Page 1

Data sheet

Differential pressure controller with flow limitation and

with integrated control valve (PN 16)

AHPBM-F – flow mounting, fixed setting

Description

AHPBM-F is a self-acting differential pressure

controller with flow limitation primarily for use in

direct-connected district heating systems with

mixing loop only. The controller closes on rising

differential pressure or when set max. flow is

exceeded.

It can be combined with Danfoss electrical

actuators AMV(E) and controlled by ECL

electronic controllers.

The controller has a control valve with adjustable

flow restrictor, connection neck for electrical

actuator, and an actuator with one control

diaphragm.

Controllers are used together with Danfoss

electrical actuators:

- AMV(E) 10

- AMV(E) 13 with spring return function

- AMV(E) 130, AMV(E) 140

- AMV(E) 130H, AMV(E) 140H with manual

override knob

AHPBM-F combined with AMV(E) 13 has been

approved according to DIN EN 14597.

Main data:

• DN 15-32

• kvs 1.0-6.3 m3/h

• PN 16

• Fixed ∆p setting:

- 0.12 bar for DN 15-20

- 0.14 bar for DN 25-32

• Temperature:

- Circulation water / glycolic water up to 30%:

2 … 120 °C

• Connections:

- Ext. thread (weld-on, thread and flange

tailpieces)

Ordering

Example:

Differential pressure controller

with flow limitation (fixed setting)

and integrated control valve,

DN 15, kVS 1.6, PN 16, flow restrictor

Δp 0.12 bar, t

- 1× AHPBM-F DN 15 controller

Code No.: 003L3582

Option:

- 1× Impulse tube set AH, 1.5 m

Code No: 003L8152

- 1× Fitting for imp. tube

Code No: 003L5042

- 1× Weld-on tailpieces

Code No.: 003H6908

External impulse tube (AH), nipple

for impulse tube and electrical

actuators AMV(E) must be ordered

separately.

DH-SMT/SI

120 °C, ext. thread

max

AHPBM-F Controller

Picture

VD.LR. K1.02 © Danfoss 03/2011

DN

(mm)

15

20 2.5 G 1 A 003L3583

25 4.0 G 1¼ A

32 6.3 G 1¾ A 003L3585

k

VS

(m3/h)

1.0

1.25 003L3581

1.6 003L3582

Connection

G ¾ A

Cylin. ext. thread

acc. to ISO 228/1

∆p setting range

(bar)

0.12

0.14

Code No.

003L3580

003L3584

1

Page 2

Data sheet

0.12(0.14)

Diff. press. controller with flow limitation and with integrated control valve AHPBM-F (PN 16)

Ordering (continuous)

Accessories

Picture Type designation DN Connection Code No.

15

Weld-on tailpieces

External thread tailpieces

Flange tailpieces

Impulse tube set AH

Impulse tube set AH for

pressure reduction

Fitting for impulse tube connection to pipe

10 EPDM o-rings for impulse tube 003L8175

20 003H6909

25 003H6910

-

32 003H6911

15

20 R ¾ 003H6903

25 R 1 003H6904

Conical ext. thread acc. to

EN 10226-1

R ½ 003H6902

32 R 1¼ 003H6905

15

20 003H6916

Flanges PN 25, acc. to EN 1092-2

25 003H6917

Description:

- 1× copper tube Ø 3 × 1 mm

- 2× fitting for imp. tube connection

to actuator and pipe G /

1.5 m 003L3561

2.5 m 003L5043

5 m 003L3562

Description:

- 1× stainless steel tube Ø 0.8 × 0.2 mm

- 2× fitting for imp. tube connection

0.8 m 003L3560

to actuator and pipe G /

G /-R / 003L5042

G /-R ¼ 003L8151

003H6908

003H6915

Technical data

Valve

Nominal diameter DN 15 20 25 32

k

value

VS

Q

min

Q

* 0.43 0.7 1.0 1.2 2.2 3.4

nom

m3/h

Stroke mm 5.5 5

Control ratio > 1:30 > 1:50 > 1:100

Control characteristic Linear

Cavitation factor z ** ≥ 0.6

Leakage acc. to standard IEC 60534 0.05

Nominal pressure PN 16

Min. differential pressure

Max. differential pressure 4

bar

Medium Circulation water / glycolic water up to 30%

Medium pH Min. 7, max. 10

Medium temperature °C 2 … 120

Connections External thread

Materials

Valve body /valve seat / valve cone Dezincing free brass CuZn36Pb2As

Sealing EPDM

* At differential p ressure across the controller Δp

** kv / kVS ≤ 0.5 at DN 25 and hig her

*** Depe nds on the flow rate and valve k

1)

Depends o n DN

;

Δp +

VS

≥ 0.5 bar

AHPBM-F

2

⎛

⎞

Q

nom

⎜

⎟

=

min

⎜

⎟

k

vs

⎝

⎠

1.0 1.25 1.6 2.5 4.0 6.3

0.035 0.11 0.2 0.25 0.43 0.65

See remark ***

1)

2

VD.LR. K1.02 © Danfoss 03/2011

DH-SMT/SI

Page 3

Data sheet

Diff. press. controller with flow limitation and with integrated control valve AHPBM-F (PN 16)

Technical data (continuous)

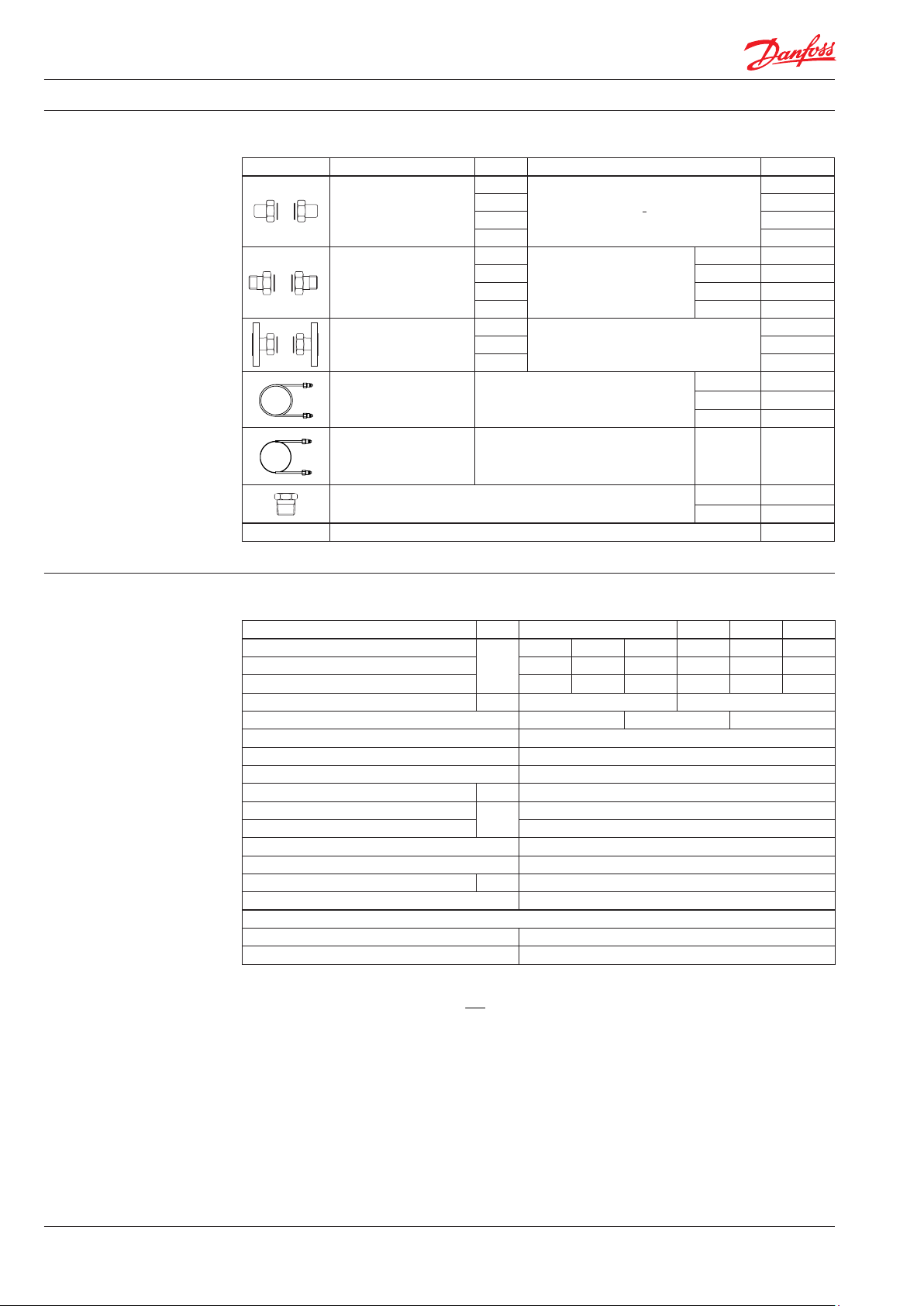

Application principles

AHPBM-F controller must be

installed in the flow pipeline

only.

Actuator

Type DN 15 20 25 32

Actuator size cm

Nominal pressure PN 16

Flow restrictor differential pressure (AHQM)

Fixed differential pressure setting (AHPBM-F)

Materials

Housing*

Diaphragm EPDM

Impulse tube

* Actuator ho using is part of valve body

Direct-connected district heating system with mixing

loop only

bar

2

8.5 13 20 32

0.12 0.14

Dezincing free brass CuZn36Pb2As

Copper tube Ø 3 × 1 mm

Stainless steel tube Ø 0.8 × 0.2 × 800 mm

Installation positions The controllers can be installed in horizontal

or vertical pipes with (connection neck for)

electrical actuator oriented upwards.

Electrical actuator

Note!

Installation positions for electrical actuator

AMV(E) have to be observed as well. Please see

relevant Data Sheet.

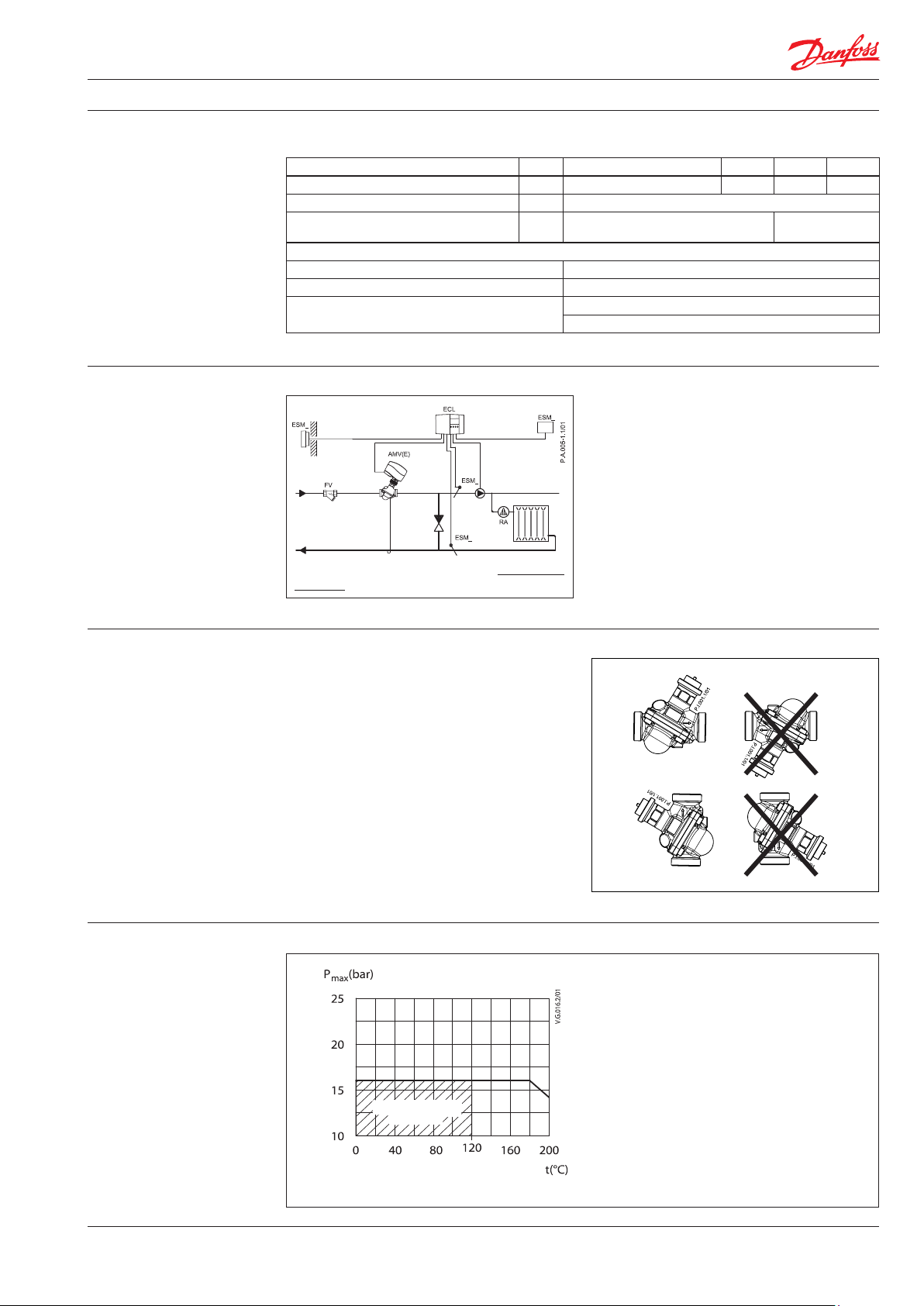

Pressure temperature

diagram

working area

CuZn36Pb2As (DZR) PN 16

DH-SMT/SI

Maximum allowed operating pressure as a function of medium temperature (according to EN 1092-3).

VD.LR. K1.02 © Danfoss 03/2011

3

Page 4

Data sheet

Diff. press. controller with flow limitation and with integrated control valve AHPBM-F (PN 16)

Flow diagram Sizing and setting diagram

Relation between actual flow and number of revolutions on flow restrictor. Values given are

approximate.

DN 32 kVS 6.3

DN 25 kVS 4.0

DN 20 kVS 2.5

DN 15 kVS 1.6

DN 15 kVS 1.25

DN 15 kVS 1.0

Flow can be adjusted by turning flow restrictor screw

counter-clockwise as shown in this diagram

1 = 360º

Water flow shown at differential pressure across the

controller from 0.5 bar (50 kPa) to 4 bar (400 kPa).

4

VD.LR. K1.02 © Danfoss 03/2011

DH-SMT/SI

Page 5

Data sheet

Diff. press. controller with flow limitation and with integrated control valve AHPBM-F (PN 16)

Sizing

- Directly connected heating

system

Example AHPBM-F

(flow mounting only)

Motorised control valve (MCV) for mixing circuit

in direct-connected heating systems requires

differential pressure of 0.12 bar (12 kPa) and flow

less than 600 l/h.

Given data:

Q

= 0.6 m3/h (600 l/h)

max

p

= 0.8 bar (80 kPa)

min

*p

= 0.1 bar (10 kPa)

circuit

p

= 0.12 bar (12 kPa) selected

MCV

* Remark:

p

corresponds to the required pump

circuit

pressure in the heating circuit and is not to be

considered when sizing the AHPBM-F.

The total (available) pressure loss across the

controller is:

p

p

= p

AHPBM-F,A

= 0.8 bar (80 kPa)

AHPBM-F,A

min

Possible pipe pressure losses in tubes, shut-off

fittings, heatmeters, etc. are not included.

Select controller from flow diagram, page 5,

with the smallest possible kVS value considering

available flow ranges.

kVS = 1.6 m3/h

The min. required differential pressure across

the selected controller is calculated from the

formula:

2

Q

max

p

p

p

AHPBM-F,MI N

p

AHPBM-F,A

MINF,-AHPBM

k

VS

2

0.6

MINF,-AHPBM

1.6

0.12

= 0.26 bar (26 kPa)

> p

AHPBM-F,MI N

p

MCV

0.8 bar > 0.26 bar

Solution:

The example selects AHPBM-F DN 15, kVS value

1.6, flow setting range 0.06-0.79 m3/h.

DH-SMT/SI

VD.LR. K1.02 © Danfoss 03/2011

5

Page 6

Data sheet

Design

1. Valve body

2. Control valve insert

3. Adjustable flow restrictor

4. Control valve stem

5. Differential pressure actuator

6. Control diaphragm

7. Built-in spring for flow rate

control

8. Pressure relieved valve cone

9. Impulse tube

Diff. press. controller with flow limitation and with integrated control valve AHPBM-F (PN 16)

Function Pressure changes from the flow and return

pipeline are being transferred through the

impulse tube and control drain to the actuator

chambers and act on control diaphragm. Control

valve closes on rising differential pressure and

opens on falling differential pressure to maintain

constant differential pressure. Flow volume is

controlled and limited by means of the flow

restrictor.

Additionally the electrical actuator will operate

from zero to set max. flow according to the load.

Settings

Flow setting

Flow setting is being done by the adjustment of

the flow restrictor position. The adjustment can

be performed on the basis of flow adjustment

diagram (see relevant instructions) and/or by the

means of heat meter.

6

VD.LR. K1.02 © Danfoss 03/2011

DH-SMT/SI

Page 7

Data sheet

Dimensions

Diff. press. controller with flow limitation and with integrated control valve AHPBM-F (PN 16)

DN 15 20 25 32

L

H 24 31 39 49

H

1

D (ISO 228/1) G ¾A G 1A G 1¼A G 1¾A

Valve weight kg 0.51 0.67 1.47 2.23

65 82 104 130

mm

57 59 72 84

DN 15 20 25 32

SW

32 (G ¾A) 41 (G 1A) 50 (G 1¼A) 63 (G 1¾A)

d 21 26 33 42

1)

R

2)

L1

L2 131 144 160 177

mm

½ ¾ 1 1 ¼

130 150 160 -

L3 139 154 159 184

k 65 75 85 -

d

2

n 4 4 4 -

1)

Conical ex t. thread acc. to EN 10226-1

2)

Flanges PN 25, acc. to EN 1092-2

14 14 14 -

Fittings

DH-SMT/SI

VD.LR. K1.02 © Danfoss 03/2011

7

Page 8

Data sheet

Dimensions (continuous)

Diff. press. controller with flow limitation and with integrated control valve AHPBM-F (PN 16)

AMV(E) 10 + AHPBM-F

DN 15 20 25 32

AMV(E) 10

L*

AMV(E) 13 147 147 164 183

AMV(E) 10 178 186 204 224

L**

AMV(E) 13 188 196 214 234

AMV(E) 10 195 201 223 245

H*

AMV(E) 13 210 216 238 260

AMV(E) 10 174 184 202 222

H**

AMV(E) 13 180 190 208 228

137 137 153 172

mm

AMV(E) 13 + AHPBM-F

AMV(E) 130(H)/140(H) + AHPBM-F

DN 15 20 25 32

L*

L** 148 156 174 194

H* 168 178 196 216

H** 152 162 180 200

8

VD.LR. K1.02

118 125 141 160

mm

Produce d by Danfoss A/S © 03/2011

Loading...

Loading...