Danfoss heating solutions

Installation manual for Danfoss

Air Flex duct systems

air.danfoss.com

Index

1 Before you start........................................................................... 3

2 Legislation................................................................................ 3

3 Dimensioning ............................................................................3

4 Positioning manifold......................................................................3

5 Mounting manifold .......................................................................4

6 Mounting inspection hatch ...............................................................5

7 Positioning supply air box on the oor ....................................................5

8 Mounting supply air box on the oor ......................................................6

9 Before casting ............................................................................ 8

10 Positioning of valves on wall and ceiling ..................................................10

11 Mounting valves on wall and ceiling......................................................10

12 Mounting Flex pipes ..................................................................... 11

13 Insulation................................................................................14

14 Sound-damping the system..............................................................14

15 Positioning roof terminals and wall grills..................................................14

2

VI.FY.A2.02_Sep2014 Instructions - Danfoss Air Flex

1 Before you start

In the following pages we will take you through

the steps needed to properly install the duct

system and ttings. If you follow these instructions, you can rest assured that your house will

have a well-functioning and energy-ecient

ventilation system.

The installation manual for Danfoss Air units can

be found in separate material.

Please check the packing list to ensure that the

shipment is complete, and inspect to ensure that

no parts or components have been damaged.

2 Legislation

3 Dimensioning

Please be aware that Danfoss Air Flex systems

are covered by applicable Danish legislation, and

reference is made to:

• Danish Standard DS 428: Code of practice for

technical measures for re protection in ventilation systems

When dimensioning Danfoss Air Flex there are

few, but very important guidelines that must be

followed:

1) We recommend that the combined pressure

loss for fresh air intake + supply does not

exceed 100 Pa.

+ = 100 Pa

Fresh air intake Supply air

2) We also recommend that the pressure loss for

extract + outlet does not exceed 100 Pa.

+

Extra ct Outlet

= 100 Pa

• Danish Standard DS 447: Code of Practice for

mechanical ventilation installations.

3) Main rules when dimensioning:

Flow per pipe Max. pipe length

3

/h 16 m

≤ 25 m

3

25 - 30 m

/h 13 m

4) There should be no more than a 10 m dier-

ence between the shortest and longest pipes

connected to the same manifold.

5) Min. pipe length is 5 m.

Pressure loss values for the individual components can be found in the Danfoss Air Flex

product catalogue.

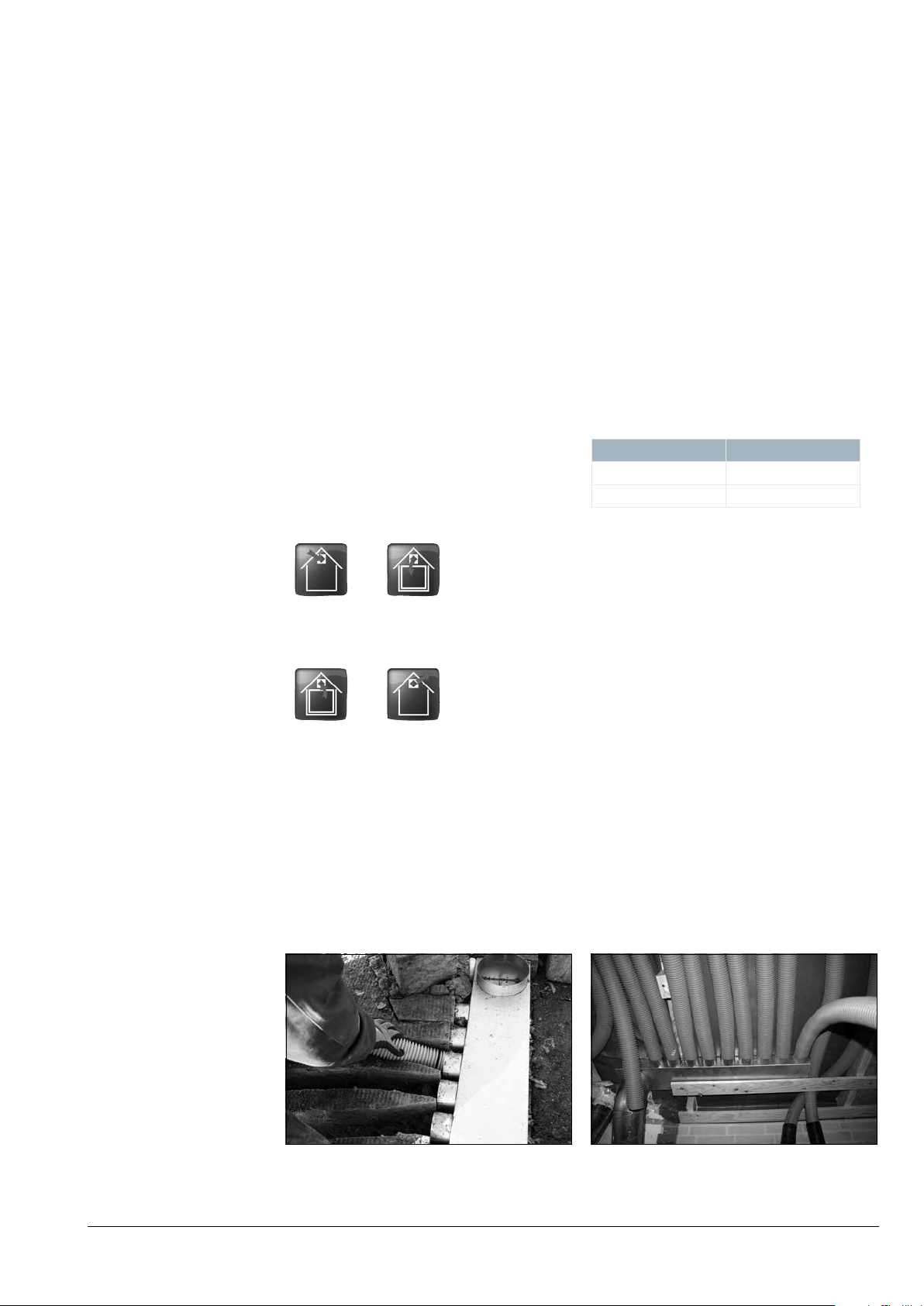

4 Positioning manifold

Position the manifold (if possible) in the immediate proximity of the Danfoss Air ventilation unit,

or determine its position based on an accompanying assembly drawing (if available).

An assembly drawing should be considered to

be a guide only; if the manifold in the drawing is

positioned unsuitably in relation to the construction or to other technical installations, move the

Manifold placed in insulating material

on the oor before casting.

manifold so that the installation is not unnecessarily hindered.

The manifold can be mounted on walls or the

ceiling, or cast in concrete slabs depending on

what is most appropriate in relation to routing.

Manifold positioned beneath

ceiling inside climate shield.

VI.FY.A2.02_Sep2014Instructions - Danfoss Air Flex

3

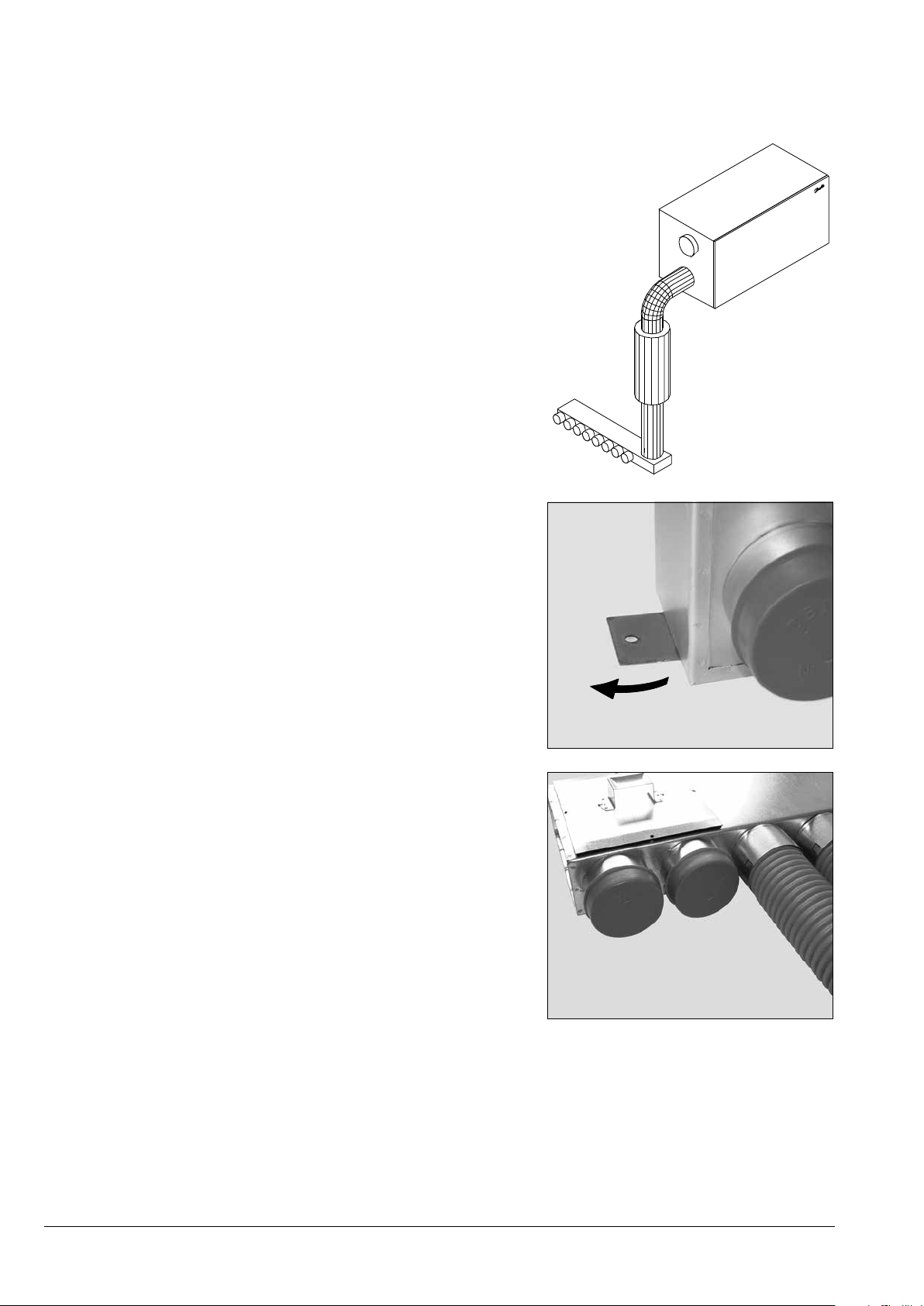

5 Mounting manifold

A silencer must be placed between ventilation unit and manifold - for supply as well as

for extract (only supply is illustrated).

The silencer should have the same diameter

as the connecting pipe on the ventilation

unit , and have a length of 600 mm.

Fasten the manifold using the two brackets

mounted beneath the base. Turn the

brackets and fasten them to the substrate.

If it is not possible to use the mounting

brackets, the manifold can be fastened with

metal strapping.

To prevent possible nuisance, place a soft

material (e.g. 2-3 mm of oor underlay)

between the metal strapping and manifold.

Close all unused spigots on the manifold

with a plastic plug, type DEC-77 (item no.

089 F0615).

4

VI.FY.A2.02_Sep2014 Instructions - Danfoss Air Flex

6 Mounting

inspection hatch

When mounting the inspection hatch, cut a hole

in the manifold where the inspection is to be

performed:

max. diameter 150 mm

max 150 x 150 mm

Place the inspection hatch, type DCH-150x150

(item no. 089F0643) over the hole and fasten

with 4 self-tapping screws.

7 Positioning

supply air box

on the oor

Supply air box and grill should ideally be

positioned against the wall at the following

locations:

• beneath a window

• beneath a radiator

• beside a replace/stove

To the extent possible, avoid placing the grill in

the following places:

• underneath furniture

• near places where people relax for longer

periods of time

If an assembly drawing is enclosed, use it for

guidance in positioning the box and grill.

Note!

Installing oor air extract is highly discouraged.

VI.FY.A2.02_Sep2014Instructions - Danfoss Air Flex

5

8 Mounting

supply air box

on the oor

Place the supply air box in insulation material so

that the distance to the top edge of the nished

oor can be adjusted with the telescopic collar

(collar can be extended by 100 mm).

220 - 320 mm

Fasten the box with the two brackets mounted

beneath the base. Turn the brackets and fasten

them to the substrate.

Mount an o-ring in the second groove on the

Flex pipe.

Mount the Flex pipe on the box.

6

VI.FY.A2.02_Sep2014 Instructions - Danfoss Air Flex

When the pipe is in place, fasten it by folding at

least two of the four cut-outs in with a screwdriver or the like.

Close unused spigots on the box and manifold

with a plastic plug, type DEC-77 (item no.

089F0615).

VI.FY.A2.02_Sep2014Instructions - Danfoss Air Flex

7

9 Before casting

What follows is an example of how a oor box

can be mounted.

The drawing shows the structure of an example

solution.

Note!

A majority of the following photos are staged.

Lead the Flex pipe from underneath the

insulation material.

The recommended distance between the stand

and insulation layer is 300 mm.

Concrete

Insulation material (EPS)

Sand

Place a piece of EPS over the pipe ends before

casting. Fasten to ensure that the position is

maintained during casting.

In this example, two pieces of soft steel are used

for the fastening.

After casting, remove the fastened insulation

material and mount the oor box.

8

VI.FY.A2.02_Sep2014 Instructions - Danfoss Air Flex

To fasten the oor box, use the two pre-mounted

brackets.

Before post-casting around the box, raise the

telescoping collar to a level just above the

nished oor height.

Tape the passage between the telescoping collar

and the box itself.

Tape a piece of insulation material in the box’s

opening.

Finally, ll the area around the box with insulation material, and cast in place.

When the concrete is dry, the telescoping collar

can be loosened with a light blow and then

lowered all the way down into the nished oor.

In some cases, it may be easier to ll all or part of

the hole with light expanded clay aggregate

mixed with concrete.

This will help prevent the relatively small pieces

of insulation material from oating on the

concrete during casting.

VI.FY.A2.02_Sep2014Instructions - Danfoss Air Flex

9

When the nished oor has been laid, pull out

the box’s adjustable insert and click the grill in

place by using the 4 leaf springs.

Place the grill in the insert and press the grill in

place evenly on both sides.

If a damper is selected for the grill, mount it

beneath the grill by using the pre-mounted clips.

The nished result.

For wall mounting use a DPGW box, which is

smaller and therefore ts in most inner walls. All

physical dimensions of the DPGW box are listed

in the Danfoss Air Flex product catalogue.

To fasten the grill and mount the damper, use

exactly the same method as for oor mounting.

10

VI.FY.A2.02_Sep2014 Instructions - Danfoss Air Flex

10 Positioning of valves

on wall and ceiling

The box and valves should be positioned in

accordance with the room’s function and design.

The supply valve should preferably be positioned:

• near a replace/stove (if present)

• near a window

• above a radiator

To the extent possible, avoid placing supply

valves directly over areas where people may be

located for longer periods of time, i.e. above

beds, sofas, dining tables, etc.

The extract valve should be mounted in ‘wet’

rooms, e.g. the kitchen, bathroom and utility

room.

If possible, the valve should be positioned where

moisture develops, i.e. near showers, sinks, etc.

If an assembly drawing is enclosed, it should be

used as a guide for positioning the box and

valve.

Note!

Please be aware that there is a dierence

between supply and extract valves.

11 Mounting valves

on wall and ceiling

Mount the box so that the spigots to the valve

are even with the nished wall/ceiling.

The valve can then be pushed in place in the box

(a supply valve is shown here).

Correct valve placement.

VI.FY.A2.02_Sep2014Instructions - Danfoss Air Flex

11

12 Mounting

Flex pipe

Floor mounting

Cut/furrow a route for the pipes in the insulation

material. The width of the route should be

adjusted to ensure a secure installation of the

pipe.

If it is not possible to t the pipes into furrows in

the insulation material, they can be fastened to

the Rionet.

The maximum distance between the fastening

points/strips is 50-70 cm.

To attain the greatest possible seal in the system,

mount an o-ring at each end of all pipes. Place

the o-ring in the second groove from the end

before mounting the pipe in the desired

manifold, box or coupler.

The pipes can then be mounted in the manifold.

When the pipe is in place, fasten it by folding at

least two of the four cut-outs in with a screwdriver or the like.

12

VI.FY.A2.02_Sep2014 Instructions - Danfoss Air Flex

To keep concrete, building dust or other material

from soiling the pipes during mounting, close all

unused spigots.

If the system is not used immediately after

installation, the pipes must be sealed to prevent

the accumulation of moisture. The pipes can be

sealed with a plastic plug, type DEC (089F0613),

or by closing the valves/grills.

To the extent possible, avoid making ‘sharp’

bends on the pipe, as this will increase the

system pressure loss.

Note!

When all pipes are mounted, thoroughly clean the manifold via the connecting pipe.

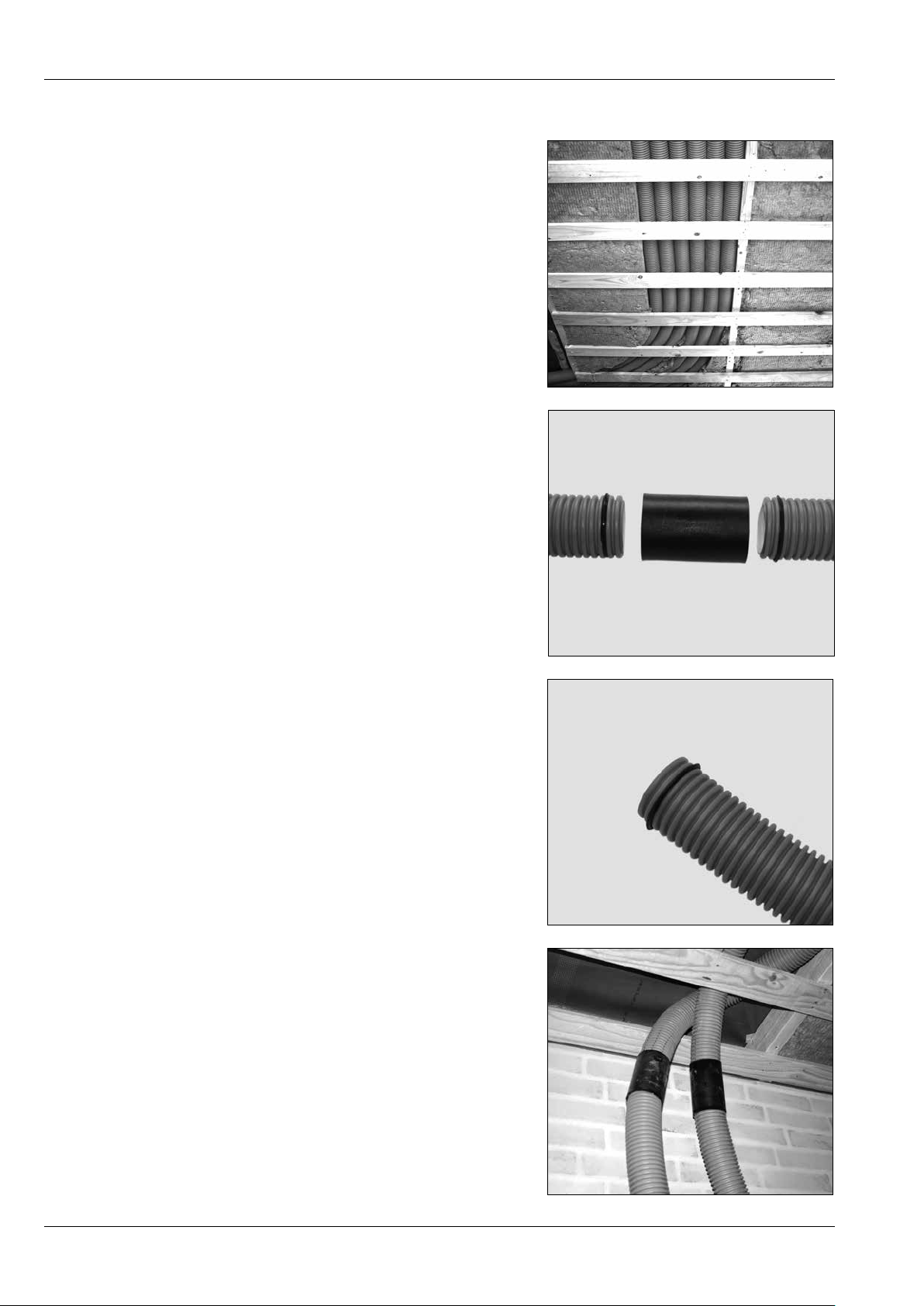

Wall/ceiling mounting

Wall mounting is recommended exclusively for

internal partitions to prevent thermal bridges

and penetrations of the climate shield.

For ceiling mounting, we also recommend

mounting the pipes inside a climate shield. If this

is not possible, the climate shield/damp-proof

membrane must be thoroughly sealed with

weather-resistant tape or the specially developed membranes shown here.

For systems with geothermal surfaces, the

supply pipe must be insulated with at least 30

mm of insulation material due to the risk of

external condensation on the pipes.

If the enclosed mounting brackets cannot be

used, metal strapping can be used to fasten the

boxes.

It is important that the pipes are fully extended

before tting to minimise pressure loss in the

system.

VI.FY.A2.02_Sep2014Instructions - Danfoss Air Flex

13

Here we see six correctly laid pipes beneath the

ceiling on the inside of the climate shield.

When the ceiling is set up, the length of the

screws must be adjusted so that they do not penetrate the pipes.

Connecting pipes in the coupling

If it is necessary to extend or simply connect two

pipe ends, this can be done using a coupling,

type DPC (089F0607).

Connect an o-ring in the second groove to both

pipes that are to be connected.

Completed couplings.

14

VI.FY.A2.02_Sep2014 Instructions - Danfoss Air Flex

13 Insulation

It is important that the entire Danfoss Air Flex

system is thoroughly insulated to minimise heat

loss and prevent condensation.

We recommend insulating pipes with at least 100

mm of insulation against cold surfaces.

14 Sound-damping the

system

15 Positioning roof termi-

nals and wall grills

Sound-damping the system is important for

general comfort and wellbeing.

Between the unit and manifold, mount a silencer

with a length of 600 mm to reduce any noise that

might otherwise be capable of spreading

Roof terminals/wall grills are the visible part of

the ventilation system from the outside. To the

extent possible, they should therefore always be

adapted to the architectural style of the house.

We recommend positioning the terminals at least

3 metres apart measured vertically or 1 metre

apart measured horizontally, always with the

outlet terminal at the top.

We also recommend placing terminals and grills

on a north-facing or east-facing surface for

optimal comfort.

through the rest of the system and throughout

the home.

In some cases, it might also be advisable to

mount silencer at the outlet and air inlet ends.

Note!

The outlet should be positioned:

- above the house’s top window

- at least one metre from the closest window

3 m

3 m

1 m

VI.FY.A2.02_Sep2014Instructions - Danfoss Air Flex

15

For generations now, Danfoss has been

delivering solutions used in all aspects of

heating and cooling , such as valves, thermostats,

pumps and highly advanced control systems.

The Danfoss Group cons ists of a global network

of sales companies, agents and distributors, and

Danfoss produc ts are sold, serviced and valued

around the world. Danfoss products also play

an important role when it comes to creating

optimal indoor climate and comfort.

Danfoss A/S

Ulvehavej 61 • DK-7100 Vejle • Denmark

Tel. +45 88 85 00 • Fax +45 74 88 86 03 • air@danfoss.com • www.danfoss.com • www.air.danfoss.com

This has always been our legacy, and the new

Danfoss Air system is set to carry on this proud

tradition.

www.danfoss.comVI.FY.A2.02_Sep2014

Loading...

Loading...