Data sheet

Pressure independent control valve with integrated ow limiter

AFQM 2 - return and flow mounting

AFQM 2

Description

virtus.danfoss.com

AFQM 2 is a self-acting flow controller with

integrated control valve developed for the

use in district heating / cooling systems. The

controller prevents flow to exceed set max

flow. In a combination with electrical actuators

AMV(E) and ECL electronic controllers the flow

and temperature can be controlled to achieve

highest energy savings.

has a control valve with adjustable flow

limiter, connection neck for electrical actuator and

a pressure actuator with one control diaphragm.

Controllers are used together with Danfoss

electrical actuators:

• AFQM 2 PN 16/25/40 DN 65-250

- AMV(E) 655 without spring return function

and with manual operation;

- AMV(E) 658 SD 2) spring return function and

manual operation;

- AMV(E) 659 SD 1) spring return function;

- AMV(E) 55

• AFQM 2 PN 16/25/40 DN 65-125

- AMV(E) 56

1)

DIN approve d (according to EN 1457)

2)

not DIN appr oved

Main data:

• DN 65-250

• k

60-800 m3/h

VS

• Flow range 5.6-500 m3/h

• PN 16, 25, 40 *

* PN 40 available i n Q1-2022

• Differential pressure over the flow control

cone ∆pCV:

0.2 bar (standard version) or

0.5 bar (high flow version)

• Temperature:

- Circulation water / glycolic water up to 30 %:

2 … 150°C

• Connections: Flange

© Danfoss | 2022.01 AI268359228474en-010302 | 1

Data sheet AFQM 2

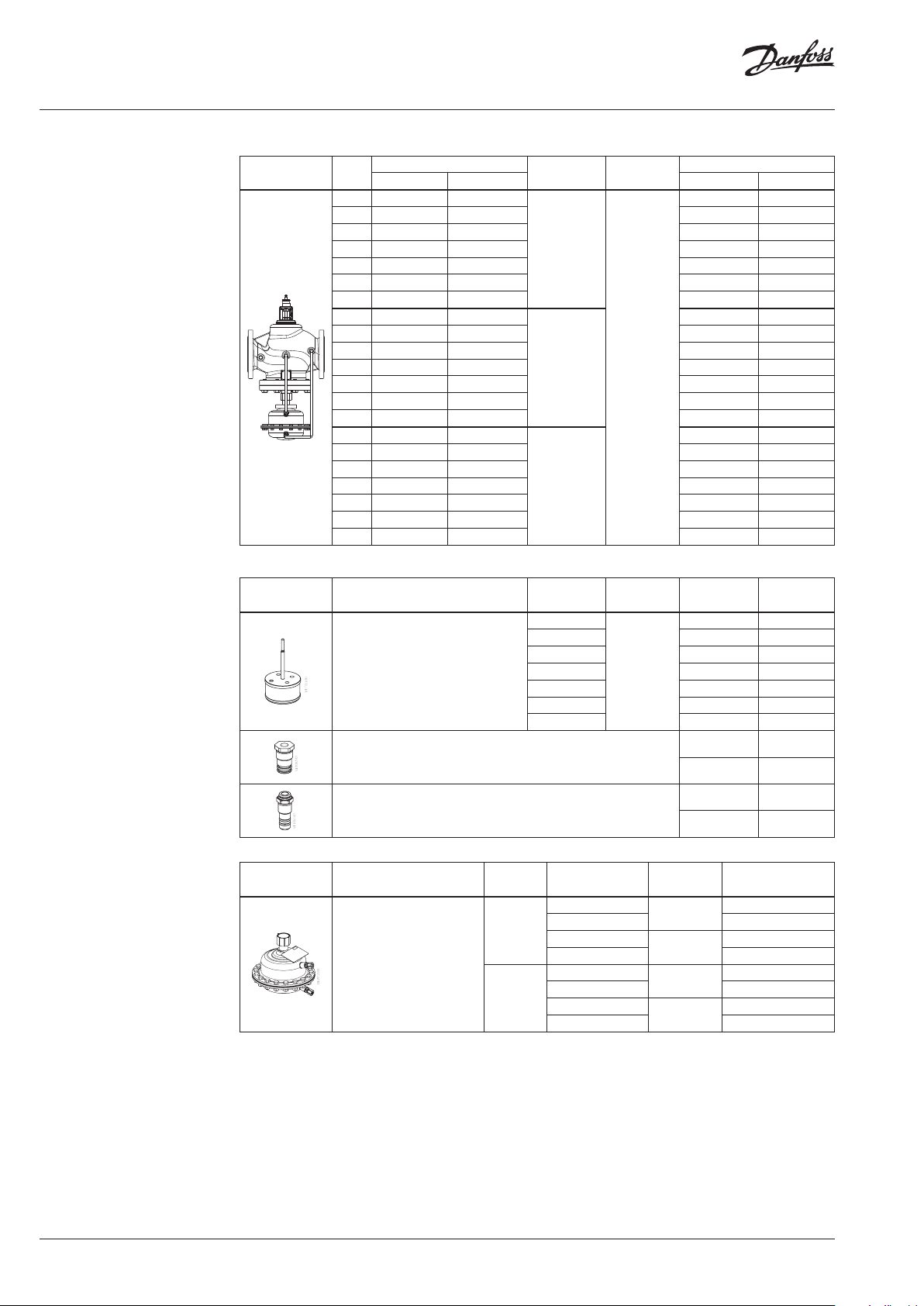

Ordering

Example:

Flow controller with integrated

control valve for flow rate,

DN65, kVS 60, PN 16, flow restrictor

ΔpCV 0.2 bar, T

- 1× AFQM 2 DN 65 controller

Code No.: 003G5500

The controller will be delivered

completely assembled, inclusive

impulse tubes between valve and

actuator. Electrical actuator AMV(E)

must be ordered separately.

150 °C, flange

max

AFQM 2 Controller

Picture DN

65 28 42

80 40 60 003G5502 003G5503

100 63 95 003G5504 003G5505

125 100 150 003G5506 003G5507

150 160 240 003G5508 003G5509

200 270 340 003G5510 00 3G 5511

250 360 500 003G 5512 0 03G55 13

65 28 42

80 40 60 00 3G5516 0 03G5517

100 63 95 003G5518 0 03G5519

125 100 150 003G552 0 003G 5521

150 160 240 003G552 2 003G5523

200 270 340 003G 5524 003G5525

250 360 500 003G5526 003G5527

65 28 42

80 40 60 003G5530 0 03G5531

100 63 95 003G5532 003G5533

125 100 150 003G5534 003G5535

150 160 240 003G5536 00 3G5537

200 270 340 003G5538 003G5539

250 360 500 003G5540 00 3G5541

Service kits

Picture Typ e

Pressure control insert VFG/Q 221

Q

ΔpCV=0.2 bar ΔpCV=0.5 bar ΔpCV=0.2 bar ΔpCV=0.5 bar

max

Flow stuffing box VFG/Q 22(1)

PN Connection

16

25

40

k

VS

(m3/h)

60

80 80 00 3G1808

160 100 0 03G1809

250 125 0 03G1810

380 150 0 03G18 11

650 200 00 3G1812

800 250 003 G1813

Flange EN

1092-1

PN DN Code No.

16/2 5/40

Code No.

003G5500 003G 5501

00 3G5514 003 G5515

003G5528 003G5529

65 0 03G1807

65 -125 00 3G1720

150-250 00 3G1721

Pressure stuffing box VFG/Q 22(1)

Picture Typ e PN

16

Pressure actuator

40

65 -125 003G1730

150-250 003G1731

∆p

CV

(bar)

0.2

0.5 003G5601

0.2

0.5 003G5597

0.2

0.5 003G5603

0.2

0.5 003G5599

Actuator size

(cm2)

160

320

160

320

Code no.

003G5600

003G5596

003G5602

003G5598

2 | AI268359228474en-010302 © Danfoss | 2022.01

Data sheet AFQM 2

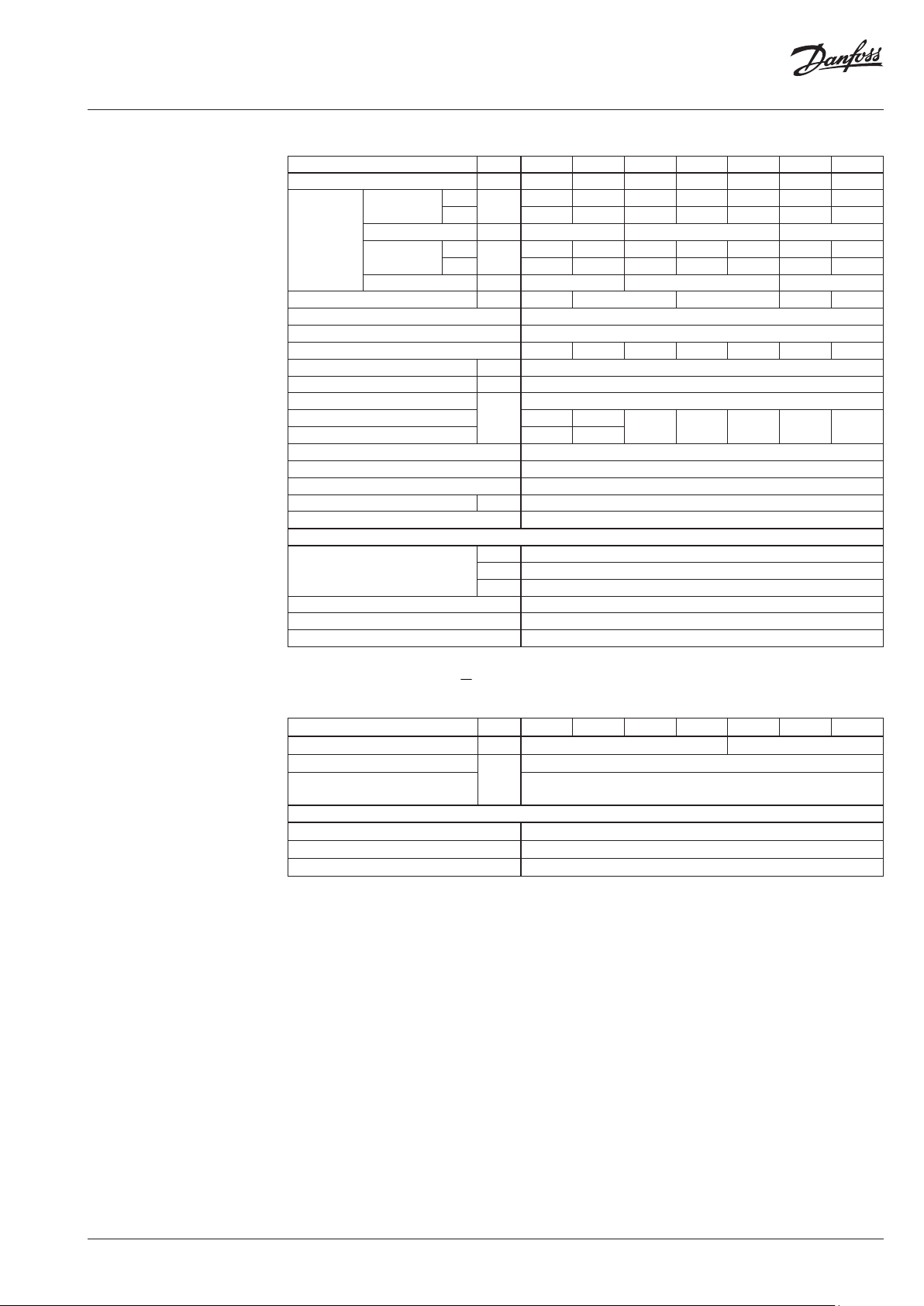

Technical data AFQM 2 valve

Nominal diameter DN 65 80 10 0 125 150 200 250

kVS value m3/h 60 80 160 250 380 650 800

Range of max.

flow setting

Stroke mm 12 19 23 28 32

Control valve authority 1 (100 %) in the range of flow setting

Control characteristic split

Cavitation factor z 0.65 0.55 0.4 0.4 0.4 0.4 0.3

Leakage acc. to standard IEC 534 % of k

Nominal pressure PN 16, 25, 40

Min. differential pressure

Max. dif ferential pressure PN 16 16 16

Max. dif ferential pressure PN 25/40 20 20

Pressure relievement system Chamber relieved

Media Circulation water / Glycolic water up to 30 %

Media pH Min .7, ma x.1 0

Media temperature °C 2 … 150

Connections Flange

Valve body

Valve seat DP, CV Stainless steel, mat. No. 1.4021

Valve cone DP, CV Stainless steel, mat. No. 1.4021

Sealing DP, CV EPDM

1)

DP-dif f. pressure over the pressure contro l cone, CV-diff. pres sure over the flow control cone , ∆p

2)

For flows sma ller than Q

AFQM 2 actuator

Actuator size cm

Max. operational pressure

Differential pressure over the f low control

cone

∆p

CV

Housing Steel, mat. No. 1.0345, zinc plated

Diaphragm EPDM (Rolling; fibre enforced)

Impulse tube Stainless steel tube Ø10 × 0.8 mm

∆pCV 1) = 0.2 bar

1)

∆p

AFQM

∆pCV 1) = 0.5 bar

1)

∆p

AFQM

Q

min

m3/h

Q

max

bar 0.45 0.4 0.45

Q

min

m3/h

Q

max

bar 1.0 0.9 0.8

bar

5.6 8.0 12.6 20 32 54 72

28 40 63 100 160 270 360

8.4 12 19 30 48 68 100

42 60 95 150 24 0 340 500

VS

≤ 0.01

see remark

2)

15 15 12 10 10

Materials

PN 16 Grey cast iron EN-GJL-250 (GG-25)

PN 25 Ductile iron EN-GJS-400-18-LT (GGG-4 0.3)

PN 40 Cast steel GP240GH (GS -C 25)

- diff. pressur e required for Q

max

p

->

AFQM

2

Q

p

CV

k

VS

AFQM

max

For valve DN 65 80 10 0 125 150 200 250

2

160 320

16 or 40

bar

0.2 or 0.5

Materials

AI268359228474en-010302 | 3© Danfoss | 2022.01

Loading...

Loading...