Data sheet

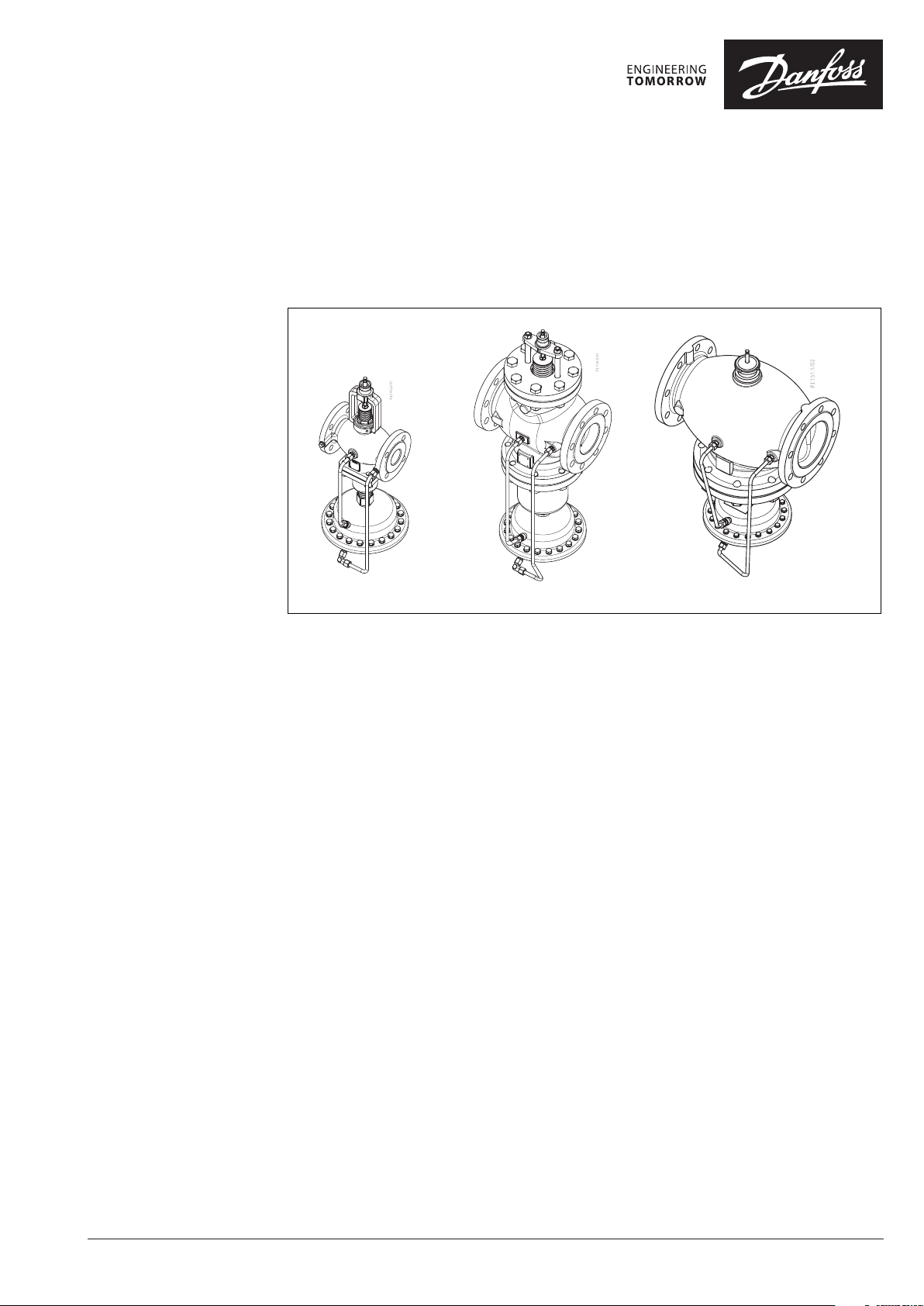

Flow controller with integrated control valve (PN 16, 25, 40*)

AFQM, AFQM 6 - return and flow mounting

Description

AFQM 6 DN 40, 50 AFQM DN 65-125 AFQM DN 150-250

AFQM(6) is a self-acting flow controller with

integrated control valve with full authority,

primarily for use in district heating systems. The

controller closes when set max. flow is exceeded.

In combination with Danfoss electrical actuators

AMV(E) can be controlled by ECL electronic

controllers.

The AFQM (6) is pressure independent which

means that the control characteristic is

independent from the available pressure and is

not influenced by a low authority.

The controller has a control valve with adjustable

flow restrictor, connection neck for electrical

actuator and an actuator with one control

diaphragm. Further on control valve can be:

- not pressure relieved (AFQM 6 DN 40-50) or

- pressure relieved (AFQM DN 65-250).

Controllers are used together with Danfoss

electrical actuators:

• AFQM 6 PN 16/25, AFQM PN 16/25 DN 65-125 3)

- AMV(E) 65x

without spring return function and with

manual operation:

- AMV(E) 655

spring return function and manual operation:

- AMV(E) 658 SD

2)

spring return function:

- AMV(E) 659 SD 1)

• AFQM 6 PN 16/25, AFQM PN 16/25 DN 65-125

- AMV(E) 55, 56

• AFQM PN 16 DN 150-250

- AMV(E) 85, 86

1)

DIN approved , according to EN 1457

2)

not DIN approved

3)

For AFQM 6 PN 16/25 and AFQM PN 25/40 controllers ,

produced be fore March 2015, adapter code 0 65B3527 need

to be separately o rdered

Main data:

• DN 40-250

• kVS 20-400 m3/h

• Flow range 2.2-420 m3/h

• PN 16, 25

* PN 40 on special request

• Flow restrictor ∆pb: 0.2 or 0.5 bar

• Temperature:

- Circulation water / glycolic water up to 30 %:

2 … 150 °C for DN 40-125

2 … 140 °C for DN 150-250

• Connections:

- Flange

• AFQM 6 and AFQM PN 25 combined with

AMV(E) 659 SD have been DIN approved

according to EN 14597.

© Danfoss | 2017.02

VD.LR.A8.02 | 1

Data sheet Flow controller with integrated control valve AFQM(6), PN 16, 25, 40*

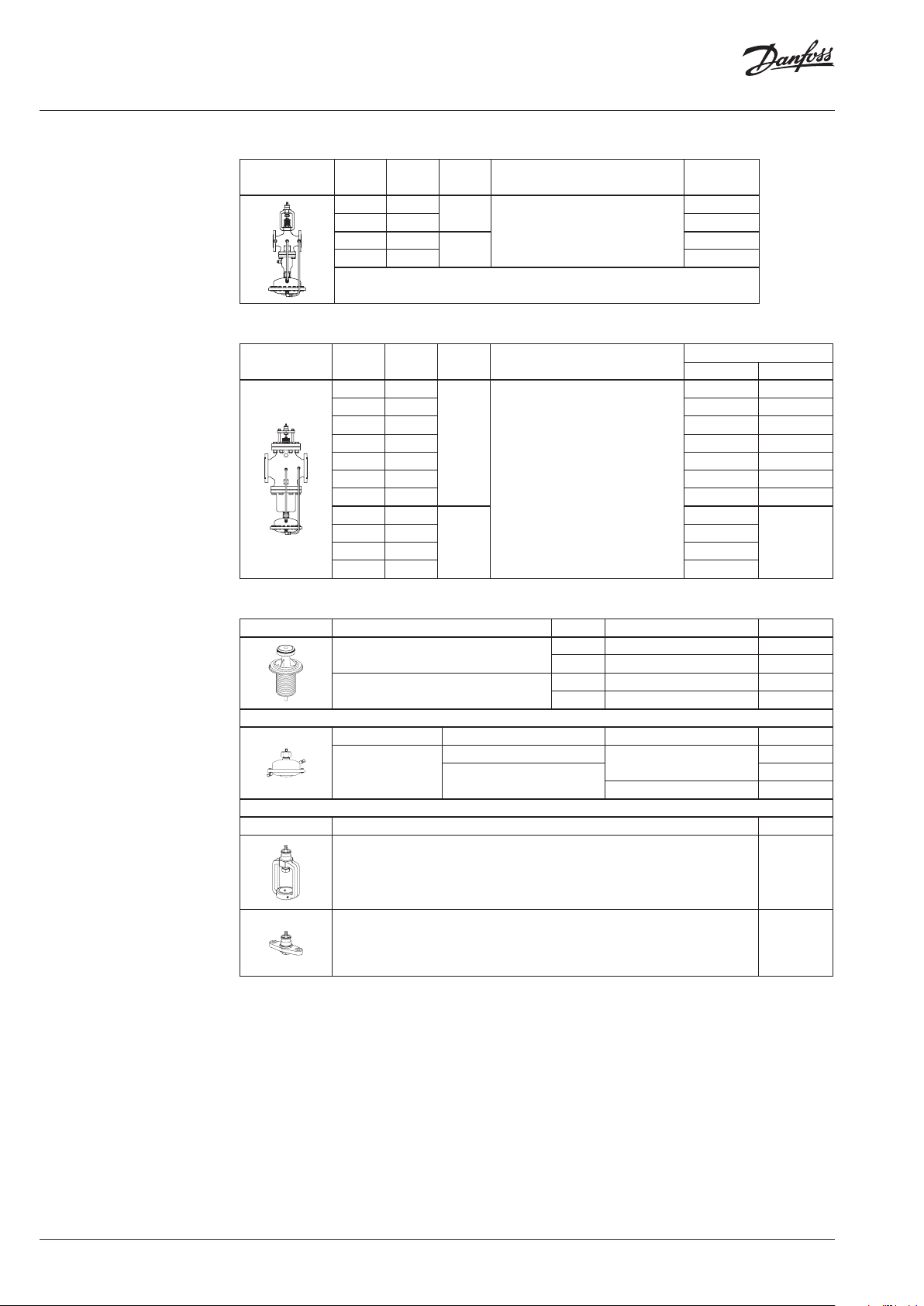

Ordering

Example:

Flow controller with integrated

control valve, DN 65, kVS 50,

PN 16, flow restrictor Δpb 0.2 bar,

T

150 °C, flange

max

- 1× AFQM DN 65 controller

Code No.: 003G6056

The controller will be delivered

completely assembled, inclusive

impulse tubes bet ween valve and

actuator. Electrical actuator AMV(E)

must be ordered separately.

AFQM 6 Controller

Picture DN

AFQM Controller

Picture DN

kVS

m3/h

40 20

50 32 003 G1083

40 20

50 32 003 G1085

k

VS

(m3/h) ΔPb=0.2 bar ΔPb=0.5 bar

65 50

80 80 003G6057 003G6064

100 125 003G6058 003G6065

125 160 003G6059 003G6066

150 280 003G6060 003G6067

200 320 003G6061 003G6068

250 400 003G6062 003G6069

65 50

80 80 003G108 9

100 125 003G10 90

125 160 003G10 91

PN Connection Code No.

16

Flange EN 1092-1

25

PN Connection

16

Flange EN 1092-1

25

003 G1082

003 G1084

003G6056 003G6063

003 G1088

Code No.

—

Service kits

Picture Type designation DN k

Valve insert

Control valve insert

Type designation For controller Δpb (bar) Code No.

AFQM 6

Actuator

Connection kit AMV(E) 41x, 61x, 63x/AFQM 6 00 3G1425

Connection kit AMV(E) 41x , 61x, 63x/AFQM 00 3G1426

AFQM

Type designation Code No.

65/80 50/80 065B2794

100/125 125/160 065B2795

65 50 065B2972

80 80 065B2973

(m3/h) Code No.

VS

0.2

0.5 003G1027

003 G1024

003 G1026

2 | VD.LR.A8.02

© Danfoss | 2017.02

Data sheet Flow controller with integrated control valve AFQM(6), PN 16, 25, 40*

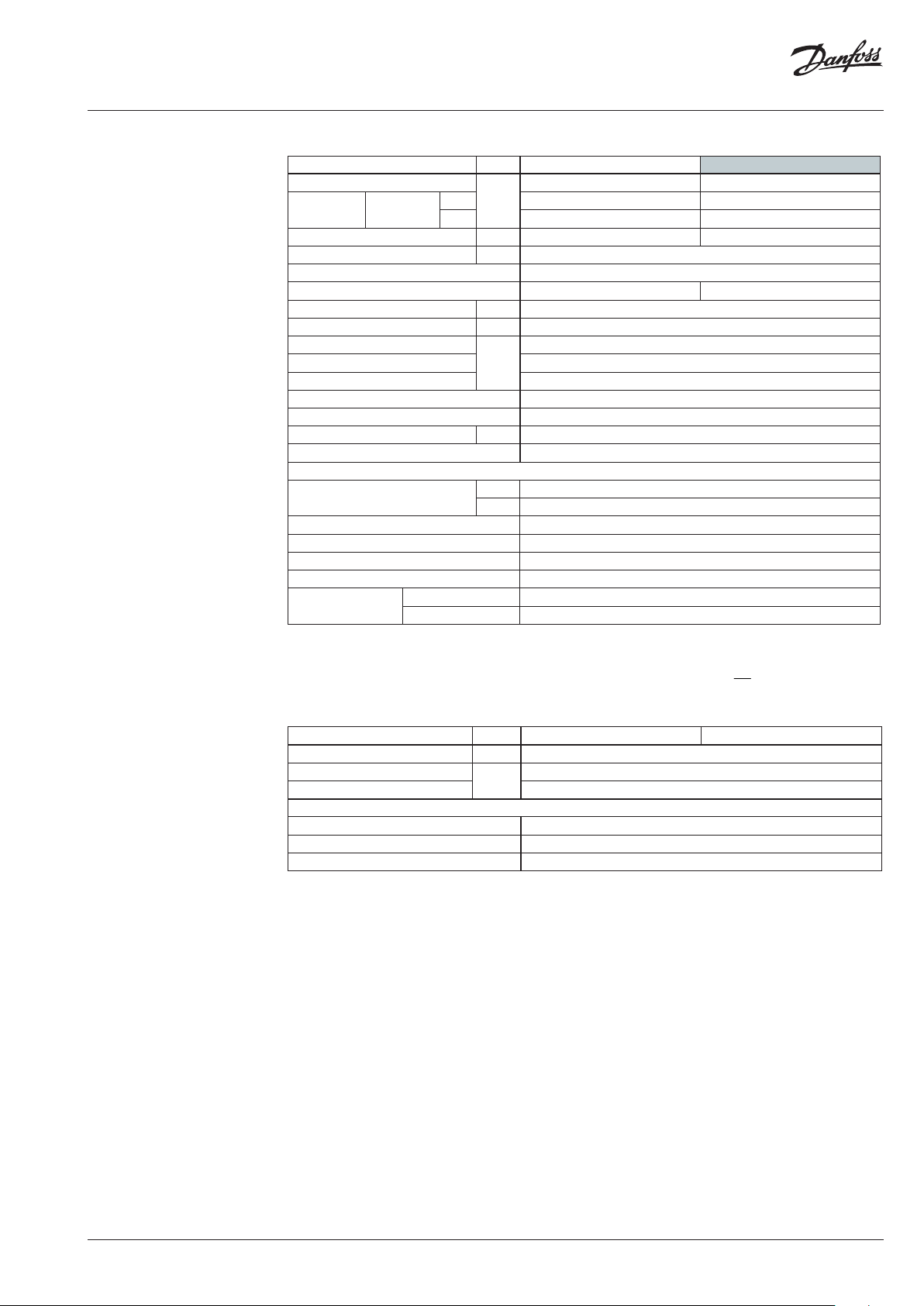

Technical data

AFQM 6 valve

Nominal diameter DN 40

k

value

VS

Range of max.

flow setting

∆p

1)

= 0.2 bar

b

m3/h

from 2.2 3.2

to 11 16

20 32

Stroke mm 8 12

Control valve authority % 100

Control characteristic Linear

Cavitation factor z 0.55 0.5

Leakage acc. to standard IEC 534 % of k

VS

Nominal pressure PN 16, 2 5

Min. differential pressure

Max. dif ferential pressure PN 16 16

bar

Max. dif ferential pressure PN 25 20

Medium Circulation water / glycolic water up to 30%

Medium pH Min .7, ma x.1 0

Medium temperature °C 2 … 150

Connections Flange

Materials

Valve body

PN 16 Grey cast iron EN-GJL-250 (GG-25)

PN 25 Ductile cast iron EN -GJS-400-18-LT (GGG-40.3)

Valve seat DP, CV Stainless steel mat. No. 1.4021

Valve cone DP, CV Stainless steel mat. No. 1.4404

Sealing DP EPDM

Sealing CV Metal

Pressure relieve

system

Control valve insert -

Valve insert Bellows (Stainless steel mat. No. 1.4571)

Note:

DP - diff. pressu re controller, CV - control valve

1)

∆pb - differe ntial pressure over flow restri ctor

2)

Depends o n the flow rate and valve kVS ; For Q

3)

Could be conver ted by actuator AME 65x to logarithm ic

= Q

-> ∆p

set

max

≥ 0.5 bar; For Q

min

< Q

set

≤ 0.01

see remark

->

p

max

50

3)

2)

2

Q

min

p

k

VS

b

AFQM 6 Actuator

For valve DN 40 50

Actuator size cm

Max. operational pressure

Flow restrictor dif f. pressure

ΔP

b

Materials

Housing Stainless steel M. No. 1.0338

Diaphragm

Impulse tube Stainless steel tube Ø10 × 0.8 mm

bar

2

250

25

0.2

EPDM (Rolling; fibre enforced)

© Danfoss | 2017.02

VD.LR.A8.02 | 3

Data sheet Flow controller with integrated control valve AFQM(6), PN 16, 25, 40*

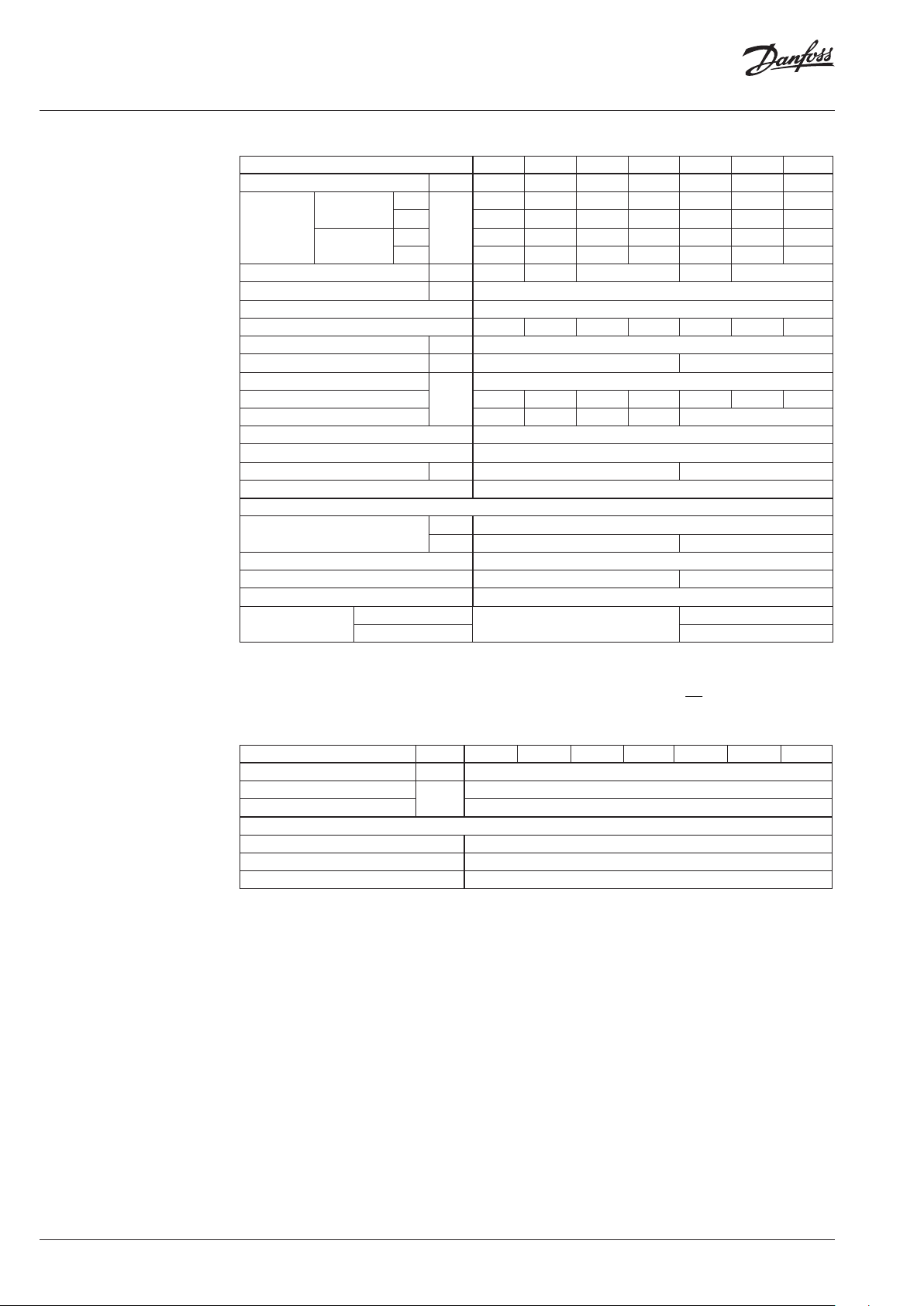

Technical data (co ntinuous)

AFQM valve

Nominal diameter DN 65 80 10 0 125 150 200 250

kVS value m3/h 50 80 125 160 280 320 400

from

to 28 40 63 80 145 190 280

m3/h

from 5.6 8.0 12.6 16 30 38 56

to 40 58 76 91 220 285 420

Range of max.

flow setting

∆pb 1) = 0.2 bar

∆pb 1) = 0.5 bar

Stroke mm 12 18 20 25 27

Control valve authority % 100

Control characteristic Linear

Cavitation factor z 0.5 0.4 0.35 0.3 0.3 0.2 0.2

Leakage acc. to standard IEC 534 % of k

Nominal pressure PN 16, 2 5 16

Min. differential pressure

Max. dif ferential pressure PN 16 16 16 15 15 12 10 10

bar

Max. dif ferential pressure PN 25 20 20 15 15 -

Medium Circulation water / Glycolic water up to 30 %

Medium pH Min .7, ma x.1 0

Medium temperature °C 2 … 150 2 … 140

Connections Flange

Materials

Valve body

PN 16 Grey cast iron EN-GJL-250 (GG-25)

PN 25 Ductile iron EN- GJS-400 -18-LT (GGG-40. 3) -

Valve seat DP, CV Stainless steel M. No. 1.4021

Valve cone DP, CV Stainless steel mat No. 1.4404 Stainless steel mat. No. 1.4021

Sealing DP, CV EPDM

Pressure relieve

system

Control valve insert

Valve insert Diaphragm (EPDM)

Note:

DP - diff. pressu re controller, CV - control valve

1)

∆pb - differe ntial pressure over flow restri ctor

2)

Depends o n the flow rate and valve kVS ; For Q

3)

Could be conver ted by actuator AME 65x to logarithm ic

5.6 8.0 12.6 16 30 38 56

3)

VS

≤ 0.01

see remark

2)

Bellows

(stainless steel mat No. 1.4571)

= Q

-> ∆p

set

max

≥ 0.5 bar; For Q

min

< Q

->

max

p

min

set

2

Q

k

VS

p

Piston

b

AFQM actuator

For valve DN 65 80 10 0 125 15 0 200 250

Actuator size cm

Max. operational pressure

Flow restrictor dif f. pressure

∆pb 0.2 or 0.5

Materials

Housing Stainless steel M. No. 1.0338

Diaphragm EPDM (Rolling; fibre enforced)

Impulse tube Stainless steel tube Ø10 × 0.8 mm

bar

2

250

16 or 25

4 | VD.LR.A8.02

© Danfoss | 2017.02

Data sheet Flow controller with integrated control valve AFQM(6), PN 16, 25, 40*

Application principles

- Return mounting

Direct-connected heating system Indirectly connected heating system

- Flow mounting

Direct-connected heating system Indirectly connected heating system

Installation positions DN 40-80 T

The controllers can be installed with (connection

neck for) electrical actuator oriented horizontal

or upwards.

DN 40-80 T

DN 100-250

The controllers can be installed with (connection

neck for) electrical actuator oriented upwards.

≤ 120 °C

max

> 120 °C

max

DN 40-80 T

DN 40-80 T

DN 100-250

≤ 120 °C

max

> 120 °C

max

© Danfoss | 2017.02

VD.LR.A8.02 | 5

Data sheet Flow controller with integrated control valve AFQM(6), PN 16, 25, 40*

Pressure temperature diagram

PN 25

PN 16

EN -GJL-2 50

(GG -25)

Maximum allowed operating pressure as a function of medium temperature (according to EN 1092-2)

EN-GJS- 400

(GGG-40.3)

Flow diagram

Sizing and setting diagram

Relation between actual flow and number of revolutions on flow restictor. Values given are approximate.

DN 250 kVS 400

DN 200 kVS 320

DN 150 kVS 280

DN 125 kVS 160

DN 100 kVS 125

DN 80 kVS 80

DN 65 kVS 50

DN 50 kVS 32

DN 40 kVS 20

6 | VD.LR.A8.02

Flow can be adjusted by turning flow restrictor screw

counter-clockwise as shown in this diagram

1 = 360º

Water flow shown at differential pressure across flow

restrictor 0.2 bar (20 kPa) and across the controller

from 0.5 bar (50 kPa) to max. diff. pressure.

© Danfoss | 2017.02

Data sheet Flow controller with integrated control valve AFQM(6), PN 16, 25, 40*

Flow diagram

Sizing and setting diagram

Relation between actual flow and number of revolutions on flow restictor. Values given are approximate.

DN 250 kVS 400

DN 200 kVS 320

DN 150 kVS 280

DN 125 kVS 160

DN 100 kVS 100

DN 80 kVS 80

DN 65 kVS 50

Flow can be adjusted by turning flow restrictor screw

counter-clockwise as shown in this diagram

1 = 360º

Water flow shown at differential pressure across flow

restrictor 0.5 bar (50 kPa) and across the controller

from 0.5 bar (50 kPa) to max diff. pressure.

© Danfoss | 2017.02

VD.LR.A8.02 | 7

Data sheet Flow controller with integrated control valve AFQM(6), PN 16, 25, 40*

Sizing

- Directly connected heating

system

Example 1

Motorised control valve (MCV) for mixing circuit

in direct-connected heating systems requires

differential pressure of 0.2 bar (20 kPa) and flow

less than 8000 l/h.

Given data:

Q

= 8.0 m3/h (8000 l/h)

max

∆p

= 0.8 bar (80 kPa)

min

1)

∆p

= 0.1 bar (10 kPa)

circuit

∆p

= 0.2 bar (20 kPa) selected

MCV

Remark:

1)

∆p

corresponds to the r equired pump pressure in the

circuit

heating circuit a nd is not to be considered when sizin g the

AFQM.

The total (available) pressure loss across the

controller is:

∆p

= ∆p

∆p

AFQM,A

AFQM,A

min

= 0.8 bar (80 kPa)

Possible pipe pressure losses in tubes, shut-off

fittings, heatmeters, etc. are not included.

Select controller from flow diagram, page 7,

with the smallest possible kVS value considering

available flow ranges.

kVS = 20 m3/h

The min. required differential pressure across

the selected controller is calculated from the

formula:

p

∆p

∆p

MIN,AFQM

= 0.36 bar (36 kPa)

AFQM,MI N

> ∆p

AFQM,A

Q

max

k

VS

AFQM,MIN

2

p

MCV

2

0.8

20

2.0

0.8 bar > 0.36 bar

Solution:

The example selects AFQM 6 DN 40, kVS value 20,

flow setting range 2.2-11 m3/h.

8 | VD.LR.A8.02

© Danfoss | 2017.02

Data sheet Flow controller with integrated control valve AFQM(6), PN 16, 25, 40*

Sizing (continuous)

- Indirectly connected heating

system

Example 2

Motorised control valve (MCV) for indirectly

connected heating system control requires

differential pressure of 0.2 (20 kPa) bar and flow

less than 22.000 l/h.

Given data:

Q

= 22 m3/h (22.000 l/h)

max

∆p

= 0.8 bar (80 kPa)

min

∆p

∆p

= 0.1 bar (10 kPa)

exchanger

= 0.2 bar (20 kPa) selected

MCV

The total (available) pressure loss across the

controller is:

∆p

= ∆p

AFQM,A

∆p

= 0.7 bar (70 kPa)

AFQM,A

min

−∆p

exchanger

= 0.8−0.1

Possible pipe pressure losses in tubes, shut-off

fittings, heatmeters, etc. are not included.

Select controller from flow diagram, page 7,

with the smallest possible kVS value considering

available flow ranges.

kVS = 50 m3/h

The min. required differential pressure across

the selected controller is calculated from the

formula:

∆p

∆p

p

MIN,AFQM

= 0.39 bar (39 kPa)

AFQM,MIN

> ∆p

AFQM,A

Q

AFQM,MIN

2

.max

p

MCV

k

VS

2

22

50

2.0

0.7 bar > 0.39 bar

Solution:

The example selects AFQM DN 65, kVS value 50,

flow setting range 5.6-28 m3/h.

© Danfoss | 2017.02

VD.LR.A8.02 | 9

Data sheet Flow controller with integrated control valve AFQM(6), PN 16, 25, 40*

18

Design

1. Valve body

2. Control valve insert

3. Adjustable flow restrictor

4. Control valve stem

5. Valve seat

6. Actuator

7. Control diaphragm for flow

control

8. Built-in spring for flow rate

control

9. Excess pressure safety valve

10. Valve insert

11. Pressure relieved valve cone

12. Valve stem

13. Bellows for pressure relief of

valve cone

14. Diaphragm for pressure relief

of valve cone

15. Impulse tube

16. Union nut

17. Upper casing of diaphragm

18. Lower casing of diaphragm

19. Cover

20. Bellows for pressure relieve

of control valve cone

10

19

15

17

4

2

3

1

5

11

13

12

15

16

8

6

7

19

15

17

4

2

20

1

3

5

11

10

13

12

15

16

8

6

9

7

18

AFQM 6 DN 40, 50

AFQM DN 65-125

AFQM DN 150-250

Function

10 | VD.LR.A8.02

Flow volume causes pressure drop across the

adjustable flow restrictor. Resulting pressures

are being transferred through the impulse tubes

to the actuator chambers and act on control

on falling differential pressure to control max

flow.

Additionally the electrical actuator will operate

from zero to set max. flow according to the load.

diaphragm for flow control. The flow restrictor

diff. pressure is controlled and limited by means

of built-in spring for flow control. Control valve

closes on rising differential pressure and opens

Controller AFQM is equipped with excess

pressure safety valve, which protect control

diaphragm for flow control from too high

differential pressure.

© Danfoss | 2017.02

Data sheet Flow controller with integrated control valve AFQM(6), PN 16, 25, 40*

Settings

Dimensions

Flow setting

Flow setting is being done by the adjustment of

the flow restrictor position. The adjustment can

be performed on the basis of flow adjustment

diagram (see relevant instructions) and/or by the

means of heat meter.

L

2

H

1

H

Ø 263

AMV(E) 55, 56/AFQM 6

L

2

H

1

H

Ø 263

AMV(E) 65X/AFQM 6

3)

L

H

DN

40

200 390 645 17

50

230 390 645 22

1

mm (kg)

H

2

Valve weight

L

DN

40

50

H1H

mm (kg)

200 390 590 17

230 390 590 22

Valve weight

2

© Danfoss | 2017.02

VD.LR.A8.02 | 11

Danf

already on order pro

All trademarks in this material are property of the respec

Data sheet Flow controller with integrated control valve AFQM(6), PN 16, 25, 40*

Dimensions (continuous)

4

H

3

2

H

H

1

1

H

L

AMV(E) 55, 56/AFQM

DN 65-125, PN 16/25

3)

For AFQM 6 PN 16/25 and AFQM PN 25/40 controllers , produced before March 2015, adapter code 0 65B3527 need to be

H

L

AMV(E) 65X/AFQM

DN 65-125, PN 16/25

3)

1

H

L

AMV(E) 85, 86/AFQM

DN 150-250, PN 16

separately ord ered

DN

L

H

H

1

H

2

3

mm PN 16 PN 25

Valve weight (kg)

H

4

65 290 425 604 640 - 52 58.5

80 310 425 624 650 - 61 60.5

100 350 530 634 665 - 93.6 96

125 400 530 664 690 - 117. 2 13 9

150 480 576 - - 455 142 -

200 600 652 - - 483 219 -

250 730 656 - - 533 342 -

oss can accept no responsibility for possible errors in catalogues, brochures and other printed material. Danfoss reserves the right to alter its products without notice. This also applies to products

vided that such alterations can be made without subsequential changes being necessary eady agreed.

12 | VD.LR.A8.02

tive companies. Danfoss and the Danfoss logotype are trademarks of Danfoss A/S. All rights reserved.

© Danfoss | DHS-SRMT/SI | 2017.02

Loading...

Loading...