Data sheet

Differential pressure and flow controller (PN 16, 25, 40)

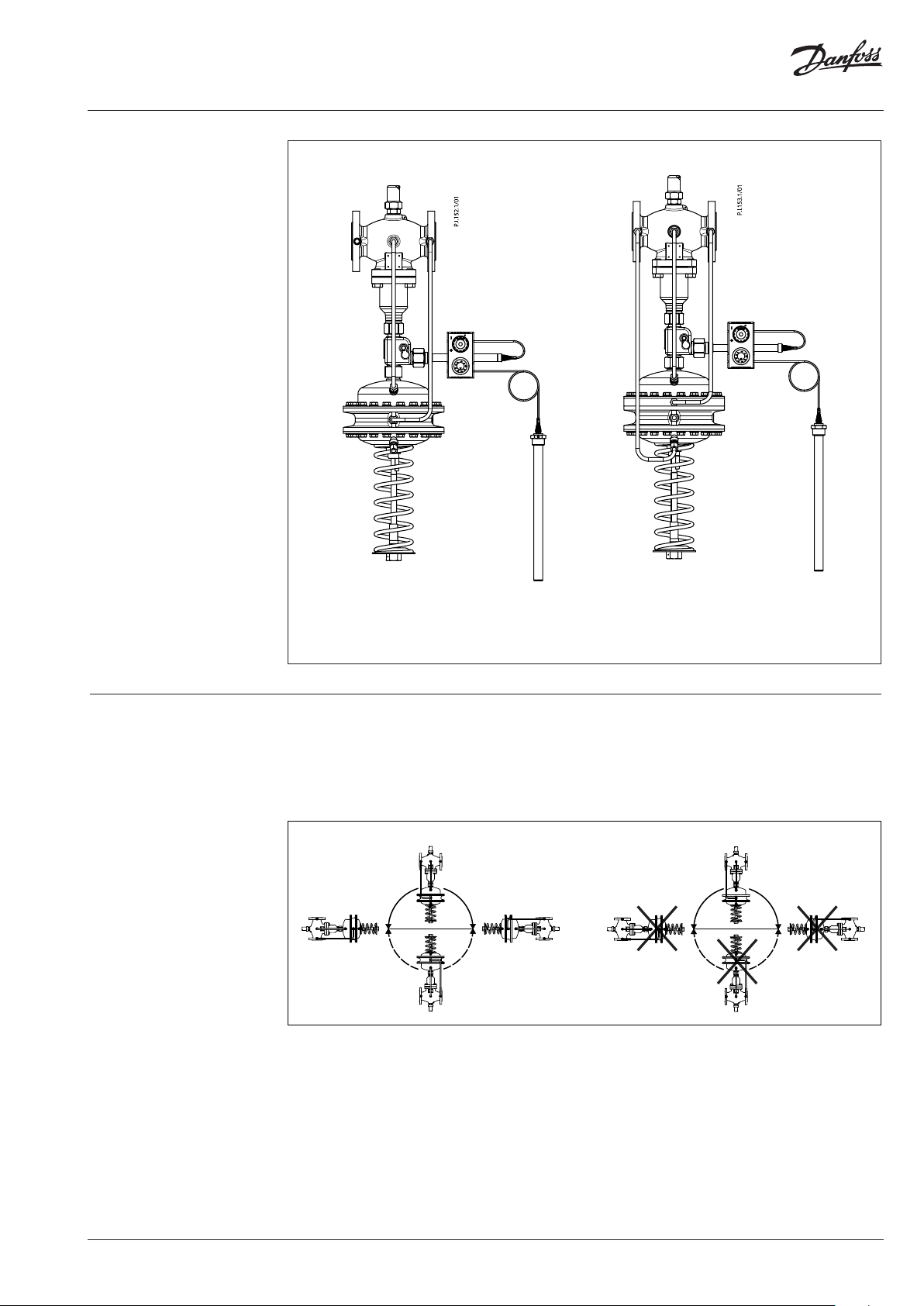

AFPQ / VFQ 2(1) - return mounting, adjustable setting

AFPQ 4 / VFQ 2(1) - flow mounting, adjustable setting

Description

The controller is a self-acting differential pressure

and flow controller primarily for use in district

heating systems. The controller closes on rising

differential pressure or when set max. flow is

exceeded.

The controller has a control valve with adjustable

flow restrictor, an actuator with two control

diaphragms and spring for differential pressure

setting. Differential pressure control and flow

control are independent.

Further on two valve versions are available:

– VFQ 2 with metallic sealing cone

– VFQ 21 with soft sealing cone (on special

request)

Main data:

∙ DN 15 -250

∙ kVS 4.0-400 m3/h

∙ Flow range: 0.1-250 m3/h

∙ PN 16, 25, 40

∙ Setting range: 0.1-0.7 bar / 0.15-1.5 bar

∙ Flow restrictor pb: 0.2 bar or 0.5 bar

∙ Temperature:

– Circulation water / glycolic water up to 30 %:

2 … 150/200 °C

∙ Connections:

– Flange

Ordering

Example 1:

Differential pressure and flow

controller; return mounting;

DN 15; kVS 4.0; PN 16; metallic

sealing; setting range 0.1-0.7 bar;

flow restrictor ∆ pb 0.2 bar;

T

150 °C; flange;

max

– 1× VFQ 2 DN 15 valve

Code no: 065B2654

– 1× AFPQ actuator

Code no: 00 3G10 2 9

– 1× AFPQ DN 15 impulse tubes

Code no: 003G1365

– 1× Impulse tube set AF

Code no: 003G1391

Products will be delivered separatly.

Impulse t ubes AFPQ

Impulse tube set AF

VFQ 2 Valves (metallic sealing cone)

Picture

1)

At temperature s above 150 °C only with seal p ots (see Accessories)

DN

(mm)

15 4.0

20 6.3 065B2655 065B2668 065B2678

25 8.0 065B2656 065B2669 065B2679

32 16 065B2657 065B2670 065B2680

40 20 065B2658 065B2671 065B2681

50 32 065B2659 065B2672 065B2682

65 50 065B2660 065B2673 065B2683

80 80 065B2661 065B2674 065B2684

100 125 065B2662 065B2675 065B2685

125 160 065B2663 065B2676 065B2686

150 280

200 320 065 B2758 – 065B2688

250 400 065B2759 – 065B2689

k

VS

(m3/h)

Connections

Flanges acc. to

EN 1092-1

T

( °C)

150

150

max

Code No.

PN 16 PN 25 PN 40

065B2654

065B2664

T

( °C)

200

150

max

1)

Code No.

065B2667 065B2677

– 065B2687

© Danfoss | 2018.10

VD.CA.A7.02 | 1

Data sheet Differential pressure and flow controller AFPQ (4) / VFQ 2(1) (PN 16, 25, 40)

Ordering (continuous)

Example 2:

Differential pressure and flow

controller; return mounting;

DN 15; kVS 4.0; PN 25; metallic

sealing; setting range 0.1-0.7 bar;

flow restrictor ∆ pb 0.2 bar;

T

200 °C; flange;

max

– 1× VFQ 2 DN 15 valve

Code no: 065B2667

– 1× AFPQ actuator

Code no: 003 G102 9

– 1× AFPQ DN 15 impulse tubes

Code no: 003G1365

– 1× Impulse tube set AF

Code no: 003G1391

– 1× Seal pot V1

Code no: 003G1392

Products will be delivered separatly.

Seal pot V1

Impulse t ubes AFPQ

Impulse tube set AF

Example 3:

Differential pressure and flow

controller; flow mounting; DN 15;

kVS 4.0; PN 25; metallic sealing;

setting range 0.1-0.7 bar; flow

restrictor ∆pb 0.2 bar; T

flange;

– 1× VFQ 2 DN 15 valve

Code no: 065B2667

– 1× AFPQ actuator

Code no: 00G10 33

– 4× Impulse tube set AF

Code no: 003G1391

– 3× Seal pot V1

Code no: 003G1392

Products will be delivered separatly.

200 °C;

max

Impulse tube set AF

Seal pot V1

Impulse tube set AF

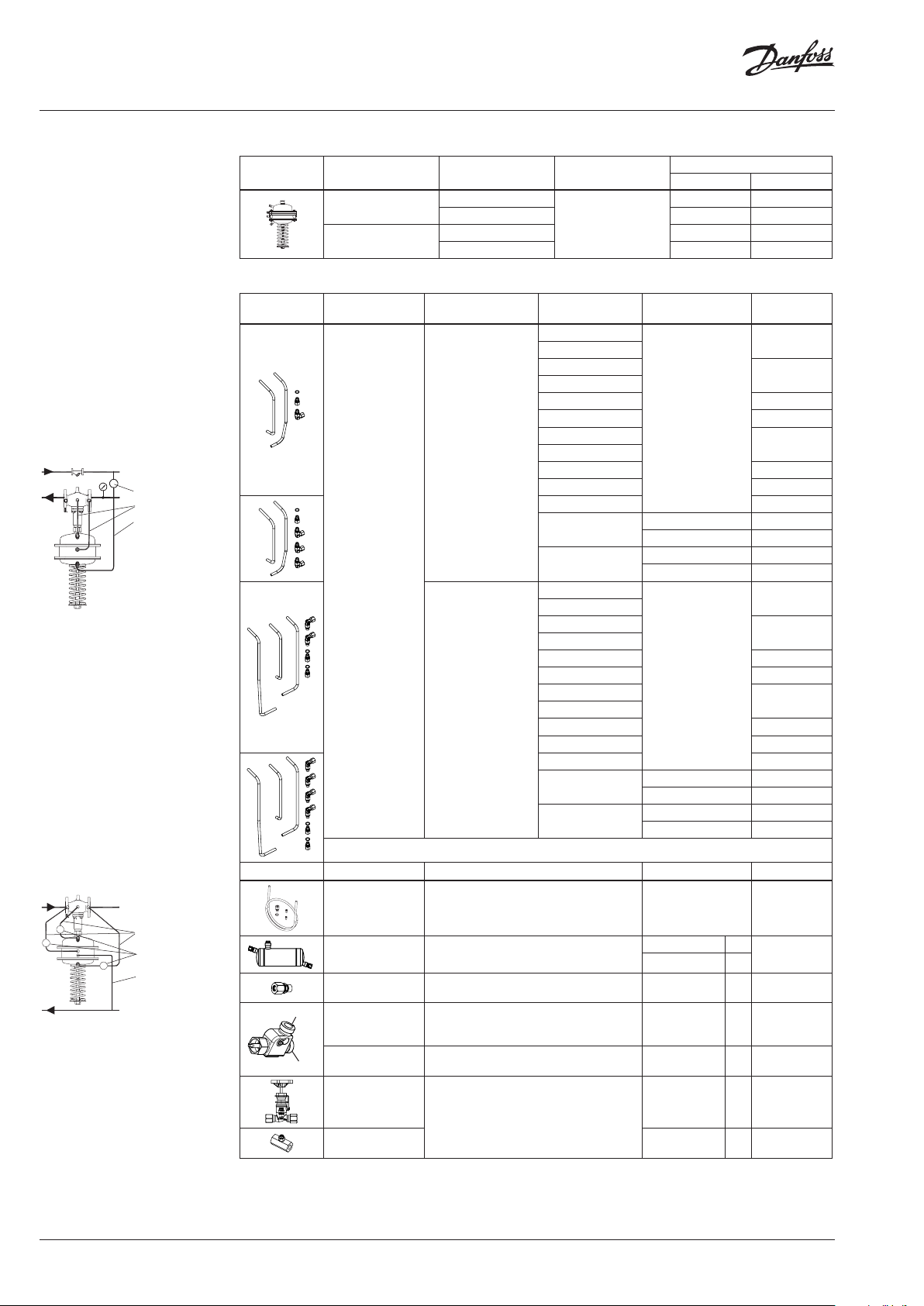

AFPQ / AFPQ 4 Actuators

Picture

∆p setting range

(bar)

0.1-0.7

0.15 -1.5

Flow restrictor ∆p

(bar)

0.2

0.5 003G1030 003G1034

0.2 003G1031 003G1035

0.5 003G1032 003G1036

Nominal pressure

b

(PN)

40

AFPQ (retur n) AFPQ 4 (flow)

Code No.

003 G1029 003G1033

Accessories

Picture Type designation For controller

AFPQ

Impulse tubes

(Stainless steel)

Picture Type designation Description Ordering number Code No.

Impulse tube set AF

Seal pot V1

Compression

fitting

port B

Combination piece

KF3

port A

4)

Combination piece

KF2

3)

AFPQ 4

– 1× Copper tube Ø10 × 1 × 1500 mm

– 1 × compression fitting for imp. tube

connection to pipe (G ⁄)

– 2 × socket

1)

2)

Capacit y 1 liter; with compression fittings for

imp. tube Ø10

For impulse tube Ø10 connections to

controller

For combination with pressure actuators.

Electrical actuator connected on side (port B)

only for ON/OFF function

For combination with thermostat - side

connection to port B

DN

(mm)

15

20

25

32

40 003G1369

50 0 03G1370

65

80

100 00 3G1373

125 0 03G1374

150 0 03G1375

200

250

15

20

25

32

40 00 3G1382

50 003G1383

65

80

100 003 G1386

125 0 03G1387

150 00 3G1388

200

250

PN Code No.

16, 25, 40

16 00 3G1416

40 00 3G1376

16 00 3G1417

40 003 G1405

16, 25, 40

16 00 3G1418

40 003 G1389

16 00 3G1419

40 003 G1406

– 003G1391

AFPQ 1×

AFPQ 4 3×

G ⁄ 003G1468

G 1⁄ / 2× G 1⁄ 00 3G1441

00 3G1365

00 3G1367

00 3G1371

00 3G1378

00 3G1380

00 3G1384

003G1392

00 3G1440

2 | © Danfoss | 2018.10

Shut off valve

Throttle valve 065B2909

1)

Seal pot has to be use d on impulse tubes always wh en T

2)

Consist of a nipple, com pression ring and nut

3)

With combination pi ece KF2 or KF3 use 2× 003G1391 at PN 16 and T<150 °C. Other wise impulse tubes on speci al request.

4)

Port A - for connect ion of any type of actu ator

For impulse tube Ø10

≥ 150 °C

max

– 00 3G1401

VD.CA.A7.02

Data sheet Differential pressure and flow controller AFPQ (4) / VFQ 2(1) (PN 16, 25, 40)

Ordering (continuous)

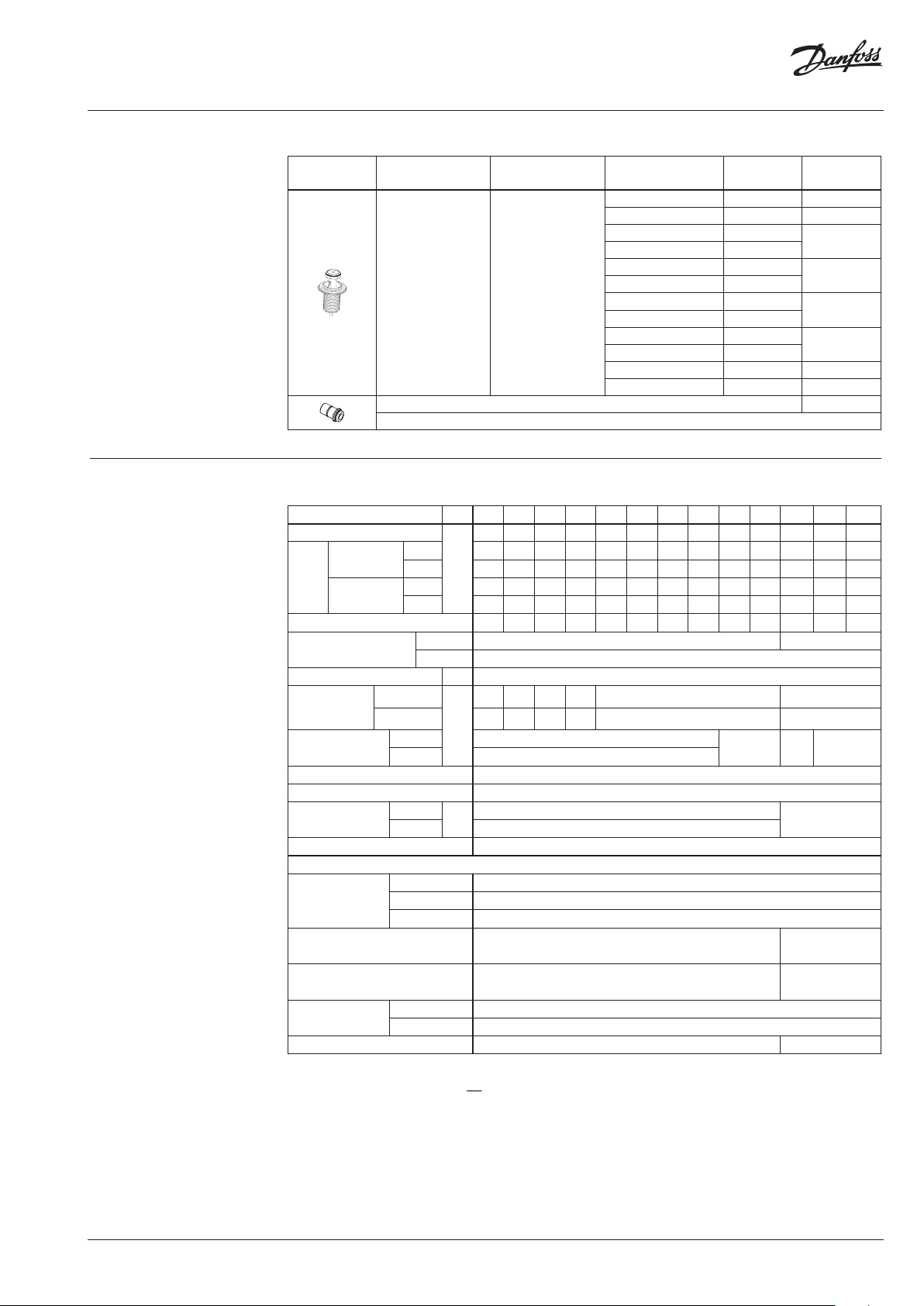

Technical data

Service kits

Picture Type designation For valve

Valve insert VFQ 2

Stuffing cone (with EPDM O-rings) 003G1464

DN

(mm)

15 4.0 065B2796

20 6.3 065B2797

25 8

32 16

40 20

50 32

65 50

80 80

100 125

125 160

150 280 065B2964

250 400 065B2965

k

VS

(m3/h)

Code No.

065B2798

065B2799

065B2800

065B2801

Valve

Nominal diameter DN 15 20 25 32 40 50 65 80 100 125 150 200 250

kVS value of p controller

Range

of

max.

flow

setting

pb 1) = 0.2 bar

pb 1) = 0.5 bar

from 0.1 0.2 0.2 0.4 0.6 0.8 3 4 6 8 12 15 18

to 2 3 4 7 11 16 28 40 63 80 125 150 180

from 0.2 0.3 0.3 0.5 0.8 1. 2 4 6 9 12 18 22 25

to 3 4.5 6 10 16 24 40 58 90 120 180 220 250

Cavitation factor z 0.6 0.6 0.6 0.55 0.55 0.5 0.5 0.45 0.4 0.35 0.3 0.2 0.2

Leakage acc. to standard

IEC 534 (% of kVS)

VFQ 2 ≤ 0.03 ≤ 0.05

VFQ 21 ≤ 0.01

Nominal pressure PN 16, 25, 40

Min. differential

pressure for max

2)

flow

Max. differential

pressure

pb 1) = 0.2

pb 1) = 0.5 0.8 0.7 0.8 0.7 0.8 0.7

PN 16 16

PN 25, 40 20

Media Circulation water / glycolic water up to 30 %

Media pH Min. 7, max. 10

Media temperature

VFQ 2

VFQ 21 2 … 150

Connections Flange

Materials

PN 16 Grey cast iron EN-GJL-250 (GG-25)

Valve body

PN 25 Ductile iron EN-GJS-400(GGG-40.3)

PN 40 Cast steel GP240GH (GS-C 25)

Valve seat Stainless steel, mat. No. 1.4021

Valve cone Stainless steel, mat. No. 1.4404

Sealing

VFQ 2 Metal

VFQ 21 EPDM

Pressure relieve system Bellows (Stainless steel, mat. No. 1.4571) Diaphragm (EPDM)

1)

∆pb – differe ntial pressure over flow restri ctor

2)

For flows smal ler than Q

3)

at temperatures ab ove 150 °C only with seal pot s (see Accessories)

->

max

4.0 6.3 8.0 16 20 32 50 80 125 160 280 320 400

m3/h

0.5 0.4 0.5 0.4 0.5 0.4

bar

15 12 10

°C

2

Q

p

p

min

b

k

VS

2 … 150/2 … 200

3)

2 … 150

Stainless steel,

mat. No. 1.4313

Stainless steel,

mat . No. 1.4021

VD.CA.A7.02

© Danfoss | 2018.10 | 3

Data sheet Differential pressure and flow controller AFPQ (4) / VFQ 2(1) (PN 16, 25, 40)

Technical data (continuous)

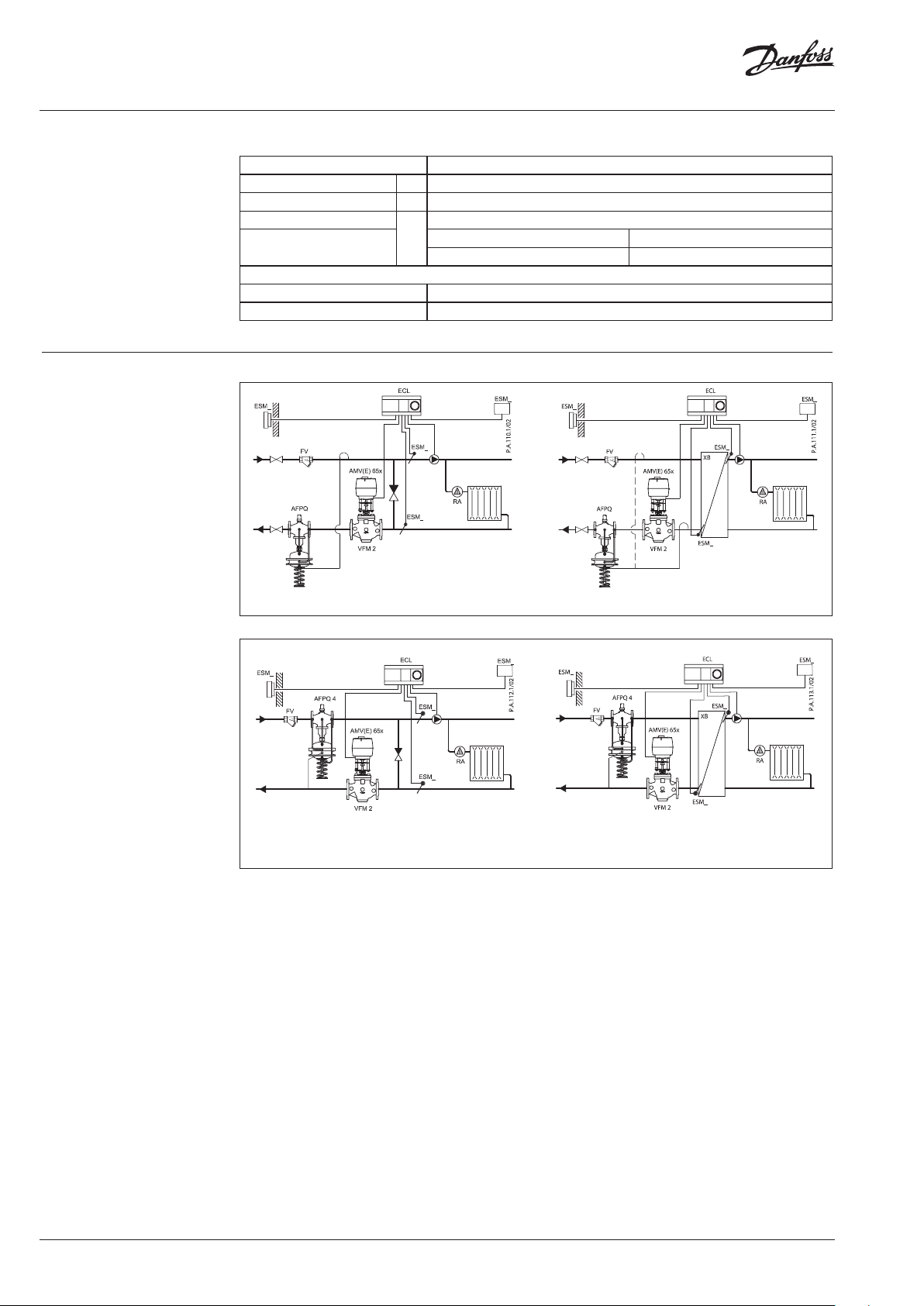

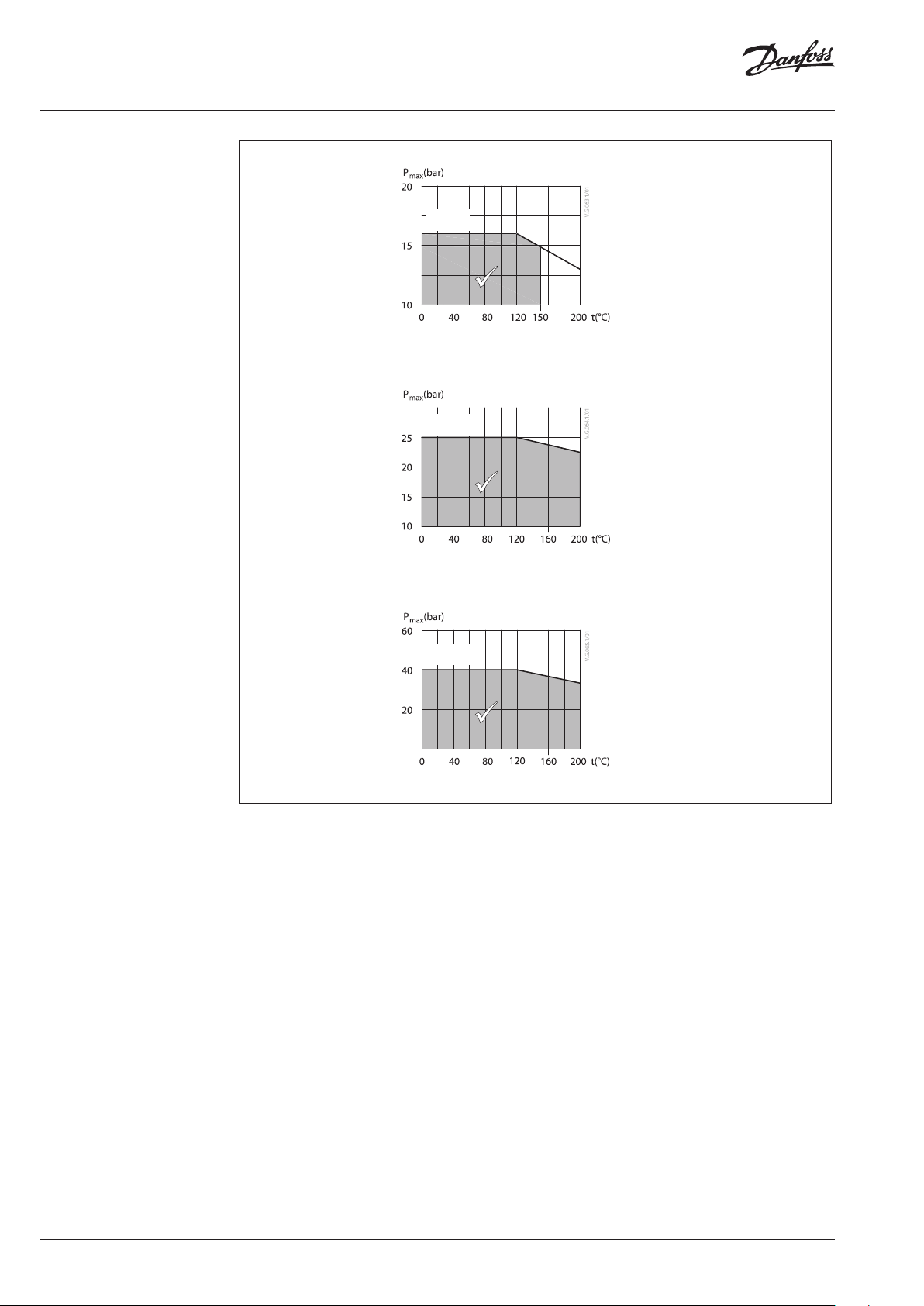

Application principles

– Return mounting

Actuator

Typ e AFPQ, AFPQ 4

Actuator size cm

Nominal pressure PN 40

Flow restrictor dif f. pressure p

Diff. pressure setting ranges

and spring colours

Materials

Actuator housing Steel, mat. No.1.0338, zinc plated

Control diaphragm EPDM (Rolling; fibre enforced)

2

b

bar

0.1-0.7 0.15 -1.5

yellow red

250

0.2 / 0.5

– Flow mounting

Direct-connected heating system Indirectly connected heating system

Direct-connected heating system Indirectly connected heating system

4 | © Danfoss | 2018.10

VD.CA.A7.02

Data sheet Differential pressure and flow controller AFPQ (4) / VFQ 2(1) (PN 16, 25, 40)

Combinations

Example:

Differential pressure, flow and

temperature controller, return

mounting; DN 15; kVS 4.0; PN 16;

metallic sealing; setting range

0.1-0.7 bar; flow restrictor

∆pb 0.2 bar; T

– 1× VFQ 2 DN 15 valve

Code no: 065B2654

– 1× AFPQ actuator

Code no: 003G1029

– 3× Impulse tube set AF

Code no: 003G1391

– 1× AFT06 thermostat

Code no: 065-4390

– 1× Combination piece KF2

Code no: 003G1398

Products will be delievered

separatelly.

Note:

For AFT 06 thermostat data see

relevant data sheet

150 °C; flange;

max

AFT 06 / KF2 / AFPQ / VFQ2

– Differential pressure, flow and temperature controller,

return mounting

Installation positions DN 15-80 T

The controllers can be installed in any position.

DN 15-80 T

≤ 120 °C

max

≤ 120 °C

max

AFT 06 / KF2 / AFPQ 4 / VFQ2

– Differential pressure, flow and temperature controller,

flow mounting

DN 15-80 T

> 120 °C; DN 100-250

max

The controllers can be installed in horizontal

pipes only, with a pressure actuator oriented

downwards.

DN 15-80 T

> 120 °C; DN 100-250

max

VD.CA.A7.02

© Danfoss | 2018.10 | 5

Data sheet Differential pressure and flow controller AFPQ (4) / VFQ 2(1) (PN 16, 25, 40)

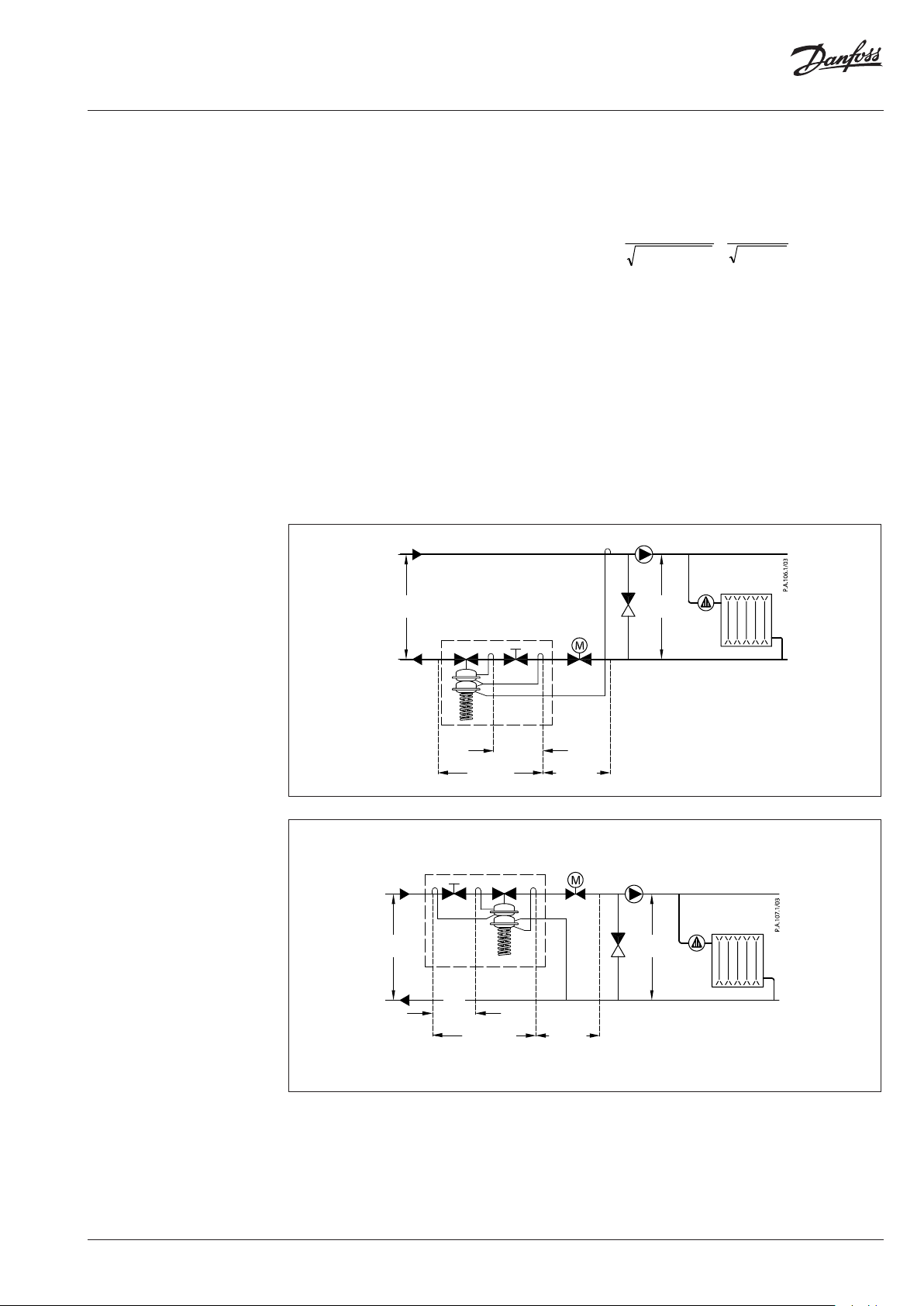

Pressure temperature

diagram

Working area is below P-T line

and it ends at Tmax for each

valve

Maximum allowed operating pressure as a function of media temperature (according to EN 1092-2)

PN 16

EN - GJL- 250

(GG -25)

PN 25

EN-GJS- 400

(GGG-40.3)

Maximum allowed operating pressure as a function of media temperature (according to EN 1092-2)

PN 40

EN-GP-240-GH

(GS- C 25)

Maximum allowed operating pressure as a function of media temperature (according to EN 1092-1)

6 | © Danfoss | 2018.10

VD.CA.A7.02

Data sheet Differential pressure and flow controller AFPQ (4) / VFQ 2(1) (PN 16, 25, 40)

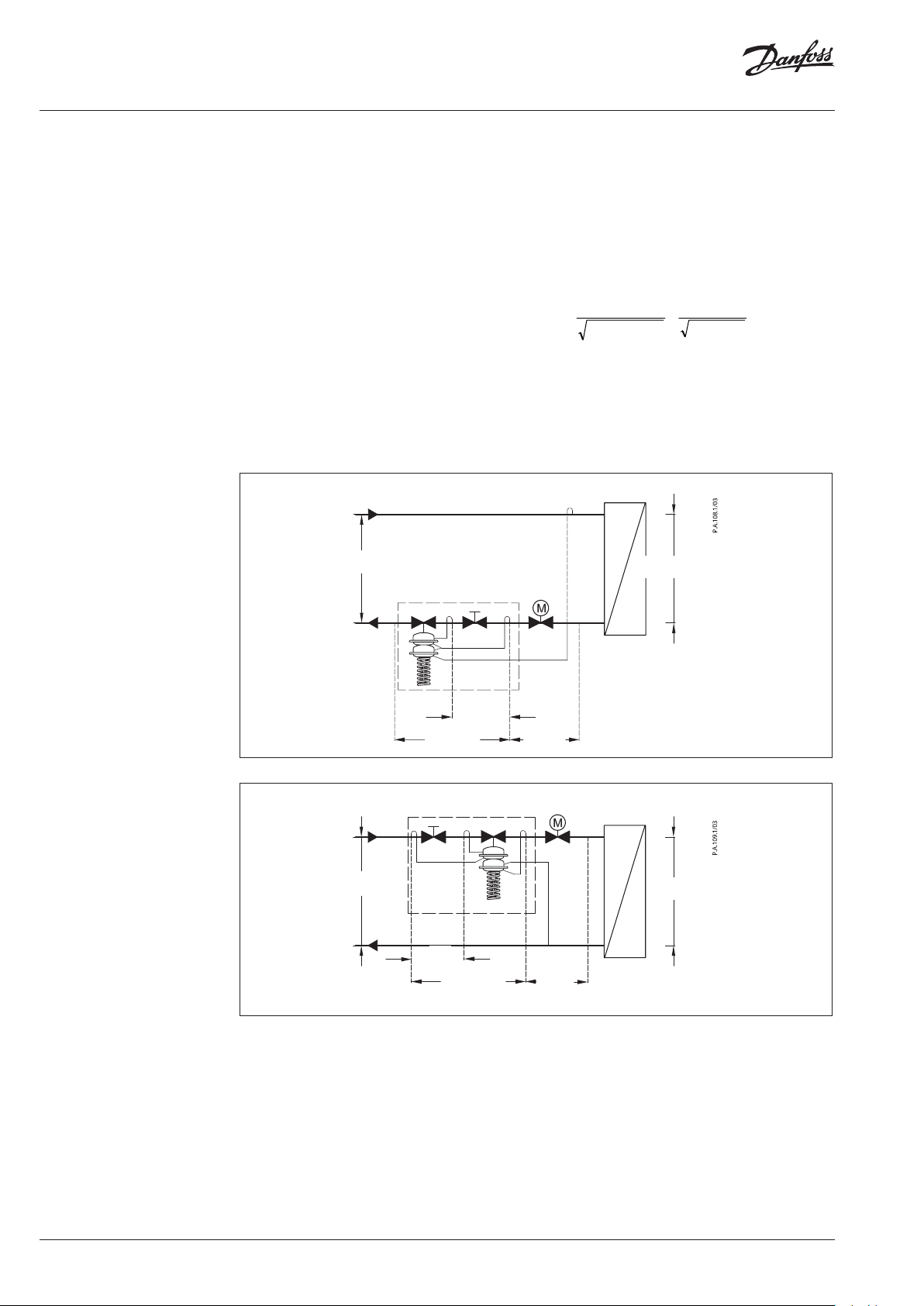

Sizing

– Directly connected heating

system

Example 1

Motorised control valve (MCV) for mixing circuit

in direct-connected heating system requires

differential pressure of 0.3 bar (30 kPa) and flow

less than 1.900 l/h.

Given data:

Q

= 1.9 m3/h (1.900 l/h)

max

p

= 0.9 bar (90 kPa)

min

1)

p

= 0.1 bar (10 kPa)

circuit

p

= 0.3 bar (30 kPa) selected

MCV

2)

p

= 0.2 bar (20 kPa)

b

Remark:

1)

∆p

corresponds to the r equired pump pressure in t he heating

circuit

circuit and is not to b e considered when sizing the AFPQ (4).

2)

pb is differe ntial pressure over flow restri ctor.

The differential pressure set value is:

p

p

= p

set value

= 0.3 bar (30 kPa)

set value

MCV

The total pressure loss across the controller is:

p

= p

AFPQ

p

= 0.6 bar (60 kPa)

AFPQ

min

− p

= 0.9 – 0.3

MCV

Q

max

Possible pipe pressure losses in tubes, shut-off

fittings, heatmeters, etc. are not included.

kv value is calculated according to formula:

Q

k

v

max

pp

bAFPQ

9,1

2,06,0

kv = 3.0 m3/h

Solution:

The example selects AFPQ 4 DN 15, kVS value 4.0,

with differential pressure setting range 0.1-0.7 bar

flow setting range 0.1-2.0 m3/h.

,

∆p

∆p

min

∆p

∆p

circuit

circuit

min

AFPQ

∆p

b

∆p

AFPQ

AFPQ 4

Q

max

∆p

b

∆p

AFPQ

∆p

∆p

MCV

MCV

VD.CA.A7.02

© Danfoss | 2018.10 | 7

Data sheet Differential pressure and flow controller AFPQ (4) / VFQ 2(1) (PN 16, 25, 40)

Sizing (continuous)

– Indirectly connected heating

system

Example 2

Motorised control valve (MCV) for indirectly

connected heating system requires differential

pressure of 0.3 (30 kPa) bar and flow less than

1.800 l/h.

Given data:

Q

= 1.8 m3/h (1.800 l/h)

max

p

= 1.0 bar (100 kPa)

min

p

p

p

Remark:

1)

pb is differe ntial pressure over flow restri ctor

= 0.05 bar (5 kPa)

exchanger

= 0.3 bar (30 kPa) selected

MCV

1)

= 0.2 bar (20 kPa)

b

The differential pressure set value is:

p

= p

set value

p

= 0.05 + 0.3

set value

p

= 0.35 bar (35 kPa)

set value

exchanger

+ p

∆p

min

MCV

Q

max

AFPQ

The total pressure loss across the controller is:

p

= p

AFPQ

p

= 1.0 − 0.05 − 0.3

AFPQ

p

= 0.65 bar (65 kPa)

AFPQ

min

− p

exchanger

− p

MCV

Possible pipe pressure losses in tubes, shut-off

fittings, heatmeters, etc. are not included.

kv value is calculated according to formula:

Q

k

v

max

pp

bAFPQ

8,1

2,065,0

kv = 2.7 m3/h

Solution:

The example selects AFPQ 4 DN 15, kVS value 4.0,

with differential pressure setting range

0.1-0.7 bar, flow setting range 0.1-2.0 m3/h.

∆p

exchanger

∆p

∆p

b

∆p

AFPQ

AFPQ 4

Q

max

min

∆p

b

∆p

AFPQ

∆p

∆p

MCV

MCV

∆p

exchanger

8 | © Danfoss | 2018.10

VD.CA.A7.02

Data sheet Differential pressure and flow controller AFPQ (4) / VFQ 2(1) (PN 16, 25, 40)

17

21

18

14

11

13

12

22

15

16

3

17

21

18

14

11

13

22

12

15

16

Design

1. Valve body

2. Cover

3. Adjustable flow restrictor

4. Valve seat

5. Valve insert

6. Pressure relieved valve cone

7. Valve stem

8. Bellows for pressure relief of

valve cone

9. Diaphragm for pressure relief

of valve cone

10. Actuator

11. Control diaphragm for flow

control

12. Control diaphragm for diff.

pressure control

13. Excess pressure safety valve

14. Built-in spring for flow

control

15. Setting spring for diff.

pressure control

16. Adjuster for diff. pressure

setting, prepared for sealing

17. Stuffing cone

18. Union nut

19. Impulse tube

20. Compression fitting for

impulse tube

21. Upper casing of diaphragm

22. Lower casing of diaphragm

23. Valve body extension

24. Shut off valve for water filling

25. Closing plug

19

10

20

20

AFPQ VFQ 2(1), DN 15-125

3

1

4

6

7

19

5

8

2

10

20

AFPQ 4 VFQ 2(1), DN 15-125

1

4

6

7

5

8

2

9 2

VFQ 2(1) DN 150-250, T

25

24

max

150 °C

23

9

2

Function

Setting

Flow volume causes pressure drop across the

adjustable flow restrictor. Resulting pressures

are being transferred through the impulse tubes

to the actuator chambers and act on control

diaphragm for flow control. The flow restrictor

diff. pressure is controlled and limited by means

of built-in spring for flow control. Control valve

closes on rising differential pressure and opens

on falling differential pressure to control max

flow.

Flow setting

Flow setting is being done by the adjustment of

the flow restrictor position. The adjustment can

be performed on the basis of flow adjustment

diagram (see relevant instructions) and/or by the

means of heat meter.

VFQ 2 DN 150-250, T

max

200 °C

Pressure changes from flow and return pipes are

being transferred through the impulse tubes

to the actuator chambers and act on control

diaphragm for diff. pressure control. The diff.

pressure is controlled by means of setting spring

for diff. pressure control. Control valve closes

on rising differential pressure and opens on

falling differential pressure to maintain constant

differential pressure.

Controller is equipped with two excess pressure

safety valves, which protect control diaphragms

for flow and diff. pressure control from too high

differential pressure.

Differential pressure setting

Differential pressure setting is being done by the

adjustment of the setting spring for diff. pressure

control. The adjustment can be done by means

of adjuster for diff. pressure setting and pressure

indicators.

VD.CA.A7.02

© Danfoss | 2018.10 | 9

Data sheet Differential pressure and flow controller AFPQ (4) / VFQ 2(1) (PN 16, 25, 40)

ø89

Dimensions

L

2

B

3

H

B

B

L

VFQ DN 15-125

L

2

B

H

B

1

H

1

B

VFQ DN 150-250

VFQ DN 150-250

with valve body extension up to 200 °C

VFQ 2, VFQ 21 Valves

DN 15 20 25 32 40 50 65 80 100 125 150 200 250

L

B 213 213 239 239 241 241 276 276 381 3 81 326 354 401

B

2

H 337 337 374 374 393 393 440 440 575 575 595 686 756

PN 16 / 25

Weight

PN 40 31 34 63 72 147 264 347

B

1

B

3

H

1

Weight (valve

with body

extension)

PN 16 / 25

PN 40 187 350 526

130 150 160 180 200 230 290 310 350 400 480 600 730

mm

124 124 135 13 5 152 152 164 16 4 194 19 4 269 332 355

kg 8 9 10.5 12 .5 15. 5 18.5

mm

kg

28.5 31 61 71 120 193 337

620 852 119 9

269 332 356

889 1184 1555

160 314 489

ø60

AFPQ, AFPQ 4 Actuators

Actuator type AFPQ / AFPQ 4

Ø A

H for xs = 0.1-0.7 / 0.15-1.5 520/540

Weight kg 34

mm

257

SW 22

Shut off valve

Ø10

110

78

10 | © Danfoss | 2018.10

240

Seal pot V1

Comb. piece KF2, KF3

40

G⁄

SW19

Compression fitting

VD.CA.A7.02

Data sheet Differential pressure and flow controller AFPQ (4) / VFQ 2(1) (PN 16, 25, 40)

VD.CA.A7.02

© Danfoss | 2018.10 | 11

Data sheet Differential pressure and flow controller AFPQ (4) / VFQ 2(1) (PN 16, 25, 40)

12 | © Danfoss | DHS-SRMT/SI | 2018.10

VD.CA.A7.02

Loading...

Loading...