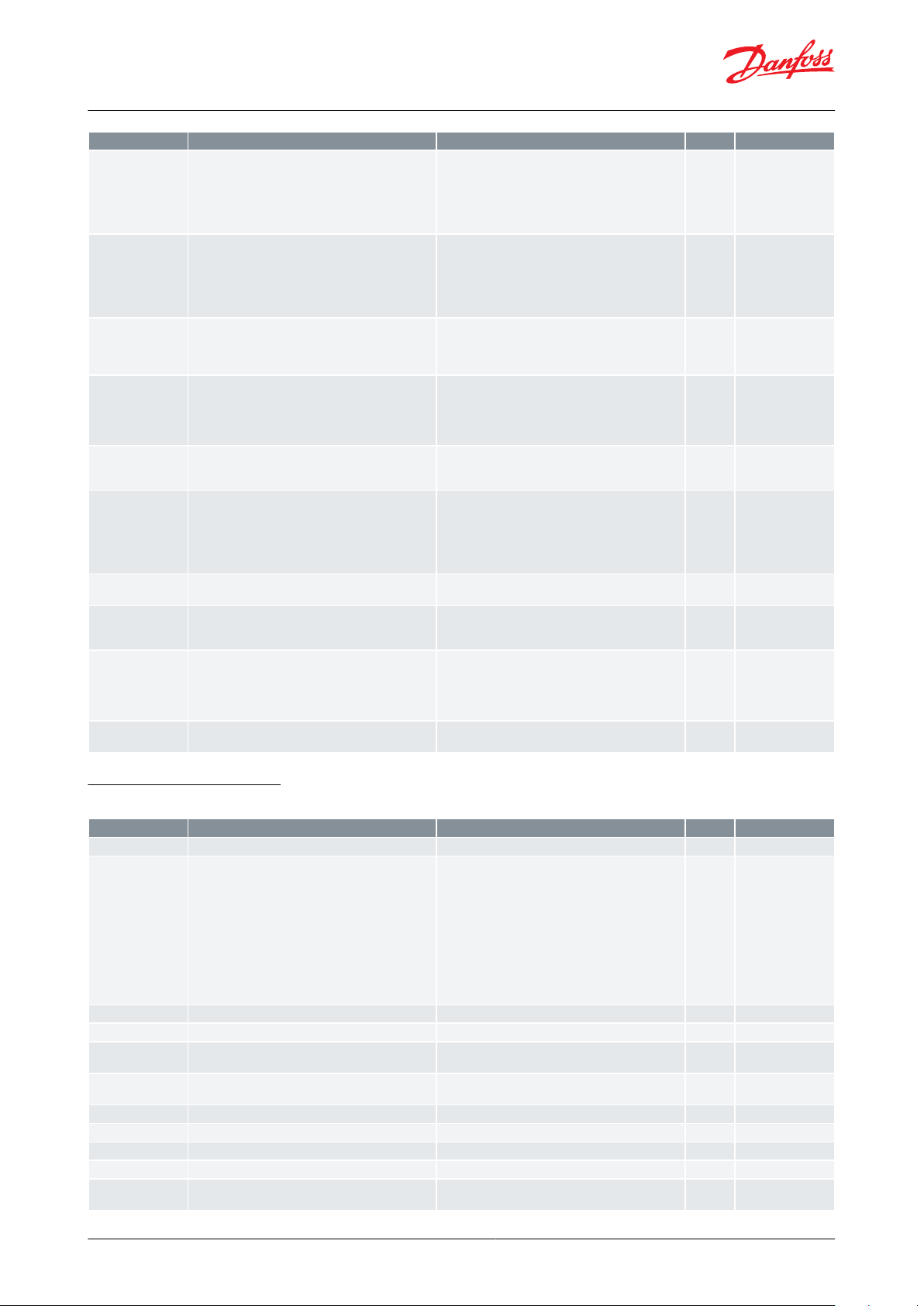

Product identication

The controller is provided with labels from the factory, indicating a generic application. When selecting the required

application, specic labels are provided so that you can mount the relevant one.

The application number is indicated on the left-hand side of the labels. Use the label tting the selected application.

Some of the labels are applicable to multiple application options.

Figure 45: Product identication

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 34

Page 35

230 V AC (115 AC)

AO1/

PWM

60 61 70 71

SSR

Danfoss

80G8234

AK-CC55 Single Coil and AK-CC55 Single Coil UI

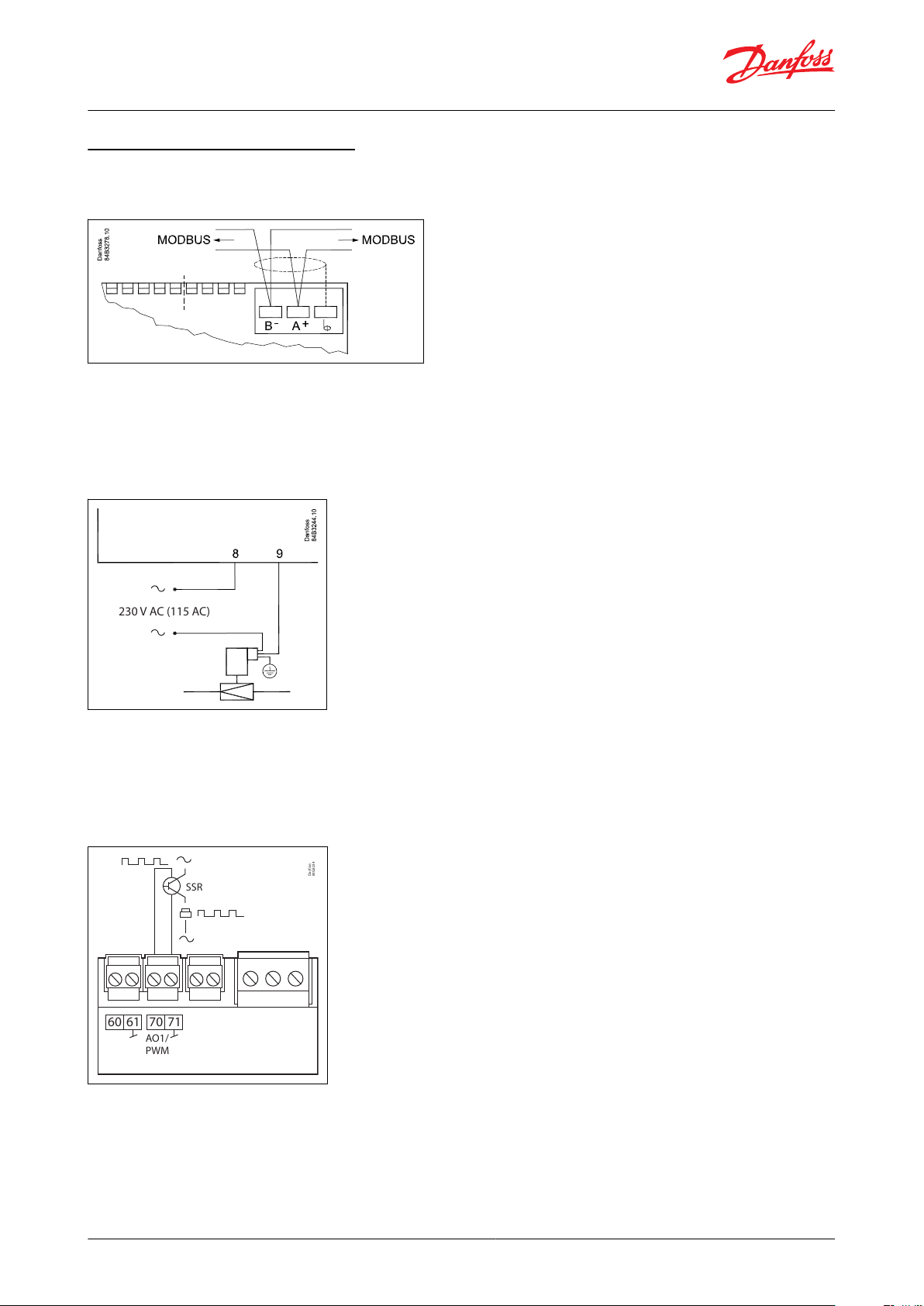

AK-CC55 Single Coil connections

Data communication

Figure 46: Data communication

IMPORTANT:

It is important that the installation of the data communication cable is performed correctly with sucient distance

to high voltage cables.

AKV info

Figure 47: AKV info

230 V or 115 V

AC coil

Max. 0.5 A

External solid state relay for rail heat

Figure 48: External solid state relay for rail heat

0 / 10 V Pulse Width Modulated (PWM)

Max. 15 mA.

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 35

Page 36

A

AKS 32R

B

out

C

ABC

Black

Brown

Blue

Danfoss

84B8239

AK-CC55 Single Coil and AK-CC55 Single Coil UI

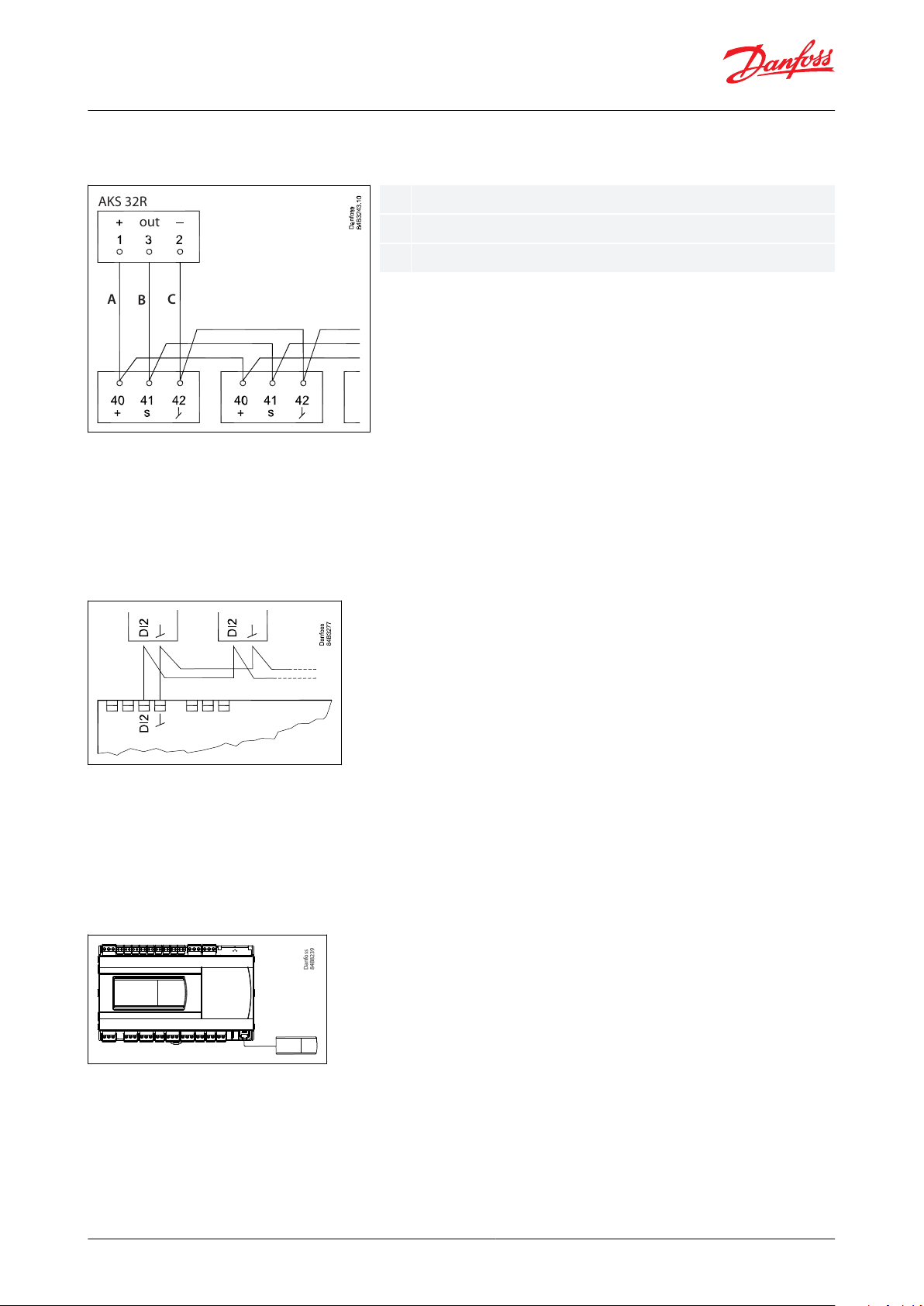

AKS 32R info

Figure 49: AKS 32R info

NOTE:

A ratiometric pressure transmitter with a 5 V, 10 – 90% voltage output signal must be used.

The signal from one pressure transmitter can be received by up to 10 controllers. There must not be a signicant

pressure drop from the pressure transmitter's position in the suction line to the individual evaporators.

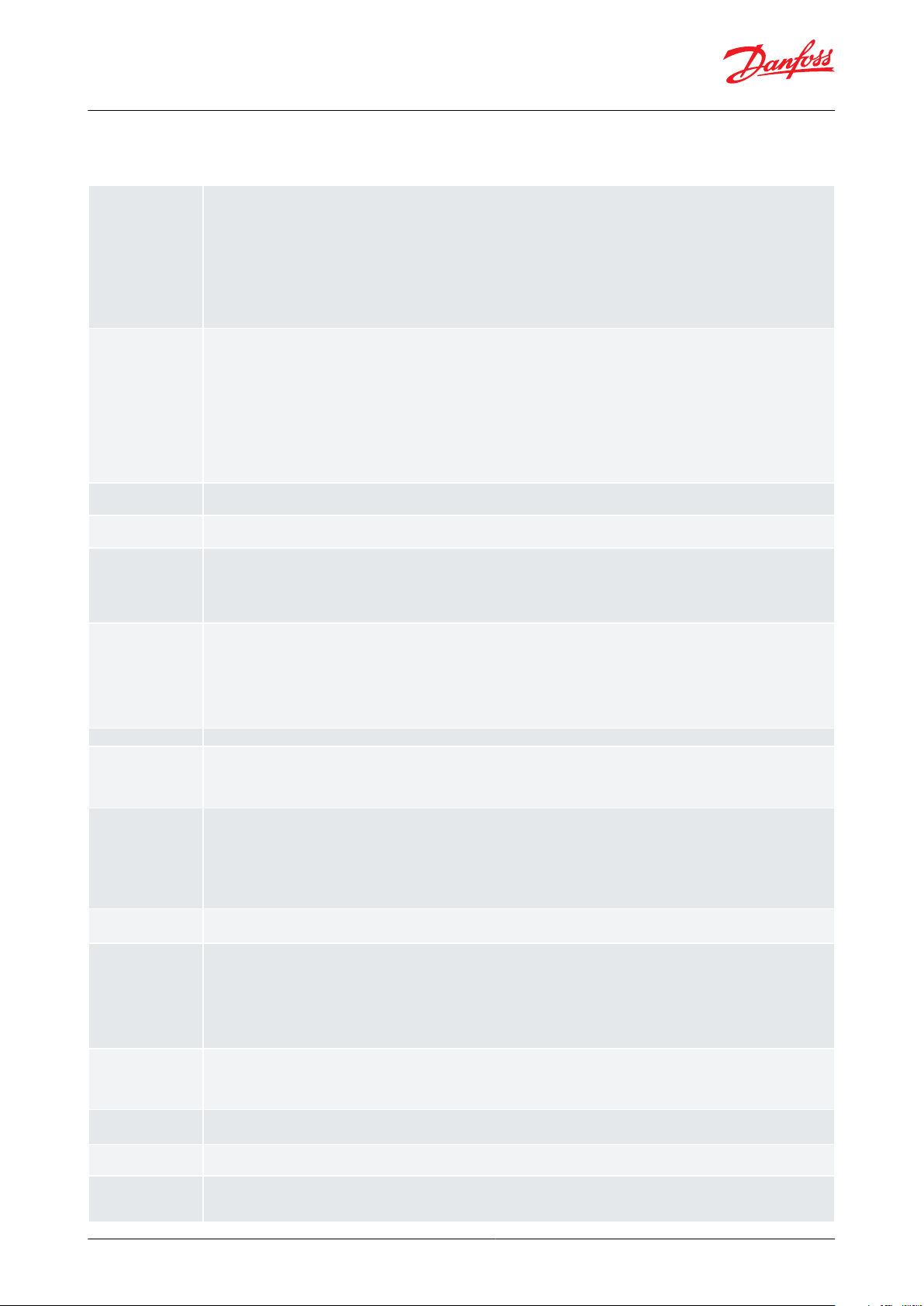

Coordinated defrost via cable connections

Figure 50: Coordinated defrost via cable connections

Max. 10

The following controllers can be connected in this way:

EKC 204A, AK-CC 210, AK-CC 250, AK-CC 450, AK-CC 550 and AK-CC55.

Refrigeration is resumed at the same time when all controllers have terminated defrost.

External display AK-UI55

Figure 51: External display AK-UI55

Display

084B4075 / 084B4076 / 084B4077

Cable 3 m: 084B4078

Cable 6 m: 084B4079

(Total length: max. 100 m)

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 36

Page 37

AI1

Pressure transmitter

AKS 32R

Connect to terminal 40, 41 and 42.

(Use cable 060G1034: Black=40, Brown=41, Blue=42)

The signal from one pressure transmitter can be received by up to 10 controllers. But only if there are no signicant pressure drops between the evaporators to be controlled. See Figure 49: AKS 32R info.

NOTE:

When replacing AK-CC 550 with AK-CC55, S and ground must be switched.

AI2 - AI7

Primarily for temperature inputs

• S2

Pt 1000 ohm sensor AKS11, placed at the evaporator outlet

• S3, S4, S5

Pt 1000 AKS11, PTC 1000 EKS111, NTC5K EKS211, NTC10K EKS221 or a user-dened sensor type. All have to be of the same type.

• S3, return air sensor, placed in the warm air before the evaporator

• S4, discharge air sensor, placed in the cold air after the evaporator

(the need for either S3 or S4 can be selected in the conguration)

•

S5, defrost sensor, placed in the evaporator

• S6, Pt 1000 ohm sensor, food temperature sensor placed in-between the food products

(If the DI1 input is used for a temperature measurement e.g. S5B, it will appear as AI7.)

DI1

Digital input signal

The dened function is active when the input is short-circuited or opened, depending on the function dened in o02.

DI2

Digital input signal

The dened function is active when the input is short-circuited or opened, depending on the function dened in o37.

AO1

Analogue output signal

• Analogue 0 – 10 V

Can be used to drive an external stepper driver.

• Pulse width modulated signal

Can be used for fast pulse control of rail heat via an external power solid state relay.

MODBUS

For data communication:

• Terminal 83 = B-

• Terminal 84 = A+

• Terminal 85 = screen

NOTE:

When replacing AK-CC 550 with AK-CC55 A+, B- and shield must be switched.

Supply voltage

230 V AC or 115 V AC

DO1

• AKV valve

Connection of expansion valve type AKV, AKVA, AKVH or AKVP. The coil must be a 230 V or 115 V AC coil.

• Liquid line solenoid valve

Connection of normally closed valve in connection with stepper valve.

DO2

• Alarm

There is a connection between terminal 10 and 12 in alarm situations and when the controller is without power. DO2 has reinforced

insulation that can be used with 24 V.

• Light, Rail heat, Compressor, Night blind

There is connection between terminal 10 and 11 (10 and 12 at light) when the function is on.

• Suction line valve

There is connection between terminal 10 and 11 when the suction line must be open.

DO3

• Compressor, Rail heat, Defrost, Drain valve, Humidity

There is connection between terminal 13 and 14 when the function must be active.

DO4

• Defrost

There is connection between terminal 15 and 16 when defrosting takes place.

• Hot gas

There is connection between terminal 15 and 16 when the hot gas valves must open.

NOTE:

When replacing AK-CC 550 with AK-CC55, wires must be switched.

DO5

• Light

There is connection between terminal 18 and 20 when the function must be active.

• Rail heat

There is connection between terminal 18 and 19 when the rail heat must be on.

DO6

• Fan

There is connection between terminal 21 and 22 when the fan is on.

DO2-DO6 + AO1 and

Application 9

Here, the dierent outputs can be custom dened in q02-q09

DI3

Digital input signal

The signal must have a voltage of 0 / 230 V AC (115 V AC)

The function is dened in o84.

AK-CC55 Single Coil and AK-CC55 Single Coil UI

Connections

Table 11: Connection details

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 37

Page 38

AK-CC55 Single Coil and AK-CC55 Single Coil UI

Display (RJ12 plug)

If external readings/operation of the controller is required, a display can be connected. If there is no display on the

front, two external displays can be connected. For one display the max. cable length is 100 m. For two displays the

sum of the two cable lengths must not exceed 100 m.

NOTE:

When replacing AK-CC 550 with AK-CC55, AKA 16X remote displays and cables have to be replaced with new AKUI55 displays and cables.

Electric noise

Cables for sensors, low voltage DI inputs and data communication must be kept separate from other high voltage

cables:

• Use separate cable trays

• Keep a distance between cables of at least 10 cm

• Long cables at the low voltage DI input should be avoided

Installation considerations

Accidental damage, poor installation, or site conditions, can give rise to malfunctions of the control system, and

ultimately lead to a plant breakdown.

Every possible safeguard is incorporated into our products to prevent this. However, a wrong installation could still

present problems. Electronic controls are no substitute for normal, good engineering practice.

Danfoss will not be responsible for any goods, or plant components, damaged as a result of the above defects. It is

the installer's responsibility to check the installation thoroughly, and to t the necessary safety devices.

Special reference is made to the necessity of signals to the controller when the compressor is stopped and to the

need of liquid receivers before the compressors.

Your local Danfoss agent will be pleased to assist with further advice, etc.

Replacing AK-CC 550 with AK-CC55

NOTE:

Be aware when exchanging an AK-CC 550 controller with a new AK-CC55 controller - new wiring principles!

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 38

Page 39

AK-CC 550

AK-CC55

Pressure sensor has new connection – signal and ground are switched

SPDT relays have a new wiring scheme – NO and NC terminals are switched (e.g. defrost

heater on when it should be o)

Modbus has new connection scheme (A,B and screen)

New AK-UI55 displays and cables with 6 wires vs. 3 wires for EKA 16x

AK-CC55 Single Coil and AK-CC55 Single Coil UI

Table 12: Replacing AK-CC 550 with AK-CC55

• AK-CC55 does not support two EEC coils connected to one AKV output.

• Pressure transmitter can be shared between AK-CC 550 and AK-CC55.

• DI2 defrost coordination can be wired between AK-CC 550 and AK-CC55.

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 39

Page 40

012

The display keys are always operative

The display keys will be locked automatically when not used for some time and the keyboard must be

unlocked by pressing the arrow-up and arrow-down keys at the same time.

The display keys will be locked and unlocked by means of a master control signal from the System Manager.

AK-CC55 Single Coil and AK-CC55 Single Coil UI

Operation

The controller can be operated in dierent ways depending on the user interface.

The following options are available:

• Via data commmunication

• Via AK-UI55 Setting Display

• Via AK-UI55 Bluetooth display

Operation via data communication

Via system manager's display

All AK-CC55 controllers can be operated from a central location, e.g. AK-SM 800.

Data communication is to take place via MODBUS or Lon.

Via system manager and service tool

Operation can also be performed from a central location with PC software "Service Tool" connected to a system

manager AK-SM 720 via MODBUS or Lon.

Programming via KoolProg

Programming by use of PC software type KoolProg® via interface MMIMYK connected to RJ12 display connector.

Direct operation

Operation via AK-UI55 setting display

The display can be located on the front of the controller or at a distance of up to 100 metres from the controller.

Smart phone and app via AK-UI55 Bluetooth display

The "AK-CC55 connect" app is used for smart phone operation.

AK-CC55 connect can be downloaded freely to a compatible iOS/Android smartphone device.

The display can be placed at a distance of up to 100 metres from the controller.

Menu operation is established by activating Bluetooth communication to the app.

Operation via AK-UI55 Set

Display AK-UI55 Set

The values will be shown with three digits, and with a setting you can determine whether the temperature is to be

shown in °C or in °F.

To prevent any passing-by user from making unauthorized changes, the access to the display menu is restricted by

access codes.

Besides this, the parameter P89 provides the following options for handling of the display keyboard:

© Danfoss | Climate Solutions | 2022.03 BC364229688105en-000201 | 40

Page 41

ABCDE

F

Danfoss

84B8325

D

C

A

B

E

F

Lights up in event of: Energy optimization, Cool-

ing, Defrosting, Fan operation

Lights in event of alarm

Long press (3 seconds) on alarm button alarm —

relay is reset — alarm code displayed — e.g. “A1”

Long press (3 seconds) gives access to the infor-

mation menu “InF”

Up arrow / Down arrow / Arrow to left: Navigation

in the menu and setting of values.

Long press (3 seconds) will start a defrost, “-d-” is

shown in the display. Ongoing defrosting can be

stopped by a long press.

SET: Long press (3 seconds) gives access to the