Installation Guide

84B3239

7

84B8289

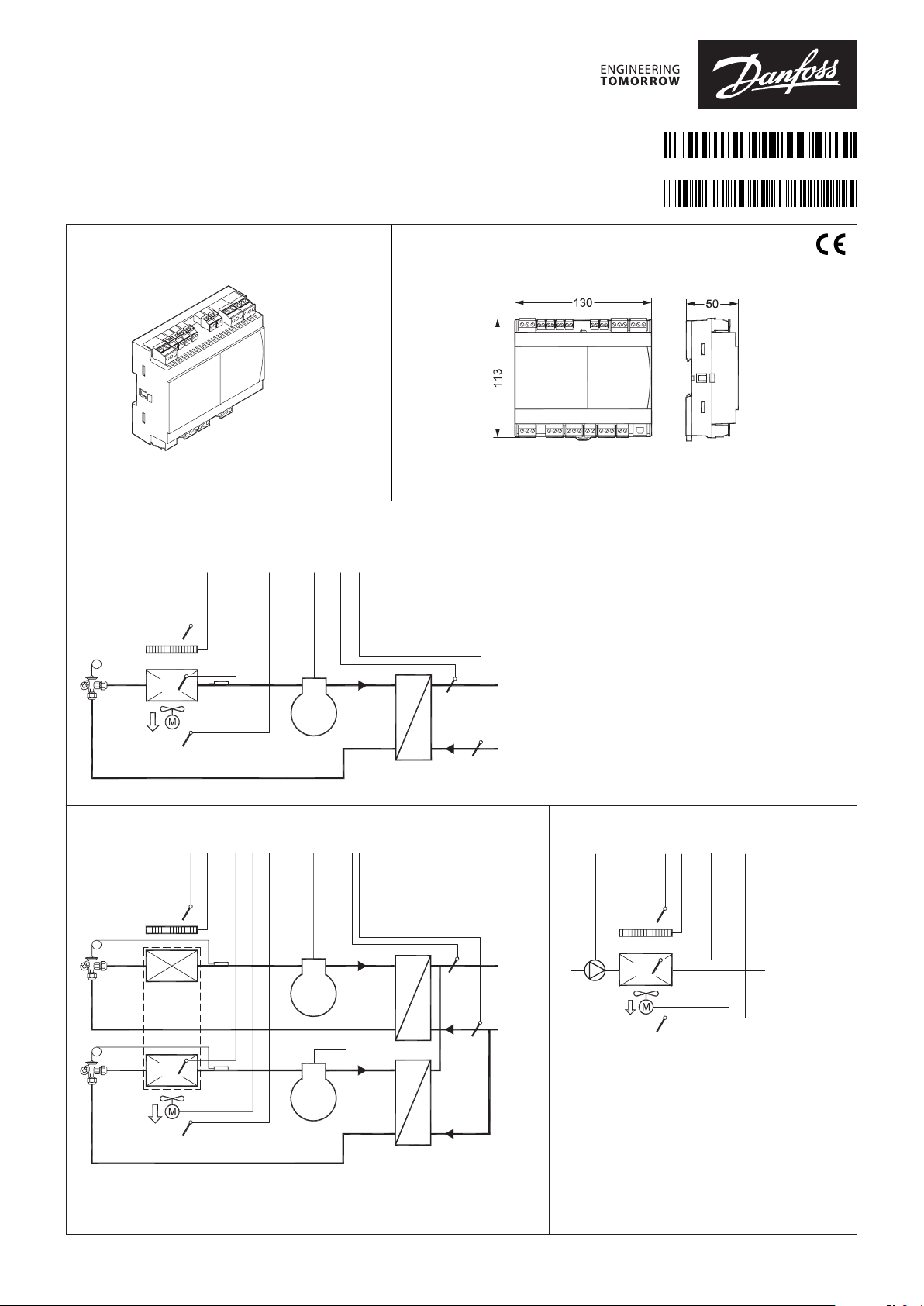

AK-CC55

084R8062

Water Loop

Identification

Principle

Application 1,2,5 and 6

S

3

084B4058

Dimensions

Danfoss

AN376928388884en-000101

Danfoss

84B8288

S

S

5

8

S

S

4

Application 3 and 4 Application 7 and 8

Danfoss

S

3

S

8

S

S

5

7

Danfoss

84B8298

S

3

S

5

S

4

S

4

© Danfoss | Climate Solutions | 2021.06

AN376928388884en-000101 | 1

2

Dan

84B8291

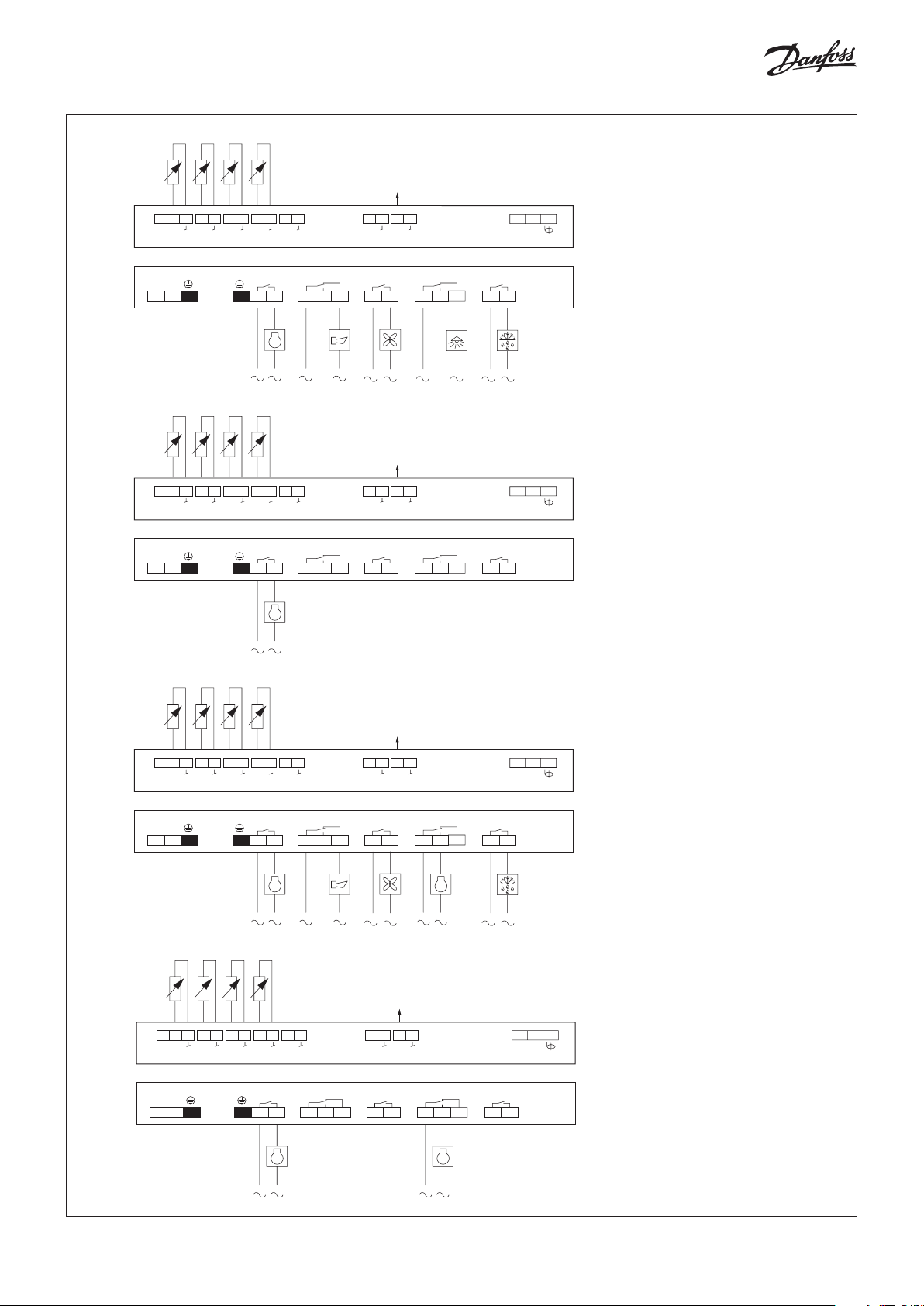

1.

1

84B8290

3

84B8292

Dan

84B8293

0 – 10 V

Frequency

PWM

43 44 45 46 47 48 49 5041 4240 83 84

AI1S35V AI2S4AI3S5AI4S7DI1

115 – 230 V AC

LN

2 3 7 8 9 10 11 12 13 14 15 16 17

1

AI5

Comp. AlarmFan Light

60 61 70 71

DI2AO1

Defrost

18 19

B-A

MODBUS

85

+

Danfoss

2.

0 – 10 V

Frequency

PWM

43 44 45 46 47 48 49 5041 4240 83 84

AI1S35V AI2S4AI3S5AI4S7DI1

115 – 230 V AC

LN

1 2 3 7 8 9 10 11 12 13 14 15 16 17

AI5

Comp.DO2 DO3DO4

60 61 70 71

DI2AO1

User defined

DO5

18 19

B-A

MODBUS

85

+

foss

3.

0 – 10 V

Frequency

PWM

43 44 45 46 47 48 49 5041 4240 83 84

AI1S35V AI2S4AI3S5AI4S7DI1

115 – 230 V AC

LN

2 3 7 8 9 10 11 12 13 14 15 16 17

1

AI5

Comp. 1 AlarmFan Comp. 2

1 2

60 61 70 71

DI2AO1

Defrost

18 19

B-A

MODBUS

85

+

Danfoss

4

0 – 10 V

Frequency

43 44 45 46 47 48 49 5041 4240 83 84

AI1S35V AI2S4AI3S5AI4S7DI1

115 – 230 V AC

LN

2 3 7 8 9 10 11 12 13 14 15 16 17

1

AI5

Comp. 1DO2 DO3Comp. 2

60 61 70 71

DI2AO1

User defined User defined

1 2

PWM

B-A

MODBUS

DO5

18 19

4

85

+

2 | AN376928388884en-000101

foss

© Danfoss | Climate Solutions | 2021.06

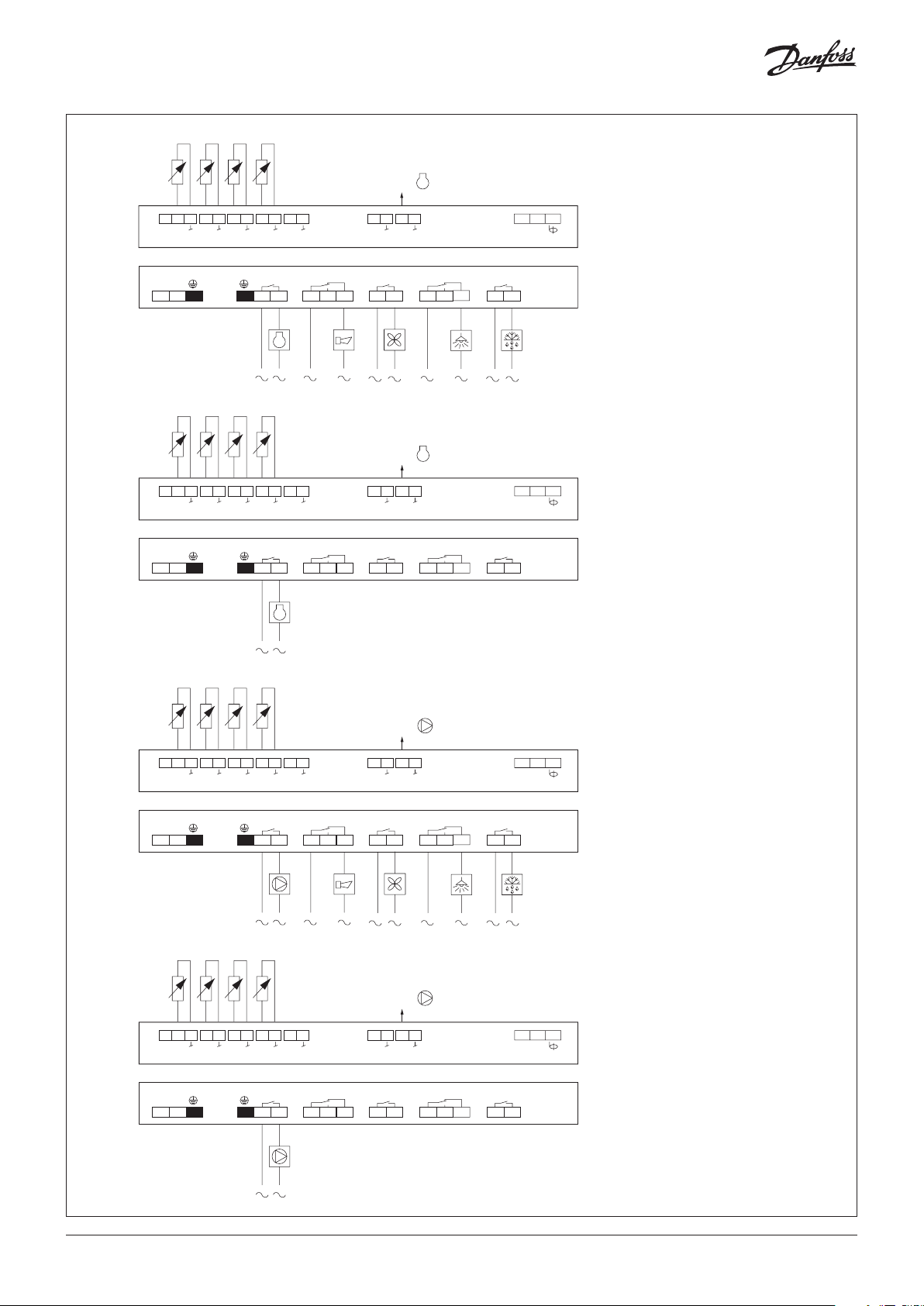

5.

5

84B8294

6

Dan

84B8295

7

84B8296

8

Dan

84B8297

0 – 10 V

Frequency

PWM

43 44 45 46 47 48 49 5041 4240 83 84

AI1S35V AI2S4AI3S5AI4S7DI1

115 – 230 V AC

LN

2 3 7 8 9 10 11 12 13 14 15 16 17

1

AI5

Comp. AlarmFan Light

60 61 70 71

DI2AO1

Defrost

18 19

B-A

MODBUS

85

+

Danfoss

6.

0 – 10 V

Frequency

PWM

43 44 45 46 47 48 49 5041 4240 83 84

AI1S35V AI2S4AI3S5AI4S7DI1

115 – 230 V AC

LN

1 2 3 7 8 9 10 11 12 13 14 15 16 17

AI5

Comp.DO2 DO3DO4

60 61 70 71

DI2AO1

User defined

DO5

18 19

B-A

MODBUS

85

+

foss

7.

0 – 10 V

Frequency

PWM

43 44 45 46 47 48 49 5041 4240 83 84

AI1S35V AI2S4AI3S5AI4S7DI1

115 – 230 V AC

LN

2 3 7 8 9 10 11 12 13 14 15 16 17

1

AI5

Pump AlarmFan Light

60 61 70 71

DI2AO1

Defrost

18 19

B-A

MODBUS

85

+

Danfoss

8.

0 – 10 V

Frequency

PWM

43 44 45 46 47 48 49 5041 4240 83 84

AI1S35V AI2S4AI3S5AI4S7DI1

115 – 230 V AC

LN

2 3 7 8 9 10 11 12 13 14 15 16 17

1

AI5

Pump DO2DO3 DO4

60 61 70 71

DI2AO1

User defined

DO5

18 19

B-A

MODBUS

85

+

© Danfoss | Climate Solutions | 2021.06

foss

AN376928388884en-000101 | 3

Data communication

Important

It is important that the installation of the data

communication cable is performed correctly with

sufficient distance to high voltage cables.

Coordinated defrost via

Max. 10

cable connections

The following controllers can be connected in

this way:

AK-CC 210, AK-CC 250, AK-CC 450,

AK-CC 550 and AK-CC55.

Refrigeration is resumed at the same time when

all controllers have terminated defrost.

External display

AK-UI55

RJ 12

Display

084B4075 / 084B4076 / 084B4077

Cable 3 m: 084B4078

Cable 6 m: 084B4079

(L: Max. 100 m)

Electric noise

Cables for sensors, low voltage DI inputs and data communication must be kept separate from other electric cables:

- Use separate cable trays

- Keep a distance between cables of at least 10 cm

- Long cables at the low voltage DI input should be avoided

Installation considerations

Accidental damage, poor installation, or site conditions, can give rise to malfunctions of the control system, and ultimately lead to a

plant breakdown.

Every possible safeguard is incorporated into our products to prevent this. However, a wrong installation could still present

problems. Electronic controls are no substitute for normal, good engineering practice.

Danfoss will not be responsible for any goods, or plant components, damaged as a result of the above defects. It is the installer's

responsibility to check the installation thoroughly, and to fit the necessary safety devices.

Special reference is made to the necessity of signals to the controller when the compressor is stopped and to the need of liquid

receivers before the compressors.

Your local Danfoss agent will be pleased to assist with further advice, etc.

4 | AN376928388884en-000101

© Danfoss | Climate Solutions | 2021.06

Technical data

Electrical specifications Function data

Electrical data Value

Supply voltage AC [V] 115 V / 230 V, 50/60 Hz

Power consumption [VA] 5 VA

Power ON indicator Green LED

Electrical cable dimensioning [mm] Max. 1.5 mm multi-core cable

Sensor and measuring data

Sensor and measuring data Value

Sensor S3, S4, S5, S7, S8 Pt 1000 AKS11

PTC 1000 EKS111

NTC5K EKS211

NTC10K EKS221 sensor

(All 5 must be of the same type)

Temperature measuring accuracy Pt1000: -60 – 120 °C. ±0.5 K

PTC1000: -60 – 80 °C. ±0.5 K

NTC5K: -40 – 80 °C. ±1.0 K

NTC10K: -40 – 120 °C. ±1.0 K

Pt1000 sensor specification ±0.3 K at 0 °C

±0.005 K per degree

Input and output relay specifications

Input and

output relay

specifications

Digital input DI1

Relays DO1

Analogue

output

NOTE:

• DO1 - DO5 are 16 A relays.

• Max. load must be observed.

• DO2 / DO3 / DO4 is recommended for load with high inrush current

e.g. EC Fan and LED light.

• All relays are sealed for use with flammable refrigerant like Propane R290.

• Compliance with EN 60 335-2-89: 2010 Annex BB.

Input/

output

DI2

DO2

DO3

DO4

DO5

AO1 0 – 10 V DC, Max. 2 mA

Description

Signal from dry contact functions

Requirements to contacts: Gold plating

Cable length must be max. 15 m

Use auxiliary relays when the cable is longer

Open loop: 12 V (SELV)

Contact 3.5 mA

115 V / 230 V AC

Load max.: CE. 8 (6)A

UL. 8A res. 3FLA 18LRA

Load min.: 1VA

Inrush: DO2 DO3 DO4 TV-5 80A

Frequency: 10 – 500 Hz, Max. 2 mA

PWM: 0/10V Pulse Width Modulated

(100 – 500 Hz), Max. 2 mA

PWM Railheat: 4 – 60 s period time,

Max. 15 mA

Function data Value

Display LED 3 digit

External display, AK-CC55 Water Loop 1 external display

External display connection RJ12

Max. display cable length [m] 100 m

Data communication built-in MODBUS

Clock battery backup power reserve 4 days

Mounting DIN rail

Environmental conditions

Environmental conditions Value

Ambient temperature range, operating [°C] 0 – 55 °C

Ambient temperature range, transport [°C] -40 – 70 °C

Enclosure rating IP IP20

Relative humidity range [%] 20 – 80%, non-condensing

Shocks/Vibrations No shocks and vibrations

allowed

© Danfoss | Climate Solutions | 2021.06

AN376928388884en-000101 | 5

Operation with setting display

Display AK-UI 55 Set

The values will be shown with three digits, and with a setting you can determine whether the temperature is to be shown in °C or in °F.

Lights in event of alarm — press on alarm button — alarm relay is reset — alarm code displayed — e.g. “A1”

Alarm codes are shown on page 7

Lights up in event of:

Energy optimization

Cooling

Defrosting

Fan operation

SET:

Long press (3 seconds) gives access to the “SEt” menu.

If the operation is locked with a password, “PS” is shown. Enter the code.

Shows the setting for a chosen parameter / saves a changed setting.

Short press gives access to entering of the thermostat’s cut-out limit.

The display can give the following messages:

-d- Defrost is in progress

Err The temperature cannot be displayed due to a sensor error

Err1 The display cannot load data from the controller. Disconnect and then reconnect the display

Err2 Lost display communication

ALA The alarm button is activated. The first alarm code is then shown

- - - At top position of the menu or when max. value has been reached, the three dashes are shown in the top of the display

- - - At bottom position of menu or when min. value has been reached, the three dashes are shown in the bottom of the display

Loc The menu operation is locked. Unlock by pressing (for 3 seconds) on the ‘up arrow’ and ‘down arrow’ simultaneously

UnL The menu operation is unlocked

- - - The parameter has reached min. or max. limit

PS A password is required for access to the menu

Fan Appliance cleaning has been initiated. The fans are running

OFF Appliance cleaning is activated and the appliance can now be cleaned

OFF The main switch is set to Off

SEr The main switch is set to service / manual operation

Long press (3 seconds) gives access to the

information menu “InF”.

Up arrow / Down arrow / Arrow to left:

Navigation in the menu and setting of values.

Long press (3 seconds) will start a defrost,

“-d-” is shown in the display. Ongoing

defrosting can be stopped by a long press.

Factory setting

If you need to return to the factory-set values, do the following:

- Cut off the supply voltage to the controller

- Keep up "∧" and down "∨" arrow buttons depressed at the same time as you reconnect the supply voltage

- When FAc is shown in the display, select "yes".

6 | AN376928388884en-000101

© Danfoss | Climate Solutions | 2021.06

Parameter grouping at display operation

SET

Set

(PS)

<

cFg SET

<

r--

A-- o03 MODBUS address

c-- r89 Food type

d-- r00 Cut-out temperature

F-- r15 Ther. sensor S4 %

t-- r61 Ther. sensor S4 % night

o-- A36 Alarm sensor S4%

p-- o17 Display air S4%

q-- d01 Defrost method

u-- d03 Defrost interval

< d10 Defrost sensor

(Return) d04 Max. defrost time

Menu groups

SET button, 3 s: Configuration settings

PS: Password (if any)

r12 Main switch

Þ

o61 Application

P99 Condenser sensors

See also the following pages.

d02 Defrost stop temperature

<

(Return)

<

Inf

StA SET See control state message

App SET See selected application

in SET

out SET

buS SET MODBUS quality do2

SoF SET See SW version do3

< do4

(Return)

Output status

When you want info on a relay

output, the dot will show whether

the relay is activated (energized)

for e.g.:

do4 = not activated

do.4 = activated

*)

The output's function.

(Determined at configuration).

The DOs and AOs can also be forced controlled from this menu, when r12

Main switch has been set in position "service".

Forced control of a function can also be performed in codes q12 to q50.

Info button, 3 s: Information for service

use

Þ

Þ

do1

do5 *

<

(Return)

AI1

S3

Read output status

AI2

AI3

AI4

AI5

di1

di2

<

(Return)

S4

S5

S7

**

**

**

*

*

*

*

Read input status

Get a good start

With the following procedure you can start regulation very quickly:

1. Open parameter r12 and stop the regulation (in a new and

not previously set unit, r12 will already be set to 0 which

means stopped regulation.)

2. Select application based on the wiring diagrams on pages 2-4

3. Open parameter o61 and set the application number

4. Select whether to use one or two temperature sensors for the

water cooled condenser

5. For network. Set the address in o03

6. Then select a set of presets from the "Food type" help table

7. Open parameter r89 and set the number for the array of

presettings. The few selected settings will now be transferred

to the menu

8. Set the desired cut-out temperature r00

9. Set the weighted thermostat air temperature between S4 and

S3 sensor r15

10. Set the weighted thermostat air temperature between S4 and

S3 during night operation r61

11. Set the weighted alarm air temperature between S4 and S3

A36

12. Set the weighted display readout between S4 and S3 o17

13. Set the desired defrost method in d01

14. Set the interval time between defrost starts in d03

**)

The input's function.

(Determined at configuration).

15. Set the desired defrost sensor in d10

16. Set the maximum defrost time in d04

17. Set the defrost stop temperature in d02

18. Open parameter r12 and start the regulation

19. Go through the parameter list and change the factory values

where needed.

20. Get the controller up and running on network:

• MODBUS: Activate scan function in system unit

• If another data communication card is used in the controller:

- Lon RS485: Activate the function o04

Food type

Setting of presettings (r89).

After setting 1-5,

setting is returned to 0.

Food type =

Temperature (r00) 8 °C 0 °C -2 °C -20 °C -24 °C

Max. temp. setting (r02) 10 °C 4 °C 2 °C -16 °C -20 °C

Min. temp. setting (r03) 4 °C -4 °C -6 °C -24 °C -28 °C

Upper alarm limit (A13) 14 °C 8 °C 8 °C -15 °C -15 °C

Lower alarm limit (A14) 0 °C -5 °C -5 °C -30 °C -30 °C

Upper alarm limit for S6 (A22) 14 °C 8 °C 8 °C -15 °C -15 °C

Lower alarm limit for S6 (A23) 0 °C -5 °C -5 °C -30 °C -30 °C

Can only be set when r12=0.

1

Vege-

tables2Milk

3

Meat/

fish

4

Frozen

food

5

Ice

cream

© Danfoss | Climate Solutions | 2021.06

AN376928388884en-000101 | 7

Fault message

In an error situation the alarm LED on the front will be on and the alarm relay will be activated (depending on priority).

If you push the alarm button for 3 seconds you can see the alarm report in the display.

(Alarm priorities can be changed. See the User Guide.)

Here are the messages that may appear:

Code Alarm text Description

E01 Hardware failure The controller has a hardware failure

E06 Clock lost time Clock has lost valid time

E25

S3 Air ON evap. A - Sensor error

Sensor signal is out of range. Please check the sensor for correct operation

E26 S4 Air OFF evap. A - Sensor error Sensor signal is out of range. Please check the sensor for correct operation

E27 S5 Evaporator A - Sensor error Sensor signal is out of range. Please check the sensor for correct operation

E50 S7 error Error on S7 sensor

E65 S8 error Error on S8 sensor

A01 High temperature alarm A

A02 Low temperature alarm A

The alarm temperature has been above the max alarm limit for a longer time period

than the set alarm delay.

The alarm temperature has been below the min alarm limit for a longer time period

than the set alarm delay.

A04 Door open alarm The door has been open for a too long time

A05 Max defrost hold time exceeded

The controller has been waiting longer time than permitted after a co-ordinated

defrost.

A15 DI alarm 1 Alarm signal from digital input signal

A16 DI alarm 2 Alarm signal from digital input signal

A19 Comp. fault Compressor is cut-out by safety signal on DI input

A45 Main switch set OFF

The controller manin switch has been set to either Stop or Manaual control.

Alternatively a digital input set up for "main switch" function, has stopped control

A59 Case in cleaning mode A case cleaning operation has been started on a case

A93 SpeedDriveAl Speed drive has tripped, safety signal on DI input

AA3 Refrigerant leak detected Refrigerant is leaking from the refrigeration system

AA4 MaxBrineTemp The S7 brine inlet temperature on condenser has violated high temperature limit

a04

Z01

Data communication

The importance of individual alarms can be defined with a setting. The setting must be carried out in the group "Alarm destinations"

Wrong IO configuration

Max defrost time exceeded A

Inputs and outputs have not been configured correctly

The last defrost cycle has stopped on time instead of set temperature

Additional information not relevant for safe installation and use can be found on Danfoss Store:

For more detailed information, please see the respective User Guide.

8 | AN376928388884en-000101

© Danfoss | Climate Solutions | 2021.06

Loading...

Loading...