Page 1

Data sheet

Differential pressure and flow controller (PN 16, 25, 40)

AFPQ 2 / VFQ 22(1) – return mounting, adjustable setting

AFPQ 24 / VFQ 22(1) – flow mounting, adjustable setting

Description

virtus.danfoss.com

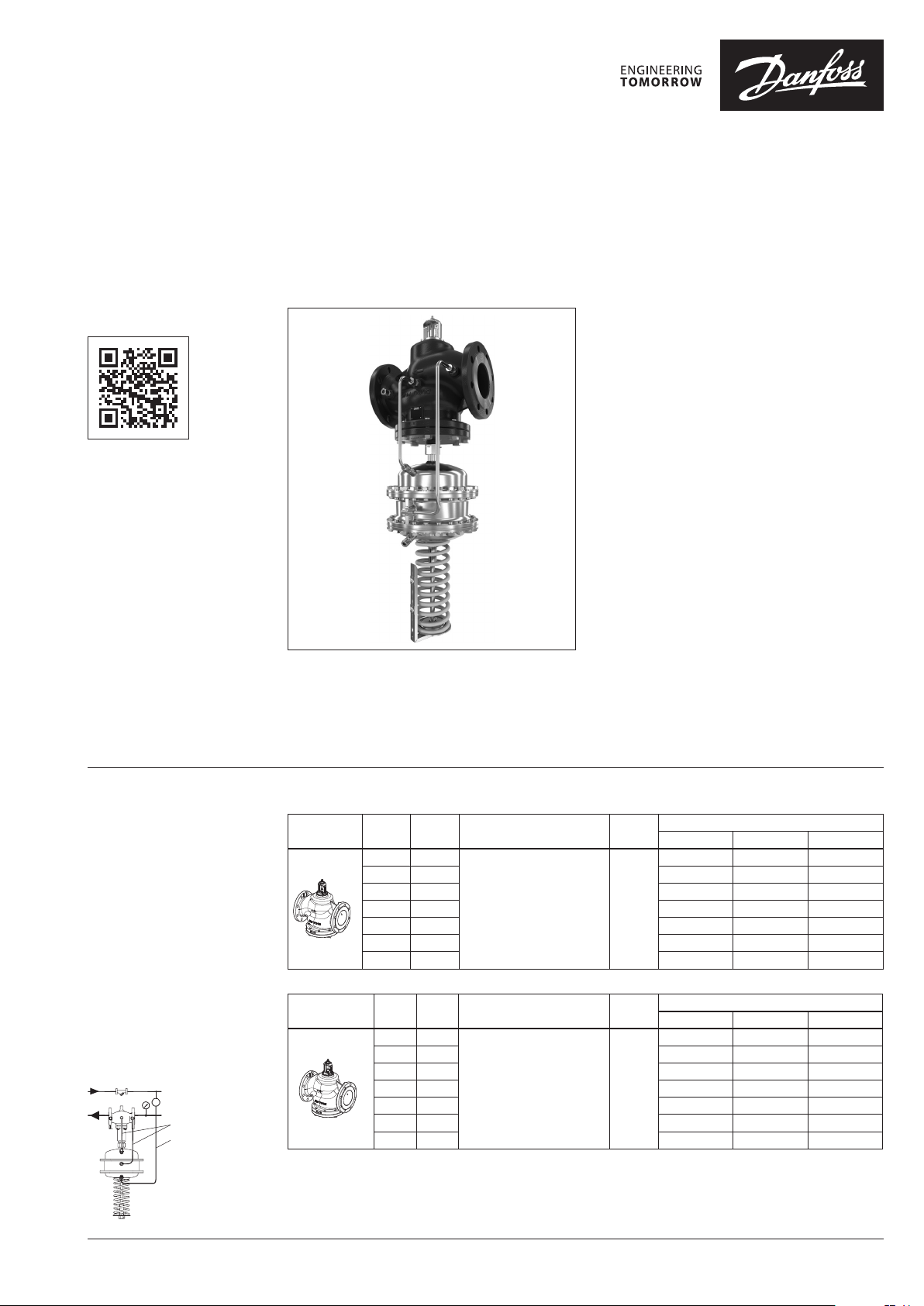

The controller is a self-acting differential pressure

and flow controller primarily for use in district

heating systems. Direct operated, reliable and

high precise controller closes on rising differential

pressure or when set max. flow is exceeded.

The controller has a control valve with adjustable

flow restrictor, an actuator with two control

diaphragms and spring for differential pressure

setting. Differential pressure control and flow

control are independent.

Further on two valve versions are available:

∙ VFQ 22 with metallic sealing cone

∙ VFQ 221 with soft sealing cone

Together with Danfoss intelligent electrical

actuator AMEi 6 intelligent optimization

functions are available:

∙ iSET-intelligent substation efficiency

optimization

∙ iNET-intelligent network balancing

Main data:

∙ DN 65-250

∙ kVS 60-800 m3/h

∙ Flow range 5.6-500 m3/h

∙ PN 16, 25, 40

∙ Setting range: 0.2-1 bar / 0.5-1.5 bar

∙ Flow restrictor ∆pb: 0.2 bar or 0.5 bar

∙ Temperature: – Circulation water / glycolic

water up to 30%: 2 … 150°C

∙ Connections: – Flange

Ordering

Example 1:

Differential pressure controller,

return mounting, DN 65, kVS 60,

PN 16, metallic sealing, setting

range 0.5-1.5 bar, flow restrictor

Δpb 0.2 bar, T

– 1× VFQ 22 DN 65 valve

Code no: 065B 5570

– 1× AFPQ 2 actuator

Code no: 00 3G 5712

– 1×

Code no: 003G1838

– 1× Impulse tube set AF

Code no: 003G1391

Products will be delivered

separately.

150 °C, flange

max

AFPQ 2 DN 65 impulse tube set

AFPQ 2 impuls e tube set

Impulse t ube set AF

VFQ 22 Valve (metallic sealing cone)

Picture

DN

(mm)

65 60

80 80 065B5571 065B5578 065B5585

100 160 065B5572 065B5579 065B5586

125 250 065B5573 065B5580 065B5587

150 380 065B5574 065B5581 0 65B5588

200 650 065B5575 065B5582 065B5589

250 800 06 5B5576 065B5583 065B5590

k

VS

(m3/h)

Flanges acc. to EN 1092-1 150

VFQ 221 Valve (soft sealing cone)

DN

k

Picture

1)

PN40 available Q1 2022

(mm)

100 160 065B5602 065B5609 065B5616

125 250 065B5603 065B5610 0 65B 5617

150 380 065B5604 06 5B5 611 065B5618

200 650 065B5605 065B5612 0 65B5 619

250 800 065B5606 06 5B5613 065B5620

VS

(m3/h)

65 60

80 80 065B5601 065B5608 065 B5615

Flanges acc. to EN 1092-1 150

Connections

Connections

T

(°C)

T

(°C)

max.

max.

PN 16 PN 25 PN 40

065B5570 065B5577 065B5584

PN 16 PN 25 PN 40

065B5600 065B5607 06 5B5614

Code No.

Code No.

1)

1)

© Danfoss | 2022.03 AI388353838246en-010203 | 1

Page 2

Data sheet AFPQ 2, AFPQ 24 / VFQ 22(1)

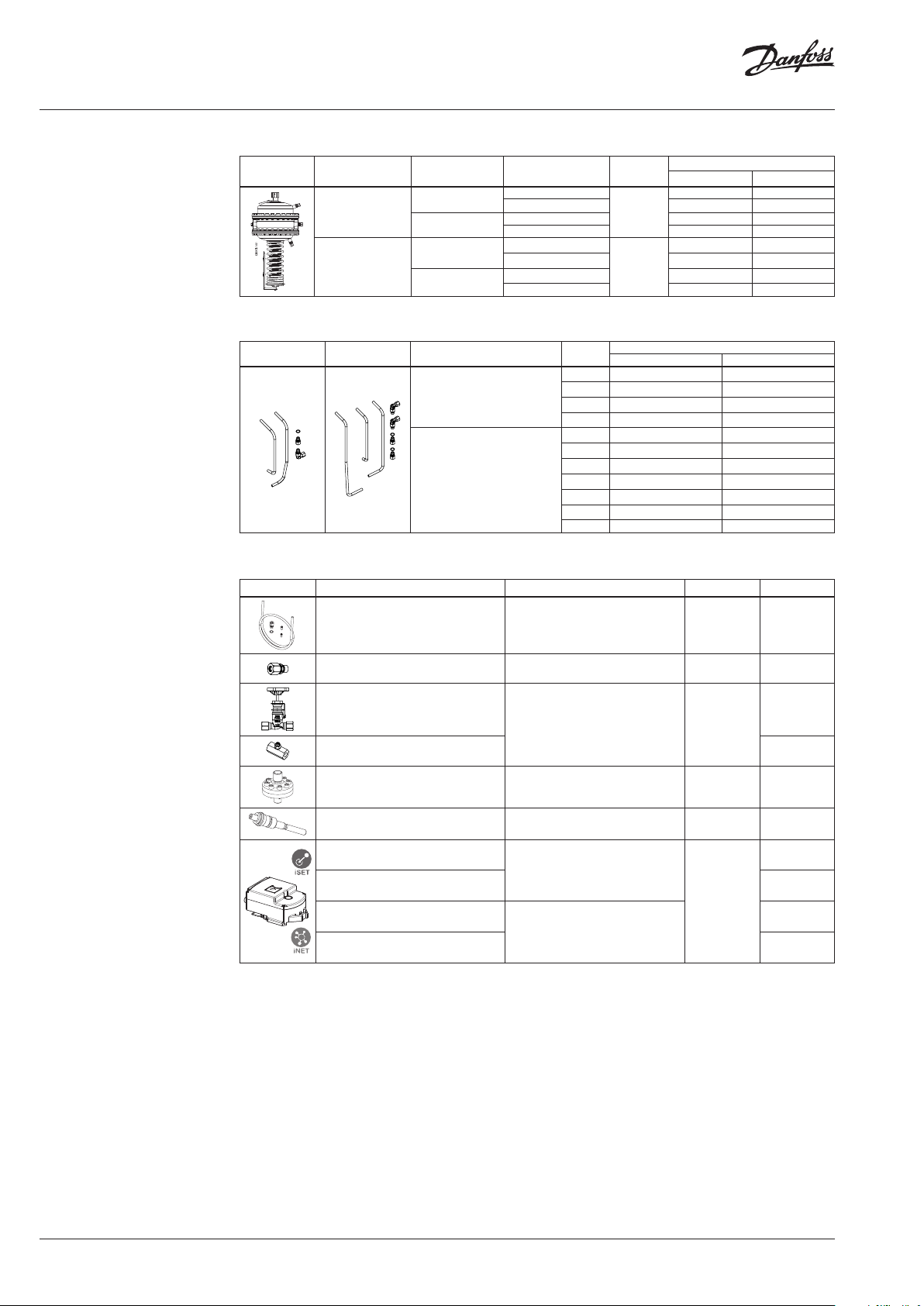

Ordering (continuous) AFPQ 2 / AFPQ 24 Actuators

Picture

Actuator size

(cm3)

160*

320

* avaliable from Q4/2022

Acessories - Impulse tube set

Picture

AFPQ 2 (return)

* avaliable from Q4/2022

Picture

AFPQ 24 (flow)

Accessories

Picture Type designation Description Connections Code No.

Impulse tube set AF

Compression fitting

Δp setting range

(bar)

0.2 - 1

0.5 - 1.5

0.2 - 1

0.5 - 1.5

Actuator size

(cm2)

160*

1)

Flow restrictor Δpb

(bar)

0.2

0.5 00 3G5 711 003G 5719

0.2 003 G5712 003G5720

0.5 003 G5713 0 03G5721

0.2

0.5 003 G5715 003G 5723

0.2 003G 5716 003G5724

0.5 003 G5717 003G5725

Valve

(DN)

65 0 03G1838 003G1839

80 00 3G1844 003G18 47

100 003G1845 003G1848

125 003G1846 003G18 49

65 0 03G184 0 003G18 41

80 003G186 2 003G18 68

100 003G1863 003G1869

320

125 003G18 64 00 3G1870

150 003G18 65 003G1871

200 003 G1866 0 03G1872

250 003G1867 003G1873

– 1× Copper tube Ø10 × 1 × 1500 mm

– 1× compression fitting for imp.

tube connection to pipe (G ⁄)

– 2× socket

For impulse tube Ø10 connections

to controller

for DN

AFPQ 2 (ret urn) AFPQ 24 (flow)

Code No.

003 G5710 003 G5718

65 -125

00 3G5714 0 03G5722

150-250

Code No.

AFPQ 2 (ret urn) AFPQ 24 (flow)

– 003G1391

G⁄ 003G1468

Shut off valve

Static throt tle valve 065B2909

Dynamic throttle valve

Adapter new AFP 2old VFG DN 15-2 50 0 03G17 80

AMEi 6 iSET

el actuator 230 V

AMEi 6

iSET

el actuator 24 V

AMEi 6 iNET

el actuator 230 V

AMEi 6 iNET

el actuator 24 V

1)

Consist of a nipple , compression ring and nut

2)

Available in 2022

For impulse tube Ø10 –

00 3G1401

2)

For impulse tube Ø10 /

connection to pressure actuator

Intelligent ∆p actuator with iSET

function

Intelligent ∆p actuator with iNET

function

G⁄ 0 03G17 71

082G4300

082G4301

082G4302

082G4303

2 | AI388353838246en-010203 © Danfoss | 2022.03

Page 3

Data sheet AFPQ 2, AFPQ 24 / VFQ 22(1)

Installation position

Service kits

Picture Typ e

Pressure control

insert VFG/Q 22

Pressure control

insert VFG/Q 221

Pressure stuffing box VFG/Q 221

k

VS

(m3/h)

60

80 80 003 G1801

160 100 003 G1802

250 125 003G1803

380 150 003G18 04

650 200 0 03G1805

800 250 00 3G1806

60 65 00 3G1807

80 80 003G1808

160 100 003 G1809

250 125 003G1810

380 150 00 3G18 11

650 200 003 G1812

800 250 0 03G1813

PN DN Code No.

65 003G1800

16/2 5/40

65 -125 00 3G1730

150-250 00 3G1731

The controllers can be installed in any position.

AI388353838246en-010203 | 3© Danfoss | 2022.03

Page 4

Data sheet AFPQ 2, AFPQ 24 / VFQ 22(1)

p

at z = 0,2 ... 0,6 [bar]

Inlet pressure bar p [bar]

z =

Example :

Technical data

VFQ 22(1) Valve

Nominal diameter DN 65 80 100 125 150 200 250

kVS value of ∆p controller

Range of max. flow

setting

∆pb 1) = 0.2 bar

∆pb 1) = 0.5 bar

from 5.6 8 12.6 20 32 54 72

to 28 40 63 100 160 270 360

from 8.4 12 19 30 48 68 100

to 42 60 95 150 240 340 500

60 80 160 250 380 650 800

m3/h

Cavitation factor z 0.65 0.55 0.4 0.4 0.4 0.35 0.3

Leakage acc. to standard

IEC 534 (% of kVS)

VFQ 22 ≤ 0.03 ≤ 0.05

VFQ 221 ≤ 0.01

Nominal pressure PN 16, 25, 40

Min. differential pressure

Max. dif ferential pressure PN 16 16

bar

Max. dif ferential pressure PN 25/40 20

see remark

15 15 12 10 10

2)

Pressure relieve system Chamber relieved

Media Circulation water / glycolic water up to 30%

Media pH Min. 7, max. 10

Media temperature °C 2 … 150

Connections Flange

Materials

PN 16 Grey cast iron EN-GJL-250 (GG-25)

Valve body

PN 25 Ductile iron EN-GJS-400(GGG-40.3)

PN 40 Cast steel GP240GH (GS-C 25)

Valve seat / Valve cone Stainless steel, mat. No. 1.4021

Sealing EPDM

1)

Δpb – differe ntial pressure over flow restri ctor

2)

For flows smal ler than Q

maks.

->

p

Q

min

k

VS

2

p

b

AFPQ 2(4) Actuator

bar

2

160 320

0.2 / 0.5

0. 2-1 0.5-1.5 0.2-1 0.5-1.5

blue yellow orange red

Materials

Actuator size cm

Max. operating pressure bar 40

Flow restrictor differential pressure ∆pb

Diff. pressure setting ranges and spring

colours

For valve DN 65 -125 65-250

Actuator housing Steel, mat. No. 1.0345, zinc plated

Control diaphragm EPDM (Rolling; fibre enforced)

Impulse tube set AFPQ 2(4) Stainless steel, mat. No. 1.4571

Operating area

Maximum allowed differential pressure over the controller (∆p

max

T = 100°C

T = 110°C

[bar]

max

) at different cavitation factors (z)

max

T = 80°C

T = 90°C

T = 140°C

T = 150°C

p = 6 bar

T = 140°C

z = 0,4

= 1,35 bar

p

max

T = 130°C

p

4 | AI388353838246en-010203 © Danfoss | 2022.03

Page 5

Data sheet AFPQ 2, AFPQ 24 / VFQ 22(1)

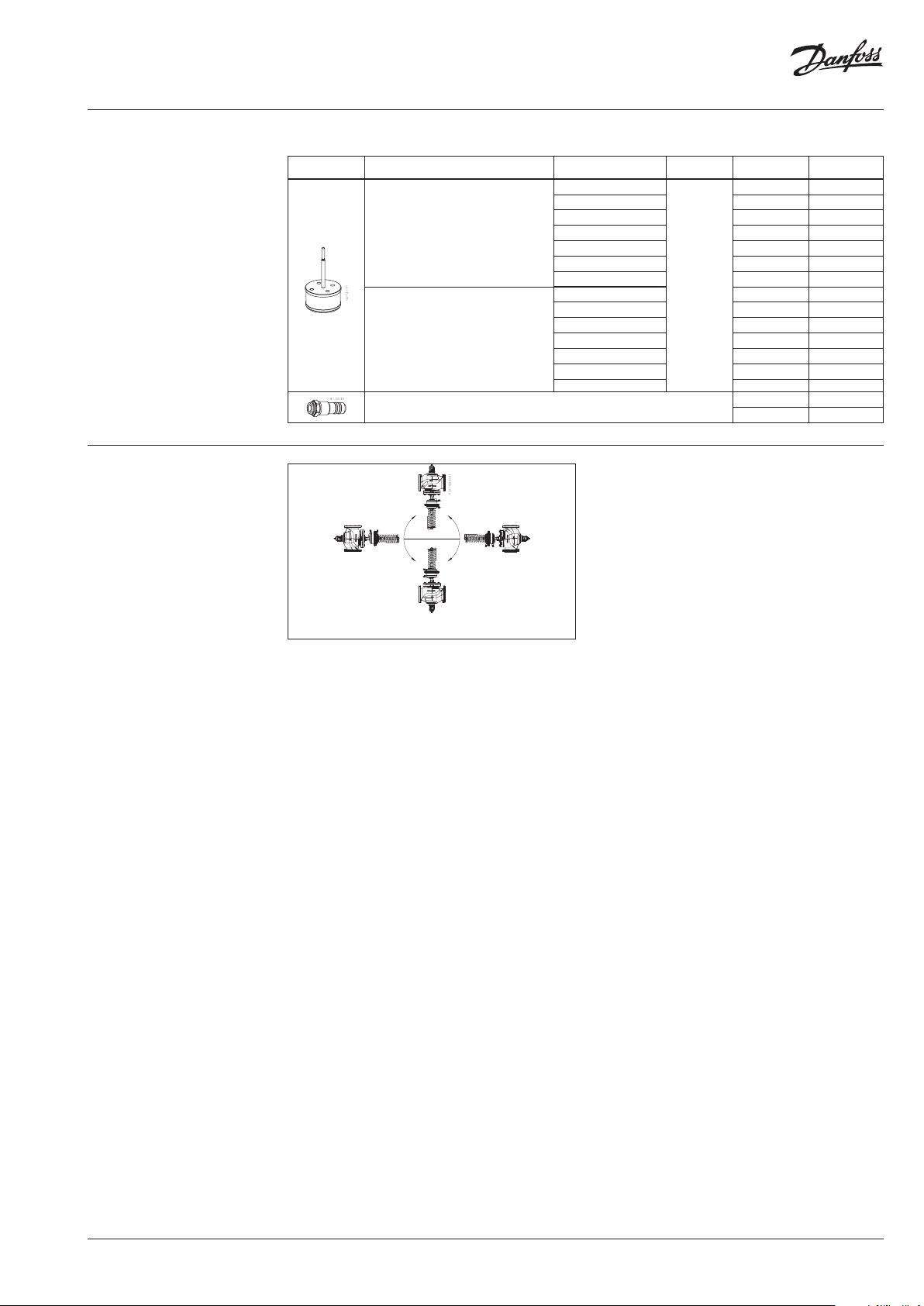

Application principles

– Return mounting

Direct-connected heating system Indirectly connected heating system

– Flow mounting

Pressure temperature

diagram

Working area is below P-T line and it

ends at T

for each valve

max

Direct-connected heating system

Indirectly connected heating system

PN 25

PN 16

EN - GJL- 250

(GG -25)

150

150

Maximum allowed operating pressure as a function of media temperature (according to EN 1092-2)

PN 40

EN-GP-240-GH

(GS- C 25)

EN-GJS- 400

(GGG-40.3)

150

Maximum allowed operating pressure as a function of media temperature (according to EN 1092-1)

AI388353838246en-010203 | 5© Danfoss | 2022.03

Page 6

Data sheet AFPQ 2, AFPQ 24 / VFQ 22(1)

pp

Sizing

– Directly connected heating

system

Example 1

Motorised control valve (MCV) for mixing circuit

in direct-connected heating system requires

differential pressure of 0.5 bar (50 kPa) and flow

less than 25.000 l/h.

Given data:

Q

= 25 m3/h (25.000 l/h)

max

p

= 1 bar (100 kPa)

min

1)

p

= 0.1 bar (10 kPa)

circuit

p

= 0.5 bar (50 kPa) selected

MCV

2)

p

= 0.2 bar (20 kPa)

b

Remark:

1)

∆p

corresponds to the r equired pump pressure in t he heating

circuit

circuit and is not to b e considered when sizing the AFPQ (4).

2)

pb is differe ntial pressure over flow restri ctor.

The differential pressure set value is:

p

p

= p

set value

set value

MCV

= 0.5 bar (50 kPa)

The total pressure loss across the controller is:

p

= p

AFPQ

p

= 0.5 bar (50 kPa)

AFPQ

min

− p

= 1 – 0.5

MCV

Q

max

Possible pipe pressure losses in tubes, shut-off

fittings, heatmeters, etc. are not included.

kv value is calculated according to formula:

Q

k

v

max

25

bAFPQ

2.00.5

kv = 45.6 m3/h

Solution:

The example selects AFPQ 2 (return mounting)

or AFPQ 24 (flow mounting) DN 65, kVS value 60,

with differential pressure setting range 0.2-1 bar,

flow setting range 5.6-28 m3/h.

∆p

∆p

min

AFPQ 2

∆p

b

∆p

AFPQ

AFPQ 24

Q

max

min

∆p

b

∆p

AFPQ

∆p

∆p

MCV

MCV

∆p

∆p

circuit

circuit

6 | AI388353838246en-010203 © Danfoss | 2022.03

Page 7

Data sheet AFPQ 2, AFPQ 24 / VFQ 22(1)

pp

Sizing (continuous)

– Indirectly connected heating

system

Example 2

Motorised control valve (MCV) for indirectly

connected heating system requires differential

pressure of 0.5 (50 kPa) bar and flow less than

24.000 l/h.

Given data:

Q

= 24 m3/h (24.000 l/h)

max

p

= 1.0 bar (100 kPa)

min

p

p

p

Remark:

1)

pb is differe ntial pressure over flow restri ctor

= 0.1 bar (10 kPa)

exchanger

= 0.5 bar (50 kPa) selected

MCV

1)

= 0.2 bar (20 kPa)

b

The differential pressure set value is:

p

= p

set value

p

= 0.1 + 0.5

set value

p

= 0.6 bar (60 kPa)

set value

exchanger

+ p

∆p

min

MCV

Q

max

AFPQ 2

The total pressure loss across the controller is:

p

= p

AFPQ

p

= 1.0 − 0.1 − 0.5

AFPQ

p

= 0.4 bar (40 kPa)

AFPQ

min

− p

exchanger

− p

MCV

Possible pipe pressure losses in tubes, shut-off

fittings, heatmeters, etc. are not included.

kv value is calculated according to formula:

Q

k

v

max

24

bAFPQ

2.00.4

kv = 53.7 m3/h

Solution:

The example selects AFPQ 2 (return mounting)

or AFPQ 24 (flow mounting) DN 65, kVS value 60,

with differential pressure setting range

0.2-1 bar, flow setting range 5.6-28 m3/h.

∆p

exchanger

∆p

∆p

b

∆p

AFPQ

AFPQ 24

Q

max

min

∆p

b

∆p

AFPQ

∆p

∆p

MCV

MCV

∆p

exchanger

AI388353838246en-010203 | 7© Danfoss | 2022.03

Page 8

Data sheet AFPQ 2, AFPQ 24 / VFQ 22(1)

Design

1. Valve body

2. Cover

3. Adjustable flow restrictor

4. Valve seat

5. Valve insert

6. Pressure relieved valve cone

7. Valve stem

8. Stem thread protection

bellow

9. Control diaphragm for flow

control

10. Control diaphragm for diff.

pressure control

11. Excess pressure safety valve

12. Built-in spring for flow

control

13. Setting spring for diff.

pressure control

14. Adjuster for diff. pressure

setting, prepared for sealing

15. Stuffing cone

16. Union nut

17. Impulse tube

18. Compression fitting for

impulse tube

19. Upper casing of diaphragm

20. Lower casing of diaphragm

AFPQ 2 VFQ 22(1), DN 65-250 AFPQ 24 VFQ 22(1), DN 65-250

Function

Flow volume causes pressure drop across the

adjustable flow restrictor. Resulting pressures

are being transferred through the impulse tubes

to the actuator chambers and act on control

diaphragm for flow control. The flow restrictor

diff. pressure is controlled and limited by means

of built-in spring for flow control. Control valve

closes on rising differential pressure and opens

on falling differential pressure to control max

flow.

Settings Differential pressure setting

Differential pressure setting is being done by the

adjustment of the setting spring for diff. pressure

control. This is done by rotating the differential

pressure setting nut. Set differential pressure

should be checked by observing the pressure

indicators.

Pressure changes from flow and return pipes are

being transferred through the impulse tubes

to the actuator chambers and act on control

diaphragm for diff. pressure control. The diff.

pressure is controlled by means of setting spring

for diff. pressure control. Control valve closes

on rising differential pressure and opens on

falling differential pressure to maintain constant

differential pressure.

Controller is equipped with two excess pressure

safety valves, which protect control diaphragms

for flow and diff. pressure control from too high

differential pressure.

Flow setting

Flow setting is being done by the adjustment of

the flow restrictor position. The adjustment can

be performed on the basis of flow adjustment

diagram (see relevant instructions) and/or by the

means of heat meter.

8 | AI388353838246en-010203 © Danfoss | 2022.03

Page 9

Data sheet AFPQ 2, AFPQ 24 / VFQ 22(1)

Dimensions

L

V

H

H

B

VFQ 22(1) DN 65-250

VFQ 22, VFQ 221 Valves

Weight

PN 16 PN 25 PN 40

DN

L B H H

V

mm kg

65 290 237 473 396 28 29 31

80 310 237 473 396 33 34 36

100 350 272 547 472 52 53 57

125 400 268 582 514 71 72 79

150 480 326 670 610 123 12 6 135

200 600 361 773 7 13 230 236 286

250 730 419 843 783 382 392 441

ØA

A

H

AFPQ 2, AFPQ 24 Actuators

Typ e Size ØA HAH

(cm2) mm AFPQ 2(4)

AFPQ 2

AFPQ 24

160 230 630 730 26 29

320 300 630 730 38 41

160 230 650 750 33 36

320 300 650 750 45 48

AI

Weight (kg)

AFPQ 2(4)

+ AMEi 6

Total installation height o f the controller (VFQ 22(1) valve + AFPQ 2

pressure actu ator) is sum of HV and HA (H

)

AI

ØA

AI

H

min. 250

AMEi 6 intellige nt

Ø60

SW 22

110

Ø10

40

G⁄

SW19

actuator with iSE T/ iNET

function ality should be

ordered sepa rately

78

Shut off valve

Compression fitting

© Danfoss | DCS-SGDPT/SI | 2022.039 | AI388353838246en-010203

Loading...

Loading...