Page 1

Data sheet

Pressure independent control valve with integrated flow limiter

AFQMP 2 - return and flow mounting, adjustable setting

Description

virtus.danfoss.com

AFQMP 2 is a self-acting flow controller with

integrated control valve and with pressure

actuator with adjustable spring, developed for

the use in district heating / cooling systems. The

controller prevents flow to exceed set max flow.

Pressure actuator with adjustable spring enables

adjustment of differential pressure over the

control cone from 0.1 to 1 bar. Increased flows

can be provided. In a combination with electrical

actuators AMV(E) and ECL electronic controllers

the flow and temperature can be controlled to

achieve highest energy savings.

AFQMP 2

limiter, connection neck for electrical actuator and

a pressure actuator with one control diaphragm.

Controllers are used together with Danfoss

electrical actuators:

• AFQMP 2 PN 16/25/40 DN 65-250

- AMV(E) 655 without spring return function

- AMV(E) 658 SD 2) spring return function and

- AMV(E) 659 SD 1) spring return function;

- AMV(E) 55

• AFQMP 2 PN 16/25/40 DN 65 -125

- AMV(E) 56

1)

DIN approve d (according to EN 1457)

2)

not DIN approved

Together with Danfoss intelligent electrical

actuator AMEi 6 intelligent optimization

functions are available:

iSET-intelligent substation efficiency

iNET-intelligent pump optimization

Main data:

• DN 65-250

• kVS 60-800 m3/h

• Flow range 4.2-630 m3/h

• PN 16, 25, 40

• Differential pressure over the flow control

• Temperature:

• Connections: Flange

• AFQMP 2 combined with AMV(E) 659 SD have

has a control valve with adjustable flow

and with manual operation;

manual operation;

optimization

cone ∆pCV:

0.1-1 bar (adjustable by the spring)

- Circulation water / glycolic water up to 30 %:

2 … 150°C

been DIN approved according to EN 14597.

© Danfoss | 2022.01

AI343441104258en-010103 | 1

Page 2

Data sheet AFQMP 2

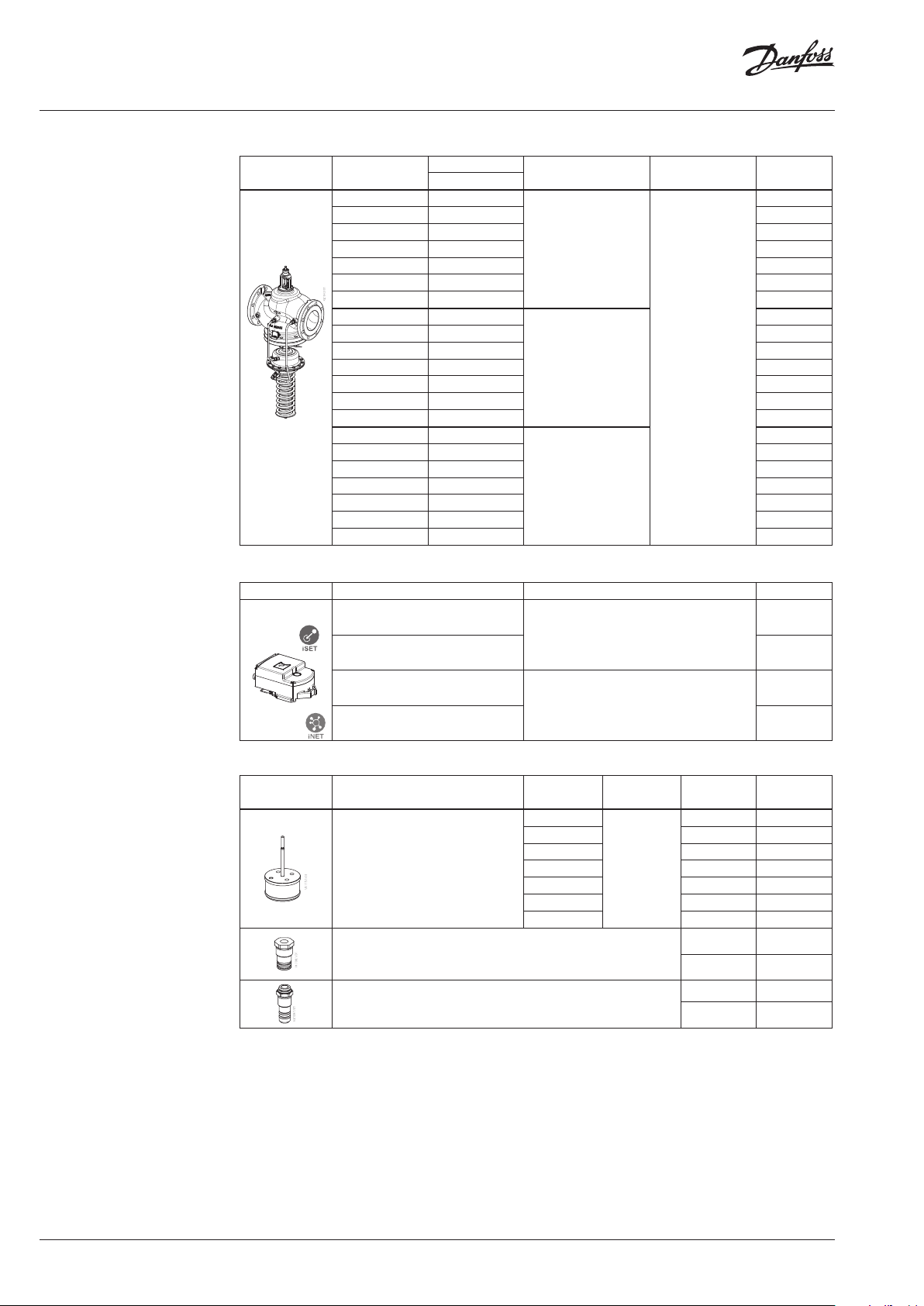

Ordering

Example:

Flow controller with integrated

control valve for flow rate, DN65,

kVS 60, PN 16, T

- 1× AFQMP 2 DN 65 controller

Code No.: 003G5560

The controller will be delivered

completely assembled, inclusive

impulse tubes between valve and

actuator. Electrical actuator AMV(E)

must be ordered separately.

150 °C, flange

max

AFQMP 2 Controller

Q

Picture DN

65 27- 61

80 40 -100 003G5561

100 60 -138 003G5562

125 100 -230 003G5563

150 130 -290 003G5564

200 180-450 003G5565

250 280-630 003G5566

65 27- 61

80 40 -100 003G5571

100 60 -138 003G5572

125 100 -230 003G5573

150 130 -290 0 03G55 74

200 180-450 003G5575

250 280-630 003G 5576

65 27- 61

80 40 -100 003G 5581

100 60 -138 003G5582

125 100 -230 003G5583

150 130 -290 003G5584

200 180-450 003G5585

250 280-630 003G5586

max

pCV= 0.1-1 bar

PN Connection Code No.

16

25

40

Flange EN 1092-1

Accessories

Picture Type designation Description Code No.

AMEi 6 iSET

el actuator 230 V

AMEi 6

iSET

el actuator 24 V

AMEi 6 iNET

el actuator 230 V

AMEi 6 iNET

el actuator 24 V

Intelligent p actuator with iSET function

Intelligent p actuator with iNET function

003G5560

003G5570

003G5580

082G4300

082G4301

082G4302

082G4303

Service kits

Picture Typ e

Pressure control insert VFG/Q 221

k

VS

(m3/h)

60

80 80 003G18 08

160 100 003 G1809

250 125 003 G1810

380 150 003 G1811

650 200 003 G1812

800 250 00 3G1813

Flow stuffing box VFG/Q 22(1)

Pressure stuffing box VFG/ Q 22(1)

PN DN Code No.

65 003G1807

16/2 5/40

65 -125 00 3G1720

150-250 00 3G1721

65 -125 003G1730

150-250 003G1731

2 | AI343441104258en-010103

© Danfoss | 2022.01

Page 3

Data sheet AFQMP 2

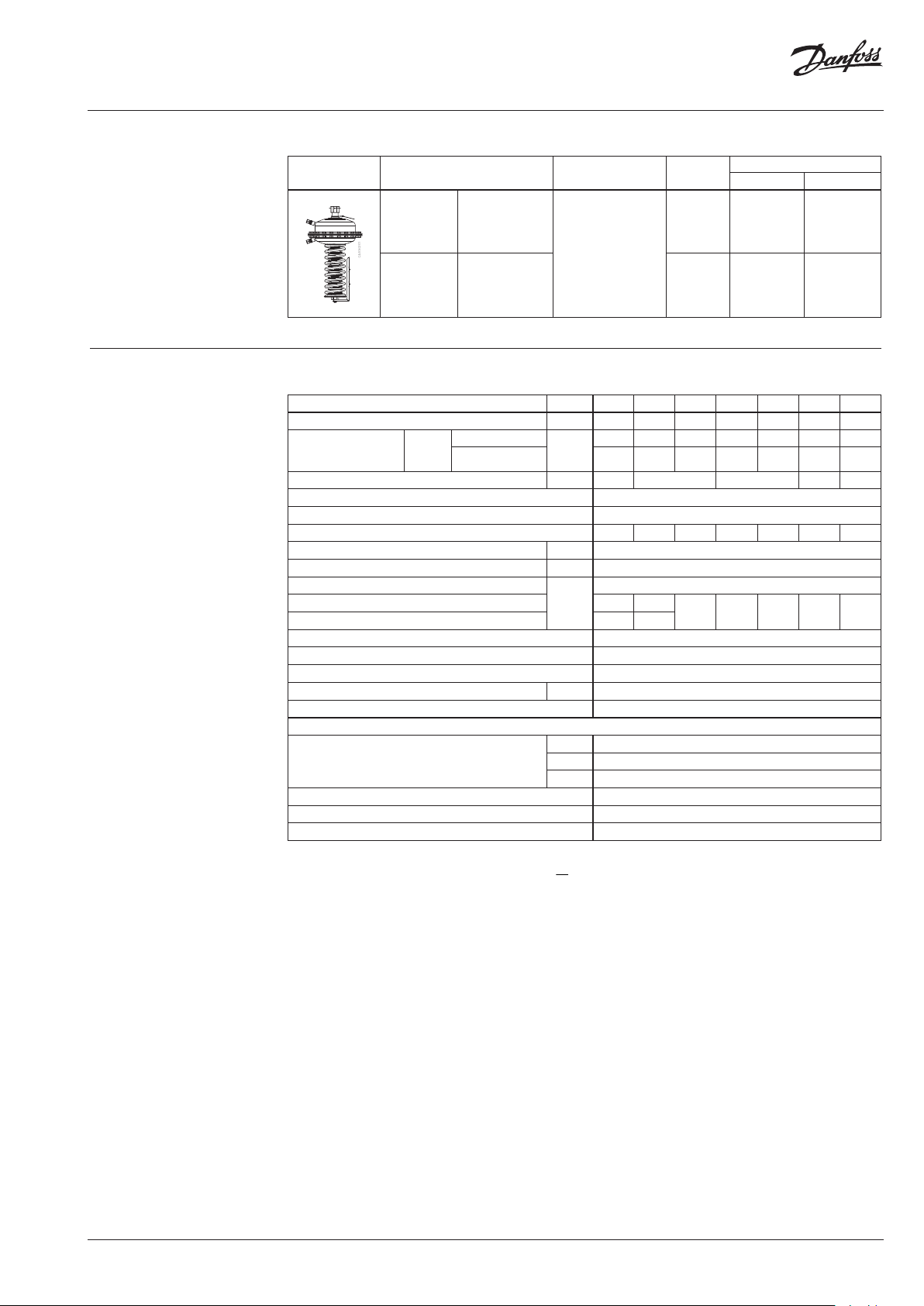

AFQMP 2 Actuator

Picture

Actuator size

(cm)

∆p setting range

(bar)

for DN

Code No.

PN 16 PN 40

Technical data AFQMP 2 valve

kVS value m3/h 60 80 160 250 380 650 800

Range of max. flow

settings Q

Stroke mm 12 19 23 28 32

Control valve authority 1 (100 %) in the range of flow setting

Control characteristic linear-split

Cavitation factor z 0.65 0.55 0.4 0.4 0.4 0.4 0.3

Leakage acc. to standard IEC 534 % of k

Nominal pressure PN 16, 25, 40

Min. differential pressure

Max. dif ferential pressure PN 16 16 16

Max. dif ferential pressure PN 25/40 20 20

Pressure relievement system Chamber relieved

Media Circulation water / Glycolic water up to 30 %

Media pH Min .7, ma x.1 0

Media temperature °C 2 … 150

Connections Flange

Valve body

Valve seat DP, CV Stainless steel, mat. No. 1.4021

Valve cone DP, CV Stainless steel, mat. No. 1.4021

Sealing DP, CV EPDM

1)

DP-dif f. pressure over the pressure contro l cone, CV-diff. pres sure over the flow control cone , ∆p

2)

Required dif ferential pressure for d esired flow Q ->

160 blue

65 -125 003G5612 003G5622

0.1-1

320 orange 150-250 003G5610 003G5620

Nominal diameter DN 65 80 100 125 150 200 250

∆pCV 1) = 0.1 bar

max

∆pCV 1) = 1 bar 61 10 0 13 8 230 290 450 630

m3/h

bar

27 40 60 100 130 180 280

VS

≤ 0.01

see remark

2)

15 15 12 10 10

Materials

PN 16 Grey cast iron EN-GJL-250 (GG-25)

PN 25 Ductile iron EN- GJS-400 -18-LT (GGG-40.3)

PN 40 Cast steel GP240GH (GS-C 25)

- diff. pressur e over AFQMP 2 valve

p

AFQMP

k

2

Q

p

, ∆pCV can be set bet ween 0.1 - 1 bar

CV

VS

AFQMP

© Danfoss | 2022.01

AI343441104258en-010103 | 3

Page 4

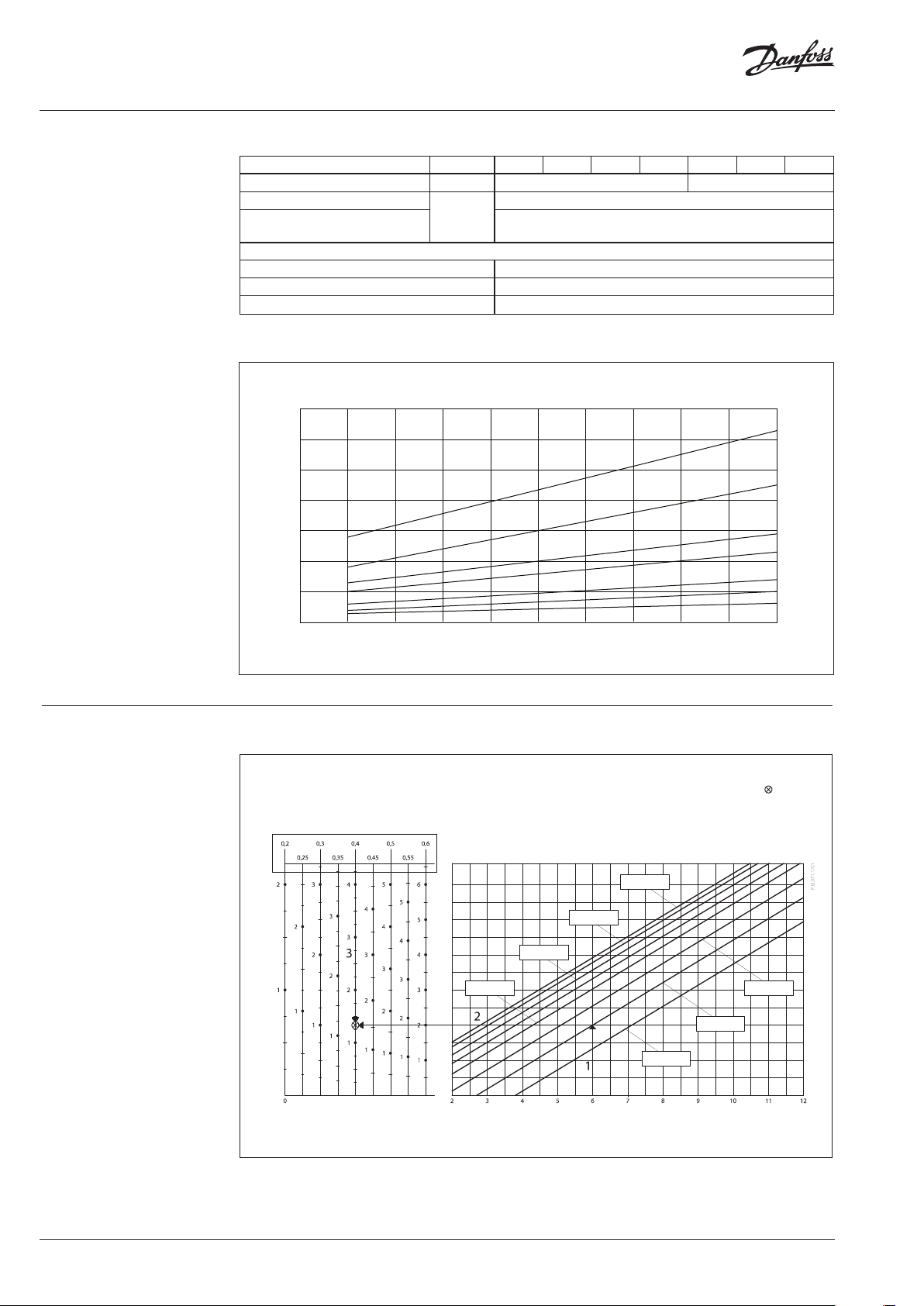

Data sheet AFQMP 2

p

at z = 0,2 ... 0,6 [bar]

Inlet pressure bar p [bar]

z =

Example :

100

200

300

400

500

600

700

00.1 0.20.3 0.40.5 0.60.7 0.80.9 1

AFQMP 2 actuator

Actuator size cm

Max. operational pressure

Differential pressure over the f low control

cone

∆p

CV

Housing Steel, mat. No. 1.0345, zinc plated

Diaphragm EPDM (Rolling; fibre enforced)

Impulse tube Stainless steel tube Ø10 × 0.8 mm

Range of max. flow settings

Qmax

(m3/h)

For valve DN 65 80 100 12 5 15 0 200 250

2

160 320

16 or 40

bar

0.1-1 (adjustable)

Materials

DN250

DN200

DN15 0

DN125

Operating area

0

4)

Set by the spring on the adjustable pressure actuator

Maximum allowed differential pressure over the controller (p

max

T = 90°C

T = 110°C

T = 100°C

) at different cavitation factors (z)

max

p = 6 bar

T = 140°C

z = 0,4

= 1,35 bar

p

max

T = 80°C

T = 130°C

T = 140°C

DN100

DN80

DN65

∆pCV

(bar)

4)

4 | AI343441104258en-010103

[bar]

max

p

T = 150°C

© Danfoss | 2022.01

Page 5

Data sheet AFQMP 2

Application principles

- Return mounting

- Flow mounting

AFQMP 2

Direct-connected heating system

AFQMP 2

Indirectly connected heating system

AFQMP 2

AFQMP 2

Direct-connected heating system Indirectly connected heating system

Installation positions

Note!

Installation positions for electrical

actuators AMV(E) have to be observed

as well. Please see relevant Data sheet.

© Danfoss | 2022.01

AI343441104258en-010103 | 5

Page 6

Data sheet AFQMP 2

Pressure temperature diagram

PN 16

EN - GJL- 250

(GG -25)

150

PN 25

EN-GJS-400

(GGG-40.3)

150

PN 40

EN-GP-240-GH

(GS- C 25)

150

Maximum allowed operating pressure as a function of media temperature (according to EN 1092-2)

6 | AI343441104258en-010103

© Danfoss | 2022.01

Page 7

Data sheet AFQMP 2

0

10

20

30

40

50

60

70

80

90

100

0 12345678910

Design

1. Valve body

2. Flow control insert

3. Flow stuffing box

4. Max. flow limitation nut

5. Valve seat

6. Pressure control insert

7. Pressure actuator

8. Pressure actuator diaphragm

9. Pressure actuator spring

10. Diaphragm excess pressure

safety valve

11. Flow control cone (CV)

12 . Pressure control cone (DP)

13 . Impulse tube

14 . Union nut

15 . Cover

16. Connection for electrical

actuator

17. Pressure stuffing box

18. Setting scale

19. Setting indicator

20. Differential pressure setting

nut

Settings Differential pressure setting

Flow setting

Flow limitation is being done by the adjustment

of the max. flow limitation nut. The adjustment

can be performed on the basis of flow limiting

diagram (see relevant instructions) and/or by

the means of heat meter. Flow limiting curves

in diagrams represent informational values, for

Differential pressure setting is being done by the

adjustment of the setting spring for diff. pressure

control. This is done by rotating the differential

pressure setting nut. Set differential pressure

should be checked by observing the pressure

indicators.

more accurate flow limitation setting use flow/

heat meter.

Flow limiting

turns indicator

1 revoluti on =360°

DN 65

/h

3

flow m

© Danfoss | 2022.01

p

No. of revolutions

= max

b

p

= min

b

AI343441104258en-010103 | 7

Page 8

Data sheet AFQMP 2

10

11

120

012345678910 11 12 13 14

0

20

40

60

80

100

120

140

160

012345678910111213

0

20

40

60

80

100

120

140

160

180

200

220

240

012345678910 11 12 13 14 15

0

20

40

60

80

100

120

140

160

180

200

220

240

260

280

300

320

0123456789101112131415

Flow limiting (continuous)

3

/h

3

flow m

/h

flow m

0

DN 80

0

90

80

70

60

50

40

30

20

10

0

No. of revolutions

= max

b

p

p

b

= min

DN 10 0

= max

b

p

= min

b

p

/h

3

flow m

/h

3

flow m

© Danfoss | 2022.01

DN 125

DN 150

No. of revolutions

b

p

No. of revolutions

No. of revolutions

= max

p

= min

b

p

p

b

= max

b

= min

AI343441104258en-010103 | 8

Page 9

Data sheet AFQMP 2

500

10

15

20

25

30

35

40

45

50

55

60

65

700

21

Flow limiting (continuous)

450

DN 200

400

350

300

250

/h

3

200

150

flow m

100

50

0

012345678910 11 12 13 14 15 16 17 18 19

No. of revolutions

0

DN 250

0

0

0

0

0

/h

3

0

0

0

flow m

0

0

0

50

0

012345678910 11 12 13 14 15 16 17 18 19 20

p

= 0.7 bar

b

p

b

p

= 0.1 bar

= 0.7 bar

b

= 0.1 bar

p

b

Function Flow control

No. of revolutions

Flow control cone adjusts the flow by opening

and closing. This action is provided by an electric

actuator. The max flow is limited by limiting the

maximal opening of the flow control cone. This

is done by rotating the flow limitation nut. The

pressure independent flow control is achieved by

maintaining a constant differential pressure over

the flow control cone.

The differential pressure over the flow control

cone is lead to the pressure actuator diaphragm

through the impulse tubes. It is factory preset.

The opening/closing of the pressure control cone

is performed by changing differential pressure

over the diaphragm.

When differential pressure over the flow control

cone:

a) rises, the pressure control cone takes over the

exceeded differential pressure by closing, until

set differential pressure over the flow control

cone is reached.

b) drops, the pressure control cone compensates

the missing differential pressure by opening,

until set differential pressure over the flow

control cone is reached.

Pressure actuator diaphragm is equipped

with excess pressure safety valve to protect

diaphragm from the damages caused by too

high differential pressure.

Differential pressure control

Is achieved by maintaining a constant differential

pressure over the control valve.

The differential pressure over the control valve is

lead to the pressure actuator diaphragm through

the impulse tubes.

The opening/closing of the pressure control cone

is performed by changing differential pressure

over the diaphragm.

When differential pressure over the control valve:

a) rises, the pressure control cone takes over the

exceeded differential pressure by closing, until

set differential pressure over the control valve/

application is reached.

b) drops, the pressure control cone compensates

the missing differential pressure by opening,

until set differential pressure over the control

valve/application is reached.

The pressure actuator diaphragm is equipped

with excess pressure safety valve to protect

diaphragm from the damages caused by too

high differential pressure.

9 | AI343441104258en-010103

© Danfoss | 2022.01

Page 10

Data sheet AFQMP 2

Dimensions

AFQMP 2 pressure actuator

Ø295

AMEi 6 iSET/iNET electric actuator

100

140

mi n. 150

220

770

39 51 54

3

H

mi n. 150

AMEi 6 intellig ent

actuator wit h iSET/iNET

functionality should be

622

mi n. 150

ordered sep arately

min. 250

mi n. 150

L H1H2H3HAIValve weight (kg)

DN

65 290 670 520 545

80 310 670 520 545 44 56 59

100 350 705 545 475 805 63 76 81

125 400 710 580 610 810 82 94 102

150 480 775 610 635 875 138 159 174

200 600 810 665 695 910 245 267 295

250 730 870 680 705 970 397 424 478

2

H

mm PN 16 PN 25 PN 40

© Danfoss | 2022.01

Ai

H

AMV(E) 55, 56/ AMEi 6

iSET/iNET AFQMP 2

DN 65-125

Ai

H

AMV(E) 65X/ AMEi 6

iSET/ iNET AFQMP 2

DN 65-250

1

H

L

AMV(E) 55, 56/AFQMP 2

DN 65-125

AI343441104258en-010103 | 10

1

H

L

AMV(E) 65X/AFQMP 2

DN 65-250

Page 11

Data sheet AFQMP 2

11 | AI343441104258en-010103

© Danfoss | DCS-SGDPT/SI | 2022.01

Loading...

Loading...